Page 1

查询MC624供应商

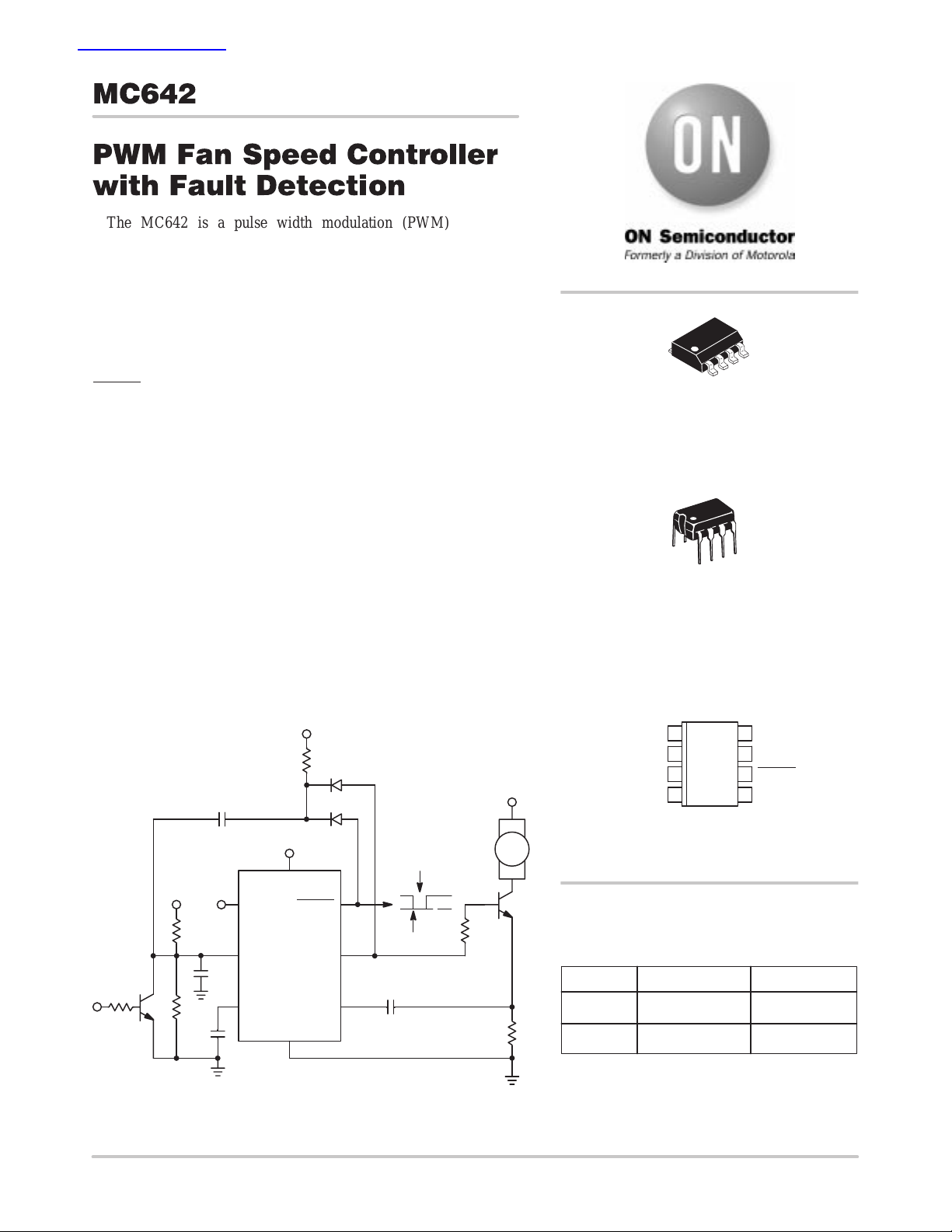

MC642

PWM Fan Speed Controller

with Fault Detection

The MC642 is a pulse width modulation (PWM) fan speed

controller for use with DC motors. It provides temperature

proportional speed control. A thermistor connected to the V

furnishes the required control voltage of 1.25V to 2.65V for 0% to

100% PWM duty cycle. Minimum fan speed is set by a simple resistor

divider on the V

input. An integrated Start–Up Timer ensures

MIN

reliable motor start–up at turn–on, coming out of Shutdown Mode, or

following a transient fault. A stalled, open, or unconnected fan causes

the MC642 to trigger its start–up timer once. If the fault persists, the

FAULT

output goes low, and the device is latched in Shutdown Mode.

Features

• Shutdown Mode for Power Saving

• Supports Low Cost NTC/PTC Thermistors

• T emperature Proportional Speed for Acoustic Control /

Longer Fan Life

• Fan Voltage Independent of MC642 Supply Voltage

• Fault Detection Circuits Protect Against Fan Failure and

Aid System T esting

• Operating T emperature Range: 0°C to +85°C

Typical Applications

• Power Supplies

• Personal Computers

• UPS’s, Power Amplifiers, etc.

TYPICAL APPLICATION DIAGRAM

V

DD

D1

IN

input

+12 V

http://onsemi.com

SO–8

D SUFFIX

PRELIMINARY INFORMATION

PRELIMINARY INFORMATION

CASE TBD

8–Pin DIP

P SUFFIX

CASE TBD

PIN CONFIGURATION

V

V

MIN

GND

1

IN

C

2

MC642D

F

MC642P

3

4

8

7

6

5

V

DD

V

OUT

FAULT

SENSE

+5 V

From

Temp

Sensor

V

16

8

V

DD

FAULT

in

MC642

V

min

3

C

2

(Optional)

