Page 1

查询MC100210供应商

MC33178, MC33179

Low Power, Low Noise

Operational Amplifiers

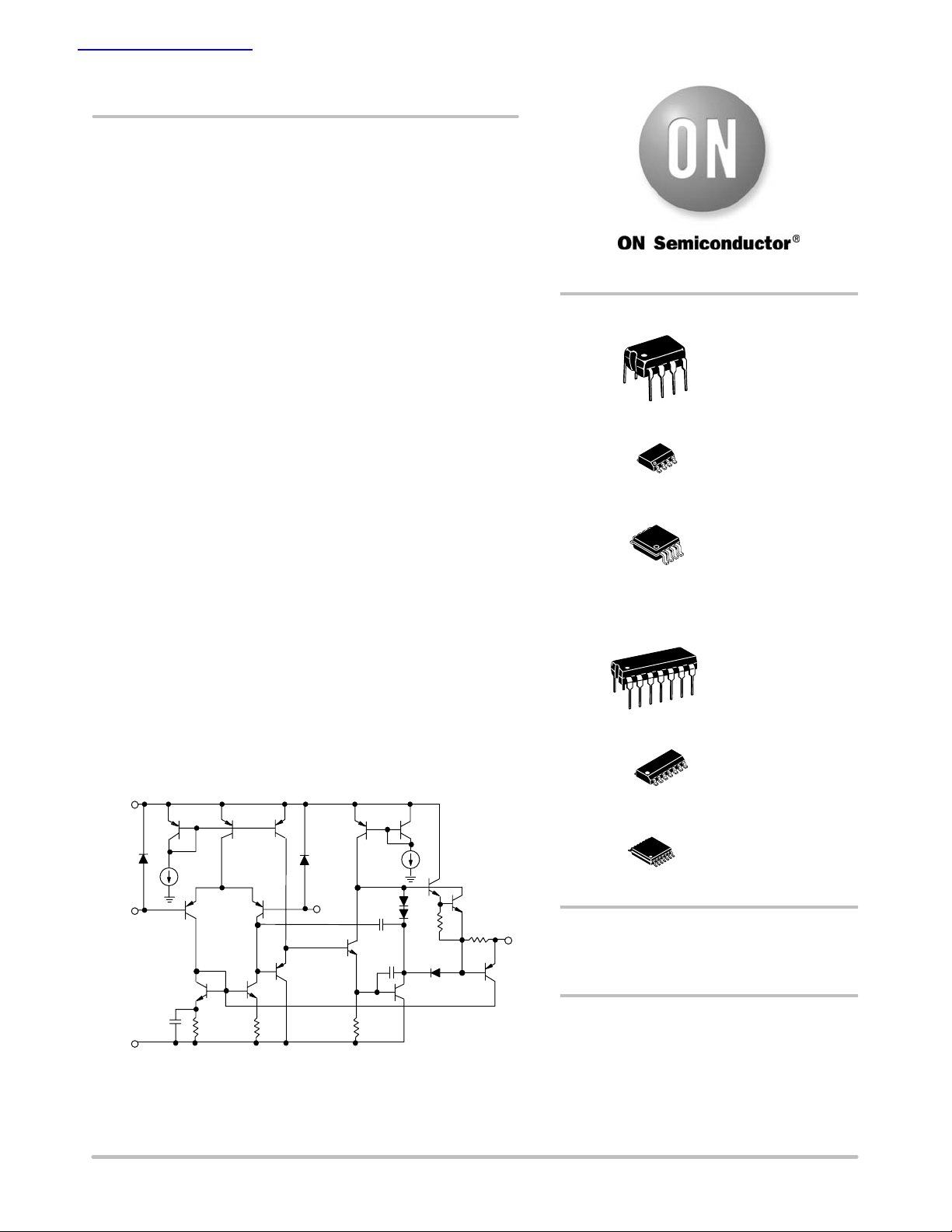

The MC33178/9 series is a family of high quality monolithic

amplifiers employing Bipolar technology with innovative high

performance concepts for quality audio and data signal processing

applications. This device family incorporates the use of high

frequency PNP input transistors to produce amplifiers exhibiting low

input offset voltage, noise and distortion. In addition, the amplifier

provides high output current drive capability while consuming only

420 mA of drain current per amplifier. The NPN output stage used,

exhibits no deadband crossover distortion, large output voltage swing,

excellent phase and gain margins, low open−loop high frequency

output impedance, symmetrical source and sink AC frequency

performance.

The MC33178/9 family offers both dual and quad amplifier

versions in several package options.

Features

• 600 W Output Drive Capability

• Large Output Voltage Swing

• Low Offset Voltage: 0.15 mV (Mean)

• Low T.C. of Input Offset Voltage: 2.0 mV/°C

• Low Total Harmonic Distortion: 0.0024%

(@ 1.0 kHz w/600 W Load)

• High Gain Bandwidth: 5.0 MHz

• High Slew Rate: 2.0 V/ms

• Dual Supply Operation: ±2.0 V to ±18 V

• ESD Clamps on the Inputs Increase Ruggedness without Affecting

Device Performance

• Pb−Free Packages are Available

V

CC

http://onsemi.com

DUAL

8

1

8

1

8

1

QUAD

14

1

14

1

PDIP−8

P SUFFIX

CASE 626

SOIC−8

D SUFFIX

CASE 751

Micro8

DM SUFFIX

CASE 846A

PDIP−14

P SUFFIX

CASE 646

SOIC−14

D SUFFIX

CASE 751A

I

ref

Vin −

V

EE

Figure 1. Representative Schematic Diagram

(Each Amplifier)

© Semiconductor Components Industries, LLC, 2005

October, 2005 − Rev. 6

Vin +

I

ref

C

C

V

C

M

1 Publication Order Number:

O

14

1

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 2 of this data sheet.

DEVICE MARKING INFORMATION

See general marking information in the device marking

section on page 4 of this data sheet.

TSSOP−14

DTB SUFFIX

CASE 948G

MC33178/D

Page 2

MC33178, MC33179

MAXIMUM RATINGS

Rating Symbol Value Unit

Supply Voltage (VCC to V

EE)

Input Differential Voltage Range V

Input Voltage Range V

Output Short Circuit Duration (Note 2) t

Maximum Junction Temperature T

Storage Temperature Range T

Maximum Power Dissipation P

Operating Temperature Range T

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously. If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

1. Either or both input voltages should not exceed VCC or VEE.

2. Power dissipation must be considered to ensure maximum junction temperature (TJ) is not exceeded. (See power dissipation performance

characteristic, Figure 2.)

