Page 1

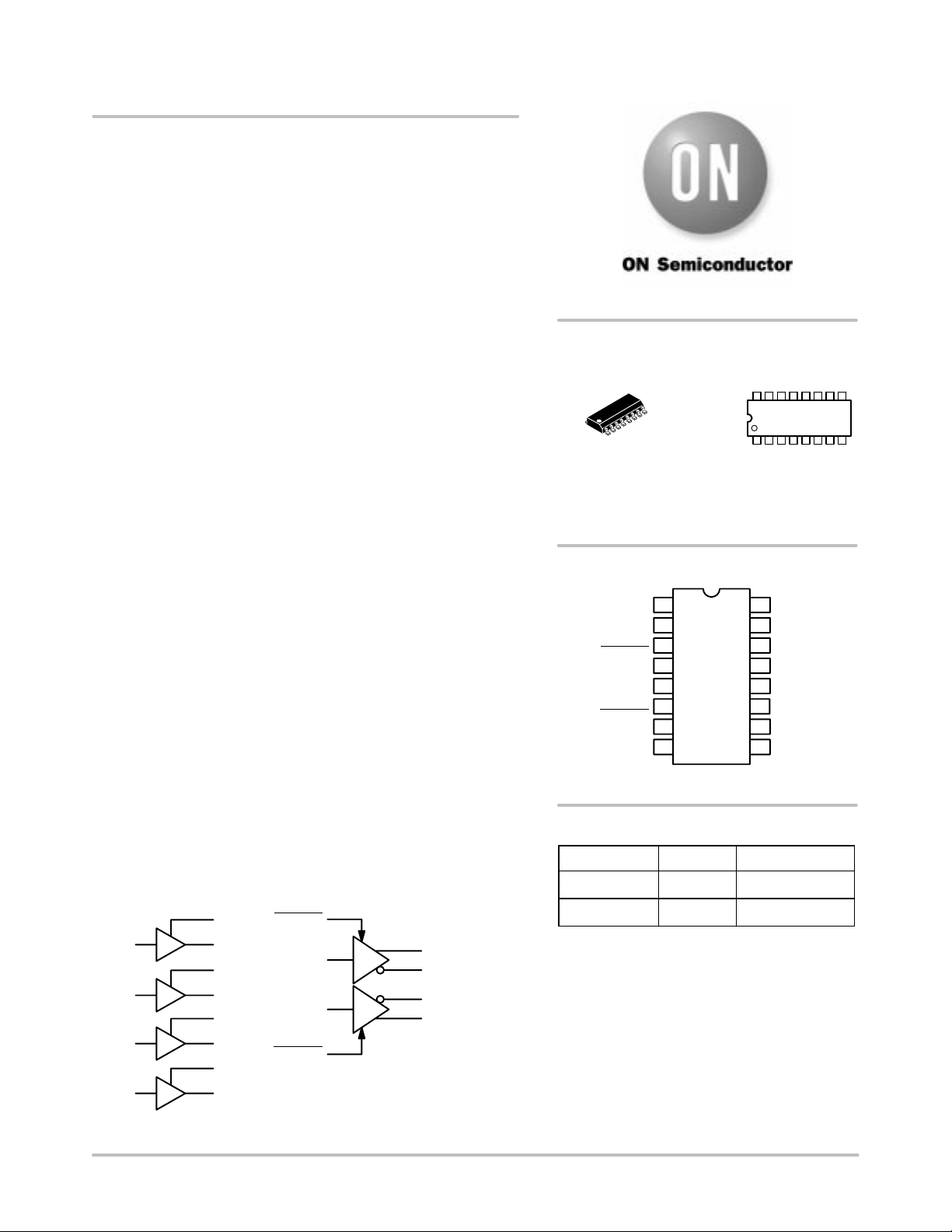

MC26LS30

Dual Differential

(EIA-422-A)/

Quad Single-Ended

(EIA-423-A) Line Drivers

The MC26LS30 is a low power Schottky set of line drivers which

can be configured as two differential drivers which comply with

EIA–422–A standards, or as four single–ended drivers which comply

with EIA–423–A standards. A mode select pin and appropriate choice

of power supplies determine the mode. Each driver can source and

sink currents in excess of 50 mA.

In the differential mode (EIA–422–A), the drivers can be used up to

10 Mbaud. A disable pin for each driver permits setting the outputs

into a high impedance mode within a +10 V common mode range.

In the single–ended mode (EIA–423–A), each driver has a slew rate

control pin which permits setting the slew rate of the output signal so

as to comply with EIA–423–A and FCC requirements and to reduce

crosstalk. When operated from symmetrical supplies (+5.0 V), the

outputs exhibit zero imbalance

The MC26LS30 is available in a 16–pin surface mount package.