Semiconductor Components Industries, LLC, 1999

February , 2000 – Rev. 0

+

SENSE

F

GND

4

D2

V

out

7

5

C

SENSE

MC642

Reset

1

0

Detected

Fault

FAN

Q1

R

BASE

MC642DR2 8–Pin SOIC 2500 Tape/Reel

R

SENSE

1 Publication Order Number:

MC642P 8–Pin Plastic DIP 50 Tape/Reel

ORDERING INFORMATION

Device Package Shipping

MC642/D

Page 2

V

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

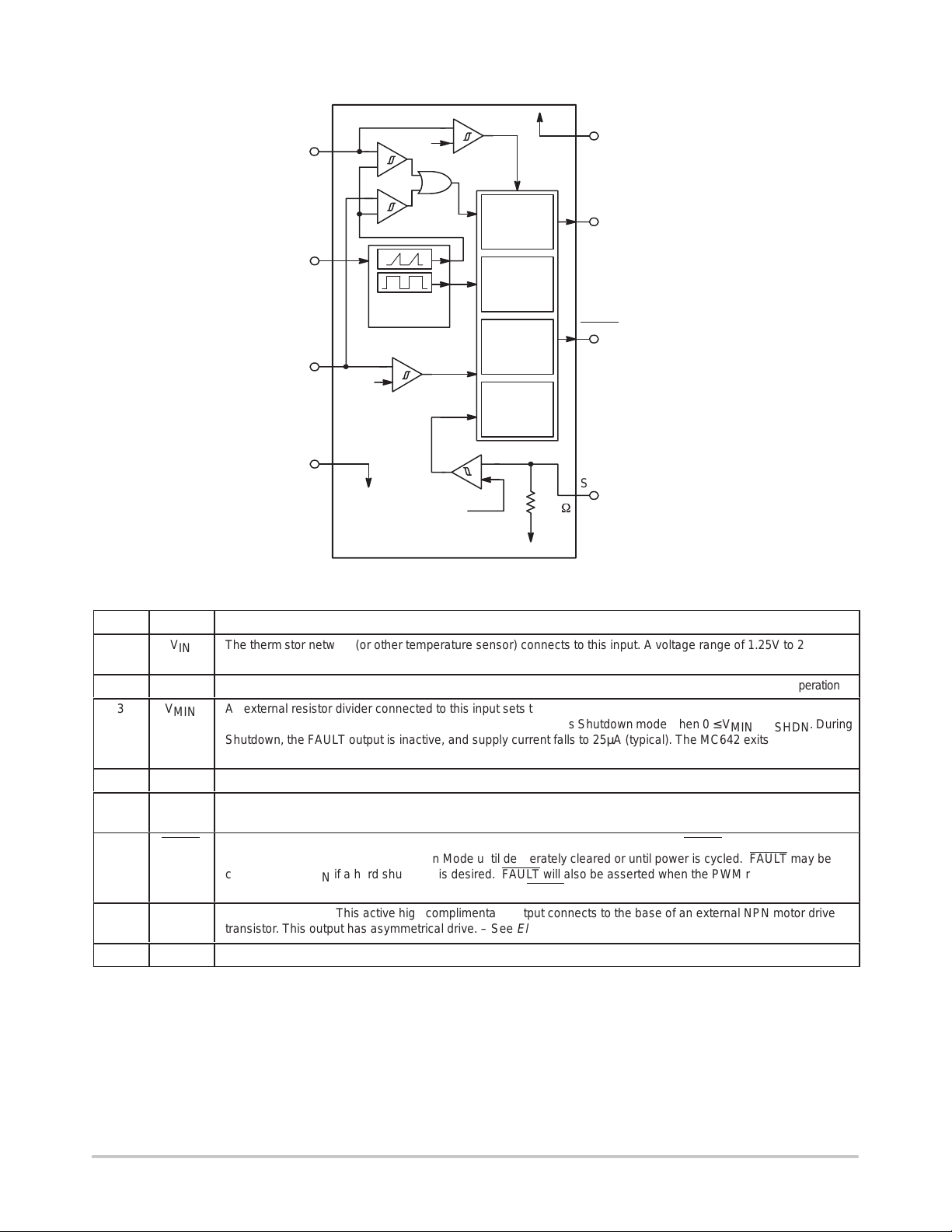

MC642

FUNCTIONAL BLOCK DIAGRAM

V

IN

C

MIN

GND

V

OTF

–

+

–

+

F

Clock

Generator

+

V

SHDN

–

MC642

70 mV (typ.)

+

–

SHDN

+

–

Control

Logic

3 X T

PWM

Timer

Start–Up

Timer

Missing

Pulse

Detector

OTF

10 k

W

V

DD

V

OUT

FAULT

SENSE

PIN DESCRIPTION

Pin No. Symbol Description

1

ÁÁ

2

3

ÁÁ

ÁÁ

4

5

6

ÁÁ

ÁÁ

7

ÁÁ

8

V

IN

Á

C

F

V

MIN

Á

Á

GND

SENSE

FAULT

Á

Á

V

OUT

Á

V

DD

The thermistor network (or other temperature sensor) connects to this input. A voltage range of 1.25V to 2.65V

(typical) on this pin drives an active duty cycle of 0% to 100% on the V

ББББББББББББББББББББББББББ

Positive terminal for the PWM ramp generator timing capacitor. The recommended CF is 1µF for 30Hz PWM operation.

An external resistor divider connected to this input sets the minimum fan speed by fixing the minimum PWM duty

cycle (1.25V to 2.65V = 0% to 100%, typical). The MC642 enters Shutdown mode when 0 ≤ V

ББББББББББББББББББББББББББ

Shutdown, the FAULT output is inactive, and supply current falls to 25µA (typical). The MC642 exits Shutdown

mode when V

ББББББББББББББББББББББББББ

MIN

≥ V

REL

. See

Applications

section for more details.

Ground Terminal

Pulses are detected at this pin as fan rotation chops the current through a sense resistor. The absence of pulses

indicates a fault.

Fault (open collector) output. This line goes low to indicate a fault condition. When FAULT goes low due to a fan

ББББББББББББББББББББББББББ

fault, the device is latched in Shutdown Mode until deliberately cleared or until power is cycled. FAULT

connected to V

ББББББББББББББББББББББББББ

cycle, however the device will not latch itself off unless FAULT

if a hard shutdown is desired. FAULT

MIN

will also be asserted when the PWM reaches 100% duty

PWM signal output. This active high complimentary output connects to the base of an external NPN motor drive

ББББББББББББББББББББББББББ

transistor. This output has asymmetrical drive. – See

Electrical Characteristics

Power Supply Input. May be independent of fan power supply. See

pin.

OUT

is tied to V

externally.

MIN

section.

Electrical Characteristics

≤ V

MIN

section.

SHDN

may be

. During

http://onsemi.com

2

Page 3

MC642

ABSOLUTE MAXIMUM RATINGS*

Parameter Value Unit

Package Power Dissipation (TA ≤ 70°C)

Plastic DIP

Small Outline (SOIC)

Derating Factors 8.0 mW/°C

Supply Voltage 6.0 V

Input Voltage, Any Pin (GND – 0.3) to (VCC + 0.3) V

Operating Temperature Range 0 to +85 °C

Maximum Chip Temperature 150 °C

Storage Temperature Range –65 to +150 °C

Lead Temperature (Soldering, 10 Seconds) +300 °C

* Maximum Ratings are those values beyond which damage to the device may occur.

