Page 1

NB2305A

3.3 V Zero Delay

Clock Buffer

The NB2305A is a versatile, 3.3 V zero delay buffer designed to

distribute high−speed clocks. It accepts one reference input and drives

out five low−skew clocks. It is available in a 8 pin package.

The −1H version of the NB2305A operates at up to 133 MHz, and

has higher drive than the −1 devices. All parts have on−chip PLL’s that

lock to an input clock on the REF pin. The PLL feedback is on−chip

and is obtained from the CLKOUT pad.

Multiple NB2305A devices can accept the same input clock and

distribute it. In this case the skew between the outputs of the two

devices is guaranteed to be less than 700 ps.

All outputs have less than 200 ps of cycle−to−cycle jitter. The input

and output propagation delay is guaranteed to be less than 350 ps, and

the output to output skew is guaranteed to be less than 250 ps.

The NB2305A is available in two different configurations, as shown

in the ordering information table. The NB2305AI is the base part. The

NB2305AI1H is the high drive version of the −1 and its rise and fall

times are much faster than −1 part.

Features

• 15 MHz to 133 MHz Operating Range, Compatible with CPU and

PCI Bus Frequencies

• Zero Input − Output Propagation Delay

• Multiple Low−Skew Outputs

• Output−Output Skew Less than 250 ps

• Device−Device Skew Less than 700 ps

• One Input Drives 5 Outputs

• Less than 200 ps Cycle−to−Cycle Jitter is Compatible with PentiumR

Based Systems

• Accepts Spread Spectrum Clock at the Input

• Available in 8 Pin, 150 mil SOIC Package and 8 Pin TSSOP 4.4 mm

• 3.3 V Operation, Advanced 0.35 CMOS Technology

• Guaranteed Across Commercial and Industrial Temperature Ranges

• These are Pb−Free Devices

www.

onsemi.com

MARKING

DIAGRAMS*

8

1

SOIC−8

D SUFFIX

CASE 751

8

1

TSSOP−8

DT SUFFIX

CASE 948S

XXXX = Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

*For additional marking information, refer to

Application Note AND8002/D.

ORDERING INFORMATION

See detailed ordering, marking and shipping information in the

package dimensions section on page 6 of this data sheet.

