ON Semiconductor NB3x6x1xxG8DFN User Manual

NB3x6x1xxG8DFNEVK

NB3x6x1xxG8DFN

OmniClock

Evaluation

KitManual

Devices Supported

• NB3H60113G (DFN8, 3.3 V)

• NB3V60113G (DFN8, 1.8 V)

Introduction

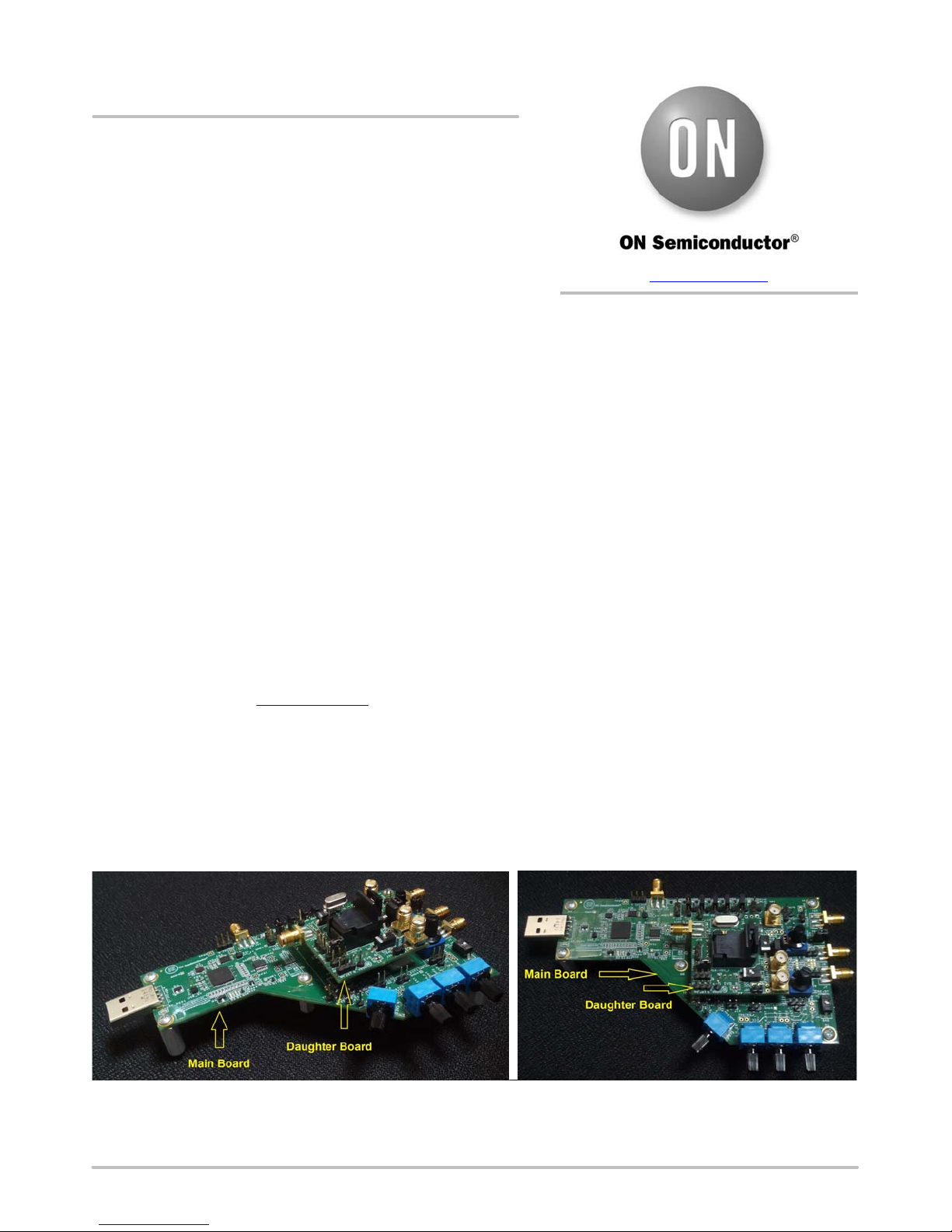

NB3x6x1xxG8DFNEVK is an evaluation kit offering a

convenient solution for evaluating DFN8 devices. Included

are one main board, a daughter board, and a USB cable. The

main board and daughter board are 4 layer boards with

dedicated power and GND planes.