Operating temperature range is –40° to +85°C.

16

http://onsemi.com

SO–16

D SUFFIX

1

CASE 751B

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W= Work Week

PIN CONNECTIONS

MARKING

DIAGRAM

16

MC26LS30D

AWLYWW

1

• Operates as Two Differential EIA–422–A Drivers, or Four

Single–Ended EIA–423–A Drivers

• High Impedance Outputs in Differential Mode

• Short Circuit Current Limit In Both Source and Sink Modes

• ±10 V Common Mode Range on High Impedance Outputs

• ±15 V Range on Inputs

• Low Current PNP Inputs Compatible with TTL, CMOS, and MOS

Outputs

• Individual Output Slew Rate Control in Single–Ended Mode

• Replacement for the AMD AM26LS30 and National Semiconductor

DS3691

Representative Block Diagrams

Single–Ended Mode

EIA–423–A

Input A

Input B

Input C

Input D

SR-A

Out A

SR-B

Out B

SR-C

Out C

SR-D

Out D

Differential Mode

Enable AB

Input A

Input D

Enable CD

V

CC

VEE-8

EIA–422–A

-1

Out A

Out B

Out C

Out D

Gnd-5

Mode-4

V

Input A

Input B/

Enable AB

Mode

Gnd

Input C/

Enable CD

Input D

V

1

CC

2

3

4

5

6

7

8

EE

(Top View)

