Page 1

NCD5703A, NCD5703B,

NCD5703C

High Current IGBT Gate

Drivers

The NCD5703A, NCD5703B and NCD5703C are high−current,

high−performance stand−alone IGBT drivers for high power

applications that include solar inverters, motor control and

uninterruptible power supplies. The devices offer a cost−effective

solution by eliminating external output buffer. Devices protection

features include accurate Under−voltage−lockout (UVLO),

desaturation protection (DESAT) and Active open−drain FAULT

output. The drivers also feature an accurate 5.0 V output. The drivers

are designed to accommodate a wide voltage range of bias supplies

including unipolar and NCD5703B even bipolar voltages.

Depending on the pin configuration the devices also include Active

Miller Clamp (NCD5703A) and separate high and low (V

driver outputs for system design convenience (NCD5703C).

All three available pin configuration variants have 8−pin SOIC

package.

Features

• High Current Output (+4/−6 A) at IGBT Miller Plateau voltages

• Low Output Impedance for Enhanced IGBT Driving

• Short Propagation Delay with Accurate Matching

• Direct Interface to Digital Isolator/Opto−coupler/Pulse Transformer

for Isolated Drive, Logic Compatibility for Non−isolated Drive

• DESAT Protection with Programmable Delay

• Tight UVLO Thresholds for Bias Flexibility

• Wide Bias Voltage Range

• This Device is Pb−Free, Halogen−Free and RoHS Compliant

NCD5703A Features

• Active Miller Clamp to Prevent Spurious Gate Turn−on

NCD5703B Features

• Negative Output Voltage for Enhanced IGBT Driving

NCD5703C Features

• Separate Outputs for V

OL

and V

OH

Typical Applications

• Solar Inverters

• Motor Control

• Uninterruptible Power Supplies (UPS)

• Rapid Shutdown for Photovoltaic Systems

and VOL)

OH

www.onsemi.com

MARKING

8

1

SOIC−8

D SUFFIX

CASE 751

NCD5703 = Specific Device Code

X = A, B or C

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

DIAGRAM

8

NCD5703X

ALYW

G

1

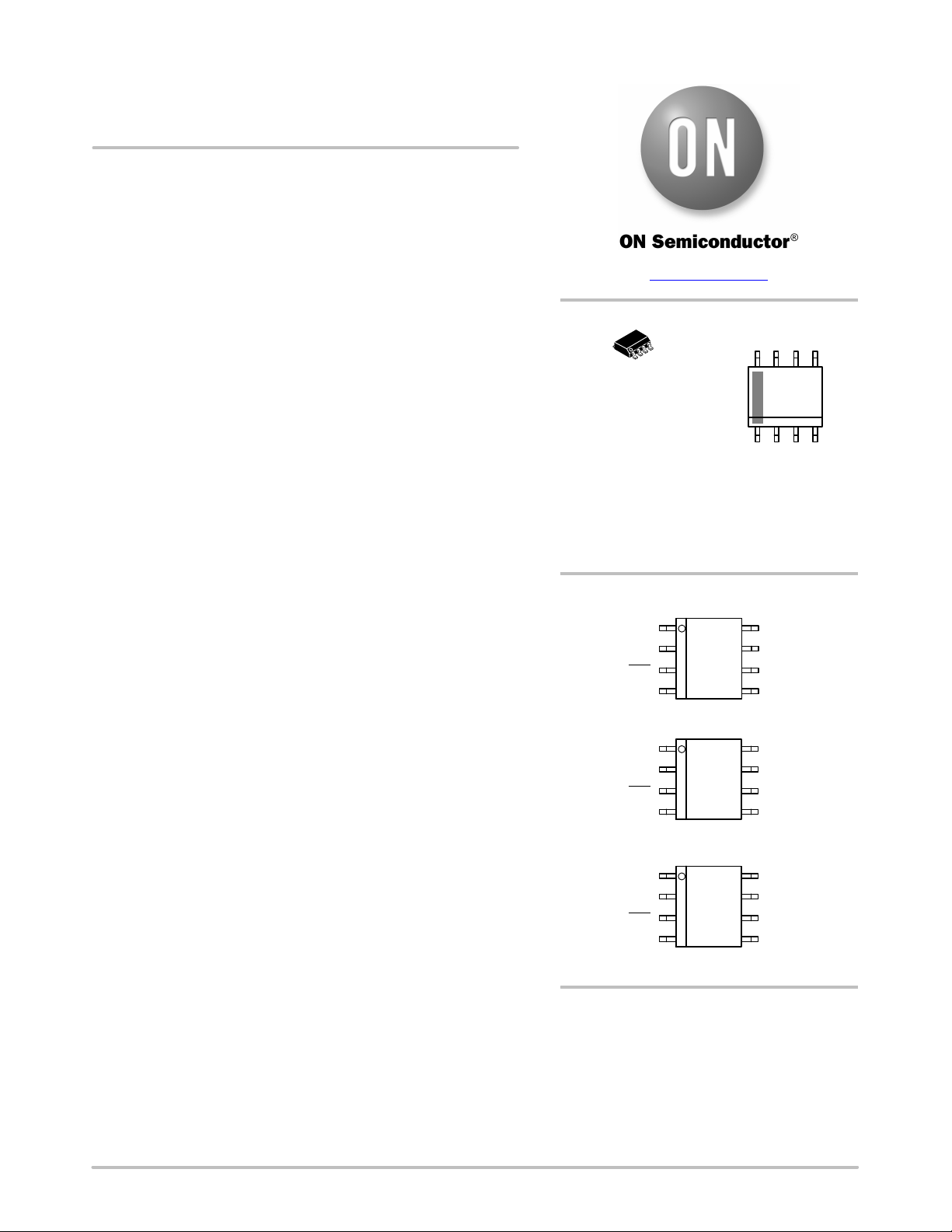

PIN CONNECTIONS

VIN

VREF

FLT

DESAT

VIN

VREF

FLT

DESAT

VIN

VREF

FLT

DESAT

1

2

3

4

NCD5703A

1

2

3

4

NCD5703B

1

2

3

4

NCD5703C

8

7

6

5

8

7

6

5

8

7

6

5

CLAMP

GND

VO

VCC

VEE

GND

VO

VCC

GND

VOL

VOH

VCC

ORDERING INFORMATION

See detailed ordering and shipping information on page 9 of

this data sheet.