8

XXXX

ALYW

G

1

8

XXX

YWW

A G

1

© Semiconductor Components Industries, LLC, 2015

May, 2015 − Rev. 11

1 Publication Order Number:

NB2305A/D

Page 2

NB2305A

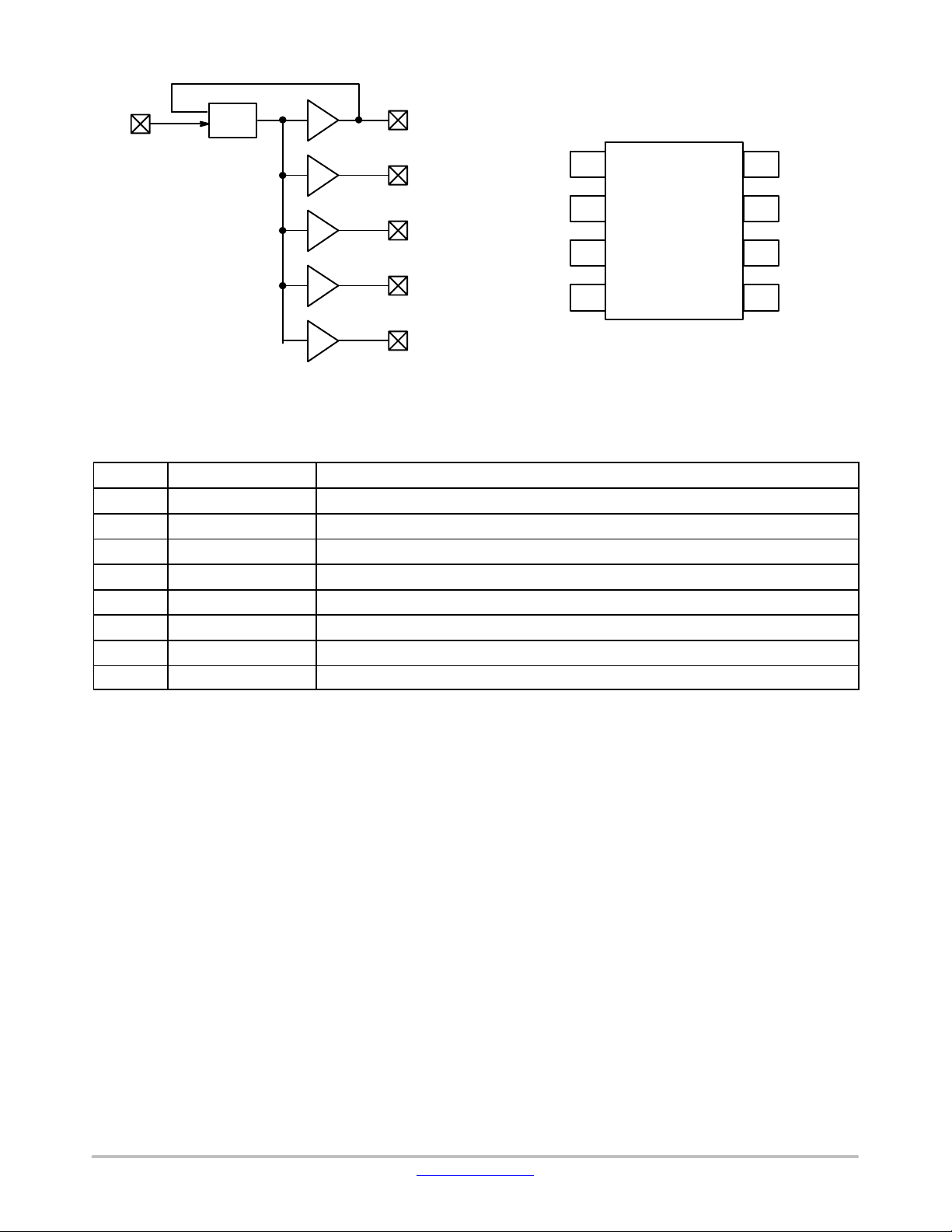

REF

PLL

CLKOUT

CLK1

CLK2

CLK3

CLK4

REF

CLK2

CLK1

GND

Figure 1. Block Diagram

Table 1. PIN DESCRIPTION

Pin # Pin Name Description

1 REF (Note1) Input reference frequency, 5 V tolerant input.

2 CLK2 (Note 2) Buffered clock output.

3 CLK1 (Note 2) Buffered clock output.

4 GND Ground.

5 CLK3 (Note 2) Buffered clock output.

6 V

DD

3.3 V supply.

7 CLK4 (Note 2) Buffered clock output.

8 CLKOUT (Note 2) Buffered clock output, internal feedback on this pin.

1. Weak pulldown.

2. Weak pulldown on all outputs.

1

2

NB2305A

3

4

Figure 2. Pin Configuration

8

7

6

5

CLKOUT

CLK4

V

DD

CLK3

www.onsemi.com

2

Page 3

NB2305A

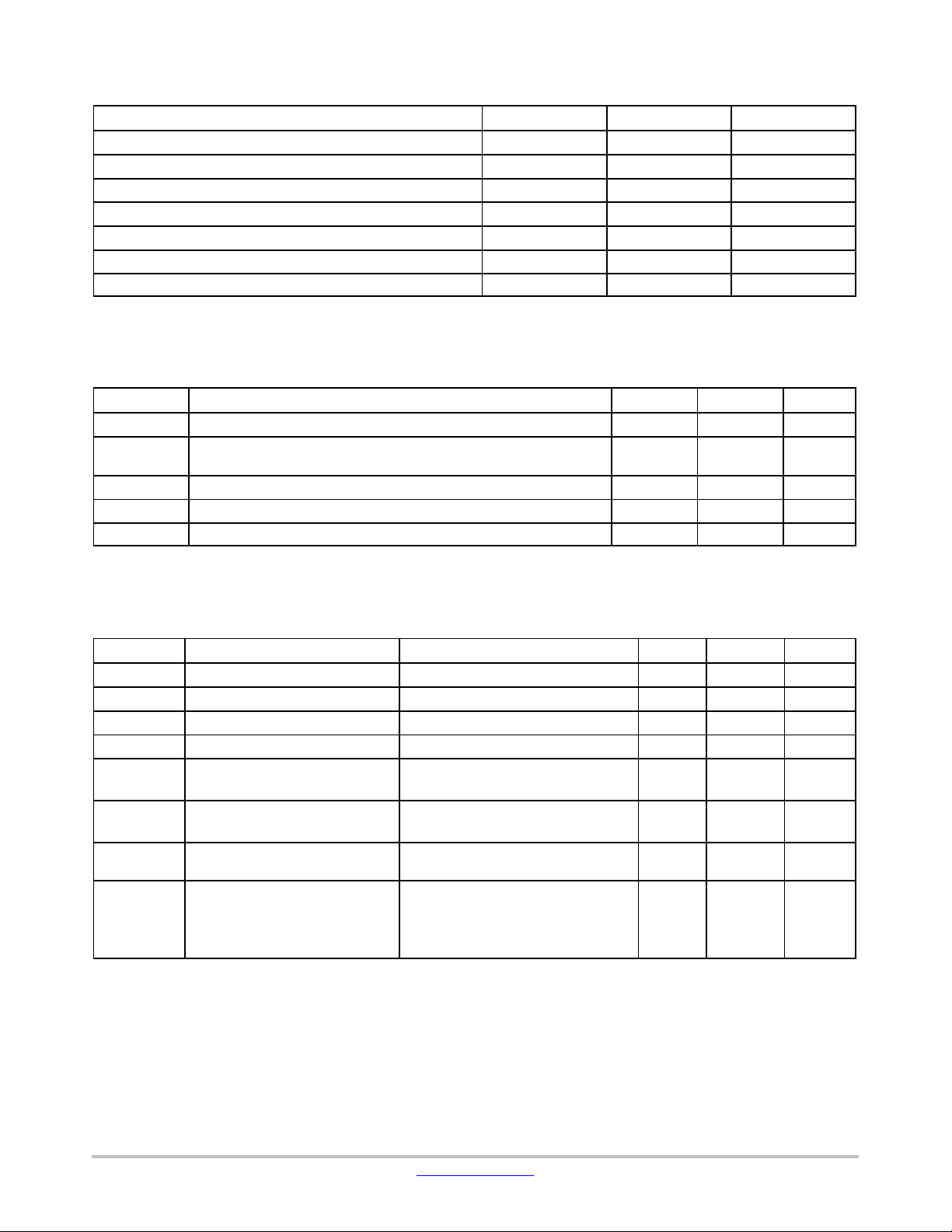

Table 2. MAXIMUM RATINGS

Parameter Min Max Unit

Supply Voltage to Ground Potential −0.5 +7.0 V