The daughter board plugs directly on to the main board

using four 4−pin header connectors. These connectors route

the signal, power and ground to the device on the daughter

board. The two boards correctly plug into one another in

only one orientation ensuring proper pin alignment. The

daughter board has a DFN8 socket to test NB3x6x1xxG

devices. A view of the main board with the DFN8 daughter

board is shown in Figures 1 and 2.

The Clock Cruiser Software is the GUI software

developed to be used with this evaluation kit, and can be

downloaded for free from www.onsemi.com

user to set programmable parameters and generate solutions

that fit application needs. These solutions can then be

programmed in to device’s OTP memory or be temporarily

written into device registers for evaluation. For more

information on using the GUI, refer to Clock Cruiser User

Guide.

. It allows the

www.onsemi.com

EVAL BOARD USER’S MANUAL

Description

The NB3x6x1xxG, which is a member of the OmniClock

family, is a versatile user programmable clock generator

designed by ON Semiconductor with customer experience

in mind. These devices are tailored to fit into an extensive

array of applications including wearable technology, smart

phones, digital cameras, E−books, portable electronics, and

Internet of Things. The NB3H designated parts are powered

by 3.3 V and 2.5 V supplies while NB3V parts support 1.8

V operation.

These devices are One Time Programmable (OTP), low

power PLL based clock generators that accept fundamental

mode parallel resonant crystals of up to 50 MHz or a single

ended LVCMOS/LVTTL reference clock input of up to

200 MHz. The outputs can be configured as either three

single ended LVCMOS/LVTTL outputs or a combination of

one single ended output and one differential

LVPECL/LVDS/HCSL/CML output. The generated clock

output’s frequency can range between 8 kHz to 200 MHz.

Other programmable parameters include internal crystal

load capacitor, drive strength for LVCMOS outputs, output

frequency modulation controls (type, depth, modulation

rate), output phase inversion, and PLL bypass mode. The

devices are fully functional between −40°C to +85°C.

