Page 1

ON Semiconductor

Single IGBT Gate Driver

The MC33153 is specifically designed as an IGBT driver for high

power applications that include ac induction motor control, brushless

dc motor control and uninterruptable power supplies. Although

designed for driving discrete and module IGBTs, this device offers a

cost effective solution for driving power MOSFETs and Bipolar

Transistors. Device protection features include the choice of

desaturation or overcurrent sensing and undervoltage detection. These

devices are available in dual–in–line and surface mount packages and

include the following features:

• High Current Output Stage: 1.0 A Source/2.0 A Sink

• Protection Circuits for Both Conventional and Sense IGBTs

• Programmable Fault Blanking Time

• Protection against Overcurrent and Short Circuit

• Undervoltage Lockout Optimized for IGBT’s

• Negative Gate Drive Capability

• Cost Effectively Drives Power MOSFETs and Bipolar Transistors

MC33153

SINGLE IGBT

GATE DRIVER

SEMICONDUCTOR

TECHNICAL DATA

8

1

P SUFFIX

PLASTIC PACKAGE

CASE 626

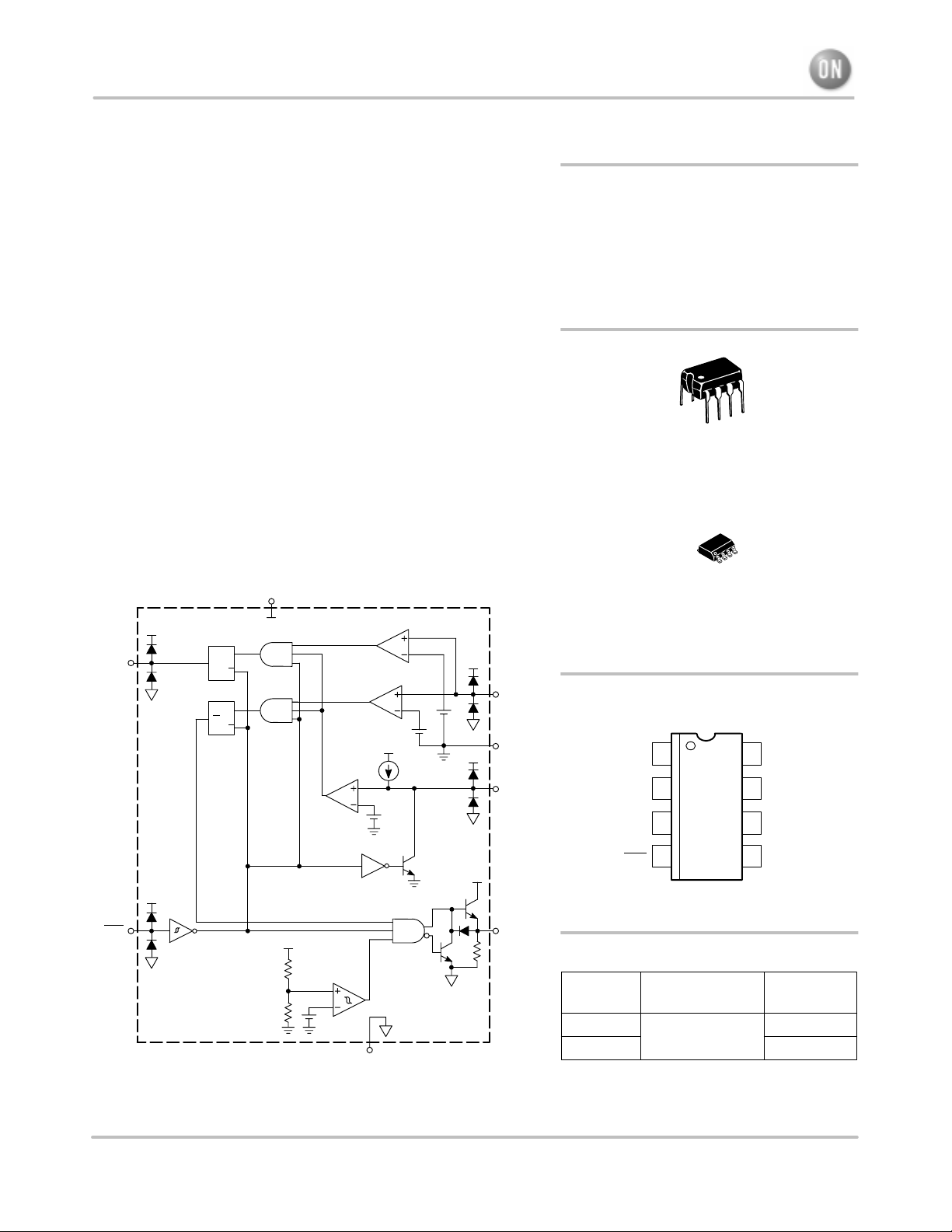

Representative Block Diagram

V

CC

6

V

CC

Short Circuit

Fault

Output

7

Input

4 5

Latch

Q

Overcurrent

Latch

V

EE

V

CC

V

EE

Q

V

CC

S

R

S

R

V

CC

This device contains 133 active transistors.

Short Circuit

Comparator

Overcurrent

Comparator

Fault Blanking/

Desaturation

Comparator

Under

Voltage

Lockout

12 V/

11 V

130 mV

65 mV

V

CC

270 µA

6.5 V

3

V

EE

Output

Stage

100 k

V

EE

V

V

V

V

V

CC

EE

CC

EE

CC

Current

Sense

1

Input

Kelvin

Gnd

2

Fault

Blanking/

8

Desaturation

Input

Drive

Output

Current Sense

Kelvin Gnd

ORDERING INFORMATION

Device

MC33153D

MC33153P

8

1

D SUFFIX

PLASTIC PACKAGE

CASE 751

(SO–8)

PIN CONNECTIONS

18

Input

2

3

V

EE

4

Input

(Top View)

Operating

Temperature Range

= –40° to +105°C

T

A

7

6

5

Fault Blanking/

Desaturation Input

Fault Output

V

CC

Drive Output

Package

SO–8

DIP–8

Semiconductor Components Industries, LLC, 2001

April, 2001 – Rev. 3

1 Publication Order Number:

MC33153/D

Page 2

MC33153

MAXIMUM RATINGS

Rating Symbol Value Unit

Power Supply Voltage V

VCC to V

EE

Kelvin Ground to VEE (Note 1) KGnd – V

Logic Input V

Current Sense Input V

Blanking/Desaturation Input V

Gate Drive Output

Source Current

Sink Current

Diode Clamp Current

Fault Output

Source Current

Sink Current

Power Dissipation and Thermal Characteristics

D Suffix SO–8 Package, Case 751

Maximum Power Dissipation @ T

= 50°C

A

Thermal Resistance, Junction–to–Air

P Suffix DIP–8 Package, Case 626

Maximum Power Dissipation @ T

= 50°C

A

Thermal Resistance, Junction–to–Air

Operating Junction Temperature T

Operating Ambient Temperature T

Storage Temperature Range T

NOTE: ESD data available upon request.

