ON Semiconductor NCD57090A,NCV57090A,NCD57091A,NCV57091A,NCD57090B,NCV57090B,NCD57091B,NCV57091B,NCD57090C,NCV57090C,NCD57091C,NCV57091C,NCD57090D,NCV57090D,NCD57091D,NCV57091D,NCD57090E,NCV57090E,NCD57091E,NCV57091E,NCD57090F,NCV57090F,NCD57091F,NCV57091F User Manual

Page 1

Isolated High Current

IGBT/MOSFET Gate Driver

NCx57090y, NCx57091y

(x = D or V, y = A, B, C, D, E or F)

NCx57090y, NCx57091y are high−current single channel

IGBT/MOSFET gate drivers with 5 kVrms internal galvanic isolation,

designed for high system efficiency and reliability in high power

applications. The devices accept complementary inputs and depending

on the pin configuration, offer options such as Active Miller Clamp

(version A/D/F), negative power supply (version B) and separate high

and low (OUTH and OUTL) driver outputs (version C/E) for system

design convenience. The driver accommodate wide range of input

bias voltage and signal levels from 3.3 V to 20 V and they are

available in wide−body SOIC−8 package.

Features

• High Peak Output Current (+6.5 A/−6.5 A)

• Low Clamp Voltage Drop Eliminates the Need of Negative Power

Supply to Prevent Spurious Gate Turn−on (Version A/D/F)

• Short Propagation Delays with Accurate Matching

• IGBT/MOSFET Gate Clamping during Short Circuit

• IGBT/MOSFET Gate Active Pull Down

• Tight UVLO Thresholds for Bias Flexibility

• Wide Bias Voltage Range including Negative V

• 3.3 V, 5 V, and 15 V Logic Input

• 5 kVrms Galvanic Isolation

• High Transient Immunity

• High Electromagnetic Immunity

• NCV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q100

Qualified and PPAP Capable

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

Typical Applications

• Motor Control

• Uninterruptible Power Supplies (UPS)

• Automotive Applications

• Industrial Power Supplies

• Solar Inverters

(Version B)

EE2

www.onsemi.com

SOIC8 WB

CASE 751EW

MARKING DIAGRAM

8

5709zy

ALYW

G

1

5709zy = Specific Device Code

z = 0/1

y = A/B/C/D/E/F

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

PIN CONNECTIONS

See detailed pin connection information on page 2 of this

data sheet.

ORDERING INFORMATION

See detailed ordering and shipping information on page 23 of

this data sheet.

