ON Semiconductor NB4N527S Owner's Manual

© Semiconductor Components Industries, LLC, 2012

February, 2012 − Rev. 2

1 Publication Order Number:

EVBUM2077/D

NB4N527SMNEVB

Evaluation Board User's

Manual for NB4N527S

INTRODUCTION

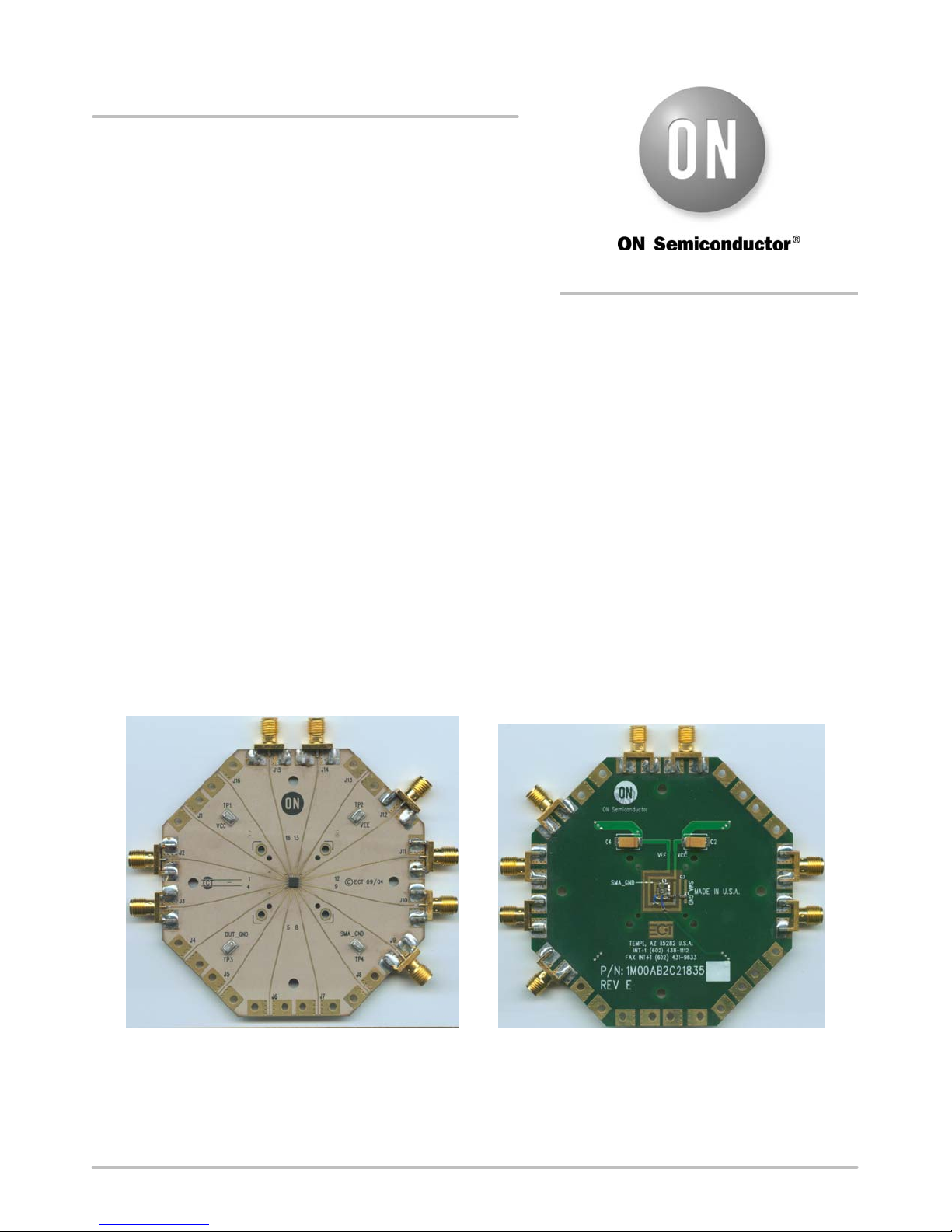

ON Semiconductor has developed an evaluation board for

the NB4N527S device as a convenience for the customers

interested in performing their own device engineering

assessment. This board provides a high bandwidth 50 W

controlled impedance environment. The pictures in Figure 1

show the top and bottom view of the evaluation board, which

can be configured in several different ways.