© Semiconductor Components Industries, LLC, 2018

August, 2019 − Rev. 1

1 Publication Order Number:

NCD5703/D

Page 2

NCD5703A, NCD5703B, NCD5703C

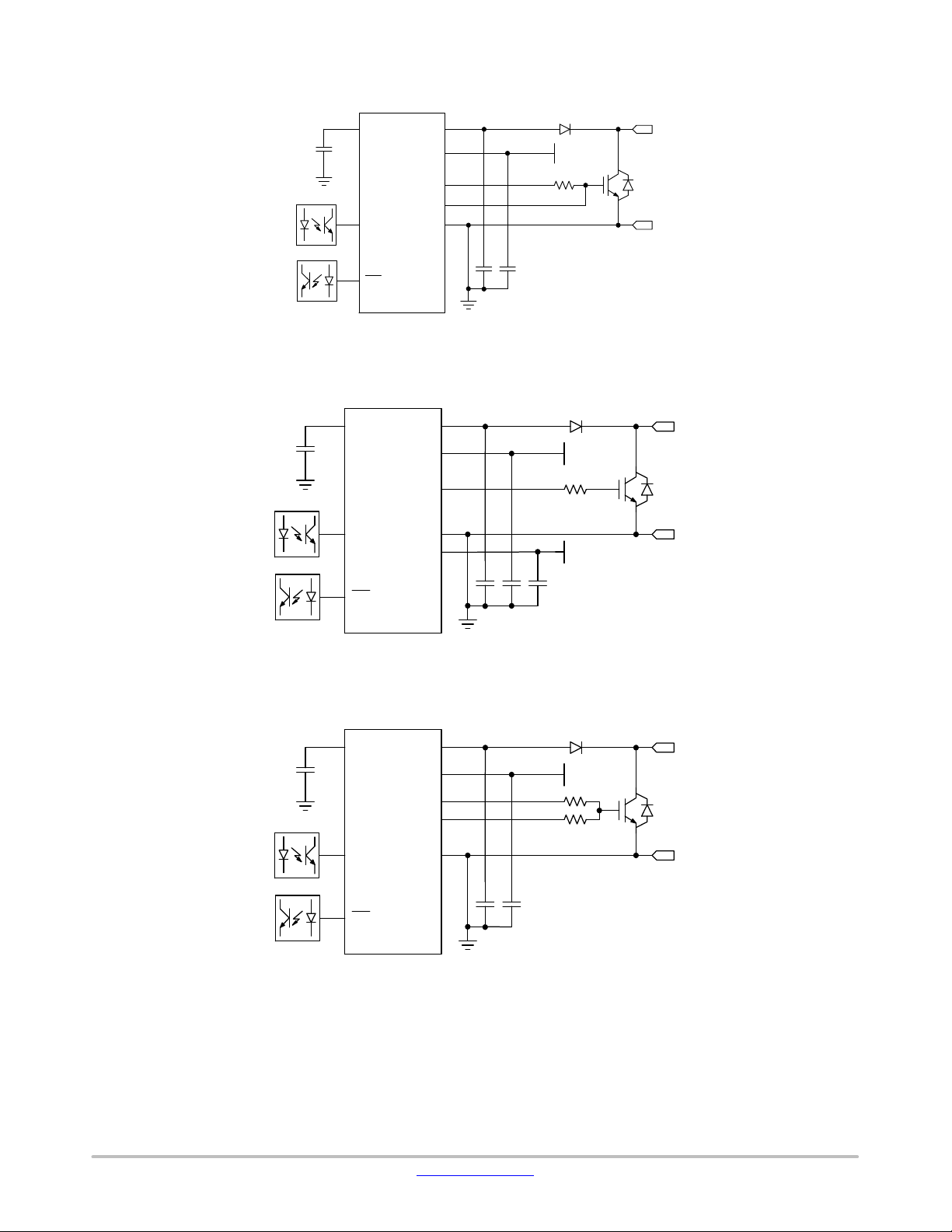

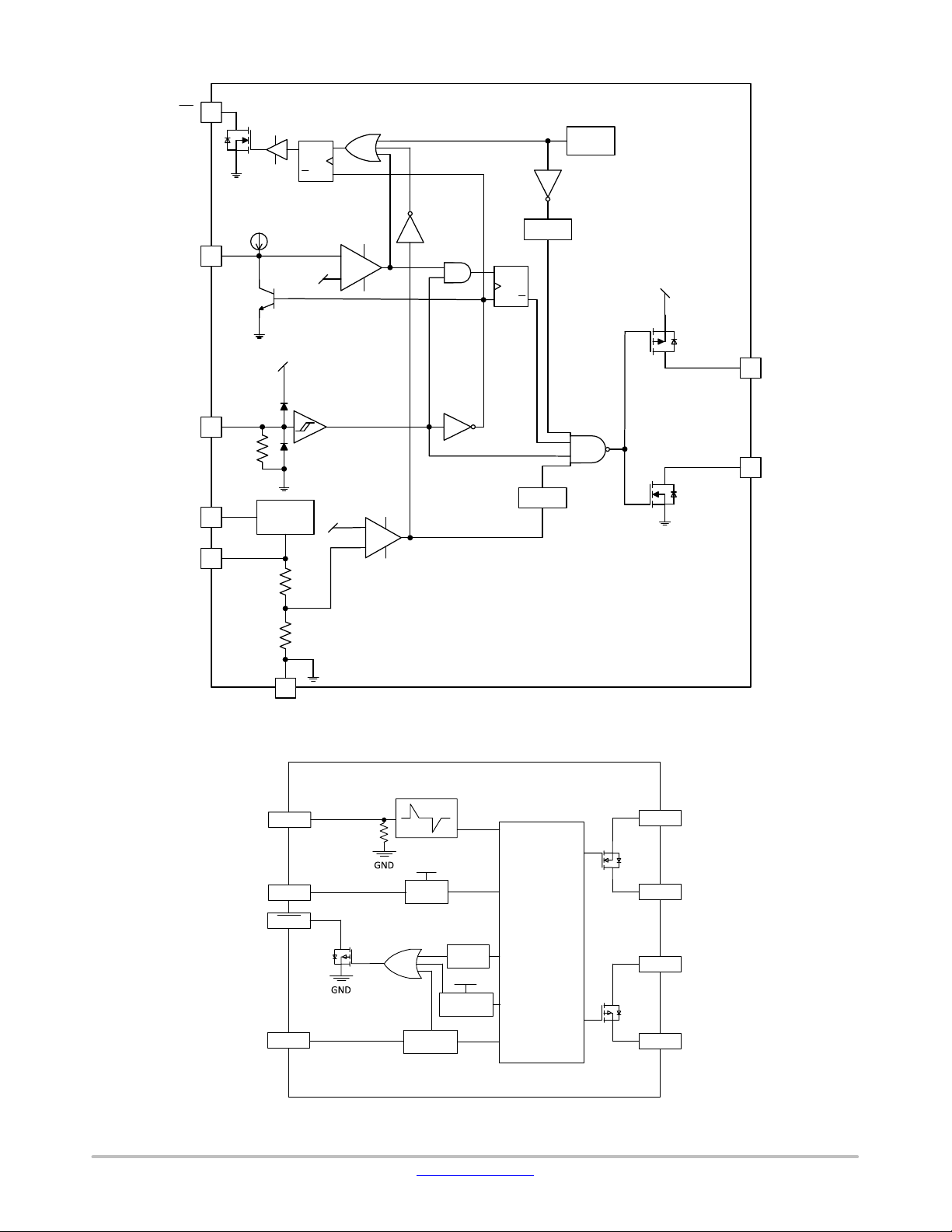

NCD5703A

DESAT

VREF

VCC

VIN

FLT

VCC

VO

CLAMP

GND

NCD5703B

VREF

VIN

FLT

DESAT

VCC

VO

GND

VEE

NCD5703C

VREF

VIN

DESAT

VCC

VOH

VOL

GND

VCC

VEE

VCC

FLT

Figure 1. Simplified Application Schematics

www.onsemi.com

2

Page 3

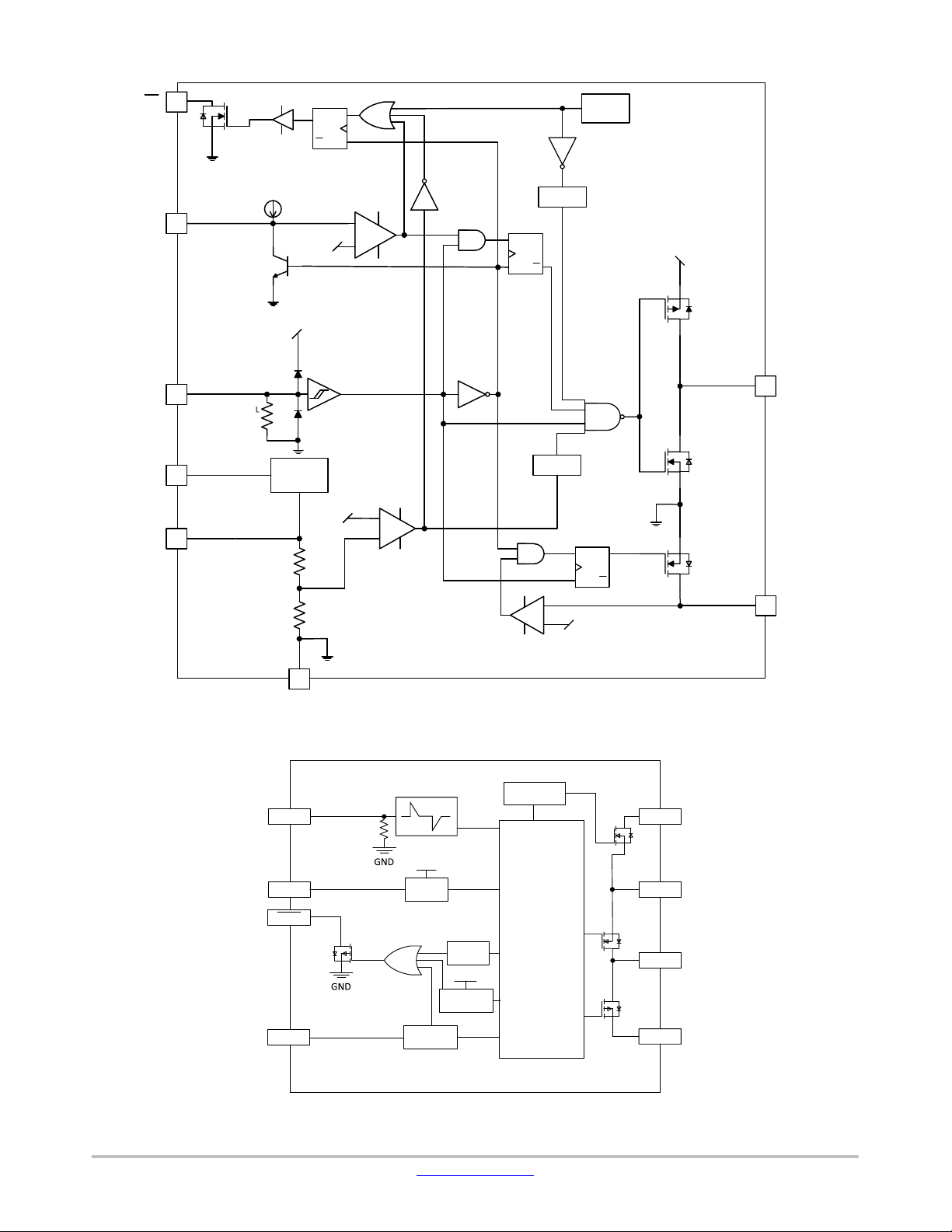

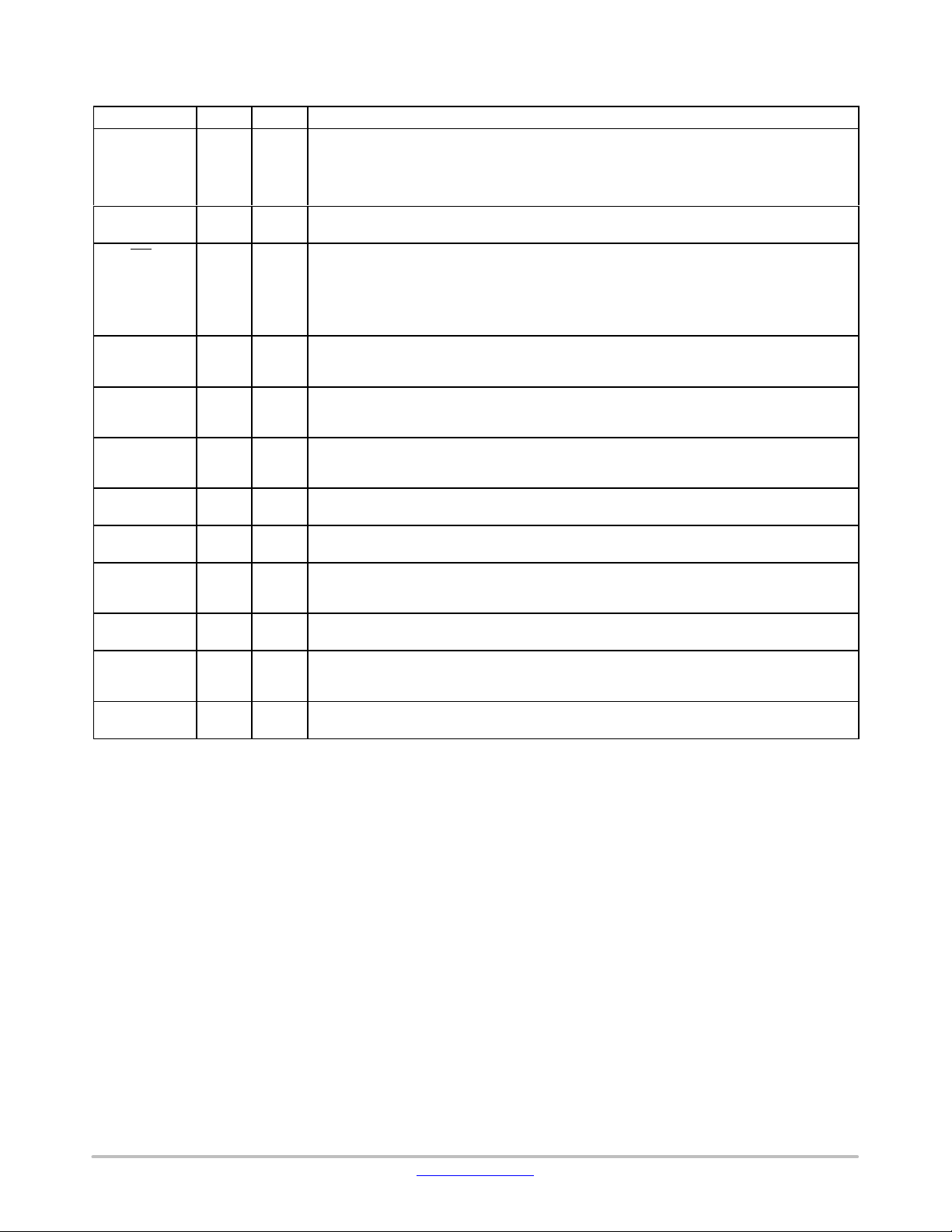

NCD5703A, NCD5703B, NCD5703C

FLT

DESAT

V

V

REF

V

SET

Q S

CLR

Q R

TSD

NCD5703A

I

DESAT-CHG

V

DESAT-THR

V

REF

IN

R

IN-

+

-

Bandgap

V

UVLO

-

CC

+

SET

S Q

CLR

R Q

DELAY

DELAY

-

+

V

MC-THR

SET

S Q

CLR

R Q

V

CC

V

O

CLAMP

GND

Figure 2(a). Detailed Block Diagram NCD5703A

NCD5703A

CLAMP

VIN

VCC

VREF

FLT

LDO

TSD

VCC

Logic Unit

UVLO

DESAT

Figure 2(b). Simplified Block Diagram NCD5703A

DESAT

CLAMP

GND

VO

VCC

www.onsemi.com

3

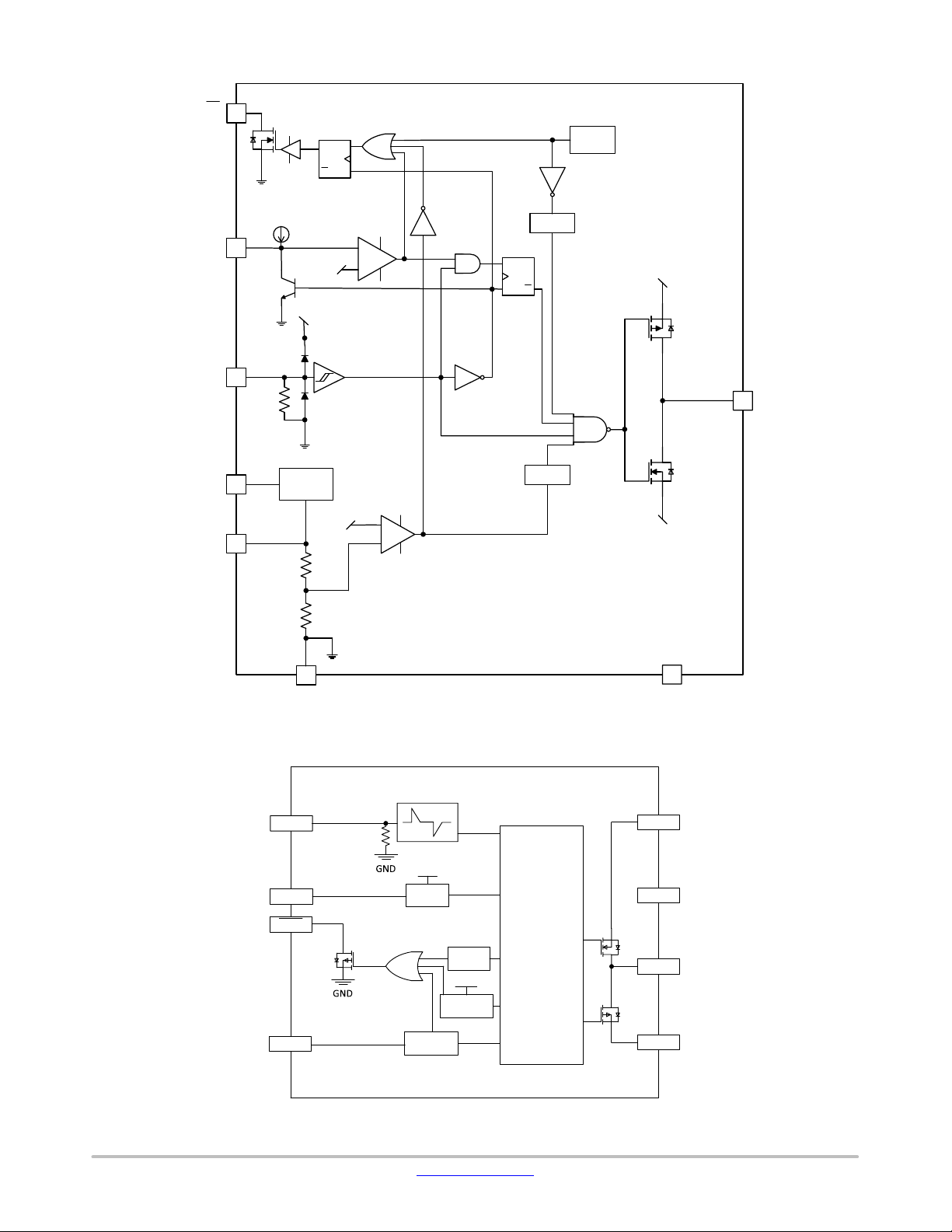

Page 4

FLT

NCD5703A, NCD5703B, NCD5703C

DESAT

V

V

V

CC

REF

SET

Q S

CLR

Q R

I

DESAT-CHG

V

DESAT-THR

V

IN

R

IN-L

+

-

REF

Bandgap

V

UVLO

-

+

SET

S Q

CLR

R Q

DELAY

DELAY

TSD

NCD5703B

V

CC

V

EE

V

O

GND

Figure 3(a). Detailed Block Diagram NCD5703B

NCD5703B

VIN

VCC

VREF

FLT

LDO

TSD

VCC

Logic Unit

UVLO

DESAT

Figure 3(b). Simplified Block Diagram NCD5703B

DESAT

VEE

GND

VO

VCC

V

EE

www.onsemi.com

4

Page 5

FLT

NCD5703A, NCD5703B, NCD5703C

DESAT

V

V

REF

V

SET

Q S

CLR

Q R

I

DESAT-CHG

V

DESAT-THR

V

REF

IN

R

IN-L

+

-

SET

S Q

CLR

R Q

DELAY

TSD

NCD5703C

V

CC

V

OH

V

OL

DELAY

Bandgap

CC

V

UVLO

-

+

GND

Figure 4(a). Detailed Block Diagram NCD5703C

NCD5703C

VIN

VCC

VREF

FLT

LDO

TSD

VCC

UVLO

DESAT

Figure 4(b). Simplified Block Diagram NCD5703C

DESAT

Logic Unit

GND

VOL

VOH

VCC

www.onsemi.com

5

Page 6

NCD5703A, NCD5703B, NCD5703C

Table 1. PIN FUNCTION DESCRIPTION

Pin Name No. I/O/x Description

VIN 1 I Input signal to control the output. In applications which require galvanic isolation, VIN is generat-

VREF 2 O 5 V Reference generated within the driver is brought out to this pin for external bypassing and