V

IDR

IR

SC

stg

A

S

+36 V

Note 1 V

Note 1 V

Indefinite sec

J

+150 °C

−60 to +150 °C

D

Note 2 mW

−40 to +85 °C

ORDERING INFORMATION

Device Package Shipping

MC33178D SOIC−8 98 Units / Rail

MC33178DG SOIC−8

(Pb−Free)

98 Units / Rail

MC33178DR2 SOIC−8 2500 / Tape & Reel

MC33178DR2G SOIC−8

(Pb−Free)

2500 / Tape & Reel

MC33178P PDIP−8 1000 Units / Rail

MC33178PG PDIP−8

(Pb−Free)

1000 Units / Rail

MC33178DMR2 Micro8 4000 / Tape & Reel

MC33178DMR2G Micro8

(Pb−Free)

4000 / Tape & Reel

MC33179D SOIC−14 55 Units / Rail

MC33179DG SOIC−14

(Pb−Free)

55 Units / Rail

MC33179DR2 SOIC−14 2500 / Tape & Reel

MC33179DR2G SOIC−14

(Pb−Free)

2500 / Tape & Reel

MC33179P PDIP−14 500 Units / Rail

MC33179PG PDIP−14

(Pb−Free)

MC33179DTBR2G TSSOP−14

(Pb−Free)

500 Units / Rail

2500 / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

†

http://onsemi.com

2

Page 3

MC33178, MC33179

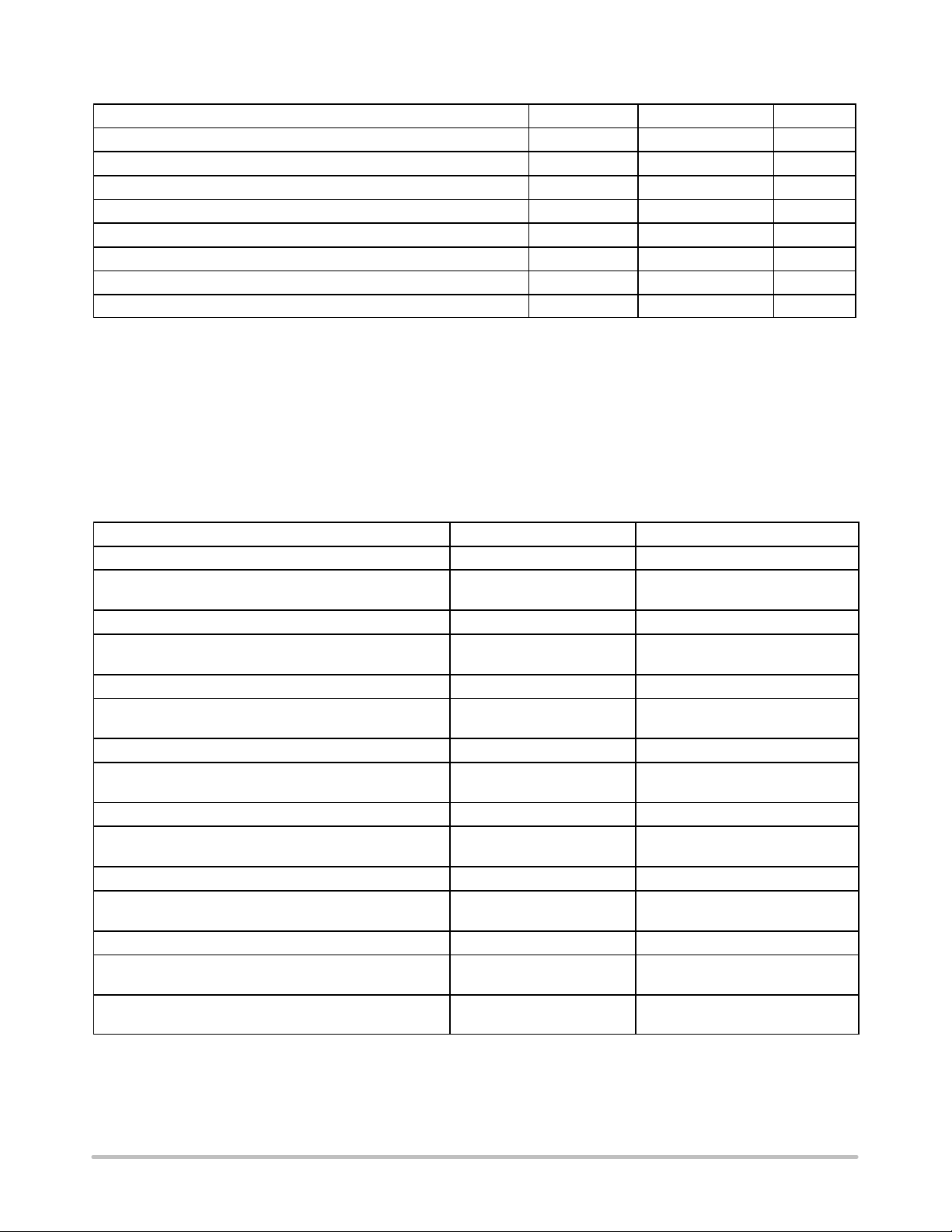

MARKING DIAGRAMS

DUAL QUAD

PDIP−8

CASE 626

8

MC33178P

AWL

YYWWG

1

8

1

Micro8

CASE 846A

8

3178

AYWG

G

1

SOIC−8

CASE 751

33178

ALYW

G

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W = Work Week

G, G = Pb−Free Package

(Note: Microdot may be in either location)

PIN CONNECTIONS

PDIP−14

CASE 646

14

MC33179P

AWLYYWWG

1

SOIC−14

CASE 751A

14

MC33179DG

AWLYWW

1

TSSOP−14

CASE 948G

14

MC33

179

ALYW

1

DUAL

CASE 626/751/846A

Output 1

1

2

Inputs 1

−

+

3

4

V

EE

(Top View)

−

+

8

V

CC

7

Output 2

6

5

Inputs 2

CASE 646/751A/948G

Output 1

Inputs 1

Inputs 2

Output 2

1

2

3

4

V

CC

5

−−

6

78

QUAD

14

Output 4

−−

1

++

++

23

13

4

Inputs 4

12

11

V

EE

10

Inputs 3

9

Output 3

(Top View)