VCC – V

in

S

BD

I

O

I

FO

P

D

R

θ

JA

P

D

R

θ

JA

J

A

stg

EE

EE

20

20

VEE –0.3 to V

–0.3 to V

–0.3 to V

CC

CC

CC

1.0

2.0

1.0

25

10

0.56

180

1.0

100

+150 °C

–40 to +105 °C

–65 to +150 °C

V

V

V

A

mA

W

°C/W

W

°C/W

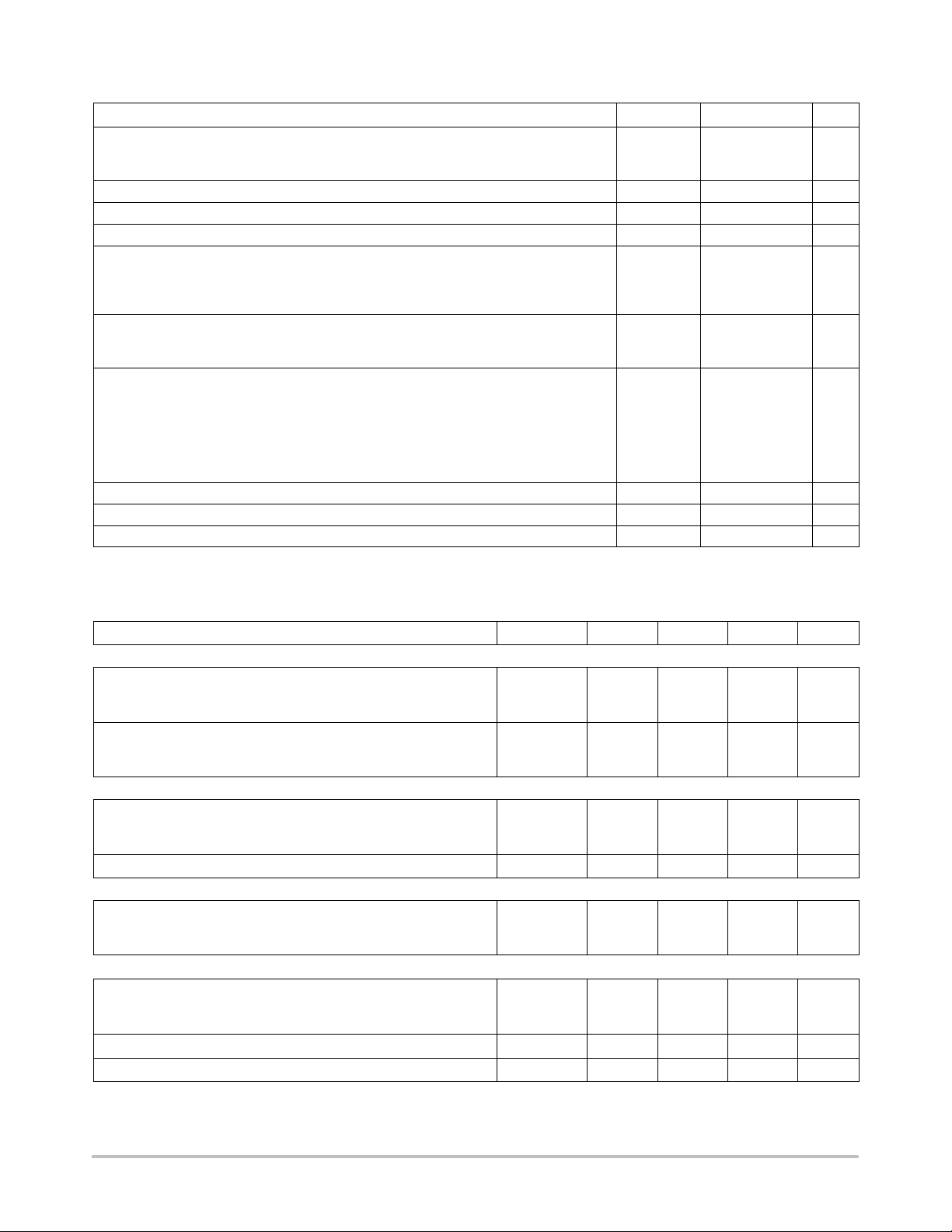

ELECTRICAL CHARACTERISTICS (V

= 25°C, for min/max values TA is the operating ambient temperature range that applies (Note 2), unless otherwise noted.)

T

A

Characteristic

= 15 V, VEE = 0 V, Kelvin Gnd connected to VEE. For typical values

CC

Symbol Min Typ Max Unit

LOGIC INPUT

Input Threshold Voltage

High State (Logic 1)

Low State (Logic 0)

V

IH

V

IL

1.2

–

2.70

2.30

Input Current

High State (V

Low State (V

= 3.0 V)

IH

= 1.2 V)

IL

I

IH

I

IL

–

–

130

50

DRIVE OUTPUT

Output Voltage

Low State (I

High State (I

Sink

Source

= 1.0 A)

= 500 mA)

Output Pull–Down Resistor R

V

OL

V

OH

PD

–

12

2.0

13.9

– 100 200 kΩ

FAULT OUTPUT

Output voltage

Low State (I

High State (I

= 5.0 mA)

Sink

Source

= 20 mA)

V

FL

V

FH

12

–

0.2

13.3

SWITCHING CHARACTERISTICS

Propagation Delay (50% Input to 50% Output CL = 1.0 nF)

Logic Input to Drive Output Rise

Logic Input to Drive Output Fall

Drive Output Rise Time (10% to 90%) CL = 1.0 nF t

Drive Output Fall Time (90% to 10%) CL = 1.0 nF t

NOTES: 1.Kelvin Ground must always be between VEE and VCC.

2.Low duty cycle pulse techniques are used during test to maintain the junction temperature as close to ambient as possible.