ELECTRICAL CHARACTERISTICS (T

Symbol Characteristic Min Typ Max Unit

V

DD

I

DD

I

DD(SHDN)

I

IN

V

Output

OUT

t

R

t

F

t

(SHDN)

I

OL

I

OH

VIN, V

V

C(MAX)

V

C(SPAN)

V

SHDN

V

REL

Pulse–Width Modulator

F PWM Frequency (CF = 1.0µF) 26 30 34 Hz

Sense Input

V

TH(SENSE)

Fault Output

V

OL

t

MP

t

STARTUP

t

DIAG

1. Guaranteed by design, not tested.

MIN

, Inputs

, V

Supply Voltage 3.0 — 5.5 V

Supply Current, Operating

Pins 3, 5, 7 Open, CF = 1µF, VIN = V

Supply Current, Shutdown Mode

Pins 1, 5, 6, 7 Open, CF = 1µF, VIN = 0.35V

VIN, V

V

OUT

V

OUT

Pulse Width (On V

Sink Current at V

Source Current at V

Input Voltage at VIN or V

OTF

V

C(MAX)

Voltage Applied to V

Voltage Applied to V

SENSE Input Threshold Voltage with Respect to GND 50 70 90 mV

Output Low Voltage (IOH = 2.5mA) — — 0.3 Hz

Missing Pulse Detector Timeout — 32/F — Sec

Startup Time — 32/F — Sec

Diagnostic Timer Period — 3/F — Sec

Input Leakage (Note 1.)

MIN

Rise Time (IOH = 5.0mA) (Note 1.)

Fall Time (IOH = 1.0mA) (Note 1.)

, V

MIN

Specifications

HYST

OUT

DD

DD

C(MIN)

V

SHDN

VOL = 10% of V

VOH = 80% of V

– V

VDD = 5V

< TA < T

MIN

) to Clear Fault Mode

Output

Output

OUT

for 100% PWM Duty Cycle 2.5 2.65 2.8 V

MIN

to Guarantee Shutdown Mode — — VDD x 0.13 V

MIN

to Release Shutdown Mode

MIN

, VDD = 3.0V to 5.5V, unless otherwise noted.)

MAX

(CMAX)

(Note 1.)

— 0.5 1.0

— 25 —

–1.0 — 1.0 µA

— — 50 µsec

— — 50 µsec

30 — —

1.0 — —

5.0 — —

1.3 1.4 1.5 V

VDD x 0.19 — —

730

470

mW

mA

µA

µsec

mA

mA

V

http://onsemi.com

3

Page 4

MC642

DET AILED OPERATING DESCRIPTION

PWM

The PWM (Pulse Width Modulation) circuit consists of a

ramp generator and threshold detector. The frequency of the

PWM is determined by the value of the capacitor connected

to the C

input. A frequency of 30Hz is recommended (C

F

= 1µF). The PWM is also the timebase for the startup and

fault timer (see below). The PWM voltage control range is

1.25V to 2.65V (typical) for 0% to 100% output duty cycle.

V

Output

OUT

The V

pin is designed to drive a low–cost transistor or

OUT

MOSFET as the low side power switching element in the

system. V arious examples of driver circuits are shown in the

following pages. This output has asymmetric

complementary drive and is optimized for driving NPN

transistors or N–channel MOSFET’s. Since the system

relies on PWM rather than linear power control, the

dissipation in the power switch is kept to a minimum.

Generally , very small devices (TO–92 or SOT package) will

suffice. (See Output Drive Transistor Selection paragraph in

Applications Information section.)

Start–Up Timer

T o ensure reliable fan startup, the StartUp Timer turns the

V

output on for 32 cycles of the PWM whenever the fan

OUT

is started from the off–state. This occurs at power–up and

when coming out of shutdown mode. If the PWM frequency

is 30Hz (C

= 1µF), the resulting start–up time will be about

F

one second. If a Fault is detected (see below), the Diagnostic

Timer is triggered once, followed by the Startup–Up T imer .

If the fault persists, the device is shut down. See FAULT

Output below .

Shutdown Control (Optional)

When V

(pin 3) is pulled below V

MIN

, the MC642 will

SHDN

go into Shutdown mode. This can be accomplished by

driving V

with an open drain logic signal or using an

MIN

external transistor as shown in Figure 1. All functions are

suspended until the voltage on V

V

(0.85V @ VDD = 5.0V). Pulling V

REL

becomes higher than

MIN

below V

MIN

SHDN

will

always result in complete device shutdown and reset. The

FAULT output is unconditionally inactive in Shutdown

mode.

A small amount of hysteresis, typically one percent of V

(50mV at VDD = 5.0V), is designed into the V

threshold. The levels specified for V

SHDN

and V

DD

SHDN/VREL

in the

REL

Electrical Characteristics section include this hysteresis

plus adequate margin to account for normal variations in the

absolute value of the threshold and hysteresis.

CAUTION: Shutdown mode is unconditional. i.e., the

fan will not activate regardless of the voltage on V

The fan should not be shut down until all heat–producing

activity in the system is at a negligible level.)

F

SENSE Input

The SENSE input, pin 5, is connected to a low–value

current sensing resistor in the ground return leg of the fan

circuit. During normal fan operation commutation occurs as

each pole of the fan is energized. This commutation causes

brief interruptions in the fan current, which is seen as pulses

across the sense resistor. When the device is not in

Shutdown Mode and pulses are not appearing at the SENSE

input, a fault condition exists.

The short, rapid changes in fan current (high dI/dt) cause

corresponding dV/dt pulses across the sense resistor, R

The waveform on R

a logic–level pulse–train by C

is differentiated and converted to

SENSE

and the internal signal

SENSE

processing circuitry (See Figure 1). The presence and

frequency of this pulse–train is a direct indication of fan

operation. See the Applications Information section for

more details.

FAULT Output

The MC642 detects faults in two ways:

(1) Pulses appearing at SENSE due to the PWM turning on

are blanked and the remaining pulses are filtered by a

missing pulse detector. If consecutive pulses are not

detected for 32 PWM cycles (1 Sec if CF = 1µF), the

Diagnostic Timer is activated and V

OUT

continuously for three PWM cycles (100msec if CF = 1µF).