http://onsemi.com

3

Page 4

MC33178, MC33179

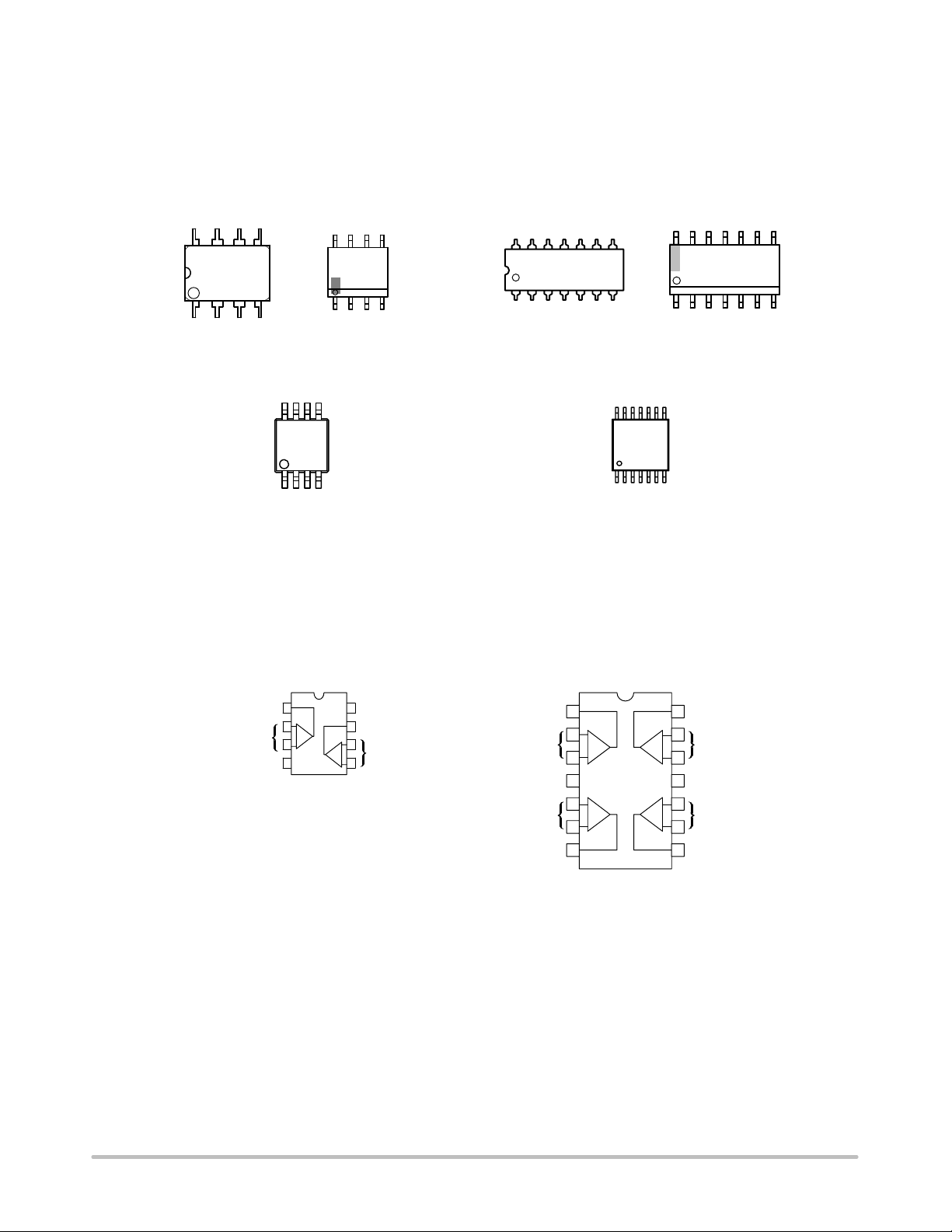

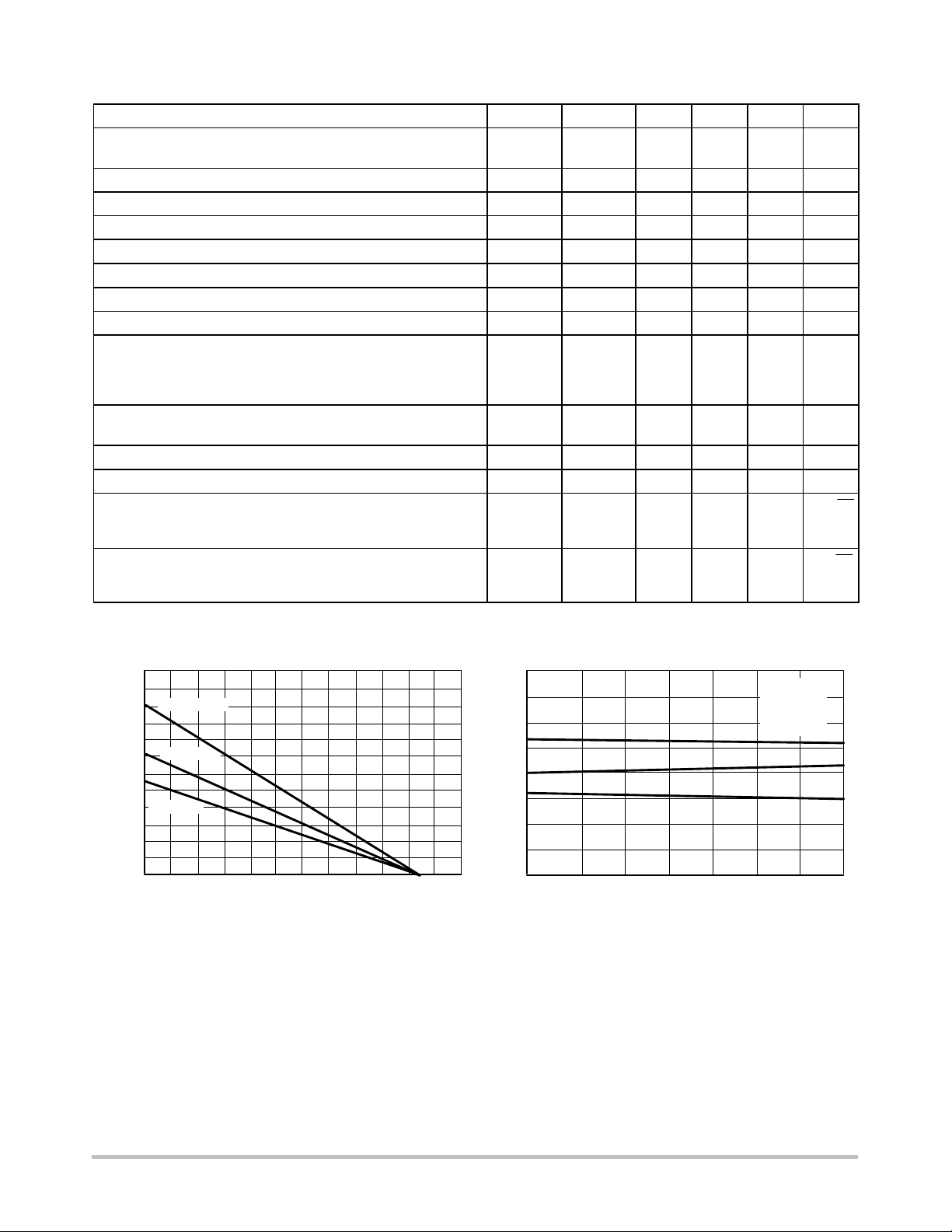

DC ELECTRICAL CHARACTERISTICS (V

Characteristics

Input Offset Voltage (RS = 50 W, VCM = 0 V, VO = 0 V)

= +15 V, VEE = −15 V, TA = 25°C, unless otherwise noted.)

