Page 1

© Semiconductor Components Industries, LLC, 2012

February, 2012 − Rev. 1

1 Publication Order Number:

EVBUM2071/D

NB4N11MDTEVB

Evaluation Board User's

Manual for NB4N11M

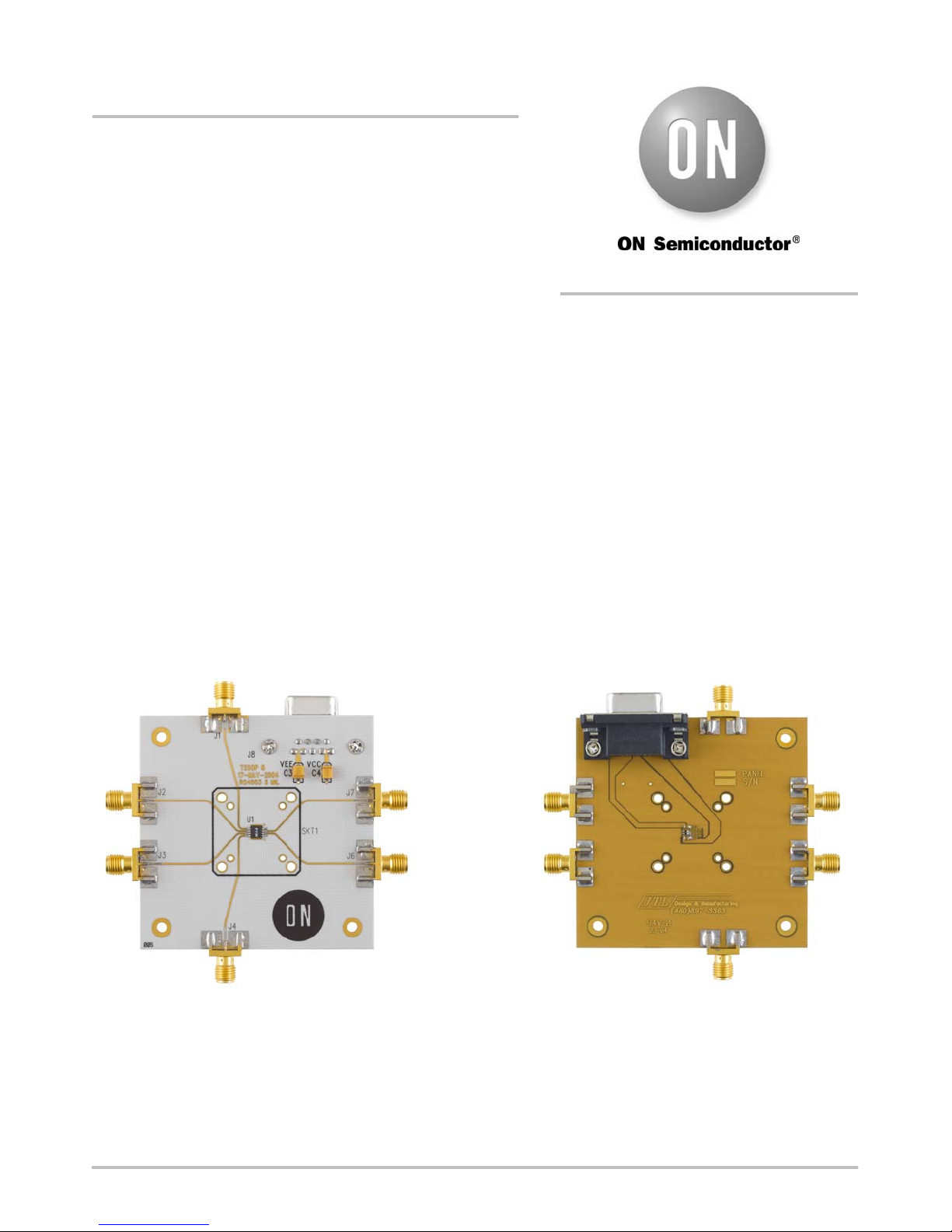

Description

ON Semiconductor has developed an evaluation board for

the NB4N11M device as a convenience for the customers

interested in performing their own device engineering

assessment. This board provides a high bandwidth 50 W

controlled impedance environment. The pictures in Figure 1

show the top and bottom view of the evaluation board, which

can be configured in several different ways.