This evaluation board manual contains:

• Information on 16−lead QFN Evaluation Board

• Assembly Instructions

• Appropriate Lab Setup

• Bill of Materials

This manual should be used in conjunction with the

NB4N527S device data sheet, which contains full technical

details on the device specifications and operation.

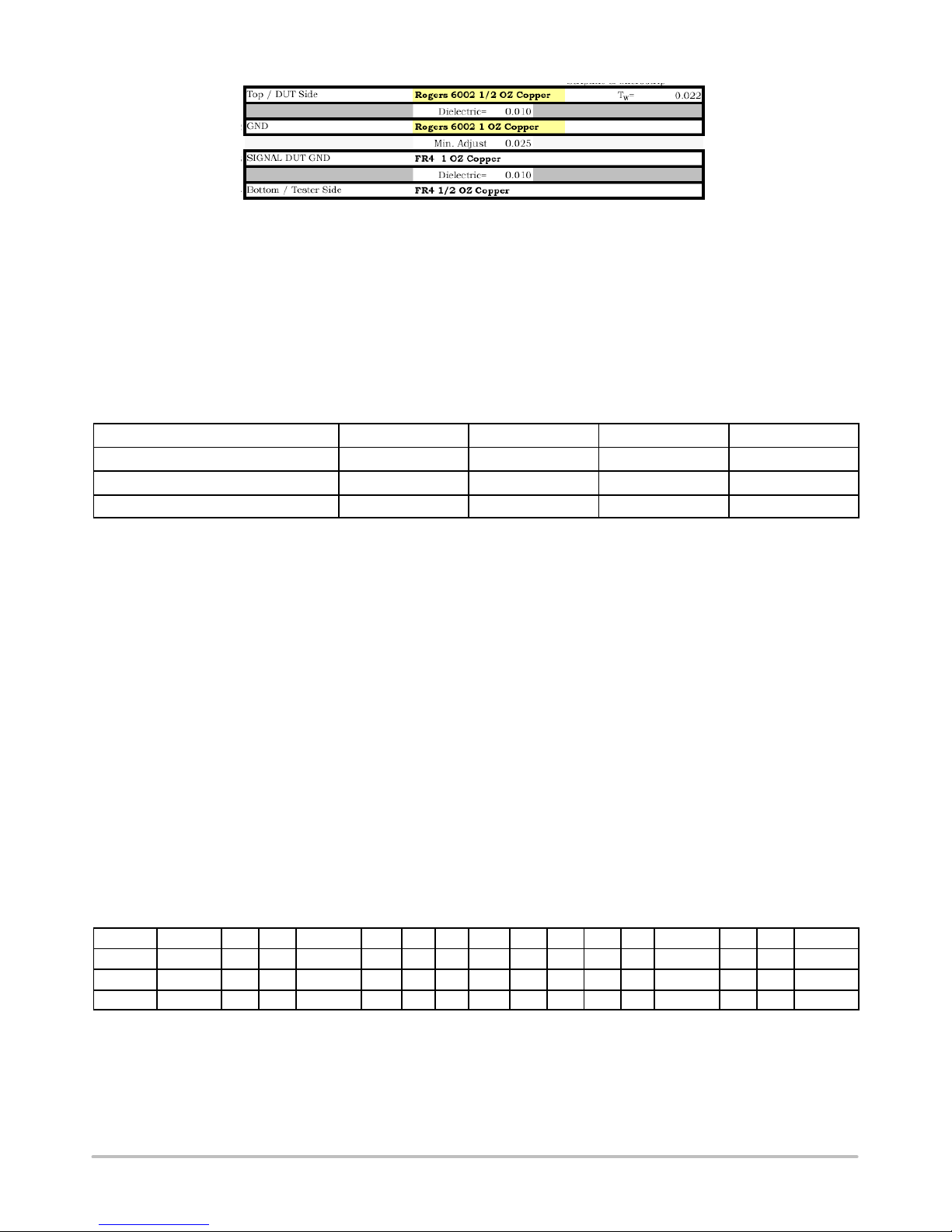

Board Lay−Up

The 16−lead QFN evaluation board is implemented in

four layers with split (dual) power supplies (Figure 2,

Evaluation Board Lay−up). For standard lab setup, a split

(dual) power supply is essential to enable the 50 W internal

impedance in the oscilloscope as a device termination. The

first layer or primary trace layer is 0.005, thick Rogers

RO6002 material, which is designed to have equal electrical

length on all signal traces from the device under the test

(DUT) to the sense output. The second layer is the 1.0 oz.