FLT 3 O Fault open drain output (active low) that allows communication to the main controller that the

DESAT 4 I Input for detecting the desaturation of IGBT due to a fault condition. A capacitor connected to

VCC 5 x Positive bias supply for the driver. The operating range for this pin is from UVLO to the maxi-

VO

(NCD5703A,

NCD5703B)

VOH

(NCD5703C)

VOL

(NCD5703C)

GND

(NCD5703A,

NCD5703B)

GND

(NCD5703C)

VEE

(NCD5703B)

CLAMP

(NCD5703A)

6 O Driver output that provides the appropriate drive voltage, source and sink current to the IGBT

6 O Driver high output that provides the appropriate drive voltage and source current to the IGBT

7 O Driver low output that provides the appropriate drive voltage and sink current to the IGBT gate.

7 x This pin should connect to the IGBT Emitter with a short trace. All power pin bypass capacitors

8 x This pin should connect to the IGBT Emitter with a short trace. All power pin bypass capacitors

8 x A negative voltage with respect to GND can be applied to this pin and that will allow VO to go to

8 I/O Provides clamping for the IGBT gate during the off period to protect it from parasitic turn−on. To

ed at the opto output, the pulse transformer secondary or the digital isolator output. VO (VOH/

VOL) signal is in phase with VIN. VIN is internally clamped to GND and has a pull−down resistor

of 1 MW to ensure that an output is low in the absence of an input signal. A minimum pulse−

width is required at VIN before VO (VOH/VOL) is activated.

for powering low bias circuits (such as digital isolators).

driver has encountered a fault condition and has deactivated the output. Open drain allows easy

setting of (inactive) high level and parallel connection of multiple fault signals.

Connect to 10k pull−up resistor recommended. Truth Table is provided in the datasheet to indicate conditions under which this signal is asserted. Capable of driving optos or digital isolators

when isolation is required.

this pin allows a programmable blanking delay every ON cycle before DESAT fault is processed,

thus preventing false triggering.

mum. A good quality bypassing capacitor is required from this pin to GND and should be placed

close to the pins for best results.

gate. VO is actively pulled low during start−up and under Fault conditions.

gate.