CC

Figure Symbol Min Typ Max Unit

3 |VIO|

(VCC = +2.5 V, VEE = −2.5 V to VCC = +15 V, VEE = −15 V)

TA = +25°C

T

= −40° to +85°C

A

Average Temperature Coefficient of Input Offset Voltage

−

−

3

DVIO/DT

0.15

−

3.0

4.0

(RS = 50 W, VCM = 0 V, VO = 0 V)

TA = −40° to +85°C

Input Bias Current (VCM = 0 V, VO = 0 V)

TA = +25°C

TA = −40° to +85°C

Input Offset Current (VCM = 0 V, VO = 0 V)

TA = +25°C

TA = −40° to +85°C

Common Mode Input Voltage Range

(DVIO = 5.0 mV, VO = 0 V)

Large Signal Voltage Gain (VO = −10 V to +10 V, RL = 600 W)

TA = +25°C

TA = −40° to +85°C

Output Voltage Swing (VID = ±1.0 V)

4, 5 I

6 V

7, 8 A

9, 10, 11

IB

|IIO|

ICR

VOL

− 2.0 −

−

−

−

−

−13

−

50

25

100

−

5.0

−

−14

+14

200

−

500

600

50

60

−

+13

−

−

(VCC = +15 V, VEE = −15 V)

RL = 300 W

RL = 300 W

RL = 600 W

RL = 600 W

RL = 2.0 kW

RL = 2.0 kW

VO+

VO−

VO+

VO−

VO+

VO−

−

−

+12

−

+13

−

+12

−12

+13.6

−13

+14

−13.8

−

−

−

−12

−

−13

(VCC = +2.5 V, VEE = −2.5 V)

RL = 600 W

RL = 600 W

VO+

VO−

1.1

−

1.6

−1.6

−

−1.1

Common Mode Rejection (Vin = ±13 V) 12 CMR 80 110 − dB

Power Supply Rejection

VCC/VEE = +15 V/ −15 V, +5.0 V/ −15 V, +15 V/ −5.0 V

Output Short Circuit Current (VID = ±1.0 V, Output to Ground)

Source (VCC = 2.5 V to 15 V)

Sink (VEE = −2.5 V to −15 V)

Power Supply Current (VO = 0 V)

13 PSR

14, 15 I

16 I

SC

80 110 −

+50

−50

D

+80

−100

−

−

(VCC = 2.5 V, VEE = −2.5 V to VCC = +15 V, VEE = −15 V)

MC33178 (Dual)

TA = +25°C

TA = −40° to +85°C

−

−

−

−

1.4

1.6

MC33179 (Quad)

TA = +25°C

TA = −40° to +85°C

−

−

1.7

−

2.4

2.6

mV

mV/°C

nA

nA

V

kV/V

V

dB

mA

mA

http://onsemi.com

4

Page 5

MC33178, MC33179

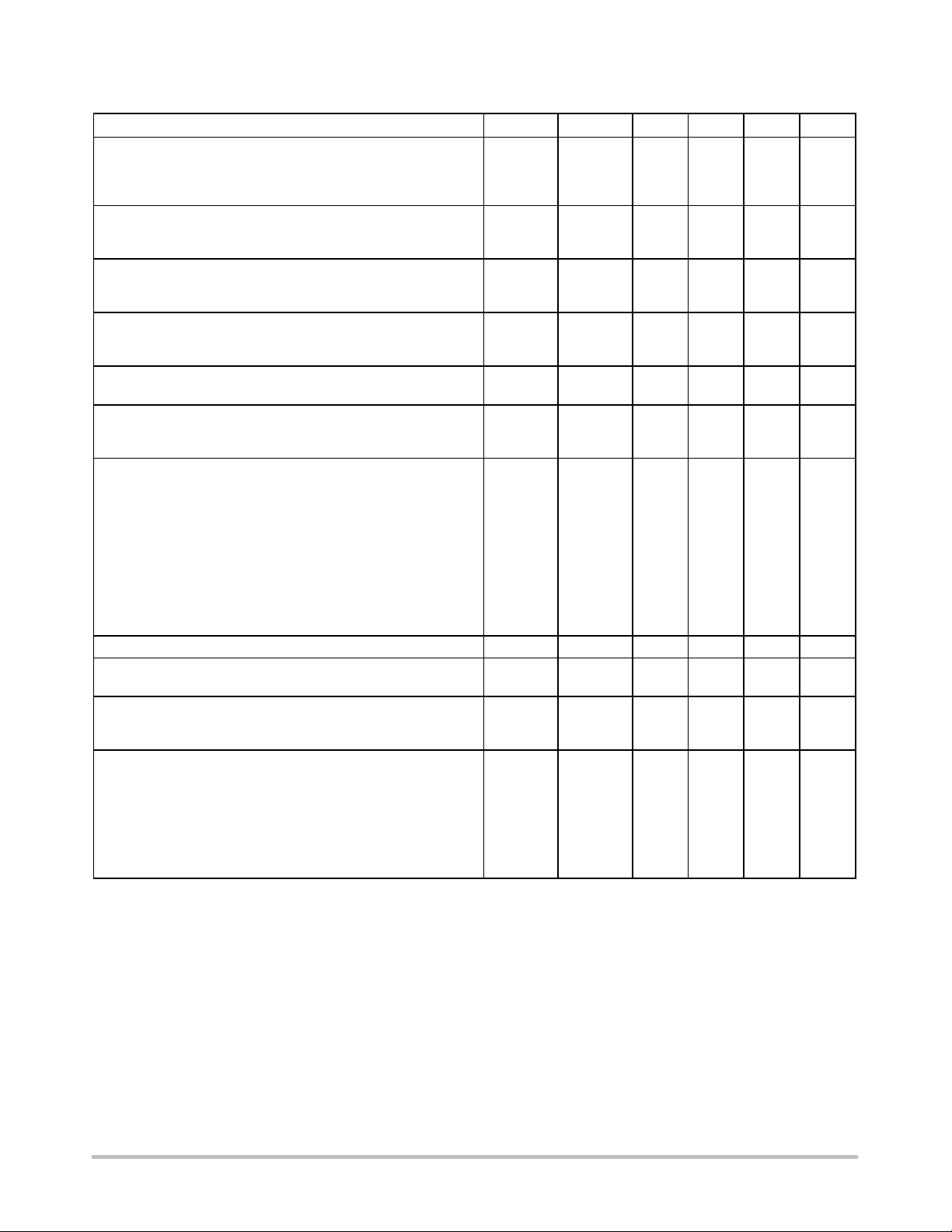

AC ELECTRICAL CHARACTERISTICS (V

Characteristics

Slew Rate

(Vin = −10 V to +10 V, RL = 2.0 kW, CL = 100 pF, AV = +1.0 V)

= +15 V, VEE = −15 V, TA = 25°C, unless otherwise noted.)