copper ground plane. The FR4 dielectric material is placed

between the second and third layer, and between the third

and fourth layer. The third layer is also a 1.0 oz copper

ground plane. The fourth layer is the secondary trace layer.

Top View Bottom View

Figure 1. Top and Bottom View of the 16 QFN Evaluation Board

http://onsemi.com

EVAL BOARD USER’S MANUAL

NB4N527SMNEVB

http://onsemi.com

2

Figure 2. Evaluation Board Lay−up

Connecting Power and Ground Planes

Top side of the evaluation board has the four surfaces

mount test point clips labeled V

CC

, VEE, SMA_GND, and

DUT_GND. DUT_GND is connected to the exposed flag of

the QFN package. For proper operation, the exposed flag is

recommended to be ELECTRICALLY left floating or tied

to V

EE

, but must be THERMALLY connected to a

sufficient heat conduit such as a thermal plane Exact supply

voltage values that need to be applied can be found in

Table 1 and Figures 4 and 5.

Table 1. Power Supply Levels

Power Supply Span V

CC

V

EE

SMA_GND DUT_GND

3.0 V 1.75 V −1.25 V 0 V Float or V

EE

3.3 V 2.05 V −1.25 V 0 V Float or V

EE

3.6 V 2.35 V −1.25 V 0 V Float or V

EE

Stimulus (Generator) Termination

All ECL outputs need to be terminated to V

TT

(VTT = V

CC

–2.0 V = GND) via a 50 W resistor. The current board design

utilizes the internal resistors and the V

TDx

pins are wired to

ground. (More information on termination is provided in

AN8020). If evaluation does not require use of internal

termination resistors, 0402 chip resistor pads are provided

on the bottom side of the evaluation board. The jumper wires

of the V

TDx

pin pads should be removed (J1, J4, J13 and J15

to SMA_GND jumper). Solder the chip resistors to the

bottom side of the board between the appropriate input of the

device pin pads and the ground pads (for split power supply

setup).

Likewise for CML outputs, CML stimulus signal need to

be terminated to V

CC

via a 50 W resistor. If internal resistors

are used, the V

TDx

pin pads should be wired to VCC. To

accomplish this configuration, the jumper wire has to be

moved from SMA_GND ring to V

CC

ring on the bottom of

the board.

For the LVDS configuration, V

TDx

pin pads of the D0 or

D1 input has to be shorted to form 100 W across differential

lines. This configuration is accomplished by moving the

jumper wire from SMA_GND ring to complementary V

TDx

pin pad (example: VTD0 and VTD0b for D0 input and

VTD1 and VTD1b for D1 input).

DUT Termination

For standard lab setup and test, a split (dual) power supply

is required enabling the 50 W internal impedance in the

oscilloscope to be used as a termination of the signals (in

split power supply setup SMA_GND is the system ground,

V

CC

is varied, and VEE is –1.25 V; see Table 1, Power

Supply Levels).