This NB4N11M evaluation board manual contains:

• Appropriate Lab Setup

• Assembly Instructions

• Bill of Materials

This manual should be used in conjunction with the

NB4N11M device data sheet, which contains full technical

details on the device specifications and operation.

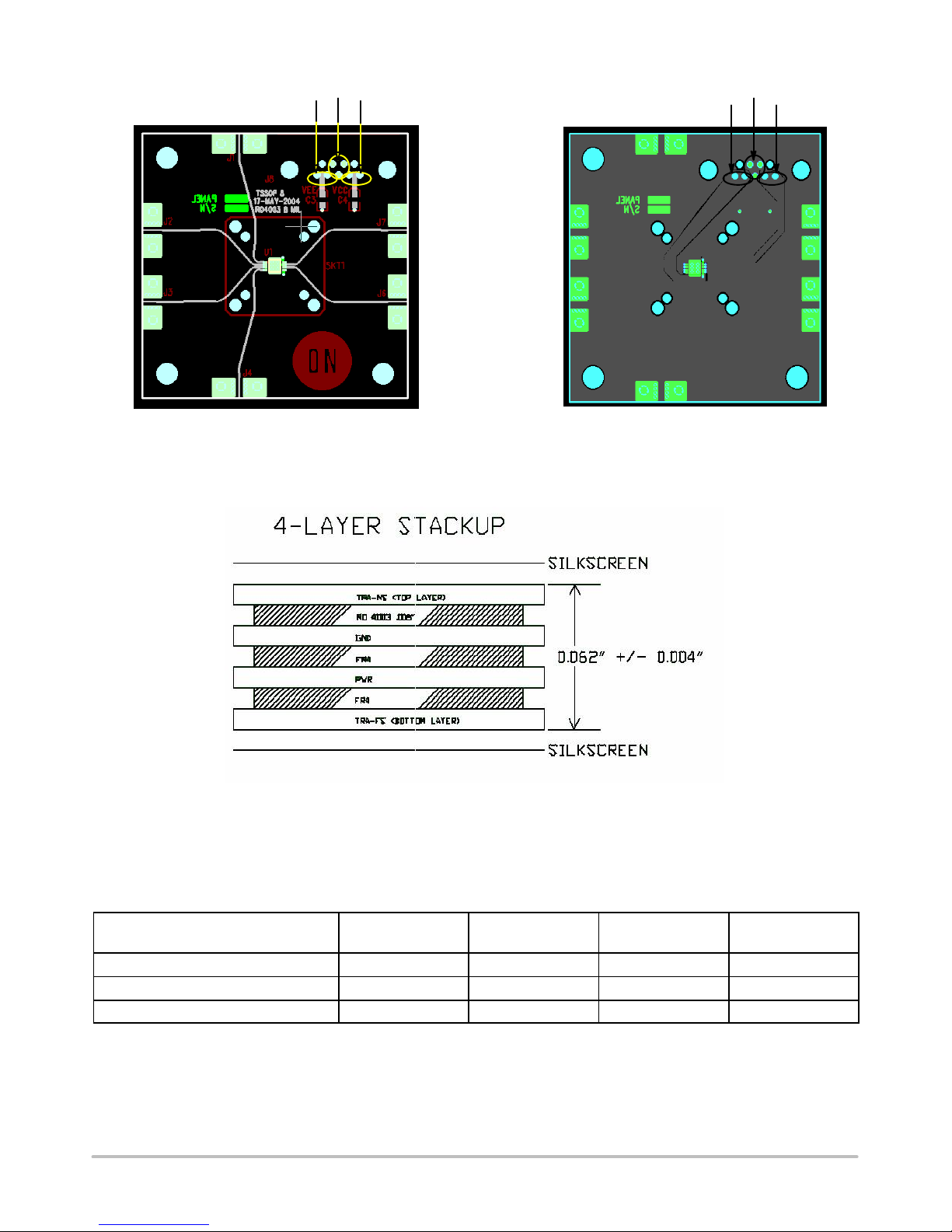

Board Lay−Up

The NB4N11M evaluation board is implemented in four

layers with split (dual) power supplies (Figure 7, Evaluation

Board Lay−up). For standard lab setup, a split (dual) power

supply is essential to enable the 50 W internal impedance in

the oscilloscope as a devices termination. The first layer or

primary trace layer is 0.005″ thick Rogers RO4003 material,

which is designed to have equal electrical length on all signal

traces from the device under the test (DUT) to the sense

output. The second layer is the 1.0 oz copper ground plane.

