Page 1

MT9V023

1/3-Inch Wide‐VGA CMOS

Digital Image Sensor

General Description

The ON Semiconductor MT9V023 is a 1/3-inch wide-VGA format

CMOS active-pixel digital image sensor with global shutter and high

dynamic range (HDR) operation. The sensor has specifically been

designed to support the demanding interior and exterior automotive

imaging needs, which makes this part ideal for a wide variety of

imaging applications in real-world environments.

This wide-VGA CMOS image sensor features ON Semiconductor’s

breakthrough low-noise CMOS imaging technology that achieves

CCD image quality (based on signal-to-noise ratio and low-light

sensitivity) while maintaining the inherent size, cost, and integration

advantages of CMOS.

The active imaging pixel array is 752 H x 480 V. It incorporates

sophisticated camera functions on-chip-such as binning 2 x 2 and

4 x 4, to improve sensitivity when operating in smaller resolutions-as

well as windowing, column and row mirroring. It is programmable

through a simple two-wire serial interface.

The MT9V023 can be operated in its default mode or be

programmed for frame size, exposure, gain setting, and other

parameters. The default mode outputs a wide-VGA-size image at 60

frames per second (fps).

An on-chip analog-to-digital converter (ADC) provides 10 bits per

pixel. A 12-bit resolution companded for 10 bits for small signals can

be alternatively enabled, allowing more accurate digitization for

darker areas in the image.

In addition to a traditional, parallel logic output the MT9V023 also

features a serial low-voltage differential signaling (LVDS) output. The

sensor can be operated in a stereo-camera, and the sensor, designated

as a stereo-master, is able to merge the data from itself and the

stereo-slave sensor into one serial LVDS stream.

The sensor is designed to operate in a wide temperature range

(–40°C to +105°C).

Features

• Array Format: Wide-VGA, Active 752 H x 480 V (360,960 pixels)

• Global Shutter Photodiode Pixels; Simultaneous Integration and

Readout

• Monochrome or Color: NIR Enhanced Performance for Use with

Non-visible NIR Illumination

• Readout Modes: Progressive or Interlaced

• Shutter Efficiency: >99%

• Simple Two-wire Serial Interface

• Real-time Exposure Context Switching - Dual Registerset

• Register Lock Capability

• Window Size: User Programmable to any Smaller Format (QVGA,

CIF, QCIF). Data Rate can be Maintained Independent of Window

Size

• Binning: 2 x 2 and 4 x 4 of the Full Resolution

www.onsemi.com

IBGA52 9x9

CASE 503AA

ORDERING INFORMATION

See detailed ordering and shipping information on page 2 of

this data sheet.

• ADC: On-chip, 10-bit Column-parallel

(Option to Operate in 12-bit to 10-bit

Companding Mode)

• Automatic Controls: Auto Exposure Control

(AEC) and Auto Gain Control (AGC);

Variable Regional and Variable Weight

AEC/AGC

• Support for Four Unique Serial Control

Register IDs to Control Multiple Imagers on

the Same Bus

• Data Output Formats:

• Single Sensor Mode:

10-bit Parallel/Stand-alone

8-bit or 10-bit Serial LVDS

• Stereo Sensor Mode:

Interspersed 8-bit Serial LVDS

• High Dynamic Range (HDR) Mode

Applications

• Automotive

• Unattended Surveillance

• Stereo Vision

• Smart Vision

• Automation

• Video as Input

• Machine Vision

© Semiconductor Components Industries, LLC, 2006

January, 2017 − Rev. 6

1 Publication Order Number:

MT9V023/D

Page 2

MT9V023

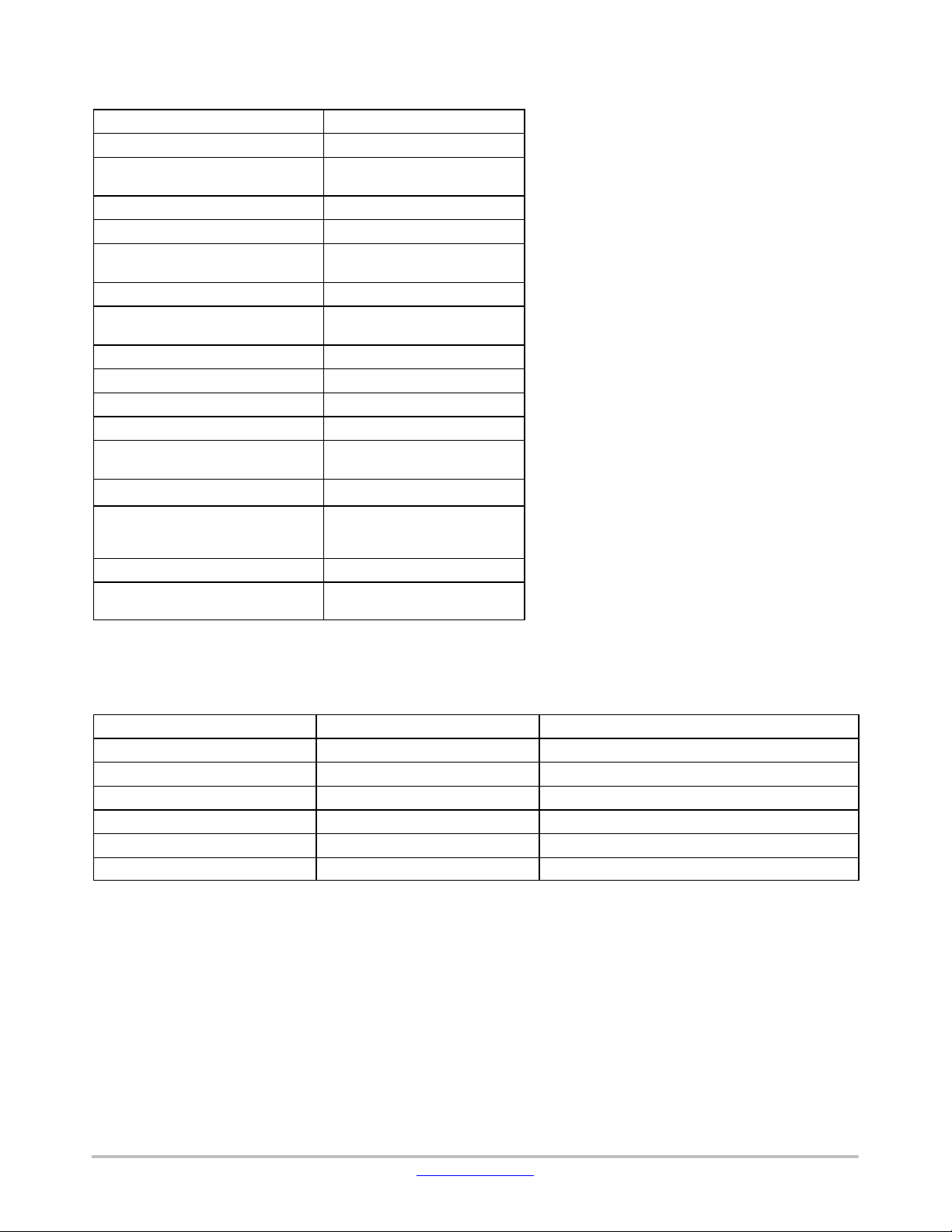

Table 1. KEY PERFORMANCE PARAMETERS

Parameter Value

Optical Format 1/3-inch

Active Imager Size 4.51 mm (H) x 2.88 mm (V)

Active Pixels 752 H x 480 V

Pixel Size 6.0 x 6.0 μm

Color Filter Array Monochrome or color RGB Bayer

Shutter Type Global Shutter

Maximum Data Rate

Master Clock

Full Resolution 752 x 480

Frame Rate 60 fps (at full resolution)

ADC Resolution 10-bit column-parallel

Responsivity 4.8 V/lux−sec (550 nm)

Dynamic Range >55 dB linear;

Supply Voltage 3.3 V ± 0.3 V (all supplies)

5.35 mm diagonal

pattern

27 Mp/s

27 MHz

>110 dB in HDR mode

Power Consumption <160 mW at maximum data rate

Operating Temperature –40°C to +105°C ambient

Packaging 52-ball IBGA, automotive-qualified;