16

15

14

13

12

11

10

9

ORDERING INFORMATION

Device Package Shipping

MC26LS30D 48 Units/RailSO–16

MC26LS30DR2 2500 Tape & ReelSO–16

SR-A

Output A

Output B

SR-B

SR-C

Output C

Output D

SR-D

Semiconductor Components Industries, LLC, 2000

July, 2000 – Rev. 1

1 Publication Order Number:

MC26LS30/D

Page 2

MC26LS30

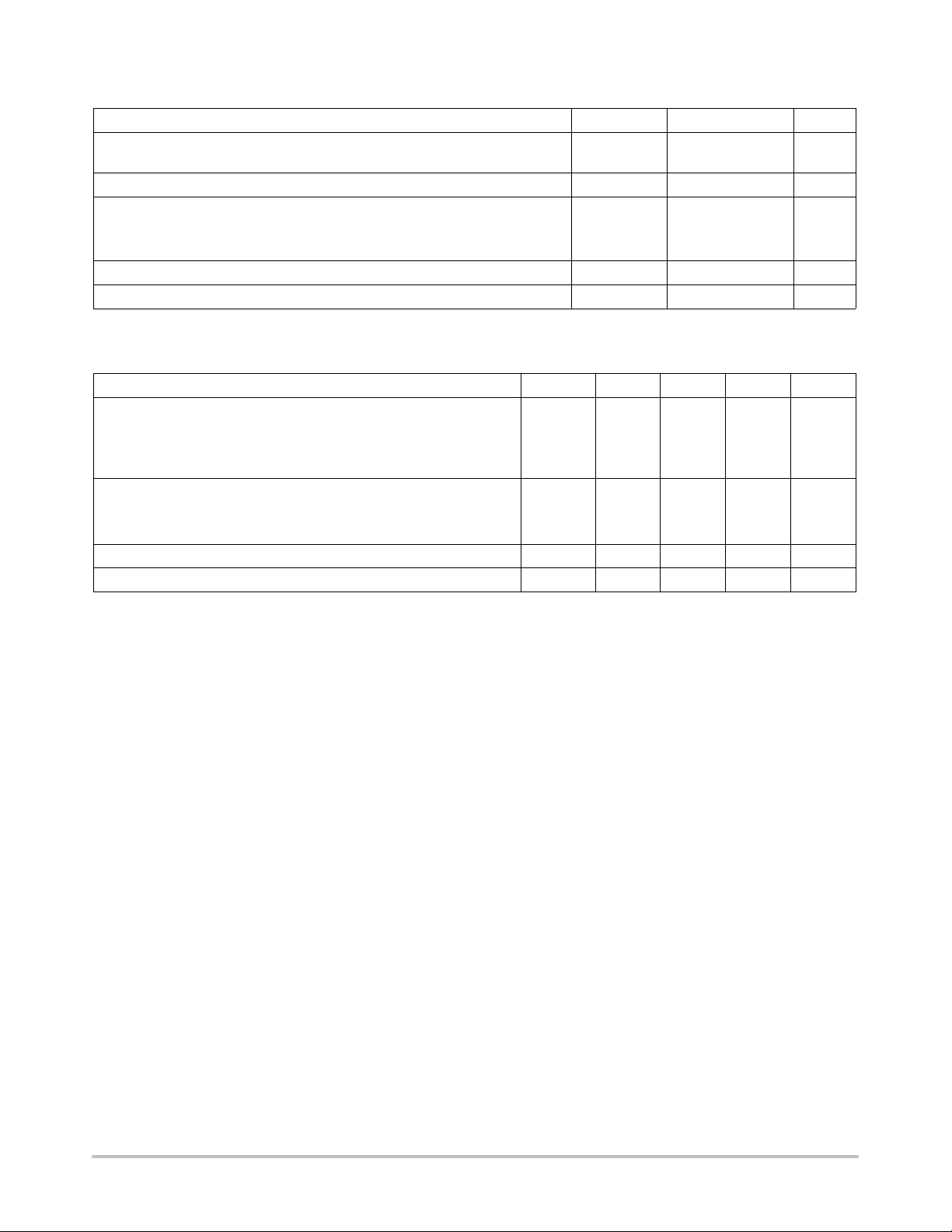

MAXIMUM OPERATING CONDITIONS (Pin numbers refer to SO–16 package only.)

Rating

Power Supply Voltage V

Input Voltage (All Inputs) V

Applied Output Voltage when in High Impedance Mode

= 5.0 V, Pin 4 = Logic 0, Pins 3, 6 = Logic 1)

(V

CC

Output Voltage with VCC, VEE = 0 V V

Output Current I

Junction Temperature T

Devices should not be operated at these limits. The “Recommended Operating Conditions” table provides conditions for actual device operation.

RECOMMENDED OPERATING CONDITIONS

Rating Symbol Min Typ Max Unit

Power Supply Voltage (Differential Mode) V

Power Supply Voltage (Single–Ended Mode) V

Input Voltage (All Inputs) V

Applied Output Voltage (when in High Impedance Mode) V

Applied Output Voltage, V

= 0 V

CC

Output Current I

Operating Ambient Temperature (See text) T

All limits are not necessarily functional concurrently.