Figure 1. 455 View of Main Board with DFN8

Daughter Board

© Semiconductor Components Industries, LLC, 2016

July, 2016 − Rev. 1

Figure 2. Top View of Main Board with DFN8

1 Publication Order Number:

EVBUM2358/D

NB3x6x1xxG8DFNEVK

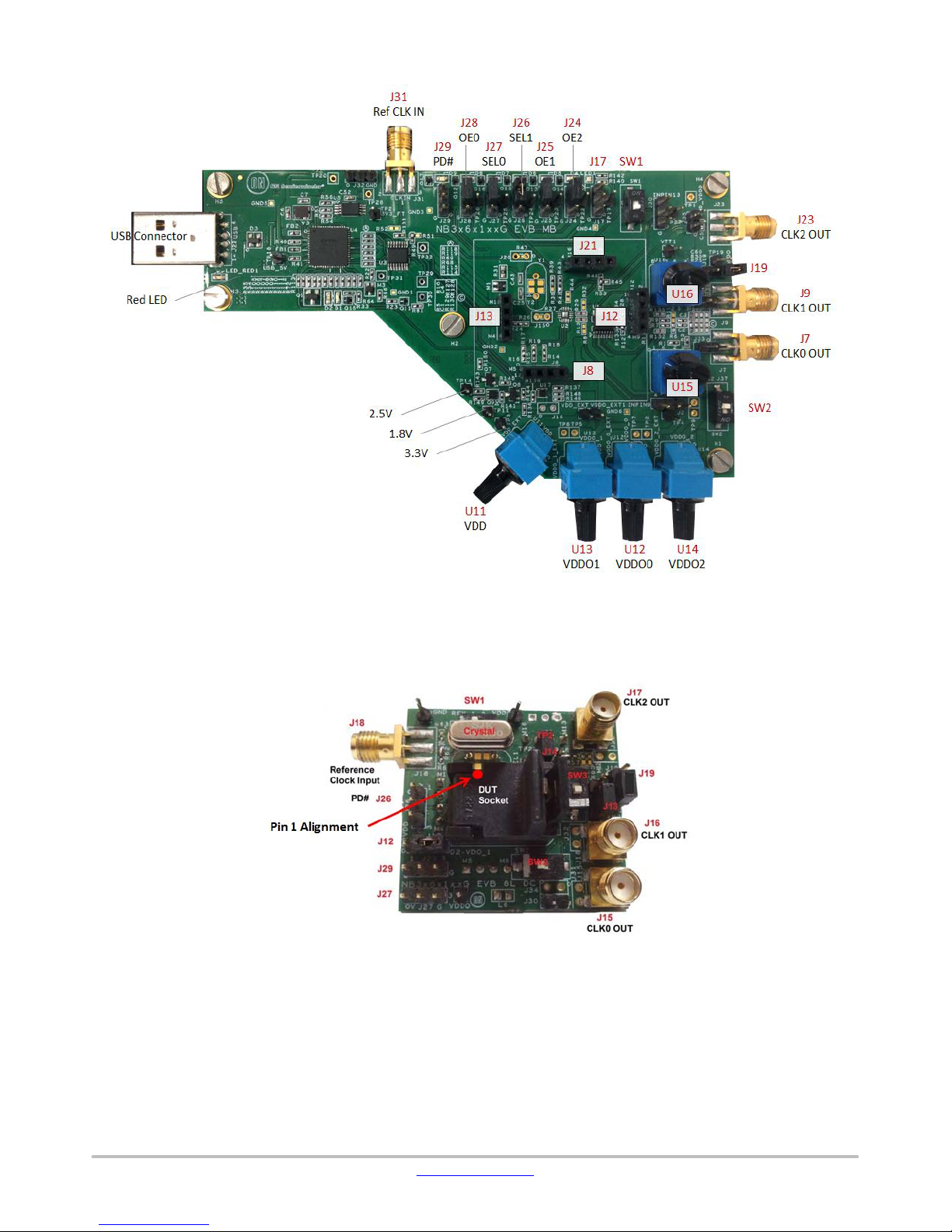

Figure 3. Main Board

Figure 4. DFN8 Daughter Board

www.onsemi.com

2

NB3x6x1xxG8DFNEVK

Step 1: Hardware Setup

Note: Skip this section if device has already been programmed.

Main Board

1. Securely connect the daughter board to the main board by lining up all four 4−pin connectors (J8, J12, J13, J21). The

daughter board can only be plugged in to the main board correctly in one orientation.

2. Make sure all SMA cables are unplugged from main board and daughter board.

3. Jumpers:

a. Use jumpers to provide connection as referenced in table below: (Pin 1 is indicated by a circle)