(LVDS disabled); 120 μW standby

power

wafer or die

ORDERING INFORMATION

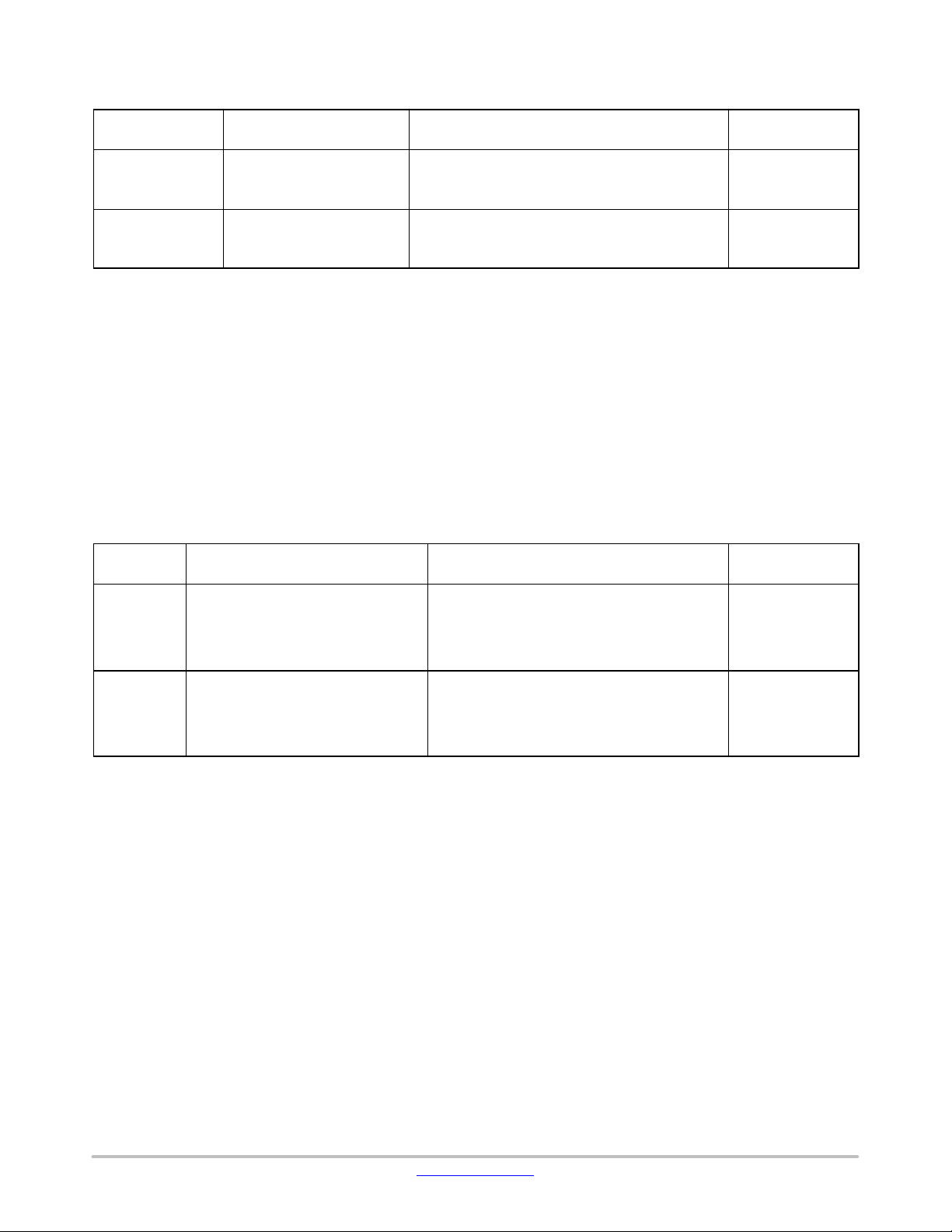

Table 2. AVAILABLE PART NUMBERS

Part Number

MT9V023IA7XTC−DP VGA 1/3” GS CIS Dry Pack with Protective Film

MT9V023IA7XTC−DR VGA 1/3” GS CIS Dry Pack without Protective Film

MT9V023IA7XTC−TP VGA 1/3” GS CIS Tape & Reel with Protective Film

MT9V023IA7XTC−TR VGA 1/3” GS CIS Tape & Reel without Protective Film

MT9V023IA7XTM−DR VGA 1/3” GS CIS Dry Pack without Protective Film

MT9V023IA7XTR−TP VGA 1/3” GS CIS Tape & Reel with Protective Film

Product Description Orderable Product Attribute Description

www.onsemi.com

2

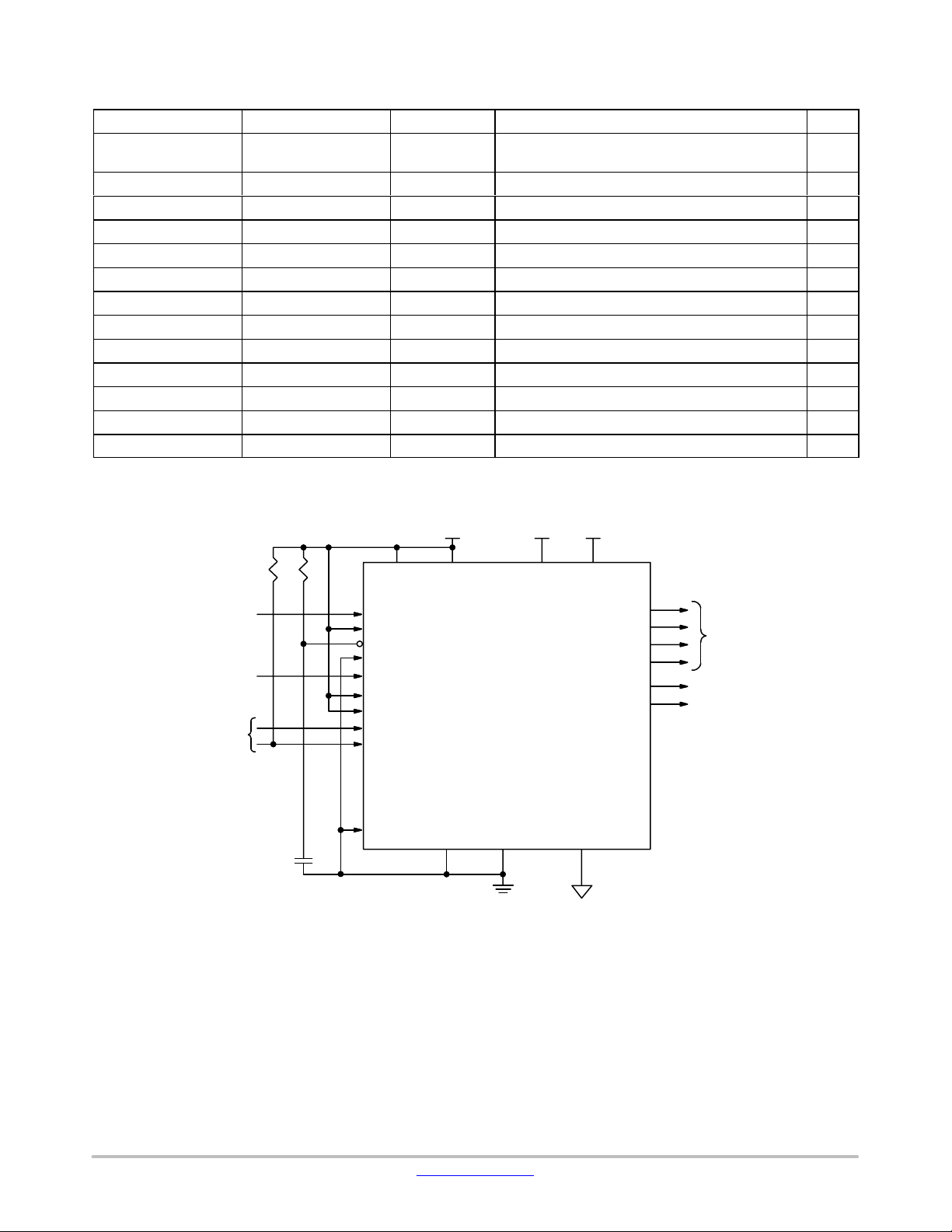

Page 3

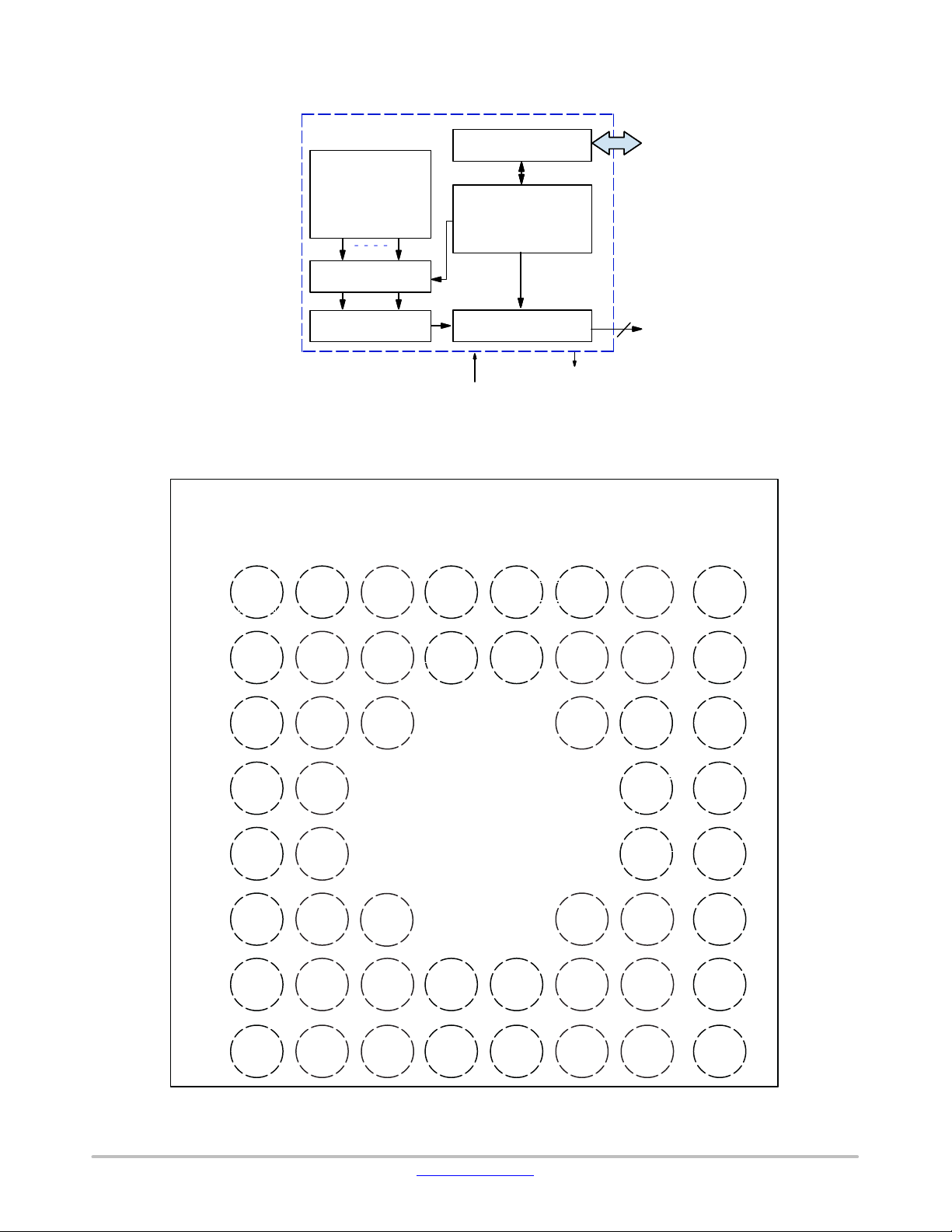

Active−Pixel

Sensor (APS)

Array

752H x 480V

Analog Processing

MT9V023

Control Register

Timing and Control

Serial

Register

I/O

A

B

C

1

VDD

LVDS

LVDS

GND

BYPASS

_CLKIN

_P

2

SER_

DATAOUT

_P

SHFT_

CLKOUT

_P

BYPASS

_CLKIN

_N

ADCs

Slave Video LVDS In

(for stereo applications only)

Figure 1. Block Diagram

3

SER_

DATAOUT

_N

SHFT_

CLKOUT

_N

LVDS

GND

4

VDD

LVDS

VDD

Digital Processing

Serial Video

LVDS Out

5

SYS−

DOUT0

CLK

PIXCLK

6

DOUT1

DGND

Parallel

Video

Data Out

7

DOUT2

DOUT4

AGND

8

DOUT3

VAAPIX

VAA

SER_

DATAIN

D

_P

DOUT5

E

DOUT6

F

DOUT8

G

DOUT9

H

SER_

DATAIN

_N

VDD

DOUT7

FRAME

_VALID

LINE_

VALID

DGND

STLN_

OUT

EXPO−

SURE

SDATA

SCLK

STFRM_

OUT

ERROR

AGND

LED_

OUT

OE

NC

NC

VAA

S_CTRL_

ADR0

RSVD

NC

NC

STAND−

BY

RESET_

BAR

S_CTRL

_ADR1

Figure 2. 52-Ball IBGA Package

www.onsemi.com

3

Page 4

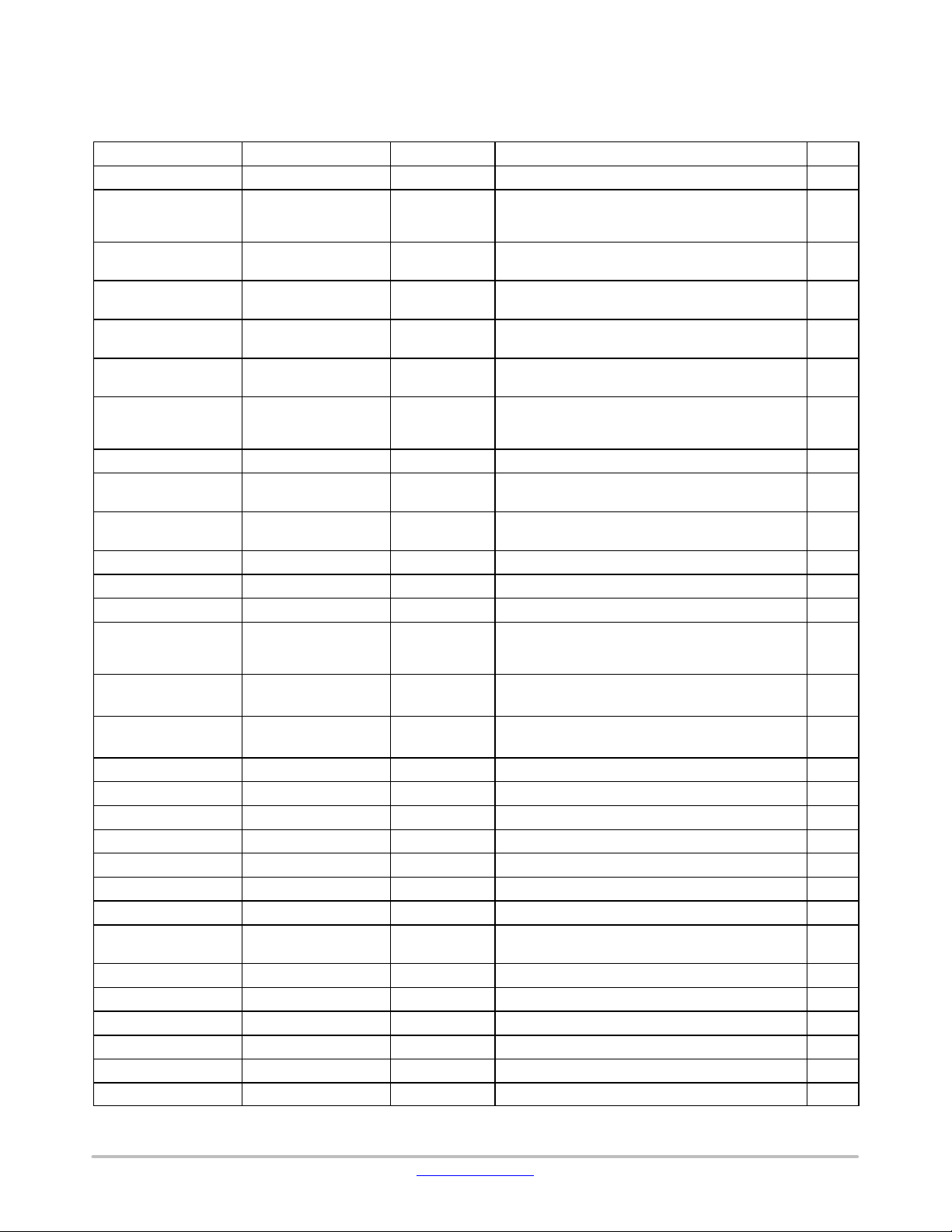

MT9V023

BALL DESCRIPTIONS

Table 3. BALL DESCRIPTIONS

52-Ball IBA Numbers Symbol Type Description Note

H7 RSVD Input Connect to DGND. 1

D2 SER_DATAIN_N Input Serial data in for stereoscopy (differential negative).

D1 SER_DATAIN_P Input Serial data in for stereoscopy (differential positive).

C2 BYPASS_CLKIN_N Input Input bypass shift-CLK (differential negative). Tie to

C1 BYPASS_CLKIN_P Input Input bypass shift-CLK (differential positive). Tie to

H3 EXPOSURE Input Rising edge starts exposure in snapshot and slave

H4 SCLK Input Two-wire serial interface clock. Connect to VDD with

H6 OE Input DOUT enable pad, active HIGH. 2

G7 S_CTRL_ADR0 Input Two-wire serial interface slave address select (see

H8 S_CTRL_ADR1 Input Two-wire serial interface slave address select (see

G8 RESET_BAR Input Asynchronous reset. All registers assume defaults.

F8 STANDBY Input Shut down sensor operation for power saving.

A5 SYSCLK Input Master clock (26.6 MHz; 13 MHz – 27 MHz).

G4 SDATA I/O Two-wire serial interface data. Connect to VDD with

G3 STLN_OUT I/O

G5 STFRM_OUT I/O

H2 LINE_VALID Output Asserted when DOUT data is valid.

G2 FRAME_VALID Output Asserted when DOUT data is valid.