V

V

Symbol Value Unit

–0.5, +7.0

–7.0, +0.5

–0.5, +20 Vdc

±15 Vdc

±15

Self limiting –

–65, +150 °C

5.0

0

+5.0

–5.0

CC

EE

CC

EE

za

zb

O

CC

V

EE

in

V

za

zb

O

J

+4.75

–0.5

+4.75

–5.25

in

0 – +15 Vdc

–10 – +10

–10 – +10

–65 – +65 mA

A

–40 – +85 °C

+5.25

+0.3

+5.25

–4.75

Vdc

Vdc

http://onsemi.com

2

Page 3

MC26LS30

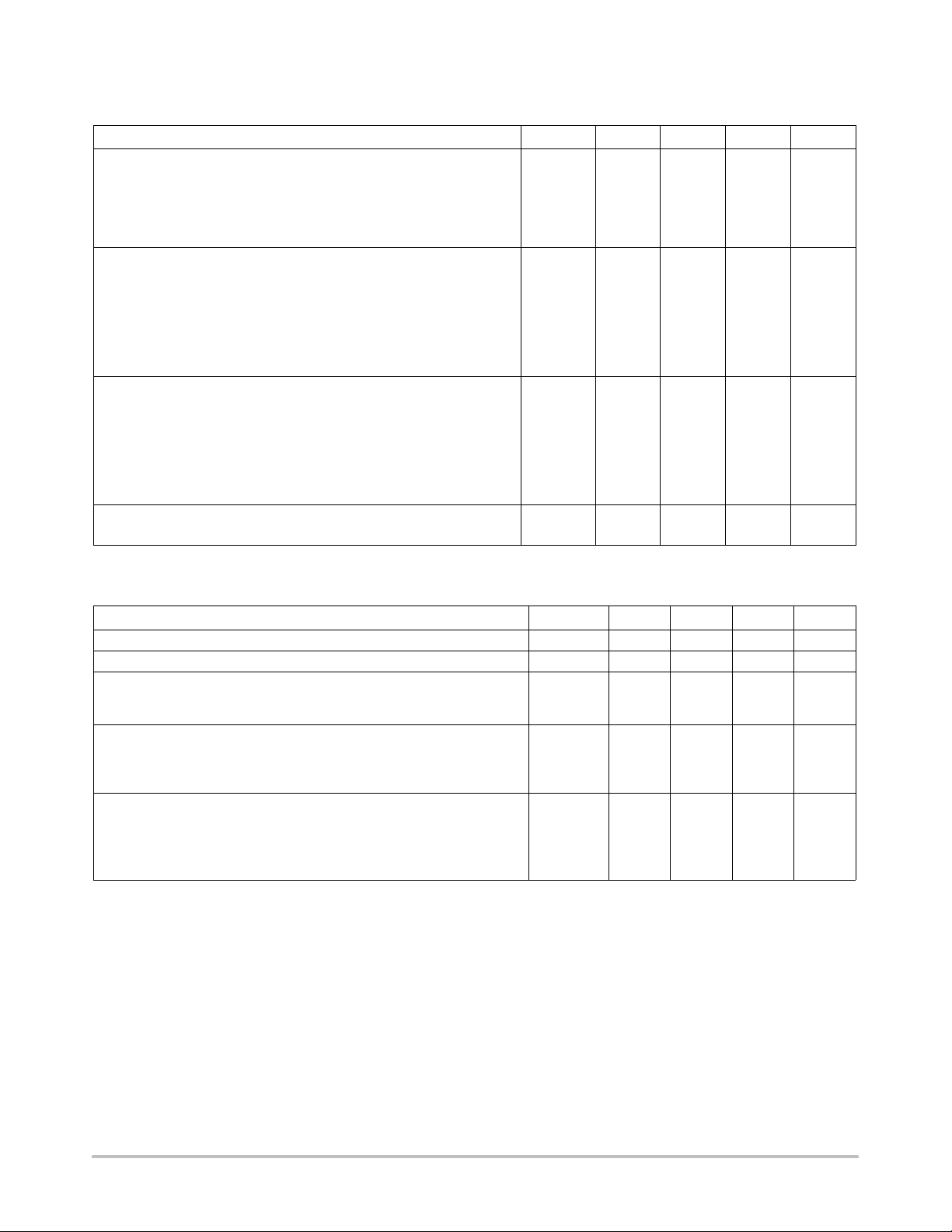

ELECTRICAL CHARACTERISTICS (EIA–422–A differential mode, Pin 4 0.8 V, –40°C T

V

= Gnd, unless otherwise noted. Pin numbers refer to SO–16 package only.)

EE

Characteristic

Output Voltage (see Figure 1)

Differential, R

Differential, R

Change in Differential Voltage, R

Offset Voltage, R

Change in Offset Voltage*, R

= ∞, VCC = 5.25 V

L

= 100 Ω, VCC = 4.75 V

L

= 100 Ω

L

L

= 100 Ω

L

= 100 Ω (Note 4.)

Output Current (each output)

Power Off Leakage, V

High Impedance Mode, V

= 0, –10 V VO +10 V

CC

= 5.25 V, –10 V VO +10 V

CC

Short Circuit Current (Note 2.)

High Output Shorted to Pin 5 (T

High Output Shorted to Pin 5 (–40°C T

Low Output Shorted to +6.0 V (T

Low Output Shorted to +6.0 V (–40°C T

= 25°C)

A

= 25°C)

A

+85°C)

A

+85°C)

A

Inputs

Low Level Voltage

High Level Voltage

Current @ V

Current @ V

Current @ V

Current, 0 V

Clamp Voltage (I

= 2.4 V

in

= 15 V

in

= 0.4 V

in

15 V, VCC = 0

in

= –12 mA)

in

Power Supply Current (VCC = +5.25 V, Outputs Open)

(0 Enable V

CC

)

Symbol Min Typ Max Unit

V

OD1

V

OD2

∆V

OD2

V

OS

∆VOS

I

OLK

I

OZ

I

SC–

I

SC–

I

SC+

I

SC+

V

IL

V

IH

I

IH

I

IHH

I

IL

I

IX

V

IK

I

CC

–

2.0

–

–

–

–100

–100

–150

–150

60

50

–

2.0

–

–

–200

–

–1.5

– 16 30

85°C, 4.75 V VCC 5.25 V,

A

4.2

2.6

10

2.5

10

0

0

–95

–

75

–

–

–

0

0

–8.0

0

–

6.0

–

400

3.0

400

+100

+100

–60

–50

150

150

0.8

–

40

100

–

–

–

Vdc

Vdc

mVdc

Vdc

mVdc

Vdc

Vdc

Vdc

µA

mA

µA

mA

TIMING CHARACTERISTICS (EIA–422–A differential mode, Pin 4 0.8 V, T

unless otherwise noted.)

Characteristic

Differential Output Rise Time (Figure 3) t

Differential Output Fall Time (Figure 3) t

Propagation Delay Time – Input to Differential Output

Input Low to High (Figure 3)

Input High to Low (Figure 3)

Skew Timing (Figure 3)

t

to t

PDH

Max to Min t

Max to Min t

Enable Timing (Figure 4)

Enable to Active High Differential Output

Enable to Active Low Differential Output

Enable to 3–State Output From Active High

Enable to 3–State Output From Active Low

1. All voltages measured with respect to Pin 5.

2. Only one output shorted at a time, for not more than 1 second.

3. Typical values established at +25°C, V

4. V

switched from 0.8 to 2.0 V.

in

5. Imbalance is the difference between V

for Each Driver

PDL

Within a Package

PDH

Within a Package

PDL

= +5.0 V, VEE = –5.0 V.