© Semiconductor Components Industries, LLC, 2019

April, 2021 − Rev. 0

1 Publication Order Number:

NCD57090A/D

Page 2

NCx57090y, NCx57091y

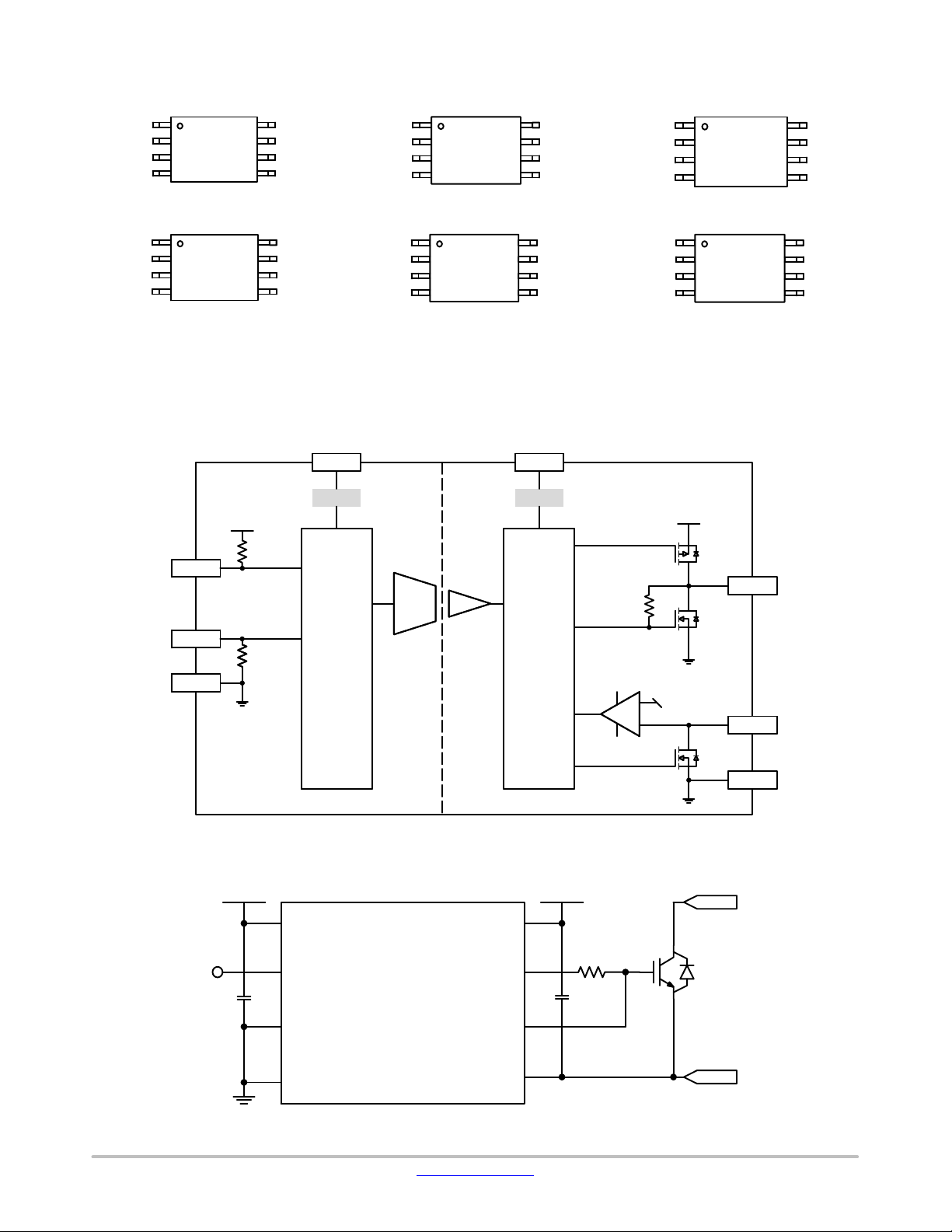

PIN CONNECTIONS

V

DD1

IN+

IN−

GND1

GND2

CLAMP

OUT

V

DD2

V

DD1

IN+

IN−

GND1

NCx57090A, NCx57091A NCx57090B, NCx57091B

V

DD1

IN+

IN−

GND1

NCx57090D

CLAMP

OUT

V

DD2

GND2

V

DD1

IN+

IN−

GND1

NCx57090E

NOTE: x = D or V

Figure 1. Pin Connections

BLOCK DIAGRAM AND APPLICATION SCHEMATIC − VERSION A/D/F

V

DD1

UVLO1

V

DD1

IN−

V

GND2

OUT

V

OUTL

OUTH

V

GND2

V

DD2

UVLO2

EE2

DD2

DD2

V

DD1

IN+

IN−

GND1

NCx57090C, NCx57091C

V

DD1

IN+

IN−

GND1

NCx57090F

V

DD2

OUT

GND2

OUTL

OUTH

V

DD2

V

DD2

OUT

CLAMP

GND2

IN+

GND1

Logic

1

Logic

+

−

V

CLAMP−THR

2

CLAMP

GND2

2

Figure 2. Simplified Block Diagram, NCD57090A/D/F

V

DD1

V

DD1

V

DD2

OUTIN+

IN−

GND1

CLAMP

GND2

V

DD2

Figure 3. Simplified Application Schematics, Version A/D/F

www.onsemi.com

2

Page 3

NCx57090y, NCx57091y

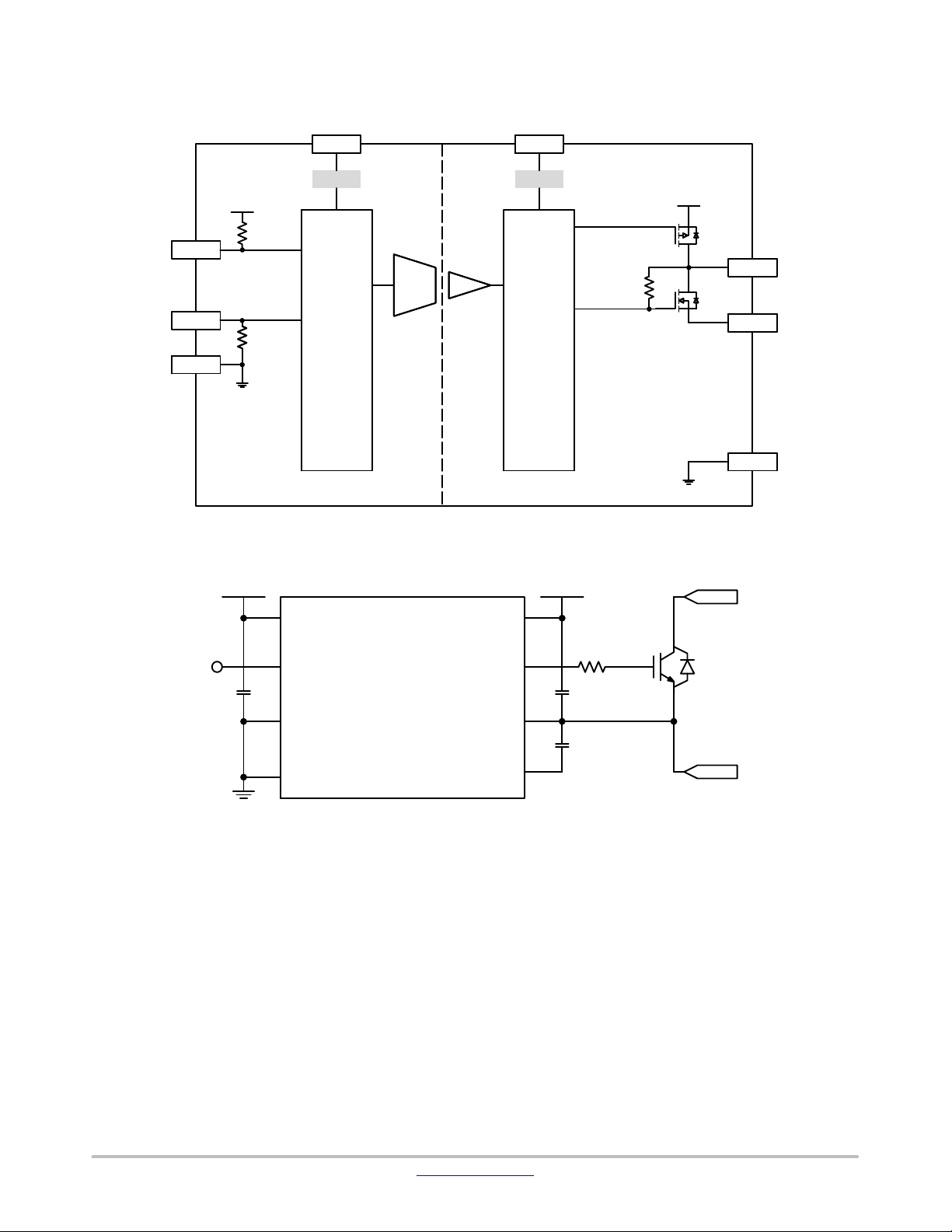

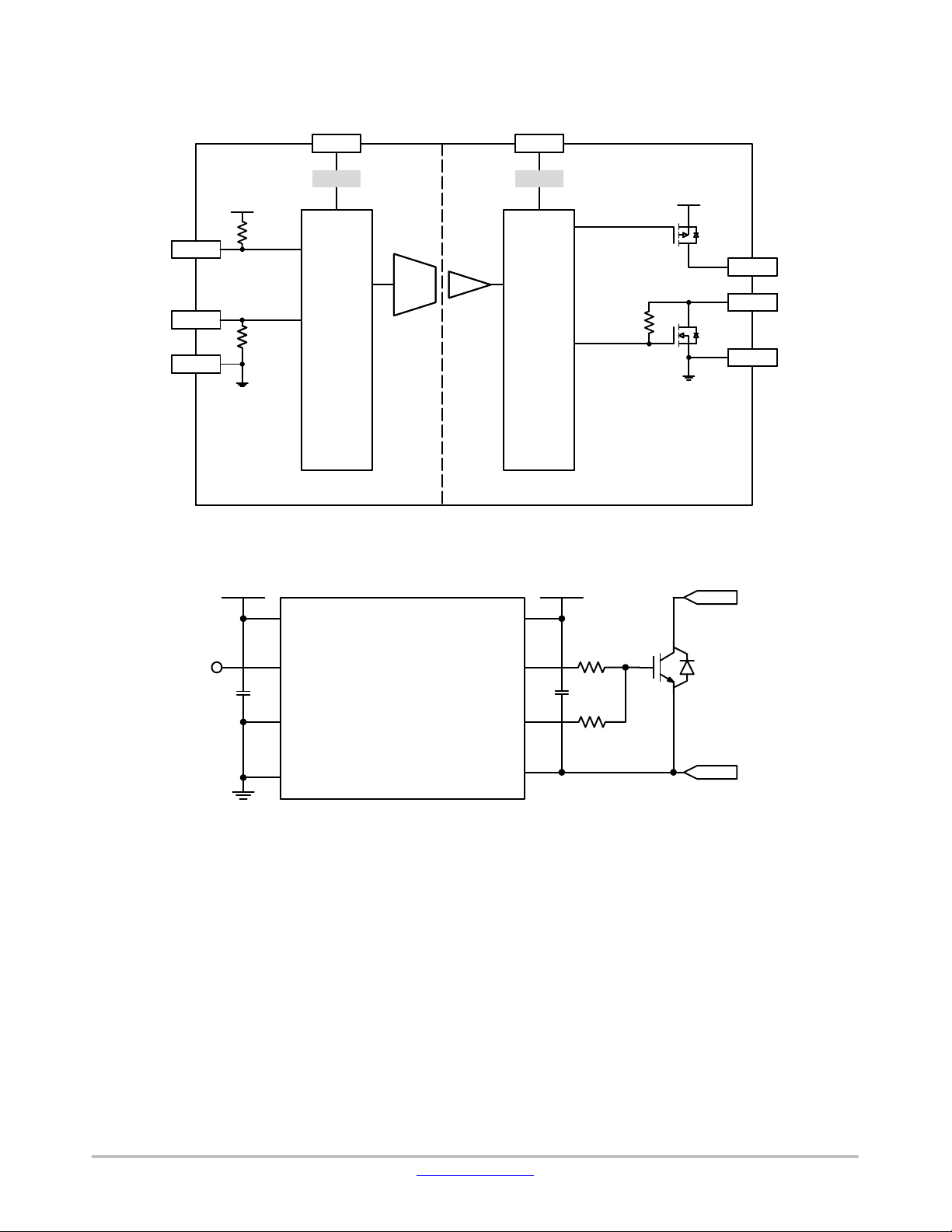

BLOCK DIAGRAM AND APPLICATION SCHEMATIC − NCx57090B, NCx57091B

IN−

IN+

GND1

V

DD1

V

DD2

UVLO2UVLO1

V

V

DD1

DD2

OUT

Logic

Logic

V

EE2

1

GND2

2

Figure 4. Simplified Block Diagram, NCx57090B, NCx57091B

V

DD1

V

DD2

V

V

DD1

DD2

OUTIN+

IN−

GND1

GND2

V

EE2

Figure 5. Simplified Application Schematics, NCx57090B, NCx57091B

www.onsemi.com

3

Page 4

NCx57090y, NCx57091y

BLOCK DIAGRAM AND APPLICATION SCHEMATIC − VERSION C/E

IN−

IN+

GND1

V

DD1

V

DD2

UVLO2UVLO1

V

V

DD1

DD2

OUTH

OUTL

Logic

Logic

GND2

1

2

Figure 6. Simplified Block Diagram, Version C/E

V

DD1

V

DD2

V

V

DD1

DD2

OUTHIN+

IN−

GND1

OUTL

GND2

Figure 7. Simplified Application Schematics, Version C/E

www.onsemi.com

4

Page 5

NCx57090y, NCx57091y

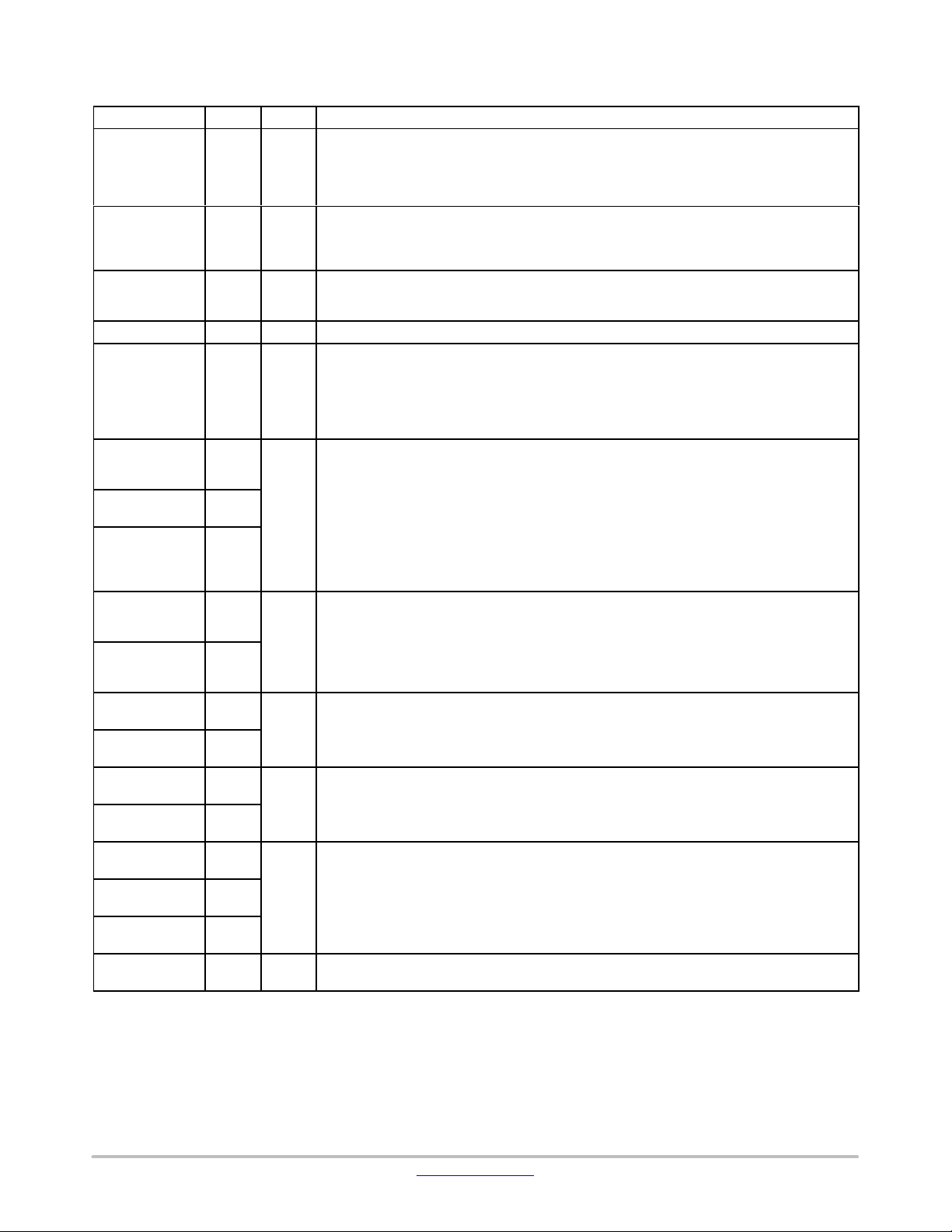

Table 1. FUNCTION DESCRIPTION

Pin Name No. I/O Description

V

DD1

IN+ 2 I Non inverted gate driver input. It is internally clamped to V

IN− 3 I Inverted gate driver input. It is internally clamped to V

GND1 4 Power Input side ground reference.

V

DD2

GND2

(NCD57090A,

NCD57090C)

GND2

(NCD57090B)

GND2

(NCD57090D,

NCD57090E,

NCD57090F)

OUT

(NCD57090A,

NCD57090B)

OUT

(NCD57090D,

NCD57090F)

OUTH

(NCD57090C)

OUTH