= –40°C for MC33153 T

T

low

= +105°C for MC33153

high

t

PLH(in/out)

t

PHL (in/out)

r

f

–

–

80

120

– 17 55 ns

– 17 55 ns

3.2

V

–

µA

500

100

V

2.5

–

V

1.0

–

ns

300

300

http://onsemi.com

2

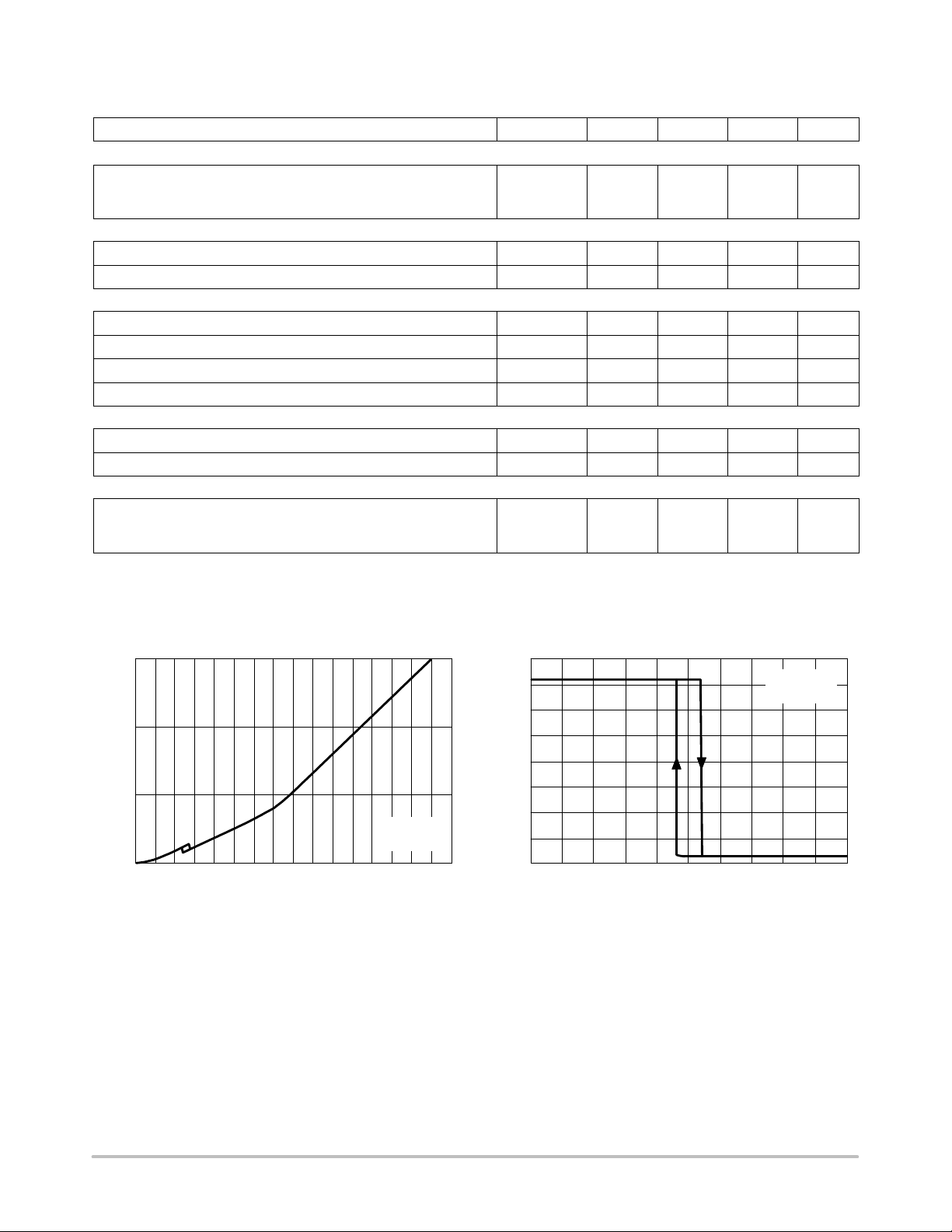

Page 3

MC33153

ELECTRICAL CHARACTERISTICS (continued) (V

= 25°C, for min/max values TA is the operating ambient temperature range that applies (Note 2), unless otherwise noted.)

T

A

= 15 V, VEE = 0 V, Kelvin Gnd connected to VEE. For typical values

CC

Characteristic UnitMaxTypMinSymbol

SWITCHING CHARACTERISTICS (continued)

Propagation Delay µs

Current Sense Input to Drive Output t

Fault Blanking/Desaturation Input to Drive Output t

P(OC)

P(FLT)

– 0.3 1.0

– 0.3 1.0

UVLO

Startup Voltage

Disable Voltage V

V

CC start

CC dis

11.3 12 12.6 V

10.4 11 11.7 V

COMPARATORS

Overcurrent Threshold Voltage (V

Short Circuit Threshold Voltage (V

Fault Blanking/Desaturation Threshold (V

> 7.0 V) V

Pin8

> 7.0 V) V

Pin8

> 100 mV) V

Pin1

Current Sense Input Current (VSI = 0 V) I

SOC

SSC

th(FLT)

SI

50 65 80 mV

100 130 160 mV

6.0 6.5 7.0 V

– –1.4 –10 µA

FAULT BLANKING/DESATURATION INPUT

Current Source (V

Discharge Current (V

Pin8

= 0 V, V

= 15 V, V

Pin8

= 0 V) I

Pin4

= 5.0 V) I

Pin4

chg

dschg

–200 –270 –300 µA

1.0 2.5 – mA

TOTAL DEVICE

Power Supply Current

Standby (V

Operating (C

NOTES: 1.Kelvin Ground must always be between VEE and VCC.

2.Low duty cycle pulse techniques are used during test to maintain the junction temperature as close to ambient as possible.

= VCC, Output Open)

Pin 4

= 1.0 nF, f = 20 kHz)

L

T

= –40°C for MC33153 T

low

= +105°C for MC33153

high

I

CC

–

–

7.2

7.9

14

20

mA

1.5

1.0

0.5

, INPUT CURRENT (mA)

in

I

0

0

2.0 4.0 6.0 8.0 10 12 14 16

Vin, INPUT VOLTAGE (V)

Figure 1. Input Current versus Input Voltage

VCC = 15 V

T

= 25°C

A

16

14

12

10

8.0

6.0

, OUTPUT VOLTAGE (V)

4.0

O

V

2.0

0

0

1.0 2.0 3.0 4.0

Vin, INPUT VOLTAGE (V)