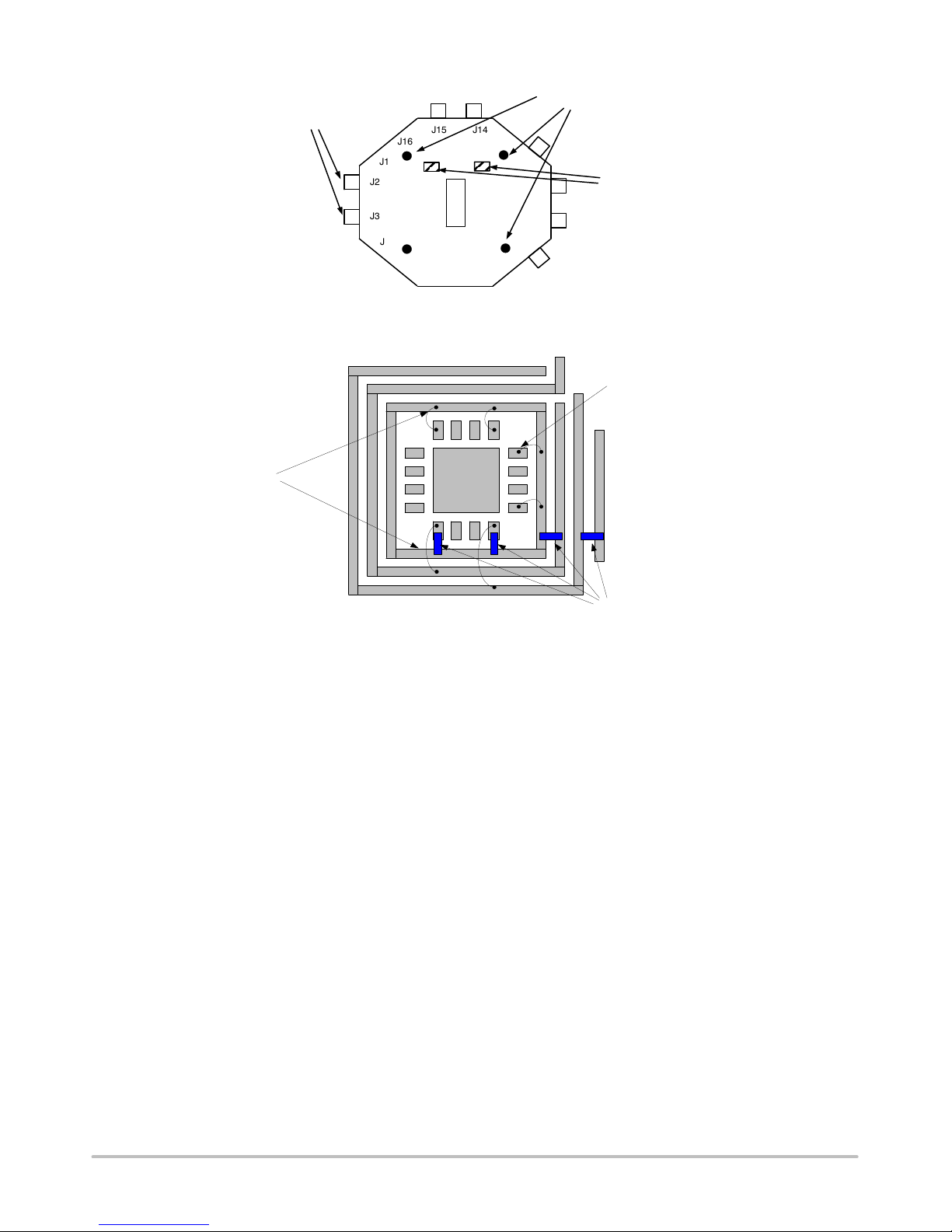

Board Components Configuration

The NB4N527SMNEVB evaluation board requires eight

side SMA connectors. Placement locations are described in

Table 2 and Figure 3.

Table 2. SMA Connectors and Jumpers Placement

Device J1 J2 J3 J4 J5 J6 J7 J8 J9 J10 J11 J12 J13 J14 J15 J16

Pin # 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Connector No Yes Yes No No No No No Ye s Yes Yes No No Yes Yes No

Wire SMA_GND No No SMA_GND V

EE

No No V

CC

No No No No SMA_GND No No SMA_GND

NB4N527SMNEVB

http://onsemi.com

3

J14J15

J16

J1

J2

J3

J4

J5

J6 J7

J8

J9

J10

J11

J12

J13

D

U

T

4 x Surface Mount Test

Points

2 x 10 mF Decoupling

Capacitors on the back of

the PCB (C4, C2)

8 x SMA Connectors

Top View

SMA_GND

VCC

VEE

Pin 1

Pad

Wire

DUT_GND

SMA_GND

4 x 0.01 mF or 0.1 mF

Decoupling Capacitors

(C1, C3, C5, C6)

Bottom View

Figure 3. Components Placement

C4 C2

Loading...

Loading...