VOL is actively pulled low during start−up and under Fault conditions.

should be referenced to this pin and kept at a short distance from the pin.

should be referenced to this pin and kept at a short distance from the pin.

a negative voltage during OFF state. A good quality bypassing capacitor is needed from VEE to

GND. If a negative voltage is not applied or available, this pin must be connected to GND.

be tied directly to IGBT gate with minimum trace length for best results.

www.onsemi.com

6

Page 7

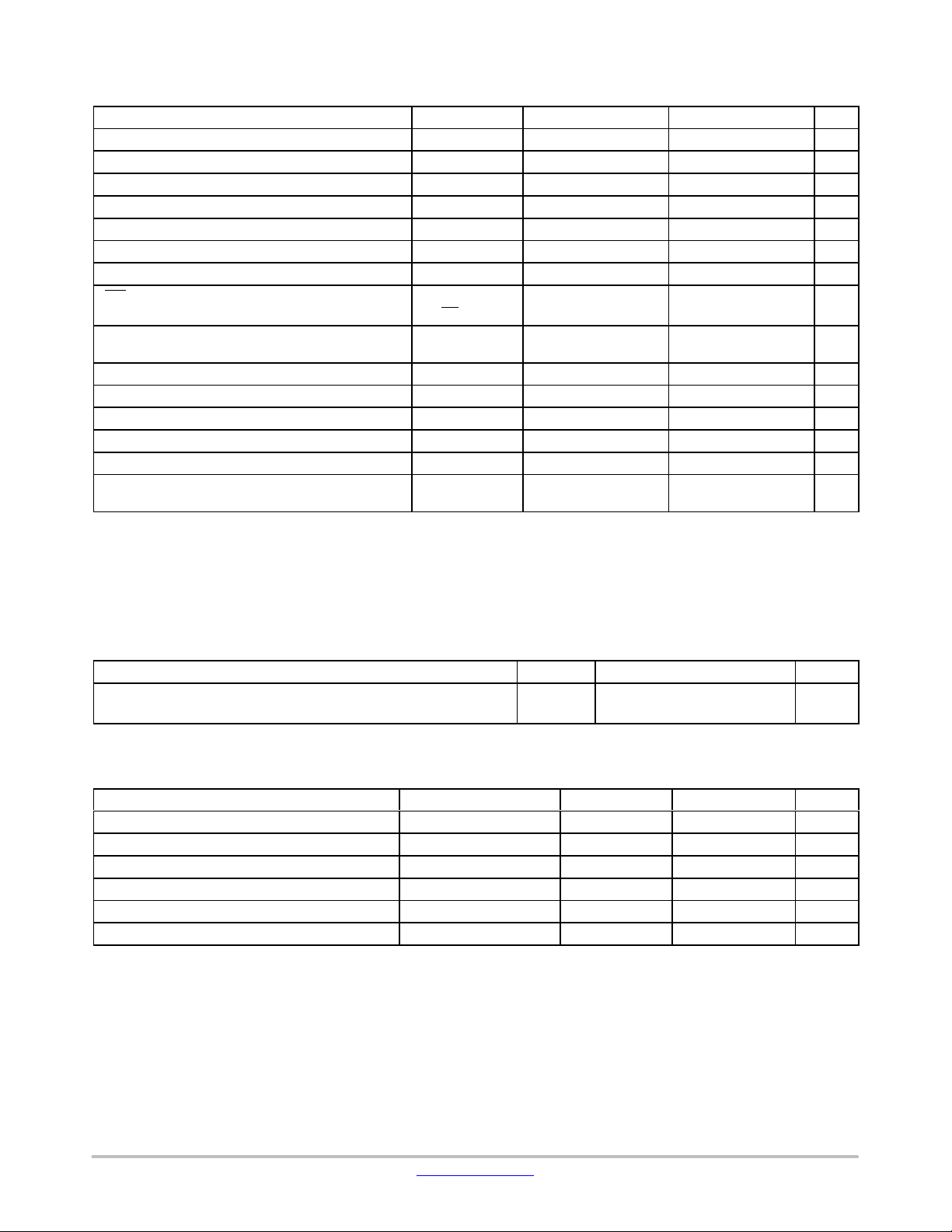

NCD5703A, NCD5703B, NCD5703C

Table 2. ABSOLUTE MAXIMUM RATINGS (Note 1)

Parameter Symbol Minimum Maximum Unit

Differential Power Supply VCC−VEE (V

Positive Power Supply VCC−GND −0.3 22 V

Negative Power Supply VEE−GND −18 0.3 V

Gate Output High (VO, VOH)−GND VCC + 0.3 V

Gate Output Low (VO, VOL)−GND VEE − 0.3 V

Input Voltage VIN−GND −0.3 5.5 V

DESAT Voltage V

DESAT

FLT current

Sink

Power Dissipation

I

FLT−SINK

PD 700 mW

SO−8 package

Maximum Junction Temperature T

J(max)

Storage Temperature Range TSTG −65 to 150 °C

ESD Capability, Human Body Model (Note 2) ESDHBM 4 kV

ESD Capability, Machine Model (Note 2) ESDMM 200 V

Moisture Sensitivity Level MSL 1 −

Lead Temperature Soldering

Reflow (SMD Styles Only), Pb−Free Versions (Note 3)

T

SLD

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

2. This device series incorporates ESD protection and is tested by the following methods:

ESD Human Body Model tested per AEC−Q100−002 (EIA/JESD22−A114)

ESD Machine Model tested per AEC−Q100−003 (EIA/JESD22−A115)

Latchup Current Maximum Rating: ≤100 mA per JEDEC standard: JESD78, 25°C

3. For information, please refer to our Soldering and Mounting Techniques Reference Manual, SOLDERRM/D.

) 0 36 V

max

−GND −0.3 VCC + 0.3 V

mA

20

150 °C

260 °C

Table 3. THERMAL CHARACTERISTICS

Parameter Symbol Value Unit

Thermal Characteristics, SOIC−8 (Note 4)

Thermal Resistance, Junction−to−Air (Note 5)

4. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

5. Values based on copper area of 100 mm

2

(or 0.16 in2) of 1 oz copper thickness and FR4 PCB substrate.

R

q

JA

176

°C/W

Table 4. OPERATING RANGES (Note 6)

Parameter

Differential Power Supply VCC−VEE (V

Positive Power Supply V

Negative Power Supply V

Input Voltage V

Input pulse width t

Ambient Temperature T

6. Refer to ELECTRICAL CHARACTERISTICS and APPLICATION INFORMATION for Safe Operating Area.

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

Symbol Min Max Unit

) 30 V

max

CC

EE

IN

on

A

UVLO 20 V

−15 0 V

0 5 V

40 ns

−40 125 °C

www.onsemi.com

7

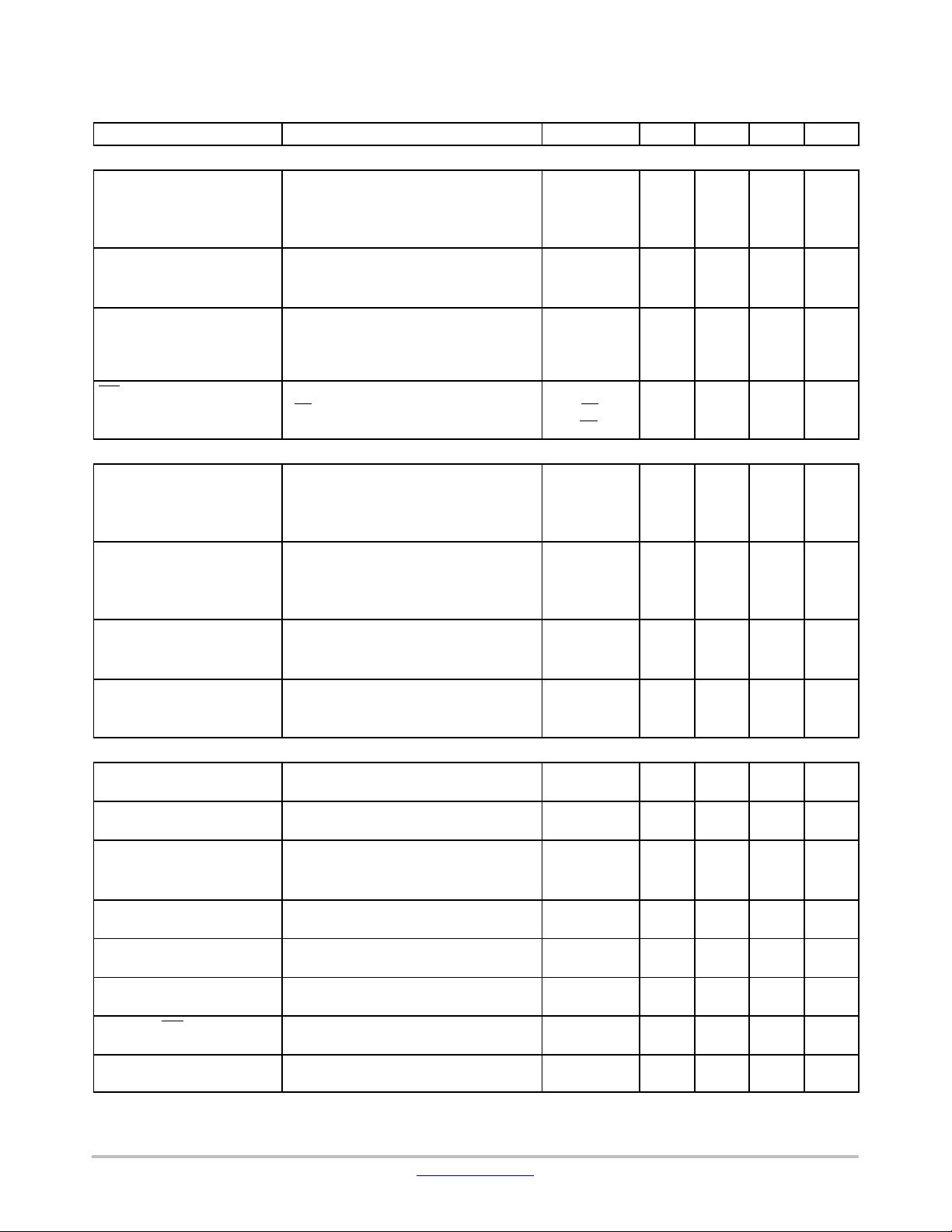

Page 8

NCD5703A, NCD5703B, NCD5703C

Table 5. ELECTRICAL CHARACTERISTICS V

for min/max values, T

Parameter

LOGIC INPUT and OUTPUT

Input Threshold Voltages

High−state (Logic 1) Required

Low−state (Logic 0) Required

No state change

Input Current

High−state

Low−state

Input Pulse−Width

No Response at the Output

Guaranteed Response at the

Output

FLT Threshold Voltage

Low State

High State

DRIVE OUTPUT

Output Low State

Output High State

Peak Driver Current, Sink

(Note 7)

Peak Driver Current, Source

(Note 7)

DYNAMIC CHARACTERISTICS

Turn−on Delay

(see timing diagram)

Turn−off Delay

(see timing diagram)

Propagation Delay Distortion

− t

(=t

pd−on

pd−off

Prop Delay Distortion between

Parts (Note 7)

Rise Time (Note 7)

(see timing diagram)

Fall Time (Note 7)

(see timing diagram)

Delay from FLT under UVLO/

TSD to VO/VOL

Delay from DESAT to VO/VOL

(Note 7)

7. Values based on design and/or characterization.

is the operating ambient temperature range that applies, unless otherwise noted.