The FR4 dielectric material is placed between second and

third layer and between third and fourth layer. The third

layer is also 1.0 oz copper ground plane. The fourth layer is

the secondary trace layer.

Top View Bottom View

Figure 1. Top and Bottom View of the NB4N11M Evaluation Board

http://onsemi.com

EVAL BOARD USER’S MANUAL

Page 2

NB4N11MDTEVB

http://onsemi.com

2

Figure 2. Top & Bottom Layers (Top View)

V

EE

SMA_GND

V

CC

TOP LAYER BOTTOM LAYER

V

EE

SMA_GND

V

CC

Figure 3. Evaluation Board Lay−up

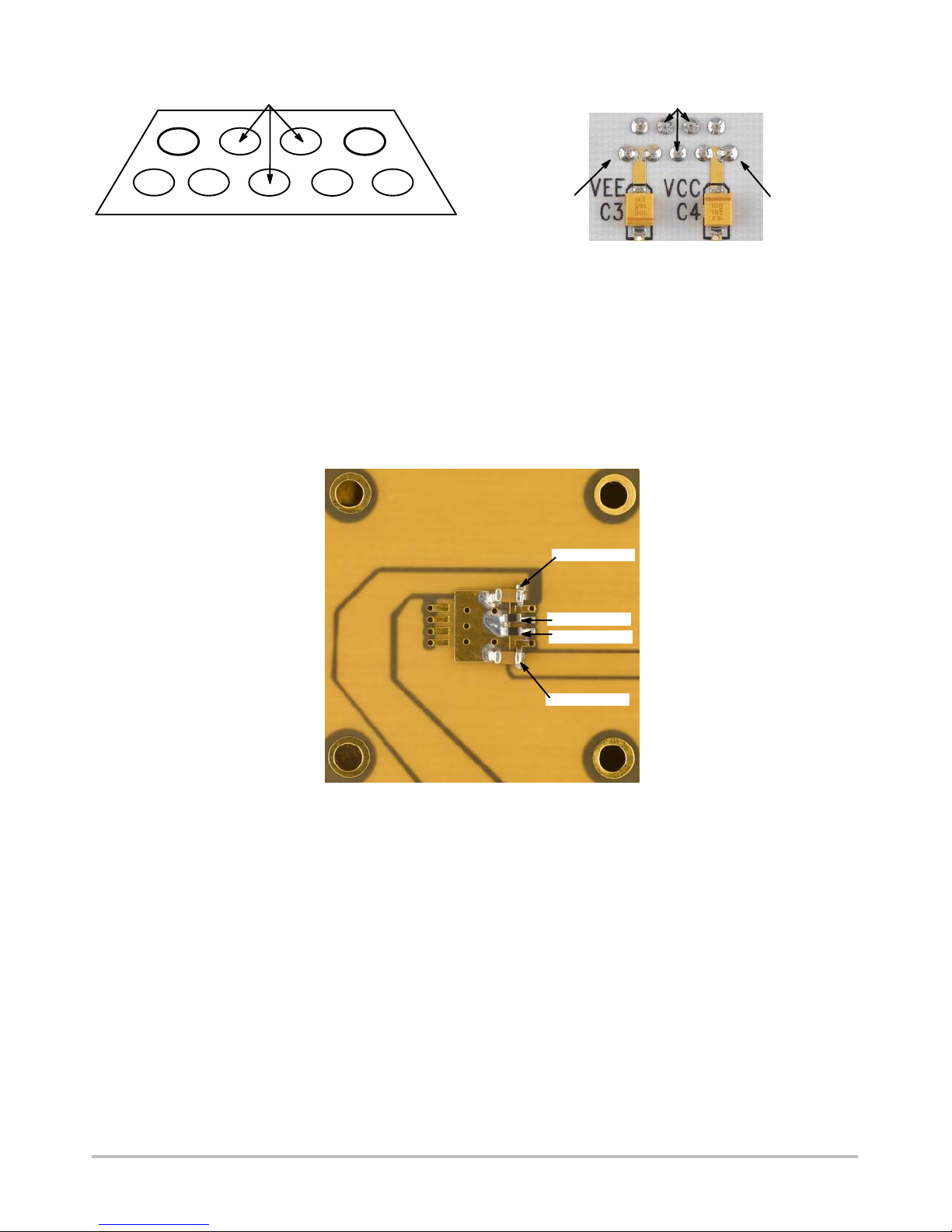

Connecting Power and Ground Planes

The side launch 9 pin power supply connector is wired as

shown in Figure 4. Test points can be soldered on the top of

the PCB to accommodated easier connections. Exact values

that need to be applied can be found in Table 1.

Table 1. Power Supply Levels

Power Supply Span V

TT

(Termination)

V

CC

(Pin 8)

VEE / GND

(Pin 5)

SMA_GND

(PCB SMA Ground)

3.3 V 1.8 V 1.5 V −1.8 V 0 V

3.3 V 2.5 V 0.8 V −2.5 V 0 V

3.3 V 3.3 V 0 V −3.3 V 0 V

Page 3

NB4N11MDTEVB

http://onsemi.com

3

V

CC

SMA_GND

V

EE

Figure 4. Power Supply Connector − 9 Pin Side

View (Left) and PCB Top View (Right)

NC

NC

V

CC

V

EE

V

CC

V

EE

SMA_GND

C3 = 10 mF; C4 = 10 mF

Stimulus (Generator) Termination

All ECL outputs need to be terminated to V

TT

(VTT =

V

CC

– 2.0 V = GND) via a 50 W resistor. The current board

design utilizes the space for placement of the external

termination resistors. (More information on termination is

provided in AN8020). The 0402 chip resistor pads are

provided on the bottom side of the evaluation board. Solder

the chip resistors to the bottom side of the board between the

appropriate input of the device pin pads and the ground pads

as shown in Figure 5 (for split power supply setup, PCB is

assembled in this configuration).