(NCD57090E)

OUTL

(NCD57090C)

OUTL

(NCD57090E)

CLAMP

(NCD57090A)

CLAMP

(NCD57090D)

CLAMP

(NCD57090F)

V

EE2

(NCD57090B)

1 Power Input side power supply. A good quality bypassing capacitor is required from this pin to GND1

and should be placed close to the pins for best results.

The under voltage lockout (UVLO) circuit enables the device to operate at power on when

a typical supply voltage higher than V

Please see Figures 9A and 9B for more details.

UVLO1−OUT−ON

pull−down resistor of 125 kW to ensure that output is low in the absence of an input signal.

A minimum positive or negative pulse−width is required at IN+ before OUT or OUTH/OUTL

responds.

resistor of 50 kW to ensure that output is low in the absence of an input signal. A minimum

positive or negative pulse−width is required at IN− before OUT or OUTH/OUTL responds.

5 Power Output side positive power supply. The operating range for this pin is from UVLO2 to its

maximum allowed value. A good quality bypassing capacitor is required from this pin to GND2

and should be placed close to the pins for best results.

The under voltage lockout (UVLO) circuit enables the device to operate at power on when

a typical supply voltage higher than V

for more details.

Power Output side gate drive reference connecting to IGBT emitter or MOSFET source.

8

UVLO2−OUT−ON

7

5

6

O Driver output that provides the appropriate drive voltage and source/sink current to the IGBT/

MOSFET gate. OUT is actively pulled low during start−up.

7

6

O Driver high output that provides the appropriate drive voltage and source current to the IGBT/

MOSFET gate.

7

7

O Driver low output that provides the appropriate drive voltage and sink current to the IGBT/

MOSFET gate. OUTL is actively pulled low during start−up.

8

7

O Provides clamping for the IGBT/MOSFET gate during the off period to protect it from parasitic

turn−on. Its internal N FET is turned on when the voltage of this pin falls below V

8

It is to be tied directly to IGBT/MOSFET gate with minimum trace length for best results.

6

8 Power Output side negative power supply. A good quality bypassing capacitor is required from this pin

to GND2 and should be placed close to the pins for best results.

is present.

and has an equivalent

DD1

and has an equivalent pull−up

DD1

is present. Please see Figure 9C and 9D

CLAMP−THR

.