E1 DOUT5 Output Parallel pixel data output 5.

F1 DOUT6 Output Parallel pixel data output 6.

F2 DOUT7 Output Parallel pixel data output 7.

G1 DOUT8 Output Parallel pixel data output 8

H1 DOUT9 Output Parallel pixel data output 9.

H5 ERROR Output Error detected. Directly connected to STEREO

G6 LED_OUT Output LED strobe output.

B7 DOUT4 Output Parallel pixel data output 4.

A8 DOUT3 Output Parallel pixel data output 3.

A7 DOUT2 Output Parallel pixel data output 2.

B6 DOUT1 Output Parallel pixel data output 1.

A6 DOUT0 Output Parallel pixel data output 0.

Tie to 1KΩ pull-up (to 3.3 V) in non-stereoscopy

mode.

Tie to D

GND in non-stereoscopy mode.

1KΩ pull-up (to 3.3 V) in non-stereoscopy mode.

D

GND in non-stereoscopy mode.

modes.

1.5 K resistor even when no other two-wire serial

interface peripheral is attached.

Table 6).

Table 6).

1.5 K resistor even when no other two-wire serial

interface peripheral is attached.

Output in master mode−start line sync to drive slave

chip in-phase; input in slave mode.

Output in master mode−start frame sync to drive a

slave chip in-phase; input in slave mode.

ERROR FLAG.

www.onsemi.com

4

Page 5

MT9V023

Table 3. BALL DESCRIPTIONS (continued)

52-Ball IBA Numbers NoteDescriptionTypeSymbol

B5 PIXCLK Output Pixel clock out. DOUT is valid on rising edge of this

B3 SHFT_CLKOUT_N Output Output shift CLK (differential negative).

B2 SHFT_CLKOUT_P Output Output shift CLK (differential positive).

A3 SER_DATAOUT_N Output Serial data out (differential negative).

A2 SER_DATAOUT_P Output Serial data out (differential positive).

B4, E2 VDD Supply Digital power 3.3 V.

C8, F7 VAA Supply Analog power 3.3 V.

B8 VAAPIX Supply Pixel power 3.3 V.

A1, A4 VDDLVDS Supply Dedicated power for LVDS pads.

B1, C3 LVDSGND Ground Dedicated GND for LVDS pads.

C6, F3 DGND Ground Digital GND.

C7, F6 AGND Ground Analog GND.

E7, E8, D7, D8 NC NC No connect. 3

1. Pin H7 (RSVD) must be tied to GND.

2. Output enable (OE) tri-states signals D

OUT0–DOUT9, LINE_VALID, FRAME_VALID, and PIXCLK.

3. No connect. These pins must be left floating for proper operation.

clock.

1.5K

Ω

Master Clock

10K

Ω

DDLVDS

V

SYSCLK

OE

RESET_BAR

STANDBY from

Controller or

Digital GND

EXPOSURE

STANDBY

S_CTRL_ADR0

S_CTRL_ADR1

Two−Wire

Serial Interface

SCLK

DATA

S

RSVD

0.1 F

μ

Note: LVDS signals are to be left floating.

Figure 3. Typical Configuration (Connection) − Parallel Output Mode

VDD

VAA VAAPIX

VDD VAA

LVDSGND

VAAPIX

D

OUT(9:0)

LINE_VALID

FRAME_VALID

PIXCLK

LED_OUT

ERROR

A

GNDDGND

To Controller

To LED output

www.onsemi.com

5

Page 6

MT9V023

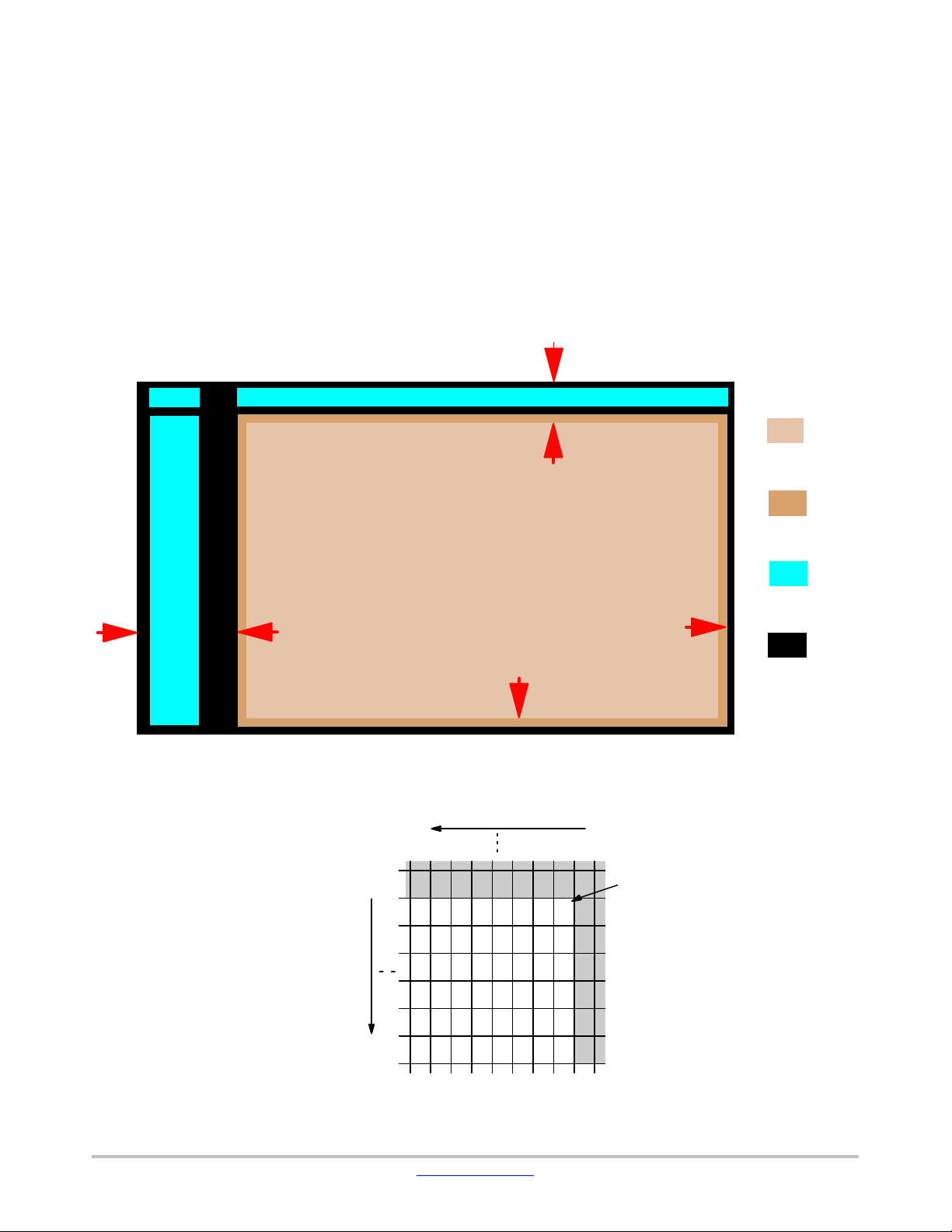

PIXEL DATA FORMAT

Pixel Array Structure

The MT9V023 pixel array is configured as 809 columns

by 499 rows, shown in Figure 4. The dark pixels are

optically black and are used internally to monitor black

level. Of the left 52 columns, 36 are dark pixels used for row

noise correction. Of the top 14 rows of pixels, two of the dark

rows are used for black level correction. Also, three black

rows from the top black rows can be read out by setting the

Show Dark Rows bit in the Read Mode register; setting

Show Dark Columns will display the 36 dark columns.

There are 753 columns by 481 rows of optically active

2 barrier + 8 (2 + 4 addressed + 2) dark + 2 barrier + 2 light dummy

pixels. While the sensor’s format is 752 x 480, one

additional active column and active row are included for use

when horizontal or vertical mirrored readout is enabled, to

allow readout to start on the same pixel. This one pixel

adjustment is always performed, for monochrome or color

versions. The active area is surrounded with optically

transparent dummy pixels to improve image uniformity

within the active area. Neither dummy pixels nor barrier

pixels can be read out.

(0, 0)

active pixel

4.92 x 3.05mm

Pixel Array

809 x 499 (753 x 481 active)

6.0 μm pixel

3 barrier + 38 (1 + 36 addressed + 1) dark

+ 9 barrier + 2 light dummy

2

2 barrier + 2 light dummy

Figure 4. Pixel Array Description

Column Readout Direction

Row Readout Direction

B

G

G

G

B

G

R

R

R

G

2 barrier + 2 light dummy

Active Pixel (0,0)

Array Pixel (4,14)

B

B

G

G

G

R

light dummy pixel

dark pixel

barrier pixel

B

G

G

B

G

R

R

G

B

G

G

B

G

R

R

G

G

G

G

G

R

R

B

B

G

G

G

G

R

R

B

B

Figure 5. Pixel Color Pattern Detail (Top Right Corner)

www.onsemi.com

6

Page 7

MT9V023

COLOR DEVICE LIMITATIONS

The color version of the MT9V023 does not support or

offers reduced performance for the following

functionalities.

Pixel Binning

Pixel binning is done on immediate neighbor pixels only,

no facility is provided to skip pixels according to a Bayer

pattern. Therefore, the result of binning combines pixels of

different colors. See “Pixel Binning” for additional

information.

Interlaced Readout

Interlaced readout yields one field consisting only of red

and green pixels and another consisting only of blue and

green pixels. This is due to the Bayer pattern of the CFA.

Automatic Black Level Calibration

When the color bit is set (R0x0F[1]=1), the sensor uses

black level correction values from one green plane, which

are applied to all colors. To use the calibration value based

on all dark pixels’ offset values, the color bit should be

cleared.

Defective Pixel Correction

For Defective Pixel Correction to calculate replacement

pixel values correctly, for color sensors the color bit must be

set (R0x0F[1] = 1). However, the color bit also applies

unequal offset to the color planes, and the results might not

be acceptable for some applications.

Other Limiting Factors

Black level correction and row-wise noise correction are

applied uniformly to each color. The row-wise noise

correction algorithm does not work well in color sensors.

Automatic exposure and gain control calculations are made

based on all three colors, not just the green channel. High

dynamic range does operate in color; however,

ON Semiconductor strongly recommends limiting use to

linear operation where good color fidelity is required.

www.onsemi.com

7

Page 8

MT9V023

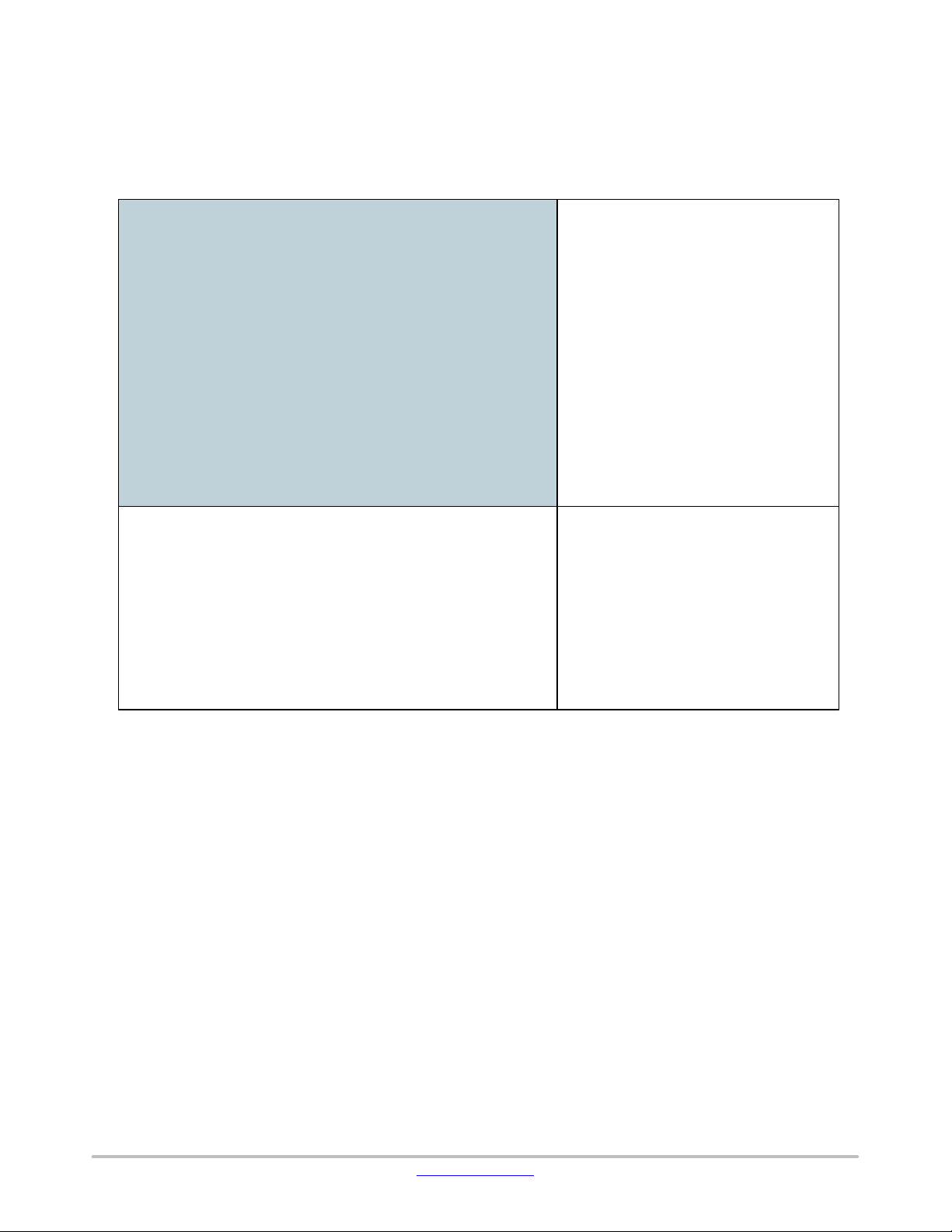

OUTPUT DATA FORMAT

The MT9V023 image data can be read out in a progressive

scan or interlaced scan mode. Valid image data is surrounded

by horizontal and vertical blanking, as shown in Figure 6.