DC Input Voltage (Except REF) −0.5 VDD + 0.5 V

DC Input Voltage (REF) −0.5 7.0 V

Storage Temperature −65 +150 °C

Maximum Soldering Temperature (10 sec) 260 °C

Junction Temperature 150 °C

Static Discharge Voltage (per MIL−STD−883, Method 3015) >2000 V

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

Table 3. RECOMMENDED OPERATING CONDITIONS FOR INDUSTRIAL TEMPERATURE DEVICES

Parameter Description Min Max Unit

V

DD

T

A

C

L

C

L

C

IN

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

Supply Voltage 3.0 3.6 V

Operating Temperature (Ambient Temperature) Industrial

Commercial

−40

0

85

70

°C

Load Capacitance, below 100 MHz 30 pF

Load Capacitance, from 100 MHz to 133 MHz 10 pF

Input Capacitance 7 pF

Table 4. ELECTRICAL CHARACTERISTICS V

Parameter

V

IL

V

IH

I

IL

I

IH

V

OL

V

OH

I

DD

I

DD

Input LOW Voltage (Note 3) 0.8 V

Input HIGH Voltage (Note 3) 2.0 V

Input LOW Current VIN = 0 V 50

Input HIGH Current VIN = V

Output LOW Voltage IOL = 8 mA (−1)