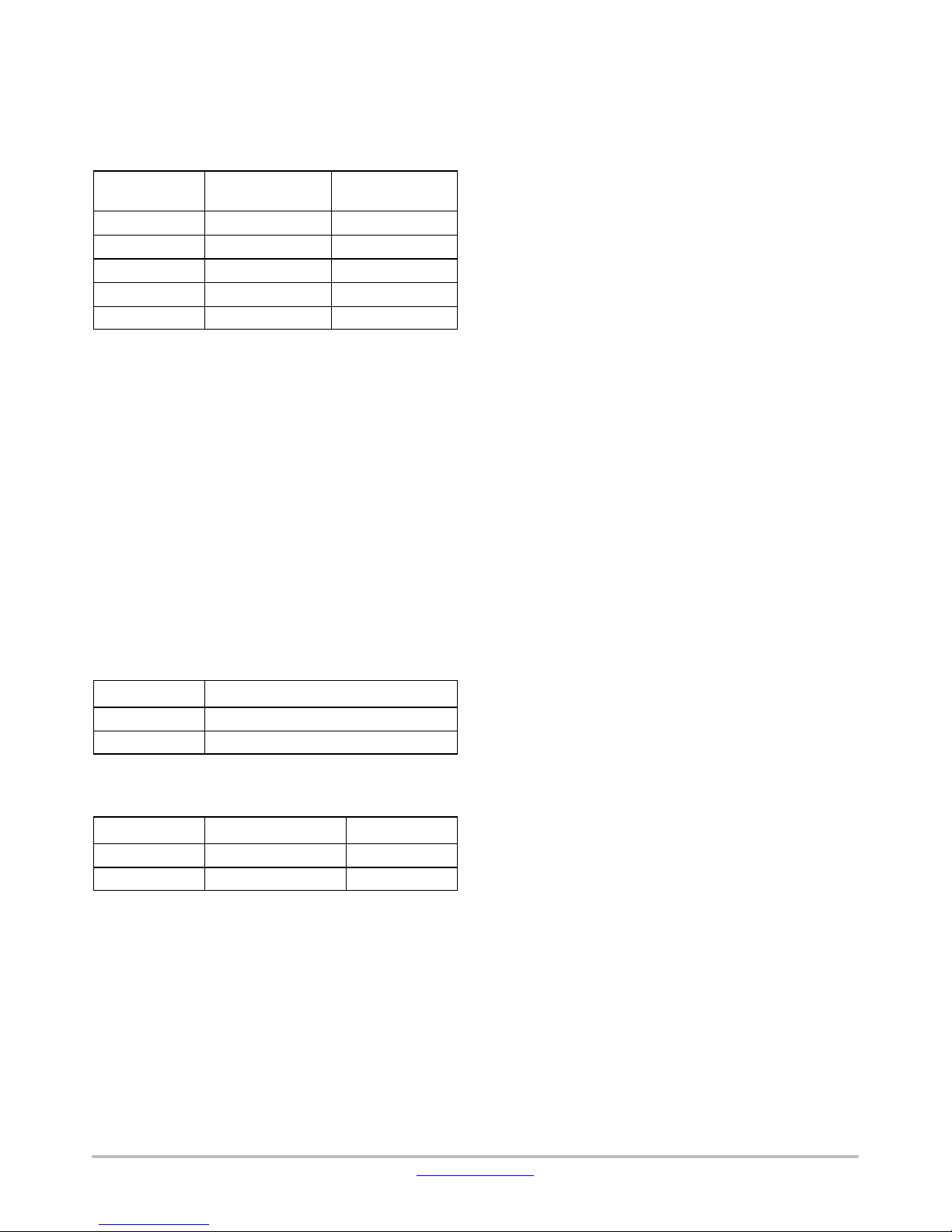

Jumper No J26 (SEL1) J27 (SEL0) J24 (OE2) J25 (OE1) J28 (OE0) J29 (PD#) J19

Pin connection 2 and 3 2 and 3 2 and 3 2 and 3 2 and 3 OPEN 2 and 3

4. Switches:

b. Slide switches to the position referenced in table below: (ON position is indicated via lettering on switch)

Switch No SW1 SW2

Position ON ON

5. Rotary Switches:

c. Turn knob on rotary switches as shown in table below: (The position number will be displayed in a slit on the knob)

Jumper No U11 U12 U13 U14 U15 U16

Dial Display 1 1 1 1 1 1

Daughter Board

1. Jumpers:

a. Use Jumpers to provide connection as referenced in table below: (Pin 1 is indicated by a circle)

Jumper No J31 (SEL1) J30 (SEL0) J29 (OE2) J28 (OE1) J27 (OE0) J26 (PD#)

Shorting Link Position OPEN OPEN OPEN OPEN OPEN OPEN

2. Switches:

b. Slide switches to the position referenced in table below: (ON position is indicated via lettering on switch)

Switch No SW1 SW2 SW3

Position ON ON ON

3. Ensure that Crystal (XTAL) is in holder.

4. Place NB3H60113G or NB3V60113G in DUT socket U2. For device pin 1 alignment refer to Figure 4.

www.onsemi.com

3

NB3x6x1xxG8DFNEVK

Step 2: Device Programming

Note: Skip this section if device has already been programmed

1. Download and install Clock Cruiser GUI Software to a computer that meets or exceeds minimum requirements found

on Clock Cruiser User guide.

2. Connect the evaluation kit to an USB port using included USB cable. A LED next to the USB connector will glow

red, indicating that +5 V supply has been applied to EVB.

3. Run the Clock Cruiser GUI software. A blue LED (D9) will light up when a connection is established, this LED will

blink periodically as activity is being conducted.

4. Follow the Clock Cruiser User Guide for detailed instructions on navigating through the program to properly

configure device.

5. In the device programming screen, a table indicates the summary of configurations that were selected. Verify that the

Hardware Connected indicator is green and that there is no error in the log.