www.onsemi.com

5

Page 6

NCx57090y, NCx57091y

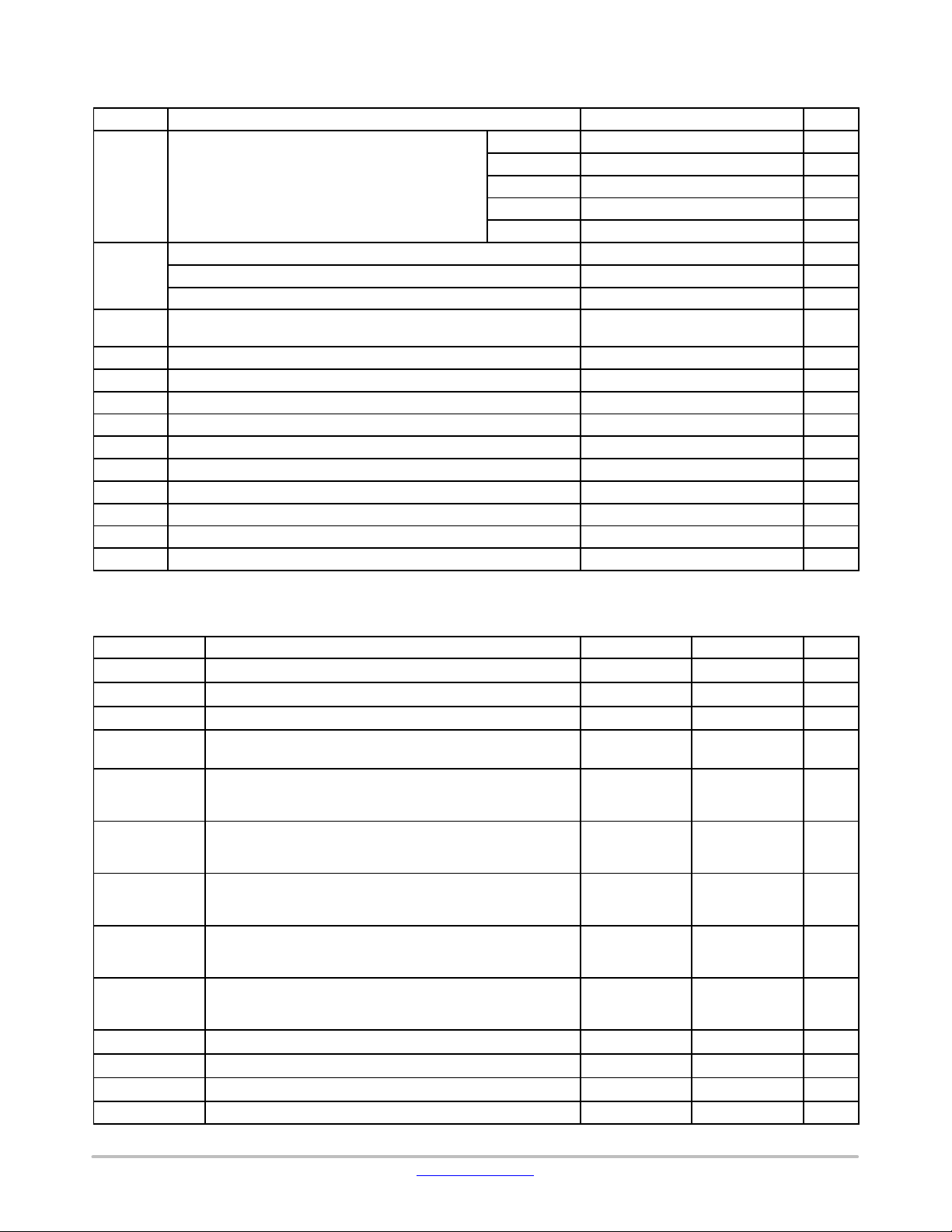

Table 2. SAFETY AND INSULATION RATINGS

Symbol Parameter Value Unit

Installation Classifications per DIN VDE 0110/1.89

Table 1 Rated Mains

Voltage

CTI

Comparative Tracking Index (DIN IEC 112/VDE 0303 Part 1) 600

Climatic Classification 40/100/21

Pollution Degree (DIN VDE 0110/1.89) 2

V

V

V

V

E

PR

IORM

IOWM

IOTM

CR

E

Input−to−Output Test Voltage, Method b, V

100% Production Test with tm = 1 s, Partial Discharge < 5 pC

× 1.875 = VPR,

IORM

Maximum Repetitive Peak Voltage 1200 V

Maximum Working Voltage 870 V

Highest Allowable Over Voltage 8400 V

External Creepage 8.0 mm

External Clearance 8.0 mm

CL

DTI Insulation Thickness 17.3

T

Case

P

S,INPUT

P

S,OUTPUT

R

Safety Limit Values – Maximum Values in Failure; Case Temperature 150 °C

Safety Limit Values – Maximum Values in Failure; Input Power 121 mW

Safety Limit Values – Maximum Values in Failure; Output Power 1349 mW

Insulation Resistance at TS, VIO = 500 V 10

IO

< 150 V

< 300 V

< 450 V

< 600 V

< 1000 V

RMS

RMS

RMS

RMS

RMS

I − IV

I − IV

I − IV

I − IV

I − III

2250 V

9

pk

pk

RMS

pk

mm

W

Table 3. ABSOLUTE MAXIMUM RATINGS (Note 1)

Over operating free−air temperature range unless otherwise noted.

Symbol

V

−GND1 Supply Voltage, Input Side −0.3 22 V

DD1

V

−GND2 Positive Power Supply, Output Side −0.3 32 V

DD2

V

−GND2 Negative Power Supply, Output Side −18 0.3 V

EE2

V

DD2−VEE2

(V

MAX2

)

Differential Power Supply, Output Side (NCD57090B) 0 36 V

Gate−driver Output High Voltage

V

V

OUTH

OUT

−GND2

−GND2

NCD57090A/B/D/F

NCD57090C/E

Gate−driver Output Low Voltage

V

−GND2

OUT

−GND2

V

OUTL

I

PK−SRC

I

PK−SNK

I

PK−CLAMP

t

CLP

V

−GND1 Voltage at IN+, IN− −0.3 V

LIM

V

−GND2 Clamp Voltage −0.3 V

CLAMP

P

D

NCD57090A/B/D/F

NCD57090C/E

Gate−driver Output Sourcing Current

(maximum pulse width = 10 ms, maximum duty cycle = 0.2%,

= 15 V, V

V

DD2

EE2

Gate−driver Output Sinking Current

(maximum pulse width = 10 ms, maximum duty cycle = 0.2%,

= 15 V, V

V

DD2

EE2

Clamp Sinking Current

(maximum pulse width = 10 ms, maximum duty cycle = 0.2%,

= 2.5 V)

V

CLAMP

Maximum Short Circuit Clamping Time (I

Power Dissipation (SOIC−8 Wide Package) − 1470 mW

Parameter Minimum Maximum Unit

−

−

V

DD2

−0.3

−

− 6.5 A

= 0 V)

− 6.5 A

= 0 V)

− 2.5 A

OUT_CLAMP

= 500 mA) − 10

DD1

DD2

+ 0.3

−

−

−

+ 0.3 V

+ 0.3 V

V

V

ms

www.onsemi.com

6

Page 7

NCx57090y, NCx57091y

Table 3. ABSOLUTE MAXIMUM RATINGS (Note 1) (continued)

Over operating free−air temperature range unless otherwise noted.

Symbol UnitMaximumMinimumParameter

TJ(max) Maximum Junction Temperature −40 150 °C

T

STG

ESDHBM ESD Capability, Human Body Model (Note 2) − ±2 kV

ESDCDM ESD Capability, Charged Device Model (Note 2) − ±2 kV

MSL Moisture Sensitivity Level − 1 −

T

SLD

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

2. This device series incorporates ESD protection and is tested by the following methods:

ESD Human Body Model tested per AEC−Q100−002 (EIA/JESD22−A114).

ESD Charged Device Model tested per AEC−Q100−011 (EIA/JESD22−C101).

Latchup Current Maximum Rating: ≤ 100 mA per JEDEC standard: JESD78, 25°C.