If a pulse is not detected within this window, the

Startup–Timer is triggered. This should clear a transient

fault condition. If the Missing Pulse Detector times out

again, the PWM is stopped and FAULT

goes low. When

FAULT is activated due to this condition, the device is

latched in Shutdown mode and will remain off indefinitely .

(Diodes D1, D2 and resistor R5 (See Figure 1) are provided

to ensure that fan restarting is the result of a fan fault, and not

an over–temperature fault. A CMOS logic OR gate may be

substituted for these components if available).

When F AUL T is activated due to this condition, the device

is latched in Shutdown mode and will remain off

indefinitely. Important: At this point, action must be

taken to restart the fan by momentarily pulling V

below V

, or by cycling system power. In either case

SHDN

the fan cannot be permitted to remain disabled due to a

fault condition, as severe system damage could result. If

the fan cannot be restarted, the system should be shut

down. The MC642 may be configured to continuously

attempt fan restarts if so desired.

. (Note:

IN

SENSE

is driven

MIN

.

http://onsemi.com

4

Page 5

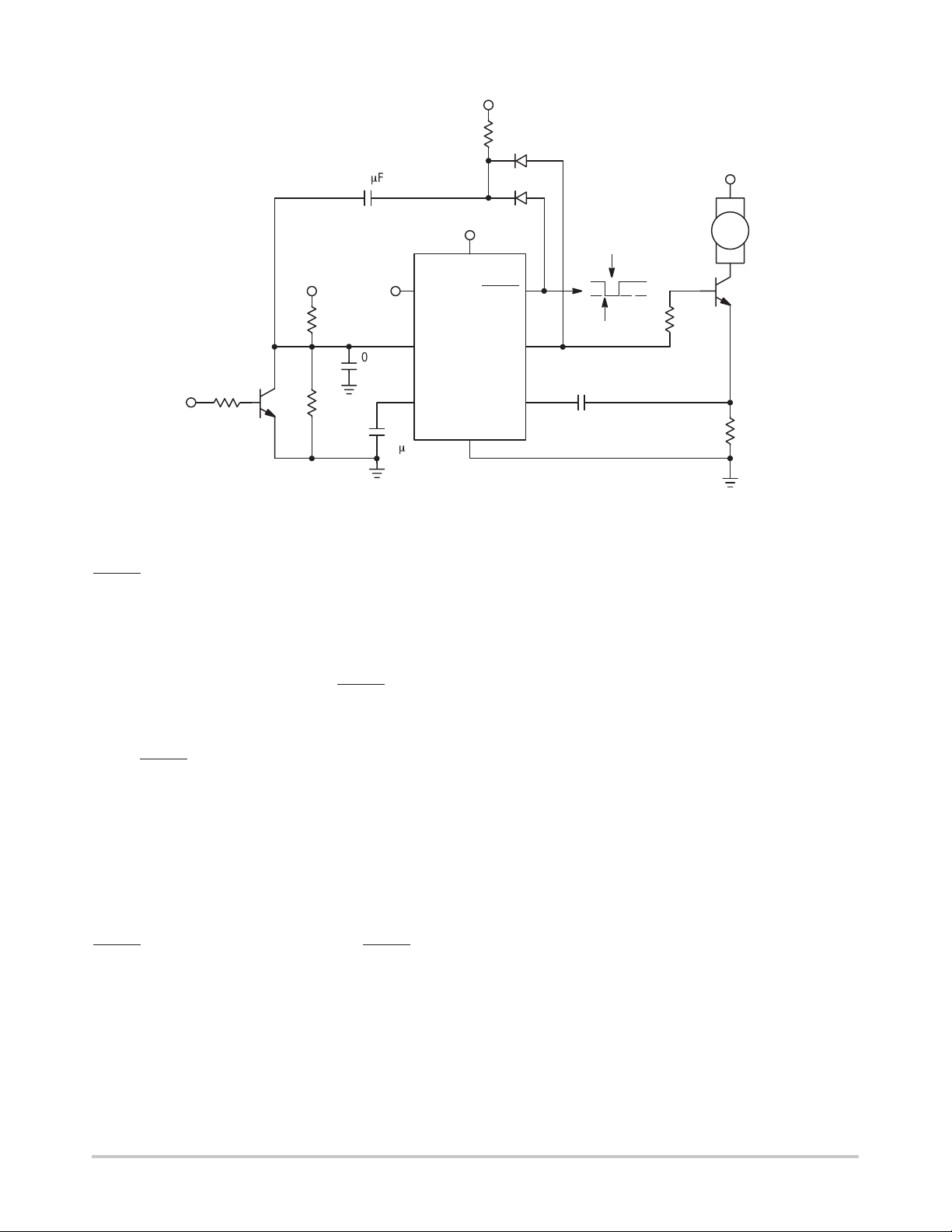

0.1 mF

MC642

V

DD

R5

10 k

D1

+12 V

From

System

Shutdown

Controller

+5 V

R1

(Optional)

* The parallel combination of R3 and R4 must be > 10 k.

R3

R4

From

Temp

Sensor

0.01

C

B

+

V

in

16

V

min

3

C

F

2

C

F

1 mF

Figure 1. T ypical Fan Control Application

Continuous restart mode is enabled by connecting the

FAULT

output to V

through a 0.1µF capacitor as shown

MIN

in Figure 1. When so connected, the MC642 automatically

attempts to restart the fan whenever a fault condition occurs.

When the fault output is driven low, the V

momentarily pulled below V

, initiating a reset and

SHDN

input is

MIN

clearing the fault condition. Normal fan startup is then

attempted as previously described. The F AUL T

output may

be connected to external logic (or the interrupt input of a

microcontroller) to shut down the MC642 if multiple fault

pulses are detected at approximately one second intervals.

(2) FAULT

is also asserted when the PWM control

voltage applied to VIN becomes greater than that needed to

drive 100% duty cycle (see Electrical Characteristics). This

indicates that the fan is at maximum drive and the potential

exists for system overheating. Either heat dissipation in the

system has gone beyond the cooling system’ s design limits

or some other fault exists such as fan bearing failure or an

airflow obstruction. This output may be treated as a System

Overheat warning and used to trigger system shutdown.

However in this case, the fan will continue to run even when

F AUL T

connected to V

is asserted. If a shutdown is desired, F AUL T may be

outside the device. This will latch the

MIN

MC642 in Shutdown Mode when any fault occurs.