The amount of horizontal and vertical blanking is

programmable through R0x05 and R0x06, respectively

(R0xCD and R0xCE for context B). LV is HIGH during the

shaded region of the figure. See “Output Data Timing” for

the description of FV timing.

P

0,0 P0,1 P0,2

P

1,0 P1,1 P1,2

.....................................P

.....................................P

0,n−1P0,n

1,n−1P1,n

VALID IMAGE

P

m−1,0 Pm−1,1

P

m,0 Pm,1

.....................................P

.....................................P

m−1,n−1Pm−1,n

m,n−1Pm,n

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

VERTICAL BLANKING

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

HORIZONTAL

BLANKING

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

VERTICAL/HORIZONTAL

BLANKING

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

Figure 6. Spatial Illustration of Image Readout

www.onsemi.com

8

Page 9

MT9V023

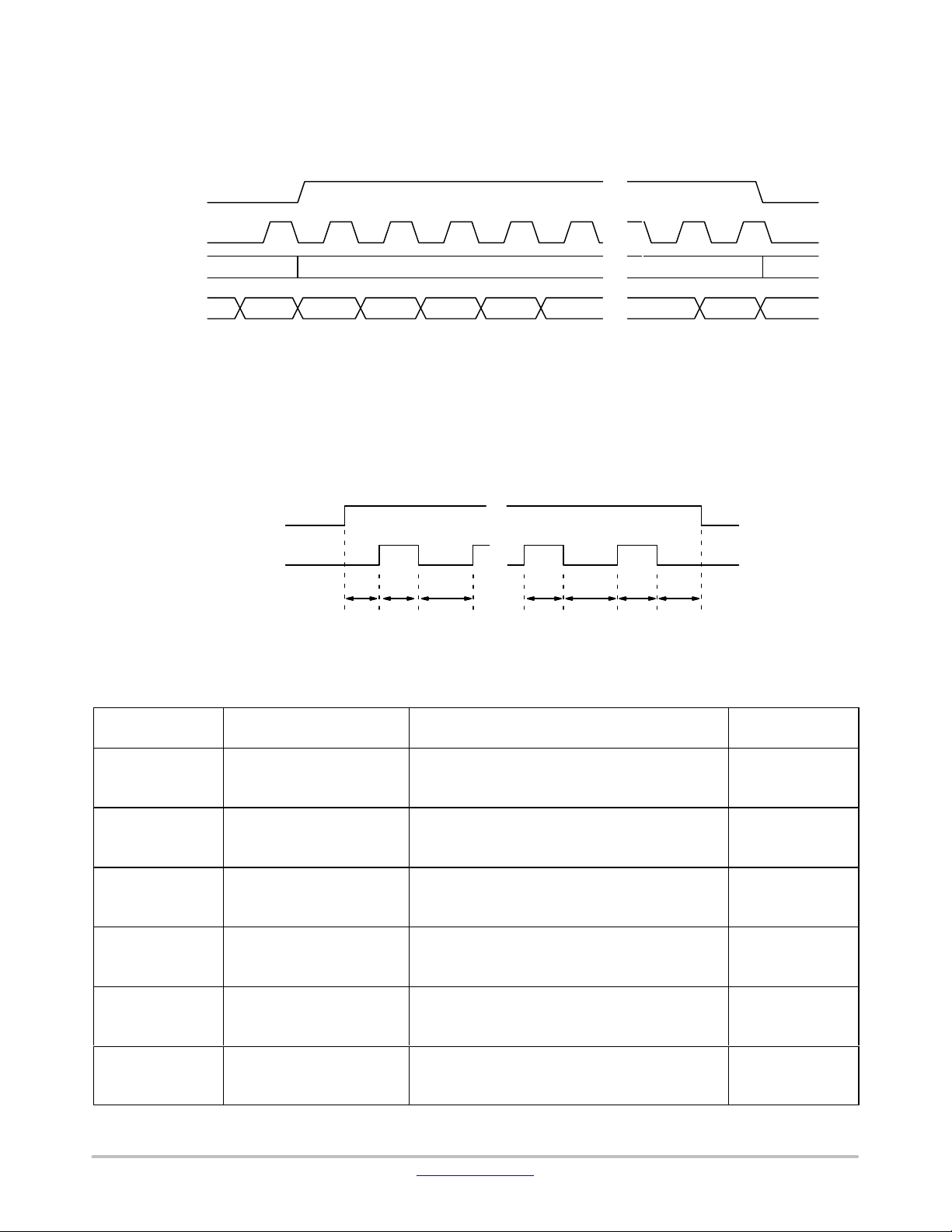

OUTPUT DATA TIMING

The data output of the MT9V023 is synchronized with the

PIXCLK output. When LINE_VALID (LV) is HIGH, one

10-bit pixel datum is output every PIXCLK period.

LINE_VALID

PIXCLK

...

...

Valid Image DataBlanking Blanking

...

D

OUT(9:0)

P

0

(9:0)

P

(9:0)

1

(9:0)

Figure 7. Timing Example of Pixel Data

The PIXCLK is a nominally inverted version of the master

clock (SYSCLK). This allows PIXCLK to be used as a clock

to latch the data. However, when column bin 2 is enabled, the

PIXCLK is HIGH for one complete master clock master

period and then LOW for one complete master clock period;

when column bin 4 is enabled, the PIXCLK is HIGH for two

FRAME_VALID

LINE_VALID

Number of master clocks

Figure 8. Row Timing and FRAME_VALID/LINE_VALID Signals

Table 4. FRAME TIME

Parameters

A Active data time Context A: R0x04

P1 Frame start blanking Context A: R0x05 - 23

P2 Frame end blanking 23 (fixed) 23 pixel clocks

Q Horizontal blanking Context A: R0x05

A+Q Row time Context A: R0x04 + R0x05

V Vertical blanking Context A: (R0x06) x (A + Q) + 4

Name Equation

P1 A QA QAP2

Context B: R0xCC

Context B: R0xCD - 23

Context B: R0xCD

Context B: R0xCC + R0xCD

Context B: (R0xCE) x (A + Q) + 4

P2

P

3

(9:0)

P

4

(9:0)

...

P

n−1

(9:0)

P

n

(9:0)

complete master clock periods and then LOW for two

complete master clock periods. It is continuously enabled,

even during the blanking period. Setting R0x72 bit[4] = 1

causes the MT9V023 to invert the polarity of the PIXCLK.

The parameters P1, A, Q, and P2 in Figure 8 are defined

in Table 4.

...

...

...

Default Timing at

752 pixel clocks

= 752 master

= 28.2 μs

71 pixel clocks

= 71master

= 2.66 μs

= 23 master

= 0.86 μs

94 pixel clocks

= 94 master

= 3.52 μs

846 pixel clocks

= 846 master

= 31.72 μs

38,074 pixel clocks

= 38,074 master

= 1.43 ms

26.66 MHz

www.onsemi.com

9

Page 10

MT9V023

Table 4. FRAME TIME (continued)

Parameters

Nrows x (A + Q) Frame valid time Context A: (R0x03) × (A + Q)

Context B: (R0xCB) x (A + Q)

F Total frame time V + (Nrows x (A + Q)) 444,154 pixel clocks

Default Timing at

EquationName

26.66 MHz

406,080 pixel clocks

= 406,080 master

= 15.23 ms

= 444,154 master

= 16.66 ms

Sensor timing is shown above in terms of pixel clock and

master clock cycles (refer to Figure 7). The recommended

master clock frequency is 26.66 MHz. The vertical blanking

and the total frame time equations assume that the

integration time (Coarse Shutter Width plus Fine Shutter

Width) is less than the number of active rows plus the

blanking rows minus the overhead rows:

Table 5. In this example it is assumed that the Coarse Shutter

Width Control is programmed with 523 rows, and the Fine

Shutter Width Total is zero.

For Simultaneous mode, if the exposure time registers

(Coarse Shutter Width Total plus Fine Shutter Width Total)

exceed the total readout time, then the vertical blanking time

is internally extended automatically to adjust for the

additional integration time required. This extended value is

Window Height ) Vertical Blanking * 2

(eq.1)

not written back to the vertical blanking registers. The

Vertical Blank register can be used to adjust frame-to-frame

If this is not the case, the number of integration rows must

be used instead to determine the frame time, as shown in

Table 5. FRAME TIME−LONG INTEGRATION TIME

Parameter Name

V’

F’

1. The MT9V023 uses column parallel analog−digital converters, thus short row timing is not possible. The minimum total row time is 690

columns (horizontal width + horizontal blanking). The minimum horizontal blanking is 61. When the window width is set below 627, horizontal

blanking must be increased.

Vertical blanking (long integration time)

Total frame time (long integration time)

Context A:

(R0x0B + 2 − R0x03) y (A + Q) + R0xD5 + 4

Context B:

(R0xD2 + 2 − R0xCB) x (A + Q) + R0xD8 + 4

Context A: (R0x0B + 2) y (A + Q) + R0xD5 +4

Context B: (R0xD2 + 2) x (A + Q) + R0xD8 +4

readout time. This register does not affect the exposure time

but it may extend the readout time.

(Number of Master Clock Cycles)

Equation

Default Timing

at 26.66 MHz

38,074 pixel

clocks

= 38,074 master

= 1.43 ms

444,154 pixel

clocks

= 444,154 master

= 16.66 ms

www.onsemi.com

10

Page 11

MT9V023

SERIAL BUS DESCRIPTION

Registers are written to and read from the MT9V023

through the two-wire serial interface bus. The MT9V023 is

a serial interface slave with four possible IDs (0x90, 0x98,

0xB0 and 0xB8) determined by the S_CTRL_ADR0 and

S_CTRL_ADR1 input pins. Data is transferred into the

MT9V023 and out through the serial data (S

S

DATA line is pulled up to VDD off-chip by a 1.5KΩ resistor.

Either the slave or master device can pull the S

down−the serial interface protocol determines which device

is allowed to pull the S

DATA line down at any given time. The

registers are 16-bit wide, and can be accessed through 16−

or 8−bit two−wire serial interface sequences.

Protocol

The two-wire serial interface defines several different

transmission codes, as shown in the following sequence:

1. a start bit

2. the slave device 8-bit address

3. a(n) (no) acknowledge bit

4. an 8-bit message

5. a stop bit

Start Bit

The start bit is defined as a HIGH-to-LOW transition of

the data line while the clock line is HIGH.

Slave Address

The 8-bit address of a two-wire serial interface device

consists of 7 bits of address and 1 bit of direction. A “0” in

the LSB of the address indicates write mode, and a “1”

indicates read mode. As indicated above, the MT9V023

allows four possible slave addresses determined by the two

input pins, S_CTRL_ADR0 and S_CTRL_ADR1.

Acknowledge Bit

The master generates the acknowledge clock pulse. The

transmitter (which is the master when writing, or the slave

when reading) releases the data line, and the receiver

indicates an acknowledge bit by pulling the data line LOW

during the acknowledge clock pulse.

No-Acknowledge Bit

The no-acknowledge bit is generated when the data line is

not pulled down by the receiver during the acknowledge

clock pulse. A no-acknowledge bit is used to terminate a

read sequence.

DATA) line. The

DATA line

Stop Bit

The stop bit is defined as a LOW-to-HIGH transition of

the data line while the clock line is HIGH.

Sequence

A typical READ or WRITE sequence begins by the

master sending a start bit. After the start bit, the master sends

the slave device’s 8-bit address. The last bit of the address

determines if the request is a read or a write, where a “0”

indicates a WRITE and a “1” indicates a READ. The slave

device acknowledges its address by sending an

acknowledge bit back to the master.

If the request was a WRITE, the master then transfers the

8-bit register address to which a WRITE should take place.

The slave sends an acknowledge bit to indicate that the

register address has been received. The master then transfers

the data 8 bits at a time, with the slave sending an

acknowledge bit after each 8 bits. The MT9V023 uses 16-bit

data for its internal registers, thus requiring two 8-bit

transfers to write to one register. After 16 bits are transferred,

the register address is automatically incremented, so that the

next 16 bits are written to the next register address. The

master stops writing by sending a start or stop bit.