Figure 2. Output Voltage versus Input Voltage

VCC = 15 V

T

= 25°C

A

5.0

http://onsemi.com

3

Page 4

MC33153

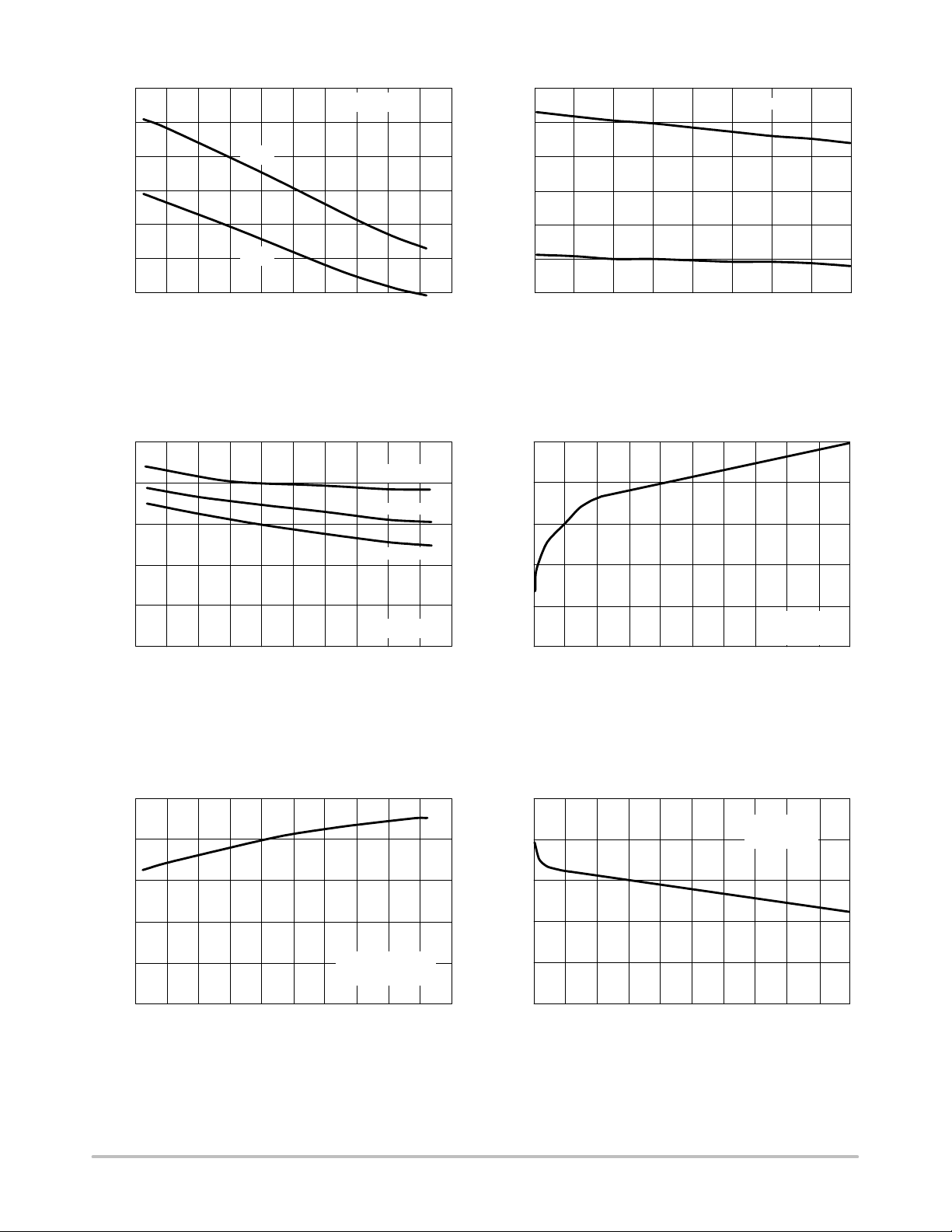

, INPUT THRESHOLD VOLTAGE (V)V

- V

3.2

VCC = 15 V

3.0

2.8

V

IH

2.6

2.4

2.2

IL

IH

2.0

-60

-40 -20 0 20 40 60 80 100 120 140

V

IL

T

, AMBIENT TEMPERATURE (°C)

A

Figure 3. Input Threshold Voltage

versus Temperature

2.5

I

= 1.0 A

2.0

Sink

, INPUT THRESHOLD VOLTAGE (V)V

- V

2.8

T

V

IH

= 25°C

A

2.7

2.6

2.5

2.4

V

2.3

IL

IH

2.2

12

13 14 15 16 17 18 19 20

IL

V

, SUPPLY VOLTAGE (V)

CC

Figure 4. Input Threshold Voltage

versus Supply V oltage

2.0

1.6

= 500 mA

1.5

1.2

1.0

0.5

, OUTPUT LOW STATE VOLTAGE (V)

OL

V

0

-60

14.0

13.9

13.8

13.7

13.6

, DRIVE OUTPUT HIGH STATE VOLTAGE (V)

13.5

OH

-60

V

= 250 mA

VCC = 15 V

-40 -20 0 20 40 60 80 100 120 140

T

, AMBIENT TEMPERATURE (°C)

A

Figure 5. Drive Output Low State Voltage

versus Temperature

VCC = 15 V

I

= 500 mA

Source

-40 -20 0 20 40 60 80 100 120 140

T

, AMBIENT TEMPERATURE (°C)

A

Figure 7. Drive Output High State Voltage

versus Temperature

0.8

0.4

, OUTPUT LOW STATE VOLTAGE (V)

OL

V

0

15.0

14.6

14.2

13.8

13.4

, DRIVE OUTPUT HIGH STATE VOLTAGE (V)

13.0

OH

V

0

0.2 0.4 0.6 0.8 1.0

, OUTPUT SINK CURRENT (A)

I

Sink

Figure 6. Drive Output Low State Voltage

versus Sink Current

VCC = 15 V

T

= 25°C

A

0

0.1 0.2 0.3 0.4 0.5

I

, OUTPUT SOURCE CURRENT (A)

Source

Figure 8. Drive Output High State Voltage

versus Source Current

T

= 25°C

A

VCC = 15 V

http://onsemi.com

4

Page 5

MC33153

0

16

14

12

10

8.0

6.0

4.0

, DRIVE OUTPUT VOLTAGE (V)

O

2.0

V

0

70

68

66

50

55 60 65 70 75 80

V

, CURRENT SENSE INPUT VOLTAGE (mV)

Pin 1

Figure 9. Drive Output Voltage

versus Current Sense Input Voltage

VCC = 15 V

V

= 0 V

Pin 4

V

> 7.0 V

Pin 8

T

= 25°C

A

VCC = 15 V

14

12

10

8.0

6.0

4.0

, FAULT OUTPUT VOLTAGE (V)

2.0

Pin 7

V

0

100

70

68

66

VCC = 15 V

V

= 0 V

Pin 4

V

> 7.0 V

Pin 8

T

= 25°C

A

110 120 130 140 150 16

V

, CURRENT SENSE INPUT VOLTAGE (mV)