Output HIGH Voltage IOH = −8 mA (−1)

Supply Current (Commercial Temp) Unloaded outputs at 66.67 MHz,

Supply Current (Industrial Temp) Unloaded outputs at 100 MHz

Description Test Conditions Min Max Unit

= 3.0 V to 3.6 V, GND = 0 V, TA = −40°C to +85°C

CC

DD

I

= 12 mA (−1H)

OL

I

= −12 mA (−1H)

OH

Select inputs at V

DD

66.67 MHz

33 MHz

Select inputs at V

Temp

or GND, at Room

DD

A

100

A

0.4 V

2.4 V

34 mA

50

mA

34

19

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

3. REF input has a threshold voltage of V

DD

/2.

www.onsemi.com

3

Page 4

NB2305A

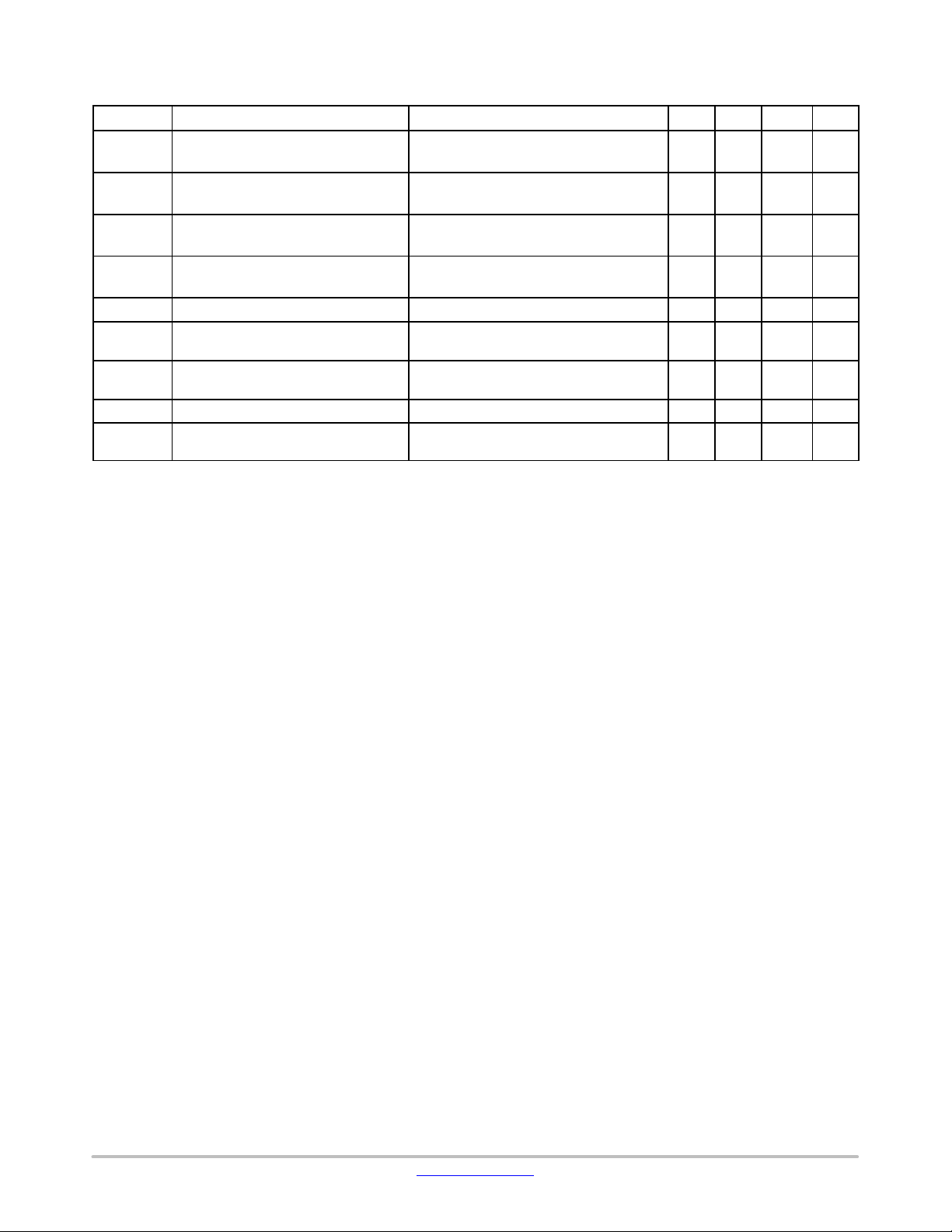

Table 5. SWITCHING CHARACTERISTICS V

Parameter

1/t

1/t

t

3

t

4

t

5

t

6

t

7

t

J

t

LOCK

1

1

Output Frequency 30 pF load

Duty Cycle = (t

Output Rise Time (−1)

Output Fall Time (−1)

Output−to−Output Skew All outputs equally loaded 250 ps

Delay, REF Rising Edge to CLKOUT

Rising Edge

Device−to−Device Skew Measured at VDD/2 on the CLKOUT pins of

Cycle−to−Cycle Jitter Measured at 66.67 MHz, loaded outputs 200 ps

PLL Lock Time Stable power supply, valid clock presented

4. All parameters specified with loaded outputs.

Description Test Conditions Min Typ Max Unit

/ t1) * 100 (−1, −1H)

2

(−1H)

(−1H)

(−1H)

= 3.0 V to 3.6 V, GND = 0 V, TA = −40°C to +85°C (Note 4)

CC

15

10 pF load

Measured at 1.4 V, F

= 66.67 MHz

OUT

< 50 MHz

15

40

45

50

50

Measured between 0.8 V and 2.0 V 2.5

Measured between 2.0 V and 0.8 V 2.5

Measured at VDD/2 0 ±350 ps

0 700 ps

the device

on REF pin

100

MHz

133

60

55

1.5

1.5

1.0 ms

%

ns

ns

www.onsemi.com

4

Page 5

NB2305A