Figure 5. Expanded Bottom View

C1 = 0.01 mF

C2 = 0.01 mF

R2 = 50 W

R1 = 50 W

Likewise for CML outputs, CML stimulus signal need to

be terminated to V

CC

via a 50 W resistor. To accomplish this

configuration the external termination resistor has to be

moved from SMA_GND ring to V

CC

ring on the bottom of

the board.

For the LVDS configuration Input pin pads of the D0 or

D1 input has to be shorted using 100 W resistor across

differential lines.

DUT Termination

For standard lab setup and test, a split (dual) power supply

is required enabling the 50 W internal impedance in the

oscilloscope to be used as a termination of the signals (in

split power supply setup SMA_GND as a system ground,

V

CC

, and VEE are varied; see Table 1, Power Supply Levels).

Board Components Configuration

The NB4N11MDTEVB evaluation board requires six

side SMA connectors. Placement locations are described in

the Table 2 below.

Page 4

NB4N11MDTEVB

http://onsemi.com

4

Table 2. SMA Connector and Jumper Placement

Device J1/Q0 J2/Q0 J3/Q1 J4/Q1 J5 J6/D J7/D J8

Pin # 1 2 3 4 5 6 7 8

Connector Yes Ye s Ye s Ye s No Ye s Yes No

Resistor

(bottom)

0402*

50 W

0402*

50 W

0402*

50 W

0402*

50 W

0402

0.01 mF

0402

50 W

0402

50 W

0402

0.01 mF

Wire No No No No to V

EE

No No to V

CC

*Optional components for 25 W load. Not populated in production

.

Figure 6. Lab Setup

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

IN2

IN3

OUT1

OUT2

OUT3

OUT4

PIN 1

D

D

Q0

Q0

Q1

Q1

SIGNAL

GENERATOR

OSCILLOSCOPE

(50 W Scope Head)

1. Connect appropriate power supplies to VCC, VEE,

and SMA_GND (See Table 1)

2. Connect a signal generator to the input SMA

connectors via matched cables. Setup input signal

according to the device data sheet

3. Connect a test measurement device on the device

output SMA connectors via matched cables.