Pin 1

Figure 10. Fault Output Voltage

versus Current Sense Input Voltage

T

= 25°C

A

64

62

, OVERCURRENT THRESHOLD VOLTAGE (mV)

60

-60

V

SOC

-40 -20 0 20 40 60 80 100 120 140

T

, AMBIENT TEMPERATURE (°C)

A

Figure 11. Overcurrent Protection Threshold

Voltage versus Temperature

135

130

, SHORT CIRCUIT THRESHOLD VOLTAGE (mV)

125

V

SSC

-40 -20 0 20 40 60 80 100 120 140 14 16 18 20

-60

T

, AMBIENT TEMPERATURE (°C)

A

Figure 13. Short Circuit Comparator Threshold

Voltage versus Temperature

VCC = 15 V

64

62

, OVERCURRENT THRESHOLD VOLTAGE (mV)

SOC

V

60

12

14 16 18 20

VCC, SUPPLY VOLTAGE (V)

Figure 12. Overcurrent Protection Threshold

Voltage versus Supply Voltage

135

130

, SHORT CIRCUIT THRESHOLD VOLTAGE (mV)

125

SSC

12

V

V

, SUPPLY VOLTAGE (V)

CC

Figure 14. Short Circuit Comparator Threshold

Voltage versus Supply Voltage

T

= 25°C

A

http://onsemi.com

5

Page 6

MC33153

)

0

µ

VCC = 15 V

T

= 25°C

A

-0.5

16

14

12

10

VCC = 15 V

V

= 0 V

Pin 4

V

> 100 mV

Pin 1

T

= 25°C

A

8.0

-1.0

6.0

4.0

, DRIVE OUTPUT VOLTAGE (V)

O

2.0

, CURRENT SENSE INPUT CURRENT ( A

SI

I

-1.5

0

4.0 6.0 8.0 10 12 14 162.0

V

, CURRENT SENSE INPUT VOLTAGE (V)

Pin 1

Figure 15. Current Sense Input Current

versus V oltage

6.6

VCC = 15 V

V

= 0 V

Pin 4

V

> 100 mV

Pin 1

V

0

6.0

6.2 6.4 6.6 6.8 7.0

V

, FAULT BLANKING/DESATURATION INPUT VOLTAGE (V)

Pin 8

Figure 16. Drive Output Voltage versus Fault

Blanking/Desaturation Input Voltage

6.6

V

Pin 4

V

Pin 1

T

= 25°C

A

= 0 V

> 100 mV

6.5

THRESHOLD VOLTAGE (V)

, FAULT BLANKING/DESATURATION

BDT

V

6.4

-60

-20 0 20 40 60 80 100 120 140-40

T

, AMBIENT TEMPERATURE (°C)

A

Figure 17. Fault Blanking/Desaturation Comparator

Threshold Voltage versus Temperature

-200

µ

, CURRENT SOURCE ( A)

I

-220

-240

-260

-280

chg

VCC = 15 V

V

Pin 8

= 0 V

6.5

THRESHOLD VOLTAGE (V)

, FAULT BLANKING/DESATURATION

BDT

V

6.4

12

14 16 18 20

V

, SUPPLY VOLTAGE (V)

CC

Figure 18. Fault Blanking/Desaturation Comparator

Threshold Voltage versus Supply Voltage

-200

V

= 0 V

µ

, CURRENT SOURCE ( A)I

-220

-240

-260

-280

chg

Pin 4

V

Pin 8

T

= 25°C

A

= 0 V

-300

-60

-20 0 20 40 60 80 100 120 140-40 15 2010

T

, AMBIENT TEMPERATURE (°C)

A

Figure 19. Fault Blanking/Desaturation Current

Source versus T emperature

-300

http://onsemi.com

6

5.0

V

, SUPPLY VOLTAGE (V)

CC

Figure 20. Fault Blanking/Desaturation Current

Source versus Supply Voltage

Page 7

MC33153

µ

, CURRENT SOURCE ( A)I

-200

-220

-240

-260

-280

chg

-300

1.0

0.8

0.6

VCC = 15 V

V

= 0 V

Pin 4

T

= 25°C

A

0

V

Pin 8

4.0 6.0 8.0 10 12 14 162.0 4.0 8.0 12 16

, FAULT BLANKING/DESATURATION INPUT VOLTAGE (V)

Figure 21. Fault Blanking/Desaturation

Current Source versus Input Voltage

VCC = 15 V

V

= 5.0 V

Pin 4

T

= 25°C

A

2.5

2.0

1.5

1.0

0.5

, DISCHARGE CURRENT (mA)I

dscg

-0.5

0

0

V

, FAULT BLANKING/DESATURATION INPUT VOLTAGE (V)

Pin 8

VCC = 15 V

V

Pin 4

T

= 25°C

A

Figure 22. Fault Blanking/Desaturation Discharge

Current versus Input Voltage

14.0

13.8

13.6

VCC = 15 V

V

= 0 V

Pin 4

V

= 1.0 V

Pin 1

Pin 8 = Open

T

= 25°C

A

= 5.0 V

0.4

, FAULT OUTPUT VOLTAGE (V)

0.2

Pin 7

V

0

16

14

12

10

8.0

6.0

4.0

, DRIVE OUTPUT VOLTAGE (V)

O

2.0

V

0

0

2.0 4.0 6.0 8.0 10

I

, OUTPUT SINK CURRENT (mA)