3. For information, please refer to our Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

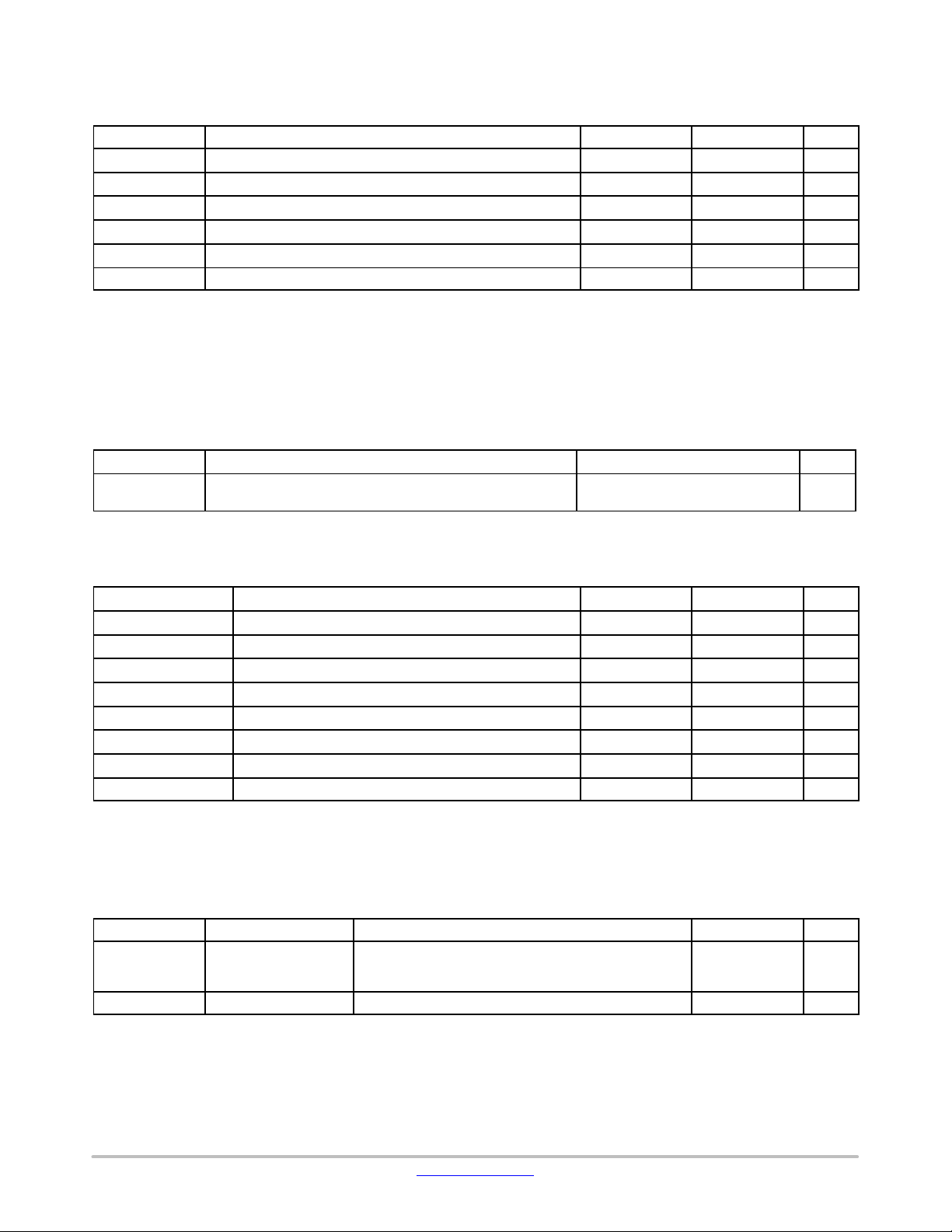

Table 4. THERMAL CHARACTERISTICS

Symbol Parameter Value Unit

RqJA Thermal Characteristics, SOIC−8 wide body (Note 4)

4. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

5. Values based on copper area of 100 mm

Storage Temperature Range −65 150 °C

Lead Temperature Soldering Reflow, Pb−Free (Note 3) − 260 °C

156 (1−Layer)

Thermal Resistance, Junction−to−Air (Note 5)

2

(or 0.16 in2) of 1 oz copper thickness and FR4 PCB substrate.

85 (4−Layer)

°C/W

Table 5. OPERATING RANGES (Note 6)

Symbol Parameter Min Max Unit

V

−GND1 Supply Voltage, Input Side UVLO1 20 V

DD1

V

−GND2 Positive Power Supply, Output Side UVLO2 30 V

DD2

V

−GND2 Negative Power Supply, Output Side (NCD57090B) −15 0 V

EE2

V

−VEE2 (V

DD2

|dV

V

V

ISO

IL

IH

) Differential Power Supply, Output Side (NCD57090B) 0 32 V

MAX2

Low Level Input Voltage at IN+, IN− (Note 7) 0 0.3 × V

High Level Input Voltage at IN+, IN− (Note 7) 0.7 × V

DD1

V

DD1

/dt| Common Mode Transient Immunity (Note 8) 100

DD1

V

V

kV/ms

TA Ambient Temperature −40 125 °C

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

6. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

7. Table values are valid for 3.3 V and 5 V V

DD1, for higher VDD1 voltages, the threshold values are maintained at the 5 V VDD1 levels.

8. Was tested by ±1500 V pulses up to 100 kV/ms.

Table 6. ISOLATION CHARACTERISTICS

Symbol Parameter Conditions Value Unit

V

ISO, input−output

R

ISO

9. Device is considered a two−terminal device: pins 1 to 4 are shorted together and pins 5 to 9 are shorted together.

10.5,000 V

11. The input−output isolation voltage is a dielectric voltage rating per UL1577. It should not be regarded as an input−output continuous voltage

RMS

rating. For the continuous working voltage rating, refer to equipment−level safety specification or DIN VDE V 0884−11 Safety and Insulation

Ratings Table.

Input−Output Isolation

Voltage

TA = 25°C, Relative Humidity < 50%,

t = 1.0 minute, I

(Note 9, 10, 11)

Isolation Resistance V

= 500 V (Note 9) 10

I−O

for 1−minute duration is equivalent to 6,000 V

< 30 mA, 50 Hz

I−O

for 1−second duration.

RMS

5000 V

11

RMS

W

www.onsemi.com

7

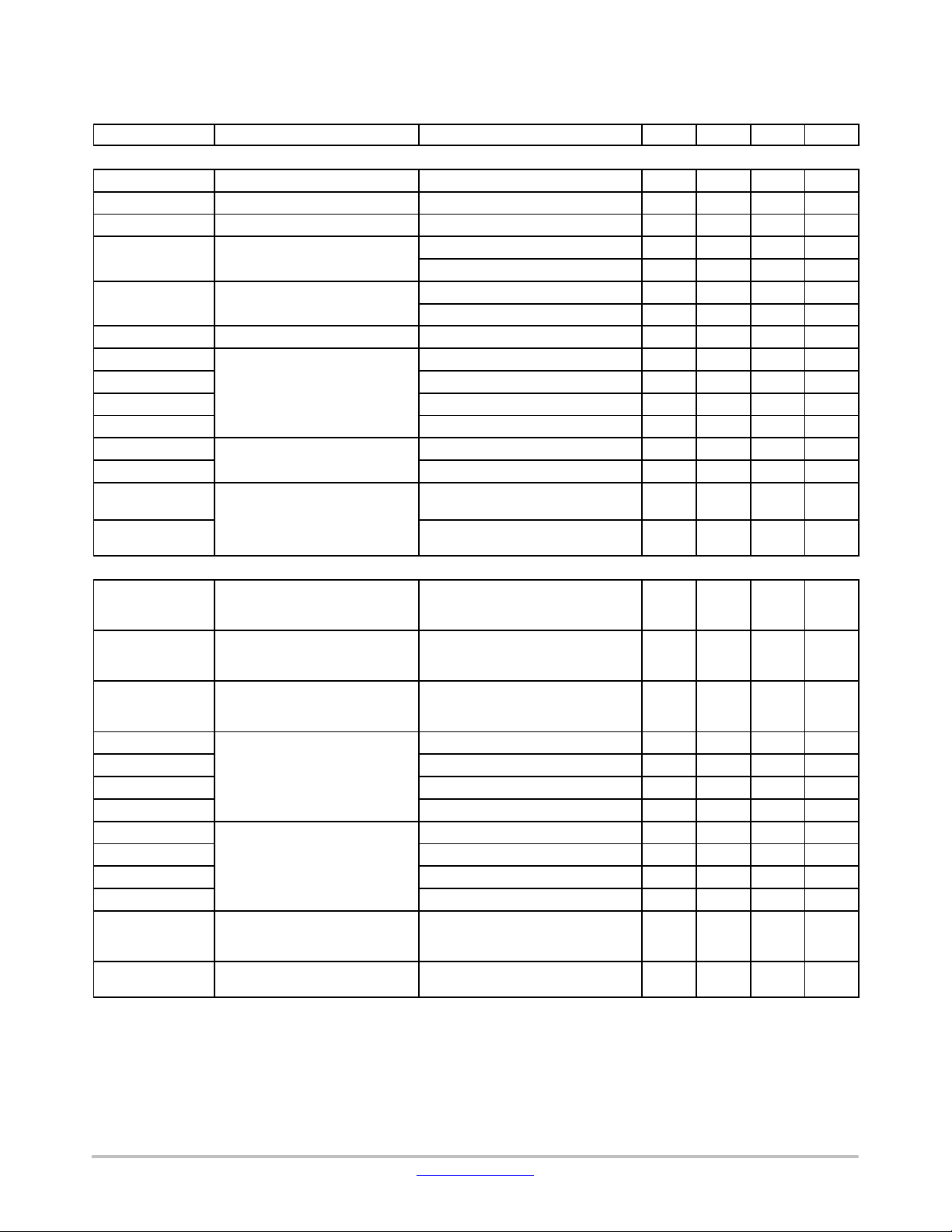

Page 8

NCx57090y, NCx57091y

ELECTRICAL CHARACTERISTICS V

For typical values T

Symbol

VOLTAGE SUPPLY

V

UVLO1−OUT−ON

V

UVLO1−OUT−OFF

V

UVLO1−HYST

V

UVLO2−OUT−ON

V

UVLO2−OUT−OFF

V

UVLO2−HYST

I

DD1−0−3.3

I

DD1−0−5

I

DD1−0−15

I

DD1−100−5

I

DD2−0

I

DD2−100

I

EE2−0

I

EE2−100

LOGIC INPUT AND OUTPUT

V

IL

V

IH

V

IN−HYST

I

IN−L−3.3

I

IN−L−5

I

IN−L−15

I

IN−L−20

I

IN+H−3.3

I

IN+H−5

I

IN+H−15

I

IN+H−20

t

ON−MIN1

t

ON−MIN2

= 25°C, for min/max values, TA is the operating ambient temperature range that applies, unless otherwise noted.