CC

Figure Symbol Min Typ Max Unit

17, 32 SR

1.2 2.0 −

V/ms

Gain Bandwidth Product (f = 100 kHz) 18 GBW 2.5 5.0 − MHz

AC Voltage Gain (RL = 600 W, VO = 0 V, f = 20 kHz)

Unity Gain Bandwidth (Open−Loop) (RL = 600 W, CL = 0 pF)

Gain Margin (RL = 600 W, CL = 0 pF)

Phase Margin (RL = 600 W, CL = 0 pF)

19, 20 A

21, 23, 24 A

22, 23, 24

VO

BW − 3.0 − MHz

m

f

m

− 50 − dB

− 15 − dB

− 60 − Deg

Channel Separation (f = 100 Hz to 20 kHz) 25 CS − −120 − dB

Power Bandwidth (VO = 20 V

= 600 W, THD ≤ 1.0%)

pp, RL

Total Harmonic Distortion (RL = 600 W,, VO = 2.0 Vpp, AV = +1.0 V)

26 THD

BW

(f = 1.0 kHz)

(f = 10 kHz)

(f = 20 kHz)

Open Loop Output Impedance

27 |ZO|

(VO = 0 V, f = 3.0 MHz, AV = 10 V)

Differential Input Resistance (VCM = 0 V) R

Differential Input Capacitance (VCM = 0 V) C

Equivalent Input Noise Voltage (RS = 100 W,)

28 e

f = 10 Hz

f = 1.0 kHz

Equivalent Input Noise Current

29 i

f = 10 Hz

f = 1.0 kHz

p

in

in

n

n

− 32 − kHz

−

0.0024

−

0.014

−

0.024

−

−

−

− 150 −

− 200 −

− 10 − pF

nV/ Hz√

−

−

8.0

7.5

−

−

pA/ Hz√

−

−

0.33

0.15

−

−

%

W

kW

2400

2000

MC33178P/9P

1600

MC33179D

1200

800

MC33178D

400

D

0

P(MAX), MAXIMUM POWER DISSIPATION (mW)

−60 −40 −20 0 20 40 60 80 100 120 180160140

TA, AMBIENT TEMPERATURE (°C)

Figure 2. Maximum Power Dissipation

versus Temperature

4.0

3.0

2.0

Unit 1

VCC = +15 V

VEE = −15 V

RS = 10 W

VCM = 0 V

1.0

0

Unit 2

Unit 3

−1.0

−2.0

−3.0

IO

V, INPUT OFFSET VOLTAGE (mV)

−4.0

−55 −25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

Figure 3. Input Offset Voltage versus

Temperature for 3 Typical Units

http://onsemi.com

5

Page 6

MC33178, MC33179

5

160

140

120

100

80

VCC = +15 V

60

VEE = −15 V

40

IB

I, INPUT BIAS CURRENT (nA)

TA = 25°C

20

0

−15 −10 −5.0 0 5.0 10 15

VCM, COMMON MODE VOLTAGE (V)

Figure 4. Input Bias Current

versus Common Mode Voltage

V

CC

VCC −0.5 V

VCC −1.0 V

VCC −1.5 V

VCC −2.0 V

VEE +1.0 V

VEE +0.5 V

, INPUT COMMON MODE VOLTAGE RANGE (V)

V

V

ICR

EE

−55 −25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

VCC = +5.0 V to +18 V

VEE = −5.0 V to −18 V

DVIO = 5.0 mV

Figure 6. Input Common Mode Voltage

Range versus Temperature

120

VCC = +15 V

110

VEE = −15 V

VCM = 0 V

100

90

80

IB

70

I, INPUT BIAS CURRENT (nA)

60

−55 −25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

Figure 5. Input Bias Current

versus Temperature

250

200

150

VCC = +15 V

100

VEE = −15 V

f = 10 Hz

DVO = 10 V to +10 V

50

, OPEN LOOP VOLTAGE GAIN (kV/V)

VOL

A

RL = 600 W

0

−55 −25 0 25 50 75 100 12

TA, AMBIENT TEMPERATURE (°C)

Figure 7. Open Loop Voltage Gain

versus Temperature

50

40

30

20

10

0

−10

−20

1A) Phase (RL = 600 W)

−30

2A) Phase (RL = 600 W, CL = 300 pF)

VOL

1B) Gain (RL = 600 W)

−40

A , OPEN LOOP VOLTAGE GAIN (dB)

2B) Gain (RL = 600 W, CL = 300 pF)

−50

2 345678910 20

f, FREQUENCY (Hz)

VCC = +15 V

VEE = −15 V

VO = 0 V

TA = 25°C

1A

1B

2B

2A

Figure 8. Voltage Gain and Phase

versus Frequency

80

100

120

140

160

180

200

220

240

260

280

φ

40

35

pp

30

25

20

15

10

, OUTPUT VOLTAGE (V )

, EXCESS PHASE (DEGREES)

O

V

5.0

0

http://onsemi.com

6

TA = 25°C

RL = 10 kW

RL = 600 W

0 5.0 10 15 20

VCC, |V

SUPPLY VOLTAGE (V)

EE|,

Figure 9. Output Voltage Swing

versus Supply Voltage

Page 7

VCC −1.0 V

VCC −2.0 V

VEE +2.0 V

VEE +1.0 V

, OUTPUT SATURATION VOLTAGE (V)

sat

V

MC33178, MC33179

V

CC

TA = +125°C

TA = −55°C

Sink

TA = −55°C

TA = +125°C

V

EE

0 5.0 10 15 20

IL, LOAD CURRENT (±mA)

Figure 10. Output Saturation Voltage

versus Load Current

Source

VCC = +5.0 V to +18 V

VEE = −5.0 V to −18 V

28

24

pp

20

16

VCC = +15 V

12

VEE = −15 V

8.0

, OUTPUT VOLTAGE (V )

O

4.0

V

RL = 600 W

AV = +1.0 V

THD = ≤1.0%

TA = 25°C

0

1.0 k 10 k 100 k 1.0 M

f, FREQUENCY (Hz)

Figure 11. Output Voltage

versus Frequency

120

100

VCC = +15 V

VEE = −15 V

VCM = 0 V

80

DVCM = ±1.5 V

TA = −55° to +125°C

60

−

A

DV

40

CM

20

CMR = 20 Log

CMR, COMMON MODE REJECTION (dB)

0

DM

+

DV

DV

DV

O

CM

x A

DM

O

10 100 1.0 k 10 k 100 k 1.0 M

f, FREQUENCY (Hz)

Figure 12. Common Mode Rejection

versus Frequency Over Temperature

100

Source

80

Sink

60

40

20

VCC = +15 V

VEE = −15 V

VID = ±1.0 V

120

TA = −55° to +125°C

100

+PSR

VCC = +15 V

VEE = −15 V

DVCC = ±1.5 V

PSR, POWER SUPPLY REJECTION (dB)

80

60

40

20

0

−

A

DM

+

PSR = 20 Log

V

CC

V

EE

DVO/A

DV

DV

−PSR

O

DM

CC

10 100 1.0 k 10 k 100 k 1.0 M

f, FREQUENCY (Hz)

Figure 13. Power Supply Rejection

versus Frequency Over Temperature

100

90

Sink

80

Source

70

60

VCC = +15 V

VEE = −15 V

VID = ±1.0 V

RL < 10 W

0

SC

I, OUTPUT SHORT CIRCUIT CURRENT (mA)

−15 −9.0 −3.0 0 3.0 9.0 15

VO, OUTPUT VOLTAGE (V)

Figure 14. Output Short Circuit Current

versus Output Voltage

50

SC

I, OUTPUT SHORT CIRCUIT CURRENT (mA)

−55 −25 0 25 50 75 100 125

http://onsemi.com

7

TA, AMBIENT TEMPERATURE (°C)