8

DD

FAULT

SENSE

4

D2

V

out

7

5

MC642

Reset

1

0

Fault Detected

C

SENSE

R

BASE

FAN

Q1

R

SENSE

+5 V

V

MC642

GND

SYSTEM BEHAVIOR

The flowcharts describing the MC642’s behavioral

algorithm are shown in Figure 3. They can be summarized

as follows:

Power–Up

(1) Assuming the device is not being held in Shutdown

mode (V

> V

MIN

(2) Turn V

):

REL

output on for 32 cycles of the PWM

OUT

clock. This ensures that the fan will start from a dead stop.

(3) During this Start–up time, if a fan pulse is detected

then branch to Normal Operation; if none are received.

(4) Activate the 32–cycle Start–up Timer one more

time and look for fan pulses; if a fan pulse is detected,

proceed to Normal Operation; if none are received....

(5) Proceed to Fan Fault

(6) End

After this period elapses, the MC642 begins normal

operation.

http://onsemi.com

5

Page 6

+5 V*

MC642

R1

R2

Shutdown

(Optional)

NOTE: *See Cautions Regarding Latch–Up Considerations in the Applications Section.

R3

R4

0.01

C

B

NTC

16

3

0.01

C

B

2

+

C

F

1 mF

Figure 2. Typical Fan Control Application using NTC thermistor

Normal Operation

Normal Operation is an endless loop which may only be

exited by entering Shutdown mode or Fan Fault. The loop

can be thought of as executing at the frequency of the

oscillator and PWM.

(1) Reset the Missing Pulse Detector

(2) Is MC642 in Shutdown? If so...

a. V

duty–cycle goes to zero.

OUT

b. FAULT is disabled.

c. Exit the loop and wait for V

MIN

> V

REL

to

resume operation (indistinguishable from Power–Up).

(3) If an over–temperature fault occurs (VIN > V

then activate FAULT; release FAULT when VIN < V

(4) Drive V

of VIN and V

to a duty–cycle porportional to greater

OUT

on a cycle by cycle basis.

MIN

OTF

OTF

.

(5) If a fan pulse is detected, branch back to the start of

the loop.

(6) If the missing pulse detector times out ...

V

V

C

in

min

F

8

V

DD

MC642

SENSE

GND

4

FAULT

V

out

1 mF

C

B

7

5

C

SENSE

Thermal

Shutdown

R

BASE

+12 V

FAN

Q1

(7) Activate the 3–cycle Diagnostic Timer and look

for pulses; if a fan pulse is detected, branch back to the

start of the loop; if none are received...

(8) Activate the 32–cycle Startup Timer and look for

pulses; if a fan pulse is detected, branch back to the start of

the loop; if none are received...

(9) Quit Normal Operation and go to Fan Fault.

(10) End

Fan Fault

Fan Fault is essentially an infinite loop wherein the

MC642 is latched in Shutdown Mode. This mode can only

be released by a Reset, i.e., V

)

then above V

, or by power–cycling.

REL

being brought below V

MIN

(1) While in this state, F AULT is latched on (low), and

the V

output is disabled.

OUT

(2) A Reset sequence applied to the V

MIN

the loop to Power Up.

(3) End

R

SENSE

pin will exit

SDHN

,

http://onsemi.com

6

Page 7

Power–Up

MC642

Normal

Operation

Power–On

Reset

FAULT = 1

V< V

IN SHDN

NO

Initiate Start–

Up Timer

(1 Sec)

Fan Pulse

Detected?

YES

Normal

Operation

YES

NO

YES

Shutdown

V

= 0

OUT

Initiate Start–

Up Timer

(1 Sec)

Fan Pulse

Detected?

NO

Fan Fault

V> V

IN REL?

YES

NO

Clear

Missing Pulse

Detector

V< V

IN SHDN?

NO

YES

V> V

IN OTF?

NO

V

OUT

Proportional

T o Greater

or V

of V

IN MIN

YES NO

Fan Pulse

Detected?

YES

FAULT = 0

Shutdown

V

= 0

OUT

V> V

IN REL

YES

Power–Up

NO

Fan Fault

FAULT = Low,

V Disabled

OUT

V< V

IN SHDN?

YES

V> V

IN REL?

YES

Power–Up

NO

NO

NO

Cycling

Power?

YES

Figure 3. MC642 Behavioral Algorithm Flowchart

NO

M.P.D.

Expired?

Initiate

Diagnostic Timer

(100 mSec)

YES NO

Fan Pulse

Detected?

YES

YES

Initiate Start–

Up Timer

(1 Sec)

Fan Pulse

Detected?

NO

Fan Fault

http://onsemi.com

7

Page 8

APPLICATIONS INFORMATION

Designing with the MC642 involves the following:

(1) The temp sensor network must be configured to

deliver 1.25V to 2.65V on V

for 0% to 100% of the

IN

temperature range to be regulated.

(2) The minimum fan speed (V

) must be set.

MIN

(3) The output drive transistor and associated circuitry

must be selected.

(4) The Sense Network, R

SENSE

and C

SENSE

, must be

designed for maximum efficiency while delivering adequate

signal amplitude.

MC642

(5) If Shutdown capability is desired, the drive

requirements of the external signal or circuit must be

considered.

T emperature Sensor Design

The temperature signal connected to VIN must output a

voltage in the range of 1.25V to 2.65V (typical) for 0% to

100% of the temperature range of interest. The circuit of

Figure 4 is a convenient way to provide this signal.

V

DD

I

DIV

R1T1

I

DIV

R2

V

in

Figure 4. T emperature Sensing Circuit Figure 5. V

V

DD

FAN

R

VOH = 80% V

DD

+

V

R(BASE)

BASE

+

V

BE(SAT)

V

R(SENSE)

–

Q1

–

+

R

SENSE

–

V

OUT

SENSE

(0.1 m

R

BASE

C

SENSE

V

DD

R1

R2

GND

MIN

F Typ.)

I

IN

V

MIN

Circuit

V

FAN

DD

Q1

R

SENSE

GND

Figure 6. Circuit for Determining R

BASE

http://onsemi.com

GND

Figure 7. SENSE Network

8

Page 9

Figure 4 illustrates a simple temperature dependent

voltage divider circuit. T1 is a conventional NTC

thermistor, and R1 and R2 are standard resistors. The supply

voltage, V

, is divided between R2 and the parallel

DD

combination of T1 and R1. (For convenience, the parallel

combination of T1 and R1 will be referred to as R

TEMP

.) The

resistance of the thermistor at various temperatures is

obtained from the manufacturer’s specifications.