A

Test Conditions Symbol Min Ty p Max Unit

Pulse−Width = 150 ns, V

Voltage applied to get output to go high

Voltage applied to get output to go low

Voltage applied without change in output state

V

= 4.5 V

IN−H

V

= 0.5 V

IN−L

Voltage thresholds consistent with input

specs

(I

FLT−SINK

= 15 mA)

External pull−up

I

= 200 mA, TA = 25°C

sink

I

= 200 mA, TA = −40°C to 125°C

sink

I

= 1.0 A, TA = 25°C

sink

I

= 200 mA, TA = 25°C

src

I

= 200 mA, TA = −40°C to 125°C

src

I

= 1.0 A, TA = 25°C

src

RG = 0.1 W, VCC = 15 V, VEE = −8 V

V

= 13 V

O

V

= 9 V (near Miller Plateau)

O

RG = 0.1 W, VCC = 15 V, VEE = −8 V

V

= −5 V

O

V

= 9 V (near Miller Plateau)

O

Negative input pulse width = 10 ms

Positive input pulse width = 10 ms

For input or output pulse width > 150 ns,

)

= 25°C

T

A

T

= −40°C to 125°C

A

C

= 1.0 nF t

load

C

= 1.0 nF t

load

= 15 V, VEE = 0 V, Kelvin GND connected to VEE. For typical values TA = 25°C,

CC

= 5 V

EN

V

IN−H1

V

IN−L1

V

IN−NC

I

IN−H

I

IN−L

t

on−min1

t

on−min2

V

FLT−L

V

FLT−H

V

OL1

V

OL2

V

OL3

V

OH1

V

OH2

V

OH3

I

PK−snk1

I

PK−snk2

I

PK−src1

I

PK−src2

t

pd−on

t

pd−off

t

distort1

t

distort2

t

distort −tot

rise

fall

t

d1−OUT

t

d2−OUT

4.3

0.75

1.2

3.7

10

1

15

35

0.5 1.0

V

+0.3

CC

14.5

14.2

13.8

0.1

0.2

0.8

14.8

14.7

14.1

0.2

0.5

1.2

6.8

6.1

7.8

4.0

45 59 75 ns

45 54 75 ns

−5

−25

5 15

25

−30 0 30 ns

9.2 ns

7.9 ns

10 12 15

220 ns

V

mA

ns

V

V

V

A

A

ns

ms

www.onsemi.com

8

Page 9

NCD5703A, NCD5703B, NCD5703C

Table 5. ELECTRICAL CHARACTERISTICS V

for min/max values, T

is the operating ambient temperature range that applies, unless otherwise noted.

A

= 15 V, VEE = 0 V, Kelvin GND connected to VEE. For typical values TA = 25°C,

CC

Parameter UnitMaxTypMinSymbolTest Conditions

DYNAMIC CHARACTERISTICS

Delay from UVLO/TSD to FLT

(Note 7)

t

d3−FLT

7.3

ms

MILLER CLAMP (NCD5703A ONLY)

I

Clamp Voltage

= 500 mA, TA = 25°C

sink

I

= 500 mA, TA = −40°C to 125°C

sink

Clamp Activation Threshold V

V

clamp

MC−THR

1.2 1.4

2.2

1.8 2.0 2.2 V

V

DESAT PROTECTION

DESAT Threshold Voltage

Blanking Charge Current I

Blanking Discharge Current I

V

DESAT−THR

DESAT−CHG

DESAT−DIS

6.0 6.35 7.0 V

0.20 0.24 0.28 mA

30 mA

UVLO

UVLO Startup Voltage

V

UVLO Disable Voltage V

UVLO Hysteresis V

UVLO−OUT−ON

UVLO−OUT−OFF

UVLO−HYST

13.2 13.5 13.8 V

12.2 12.5 12.8 V

1.0 V

VREF

I

Voltage Reference

= 10 mA V

REF

Reference Output Current

(Note 7)

Recommended Capacitance C

REF

I

REF

VREF

4.85 5.00 5.15 V

20 mA

100 nF

SUPPLY CURRENT

Current Drawn from V

Current Drawn from V

(NCD5703B ONLY)

CC

EE

VCC = 15 V

Standby (No load on output, FLT

VEE = −10 V

Standby (No load on output, FLT

, VREF)

, VREF)

I

CC−SB

I

EE−SB

0.9 1.5 mA

−0.2 −0.14 mA

THERMAL SHUTDOWN

Thermal Shutdown Temperature

(Note 7)

Thermal Shutdown Hysteresis

(Note 7)

T

SD

T

SH

188 °C

33 °C

7. Values based on design and/or characterization.

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

ORDERING INFORMATION

Device Package Shipping

NCD5703ADR2G SOIC−8

2500 / Tape & Reel

(Pb−Free)

NCD5703BDR2G SOIC−8

2500 / Tape & Reel

(Pb−Free)

NCD5703CDR2G SOIC−8

2500 / Tape & Reel

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

†

www.onsemi.com

9

Page 10

NCD5703A, NCD5703B, NCD5703C

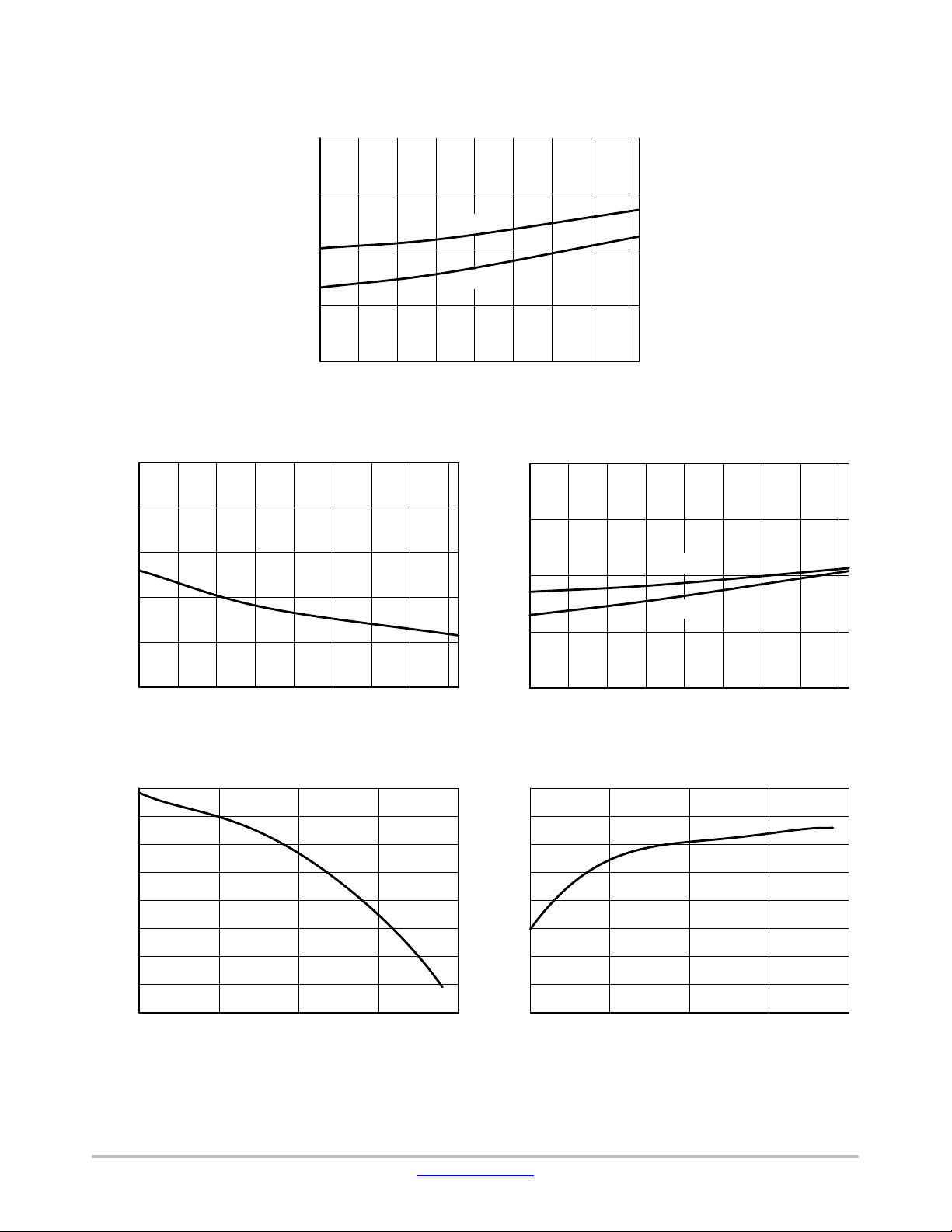

TYPICAL CHARACTERISTICS

80

70

t

pd−on

60

t

pd−off

50

PROPAGATION DELAY (ns)

40

TEMPERATURE (°C)

120

100806040200−20−40

Figure 5. Propagation Delay vs. Temperature

15

14

13

12

11

FAULT TO OUTPUT DELAY (ms)

10

TEMPERATURE (°C)

120

100806040200−20−40

20

15

10

5

RISE/FALL TIME (ns)

0

t

fall

t

rise

TEMPERATURE (°C)

120

100806040200−20−40

Figure 6. Fault to Output Low Delay Figure 7. Output Rise/Fall Time

8

7

8

7

(A)

O

I

6

5

4

3

2

1

0

VO (V, VCC = 15 V, VEE = −8 V) VO (V, VCC = 15 V, VEE = −8 V)

Figure 8. Output Source Current vs. Output

Voltage

6

5

(A)