Figure 15. Output Short Circuit Current

versus Temperature

Page 8

MC33178, MC33179

O

G

G

625

μ

500

375

250

TA = +125°C

TA = +25°C

TA = −55°C

125

CC

I , SUPPLY CURRENT/AMPLIFIER ( A)

0

0 2.0 4.0 6.0 8.0 10 12 14 16 18

V

|VEE| , SUPPLY VOLTAGE (V)

CC,

Figure 16. Supply Current versus Supply

Voltage with No Load

10

8.0

6.0

4.0

VCC = +15 V

VEE = −15 V

f = 100 kHz

2.0

GBW, GAIN BANDWIDTH PRODUCT (MHz)

0

RL = 600 W

CL = 0 pF

−55 −25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

Figure 18. Gain Bandwidth Product

versus Temperature

1.15

1.10

VCC = +15 V

VEE = −15 V

1.05

DV

= 20 V

in

pp

1.00

0.95

0.90

0.85

SR, SLEW RATE (NORMALIZED)

0.80

0.75

−55 −25 0 25 50 75 100 125

DV

−

+

in

600 W

TA, AMBIENT TEMPERATURE (°C)

Figure 17. Normalized Slew Rate

versus Temperature

50

40

30

Phase

20

10

Gain

0

−10

−20

V

A , VOLTAGE GAIN (dB)

−30

VCC = +15 V

VEE = −15 V

RL = 600 W

TA = 25°C

CL = 0 pF

−40

−50

100 k

1.0 M 10 M 100 M

f, FREQUENCY (Hz)

Figure 19. Voltage Gain and Phase

versus Frequency

V

O

100 pF

80

100

120

140

160

180

200

220

240

, EXCESS PHASE (DEGREES)

φ

260

280

50

40

30

20

AIN (dB)

10

E

0

LTA

−10

−20

1A) Phase VCC =18 V, VEE = −18 V

V

A, V

2A) Phase VCC 1.5 V, VEE = −1.5 V

−30

1B) Gain VCC = 18 V, VEE = −18 V

−40

2B) Gain VCC = 1.5 V, VEE = −1.5 V

−50

100 k

Figure 20. Voltage Gain and Phase

1B

2B

1.0 M 10 M 100 M

f, FREQUENCY (Hz)

versus Frequency

1A

2A

TA = 25°C

RL = ∞

CL = 0 pF

80

100

120

140

160

180

200

, PHASE (DEGREES)

220

φ

240

260

280

15

CL = 10 pF

12

C

= 100 pF

L

9.0

CL = 300 pF

6.0

VCC = +15 V

VEE = −15 V

3.0

RL = 600 W

m

A , OPEN LOOP GAIN MARGIN (dB)

0

−55 −25 0 25 50 75 100 125

TA, AMBIENT TEMPERATURE (°C)

Figure 21. Open Loop Gain Margin

versus Temperature

http://onsemi.com

8

Page 9

MC33178, MC33179

60

50

40

30

20

, PHASE MARGIN (DEGREES)

m

10

φ

0

−55 −25 0 25 50 75 100 125

VCC = +15 V

VEE = −15 V

RL = 600 W

CL = 10 pF

C

= 100 pF

L

CL = 300 pF

TA, AMBIENT TEMPERATURE (°C)

Figure 22. Phase Margin

versus Temperature

18

15

Phase Margin

VCC = +15 V

VEE = −15 V

VO = 0 V

12

Gain Margin

9.0

6.0

3.0

m

A, OPEN LOOP GAIN MARGIN (dB)

0

10 100 1.0 k

−

V

in

+

600 W

V

O

C

L

CL, OUTPUT LOAD CAPACITANCE (pF)

Figure 24. Open Loop Gain Margin and Phase

Margin versus Output Load Capacitance

12

10

V

CC

VEE = −15 V

8.0

R

T

VO = 0 V

6.0

TA = 25°C

4.0

m

A, GAIN MARGIN (dB)

V

2.0

in

0

100 1.0 k 10 k 100 k

60

50

150

140

40

130

30

20

10

φ

0

120

, PHASE MARGIN (DEGREES)

110

m

CS, CHANNEL SEPARATION (dB)

100

100 1.0 k 10 k 100 k 1.0 M

= +15 V

= R1+R

R

R

2

1

−

+

2

V

O

Gain Margin

Phase Margin

RT, DIFFERENTIAL SOURCE RESISTANCE (W)

Figure 23. Phase Margin and Gain Margin

versus Differential Source Resistance

Drive Channel

VCC = +15 V

CEE = −15 V

RL = 600 W

TA = 25°C

f, FREQUENCY (Hz)

Figure 25. Channel Separation

versus Frequency

60

50

40

30

20

, PHASE MARGIN (DEGREES)

m

10

φ

0

10

VCC = +15 V V

VEE = −15 V TA = 25°C

RL = 600 W

= 2.0 V

O

pp

AV = 1000

1.0

AV = 100

0.1

AV = 10

THD, TOTAL HARMONIC DISTORTION (%)

0.01

10 100 1.0 k 10 k 100 k

AV = 1.0

f, FREQUENCY (Hz)

Figure 26. Total Harmonic Distortion

versus Frequency

500

Ω

400

300

200

O

100

|Z|, OUTPUT IMPEDANCE ()

0

http://onsemi.com

9

1. AV = 1.0

2. AV = 10

3. AV = 100

4. AV = 1000

3

21

VCC = +15 V

VEE = −15 V

VO = 0 V

TA = 25°C

4

1.0 k 10 k 100 k 1.0 M 10 M

f, FREQUENCY (Hz)

Figure 27. Output Impedance

versus Frequency

Page 10

MC33178, MC33179

20

18

nV/ Hz√

16

14

Input Noise Voltage Test

+

−

12

10

8.0

6.0

4.0

2.0

n

e, INPUT REFERRED NOISE VOLTAGE ()

VCC = +15 V

VEE = −15 V

TA = 25°C

0

10 100 1.0 k 10 k 10 k

f, FREQUENCY (Hz)

Figure 28. Input Referred Noise Voltage

versus Frequency

100

90

VCC = +15 V

VEE = −15 V

80

TA = 25°C

70

60

R

50

40

= 600 W

L

RL = 2.0 kW

30

20

PERCENT OVERSHOOT (%)

10

0

10 100 1.0 k 10 k

CL, LOAD CAPACITANCE (pF)

Figure 30. Percent Overshoot versus

Load Capacitance

Circuit

0.5

pA/ Hz√

V

O

0.4

Input Noise Current Test Circuit

+

R

S

−

V

O

0.3

0.2

0.1

VCC = +15 V

VEE = −15 V

(RS = 10 kW)

TA = 25°C

0

10 100 1.0 k 10 k 100 k

n

i, INPUT REFERRED NOISE CURRENT ()

f, FREQUENCY (Hz)

Figure 29. Input Referred Noise Current

versus Frequency

VCC = +15 V

VEE = −15 V

AV = +1.0

RL = 600 W

CL = 100 pF

TA = 25°C

, OUTPUT VOLTAGE (5.0 V/DIV)

O

t, TIME (2.0 ms/DIV)