A

Parameter Test Conditions Min Typ Max Unit

UVLO1 Output Enabled − − 3.1 V

UVLO1 Output Disabled 2.4 − − V

UVLO1 Hysteresis 0.1 − − V

UVLO2 Output Enabled

UVLO2 Output Disabled

UVLO2 Hysteresis 0.7 1 − V

Input Supply Quiescent Current

Output Positive Supply

Quiescent Current

Output Negative Supply

Quiescent Current (NCD57090B)

IN+, IN−, Low Input Voltage Level scale for V

IN+, IN−, High Input Voltage Level scale for V

Input Hysteresis Voltage Level scale for V

IN− Input Current

IN+ Input Current

Input Pulse Width of IN+, IN− for

Guaranteed No Response at

Output

Input Pulse Width of IN+, IN− for

Guaranteed Response at Output

DD1

= 5 V, V

= 15 V, (V

DD2

= 0 V for NCD57090B).

EE2

NCx57090y 12.4 12.9 13.4 V

NCx57091y 8.7 9 9.3 V

NCx57090y 11.5 12 12.5 V

NCx57091y 7.7 8 8.3 V

IN+ = Low, IN− = Low, V

= 3.3 V − − 2 mA

DD1

IN+ = Low, IN− = Low − − 2 mA

IN+ = Low, IN− = Low, V

= 15 V − − 2 mA

DD1

IN+ = High, IN− = Low − − 5.5 mA

IN+ = Low, IN− = Low, no load − − 2 mA

IN+ = High, IN− = Low, no load − − 2 mA

IN+ = Low, IN− = Low, no load,

V

= −8 V

EE2

IN+ = High, IN− = Low, no load, V

= −8 V

= 3.3 to 5 V

for V

> 5 V is the same as for

DDI

= 5 V

V

DDI

for V

> 5 V is the same as for

DDI

V

= 5 V

DDI

for V

> 5 V is the same as for

DDI

V

= 5 V

DDI

V

= 0 V, V

IN−

V

= 0 V − − 100

IN−

V

= 0 V, V

IN−

V

= 0 V, V

IN−

V

= V

IN+

V

= V

IN+

V

= V

IN+

V

= V

IN+

DDI

= 3.3 to 5 V

DDI

= 3.3 to 5 V

DDI

= 3.3 V − − 100

DD1

= 15 V − − 100

DD1

= 20 V − − 100

DD1

= 3.3 V − − 100

DD1

= 5 V − − 100

DD1

= 15 V − − 100

DD1

= 20 V − − 100

DD1

EE2

− − 2 mA

− − 2 mA

− − 0.3 ×

V

DD1

0.7 ×

V

DD1

− 0.15 ×

− − V

− V

V

DD1

− − 10 ns

40 − − ns

V

mA

mA

mA

mA

mA

mA

mA

mA

www.onsemi.com

8

Page 9

NCx57090y, NCx57091y

ELECTRICAL CHARACTERISTICS V

For typical values T

Symbol UnitMaxTypMinTest ConditionsParameter

DRIVER OUTPUT

V

OUTL1

V

OUTL2

V

OUTH1

V

OUTH2

I

PK−SNK1

I

PK−SRC1

MILLER CLAMP (NCD57090A)

V

CLAMP

V

CLAMP−THR

IGBT SHORT CIRCUIT CLAMPING

V

CLAMP−OUTH

V

CLAMP−OUTL

V

CLAMP−CLAMP

DYNAMIC CHARACTERISTIC

t

PD−ON−3.3

t

PD−ON−5

t

PD−ON−15

t

PD−ON−20

t

PD−OFF−3.3

t

PD−OFF−5

t

PD−OFF−15

t

PD−OFF−20

t

DISTORT

t

DISTORT_TOT

t

Rise Time (see Figure 8) C

RISE

= 25°C, for min/max values, TA is the operating ambient temperature range that applies, unless otherwise noted.

A

Output Low State

(V

– GND2 for

OUT

NCD57090A/D/F)

– V

(V

OUT

(V

OUTL

NCD57090C/E)

for NCD57090B)

EE2

– GND2 for

Output High State

(V

– V

– V

– V

OUT

OUT

OUTL

for

for NCD57090B)

for

DD2

NCD57090A/B/D/F)

(V

DD2

(V

DD2

NCD57090C/E)

Peak Driver Current, Sink

(Note 12)

Peak Driver Current, Source

(Note 12)

Clamp Voltage

Clamp Activation Threshold 1.5 2 2.5 V

Clamping Voltage, Sourcing

(V

/ V

OUTH

– V

DD2

OUT

Clamping Voltage, Sinking

(V

− V

OUTL

DD2

)

Clamping Voltage, Clamp

(V

(NCD57090A/D/F)

CLAMP

− V

DD2

)

IN+, IN− to Output High

Propagation Delay

IN+, IN− to Output Low

Propagation Delay

Propagation Delay Distortion

PD−ON

− t

PD−OFF

(= t

Prop Delay Distortion between

Parts

DD1

)

= 5 V, V

)

= 15 V, (V

DD2

I

= 200 mA − 0.15 0.3

SINK

I

= 1.0 A, TA = 25°C − − 0.8

SINK

I

= 200 mA − 0.2 0.35

SRC

I

= 1.0 A, TA = 25°C − − 1.0

SRC

= 0 V for NCD57090B).

EE2

− 6.5 − A

− 6.5 − A

I

= 2.5 A, TA = 25°C − 2 −

CLAMP

I

= 2.5 A,

CLAMP

T

= −40°C to 125°C

A

IN+ = Low, IN− = High,

I

CLAMP−OUT/OUTH

(pulse test, t

CLPmax

= 500 mA,

= 10 ms)

IN+ = High, IN− = Low,

I

CLAMP−OUTL

(pulse test, t

= 500 mA,

= 10 ms)

CLPmax

IN+ = High, IN− = Low,

I

CLAMP−CLAMP

(pulse test, t

C

LOAD

VIH to 10% of output change

CLPmax

= 10 nF

= 500 mA

= 10 ms)

− − 3.5

− 0.7 0.9 V

− 0.8 1.5 V

− 1.1 1.7 V

− − − −

Pulse Width > 150 ns.

V

= V

IN+

= V

IN+

= V

IN+

= V

IN+

= 10 nF

= V

IN+

= V

IN+

= V

IN+

= V

IN+

= 3.3V, V

= 5 V, V

= 15 V, V

= 20 V, V

= 3.3 V, V

= 5 V, V

= 15 V, V

= 20 V, V

DD1

V

DD1

V

DD1

V

DD1

C

LOAD

V

to 10% of output change

IH

Pulse Width > 150 ns.

V

DD1

V

DD1

V

DD1

V

DD1

= 0 V 40 60 90 ns

IN−

= 0 V 40 60 90 ns

IN−

= 0 V 40 60 90 ns

IN−

= 0 V 40 60 90 ns

IN−

− − − −

= 0 V 40 60 90 ns

IN−

= 0 V 40 60 90 ns

IN−

= 0 V 40 60 90 ns

IN−

= 0 V 40 60 90 ns

IN−

TA = 25°C, PW > 150 ns − 0 − ns

TA = −40°C to 125°C, PW > 150 ns −25 − 25 ns

PW > 150 ns −30 0 30 ns

= 1 nF,

LOAD

10% to 90% of Output Change

− 13 − ns

V

V

V

www.onsemi.com

9

Page 10

NCx57090y, NCx57091y

ELECTRICAL CHARACTERISTICS V

For typical values T

= 25°C, for min/max values, TA is the operating ambient temperature range that applies, unless otherwise noted.

A

DD1

= 5 V, V

= 15 V, (V

DD2

= 0 V for NCD57090B).