Zero Delay and Skew Control

All outputs should be uniformly loaded to achieve Zero

Delay between input and output. Since the CLKOUT pin is

the internal feedback to the PLL, its relative loading can

adjust the input−output delay .

SWITCHING WAVEFORMS

t

1

t

2

1.4 V 1.4 V 1.4 V

Figure 3. Duty Cycle Timing

OUTPUT

OUTPUT

1.4 V

t

5

1.4 V

For applications requiring zero input−output delay, all

outputs, including CLKOUT, must be equally loaded. Even

if CLKOUT is not used, it must have a capacitive load equal

to that on other outputs, for obtaining zero−input−output

delay.

2.0 V

V

DD

2

0.8 V

t

4

OUTPUT

2.0 V

0.8 V

t

3

Figure 4. All Outputs Rise/Fall Time

V

DD

INPUT

OUTPUT

2

t

6

3.3 V

0 V

Figure 5. Output − Output Skew

CLKOUT, Device 1

CLKOUT, Device 2

t

7

Figure 6. Input − Output Propagation Delay

V

DD

2

V

DD

2

Figure 7. Device − Device Skew

www.onsemi.com

5

Page 6

NB2305A

8

V

TEST CIRCUITS

DD

V

DD

0.1 F

0.1 F

OUTPUTS

V

DD

GND GND

Figure 8. Test Circuit #1

CLKOUT

C

LOAD

V

DD

0.1 F

V

DD

0.1 F

GND GND

Figure 9. Test Circuit #2

For parameter t

OUTPUTS

(output slew rate) on −1H devices

1 k

1 k

10 pF

ORDERING INFORMATION

Device Marking Operating Range Package Shipping

NB2305AI1DG 5I1 Industrial &

Commercial

NB2305AI1DR2G 5I1 Industrial &

Commercial

NB2305AI1HDG 5I1H Industrial &

Commercial

NB2305AI1HDR2G 5I1H Industrial &

Commercial

NB2305AI1DTG 5I1 Industrial &

Commercial

NB2305AI1DTR2G 5I1 Industrial &

Commercial

NB2305AI1HDTG 5IH Industrial &

Commercial

NB2305AI1HDTR2G 5IH Industrial &

Commercial

SOIC−8

(Pb−Free)