4

O

I

3

2

1

151050−5

0

www.onsemi.com

10

151050−5

Figure 9. Output Sink Current vs. Output

Voltage

Page 11

NCD5703A, NCD5703B, NCD5703C

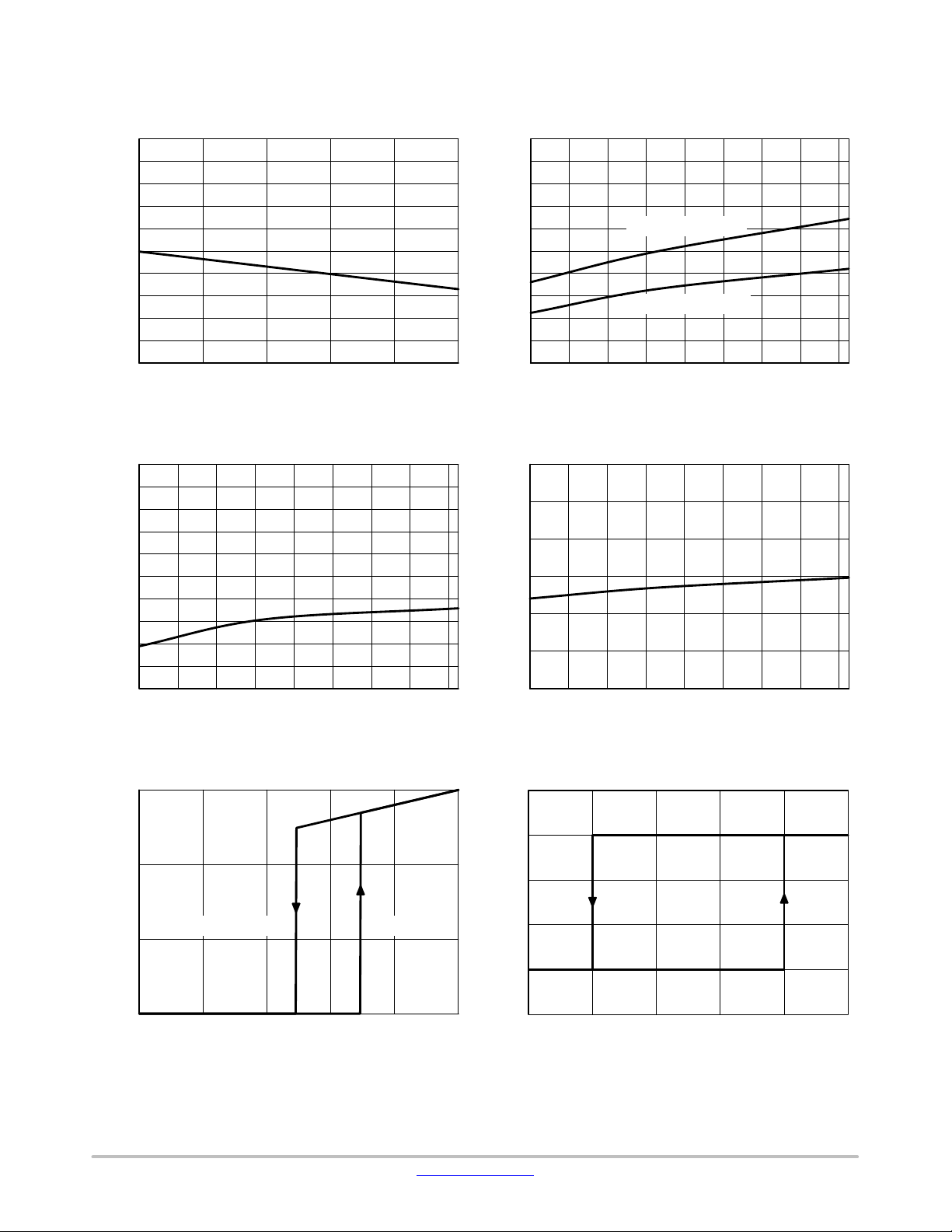

TYPICAL CHARACTERISTICS

(V)

REF

V

(mA)

DESET−CHG

I

5.05

5.04

5.03

5.02

5.01

5.00

4.99

4.98

4.97

4.96

4.95

260

250

Figure 10. V

5.05

5.04

5.03

5.02

V

@ I

V

REF

REF

@ I

5.01

(V)

5.00

REF

V

4.99

4.98

4.97

4.96

4.95

1086420

I

(mA) TEMPERATURE (°C)

REF

Voltage vs. Current Figure 11. V

REF

Voltage vs. Temperature

REF

6.5

6.4

(V)

DESAT

V

6.3

REF

REF

= 0 mA

= 10 mA

100806040200−20−40

120

240

15

10

5

, OUTPUT VOLTAGE (V)

O

V

0

100806040200−20−40

120

TEMPERATURE (°C) TEMPERATURE (°C)

6.2

Figure 12. DESAT Charge Current vs.

Temperature

Figure 13. DESAT Threshold Voltage vs.

Temperature

20

15

10

(V)

O

V

UVLO−OUT−OFF UVLO−OUT−ON

5

0

−5

151413121110

VCC, SUPPLY VOLTAGE (V) VIN (V)

Figure 14. UVLO Threshold Voltages Figure 15. VO vs. VIN at 255C

(V

= 15 V, VEE = 0 V)

CC

100806040200−20−40

120

543210

www.onsemi.com

11

Page 12

NCD5703A, NCD5703B, NCD5703C

TYPICAL CHARACTERISTICS

(V)

FLT−L

V

1.0

0.5

0

TEMPERATURE (°C)

Figure 16. Fault Output, Sinking 15 mA

1.4

1.2

1.0

0.8

2.5

2.0

(V)

1.5

CLAMP

V

1.0

120

100806040200−20−40

0.5

TEMPERATURE (°C)

Figure 17. V

I

CC

at 0.5 A (NCD5703A Only)

CLAMP

120

100806040200−20−40

0.6

0.4

SUPPLY CURRENT (mA)

0.2

0

Figure 18. Supply Current vs. Switching

Frequency (V

IEE (NCD5703B Only)

FREQUENCY (kHz)

= 15 V, VEE = −10 V, 255C)

CC

100806040200

www.onsemi.com

12

Page 13

NCD5703A, NCD5703B, NCD5703C

Applications and Operating Information

This section lists the details about key features and

operating guidelines for the NCD5703.

High Drive Current Capability

The NCD5703 driver family is equipped with many

features which facilitate a superior performance IGBT

driving circuit. Foremost amongst these features is the high

drive current capability. The drive current of an IGBT driver

is a function of the differential voltage on the output pin

(V

−VOH/VO for source current, VOL/VO−VEE for sink

CC

current) as shown in Figure 19. Figure 19 also indicates that

for a given VOH/VOL value, the drive current can be

increased by using higher V

CC/VEE

drive current tends to drop off as the output voltage goes up

(for turn−on event) or goes down (for turn−off event). As

explained in many IGBT application notes, the most critical

phase of IGBT switching event is the Miller plateau region

where the gate voltage remains constant at a voltage

(typically in 9−11 V range depending on IGBT design and

the collector current), but the gate drive current is used to

charge/discharge the Miller capacitance (C

providing a high drive current in this region, a gate driver can

significantly reduce the duration of the phase and help

reducing the switching losses. The NCD5703 addresses this

requirement by providing and specifying a high drive

current in the Miller plateau region. Most other gate driver

ICs merely specify peak current at the start of switching –

which may be a high number, but not very relevant to the

application requirement. It must be remembered that other

considerations such as EMI, diode reverse recovery

performance, etc., may lead to a system level decision to

trade off the faster switching speed against low EMI and

reverse recovery. However, the use of NCD5703 does not

preclude this trade−off as the user can always tune the drive

current by employing external series gate resistor. Important

thing to remember is that by providing a high internal drive

current capability, the NCD5703 facilitates a wide range of

gate resistors. Another value of the high current at the Miller

plateau is that the initial switching transition phase is shorter

and more controlled. Finally, the high gate driver current

(which is facilitated by low impedance internal FETs),

ensures that even at high switching frequencies, the power

dissipation from the drive circuit is primarily in the external

series resistor and more easily manageable. Experimental

results have shown that the high current drive results in

reduced turn−on energy (E

) for the IGBT switching.

ON

power supply). The

). By

GC

Figure 19. Output Current vs. Output Voltage Drop

When driving larger IGBTs for higher current

applications, the drive current requirement is higher, hence

lower R

is used. Larger IGBTs typically have high input

G

capacitance. On the other hand, if the NCD5703 is used to

drive smaller IGBT (lower input capacitance), the drive

current requirement is lower and a higher R

is used. Thus,

G

for most typical applications, the driver load RC time

constant remains fairly constant. Caution must be exercised

when using the NCD5703 with a very low load RC time

constant. Such a load may trigger internal protection

circuitry within the driver and disable the device. Figure 20

shows the recommended minimum gate resistance as a

function of IGBT gate capacitance and gate drive trace

inductance.

Figure 20. Recommended Minimum Gate Resistance

as a Function of IGBT Gate Capacitance

www.onsemi.com

13

Page 14

NCD5703A, NCD5703B, NCD5703C

Gate Voltage Range

The negative drive voltage for gate (with respect to GND,

or Emitter of the IGBT) is a robust way to ensure that the gate

voltage does not rise above the threshold voltage due to the

Miller effect. In systems where the negative power supply is

available, the VEE option offered by NCD5703B allows not

only a robust operation, but also a higher drive current for

turn−off transition. Adequate bypassing between VEE pin

and GND pin is essential if this option is used.

The V

range for the NCD5703 is quite wide and allows

CC

the user the flexibility to optimize the performance or use

available power supplies for convenience.

Under Voltage Lock Out (UVLO)

This feature ensures reliable switching of the IGBT

connected to the driver output. At the start of the driver’s

operation when V

remains turned−off. This is regardless of the signals on V

is applied to the driver, the output

CC

IN

until the VCC reaches the UVLO Output Enabled

(V

UVLO−OUT−ON

V

UVLO−OUT−ON

state of the output is controlled by signal at V

If the V

(V

UVLO−OUT−OFF

) level. After the VCC rises above the

level, the driver is in normal operation. The

.

IN

falls below the UVLO Output Disabled

CC

) level during the normal operation of the

driver, the Fault output is activated and the output is shut−down

(after a delay) and remains in this state. The driver output

does not start to react to the input signal on V

rises above the V

UVLO−OUT−ON

again. The waveform

until the V

IN

CC

showing the UVLO behavior of the driver is in Figure 21.

In an IGBT drive circuit, the drive voltage level is

important for drive circuit optimization. If V

UVLO−OUT−OFF

is too low, it will lead to IGBT being driven with insufficient

gate voltage. A quick review of IGBT characteristics can

reveal that driving IGBT with low voltage (in 10−12 V

range) can lead to a significant increase in conduction loss.

So, it is prudent to guarantee V

UVLO−OUT−OFF

at a

reasonable level (above 12 V), so that the IGBT is not forced

to operate at a non−optimum gate voltage. On the other hand,

having a very high drive voltage ends up increasing

switching losses without much corresponding reduction in

conduction loss. So, the V

UVLO−OUT−ON

value should not

be too high (generally, well below 15 V). These conditions

lead to a tight band for UVLO enable and disable voltages,

while guaranteeing a minimum hysteresis between the two

values to prevent hiccup mode operation. The NCD5703

meets these tight requirements and ensures smooth IGBT

operation. It ensures that a 15 V supply with ±8% tolerance

will work without degrading IGBT performance, and

guarantees that a fault will be reported and the IGBT will be

turned off when the supply voltage drops below 12.2 V.

A UVLO event (V

also triggers activation of FLT

voltage going below V

CC

output after a delay of t

UVLO−OUT−OFF

d3−FLT

This indicates to the controller that the driver has

encountered an issue and corrective action needs to be taken.