Sink

Figure 23. Fault Output Low State Voltage

versus Sink Current

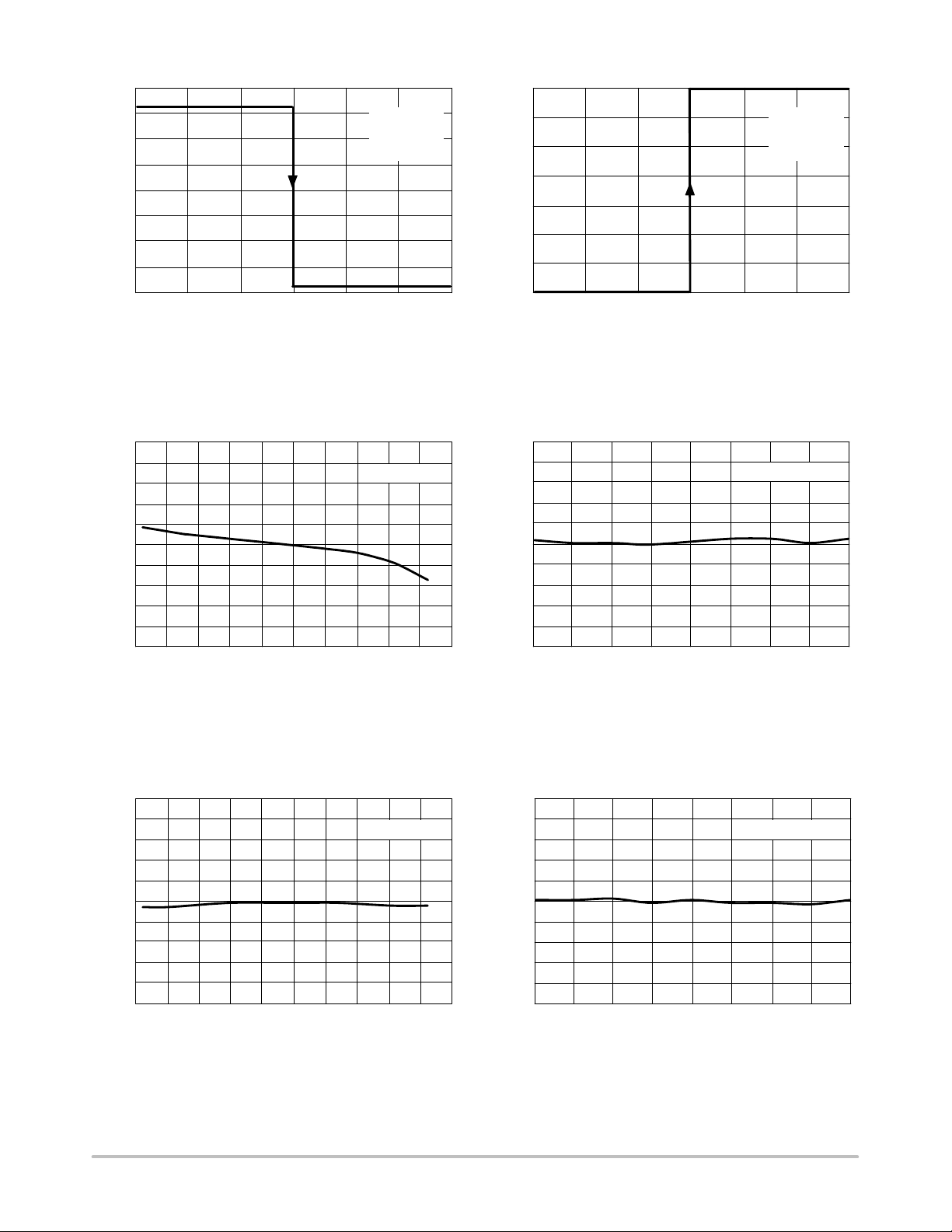

Turn-Off

Threshold

Startup

Threshold

10

11 12 13 14 15

VCC, SUPPLY VOLTAGE (V)

V

Pin 4

T

= 25°C

A

= 0 V

13.4

, FAULT OUTPUT VOLTAGE (V)

13.2

Pin 7

V

13.0

12.5

12.0

11.5

, UNDERVOLTAGE

11.0

th(UVLO)

LOCKOUT THRESHOLD (V)

V

10.5

0

4.0 6.0 8.0 10 12 14 16 18 202.0

I

, OUTPUT SOURCE CURRENT (mA)

Source

Figure 24. Fault Output High State Voltage

versus Source Current

Startup Threshold

VCC Increasing

Turn-Off Threshold

VCC Decreasing

-60

-20 20 60 100 140-40 0 40 80 120

T

, AMBIENT TEMPERATURE (°C)

A

Figure 25. Drive Output Voltage

versus Supply V oltage

Figure 26. UVLO Thresholds

versus Temperature

http://onsemi.com

7

Page 8

MC33153

, SUPPLY CURRENT (mA)

CC

I

8.0

6.0

4.0

2.0

10

Output High

Output Low

T

= 25°C

A

0

5.0

VCC, SUPPLY VOLTAGE (V)

Figure 27. Supply Current versus

10

8.0

6.0

4.0

, SUPPLY CURRENT (mA)

CC

I

2.0

0

-60

-4010 15

0 20 40 60 80 100 120 14020 -20

T

, AMBIENT TEMPERATURE (°C)

A

VCC = 15 V

V

Pin 4

Drive Output Open

Figure 28. Supply Current versus Temperature

= V

CC

Supply Voltage

, SUPPLY CURRENT (mA)

CC

I

80

60

40

20

VCC = 15 V

T

= 25°C

A

CL = 10 nF

= 5.0 nF

= 2.0 nF

= 1.0 nF

0

1.0

f, INPUT FREQUENCY (kHz)

Figure 29. Supply Current versus Input Frequency

OPERATING DESCRIPTION

GATE DRIVE

Controlling Switching Times

The most important design aspect of an IGBT gate drive

is optimization of the switching characteristics. The

switching characteristics are especially important in motor

control applications in which PWM transistors are used in a

bridge configuration. In these applications, the gate drive

circuit components should be selected to optimize turn–on,

turn–off and off–state impedance. A single resistor may be

used to control both turn–on and turn–off as shown in

Figure 30. However, the resistor value selected must be a

compromise in turn–on abruptness and turn–off losses.

Using a single resistor is normally suitable only for very low

frequency PWM. An optimized gate drive output stage is

shown in Figure 31. This circuit allows turn–on and turn–off

to be optimized separately. The turn–on resistor, R

on

provides control over the IGBT turn–on speed. In motor

control circuits, the resistor sets the turn–on di/dt that

controls how fast the free–wheel diode is cleared. The

interaction of the IGBT and free–wheeling diode determines

100010 100

the turn–on dv/dt. Excessive turn–on dv/dt is a common

problem in half–bridge circuits. The turn–off resistor, R

controls the turn–off speed and ensures that the IGBT

remains off under commutation stresses. Turn–off is critical

to obtain low switching losses. While IGBTs exhibit a fixed

minimum loss due to minority carrier recombination, a slow

gate drive will dominate the turn–off losses. This is

particularly true for fast IGBT s. It is also possible to turn–of f

an IGBT too fast. Excessive turn–off speed will result in

large overshoot voltages. Normally, the turn–off resistor is

a small fraction of the turn–on resistor.

The MC33153 contains a bipolar totem pole output stage

that is capable of sourcing 1.0 amp and sinking 2.0 amps

peak. This output also contains a pull down resistor to ensure

,

that the IGBT is off whenever there is insufficient V

MC33153.

In a PWM inverter, IGBTs are used in a half–bridge

configuration. Thus, at least one device is always off. While

CC

off

to the

,

http://onsemi.com

8

Page 9

MC33153

the IGBT is in the off–state, it will be subjected to changes

in voltage caused by the other devices. This is particularly

a problem when the opposite transistor turns on.