EE2

Symbol UnitMaxTypMinTest ConditionsParameter

DYNAMIC CHARACTERISTIC

t

FALL

t

UVF1

t

UVR1

t

UVF2

t

UVR2

Fall Time (see Figure 8) C

UVLO1 Fall Delay (Note 12) − 1500 − ns

UVLO1 Rise Delay (Note 12) − 770 − ns

UVLO2 Fall Delay (Note 12) − 1000 − ns

UVLO2 Rise Delay (Note 12) − 1000 − ns

= 1 nF,

LOAD

90% to 10% of Output Change

− 13 − ns

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

12.Values based on design and/or characterization.

www.onsemi.com

10

Page 11

IN+

NCx57090y, NCx57091y

V

IH

V

IL

t

ON−MIN2

t

PD−ON

OUT/OUTH

V

DD2

V

UVLO1−OUT−ON

V

UVLO1−OUT−OFF

V

DD1

t

RISE

t

FALL

90%

t

PD−OFF

10%

Figure 8. Propagation Delay, Rise and Fall time

V

UVLO1−HYST

t

UVR1

t

UVF1

t

UVR1

t

UVF1

t

ON−MIN1

t

ON−MIN1

t

UVR2

t

UVR1−spread

IN+

OUT/OUTH

Figure 9.

Output Ramp−up and Ramp−down Times during UVLO1

Figure 9A. UVLO1 and Associated Timing Waveforms

www.onsemi.com

11

Page 12

V

DD2

V

UVLO1−OUT−ON

V

UVLO1−OUT−OFF

V

DD1

IN+

t

UVR1

NCx57090y, NCx57091y

t

UVF1

t

UVF1

t

UVR1

t

UVR1

t

UVR1−spread

OUT/OUTH

V

DD1

V

UVLO2−OUT−ON

V

UVLO2−OUT−OFF

V

DD2

IN+

V

Glitch Filtering

DD1

Figure 9B. UVLO1 Waveforms Depicting V

V

UVLO2−HYST

t

UVR2

t

UVF2

t

UVR2

Glitch Filtering

DD1

t

UVF2

t

UVR2

t

UVR2−spread

OUT/OUTH

Output Ramp−up and Ramp−down Times during UVLO2

Figure 9C. UVLO2 and Associated Timing Waveforms

www.onsemi.com

12

Page 13

V

DD1

V

UVLO2−OUT−ON

V

UVLO2−OUT−OFF

V

DD2

IN+

t

UVR2

NCx57090y, NCx57091y

t

UVF2

t

UVR2

t

UVR2

t

UVR2

t

UVR2−spread

OUT/OUTH

V

Glitch Filtering

DD2

Figure 9D. UVLO2 Waveforms Depicting V

V

DD1

IN+

IN−

V

DD1

Clamping

Circuit

V

DD1

Clamping

Circuit

Figure 10. Input Pin Structure

Glitch Filtering

DD2

www.onsemi.com

13

Page 14

NCx57090y, NCx57091y

TYPICAL CHARACTERISTICS

6

(3)

5

4

(2)

3

(1)

2

Current [mA]

1

0

−40 −20 0 20 40 60 100 120

80

Temperature [°C]

(1) I

DD1−0−3.3

(2) I

DD1−50−3.3

(3) I

DD1−100−3.3

Figure 11. I

, IN+ = 3.3 V/200 kHz/50%

Supply Current V

DD1

DD1

5

(3)

4

3

(2)

2

Current [mA]

(1)

1

= 3.3 V

5

(3)

4

3

(2)

2

Current [mA]

(1)

1

0

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) I

DD1−0−5

(2) I

DD1−50−5

(3) I

DD1−100−5

Figure 12. I

, IN+ = 5 V/200 kHz/50%

Supply Current V

DD1

20

15

10

Current [mA]

5

= 5 V

DD1

(2)(3)

(1)

0

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) I

DD1−0−20

(2) I

DD1−50−20

(3) I

DD1−100−20

Figure 13. I

, IN+ = 20 V/200 kHz/50%

Supply Current V

DD1

2.5

2

1.5

(2)

1

Current [mA]

0.5

(1)

0

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) I

DD2−0−15

(2) I

DD2−100−15

Figure 15. I

Supply Current V

DD2

0

1 10 100 1000

= 20 V Figure 14. I

DD1

2.5

(2)

2

1.5

1

Current [mA]

(1)

0.5

0

−40 −20 0 20 40 60 100 12080

DD2

= 15 V

Figure 16. I

(1) CG = 1 nF

(2) CG = 10 nF

(3) CG = 100 nF

DD2

Temperature [°C]

(1) I

DD2−0−30

(2) I

DD2−100−30

Supply Current V

DD2

Frequency [kHz]

vs. Switching Frequency

= 30 V

DD2

www.onsemi.com

14

Page 15

NCx57090y, NCx57091y

TYPICAL CHARACTERISTICS (continued)

2.9

2.8

(1)

Voltage [V]

2.7

(2)

2.6

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) V

UVLO1−OUT−ON

(2) V

UVLO1−OUT−OFF

Figure 17. UVLO1 Threshold Voltage

3

2.5

2

Voltage [V]

1.5

1.5

1.4

(2)

1.3

1.2

1.1

Voltage [V]

(1)

1

0.9

0.8

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) V

CLAMP−OUTH

(2) V

CLAMP−CLAMP

Figure 18. IGBT Short Circuit CLAMP

Voltage Drop

2.00

1.98

1.96

1.94

Voltage [V]

1.92

1

−40 −20 0 20 40 60 100 12080

Temperature [°C]

Figure 19a. Miller Clamp Voltage (2.5 A)

13.5

(1)

13

12.5

Voltage [V]

11.5

(2)

12

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) V

UVLO2−OUT−ON

(2) V

UVLO2−OUT−OFF

Figure 20. NCx57090 UVLO2 Threshold Voltage

1.90

−40 −20 0 20 40 60 100 12080

Temperature [°C]

Figure 19b. Miller Clamp Activation

Voltage Threshold

9.5

(1)

9

8.5

Voltage [V]

(2)

8

7.5

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) V

UVLO2−OUT−ON

(2) V

UVLO2−OUT−OFF

Figure 21. NCx57091 UVLO2 Threshold Voltage

www.onsemi.com

15

Page 16

72

70

NCx57090y, NCx57091y

TYPICAL CHARACTERISTICS (continued)

71

68

(2)

66

Time [ns]

64

(1)

62

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) t

(2) t

PD−ON−5

PD−ON−5

, IN+

, IN−

Figure 22. Propagation Delay Turn−on Figure 23. Propagation Delay Turn−off

15

14

Time [ns]

13

(1)

(2)

12

−40 −20 0 20 40 60 100 12080

Temperature [°C] Temperature [°C]

(1) t

, IN+

RISE

(2) t

, IN−

RISE

Figure 24. Rise Time, V

DD1

= 5 V

69

(1)

Time [ns]

67

(2)

65

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) t

(2) t

PD−OFF−5

PD−OFF−5

, IN+

, IN−

14

13

Time [ns]

(1)

(2)

12

−40 −20 0 20 40 60 100 12080

(1) t

(2) t

FALL

FALL

, IN+

, IN−

Figure 25. Fall Time, V

DD1

= 5 V

50

40

(3)

(4)

Current [mA]

(2)

30

(1)

20

−40 −20 0 20 40 60 100 12080

Temperature [°C]

(1) I

IN+H−3.3

(2) I

IN+H−5

(3) I

IN+H−15

(4) I

IN+H−20

Figure 26. Input Current – Positive Input Figure 27. Input Current – Negative Input

−35

−35

−40

−45

Current [mA]

−50

−55

−60

www.onsemi.com

16

(1)

(2)

(3)(4)

−40 −20 0 20 40 60 100 12080

(1) I

IN−L−3.3

(2) I

IN−L−5

(3) I

IN−L−15

(4) I

IN−L−20

Page 17

NCx57090y, NCx57091y

Under Voltage Lockout (Refer to Figure 9x)

UVLO ensures correct switching of IGBT/MOSFET

connected to the driver output.