CC

with Vin 0.8 V and VO2 with Vin 2.0 V.

O2

= 25°C, VCC = 5.0 V, VEE = Gnd, (Notes 1. and 3.)

A

Symbol Min Typ Max Unit

r

f

– 70 200 ns

– 70 200 ns

ns

t

PDH

t

PDL

–

–

90

90

200

200

ns

t

SK1

t

SK2

t

SK3

–

–

–

9.0

2.0

2.0

–

–

–

ns

t

PZH

t

PZL

t

PHZ

t

PLZ

–

–

–

–

150

190

80

110

300

350

350

300

http://onsemi.com

3

Page 4

MC26LS30

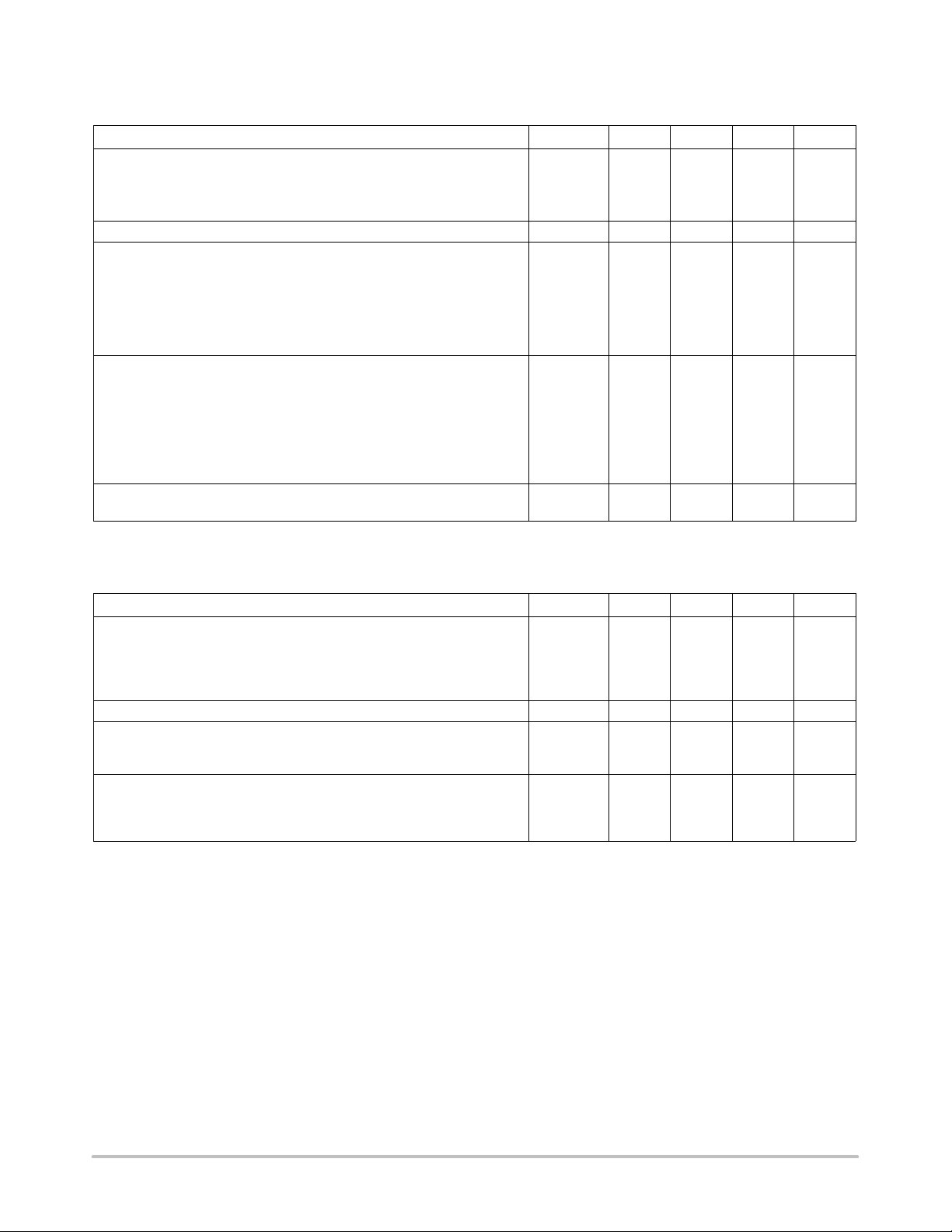

ELECTRICAL CHARACTERISTICS (EIA–423–A single–ended mode, Pin 4 2.0 V, –40°C T

|V

5.25 V, (Notes 1. and 3.) unless otherwise noted).

EE

Characteristic

Output Voltage (VCC = VEE = 4.75 V)