Thermistors are often referred to in terms of their resistance

at 25°C. A thermistor with a 25°C resistance on the order of

100kW will result in reasonable values for R1, R2, and I

DIV

In order to determine R1 and R2, we must specify the fan

duty–cycle, i.e. VIN, at any two temperatures. Equipped with

these two points on the system’s operating curve and the

thermistor data, we can write the defining equations:

VDD x R2

R

R

(t1) + R2

TEMP

VDD x R2

(t2) + R2

TEMP

Where t1 and t2 are the chosen temperatures and R

= V(t1)

= V(t2)

(1.)

TEMP

is

the parallel combination of the thermistor and R1. These

two equations permit solving for the two unknown

variables, R1 and R2. Note that resistor R1 is not absolutely

necessary, but it helps to linearize the response of the

network.

MC642

I

= 1e–4A =

DIV

R1 + R2 =

W e can further specify R1 and R2 by the condition that the

divider voltage is equal to our desired V

following equation:

.

V

MIN

Solving for the relationship between R1 and R2 results in

the following equation:

R1 = R2 x

In the case of this example, R1 = (1.762) R2. Substituting

this relationship back into Equation 4 yields the resistor

values:

R2 = 18.1kW, and

R1 = 31.9k

R1 + R2

5.0V

1e–4A

=VDD x

5.0V

VDD – V

, therefore

= 50,000W = 50k

R1

R1 + R2

MIN

V

MIN

W

. This yields the

MIN

(4.)

W

(5.)

(6.)

Minimum Fan Speed

A voltage divider on V

sets the minimum PWM duty

MIN

cycle and, thus, the minimum fan speed. As with the V

input, 1.25V to 2.65V corresponds to 0% to 100% duty

cycle. Assuming that fan speed is linearly related to

duty–cycle, the minimum speed voltage is given by the

equation:

V

MIN

Minimum Speed

=

Full Speed

x (1.4V) + 1.25V (2.)

For example, if 2500 RPM equates to 100% fan speed, and

a minimum speed of 1000 RPM is desired, then the V

MIN

voltage is:

V

MIN

The V

1000

=

2500

voltage may be set using a simple resistor

MIN

x (1.4V) + 1.25V = 1.81V (3.)

divider as shown in Figure 5. Per the Electrical

Characteristics, the leakage current at the V

pin is no

MIN

more than 1µA. It would be very conservative to design for

a divider current, I

, of 100µA. If VDD = 5.0V then...

DIV

In this case, the standard values of 32kW and 18kW are

very close to the calculated values and would be more than

IN

adequate.

One boundary condition which may impact the selection

of the minimum fan speed is the irregular activation of the

Diagnostic Timer due to the MC642 “missing” fan

commutation pulses at low speeds. Typically, this only

occurs at very low duty–cycles (25% or less). It is a natural

consequence of low PWM duty–cycles. Recall that the

SENSE function detects commutation of the fan as

disturbances in the current through R

occur when the fan is energized, i.e., V

low duty–cycles, the V

output is “off” most of the time.

OUT

. These can only

SENSE

is “on”. At very

OUT

The fan may be rotating normally, but the commutation

events are occuring during the PWM’s off–time.

The phase relationship between the fan’s commutation

and the PWM edges tends to “walk around” as the system

operates. At certain points, the MC642 may fail to capture

a pulse within the 32–cycle Missing Pulse Detector window.

When this happens, the 3–cycle Diagnostic Timer will be

activated, the V

output will be active continuously for

OUT

three cycles and, if the fan is operating normally, a pulse will

be detected. If all is well, the system will return to normal

operation. There is no harm in this behavior, but it may be

http://onsemi.com

9

Page 10

MC642

audible to the user as the fan will accelerate briefly when the

Diagnostic Timer fires. For this reason, it is recommended

that V

SENSE Network (R

be set no lower than 1.8V.

MIN

and C

SENSE

The network comprised of R

SENSE

SENSE

and C

)

SENSE

allow the

MC642 to detect commutation of the fan motor. This

network can be thought of as a differentiator and threshold

detector. The function of R

into a voltage. C

serves to AC–couple this voltage

SENSE

is to convert the fan current

SENSE

signal and provide a ground–referenced input to the SENSE

pin. Designing a proper SENSE Network is simply a matter

of scaling R

to provide the necessary amount of gain,

SENSE

i.e., the current–to–voltage conversion ratio. A 0.1µF

ceramic capacitor is recommended for C

SENSE

. Smaller

values require larger sense resistors, and higher value

capacitors are bulkier and more expensive. Using a 0.1µF

results in reasonable values for R

. Figure 7 illustrates

SENSE

a typical SENSE Network. Figure 8 shows the waveforms

observed using a typical SENSE Network.

T able 1 lists the recommended values of R

SENSE

according

to the nominal operating current of the fan. Note that the

current draw specified by the fan manufacturer may not be

the fan’s nominal operating current, but may be a worst–case

rating for near–stall conditions. The values in the table refer

to actual average operating current. If the fan current falls

between two of the values listed, use the higher resistor

value. The end result of employing T able 1 is that the signal

developed across the sense resistor is approximately 450mV

in amplitude.

Table 1. R

SENSE

vs. Fan Current

Nominal Fan Current (mA)

50 9.1

100 4.7

150 3.0

200 2.4

250 2.0

300 1.8

350 1.5

400 1.3

450 1.2

500 1.0

R

SENSE

(

W)

V

OUT

Figure 8. SENSE Waveforms

V

DD

FAN

R

R

BASE

a) Single Bipolar Transistor b) Darlington Transistor Pair c) N–Channel MOSFET

GND

Q1

R

SENSE

V

OUT

BASE

Q1

V

DD

FAN

GND

Q2

R

SENSE

V

OUT

V

DD

FAN

GND

Q1

R

SENSE

Figure 9. Output Drive Transistor Circuit Topologies

http://onsemi.com

10

Page 11

MC642

Output Drive Transistor Selection

The MC642 is designed to drive an external transistor for

modulating power to the fan. This is shown as “Q1” in

Figures 2, 6, 7, 9, 10, and 11. The V

pin has a minimum

OUT

source current of 5mA and a minimum sink current of 1mA

at V

= 5.0V . Bipolar transistors or MOSFET’ s may be used

DD

as the power switching element as shown below. When high

current gain is needed to drive larger fans, two transistors

may be used in a Darlington configuration. These circuit

topologies are shown in Figure 9: (a) shows a single NPN

transistor used as the switching element; (b) Illustrates the

Darlington pair; and (c) shows an N–channel MOSFET.