A typical READ sequence is executed as follows. First the

master sends the write mode slave address and 8-bit register

address, just as in the write request. The master then sends

a start bit and the read mode slave address. The master then

clocks out the register data 8 bits at a time. The master sends

an acknowledge bit after each 8-bit transfer. The register

address is automatically incremented after every 16 bits is

transferred. The data transfer is stopped when the master

sends a no-acknowledge bit. The MT9V023 allows for 8-bit

data transfers through the two-wire serial interface by

writing (or reading) the most significant 8 bits to the register

and then writing (or reading) the least significant 8 bits to

Byte-Wise Address register (0x0F0).

Bus Idle State

The bus is idle when both the data and clock lines are

HIGH. Control of the bus is initiated with a start bit, and the

bus is released with a stop bit. Only the master can generate

the start and stop bits.

www.onsemi.com

11

Page 12

MT9V023

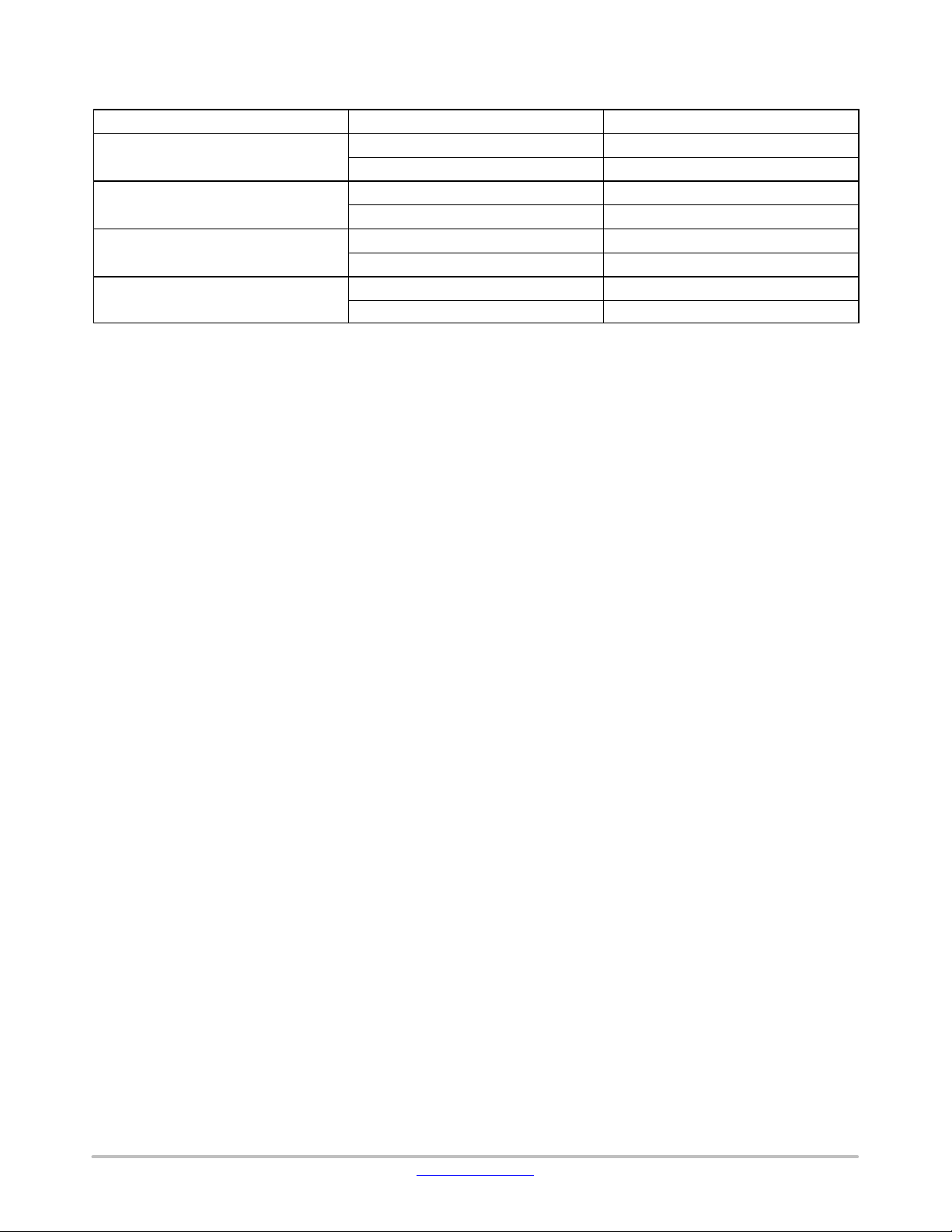

Table 6. SLAVE ADDRESS MODES

{S_CTRL_ADR1, S_CTRL_ADR0} Slave Address Write/Read Mode

00

01

10

11

0x90 Write

0x91 Read

0x98 Write

0x99 Read

0xB0 Write

0xB1 Read

0xB8 Write

0xB9 Read

Data Bit Transfer

One data bit is transferred during each clock pulse. The

two-wire serial interface clock pulse is provided by the

master. The data must be stable during the HIGH period of

the serial clock−it can only change when the two-wire serial

interface clock is LOW. Data is transferred 8 bits at a time,

followed by an acknowledge bit.

www.onsemi.com

12

Page 13

MT9V023

P

TWO-WIRE SERIAL INTERFACE SAMPLE READ AND WRITE SEQUENCES

16-Bit Write Sequence

A typical write sequence for writing 16 bits to a register

is shown in Figure 9. A start bit given by the master,

followed by the write address, starts the sequence. The

image sensor then gives an acknowledge bit and expects the

register address to come first, followed by the 16-bit data.

After each 8-bit the image sensor gives an acknowledge bit.

SCLK

SDATA

All 16 bits must be written before the register is updated.

After 16 bits are transferred, the register address is

automatically incremented, so that the next 16 bits are

written to the next register. The master stops writing by

sending a start or stop bit.

0xBA ADDR

START ACK

Reg0x09

Figure 9. Timing Diagram Showing a WRITE to Reg0x09 with the Value 0x0284

16-Bit Read Sequence

A typical read sequence is shown in Figure 10. First the

master has to write the register address, as in a write

sequence. Then a start bit and the read address specifies that

a read is about to happen from the register. The master then

SCLK

DATA

S

0xBA ADDR 0xB9 ADDR 0000 0010

START ACK

Reg0x09

ACK ACK ACK

Figure 10. Timing Diagram Showing a READ from Reg0x09, Returned Value 0x0284

8-Bit Write Sequence

To be able to write 1 byte at a time to the register a special

register address is added. The 8-bit write is done by first

writing the upper 8 bits to the desired register and then

writing the lower 8 bits to the Bytewise Address register

0000 0010

ACK ACK ACK

1000 0100

clocks out the register data 8 bits at a time. The master sends

an acknowledge bit after each 8-bit transfer. The register

address is auto-incremented after every 16 bits is

transferred. The data transfer is stopped when the master

sends a no-acknowledge bit.

1000 0100

NACK

(R0xF0). The register is not updated until all 16 bits have

been written. It is not possible to just update half of a register.

In Figure 11, a typical sequence for 8-bit writing is shown.

The second byte is written to the Bytewise register (R0xF0).

STOP

STOP

CLK

ATA

0xB8 ADDR

Figure 11. Timing Diagram Showing a Bytewise Write to R0x09 with the Value 0x0284

R0x09

0000 0010 1000 0100

ACKSTART

0xB8 ADDR

START

www.onsemi.com

13

R0xF0

ACKACKACKACK

STO

ACK

Page 14

MT9V023

8-Bit Read Sequence

To read one byte at a time the same special register address

is used for the lower byte. The upper 8 bits are read from the

desired register. By following this with a read from the

SCLK

DATA

S

0xB8 ADDR 0000 0010

START

SCLK

SDATA

0xB8 ADDR 1000 0100

START

Figure 12. Timing Diagram Showing a Bytewise Read from R0x09; Returned Value 0x0284

R0x09

R0xF0

Bytewise Address register (R0xF0) the lower 8 bits are

accessed (Figure 12). The master sets the no-acknowledge

bits shown.

0xB9 ADDR

START

ACKACKACK

0xB9 ADDR

START

NACK

STOP

NACKACKACKACK

Register Lock

Included in the MT9V023 is a register lock (R0xFE)

feature that can be used as a solution to reduce the

probability of an inadvertent noise-triggered two-wire serial

interface write to the sensor. All registers, or only the Read

Mode registers–R0x0D and R0x0E, can be locked. It is

important to prevent an inadvertent two-wire serial interface

write to the Read Mode registers in automotive applications

since this register controls the image orientation and any

unintended flip to an image can cause serious results.

At power-up, the register lock defaults to a value of

0xBEEF, which implies that all registers are unlocked and

any two-wire serial interface writes to the register gets

committed.

Lock All Registers

If a unique pattern (0xDEAD) to R0xFE is programmed,

any subsequent two-wire serial interface writes to registers

(except R0xFE) are NOT committed. Alternatively, if the

user writes a 0xBEEF to the register lock register, all

registers are unlocked and any subsequent two-wire serial

interface writes to the register are committed.

Lock Only Read Mode Registers (R0x0D and R0x0E)

If a unique pattern (0xDEAF) to R0xFE is programmed,

any subsequent two-wire serial interface writes to R0x0D or

R0x0E are NOT committed. Alternatively, if the user writes

a 0xBEEF to register lock register, registers R0x0D and

R0x0E are unlocked and any subsequent two-wire serial

interface writes to these registers are committed.

www.onsemi.com

14

Page 15

MT9V023

Real-Time Context Switching

In the MT9V023, the user may switch between two full

register sets (listed in Table 7) by writing to a context switch

all registers (no shadowing) at the frame start time and have

the new values apply to the immediate next exposure and

readout time.

change bit in register 0x07. This context switch will change

Table 7. REAL-TIME CONTEXT−SWITCHABLE REGISTERS

Register Name Register Number (Hex) For Context A Register Number (Hex) for Context B

Column Start 0x01 0xC9

Row Start 0x02 0xCA

Window Height 0x03 0xCB

Window Width 0x04 0xCC

Horizontal Blanking 0x05 0xCD

Vertical Blanking 0x06 0xCE

Coarse Shutter Width 1 0x08 0xCF

Coarse Shutter Width 2 0x09 0xD0

Coarse Shutter Width Control 0x0A 0xD1

Coarse Shutter Width Total 0x0B 0xD2

Fine Shutter Width 1 0xD3 0xD6

Fine Shutter Width 2 0xD4 0xD7

Fine Shutter Width Total 0xD5 0xD8

Read Mode 0x0D [5:0] 0x0E [5:0]

High Dynamic Range enable 0x0F [0] 0x0F [8]

ADC Resolution Control 0x1C [1:0] 0x1C [9:8]

V1 Control – V4 Control 0x31 – 0x34 0x39 – 0x3C

Analog Gain Control 0x35 0x36

Row Noise Correction Control 1 0x70 [1:0] 0x70 [9:8]

Tiled Digital Gain 0x80 [3:0] – 0x98 [3:0] 0x80 [11:8] – 0x98 [11:8]

AEC/AGC Enable 0xAF [1:0] 0xAF [9:8]

www.onsemi.com

15

Page 16

MT9V023

FEATURE DESCRIPTION

Operational Modes

The MT9V023 works in master, snapshot, or slave mode.

In master mode the sensor generates the readout timing. In

snapshot mode it accepts an external trigger to start

integration, then generates the readout timing. In slave mode

the sensor accepts both external integration and readout

controls. The integration time is programmed through the

two-wire serial interface during master or snapshot modes,

or controlled through an externally generated control signal

during slave mode.

Master Mode

There are two possible operation methods for master

mode: simultaneous and sequential. One of these operation

modes must be selected through the two-wire serial

interface.

Readout Time > Exposure Time

Simultaneous Master Mode

In simultaneous master mode, the exposure period occurs

during readout. The frame synchronization waveforms are

shown in Figure 13 and Figure 14. The exposure and

readout happen in parallel rather than sequential, making

this the fastest mode of operation.

LED_OUT

FRAME_VALID

LINE_VALID

D

OUT(9:0)

LED_OUT

FRAME_VALID

LINE_VALID

OUT(9:0)

D

Exposure Time

Vertical Blanking

xxx xxx xxx

Figure 13. Simultaneous Master Mode Synchronization Waveforms #1

Exposure Time > Readout Time

Exposure Time

Vertical Blanking

xxx xxx xxx

Figure 14. Simultaneous Master Mode Synchronization Waveforms #2

When exposure time is greater than the sum of vertical

blank and window height, the number of vertical blank rows

www.onsemi.com

is increased automatically to accommodate the exposure

time.

16

Page 17

MT9V023

Sequential Master Mode

In sequential master mode the exposure period is followed

by readout. The frame synchronization waveforms for

LED_OUT

FRAME_VALID

LINE_VALID

OUT (9:0)

D

xxx xxx xxx

Figure 15. Sequential Master Mode Synchronization Waveforms

Snapshot Mode

In snapshot mode the sensor accepts an input trigger

signal which initiates exposure, and is immediately

followed by readout. Figure 16 shows the interface signals

used in snapshot mode. In snapshot mode, the start of the

integration period is determined by the externally applied

EXPOSURE pulse that is input to the MT9V023. The

integration time is preprogrammed at R0x0B or R0xD2

sequential master mode are shown in Figure 15. The frame

rate changes as the integration time changes.