Single–Ended Voltage, R

Single–Ended Voltage, R

Voltage Imbalance (Note 5.), R

= ∞ (Figure 2)

L

= 450 Ω, (Figure 2)

L

= 450 Ω

L

Slew Control Current (Pins 16, 13, 12, 9) I

Output Current (Each Output)

Power Off Leakage, V

= VEE = 0, –6.0 V VO +6.0 V

CC

Short Circuit Current (Output Short to Ground, Note 2.)

0.8 V (TA = 25°C)

V

in

0.8 V (–40°C TA +85°C)

V

in

V

2.0 V (TA = 25°C)

in

2.0 V (–40°C TA +85°C)

V

in

Inputs

Low Level Voltage

High Level Voltage

Current @ V

Current @ V

Current @ V

Current, 0 V

Clamp Voltage (I

= 2.4 V

in

= 15 V

in

= 0.4 V

in

15 V, VCC = 0

in

= –12 mA)

in

Power Supply Current (Outputs Open)

= +5.25 V, VEE = –5.25 V, Vin = 0.4 V

V

CC

Symbol Min Typ Max Unit

VO1

V

∆V

SLEW

I

OLK

I

SC+

I

SC+

I

SC–

I

SC–

V

V

I

I

IHH

I

I

V

I

CC

I

EE

O2

O2

IL

IH

IH

IL

IX

IK

4.0

3.6

–

– ±120 – µA

–100

60

50

–150

–150

–

2.0

–

–

–200

–

–1.5

–

–22

85°C, 4.75 V V

A

4.2

3.95

0.05

0

80

–

–95

–

–

–

0

0

–8.0

0

–

17

–8.0

6.0

6.0

0.4

+100

150

150

–60

–50

0.8

–

40

100

–

–

–

30

–

CC

,

Vdc

µA

mA

Vdc

Vdc

µA

Vdc

mA

TIMING CHARACTERISTICS (EIA–423–A single–ended mode, Pin 4 2.0 V, T

3.) unless otherwise noted.)

Characteristic

Output Timing (Figure 5)

Output Rise Time, C

Output Fall Time, C

Output Rise Time, C

Output Fall Time, C

Rise Time Coefficient (Figure 16) C

Propagation Delay Time, Input to Single Ended Output (Figure 5)

Input Low to High, C

Input High to Low, C

Skew Timing, CC = 0 (Figure 5)

to t

t

PDH

Max to Min t

Max to Min t

for Each Driver

PDL

PDH

PDL

1. All voltages measured with respect to Pin 5.

2. Only one output shorted at a time, for not more than 1 second.

3. Typical values established at +25°C, V

4. V

switched from 0.8 to 2.0 V.

in

5. Imbalance is the difference between V

= 0

C

= 0

C

= 50 pF

C

= 50 pF

C

= 0

C

= 0

C

Within a Package

Within a Package

= +5.0 V, VEE = –5.0 V.

CC

with Vin 0.8 V and VO2 with Vin 2.0 V.

O2

= 25°C, VCC = 5.0 V, VEE = –5.0 V, (Notes 1. and

A

Symbol Min Typ Max Unit

t

r

t

f

t

r

t

f

rt

–

–

–

–

65

65

3.0

3.0

300

300

–

–

ns

µs

– 0.06 – µs/pF

ns

t

PDH

t

PDL

–

–

100

100

300

300

ns

t

SK4

t

SK5

t

SK6

–

–

–

15

2.0

5.0

–

–

–

http://onsemi.com

4

Page 5

Differential

+5.0

Gnd

00010000010110100

(EIA 422 A)

001X0100111Z0Z001

00X1100010Z1Z0011

00100000011001100

000100011X01100Z1

S g e ded

50

50

010000000100000

(EIA 423 A)

11100100001001000

11001001000010010

11000010010000100

V

in

(0.8 or 2.0 V)

Mode = 0

MC26LS30

T able 1

Inputs Outputs

Operation V

CC

Differential +5.0 Gnd 0 0 0 0 0 0 1 1 0

(EIA–422–A)

Single–Ended +5.0 –5.0 1 0 0 0 0 0 0 0 0

(EIA–423–A)

X 0 X X X X X X Z Z Z Z

X = Don’t Care

Z = High Impedance (Off)