When the lower device is turned on, clearing the upper

diode, the turn–on dv/dt of the lower device appears across

the collector emitter of the upper device. To eliminate

shoot–through currents, it is necessary to provide a low sink

impedance to the device that is in the off–state. In most

applications the turn–off resistor can be made small enough

to hold off the device that is under commutation without

causing excessively fast turn–off speeds.

V

CC

R

Output

5

V

V

EE

EE

3

V

EE

Figure 30. Using a Single Gate Resistor

V

CC

R

Output

5

R

D

off

IGBT

g

IGBT

on

off

that the opto’s dv/dt capability is not exceeded. Like most

optoisolators, the HCPL4053 has an active low

open–collector output. Thus, when the LED is on, the output

will be low. The MC33153 has an inverting input pin to

interface directly with an optoisolator using a pull up

resistor. The input may also be interfaced directly to 5.0 V

CMOS logic or a microcontroller.

Optoisolator Output Fault

The MC33153 has an active high fault output. The fault

output may be easily interfaced to an optoisolator. While it

is important that all faults are properly reported, it is equally

important that no false signals are propagated. Again, a high

dv/dt optoisolator should be used.

The LED drive provides a resistor programmable current

of 10 to 20 mA when on, and provides a low impedance path

when off. An active high output, resistor, and small signal

diode provide an excellent LED driver. This circuit is shown

in Figure 32.

Short Circuit

Latch Output

Figure 32. Output Fault Optoisolator

V

CC

Q

7

V

V

EE

EE

V

V

EE

EE

3

V

EE

Figure 31. Using Separate Resistors

for Turn–On and Turn–Off

A negative bias voltage can be used to drive the IGBT into

the off–state. This is a practice carried over from bipolar

Darlington drives and is generally not required for IGBTs.

However, a negative bias will reduce the possibility of

shoot–through. The MC33153 has separate pins for V

EE

and

Kelvin Ground. This permits operation using a +15/–5.0 V

supply.

INTERFACING WITH OPTOISOLATORS

Isolated Input

The MC33153 may be used with an optically isolated

input. The optoisolator can be used to provide level shifting,

and if desired, isolation from ac line voltages. An

optoisolator with a very high dv/dt capability should be

used, such as the Hewlett Packard HCPL4053. The IGBT

gate turn–on resistor should be set large enough to ensure

UNDERVOLTAGE LOCKOUT

It is desirable to protect an IGBT from insufficient gate

voltage. IGBTs require 15 V on the gate to achieve the rated

on–voltage. At gate voltages below 13 V, the on–voltage

increases dramatically , especially at higher currents. At very

low gate voltages, below 10 V, the IGBT may operate in the

linear region and quickly overheat. Many PWM motor

drives use a bootstrap supply for the upper gate drive. The

UVLO provides protection for the IGBT in case the

bootstrap capacitor discharges.

The MC33153 will typically start up at about 12 V. The

UVLO circuit has about 1.0 V of hysteresis and will disable

the output if the supply voltage falls below about 11 V.

PROTECTION CIRCUITRY

Desaturation Protection

Bipolar Power circuits have commonly used what is

known as “Desaturation Detection”. This involves

monitoring the collector voltage and turning off the device

if this voltage rises above a certain limit. A bipolar transistor

will only conduct a certain amount of current for a given

base drive. When the base is overdriven, the device is in

http://onsemi.com

9

Page 10

MC33153

saturation. When the collector current rises above the knee,

the device pulls out of saturation. The maximum current the

device will conduct in the linear region is a function of the

base current and the dc current gain (hFE) of the transistor.

The output characteristics of an IGBT are similar to a

Bipolar device. However, the output current is a function of

gate voltage instead of current. The maximum current

depends on the gate voltage and the device type. IGBTs tend

to have a very high transconductance and a much higher

current density under a short circuit than a bipolar device.

Motor control IGBTs are designed for a lower current

density under shorted conditions and a longer short circuit

survival time.

The best method for detecting desaturation is the use of a

high voltage clamp diode and a comparator. The MC33153

has a Fault Blanking/Desaturation Comparator which

senses the collector voltage and provides an output

indicating when the device is not fully saturated. Diode D1

is an external high voltage diode with a rated voltage

comparable to the power device. When the IGBT is “on” and

saturated, D1 will pull down the voltage on the Fault

Blanking/Desaturation Input. When the IGBT pulls out of

saturation or is “off”, the c u r r e n t s o u r c e w ill pull up the input

and trip the comparator. The comparator threshold is 6.5 V,

allowing a maximum on–voltage of about 5.8 V.

A fault exists when the gate input is high and V

greater than the maximum allowable V

. The output of

CE(sat)

CE

is

the Desaturation Comparator is ANDed with the gate input

signal and fed into the Short Circuit and Overcurrent

Latches. The Overcurrent Latch will turn–off the IGBT for

the remainder of the cycle when a fault is detected. When

input goes high, both latches are reset. The reference voltage

is tied to the Kelvin Ground instead of the V

to make the

EE

threshold independent of negative gate bias. Note that for

proper operation of the Desaturation Comparator and the

Fault Output, the Current Sense Input must be biased above

the Overcurrent and Short Circuit Comparator thresholds.

This can be accomplished by connecting Pin 1 to V

V

Kelvin

Gnd

CC

V

ref

6.5 V

270 µA

V

CC

D1

8

V

EE

Desaturation

Comparator

Figure 33. Desaturation Detection

CC

.

The MC33153 also features a programmable fault

blanking time. During turn–on, the IGBT must clear the

opposing free–wheeling diode. The collector voltage will

remain high until the diode is cleared. Once the diode has

been cleared, the voltage will come down quickly to the

V

considerable ringing on the collector due to the C

of the device. Following turn–on, there is normally

CE(sat)

OSS

capacitance of the IGBTs and the parasitic wiring

inductance. The fault signal from the Desaturation

Comparator must be blanked sufficiently to allow the diode

to be cleared and the ringing to settle out.

The blanking function uses an NPN transistor to clamp the

comparator input when the gate input is low. When the input

is switched high, the clamp transistor will turn “off”,

allowing the internal current source to charge the blanking

capacitor. The time required for the blanking capacitor to

charge up from the on–voltage of the internal NPN transistor

to the trip voltage of the comparator is the blanking time.

If a short circuit occurs after the IGBT is turned on and

saturated, the delay time will be the time required for the

current source to charge up the blanking capacitor from the

V

level of the IGBT to the trip voltage of the

CE(sat)

comparator. Fault blanking can be disabled by leaving Pin 8

unconnected.