However, a nominal delay t

between the initiation of the FLT

= 12 ms is introduced

d1−OUT

output and actual turning

off of the output. This delay provides adequate time for the

controller to initiate a more orderly/sequenced shutdown. In

case the controller fails to do so, the driver output shutdown

ensures IGBT protection after t

Figure 21. UVLO Function and Limits

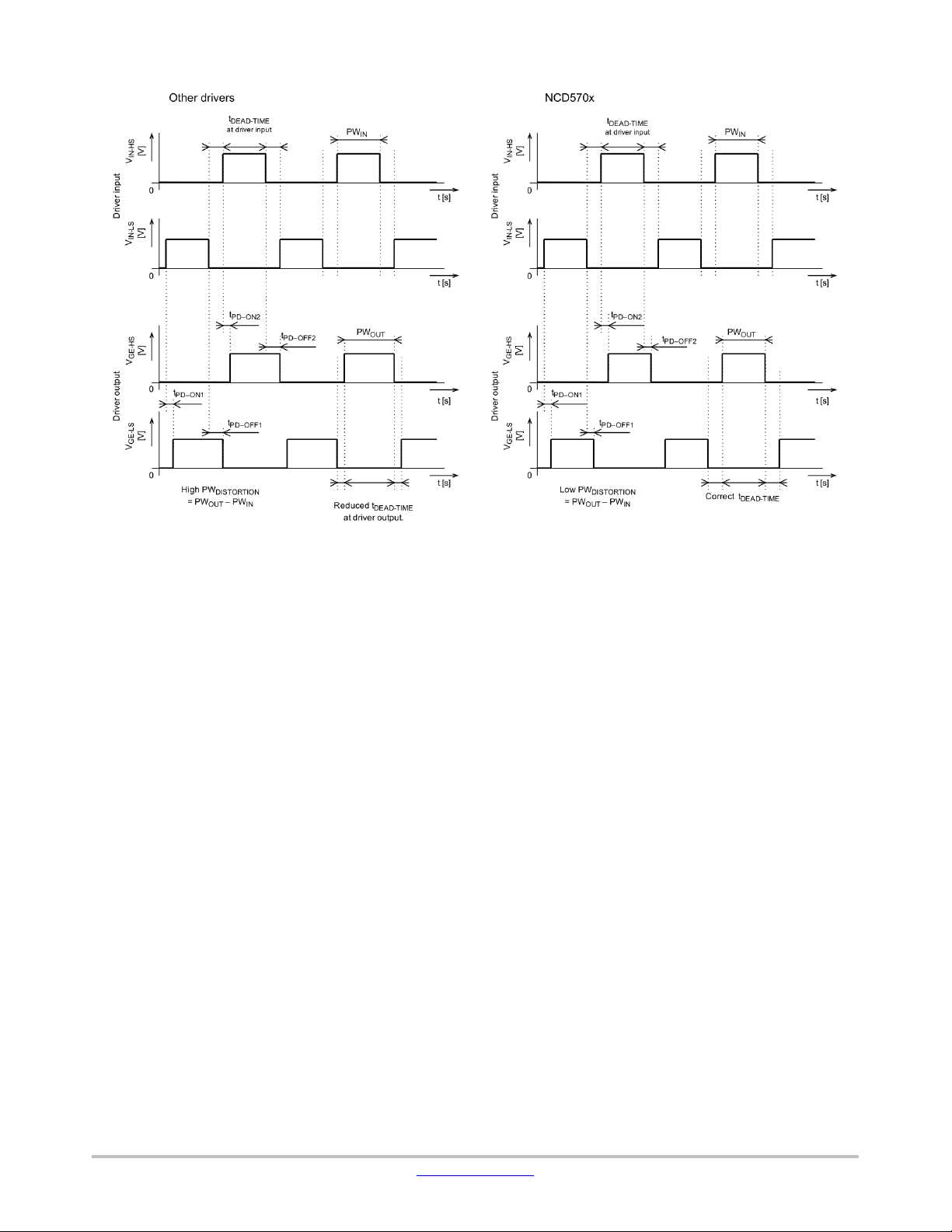

Timing Delays and Impact on System Performance

d1−OUT

.

The gate driver is ideally required to transmit the input

signal pulse to its output without any delay or distortion. In

the context of a high−power system where IGBTs are

typically used, relatively low switching frequency (in tens of

kHz) means that the delay through the driver itself may not

be as significant, but the matching of the delay between

different drivers in the same system as well as between

different edges has significant importance. With reference to

Figure 22(a), two input waveforms are shown. They are

typical complementary inputs for high−side (HS) and

low−side (LS) of a half−bridge switching configuration. The

dead−time between the two inputs ensures safe transition

between the two switches. However, once these inputs are

through the driver, there is potential for the actual gate

voltages for HS and LS to be quite different from the

intended input waveforms as shown in Figure 22(a). The end

result could be a loss of the intended dead−time and/or

pulse−width distortion. The pulse−width distortion can

create an imbalance that needs to be corrected, while the loss

of dead−time can eventually lead to cross−conduction of the

switches and additional power losses or damage to the

)

system.

.

The NCD5703 driver is designed to address these timing

challenges by providing a very low pulse−width distortion

and excellent delay matching. As an example, the delay

matching is guaranteed to t

DISTORT2

= ±25 ns while many

of competing driver solutions can be >250 ns.

www.onsemi.com

14

Page 15

NCD5703A, NCD5703B, NCD5703C

Figure 22(a). Timing Waveforms (Other Drivers) Figure 22(b). NCD5703 Timing Waveforms

Active Miller Clamp Protection

This feature (offered by NCD5703A) is a cost savvy

alternative to a negative gate voltage. The main requirement

is to hold the gate of the turned−off (for example low−side)

IGBT below the threshold voltage during the turn−on of the

opposite−side (in this example high−side) IGBT in the half

bridge. The turn−on of the high−side IGBT causes high dv/dt

transition on the collector of the turned−off low−side IGBT.

This high dv/dt then induces current (Miller current) through

the C

capacitance (Miller capacitance) to the gate

GC

capacitance of the low−side IGBT as shown in Figure 23. If

the path from gate to GND has critical impedance (caused

by R

) the Miller current could rise the gate voltage above

G

the threshold level. As a consequence the low−side IGBT

could be turned on for a few tens or hundreds of

An alternative way is to provide an additional path from

gate to GND with very low impedance. This is exactly what

Active Miller Clamp protection does. Additional trace from

the gate of the IGBT to the Clamp pin of the gate driver is

introduced. After the V

Miler Clamp threshold V

output has gone below the Active

O

MC−THR

the Clamp pin is shorted

to GND and thus prevents the voltage on the gate of the

IGBT to rise above the threshold voltage as shown in

Figure 24. The Clamp pin is disconnected from GND as

soon as the signal to turn on the IGBT arrives to the gate

driver input. The fact that the Clamp pin is engaged only

after the gate voltage drops below the V

ensures that the function of this pin does not interfere with

the normal turn−off switching performance that is user

controllable by choice of R

.

G

nanoseconds. This causes higher switching losses. One way

to avoid this situation is to use negative gate voltage, but this

requires second DC source for the negative gate voltage.

MC−THR

threshold

www.onsemi.com

15

Page 16

NCD5703A, NCD5703B, NCD5703C

Figure 23. Current Path without Miller Clamp

Protection

Desaturation Protection (DESAT)

This feature monitors the collector−emitter voltage of the

IGBT in the turned−on state. When the IGBT is fully turned

on, it operates in a saturation region. Its collector−emitter

voltage (called saturation voltage) is usually low, well below

3 V for most modern IGBTs. It could indicate an overcurrent

or similar stress event on the IGBT if the collector−emitter

voltage rises above the saturation voltage, after the IGBT is

fully turned on. Therefore the DESAT protection circuit

compares the collector−emitter voltage with a voltage level

V

DESAT−THR

to check if the IGBT didn’t leave the saturation

region. It will activate FLT output and shut down driver

output (thus turn−off the IGBT), if the saturation voltage

rises above the V

DESAT−THR

. This protection works on

every turn−on phase of the IGBT switching period.

At the beginning of turning−on of the IGBT, the

collector−emitter voltage is much higher than the saturation

voltage level which is present after the IGBT is fully turned

on. It takes almost 1 ms between the start of the IGBT turn−on

and the moment when the collector−emitter voltage falls to

the saturation level. Therefore the comparison is delayed by

a configurable time period (blanking time) to prevent false

triggering of DESAT protection before the IGBT

collector−emitter voltage falls below the saturation level.

Blanking time is set by the value of the capacitor C

BLANK

The exact principle of operation of DESAT protection is

described with reference to Figure 25.

At the turned−off output state of the driver, the DESAT pin

is shorted to ground via the discharging transistor (Q

DIS

Therefore, the inverting input holds the comparator output

at low level.

Figure 24. Current Path with Miller Clamp Protection

At the turned−on output state of the driver, the current

I

DESAT−CHG

blanking capacitor C

from current source starts to flow to the

, connected to DESAT pin.

BLANK

Appropriate value of this capacitor has to be selected to

ensure that the DESAT pin voltage does not rise above the

threshold level V

DESAT−THR

before the IGBT fully turns on.

The blanking time is given by following expression.

According to this expression, a 47 pF C

BLANK

a blanking time of (47p *6.5/0.25m =) 1.22 ms.

V

t

+ C

BLANK

BLANK

After the IGBT is fully turned−on, the I

DESAT−THR

@

I

DESAT−CHG

DESAT−CHG

through the DESAT pin to the series resistor R

through the high voltage diode and then through the

collector and IGBT to the emitter. Care must be taken to

select the resistor R

S−DESAT

value so that the sum of the

saturation voltage, drop on the HV diode and drop on the

R

S−DESAT

caused by current I

DESAT−CHG

DESAT source current is smaller than the DESAT threshold

voltage. Following expression can be used:

V

DESAT−THR

R

S−DESAT

.

Important part for DESAT protection to work properly is

u

@ I

DESAT−CHG

) V

F_HV diode

) V

the high voltage diode. It must be rated for at least same

voltage as the low side IGBT. The safety margin is

application dependent.

).

The typical waveforms for IGBT overcurrent condition

are outlined in Figure 26.

will provide

flows

S−DESAT

and

flowing from

CESAT_IGBT

www.onsemi.com

16

Page 17

NCD5703A, NCD5703B, NCD5703C

Figure 25. Desaturation Protection Schematic

Figure 26. Desaturation Protection Waveforms

www.onsemi.com

17

Page 18

NCD5703A, NCD5703B, NCD5703C

Input Signal

The input signal controls the gate driver output. Figure 27

shows the typical connection diagrams for isolated

Figure 27. Opto−coupler or Pulse Transformer At Input

applications where the input is coming through an

opto−coupler or a pulse transformer.