V

CC

/2

R

L

V

OD2

RL/2

V

Mode A B C D A B C D

EE

1

V

CC

V

in

(0.8 or 2.0 V)

V

OS

Mode = 1

V

EE

1

1

0

1

Z

0

0

0

1

R

C

L

L

V

O

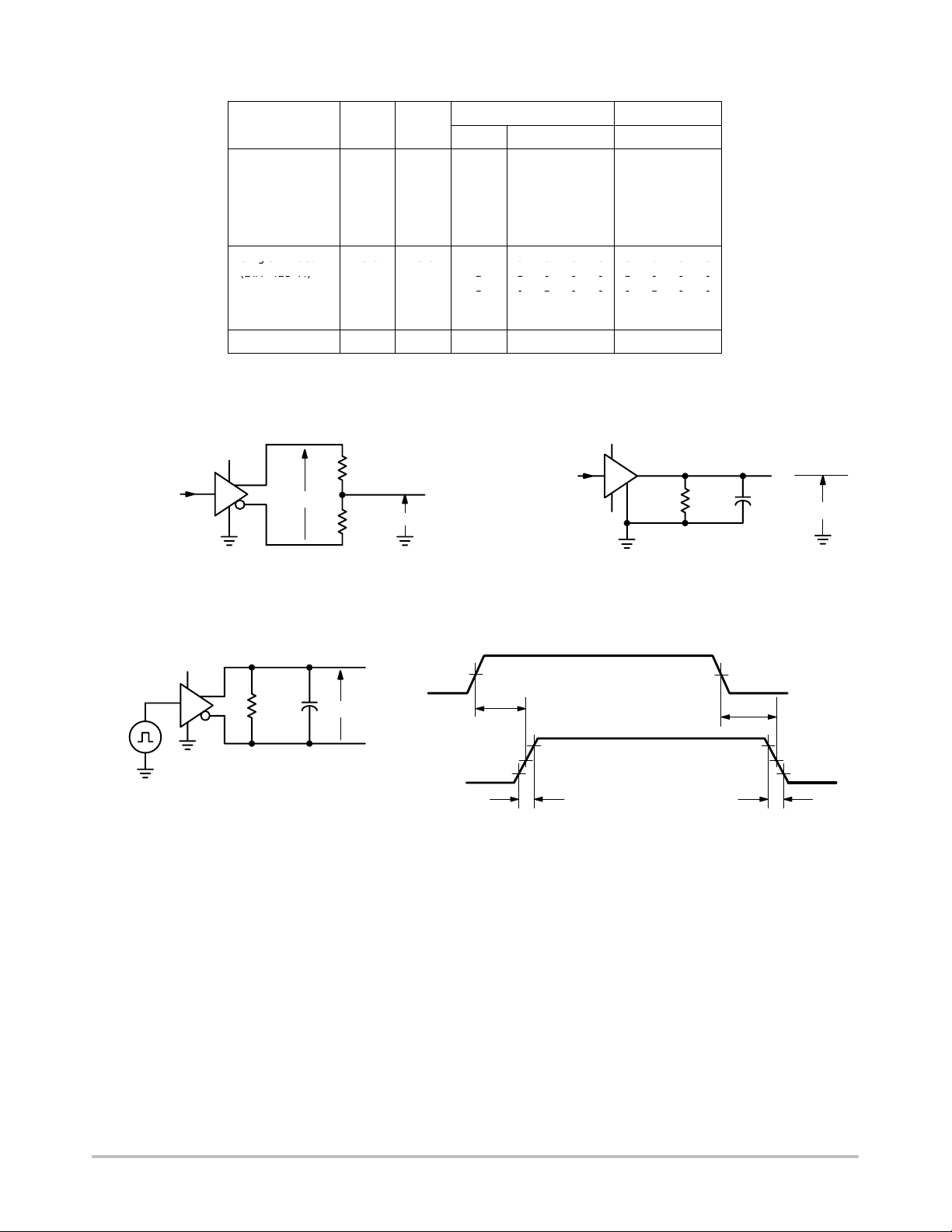

Figure 1. Differential Output Test Figure 2. Single–Ended Output Test

V

CC

V

in

100

500 pF

V

OD

S.G.

NOTES:

1. S.G. set to: f 1.0 MHz; duty cycle = 50%; t

2. t

= t

SK1

3. t

4. t

PDH–tPDL

computed by subtracting the shortest t

SK2

computed by subtracting the shortest t

SK3

for each driver.

Figure 3. Differential Mode Rise/Fall Time and Data Propagation Delay

, tf, 10 ns.

r

from the longest t

PDH

from the longest t

PDL

+3.0 V

V

in

1.5 V

t

PDH

90%

50%

V

out

10%

t

r

of the 2 drivers within a package.