One major advantage of the MC642’s PWM control

scheme versus linear speed control is that the dissipation in

the pass element is kept very low. Generally, low–cost

devices in very small packages such as TO–92 or SOT, can

be used effectively. For fans with nominal operating

currents of no more than 200mA, a single transistor usually

suffices. Above 200mA, the Darlington or MOSFET

solution is recommended. For the fan sensing function to

work correctly it is imperative that the pass transistor be

fully saturated when “on”. The minimum gain (h

) of the

FE

transistor in question must be adequate to fully saturate the

transistor when passing the full fan current while being

driven within the 5mA IOH of the V

OUT

output.

Table 2 gives examples of some commonly available

transistors. This table is a guide only. There are many

transistor types which might work as well as those listed.

The only critical issues when choosing a device to use as Q1

are: (1) the breakdown voltage, V

, must be large

CE(BR)

enough to stand off the highest voltage applied to the fan

(NOTE: this may be when the fan is off!); (2) the gain (hFE)

must be high enough for the device to remain fully saturated

while conducting the maximum expected fan current and

being driven with no more than 5mA of base/gate drive at

maximum temperature; (3) rated fan current draw must be

within the transistor’s current handling capability; and (4)

power dissipation must be kept within the limits of the

chosen device.

Table 2. Transistors for Q1

Device V

MPS2222 1.3 100 30 150 800

MPS2222A 1.2 100 40 150 800

2N4400 0.95 50 40 150 820

2N4401 0.95 100 40 150 820

MPS6601 1.2 50 25 500 780

MPS6602 1.2 50 40 500 780

BE(SAT)

MIN hFEV

BR(CEO)IC

R

BASE

(W)

A base–current limiting resistor is required with bipolar

transistors. This is shown in Figure 6. The correct value for

this resistor can be determined as follows: (see Figure 6).

V

RSENSE

V

RBASE

I

BASE

VOH = V

= I

= R

= I

SENSE

FAN

BASE

FAN

X R

/ h

+ V

SENSE

X I

BASE

FE

BE(SAT)

+ V

RBASE

(7.)

VOH is specified as 80% of VDD in the Electrical

Characteristics table; V

datasheet. It is now possible to solve for R

R

BASE

=

VOH – V

BE(SAT)

is given in the transistor

BE(SAT)

BASE

– V

RSENSE

I

RBASE

.

(8.)

Some applications require the fan to be powered from the

negative 12V supply to keep motor noise out of the positive

voltage power supplies. As shown in Figure 10, Zener diode

D2 offsets the –12V power supply voltage holding transistor

Q1 OFF when V

is LOW. When V

OUT

is HIGH, the

OUT

voltage at the anode of D2 increases by VOH, causing Q1 to

turn ON. Operation is otherwise the same as the case of fan

operation +12V.

Latch–up Considerations

As with any CMOS IC, the potential exists for latch–up if

signals are applied to the device which are outside the power

supply range. This is of particular concern during power–up

if the external circuitry, such as the sensor network, V

MIN

divider, shutdown circuit, or fan, are powered by a supply

different from that of the MC642. Care should be taken to

ensure that the MC642’s VDD supply powers–up first. If

possible, the networks attached to VIN and V

should

MIN

connect to the VDD supply at the same physical location as

the IC itself. Even if the IC and any external networks are

powered by the same supply, physical separation of the

connecting points can result in enough parasitic capacitance

and/or inductance in the power supply connections to delay

one power supply “routing” versus another.

Power Supply Routing and Bypassing

Noise present on the VIN and V

inputs may cause

MIN

erroneous operation of the F AULT output. As a result, these

inputs should be bypassed with a 0.01µF capacitor mounted

as close to the package as possible. This is particularly true

of V

, which usually is driven from a high impedance

IN

source (such as a thermistor). In addition, the VDD input

should be bypassed with a 1µF capacitor . Grounds should be

kept as short as possible. To keep fan noise off the MC642

ground pin, individual ground returns for the MC642 and the

low side of the fan current sense resistor should be used.

http://onsemi.com

11

Page 12

V

MC642

5 V

DD

FAN

MC642

V

out

GND

Figure 10. Powering Fan From –12V Supply

Design Example (Figure 11)

Step 1. Circulate R1 and R2 based on using an NTC

having a resistance of 4.6kW at T

1.1kW at T

R1 = 75k

R2 = 1k

.

MAX

W

W

Step 2. Set minimum fan speed

V

= 1.8V

MIN

12 V

Zener

MIN

D2

and

R2

2.2 k

Q1

R4

10 k

–12 V

R3

2.2

W

Limit the divider current to 100µA from

which R5 = 33k and R6 = 18k

Step 3. Design the output circuit

Maximum fan motor current = 250mA. Q1

beta is chosen at 100 from which R7 = 1.5k

W

W

Fan

Shutdown

+5 V

R8

10 k

(Optional)

R1

R2

Q2

NTC

10 k

@ 25°C

0.01 mF

C

B

+5 V

R5

33 k

R6

+5 V

W

1 mF

+

C

B

8

V

CC

V

in

16

MC642

V

min

3

0.01

C

B

C

F

2

+

C1

1 mF

Figure 11. Design Example

4

GND

FAULT

V

out

SENSE

+12 V

FAN

System

Fault

7

5

C

SENSE

0.1 mF

R7

1.5 k

Q1

R

2.2 W

SENSE

http://onsemi.com

12

Page 13

MC642

MC642 as a Microcontroller Peripheral

(Figure 12)

In a system containing a microcontroller or other host

intelligence, the MC642 can be effectively managed as a

CPU peripheral. Routine fan control functions can be

performed by the MC642 without processor intervention.

The micro–controller receives temperature data from one or

more points throughout the system. It calculates a fan

operating speed based on an algorithm specifically designed

for the application at hand. The processor controls fan speed

using complementary port bits I/01 through I/03. Resistors

R1 through R6 (5% tolerance) form a crude 3–bit DAC that

+5 V

Open

Drain

Output

CMOS

Outputs

from One or More Sensors

Analog or Digital Temperature Data

CMOS

Microcontroller

(RESET) (Optional)

I/O

0

(MSB)

I/O

1

I/O

2

I/O

3

(LSB)

+5 V

R1

110 k

R2

240 k

R3

360 k

18 k

R5

1.5 k

R4

+5 V

R6

1 k

R7

33 k

R8

18 k

translates the 3–bit code from the processor’s outputs into a

1.6V DC control signal. (A monolithic DAC or digital pot

may be used instead of the circuit shown.)