NOTE: The test measurement device must contain 50 W

termination.

Figure 7. PCB Schematic for 50 W Load

(PCB is assembled in this configuration)

SMA

SMA

SMA

SMA

SMA

SMA

C1

0.01 mF

C3

10 mF

C2

0.01 mF

C4

10 mF

V

CC

R1

50 W

R2

50 W

NB4N11M

1

2

3

4

7

6

5

8

V

EE

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

SIGNAL

GENERATOR

OSCILLOSCOPE

(50 W Scope Head)

D

D

Q0

Q0

Q1

Q1

Page 5

NB4N11MDTEVB

http://onsemi.com

5

Figure 8. PCB Schematic for 25 W Load

(50 W output resistors (Q0, Q0

, Q1, Q1) not assembled )

SMA

SMA

SMA

SMA

SMA

SMA

0.01 mF10 mF

0.01 mF

10 mF

V

CC

50 W

50 W

NB4N11M

1

2

3

4

7

6

5

8

V

EE

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

Z = 50 W

SIGNAL

GENERATOR

OSCILLOSCOPE

(50 W Scope Head)

D

D

Q0

Q0

Q1

Q1

50 W*

*50 W resistors must be added for 25 W load configuration

50 W*

50 W*

50 W*

Table 3. Bill of Materials

Components Manufacturer Description Part Number Qty. Web Site

SMA

Connector

Johnson* SMA Connector − Side

Launch

142−0701−851 6 http://www.johnsoncomponents.com

9 Pin D−Sub

Receptacle

Amphenol Connector, Female,

9−Pin, Right Angle

788796−1 1 http://www.amphenol.com

Surface Mount

Test Points{

Keystone*

SMT Miniature Test

Point

5015

3 http://www.keyelco.com

SMT Compact Test

Point

5016

Chip

Capacitor

AVC

Corporation*

0402 0.01 mF " 10%

04025C103KAT2A 2 http://www.avxcorp.com

10 mF " 10%

T491C106K016AS 2

Chip Resistor Panasonic*

0402 50 W " 1%

Precision Thick Film

Chip Resistor

ERJ−2RKF49R9X 2 http://www.panasonic.com

Evaluation

Board

ON

Semiconductor

Micro−10 Evaluation

Board

N/A 1 http://www.onsemi.com

Device

Samples

ON

Semiconductor

Micro−10 Package

Device

NB4N11MM 1 http://www.onsemi.com

*Components are available through most distributors, i.e. www.newark.com, www.Digikey.com

†Surface Mount Test Points can be used for power supply connection in place of power supply cable connector. See Figure 4 for test point

placement.

Page 6

NB4N11MDTEVB

http://onsemi.com

6

PACKAGE DIMENSIONS

Micro−10

CASE 846B−03

ISSUE D

S

B

M

0.08 (0.003) A

S

T

DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A 2.90 3.10 0.114 0.122

B 2.90 3.10 0.114 0.122

C 0.95 1.10 0.037 0.043

D 0.20 0.30 0.008 0.012

G 0.50 BSC 0.020 BSC

H 0.05 0.15 0.002 0.006

J 0.10 0.21 0.004 0.008

K 4.75 5.05 0.187 0.199

L 0.40 0.70 0.016 0.028

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION “A” DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE

BURRS SHALL NOT EXCEED 0.15 (0.006)

PER SIDE.

4. DIMENSION “B” DOES NOT INCLUDE

INTERLEAD FLASH OR PROTRUSION.

INTERLEAD FLASH OR PROTRUSION

SHALL NOT EXCEED 0.25 (0.010) PER SIDE.

5. 846B−01 OBSOLETE. NEW STANDARD

846B−02

−B−

−A−

D

K

G

PIN 1 ID

8 PL

0.038 (0.0015)

−T−

SEATING

PLANE

C

H

J

L

ǒ

mm

inches

Ǔ

SCALE 8:1

10X 10X

8X

1.04

0.041

0.32

0.0126

5.28

0.208

4.24

0.167

3.20

0.126

0.50

0.0196

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

SOLDERING FOOTPRINT*

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

EVBUM2071/D

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

Page 7

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

ON Semiconductor:

NB4N11MDTEVB

Loading...

Loading...