Figure 31. Non−inverting Amplifier Slew Rate

VCC = +15 V

VEE = −15 V

AV = +1.0

RL = 600 W

CL = 100 pF

TA = 25°C

, OUTPUT VOLTAGE (50 mV/DIV)

O

V

t, TIME (2.0 ns/DIV)

VCC = +15 V

VEE = −15 V

AV = +1.0

RL = 600 W

CL = 100 pF

TA = 25°C

, OUTPUT VOLTAGE (5.0 V/DIV) V

O

V

t, TIME (5.0 ms/DIV)

Figure 32. Small Signal Transient Response Figure 33. Large Signal Transient Response

http://onsemi.com

10

Page 11

10 k

MC33178, MC33179

To

Receiver

From

Microphone

120 k

2.0 k A2

−

+

V

R

A1

−

+

10 k

1.0 mF

200 k

820

−

+

0.05 mF

10 k

A3

300

10 k

V

R

Figure 34. Telephone Line Interface Circuit

10 k

1N4678

Tip

Phone Line

Ring

APPLICATION INFORMATION

This unique device uses a boosted output stage to combine

a high output current with a drain current lower than similar

bipolar input op amps. Its 60° phase margin and 15 dB gain

margin ensure stability with up to 1000 pF of load

capacitance (see Figure 24). The ability to drive a minimum

600 W load makes it particularly suitable for telecom

applications. Note that in the sample circuit in Figure 34

both A2 and A3 are driving equivalent loads of

approximately 600 W.

The low input offset voltage and moderately high slew

rate and gain bandwidth product make it attractive for a

variety of other applications. For example, although it i s not

single supply (the common mode input range does not

include ground), it is specified at +5.0 V with a typical

common mode rejection of 110 dB. This makes it an

excellent choice for use with digital circuits. The high

common mode rejection, which is stable over temperature,

coupled with a low noise figure and low distortion, is an

ideal op amp for audio circuits.

The output stage of the op amp is current limited and

therefore has a certain amount of protection in the event of

a short circuit. However, because of its high current output,

it is especially important not to allow the device to exceed

the maximum junction temperature, particularly with the

MC33179 (quad op amp). Shorting more than one amplifier

could easily exceed the junction temperature to the extent of

causing permanent damage.

Stability

As usual with most high frequency amplifiers, proper lead

dress, component placement, and PC board layout should be

exercised for optimum frequency performance. For

example, long unshielded input or output leads may result in

unwanted input/output coupling. In order to preserve the

relatively low input capacitance associated with these

amplifiers, resistors connected to the inputs should be

immediately adjacent to the input pin to minimize additional

stray input capacitance. This not only minimizes the input

pole frequency for optimum frequency response, but also

minimizes extraneous “pick up” at this node. Supplying

decoupling with adequate capacitance immediately adjacent

to the supply pin is also important, particularly over

temperature, since many types of decoupling capacitors

exhibit great impedance changes over temperature.

Additional stability problems c an be c aused b y h igh load

capacitances and/or a high source resistance. Simple

compensation schemes can be used to alleviate these

effects.

http://onsemi.com

11

Page 12

MC33178, MC33179

1)

If a high source of resistance is used (R1 > 1.0 kW), a

compensation capacitor equal to or greater than the input

capacitance of the op amp (10 pF) placed across the

feedback resistor (see Figure 35) can be used to neutralize

that pole and prevent outer loop oscillation. Since the closed

loop transient response will be a function of that

capacitance, it is important to choose the optimum value for

that capacitor. This can be determined by the following

Equation:

CC+ (1) [R1ńR2])2 CL(ZOńR2)

(

where: ZO is the output impedance of the op amp.

R2

C

C

−

R1

+

Z

L

For moderately high capacitive loads (500 pF < C

< 1500 pF) the addition of a compensation resistor on the

order of 2 0 W between the output and the feedback loop will

help to decrease miller loop oscillation (see Figure 36). For

high capacitive loads (CL > 1500 pF), a combined

compensation scheme should be used (see Figure 37). Both

the compensation resistor and the compensation capacitor

affect the transient response and can be calculated for

optimum performance. The value of CC can be calculated

using Equation 1. The Equation to calculate RC is as follows:

(2)