The relationship between gate driver input signal from a

pulse transformer (Figure 28) or opto−coupler (Figure 29)

and the output is defined by many time and voltage values.

The time values include output turn−on and turn−off delays

(t

pd−on

and t

), output rise and fall times (t

pd−off

and minimum input pulse−width (t

V

IN-H1

V

IN-NC

V

IN

t

pd-on

V

OUT

t

rise

Figure 28. Input and Output Signal Parameters for Pulse Transformer

on−min

V

IN-L1

t

pd-on

and t

rise

fall

). Note that the

t

fall

delay times are defined from 50% of input transition to first

10% of the output transition to eliminate the load

dependency. The input voltage parameters include input

high (V

input range for which no output change is initiated

)

(V

IN−NC

) and low (V

IN−H1

).

) thresholds as well as the

IN−L1

t

on-min

90%

10%

www.onsemi.com

18

Page 19

NCD5703A, NCD5703B, NCD5703C

V

IN-H1

V

IN-NC

V

IN

t

V

pd-on

OUT

t

rise

Use of VREF Pin

The NCD5703 provides an additional 5.0 V output

(VREF) that can serve multiple functions. This output is

capable of sourcing up to 10 mA current for functions such

as opto−coupler interface or external comparator interface.

The VREF pin should be bypassed with at least a 100 nF

capacitor (higher the better) irrespective of whether it is

being utilized for external functionality or not. VREF is

V

IN-L1

t

t

pd-on

fall

Figure 29. Input and Output Signal Parameters for Opto−coupler

t

on-min

90%

10%

highly stable over temperature and line/load variations (see

characteristics curves for details)

Fault Output Pin

This pin provides the feedback to the controller about the

driver operation. The situations in which the FLT

signal

becomes active (low value) are summarized in the Table 6.

Table 6. FLT LOGIC TRUTH TABLE

VIN UVLO DESAT Internal TSD VOUT FLT Notes

L Inactive L L L Open drain Normal operation − Output Low

H Inactive L L H Open drain Normal operation − Output High

X Active X L L L

H Inactive H L L L DESAT activated (only when VIN is High) − Output

X Inactive X H L L

UVLO activated − FLT Low (t

+ t

(t

d3-FLT

Low (t

d2_OUT

Internal Thermal Shutdown − FLT Low (t

put Low (t

d1−OUT

), FLT Low

d3-FLT

)

+ t

d1−OUT

)

d3-FLT

), Output Low

Thermal Shutdown

The NCD5703 also offers thermal shutdown function that

is primarily meant to self−protect the driver in the event that

the internal temperature gets excessive. Once the

temperature crosses the T

activated after a delay of t

threshold, the FLT output is

SD

. After a delay of t

d3-FLT

d1−OUT

(12 ms), the output is pulled low and many of the internal

circuits are turned off. The 12 ms delay is meant to allow the

controller to perform an orderly shutdown sequence as

appropriate. Once the temperature goes below the second

threshold, the part becomes active again.

d3-FLT

), Out-

www.onsemi.com

19

Page 20

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

8

1

SCALE 1:1

−Y−

−Z−

−X−

A

58

B

1

4

G

H

D

0.25 (0.010) Z

M

SOLDERING FOOTPRINT*

7.0

0.275

SOIC−8 NB

CASE 751−07

ISSUE AK

DATE 16 FEB 2011

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

S

0.25 (0.010)

M

M

Y

K

Y

C

SXS

SEATING

PLANE

0.10 (0.004)

N

X 45

_

M

J

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

____

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

GENERIC

MARKING DIAGRAM*

8

XXXXXX

AYWW

1

Discrete

(Pb−Free)

G

1.52

0.060

4.0

0.155

8

XXXXX

ALYWX

1

8

XXXXX

ALYWX

G

1

IC

IC

(Pb−Free)

XXXXX = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

8

XXXXXX

AYWW

1

Discrete

XXXXXX = Specific Device Code

A = Assembly Location

Y = Year

WW = Work Week

G = Pb−Free Package

0.6

0.024

1.270

0.050

SCALE 6:1

ǒ

inches

mm

Ǔ

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

STYLES ON PAGE 2

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42564B

SOIC−8 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

www.onsemi.com

Page 21

STYLE 1:

PIN 1. EMITTER

2. COLLECTOR

3. COLLECTOR

4. EMITTER

5. EMITTER

6. BASE

7. BASE

8. EMITTER

STYLE 5:

PIN 1. DRAIN

2. DRAIN

3. DRAIN

4. DRAIN

5. GATE

6. GATE

7. SOURCE

8. SOURCE

STYLE 9:

PIN 1. EMITTER, COMMON

2. COLLECTOR, DIE #1

3. COLLECTOR, DIE #2

4. EMITTER, COMMON

5. EMITTER, COMMON

6. BASE, DIE #2

7. BASE, DIE #1

8. EMITTER, COMMON

STYLE 13:

PIN 1. N.C.

2. SOURCE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 17:

PIN 1. VCC

2. V2OUT

3. V1OUT

4. TXE

5. RXE

6. VEE

7. GND

8. ACC

STYLE 21:

PIN 1. CATHODE 1

2. CATHODE 2

3. CATHODE 3

4. CATHODE 4

5. CATHODE 5

6. COMMON ANODE

7. COMMON ANODE

8. CATHODE 6

STYLE 25:

PIN 1. VIN

2. N/C

3. REXT

4. GND

5. IOUT

6. IOUT

7. IOUT

8. IOUT

STYLE 29:

PIN 1. BASE, DIE #1

2. EMITTER, #1

3. BASE, #2

4. EMITTER, #2

5. COLLECTOR, #2

6. COLLECTOR, #2

7. COLLECTOR, #1

8. COLLECTOR, #1

STYLE 2:

PIN 1. COLLECTOR, DIE, #1

2. COLLECTOR, #1

3. COLLECTOR, #2

4. COLLECTOR, #2

5. BASE, #2

6. EMITTER, #2

7. BASE, #1

8. EMITTER, #1

STYLE 6:

PIN 1. SOURCE

2. DRAIN

3. DRAIN

4. SOURCE

5. SOURCE

6. GATE

7. GATE

8. SOURCE

STYLE 10:

PIN 1. GROUND

2. BIAS 1

3. OUTPUT

4. GROUND

5. GROUND

6. BIAS 2

7. INPUT

8. GROUND

STYLE 14:

PIN 1. N−SOURCE

2. N−GATE

3. P−SOURCE

4. P−GATE

5. P−DRAIN

6. P−DRAIN

7. N−DRAIN

8. N−DRAIN

STYLE 18:

PIN 1. ANODE

2. ANODE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. CATHODE

8. CATHODE

STYLE 22:

PIN 1. I/O LINE 1

2. COMMON CATHODE/VCC

3. COMMON CATHODE/VCC

4. I/O LINE 3

5. COMMON ANODE/GND

6. I/O LINE 4

7. I/O LINE 5

8. COMMON ANODE/GND

STYLE 26:

PIN 1. GND

2. dv/dt

3. ENABLE

4. ILIMIT

5. SOURCE

6. SOURCE

7. SOURCE

8. VCC

STYLE 30:

PIN 1. DRAIN 1

2. DRAIN 1

3. GATE 2

4. SOURCE 2

5. SOURCE 1/DRAIN 2

6. SOURCE 1/DRAIN 2

7. SOURCE 1/DRAIN 2

8. GATE 1

SOIC−8 NB

CASE 751−07

ISSUE AK

STYLE 3:

STYLE 7:

STYLE 11:

STYLE 15:

PIN 1. DRAIN, DIE #1

2. DRAIN, #1

3. DRAIN, #2

4. DRAIN, #2

5. GATE, #2

6. SOURCE, #2

7. GATE, #1

8. SOURCE, #1

PIN 1. INPUT

2. EXTERNAL BYPASS

3. THIRD STAGE SOURCE

4. GROUND

5. DRAIN

6. GATE 3

7. SECOND STAGE Vd

8. FIRST STAGE Vd

PIN 1. SOURCE 1

2. GATE 1

3. SOURCE 2

4. GATE 2

5. DRAIN 2

6. DRAIN 2

7. DRAIN 1

8. DRAIN 1

PIN 1. ANODE 1

2. ANODE 1

3. ANODE 1

4. ANODE 1

5. CATHODE, COMMON

6. CATHODE, COMMON

7. CATHODE, COMMON

8. CATHODE, COMMON

STYLE 19:

PIN 1. SOURCE 1

2. GATE 1

3. SOURCE 2

4. GATE 2

5. DRAIN 2

6. MIRROR 2

7. DRAIN 1

8. MIRROR 1

STYLE 23:

PIN 1. LINE 1 IN

2. COMMON ANODE/GND

3. COMMON ANODE/GND

4. LINE 2 IN

5. LINE 2 OUT

6. COMMON ANODE/GND

7. COMMON ANODE/GND

8. LINE 1 OUT

STYLE 27:

PIN 1. ILIMIT

2. OVLO

3. UVLO

4. INPUT+

5. SOURCE

6. SOURCE

7. SOURCE

8. DRAIN

DATE 16 FEB 2011

STYLE 4:

PIN 1. ANODE

2. ANODE

3. ANODE

4. ANODE

5. ANODE

6. ANODE

7. ANODE

8. COMMON CATHODE

STYLE 8:

PIN 1. COLLECTOR, DIE #1

2. BASE, #1

3. BASE, #2

4. COLLECTOR, #2

5. COLLECTOR, #2

6. EMITTER, #2

7. EMITTER, #1

8. COLLECTOR, #1

STYLE 12:

PIN 1. SOURCE

2. SOURCE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 16:

PIN 1. EMITTER, DIE #1

2. BASE, DIE #1

3. EMITTER, DIE #2

4. BASE, DIE #2

5. COLLECTOR, DIE #2

6. COLLECTOR, DIE #2

7. COLLECTOR, DIE #1

8. COLLECTOR, DIE #1

STYLE 20:

PIN 1. SOURCE (N)

2. GATE (N)

3. SOURCE (P)

4. GATE (P)

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 24:

PIN 1. BASE

2. EMITTER

3. COLLECTOR/ANODE

4. COLLECTOR/ANODE

5. CATHODE

6. CATHODE

7. COLLECTOR/ANODE

8. COLLECTOR/ANODE

STYLE 28:

PIN 1. SW_TO_GND

2. DASIC_OFF

3. DASIC_SW_DET

4. GND

5. V_MON

6. VBULK

7. VBULK

8. VIN

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42564B

SOIC−8 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

Page 22

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...