6. Set appropriate device VDD/VDDO levels.

a. Set VDD and VDDO for each output by using the four rotary switches (U11, U12, U13, and U14) located on the main

board to match device configuration. Make sure that VDDO’s are less than or equal to VDD. The following table shows

which on−board LDO voltage is selected depending on the switch position (see table below).

Voltage for Each Switch Position

Rotary Switch Line

U11 VDD +3.3 V

1 2 3 4

U12 VDDO0

U13 VDDO1

U14 VDDO2

VDD

+2.5 V +1.8 V external source

7. Program the device permanently by selected [Program OTP Memory] or write to device registers by clicking [Write

to Registers]. In the case Write to Register function is utilized, powering down evaluation kit (i.e. unplugging USB

cable) will reset device registers.

Step 3: Device Evaluation

Select Input Clock

Depending on the programmed configuration, select one of the following input clock references.

1. Crystal (XTAL): The evaluation kit comes equipped with a 25 MHz fundamental crystal on the daughter board. If a

different frequency is required, place new crystal in holder. Device can accept 3 MHz to 50 MHz crystal references.

Please follow the additional step below to properly use Crystal as input reference:

a. Place SW1 on daughter board in the OFF position.

2. External Clock Reference: To use an external clock reference, connect external clock to SMA connector J31 on the

main board. Device can accept 3 MHz to 200 MHz clock references, reference device datasheet for appropriate input

levels.

Please follow additional steps below to properly use an external clock input source:

a. Close out GUI software to stop communication between GUI and EVB.

b. Unplug and Re−plug EVB to USB port.

c. Manually supply power to device with PD# pin. (See section Controlling the Device (GPIO pins) for proper use of

PD# pin)

Note: External Clock can only be used with devices that have been OTP’d.

www.onsemi.com

4

NB3x6x1xxG8DFNEVK

Select Output Termination

DUT outputs are routed to three SMA connectors on the main board (J7, J9, and J23) to provide termination for CLK0, CLK1,

and CLK2 respectively. By turning rotary switches U15 and U16, the board will automatically terminate the programmed

output level for CLK0 and CLK1, to its respective output termination in table below.

Rotary Switch

Position

1 LVCMOS LVCMOS

2 HCSL HCSL

3 LVPECL LVPECL

4 CML CML

5 LVDS LVDS

U15 output for CLK0 U16 output for CLK1

Note: CLK2 output only supports LVCMOS levels; therefore its termination is fixed.

Interfacing with Test Equipment

Monitor DUT outputs from main board with an oscilloscope with either SMA connectors or on board jumpers.

1. To use SMA connectors (J7, J9, J23), use oscilloscopes Hi−Z feature or a Hi−Z probe to monitor outputs. (Ensure

probe is properly grounded)

2. To use Jumpers (J33, J34, J35), use a Hi−Z probe connected to jumper pin marked 0. (Ensure probe is properly

grounded)

Both options can be used to monitor all three DUT outputs.

Controlling the Device (GPIO pins)

The device has multiple functions that can be programmed via control pins, below is a list of control pins and their respective

SMA connector.

OE: Pin used to enable or disable outputs individually. The main and daughter boards both have OE pins that can be easily

accessed via jumpers.

Main board: CLK0=J28, CLK1=J25, CLK2=J24

Daughter board: CLK0=J27, CLK1=J28, CLK2=J29

OE

0 CLK Disabled

1 CLK Enabled

Function

PD#: Pin used to power down device, this pin can be controlled either with J29 (main board) or J26 (daughter board). The logic

state of this signal corresponds to the LED (D9) on the main board.

PD#

0 Device Powered Down Off

1 Device Powered Up On

Function LED (D9)