Exposure Time

through the two-wire serial interface. After the frame’s

integration period is complete the readout process

commences and the syncs and data are output. Sensor in

snapshot mode can capture a single image or a sequence of

images. The frame rate may only be controlled by changing

the period of the user supplied EXPOSURE pulse train. The

frame synchronization waveforms for snapshot mode are

shown in Figure 17.

EXPOSURE

LED_OUT

FRAME_VALID

LINE_VALID

D

OUT(9:0)

EXPOSURE

SYSCLK

PIXCLK

CONTROLLER

LINE_VALID

FRAME_VALID

OUT

D

(9:0)

MT9V023

Figure 16. Snapshot Mode Interface Signals

Exposure Time

xxx xxx xxx

Figure 17.

Snapshot Mode Frame Synchronization Waveforms

www.onsemi.com

17

Page 18

MT9V023

Slave Mode

In slave mode, the exposure and readout are controlled

using the EXPOSURE, STFRM_OUT, and STLN_OUT

pins. When the slave mode is enabled, STFRM_OUT and

STLN_OUT become input pins.

The start and end of integration are controlled by

EXPOSURE and STFRM_OUT pulses, respectively. While

a STFRM_OUT pulse is used to stop integration, it is also

used to enable the readout process.

After integration is stopped, the user provides

STLN_OUT pulses to trigger row readout. A full row of data

is read out with each STLN_OUT pulse. The user must

Exposure

(input)

STFRM_OUT

(input)

LED_OUT

(output)

STLN_OUT

(input)

LINE_VALID

(output)

Integration T ime

Figure 18. Slave Mode Operation

provide enough time between successive STLN_OUT

pulses to allow the complete readout of one row.

It is also important to provide additional STLN_OUT

pulses to allow the sensors to read the vertical blanking rows.

It is recommended that the user program the vertical blank

register (R0x06) with a value of 4, and achieve additional

vertical blanking between frames by delaying the

application of the STFRM_OUT pulse.

The elapsed time between the rising edge of STLN_OUT

and the first valid pixel data is calculated for context A by

[horizontal blanking register (R0x05) + 4] clock cycles. For

context B, the time is (R0xCD + 4) clock cycles.

Vertical Blanking

Signal Path

The MT9V023 signal path consists of a programmable

gain, a programmable analog offset, and a 10-bit ADC. See

Pixel Output

(reset minus signal)

Offset Correction

Voltage (R0x48 or

result of BLC)

C1

C2

Figure 19. Signal Path

“Black Level Calibration” for the programmable offset

operation description.

Gain Selection

(R0x35 or R0x36 or

result of AGC)

V

REF

(R0x2C)

10 (12) bit ADC

ADC Data

(9:0)

www.onsemi.com

18

Page 19

MT9V023

On-Chip Biases

ADC Voltage Reference

The ADC voltage reference is programmed through

R0x2C, bits 2:0. The ADC reference ranges from 1.0 V to

2.1 V. The default value is 1.4 V. The increment size of the

voltage reference is 0.1 \V from 1.0 V to 1.6 V (R0x2C[2:0]

values 0 to 6). At R0x2C[2:0] = 7, the reference voltage

jumps to 2.1 V.

It is very important to preserve the correct values of the

other bits in R0x2C. The default register setting is 0x0004.

This corresponds to 1.4 V−at this setting 1 mV input to the

ADC equals approximately 1 LSB.

V_Step Voltage Reference

This voltage is used for pixel high dynamic range

operations, programmable from R0x31 through R0x34 for

Context A, or R0x39 through R0x3B for context B.

Chip Version

Chip version register R0x00 is read-only.

Window Control

Registers Column Start A/B, Row Start A/B, Window

Height A/B (row size), and Window Width (column size)

A/B control the size and starting coordinates of the window.

The values programmed in the window height and width

registers are the exact window height and width out of the

sensor. The window start value should never be set below

four.

To read out the dark rows set bit 6 of R0x0D. In addition,

bit 7 of R0x0D can be used to display the dark columns in

the image. Note that there are Show Dark settings only for

Context A.

Blanking Control

Horizontal Blank and Vertical Blank registers R0x05 and

R0x06 (B: 0xCD and R0xCE), respectively, control the

blanking time in a row (horizontal blanking) and between

frames (vertical blanking).

• Horizontal blanking is specified in terms of pixel

clocks.

• Vertical blanking is specified in terms of numbers of

rows.

The actual imager timing can be calculated using Table 4

and Table 5 which describe “Row Timing and FV/LV

signals”.The minimum number of vertical blank rows is 4.

Pixel Integration Control

Total Integration

Total integration time is the result of coarse shutter width

and fine shutter width registers, and depends also on whether

manual or automatic exposure is selected.

The actual total integration time,

tt t

INT * INTCoarse ) INTFint

t

INT is defined as:

(eq. 2)

= (number of rows of integration x row time) + (number

of pixels of integration x pixel time)

where:

Number of Rows of Integration

(Auto Exposure Control: Enabled)

When automatic exposure control (AEC) is enabled, the

number of rows of integration may vary from frame to

frame, with the limits controlled by R0xAC (minimum

coarse shutter width) and R0xAD (maximum coarse shutter

width).

Number of Rows of Integration

(Auto Exposure Control: Disabled)

If AEC is disabled, the number of rows of integration

equals the value in R0x0B

or

If context B is enabled, the number of rows of integration

equals the value in R0xD2.

Number of Pixels of Integration

The number of fine shutter width pixels is independent of

AEC mode (enabled or disabled):

• Context A: the number of pixels of integration equals

the value in R0xD5.

• Context B: the number of pixels of integration equals

the value in R0xD8.

Row Timing

Context A : Row time + (R0x04 ) R0x05)

master clock periods

Context B : Row time + (R0xCC ) R0xCD)

master clock periods

Typically, the value of the Coarse Shutter Width Total

registers is limited to the number of rows per frame (which

includes vertical blanking rows), such that the frame rate is

not affected by the integration time. If the Coarse Shutter

Width Total is increased beyond the total number of rows per

frame, the user must add additional blanking rows using the

Vertical Blanking registers as needed. See descriptions of

the Vertical Blanking registers, R0x06 and R0xCE in Table

4 of the MT9V023 register reference.

A second constraint is that

t

INT must be adjusted to avoid

banding in the image from light flicker. Under 60 Hz flicker,

this means the frame time must be a multiple of 1/120 of a

second. Under 50 Hz flicker, the frame time must be a

multiple of 1/100 of a second.

Changes to Integration Time

With automatic exposure control disabled (R0xAF[0] for

context A, or R0xAF[8] for context B) and if the total

integration time (R0x0B or R0xD2) is changed through the

two-wire serial interface while FV is asserted for frame n,

the first frame output using the new integration time is frame

(eq. 3)

(eq. 4)

www.onsemi.com

19

Page 20

MT9V023

(n + 2). Similarly, when automatic exposure control is

enabled, any change to the integration time for frame n first

appears in frame (n + 2) output.

The sequence is as follows:

1. During frame n, the new integration time is held in

the R0x0B or R0D2 live register.

2. At the start of frame (n + 1), the new integration

time is transferred to the exposure control module.

Integration for each row of frame (n + 1) has been

completed using the old integration time. The

earliest time that a row can start integrating using

the new integration time is immediately after that

row has been read for frame (n + 1). The actual

time that rows start integrating using the new

FRAME_VALID

New Integration

Programmed

Actual

Integration

Int = 200 rows

Int = 200 rows

integration time is dependent on the new value of

the integration time.

3. When frame (n + 1) is read out, it is integrated

using the new integration time. If the integration

time is changed (R0x0B or R0xD2 written) on

successive frames, each value written is applied to

a single frame; the latency between writing a value

and it affecting the frame readout remains at two

frames. However, when automatic exposure

control is disabled, if the integration time is

changed through the two-wire serial interface after

the falling edge of FV for frame n, the first frame

output using the new integration time becomes

frame (n+3).

Int = 300 rows

Int = 300 rows

LED_OUT

Image Data

Frame Start

Figure 20. Latency When Changing Integration

Exposure Indicator

The exposure indicator is controlled by:

• R0x1B LED_OUT Control

The MT9V023 provides an output pin, LED_OUT, to

indicate when the exposure takes place. When R0x1B bit 0

Table 8. HIGH DYNAMIC RANGE

Context A Context B

High Dynamic Enable R0x0F[0] R0x0F[8]

Shutter Width 1 R0x08 R0xCF

Shutter Width 2 R0x09 R0xD0

Shutter Width Control R0x0A R0xD1

V_Step Voltages R0x31−R0x34 R0x39−R0x3C

Output image with

Int = 200 rows

Output

image with

Int = 300

rows

is clear, LED_OUT is HIGH during exposure. By using

R0x1B, bit 1, the polarity of the LED_OUT pin can be

inverted.

High Dynamic Range

High dynamic range is controlled by:

In the MT9V023, high dynamic range (by setting R0x0F,

bit 0 or 8 to 1) is achieved by controlling the saturation level

of the pixel (HDR or high dynamic range gate) during the

exposure period. The sequence of the control voltages at the

HDR gate is shown in Figure 21. After the pixels are reset,

the step voltage, V_Step, which is applied to HDR gate, is

www.onsemi.com

set up at V1 for integration time t

then V3 for time t

, and finally it is parked at V4, which also

3

then to V2 for time t2,

1,

serves as an antiblooming voltage for the photodetector.

This sequence of voltages leads to a piecewise linear pixel

response, illustrated (approximately) in Figure 21 and

Figure 22.

20

Page 21

AA (3.3V)

V

MT9V023

Exposure

V1~1.4V

HDR

Voltage

t

1

Figure 21. Sequence of Control Voltages at the HDR Gate

Output

dV1

1/t

1

1/t

2

Figure 22. Sequence of Voltages in a Piecewise Linear Pixel Response

The parameters of the step voltage V_Step which takes

values V1, V2, and V3 directly affect the position of the knee

points in Figure 22.

Light intensities work approximately as a reciprocal of the

partial exposure time. Typically,

t

2 shorter, and so on. Thus the range of light intensities is

t

1 is the longest exposure,

shortest for the first slope, providing the highest sensitivity.

The register settings for V_Step and partial exposures are:

• V1 = R0x31, bits 5:0 (Context B: R0x39, bits 5:0)

• V2 = R0x32, bits 5:0 (Context B: R0x3A, bits 5:0)

• V3 = R0x33, bits 5:0 (Context B: R0x3B, bits 5:0)

• V4 = R0x34, bits 5:0 (Context B: R0x3C, bits 5:0)

t

•

INT = t1 + t2 + t3

There are two ways to specify the knee points timing, the

first by manual setting and the second by automatic knee

point adjustment. Knee point auto adjust is controlled for

context A by R0x0A[8] (where default is ON), and for

context B by R0xD1[8] (where default is OFF).

When the knee point auto adjust enabler is enabled (set

HIGH), the MT9V023 calculates the knee points

automatically using the following equations:

t

ttt

1 + INT * 2 * 3

t

t

2 + INT x (1ń2)

t

t

2 + INT x (1ń2)

R0x0A[3:0] or R0xD1[3:0]

R0x0A[7:4] or R0xD1[7:4]

(eq. 5)

(eq. 6)

(eq. 7)

V2~1.2V V3~1.0V

V4~0.8V

t

2

t

3

dV3

dV2

Light Intensity

1/t

3

As a default for auto exposure, t2 is 1/16 of tINT, t3 is 1/64

t

of

INT.

When the auto adjust enabler is disabled (set LOW),

t

and

3 may be programmed

through the two-wire serial interface:

t

1 + Coarse SW1 (row * times) ) Fine SW1 (pixel * times)

t

2 + Coarse SW2 * Coarse SW1 ) Fine SW2 * Fine SW1

t

3 + Total Integration * 1 * 2

+ Coarse Total Shutter Width ) Fine Shutter Width Total * 1 * 2

tt

(eq. 8)

(eq. 9)

tt

(eq. 10)

For context A these become:

t

1 + R0x08 ) R0xD3

t

2 + R0x09 * ROx08 ) R0xD4 * R0xD3

ttt

3 + R0x0B ) R0xD4 * 1 * 2

(eq. 11)

(eq. 12)

(eq. 13)

For context B these are:

t

1 + R0xCF ) R0xD6

t

2 + R0xD0 * ROxCF ) R0xD7 * R0xD6

ttt

3 + R0xD2 ) R0xD8 * 1 * 2

(eq. 14)

(eq. 15)

(eq. 16)

t

1, t2,

www.onsemi.com

21

Page 22

MT9V023

In all cases above, the coarse component of total

integration time may be based on the result of AEC or values

in Reg0x0B and Reg0xD2, depending on the settings.

Similar to Fine Shutter Width Total registers, the user

must not set the Fine Shutter Width 1 or Fine Shutter Width

ADC Companding Mode

By default, ADC resolution of the sensor is 10-bit.

Additionally, a companding scheme of 12-bit into 10-bit is

enabled by the ADC Companding Mode register. This mode

allows higher ADC resolution, which means less

10-bit

Codes

1,024

768

512

2 to 1 Companding (256 128)

256

No companding (256 256)

2 register to exceed the row time (Horizontal Blanking +

Window Width). The absolute maximum value for the Fine

Shutter Width registers is 1774 master clocks.

quantization noise at low-light, and lower resolution at high

light, where good ADC quantization is not so critical

because of the high level of the photon’s shot noise.