Sense IGBT Protection

Another approach to protecting the IGBT s is to sense the

emitter current using a current shunt or Sense IGBTs. This

method has the advantage of being able to use high gain

IGBTs which do not have any inherent short circuit

capability. Current sense IGBTs work as well as current

sense MOSFETs in most circumstances. However, the basic

problem of wo rking with very low sense voltages still exists.

Sense IGBTs sense current through the channel and are

therefore linear with respect to the collector current.

Because IGBTs have a very low incremental on–resistance,

sense IGBTs behave much like low–on resistance current

sense MOSFETs. The output voltage of a properly

terminated sense IGBT is very low, normally less than

100 mV.

The sense IGBT approach requires fault blanking to

prevent false tripping during turn–on. The sense IGBT also

requires that the sense signal is ignored while the gate is low.

This is because the mirror output normally produces large

transient voltages during both turn–on and turn–off due to

the collector to mirror capacitance. With non–sensing types

of IGBTs, a low resistance current shunt (5.0 to 50 mΩ) can

be used to sense the emitter current. When the output is an

actual short circuit, the inductance will be very low. Since

the blanking circuit provides a fixed minimum on–time, the

peak current under a short circuit can be very high. A short

circuit discern function is implemented by the second

comparator which has a higher trip voltage. The short circuit

signal is latched and appears at the Fault Output. When a

short circuit is detected, the IGBT should be turned–off for

several milliseconds allowing it to cool down before it is

turned back on. The sense circuit is very similar to the

desaturation circuit. It is possible to build a combination

circuit that provides protection for both Short Circuit

capable IGBTs and Sense IGBTs.

http://onsemi.com

10

Page 11

MC33153

APPLICATION INFORMATION

Figure 34 shows a basic IGBT driver application. When

driven from an optoisolator, an input pull up resistor is

required. This resistor value should be set to bias the output

transistor at the desired current. A decoupling capacitor

should be placed close to the IC to minimize switching noise.

A bootstrap diode may be used for a floating supply. If the

protection features are not required, then both the Fault

Blanking/Desaturation and Current Sense Inputs should

both be connected to the Kelvin Ground (Pin 2). When used

with a single supply , the Kelvin Ground and V

pins should

EE

be connected together. Separate gate resistors are

recommended to optimize the turn–on and turn–off drive.

18 V

B+

7

Fault

4

Input

6

V

CC

MC33153

V

EE

3

Bootstrap

Desat/

Blank

Output

Sense

Gnd

8

5

1

2

blanking capacitor should be connected from the

Desaturation pin to the V

pin. If a dual supply is used, the

EE

blanking capacitor should be connected to the Kelvin

Ground. The Current Sense Input should be tied high

because the two comparator outputs are ANDed together.

Although the reverse voltage on collector of the IGBT is

clamped to the emitter by the free–wheeling diode, there is

normally considerable inductance within the package itself.

A small resistor in series with the diode can be used to

protect the IC from reverse voltage transients.

18 V

6

Fault

MC33153

Input

V

CC

V

EE

3

7

4

Figure 36. Desaturation Application

Desat/

Blank

Output

Sense

Gnd

8

C

Blank

5

1

2

Figure 34. Basic Application

15 V

6

-5.0 V

7

4

Fault

MC33153

Input

V

CC

V

EE

3

Desat/

Blank

Output

Sense

Gnd

8

5

1

2

Figure 35. Dual Supply Application

When used in a dual supply application as in Figure 35, the

Kelvin Ground should be connected to the emitter of the

IGBT. If the protection features are not used, then both the

Fault Blanking/Desaturation and the Current Sense Inputs

should be connected to Ground. The input optoisolator

should always be referenced to V

EE

.

If desaturation protection is desired, a high voltage diode

is connected to the Fault Blanking/Desaturation pin. The

When using sense IGBTs or a sense resistor, the sense

voltage is applied to the Current Sense Input. The sense trip

voltages are referenced to the Kelvin Ground pin. The sense

voltage is very small, typically about 65 mV, and sensitive

to noise. Therefore, the sense and ground return conductors

should be routed as a differential pair. An RC filter is useful

in filtering any high frequency noise. A blanking capacitor

is connected from the blanking pin to V

. The stray

EE

capacitance on the blanking pin provides a very small level

of blanking if left open. The blanking pin should not be

grounded when using current sensing, that would disable the

sense. The blanking pin should never be tied high, that

would short out the clamp transistor.

18 V

6

Fault

MC33153

Input

V

CC

V

EE

3

7

4

Figure 37. Sense IGBT Application

Desat/

Blank

Output

Sense

Gnd

8

5

1

2

http://onsemi.com

11

Page 12

NOTE 2

–T–

SEATING

PLANE

H

58

–B–

14

F

–A–

C

N

D

G

0.13 (0.005) B

MC33153

PACKAGE DIMENSIONS

P SUFFIX

PLASTIC PACKAGE

CASE 626–05

ISSUE L

K

M

M

A

T

M

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

DIM MIN MAX MIN MAX

A 9.40 10.16 0.370 0.400

B 6.10 6.60 0.240 0.260

C 3.94 4.45 0.155 0.175

D 0.38 0.51 0.015 0.020

L

J

F 1.02 1.78 0.040 0.070

G 2.54 BSC 0.100 BSC

H 0.76 1.27 0.030 0.050

J 0.20 0.30 0.008 0.012

K 2.92 3.43 0.115 0.135

L 7.62 BSC 0.300 BSC

M --- 10 --- 10

N 0.76 1.01 0.030 0.040

INCHESMILLIMETERS

M

http://onsemi.com

12

Page 13

–Y–

–Z–

MC33153

PACKAGE DIMENSIONS

D SUFFIX

PLASTIC PACKAGE

CASE 751–07

(SO–8)

ISSUE W

–X–

A

58

B

1

S

0.25 (0.010)

4

M

M

Y

K

G

C

SEATING

PLANE

0.10 (0.004)

H

D

0.25 (0.010) Z

M

Y

SXS

N

X 45

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL IN

EXCESS OF THE D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

http://onsemi.com

13

Page 14

Notes

MC33153

http://onsemi.com

14

Page 15

Notes

MC33153

http://onsemi.com

15

Page 16

MC33153

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 Toll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (Mon–Fri 2:30pm to 7:00pm CET)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (Mon–Fri 2:00pm to 7:00pm CET)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (Mon–Fri 12:00pm to 5:00pm GMT)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, UK, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

Toll–Free from Mexico: Dial 01–800–288–2872 for Access –

then Dial 866–297–9322

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 1–303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Toll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

16

MC33153/D

Loading...

Loading...