SOIC−8

(Pb−Free)

SOIC−8

(Pb−Free)

SOIC−8

(Pb−Free)

TSSOP−8

(Pb−Free)

TSSOP−8

(Pb−Free)

TSSOP−8

(Pb−Free)

TSSOP−8

(Pb−Free)

98 Units / Rail

2500 Tape & Reel

98 Units / Rail

2500 Tape & Reel

100 Units / Rail

2500 Tape & Reel

100 Units / Rail

2500 Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

†

Availability

Now

Now

Now

Now

Now

Now

Now

Now

Pentium is a registered trademark of Intel Corporation.

www.onsemi.com

6

Page 7

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

8

1

SCALE 1:1

B

−Y−

−Z−

−X−

A

58

1

4

G

H

D

0.25 (0.010) Z

M

SOLDERING FOOTPRINT*

7.0

0.275

S

Y

0.25 (0.010)

C

SXS

SEATING

PLANE

0.10 (0.004)

1.52

0.060

4.0

0.155

CASE 751−07

M

M

Y

N

SOIC−8 NB

ISSUE AK

K

X 45

_

M

J

MARKING DIAGRAM*

8

XXXXX

ALYWX

1

XXXXX = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

8

XXXXX

ALYWX

G

1

IC

IC

(Pb−Free)

DATE 16 FEB 2011

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

____

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

GENERIC

8

XXXXXX

AYWW

1

Discrete

XXXXXX = Specific Device Code

A = Assembly Location

Y = Year

WW = Work Week

G = Pb−Free Package

8

XXXXXX

AYWW

1

Discrete

(Pb−Free)

G

0.6

0.024

1.270

0.050

SCALE 6:1

ǒ

inches

mm

Ǔ

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

STYLES ON PAGE 2

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42564B

SOIC−8 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 2

www.onsemi.com

Page 8

STYLE 1:

PIN 1. EMITTER

2. COLLECTOR

3. COLLECTOR

4. EMITTER

5. EMITTER

6. BASE

7. BASE

8. EMITTER

STYLE 5:

PIN 1. DRAIN

2. DRAIN

3. DRAIN

4. DRAIN

5. GATE

6. GATE

7. SOURCE

8. SOURCE

STYLE 9:

PIN 1. EMITTER, COMMON

2. COLLECTOR, DIE #1

3. COLLECTOR, DIE #2

4. EMITTER, COMMON

5. EMITTER, COMMON

6. BASE, DIE #2

7. BASE, DIE #1

8. EMITTER, COMMON

STYLE 13:

PIN 1. N.C.

2. SOURCE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 17:

PIN 1. VCC

2. V2OUT

3. V1OUT

4. TXE

5. RXE

6. VEE

7. GND

8. ACC

STYLE 21:

PIN 1. CATHODE 1

2. CATHODE 2

3. CATHODE 3

4. CATHODE 4

5. CATHODE 5

6. COMMON ANODE

7. COMMON ANODE

8. CATHODE 6

STYLE 25:

PIN 1. VIN

2. N/C

3. REXT

4. GND

5. IOUT

6. IOUT

7. IOUT

8. IOUT

STYLE 29:

PIN 1. BASE, DIE #1

2. EMITTER, #1

3. BASE, #2

4. EMITTER, #2

5. COLLECTOR, #2

6. COLLECTOR, #2

7. COLLECTOR, #1

8. COLLECTOR, #1

STYLE 2:

PIN 1. COLLECTOR, DIE, #1

2. COLLECTOR, #1

3. COLLECTOR, #2

4. COLLECTOR, #2

5. BASE, #2

6. EMITTER, #2

7. BASE, #1

8. EMITTER, #1

STYLE 6:

PIN 1. SOURCE

2. DRAIN

3. DRAIN

4. SOURCE

5. SOURCE

6. GATE

7. GATE

8. SOURCE

STYLE 10:

PIN 1. GROUND

2. BIAS 1

3. OUTPUT

4. GROUND

5. GROUND

6. BIAS 2

7. INPUT

8. GROUND

STYLE 14:

PIN 1. N−SOURCE

2. N−GATE

3. P−SOURCE

4. P−GATE

5. P−DRAIN

6. P−DRAIN

7. N−DRAIN

8. N−DRAIN

STYLE 18:

PIN 1. ANODE

2. ANODE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. CATHODE

8. CATHODE

STYLE 22:

PIN 1. I/O LINE 1

2. COMMON CATHODE/VCC

3. COMMON CATHODE/VCC

4. I/O LINE 3

5. COMMON ANODE/GND

6. I/O LINE 4

7. I/O LINE 5

8. COMMON ANODE/GND

STYLE 26:

PIN 1. GND

2. dv/dt

3. ENABLE

4. ILIMIT

5. SOURCE

6. SOURCE

7. SOURCE

8. VCC

STYLE 30:

PIN 1. DRAIN 1

2. DRAIN 1

3. GATE 2

4. SOURCE 2

5. SOURCE 1/DRAIN 2

6. SOURCE 1/DRAIN 2

7. SOURCE 1/DRAIN 2

8. GATE 1

SOIC−8 NB

CASE 751−07

ISSUE AK

STYLE 3:

STYLE 7:

STYLE 11:

STYLE 15:

STYLE 19:

STYLE 23:

PIN 1. DRAIN, DIE #1

2. DRAIN, #1

3. DRAIN, #2

4. DRAIN, #2

5. GATE, #2

6. SOURCE, #2

7. GATE, #1

8. SOURCE, #1

PIN 1. INPUT

2. EXTERNAL BYPASS

3. THIRD STAGE SOURCE

4. GROUND

5. DRAIN

6. GATE 3

7. SECOND STAGE Vd

8. FIRST STAGE Vd

PIN 1. SOURCE 1

2. GATE 1

3. SOURCE 2

4. GATE 2

5. DRAIN 2

6. DRAIN 2

7. DRAIN 1

8. DRAIN 1

PIN 1. ANODE 1

2. ANODE 1

3. ANODE 1

4. ANODE 1

5. CATHODE, COMMON

6. CATHODE, COMMON

7. CATHODE, COMMON

8. CATHODE, COMMON

PIN 1. SOURCE 1

2. GATE 1

3. SOURCE 2

4. GATE 2

5. DRAIN 2

6. MIRROR 2

7. DRAIN 1

8. MIRROR 1

PIN 1. LINE 1 IN

2. COMMON ANODE/GND

3. COMMON ANODE/GND

4. LINE 2 IN

5. LINE 2 OUT

6. COMMON ANODE/GND

7. COMMON ANODE/GND

8. LINE 1 OUT

STYLE 27:

PIN 1. ILIMIT

2. OVLO

3. UVLO

4. INPUT+

5. SOURCE

6. SOURCE

7. SOURCE

8. DRAIN

DATE 16 FEB 2011

STYLE 4:

PIN 1. ANODE

2. ANODE

3. ANODE

4. ANODE

5. ANODE

6. ANODE

7. ANODE

8. COMMON CATHODE

STYLE 8:

PIN 1. COLLECTOR, DIE #1

2. BASE, #1

3. BASE, #2

4. COLLECTOR, #2

5. COLLECTOR, #2

6. EMITTER, #2

7. EMITTER, #1

8. COLLECTOR, #1

STYLE 12:

PIN 1. SOURCE

2. SOURCE

3. SOURCE

4. GATE

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 16:

PIN 1. EMITTER, DIE #1

2. BASE, DIE #1

3. EMITTER, DIE #2

4. BASE, DIE #2

5. COLLECTOR, DIE #2

6. COLLECTOR, DIE #2

7. COLLECTOR, DIE #1

8. COLLECTOR, DIE #1

STYLE 20:

PIN 1. SOURCE (N)

2. GATE (N)

3. SOURCE (P)

4. GATE (P)

5. DRAIN

6. DRAIN

7. DRAIN

8. DRAIN

STYLE 24:

PIN 1. BASE

2. EMITTER

3. COLLECTOR/ANODE

4. COLLECTOR/ANODE

5. CATHODE

6. CATHODE

7. COLLECTOR/ANODE

8. COLLECTOR/ANODE

STYLE 28:

PIN 1. SW_TO_GND

2. DASIC_OFF

3. DASIC_SW_DET

4. GND

5. V_MON

6. VBULK

7. VBULK

8. VIN

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98ASB42564B

SOIC−8 NB

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 2 OF 2

www.onsemi.com

Page 9

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SCALE 2:1

TSSOP−8

CASE 948S−01

ISSUE C

DATE 20 JUN 2008

0.076 (0.003)

−T−

SEATING

PLANE

8x REFK

U

T

JJ1

S

S

K1

K

SECTION N−N

S

U0.20 (0.008) T

2X L/2

85

L

PIN 1

IDENT

S

U0.20 (0.008) T

0.10 (0.004) V

−U−

1

4

A

M

B

−V−

C

D

G

DETAIL E

N

0.25 (0.010)

M

−W−

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD FLASH.

PROTRUSIONS OR GATE BURRS. MOLD FLASH

OR GATE BURRS SHALL NOT EXCEED 0.15

(0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH OR

PROTRUSION SHALL NOT EXCEED 0.25 (0.010)

PER SIDE.

5. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

6. DIMENSION A AND B ARE TO BE DETERMINED

AT DATUM PLANE -W-.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.114 0.122

B 4.30 4.50 0.169 0.177

C --- 1.10 --- 0.043

D 0.05 0.15 0.002 0.006

F 0.50 0.70 0.020 0.028

G 0.65 BSC 0.026 BSC

J 0.09 0.20 0.004 0.008

J1 0.09 0.16 0.004 0.006

K 0.19 0.30 0.007 0.012

K1 0.19 0.25 0.007 0.010

L 6.40 BSC 0.252 BSC

M 0 8 0 8

____

INCHESMILLIMETERS

N

GENERIC

F

DETAIL E

MARKING DIAGRAM*

XXX

YWW

A G

G

XXX = Specific Device Code

A = Assembly Location

Y = Year

WW = Work Week

G = Pb−Free Package

DOCUMENT NUMBER:

STATUS:

NEW STANDARD:

© Semiconductor Components Industries, LLC, 2002

October, 2002 − Rev. 0

DESCRIPTION:

98AON00697D

ON SEMICONDUCTOR STANDARD

TSSOP−8

http://onsemi.com

1

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

Electronic versions are uncontrolled except when

accessed directly from the Document Repository. Printed

versions are uncontrolled except when stamped

“CONTROLLED COPY” in red.

Case Outline Number:

PAGE 1 OF 2

XXX

Page 10

DOCUMENT NUMBER:

98AON00697D

PAGE 2 OF 2

ISSUE REVISION DATE

O RELEASED FOR PRODUCTION. 18 APR 2000

A ADDED MARKING DIAGRAM INFORMATION. REQ. BY V. BASS. 13 JAN 2006

B CORRECTED MARKING DIAGRAM PIN 1 LOCATION AND MARKING. REQ. BY C.

13 MAR 2006

REBELLO.

C REMOVED EXPOSED PAD VIEW AND DIMENSIONS P AND P1. CORRECTED

20 JUN 2008

MARKING INFORMATION. REQ. BY C. REBELLO.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

© Semiconductor Components Industries, LLC, 2008

Case Outline Number:

June, 2008 − Rev. 01C

948S

Page 11

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...