• The IGBT/MOSFET is turned−off and the output is

disabled if the supply V

V

UVLO1−OUT−OFF

V

UVLO2−OUT−OFF

or V

.

drops below

DD1

drops below

DD2

• The driver output does not follow the input signal on

IN+ or IN− until the V

V

UVLOX−OUT−ON

and the input signal rising edge is

applied to the IN+ or IN−

• V

is not monitored (NCx5709zB)

EE2

With high loading gate capacitances over 10 nF it is

important to follow the decoupling capacitor routing

guidelines as shown on Figure 35/36. The decoupling

capacitor value should be at least 10 mF. Also gate resistor

rises above the

DDX

of minimal value of 2 W has to be used in order to avoid

interference of the high di/dt with internal circuitry (e.g.

UVLO2).

After the power−on of the driver there has to be a rising

edge applied to the IN+ or falling edge to the IN− in order

for the output to start following the inputs. This serves as a

protection against producing partial pulses at the output if

the V

DD1

or V

is applied in the middle of the input PWM

DD2

pulse.

If the V

will appear on the output after t

t

UVR2−spread

end of t

rises over V

DD2

UVLO2−OUT−ON

UVR2

level the PWM

+ t

UVR2−spread

time is variable and is defined as a time from

to first rising edge on IN+ input. If the V

UVR2

. The

DD2

is starting from 0 V the time until PWM is at the output of

the driver is longer than t

UVR2

+ t

UVR2−spread

. This is caused

by start up time of internal circuits of the driver.

www.onsemi.com

17

Page 18

NCx57090y, NCx57091y

ACTIVE MILER CLAMP PROTECTION (CLAMP)

NCx5709yB supports bipolar power supply to prevent

unintentional turning on.

For operation with bipolar supplies, the IGBT/MOSFET

is turned off with a negative voltage through OUT with

respect to its emitter. This prevents the IGBT/MOSFET

from unintentionally turning on because of current induced

from its collector to its gate due to Miller effect. Typical

values for bipolar operation are V

= 15 V and V

DD2

EE2

= −5

V with respect to GND2.

Driver version A/D/F supports unipolar power supply

with active Miller clamp.

OUT/OUTH

For operation with unipolar supply, typically,

V

= 15 V with respect to GND2, and V

DD2

= GND2. In

EE2

this case, the IGBT/MOSFET can turn on due to additional

charge from IGBT/MOSFET Miller capacitance caused by

a high voltage slew rate transition on the IGBT collector/

MOSFET drain. To prevent IGBT/MOSFET to turn on, the

CLAMP pin is connected directly to IGBT/MOSFET gate

and Miller current is sinked through a low impedance

CLAMP transistor. When the IGBT/MOSFET is turned−off

and the gate voltage transitions below V

CLAMP

, the CLAMP

output is activated.

OUT/OUTH

Figure 28. Current Path with Miler Clamp Protection Figure 29. Current Path without Miler Clamp Protection

Non−inverting and Inverting Input Pin (IN+, IN−)

The driver has two possible input modes to control

IGBT/MOSFET. Both inputs have defined minimum input

pulse width to filter occasional glitches.

• Non−inverting input IN+ controls the driver output

while inverting input IN− is set to LOW

• Inverting input IN− controls the driver output while

WARNING: When the application uses an independent

or separate power supply for the control

unit and the input side of the driver, all

inputs should be protected by a serial

resistor (In case of a power failure of the

driver, the driver may be damaged due to

overloading of the input protection circuits)

non−inverting input IN+ is set to HIGH

www.onsemi.com

18

Page 19

NCx57090y, NCx57091y

Power Supply (V

DD1

, V

DD2

, V

EE2

)

The driver variant A/C/D/E and F are designed to support

unipolar power supply.

The driver variant B is designed to support bipolar power

supply.

Suitable external power capacitors are required for

reliable driving of IGBT/MOSFET gate with high current.

Parallel combination of 100 nF + 4.7 mF low ESR ceramic

capacitors is optimal for a wide range of applications using

IGBT/MOSFET. For reliable driving of IGBT modules

(containing several parallel IGBT’s) with a gate capacitance

over 10 nF a higher decoupling capacity is required

(typically 100 nF + 10 mF). Capacitors should be as close as

possible to the driver’s power pins. The recommended

layout is provided in the Figure 35 and 36.

V

DD1

IN+

IN−

GND1

Figure 30. Bipolar Power Supply (Variant B)

+

−

V

DD1

100nF

10

mF

• In bipolar power supply the driver is typically supplied

with a positive voltage of 15 V at V

voltage −5 V at V

(Figure 30). Negative power supply

EE2

prevents a dynamic turn on through the internal

IGBT/MOSFET input capacitance

DD2

• In Unipolar power supply the driver is typically supplied

with a positive voltage of 15 V at V

turn−on caused by the internal IGBT/MOSFET Miller

capacitance could be prevented by Active Miler Clamp

function (variant A/D/F). CLAMP output should be

directly connected to IGBT/MOSFET gate (Figure 28)

V

EE2

GND2

OUT

V

DD2

10

mF

100nF

10

mF

100nF

V

DD2

+

−

V

EE2

−

+

and negative

. Unwanted

DD2

V

DD1

V

DD1

+

−

100nF

10

mF

IN+

IN−

GND1

GND2

CLAMP

OUT

V

DD2

10

mF

100nF

V

DD2

+

−

Figure 31. Unipolar Power Supply (Variant A/D/F)

V

DD1

V

DD1

+

−

100nF

10

mF

IN+

IN−

GND1

GND2

OUTL

OUTH

V

DD2

10

mF

100nF

V

DD2

+

−

Figure 32. Unipolar Power Supply (Variant C/E)

www.onsemi.com

19

Page 20

Common Mode Transient Immunity (CMTI)

10μF

5V

+

-

FLOATING

5V

+

-

FLOATING

+

S1

-

10μF

+

S1

-

NCx57090y, NCx57091y

VDD1

IN+

IN-

GND1

HV PULSE

VDD1

IN+

IN-

GND1

HV PULSE

GND2

CLAMP

OUT

VDD2

GND2

OUTL

OUTH

VDD2

OUT must remain stable

OUT must remain stable

10μF

10μF

15V

15V

+

-

+

-

5V

+

-

FLOATING

10μF

+

S1

-

VDD1

IN+

IN-

GND1

HV PULSE

VEE2

GND2

OUT

VDD2

OUT must remain stable

10μF

Figure 33. Common−Mode Transient Immunity Test Circuit

High-speed signals

10 mils

0.25 mm

40 mils

1mm

10 mils

0.25 mm

Keep this space free

10 mils

from traces, pads and

0.25 mm

vias

10 mils

0.25 mm

40 mils

1mm

10 mils

0.25 mm

Ground plane

Power plane

Low-speed signals

314 mils

(8 mm)

Figure 34. Recommended Layer Stack

15V

+

-

www.onsemi.com

20

Page 21

NCx57090y, NCx57091y

Figure 35. Recommended Layout for Version A/B/C

www.onsemi.com

21

Page 22

NCx57090y, NCx57091y

Figure 36. Recommended Layout for Version D/E/F

www.onsemi.com

22

Page 23

ORDERING INFORMATION

Device Package Shipping

NCD57090ADWR2G

NCD57090BDWR2G

NCD57090CDWR2G

NCD57090DDWR2G

NCD57090EDWR2G

NCD57090FDWR2G

NCx57090y, NCx57091y

SOIC−8 Wide Body

(Pb−Free)

†

2500 / Tape & Reel

NCV57090ADWR2G*

NCV57090BDWR2G*

NCV57090CDWR2G*

NCV57090DDWR2G*

NCV57090EDWR2G*

NCV57090FDWR2G*

NCD57091ADWR2G (In Development)

NCD57091BDWR2G (In Development)

NCD57091CDWR2G (In Development)

NCV57091ADWR2G* (In Development)

NCV57091BDWR2G* (In Development)

NCV57091CDWR2G* (In Development)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

*NCV Prefix for Automotive and Other Applications Requiring Unique Site and Control Change Requirements; AEC−Q100 Qualified and PPAP

Capable.

SOIC−8 Wide Body

(Pb−Free)

SOIC−8 Wide Body

(Pb−Free)

SOIC−8 Wide Body

(Pb−Free)

2500 / Tape & Reel

2500 / Tape & Reel

2500 / Tape & Reel

www.onsemi.com

23

Page 24

NCx57090y, NCx57091y

PACKAGE DIMENSIONS

SOIC8 WB

CASE 751EW

ISSUE A

q

q

www.onsemi.com

24

Page 25

NCx57090y, NCx57091y

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

25

Loading...

Loading...