With V

set to 1.8V, the MC642 has a minimum

MIN

operating speed of approximately 40% of full rated speed

when the processor’s output code is 000. Output codes 001

to 111 operate the fan from roughly 40% to 100% of full

speed. An open drain output from the processor can be used

to reset the MC642 following detection of a fault condition.

The FAULT

output can be connected to the processor’s

interrupt input, or to an I/O pin for polled operation.

+12 V

C

B

0.01 mF

+

1 mF

C

B

0.01 mF

+5 V

V

in

1

C

F

2

V

min

3

GND

4

MC642

FAULT

SENSE

V

DD

8

V

out

7

6

5

C

B

1 mF

+

R9

1.5 k

+5 V

R10

10 k

0.1 mF

+

FAN

–

2N2222A

R11

2.2 W

GND

INT

Figure 12. Design Example

http://onsemi.com

13

Page 14

MC642

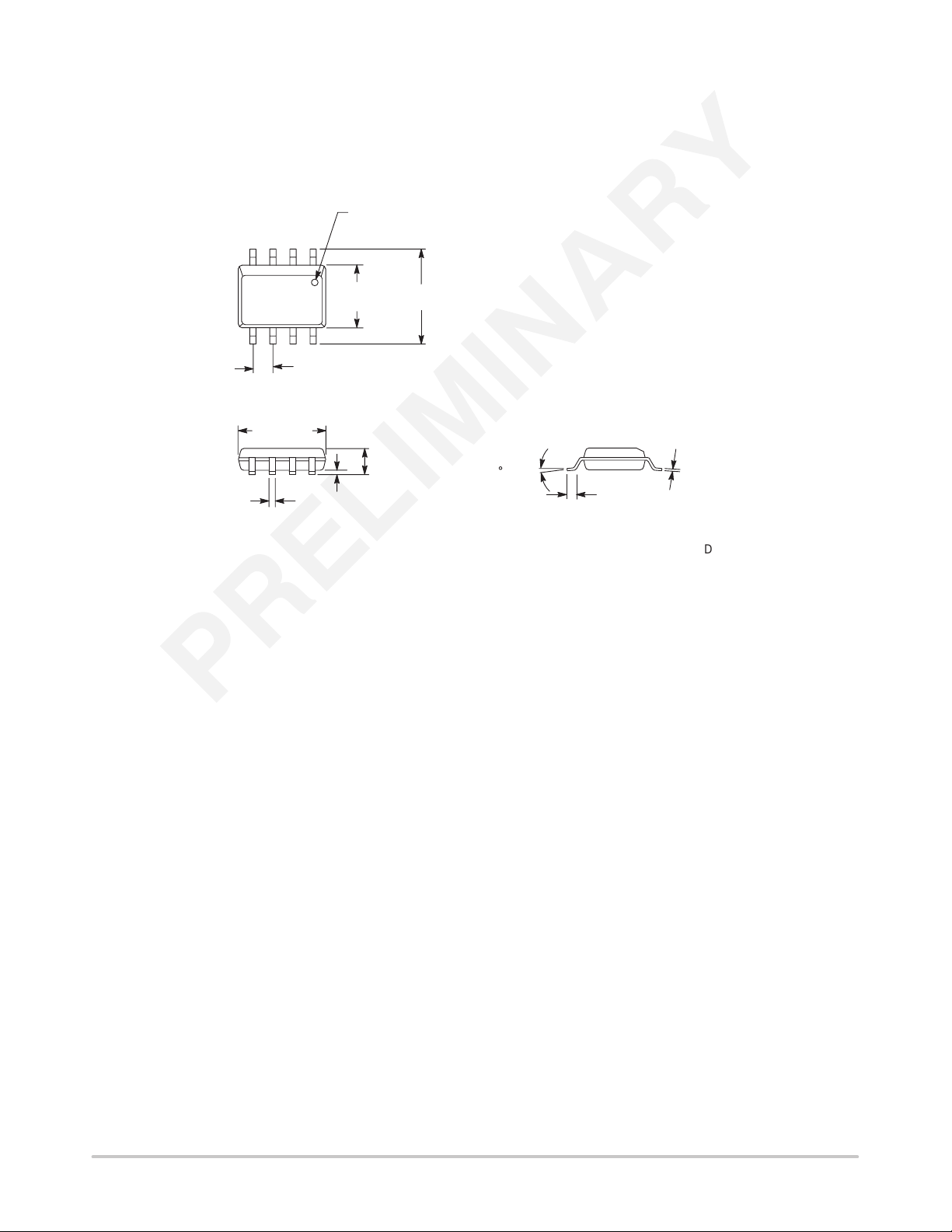

P ACKAGE DIMENSIONS

8–Pin DIP

PLASTIC PACKAGE

CASE TBD

ISSUE TBD

PIN 1

.260 (6.60)

.240 (6.10)

.045 (1.14)

.030 (0.76)

.200 (5.08)

.140 (3.56)

.150 (3.81)

.115 (2.92)

.400 (10.16)

.348 (8.84)

.110 (2.79)

.090 (2.29)

.070 (1.78)

.045 (1.14)

.022 (0.56)

.015 (0.38)

.040 (1.02)

.020 (0.51)

.015 (0.38)

.008 (0.20)

.310 (7.87)

.290 (7.37)

3 MIN.°

.400 (10.16)

.310 (7.87)

Dimensions: inches (mm)

http://onsemi.com

14

Page 15

MC642

P ACKAGE DIMENSIONS

8–Pin SOIC

PLASTIC PACKAGE

CASE TBD

ISSUE TBD

PIN 1 indicated by dot and/or beveled edge

.050 (1.27) TYP.

.197 (5.00)

.189 (4.80)

.018 (0.46)

.014 (0.36)

.157 (3.99)

.150 (3.81)

.010 (0.25)

.004 (0.10)

.244 (6.20)

.228 (5.79)

.069 (1.75)

.053 (1.35)

_

8 MAX.

.050 (1.27)

.016 (0.40)

.010 (0.25)

.007 (0.18)

Dimensions: inches (mm)

http://onsemi.com

15

Page 16

MC642

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse T ime)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (T ue–Fri 9:00am to 1:00pm, Hong Kong T ime)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

16

MC642/D

Loading...

Loading...