www.onsemi.com

5

NB3x6x1xxG8DFNEVK

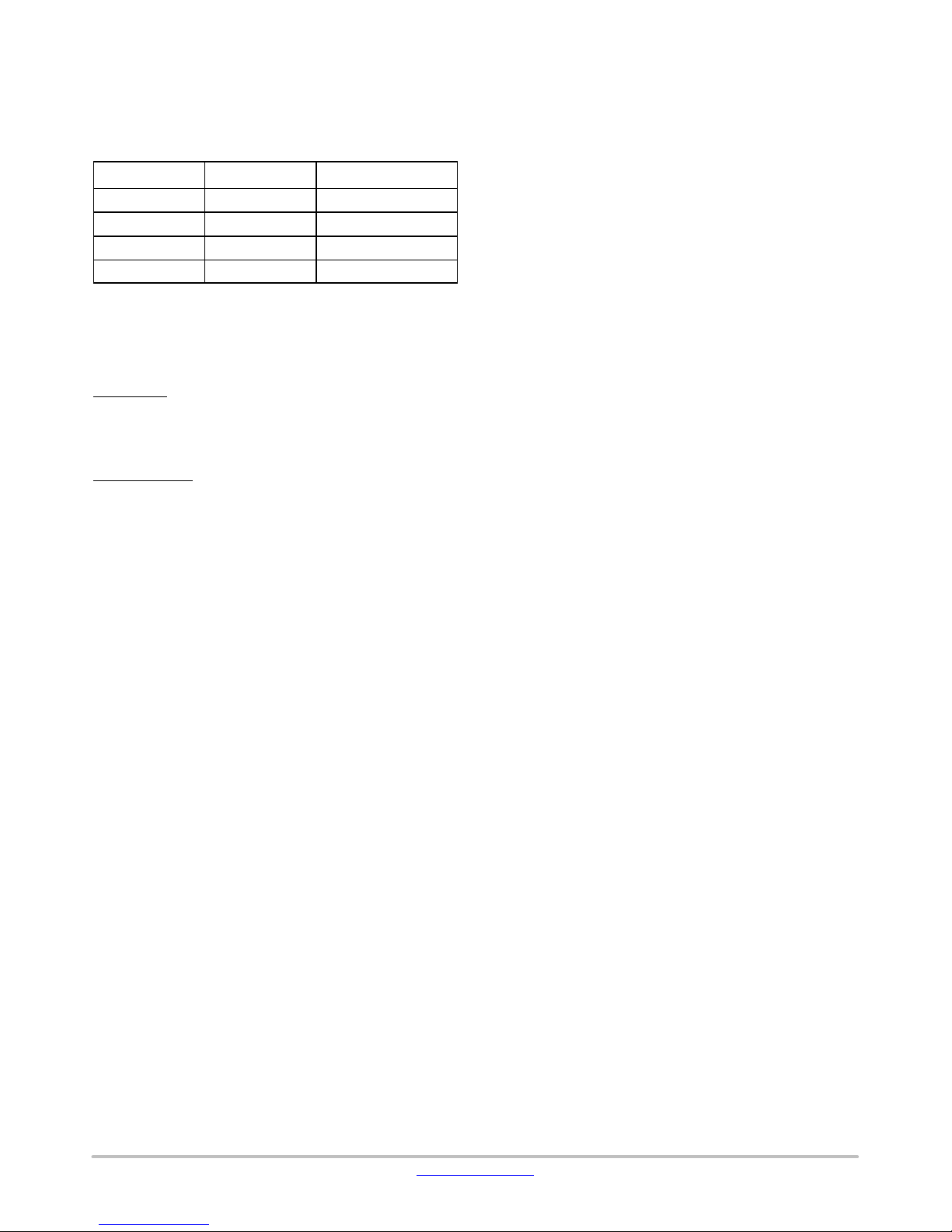

SEL: Pin is used to select between the available four output configurations that can be stored in devices OTP memory.

Main board: SEL0=J27, SEL1=J26

Daughter board: SEL0=J30, SEL1=J31

SEL0

L L I

L H II

H L III

H H IV

SEL1 Output Configuration

Programming Reminders

While communicating between the GUI and device ensure the following:

Main Board

1. Switches SW1 and SW2 are set to the ON state.

2. Rotary switches U11, U12, U13, U14, U15 and U16 are in the “1” position.

3. All SMA cables are detached from test equipment.

Daughter Board

1. Switches SW1, SW2 and SW3 are set to the ON position.

2. All SMA cables are detached from test equipment.

When re−configuring temporary device registers ensure the following:

1. Re−initiate main board hardware setup.

2. Re−initiate daughter board hardware setup.

3. Re−initiate GUI by either returning to previous page with [back] button or restarting GUI software.

Note: Even if device OTP memory has been programmed, device registers can be used to write other solutions for evaluation.

www.onsemi.com

6

Loading...

Loading...