8 to 1 Companding (2,048 256)

4 to 1 Companding (1,536 384)

12-bit

Codes

1,024512256

Figure 23. 12- to 10-Bit Companding Chart

Gain Settings

Changes to Gain Settings

When the digital gain settings (R0x80

–R0x98) are

changed, the gain is updated on the next frame start.

However, the latency for an analog gain change to take effect

depends on the automatic gain control.

FRAME_VALID

New Integration

Programmed

Actual

Gain

Image Data

Frame Start

Gain = 3.0X Gain = 3.5X

4,0962,048

If automatic gain control is enabled (R0xAF, bit 1 is set to

HIGH), the gain changed for frame n first appears in frame

(n + 1); if the automatic gain control is disabled, the gain

changed for frame n first appears in frame (n + 2).

Both analog and digital gain change regardless of whether

the integration time is also changed simultaneously. See the

“MT9V023 Developer Guide” for more details.

Gain = 3.0X Gain = 3.5X

Output image with

Gain = 3.0X

Output

image with

Gain = 3.5X

Figure 24. Latency of Analog Gain Change When AGC Is Disabled

Analog Gain

Analog gain is controlled by:

• R0x35 Global Gain context A

• R0x36 Global Gain context B

www.onsemi.com

22

Page 23

MT9V023

The formula for gain setting is:

Gain + Bits[6 : 0] 0.0625

(eq. 17)

The analog gain range supported in the MT9V023 is

1X

–4X with a step size of 6.25 percent. To control gain

manually with this register, the sensor must NOT be in AGC

mode. When adjusting the luminosity of an image, it is

recommended to alter exposure first and yield to gain

increases only when the exposure value has reached a

maximum limit.

• Analog gain = bits (6:0) x 0.0625 for values 16–31

• Analog gain = bits (6:0)/2 x 0.125 for values 32–64

For values 16–31: each LSB increases analog gain 0.0625

v/v. A value of 16 = 1X gain. Range: 1X to 1.9375X.

For values 32–64: each 2 LSB increases analog gain 0.125

v/v (that is, double the gain increase for 2 LSB). Range: 2X

to 4X. Odd values do not result in gain increases; the gain

increases by 0.125 for values 32, 34, 36, and so on.

Digital Gain

Digital gain is controlled by:

• R0x99−R0xA4 Tile Coordinates

• R0x80−R0x98 Tiled Digital Gain and Weight

In the MT9V023, the gain logic divides the image into 25

tiles, as shown in Figure 25. The size and gain of each tile

can be adjusted using the above digital gain control registers.

Separate tile gains can be assigned for context A and context

B.

Registers 0x99–0x9E and 0x9F–0xA4 represent the

coordinates X0/5–X5/5 and Y0/5–Y5/5 in Figure 25,

respectively.

Digital gains of registers 0x80–0x98 apply to their

corresponding tiles. The MT9V023 supports a digital gain

of 0.25–3.75X.

When binning is enabled, the tile offsets maintain their

absolute values; that is, tile coordinates do not scale with row

or column bin setting.

NOTE:

There is one exception, for the condition when

Column Bin 4 is enabled (R0x0D[3:2] or

R0x0E[3:2] = 2). For this case, the value for

Digital Tile Coordinate

X–direction must be doubled.

The formula for digital gain setting is:

Digital Gain + Bits[3 : 0] 0.25

(eq. 18)

X0/5 X1/5 X2/5 X3/5 X4/5 X5/5

Y0/5

x0_y0 x1_y0 x4_y0

Y1/5

x0_y1 x1_y1 x4_y1

Y2/5

x0_y2 x1_y2 x4_y2

Y3/5

x0_y3 x1_y3 x4_y3

Y4/5

x0_y4 x1_y4 x4_y4

Y5/5

Black Level Calibration

Black level calibration is controlled by:

• Frame Dark Average: R0x42

• Dark Average Thresholds: R0x46

• Black Level Calibration Control: R0x47

Figure 25. Tiled Sample

• Black Level Calibration Value: R0x48

• Black Level Calibration Value Step Size: R0x4C

The MT9V023 has automatic black level calibration

on-chip, and if enabled, its result may be used in the offset

correction shown in Figure 26.

www.onsemi.com

23

Page 24

MT9V023

Gain Selection

(R0x35 or R0x36 or

result of AGC)

VREF

(R0x2C)

Pixel Output

(reset minus signal)

Offset Correction

Voltage (R0x48 or

result of BLC)

Figure 26. Black Level Calibration Flow Chart

C1

C2

The automatic black level calibration measures the

average value of pixels from 2 dark rows (1 dark row if row

bin 4 is enabled) of the chip. (The pixels are averaged as if

they were light-sensitive and passed through the appropriate

gain.)

This row average is then digitally low-pass filtered over

many frames (R0x47, bits 7:5) to remove temporal noise and

random instabilities associated with this measurement.

Then, the new filtered average is compared to a minimum

acceptable level, low threshold, and a maximum acceptable

level, high threshold.

If the average is lower than the minimum acceptable level,

the offset correction voltage is increased by a programmable

offset LSB in R0x4C. (Default step size is 2 LSB Offset =

1 ADC LSB at analog gain = 1X.)

If it is above the maximum level, the offset correction

voltage is decreased by 2 LSB (default).

10 (12) bit ADC

ADC Data

(9:0)

To avoid oscillation of the black level from below to

above, the region the thresholds should be programmed so

the difference is at least two times the offset DAC step size.

In normal operation, the black level calibration

value/offset correction value is calculated at the beginning

of each frame and can be read through the two-wire serial

interface from R0x48. This register is an 8-bit signed two’s

complement value.

However, if R0x47, bit 0 is set to “1,” the calibration value

in R0x48 is used rather than the automatic black level

calculation result. This feature can be used in conjunction

with the “show dark rows” feature (R0x0D[6]) if using an

external black level calibration circuit.

The offset correction voltage is generated according to the

following formulas:

Offset Correction Voltage + (8 * bit signed twoȀs complement calibration value, –127 127) 0.5 mV

ADC input voltage + (Pixel Output Voltage ) Offset Correction Voltage) Analog Gain

Defective Pixel Correction

Defective pixel correction is intended to compensate for

defective pixels by replacing their value with a value based

on the surrounding pixels, making the defect less noticeable

to the human eye. The locations of defective pixels are

Row-wise Noise Correction

Row-wise noise correction is controlled by the following

registers:

• R0x70 Row Noise Control

• R0x72 Row Noise Constant

to (eq. 19)

stored in a ROM on chip during the manufacturing process;

the maximum number of defects stored is 32. There is no

provision for later augmenting the table of programmed

defects. In the defect correction block, bad pixels will be

substituted by either the average of its neighboring pixels, or

its nearest-neighbor pixel, depending on pixel location.

Defective Pixel Correction is enabled by R0x07[9]. By

default, correction is enabled, and pixels mapped in internal

ROM are replaced with corrected values. This might be

Row-wise noise cancellation is performed by calculating

a row average from a set of optically black pixels at the start

of each row and then applying each average to all the active

pixels of the row. Read Dark Columns register bit and Row

Noise Correction Enable register bit must both be set to

enable row-wise noise cancellation to be performed. The

behavior when Read Dark Columns register bit = 0 and Row

Noise Correction Enable register bit = 1 is undefined.

unacceptable to some applications, in which case pixel

correction should be disabled (R0x07[9] = 0).

www.onsemi.com

24

(eq. 20)

Page 25

MT9V023

The algorithm works as follows:

Logical columns 755-790 in the pixel array provide 36

optically black pixel values. Of the 36 values, two smallest

value and two largest values are discarded. The remaining

32 values are averaged by summing them and discarding the

5 LSB of the result. The 10-bit result is subtracted from each

pixel value on the row in turn. In addition, a positive constant

will be added (Reg0x71, bits 7:0). This constant should be

set to the dark level targeted by the black level algorithm plus

the noise expected on the measurements of the averaged

values from dark columns; it is meant to prevent clipping

from negative noise fluctuations.

Pixel value + ADC value – dark column average ) R0x71[9 : 0]

(eq. 21)

EXP. LPF

(R0xA8)

MAX. EXPOSURE (R0xBD)

MIN EXPOSURE (R0xAC)

DESIRED BIN

(desired luminance)

(R0xA5)

MAX. GAIN

(R0xAB)

16

CURRENT BIN

MIN GAIN

UNIT

(R0xBC)

(current luminance)

UNIT

Automatic Gain Control and Automatic Exposure

Control

that optimal auto settings of exposure and (analog) gain are

computed and updated every frame.

R0xAF. When AEC is disabled (R0xAF[0] = 0), the sensor

uses the manual exposure value in coarse and fine shutter

width registers. When AGC is disabled (R0xAF[1] = 0), the

sensor uses the manual gain value in R0x35 or R0x36. See

“Pixel Integration Control” and the MT9V023 Developer

Guide, for more information.

EXP. SKIP

(R0xA6)

AEC

HISTOGRAM

GENERATOR

UNIT

AGC

Note that this algorithm does not work in color sensor.

The integrated AEC/AGC unit is responsible for ensuring

AEC and AGC can be individually enabled or disabled by

Coarse Shutter

Width Total

AEC

OUTPUT

AGC OUTPUT

AEC ENABLE

(R0xAF[0 or 8])

To exposure

0

timing control

1

R0xBB

To analog

1

gain control

0

R0xBA

GAIN LPF

(R0xAB)

Figure 27. Controllable and Observable AEC/AGC Registers

GAIN SKIP

The exposure is measured in row-time by reading R0xBB.

The exposure range is 1 to 2047. The gain is measured in

gain-units by reading R0xBA. The gain range is 16 to 63

(unity gain = 16 gain-units; multiply by 1/16 to get the true

gain).

When AEC is enabled (R0xAF), the maximum auto

exposure value is limited by R0xBD; minimum auto

exposure is limited by AEC Minimum Exposure, R0xAC.

NOTE: AEC does not support sub-row timing;

calculated exposure values are rounded down to

the nearest row-time. For smoother response,

manual control is recommended for short

exposure times.

When AGC is enabled (R0xAF), the maximum auto gain

value is limited by R0xAB; minimum auto gain is fixed to

16 gain-units.

(R0xA9)

MANUAL GAIN

A or B

AGC ENABLE

(R0xAF[1 or 9])

The exposure control measures current scene luminosity

and desired output luminosity by accumulating a histogram

of pixel values while reading out a frame. All pixels are used,

whether in color or mono mode. The desired exposure and

gain are then calculated from this for subsequent frame.

When binning is enabled, tuning of the AEC may be

required. The histogram pixel count register, R0xB0, may be

adjusted to reflect reduced pixel count. Desired bin register,

R0xA5, may be adjusted as required.

Pixel Clock Speed

The pixel clock speed is same as the master clock

(SYSCLK) at 26.66 MHz by default. However, when

column binning 2 or 4 (R0x0D or R0x0E, bit 2 or 3) is

enabled, the pixel clock speed is reduced by half and

one-fourth of the master clock speed respectively. See “Read

www.onsemi.com

25

Page 26

MT9V023

Mode Options” and “Column Binning” for additional

information.

Hard Reset of Logic

The RC circuit for the MT9V023 uses a 10kΩ resistor and

a 0.1µF capacitor. The rise time for the RC circuit is 1µs

maximum.

Soft Reset of Logic

Soft reset of logic is controlled by:

• R0x0C Reset

Bit 0 is used to reset the digital logic of the sensor while

preserving the existing two-wire serial interface

configuration. Furthermore, by asserting the soft reset, the

sensor aborts the current frame it is processing and starts a

new frame. Bit 1 is a shadowed reset control register bit to

explicitly reset the automatic gain and exposure control

feature.

These two bits are self-resetting bits and also return to “0”

during two-wire serial interface reads.

STANDBY Control

The sensor goes into standby mode by setting STANDBY

to HIGH. Once the sensor detects that STANDBY is

asserted, it completes the current frame before disabling the

digital logic, internal clocks, and analog power enable

signal. To release the sensor out from the standby mode,

reset STANDBY back to LOW. The LVDS must be powered

to ensure that the device is in standby mode. See ”Appendix

A – Power-On Reset and Standby Timing” for more

information on standby.

The sensor goes into monitor mode when R0xD9[0] is set

to HIGH. In this mode, the sensor first captures a

programmable number of frames (R0xC0), then goes into a

sleep period for five minutes. The cycle of sleeping for five

minutes and waking up to capture a number of frames

continues until R0xD9[0] is cleared to return to normal

operation.

In some applications when monitor mode is enabled, the

purpose of capturing frames is to calibrate the gain and

exposure of the scene using automatic gain and exposure

control feature. This feature typically takes less than 10

frames to settle. In case a larger number of frames is needed,

the value of R0xC0 may be increased to capture more

frames.

During the sleep period, none of the analog circuitry and

a very small fraction of digital logic (including a five-minute

timer) is powered. The master clock (SYSCLK) is therefore

always required.

Read Mode Options

(Also see “Output Data Format” and “Output Data

Timing”).

Column Flip

By setting bit 5 of R0x0D or R0x0E the readout order of

the columns is reversed, as shown in Figure 28.

Row Flip

By setting bit 4 of R0x0D or R0x0E the readout order of

the rows is reversed, as shown in Figure 29.