C

L

R1

RC+ ZO R1ńR2

R2

−

+

R

C

L

Figure 35. Compensation for

High Source Impedance

R1

Figure 36. Compensation Circuit for

R2

C

C

−

+

R

C

Figure 37. Compensation Circuit for

High Capacitive Loads

Moderate Capacitive Loads

C

L

http://onsemi.com

12

Page 13

NOTE 2

−T−

SEATING

PLANE

H

58

−B−

14

F

−A−

C

N

D

G

0.13 (0.005) B

MC33178, MC33179

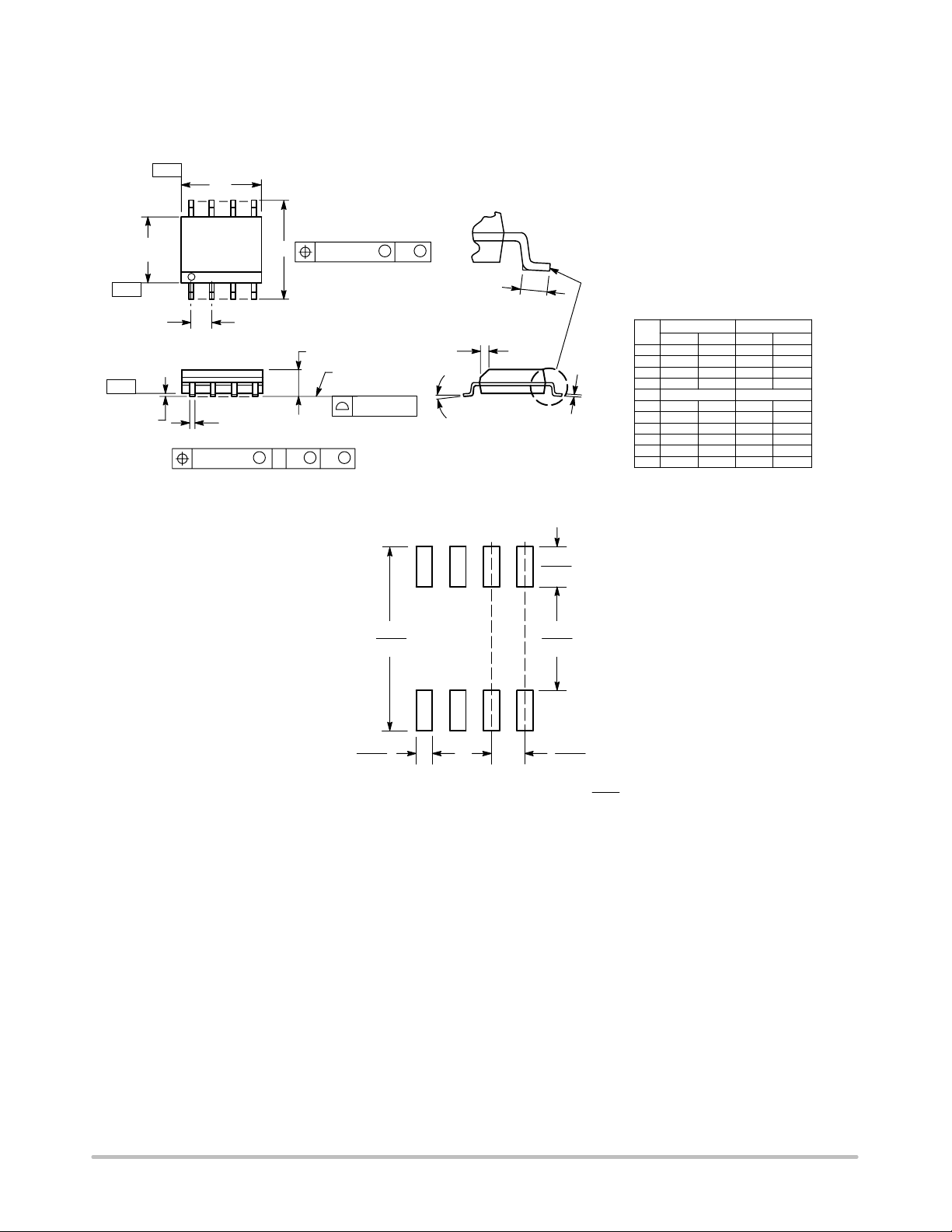

PACKAGE DIMENSIONS

PDIP−8

P SUFFIX

CASE 626−05

ISSUE L

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

DIM MIN MAX MIN MAX

A 9.40 10.16 0.370 0.400

B 6.10 6.60 0.240 0.260

C 3.94 4.45 0.155 0.175

D 0.38 0.51 0.015 0.020

L

J

K

M

M

A

T

M

M

F 1.02 1.78 0.040 0.070

G 2.54 BSC 0.100 BSC

H 0.76 1.27 0.030 0.050

J 0.20 0.30 0.008 0.012

K 2.92 3.43 0.115 0.135

L 7.62 BSC 0.300 BSC

M −−− 10 −−− 10

N 0.76 1.01 0.030 0.040

INCHESMILLIMETERS

__

SEATING

PLANE

−T−

0.038 (0.0015)

PIN 1 ID

Micro8

DM SUFFIX

CASE 846A−02

ISSUE F

−A−

K

G

−B−

D

8 PL

0.08 (0.003) A

M

T

S

B

S

C

H

J

L

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD FLASH,

PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT

EXCEED 0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD

FLASH OR PROTRUSION. INTERLEAD FLASH OR

PROTRUSION SHALL NOT EXCEED 0.25 (0.010)

PER SIDE.

5. 846A−01 OBSOLETE, NEW STANDARD 846A−02.

DIM MIN MAX MIN MAX

A 2.90 3.10 0.114 0.122

B 2.90 3.10 0.114 0.122

C −−− 1.10 −−− 0.043

D 0.25 0.40 0.010 0.016

G 0.65 BSC 0.026 BSC

H 0.05 0.15 0.002 0.006

J 0.13 0.23 0.005 0.009

K 4.75 5.05 0.187 0.199

L 0.40 0.70 0.016 0.028

INCHESMILLIMETERS

http://onsemi.com

13

Page 14

−Y−

−Z−

MC33178, MC33179

SOIC−8

D SUFFIX

CASE 751−07

ISSUE AE

NOTES:

−X−

A

58

B

1

S

0.25 (0.010)

4

M

M

Y

K

G

N

C

SEATING

PLANE

0.10 (0.004)

H

D

0.25 (0.010) Z

M

Y

SXS

X 45

_

M

J

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

____

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

SOLDERING FOOTPRINT*

1.52

0.060

7.0

0.275

0.6

0.024

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

4.0

0.155

1.270

0.050

SCALE 6:1

ǒ

inches

mm

Ǔ

http://onsemi.com

14

Page 15

MC33178, MC33179

PACKAGE DIMENSIONS

PDIP−14

P SUFFIX

CASE 646−06

ISSUE N

14 8

B

17

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

−T−

SEATING

PLANE

N

−T−

SEATING

PLANE

HG

14 8

G

A

F

−A−

−B−

71

D 14 PL

0.25 (0.010) A

M

T

K

S

B

C

D

14 PL

0.13 (0.005)

P 7 PL

0.25 (0.010) B

C

S

K

J

M

SOIC−14

D SUFFIX

CASE 751A−03

ISSUE G

M

R X 45

_

M

DIM MIN MAX MIN MAX

A 0.715 0.770 18.16 18.80

L

M

M

J

B 0.240 0.260 6.10 6.60

C 0.145 0.185 3.69 4.69

D 0.015 0.021 0.38 0.53

F 0.040 0.070 1.02 1.78

G 0.100 BSC 2.54 BSC

H 0.052 0.095 1.32 2.41

J 0.008 0.015 0.20 0.38

K 0.115 0.135 2.92 3.43

L

0.290 0.310 7.37 7.87

M −−− 10 −−− 10

N 0.015 0.039 0.38 1.01

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

F

DIM MIN MAX MIN MAX

A 8.55 8.75 0.337 0.344

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.228 0.244

R 0.25 0.50 0.010 0.019

MILLIMETERSINCHES

__

INCHESMILLIMETERS

____

http://onsemi.com

15

Page 16

MC33178, MC33179

TSSOP−14

PACKAGE DIMENSIONS

DTB SUFFIX

CASE 948G−01

ISSUE A

0.10 (0.004)

−T−

SEATING

PLANE

14X REFK

S

U

T

S

N

0.25 (0.010)

U0.15 (0.006) T

S

2X L/2

0.10 (0.004) V

14

M

8

M

L

PIN 1

IDENT.

1

S

U0.15 (0.006) T

A

−V−

B

N

−U−

F

7

DETAIL E

K

K1

J J1

SECTION N−N

C

D

G

H

DETAIL E

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH OR GATE BURRS SHALL NOT

EXCEED 0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE

INTERLEAD FLASH OR PROTRUSION.

INTERLEAD FLASH OR PROTRUSION SHALL

NOT EXCEED 0.25 (0.010) PER SIDE.

5. DIMENSION K DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.08 (0.003) TOTAL

IN EXCESS OF THE K DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

7. DIMENSION A AND B ARE TO BE

DETERMINED AT DATUM PLANE −W−.

INCHESMILLIMETERS

−W−

DIM MIN MAX MIN MAX

A 4.90 5.10 0.193 0.200

B 4.30 4.50 0.169 0.177

C −−− 1.20 −−− 0.047

D 0.05 0.15 0.002 0.006

F 0.50 0.75 0.020 0.030

G 0.65 BSC 0.026 BSC

H 0.50 0.60 0.020 0.024

J 0.09 0.20 0.004 0.008

J1 0.09 0.16 0.004 0.006

K 0.19 0.30 0.007 0.012

K1 0.19 0.25 0.007 0.010

L 6.40 BSC 0.252 BSC

M 0 8 0 8

____

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

16

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

MC33178/D

Loading...

Loading...