Monitor Mode Control

Monitor mode is controlled by:

• R0xD9 Monitor Mode Enable

• R0xC0 Monitor Mode Image Capture Control

LINE_VALID

Normal readout

OUT(9:0)

D

Reverse readout

OUT(9:0)

D

Figure 28. Readout of Six Pixels in Normal and Column Flip Output Mode

P4,1

(9:0)

P4,n

(9:0)

P4,2

(9:0)

P4,n−1

(9:0)

P4,3

(9:0)

P4,n−2

(9:0)

P4,4

(9:0)

P4,n−3

(9:0)

P4,5

(9:0)

P4,n−4

(9:0)

P4,6

(9:0)

P4,n−5

(9:0)

www.onsemi.com

26

Page 27

LINE_VALID

MT9V023

Normal readout

OUT(9:0)

D

Reverse readout

D

OUT(9:0)

Row4

(9:0)

Row484

(9:0)

Row5

(9:0)

Row483

(9:0)

Figure 29. Readout of Six Rows in Normal and Row Flip Output Mode

Pixel Binning

In addition to windowing mode in which smaller

resolutions (CIF, QCIF) are obtained by selecting a smaller

window from the sensor array, the MT9V023 also provides

the ability to down-sample the entire image captured by the

pixel array using pixel binning.

There are two resolution options: binning 2 and binning

4, which reduce resolution by two or by four, respectively.

Row and column binning are separately selected. Image

mirroring options will work in conjunction with binning.

For column binning, either two or four columns are

combined by averaging to create the resulting column. For

row binning, the binning result value depends on the

difference in pixel values: for pixel signal differences of less

than 200 LSB’s, the result is the average of the pixel values.

For pixel differences of greater than 200 LSB’s, the result is

the value of the darker pixel value.

Binning operation increases SNR but decreases

resolution. Enabling row bin2 and row bin4 improves frame

Row6

(9:0)

Row482

(9:0)

Row7

(9:0)

Row481

(9:0)

Row8

7(9:0)

Row480

7(9:0)

Row9

(9:0)

Row479

(9:0)

rate by 2x and 4x respectively. Column binning does not

increase the frame rate.

Row Binning

By setting bit 0 or 1 of R0x0D or R0x0E, only half or

one-fourth of the row set is read out, as shown in Figure 30.

The number of rows read out is half or one-fourth of the

value set in R0x03. The row binning result depends on the

difference in pixel values: for pixel signal differences less

than 200 LSB’s, the result is the average of the pixel values.

For pixel differences of 200 LSB’s or more, the result is

the value of the darker pixel value.

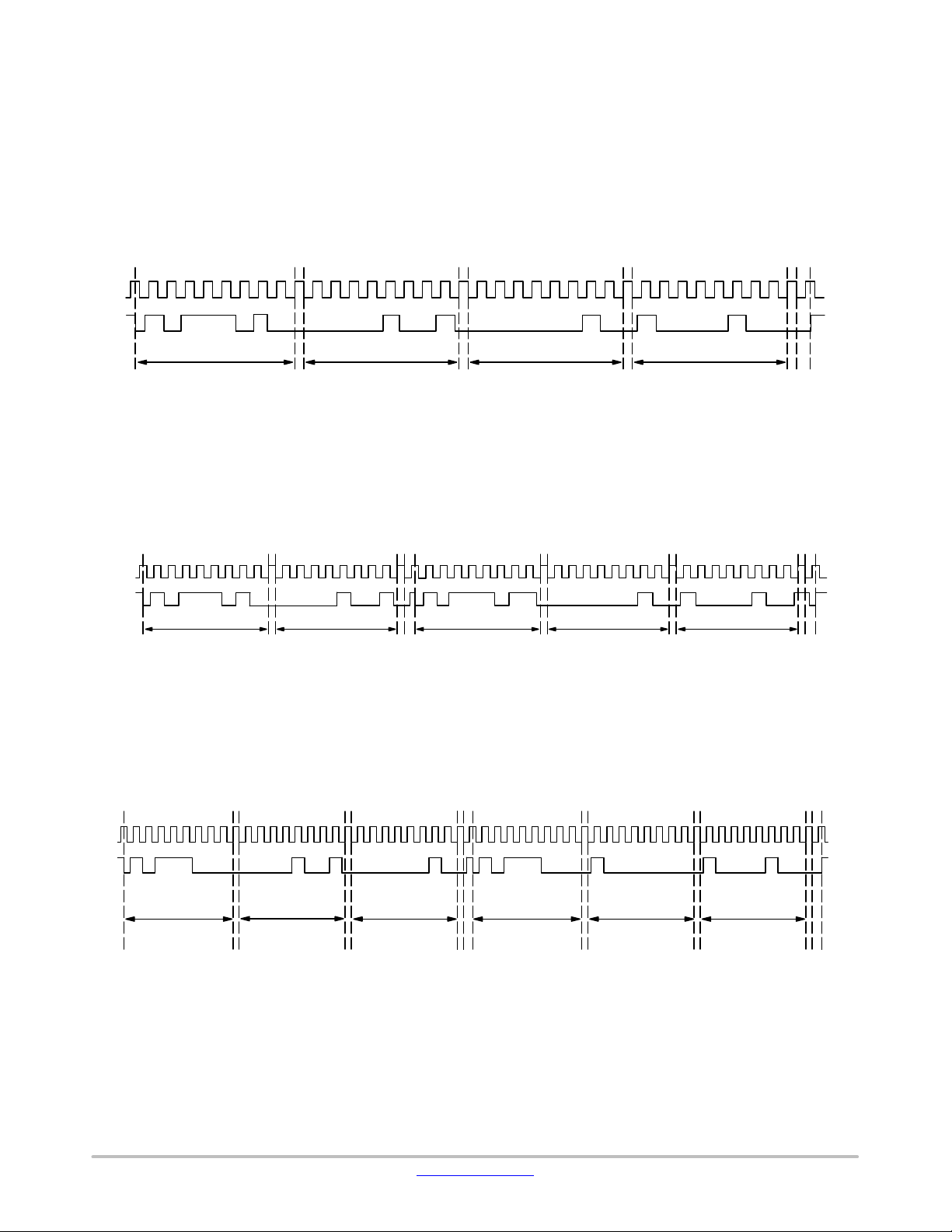

Column Binning

For column binning, either two or four columns are

combined by averaging to create the result. In setting bit 2

or 3 of R0x0D or R0x0E, the pixel data rate is slowed down

by a factor of either two or four, respectively. This is due to

the overhead time in the digital pixel data processing chain.

As a result, the pixel clock speed is also reduced accordingly.

LINE_VALID

Normal readout

DOUT(9:0)

LINE_VALID

Row Bin 2 readout

DOUT(9:0)

LINE_VALID

Row Bin 4 readout

DOUT(9:0)

Figure 30. Readout of 8 Pixels in Normal and Row Bin Output Mode

Row4

(9:0)

Row4

(9:0)

Row4

(9:0)

Row5

(9:0)

Row6

(9:0)

Row8

(9:0)

Row6

(9:0)

Row8

(9:0)

Row7

(9:0)

Row10

(9:0)

Row8

(9:0)

Row9

(9:0)

Row10

(9:0)

Row11

(9:0)

www.onsemi.com

27

Page 28

LINE_VALID

Normal readout

DOUT(9:0)

PIXCLK

LINE_VALID

Column Bin 2 readout

DOUT(9:0)

PIXCLK

LINE_VALID

Column Bin 4 readout

DOUT(9:0)

PIXCLK

MT9V023

D1

(9:0)D2(9:0)D3(9:0)D4(9:0)D5(9:0)D6(9:0)D7(9:0)D8(9:0)

D12

(9:0)

D1234

(9:0)

D34

(9:0)

D56

(9:0)

D5678

(9:0)

D78

(9:0)

Figure 31. Readout of 8 Pixels in Normal and Column Bin Output Mode

Interlaced Readout

The MT9V023 has two interlaced readout options. By

setting R0x07[2:0] = 1, all the even-numbered rows are read

out first, followed by a number of programmable field

blanking rows (set by R0xBF[7:0]), then the odd-numbered

rows, and finally the vertical blanking rows. By setting

R0x07[2:0] = 2 only one field row is read out.

P

4,1 P4,2 P4,3

P

6,0 P6,1 P6,2

P

m−2,0 Pm−2,2

P

m,2 Pm,2

00 00 00 ..................................... 00 00 00

00 00 00 ..................................... 00 00 00

P

5,1 P5,2 P5,3

P

7,0 P7,1 P7,2

P

m−3,1 Pm−3,2

P

m,1 Pm,1

00 00 00 ............................................................................................. 00 00 00

00 00 00 ............................................................................................. 00 00 00

.....................................P

.....................................P

VALID IMAGE − Even Field

.....................................P

.....................................P

.....................................P

.....................................P

VALID IMAGE − Odd Field

.....................................P

.....................................P

VERTICAL BLANKING

Consequently, the number of rows read out is half what is

set in the window height register. The row start register

determines which field gets read out; if the row start register

is even, then the even field is read out; if row start address

is odd, then the odd field is read out.

4,n−1P4,n

6,n−1P6,n

m−2,n−2Pm−2,n

m,n−1Pm,n

5,n−1P5,n

7,n−1P7,n

m−3,n−1Pm−3,n

m,n−1Pm,n

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

HORIZONTAL

BLANKING

FIELD BLANKING

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

00 00 00 .................. 00 00 00

Figure 32. Spatial Illustration of Interlaced Image Readout

www.onsemi.com

28

Page 29

MT9V023

When interlaced mode is enabled, the total number of

blanking rows are determined by both Field Blanking

Field Blanking + R0xBF[7 : 0]

Vertical Blanking + R0x06[8 : 0] – R0xBF[7 : 0] (contextA) or R0xCE[8 : 0] – R0xBF[7 : 0] (contextB)

register (R0xBF) and Vertical Blanking register (R0x06 or

R0xCE). The followings are their equations.

(eq. 22)

(eq. 23)

with

minimum vertical blanking requirement + 4 (absolute minimum operate; see Vertical Blanking Registers description for VBlank minimums

for valid image output)

(eq. 24)

Similar to progressive scan, FV is logic LOW during the

valid image row only. Binning should not be used in

conjunction with interlaced mode.

www.onsemi.com

29

Page 30

MT9V023

LINE_VALID

By setting bit 2 and 3 of R0x72, the LV signal can get three

different output formats. The formats for reading out four

Default

FRAME_VALID

LINE_VALID

Continuously

FRAME_VALID

LINE_VALID

XOR

FRAME_VALID

LINE_VALID

Figure 33. Different LINE_VALID Formats

LVDS Serial (Stand-Alone/Stereo) Output

The LVDS interface allows for the streaming of sensor

data serially to a standard off-the-shelf deserializer up to

eight meters away from the sensor. The pixels (and controls)

are packeted−12-bit packets for stand-alone mode and

18-bit packets for stereoscopy mode. All serial signalling

(CLK and data) is LVDS. The LVDS serial output could

either be data from a single sensor (stand-alone) or

stream-merged data from two sensors (self and its

stereoscopic slave pair). The appendices describe in detail

the topologies for both stand-alone and stereoscopic modes.

There are two standard deserializers that can be used. One

for a stand-alone sensor stream and the other from a

stereoscopic stream. The deserializer attached to a

stand-alone sensor is able to reproduce the standard parallel

output (8-bit pixel data, LV, FV, and PIXCLK). The

deserializer attached to a stereoscopic sensor is able to

reproduce 8-bit pixel data from each sensor (with embedded

LV and FV) and pixel-clk. An additional (simple) piece of

logic is required to extract LV and FV from the 8-bit pixel

rows and two vertical blanking rows are shown in Figure 33.

In the last format, the LV signal is the XOR between the

continuous LV signal and the FV signal.

data. Irrespective of the mode (stereoscopy/stand-alone),

LV and FV are always embedded in the pixel data.

In stereoscopic mode, the two sensors run in lock-step,

implying all state machines are in the same state at any given

time. This is ensured by the sensor-pair getting their sys-clks

and sys-resets in the same instance. Configuration writes

through the two-wire serial interface are done in such a way

that both sensors can get their configuration updates at once.

The inter-sensor serial link is designed in such a way that

once the slave PLL locks and the data-dly, shft-clk-dly and

stream-latency-sel are configured, the master sensor streams

valid stereo content irrespective of any variation voltage

and/or temperature as long as it is within specification. The

configuration values of data-dly, shft-clk-dly and

stream-latency-sel are either predetermined from the

board-layout or can be empirically determined by reading

back the stereo-error flag. This flag is asserted when the two

sensor streams are not in sync when merged. The combo_reg

is used for out-of-sync diagnosis.

Internal

PIXCLK

Internal

Parallel

Data

Internal

Line_Valid

Internal

Frame_Valid

External

Serial

Data Out

P41

P42

P43

P44

P45

1023

01

P46

1023

P51

P41 P42 P46

P43

P44

P53

P45

P54 P55 P56P52

21

P51 P52

P53

P54

P55

P56 2

3

Figure 34. Serial Output Format for a 6x2 Frame

1. External pixel values of 0, 1, 2, 3, are reserved (they only convey control information). Any raw pixel of value 0, 1, 2 and 3 will be substituted

with 4.

2. The external pixel sequence 1023, 0, 1023 is a reserved sequence (conveys control information for legacy support of MT9V021 applications).