PDH

of the 2 drivers within a package.

PDL

1.5 V

t

f

t

0 V

PDL

90%

50%

10%

http://onsemi.com

5

Page 6

MC26LS30

V

CC

V

0 or 3.0 V

V

in

S.G.

En

500 pF

450 Ω

R

L

V

SS

in

(Vin = Hi)

Output

Current

= Lo)

(V

in

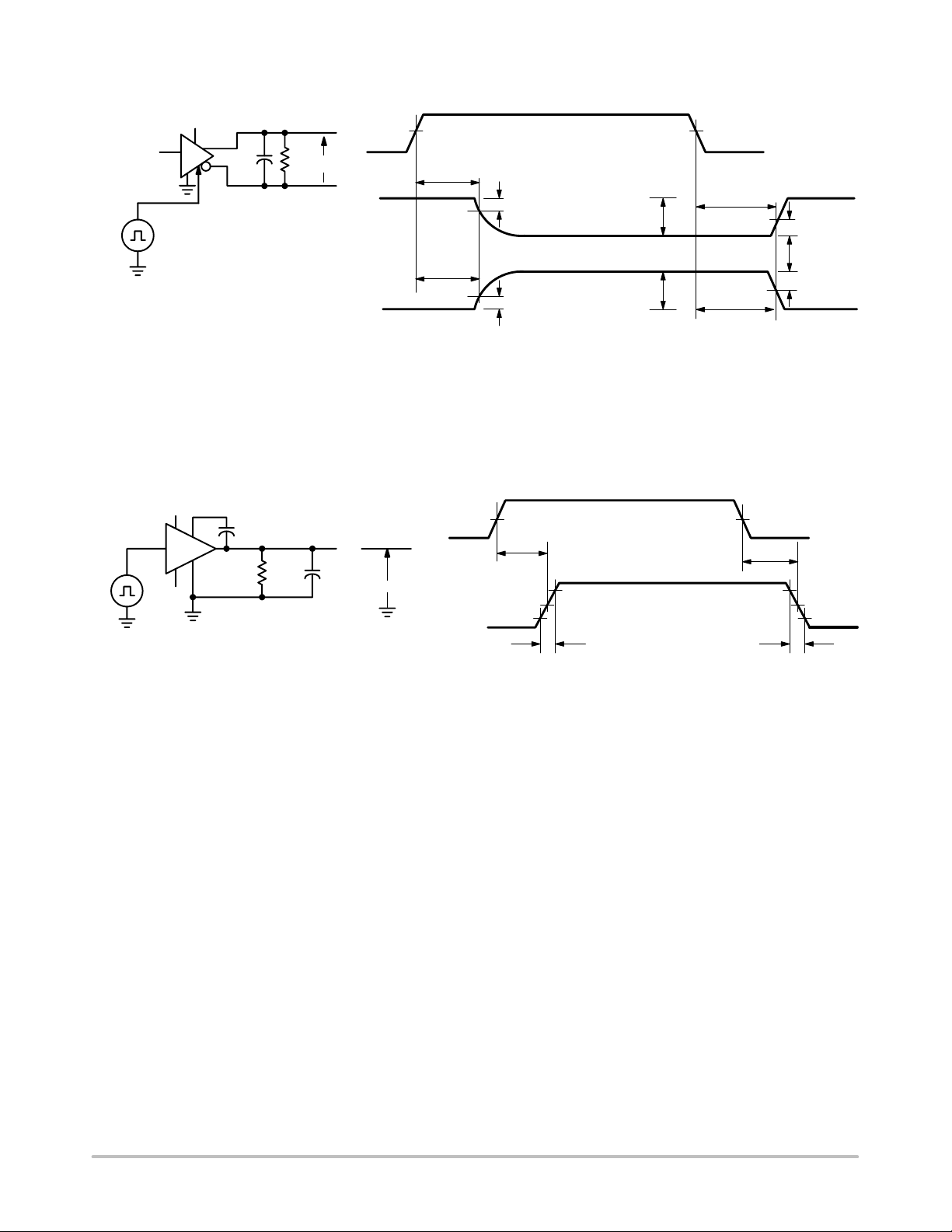

NOTES:

1. S.G. set to: f 1.0 MHz; duty cycle = 50%; t

, tf, 10 ns.

r

2. Above tests conducted by monitoring output current levels.

Figure 4. Differential Mode Enable Timing

V

CC

C

Vin

V

EE

S.G.

NOTES:

1. S.G. set to: f 100 kHz; duty cycle = 50%; t

2. t

= t

SK4

3. t

4. t

PDH–tPDL

computed by subtracting the shortest t

SK5

computed by subtracting the shortest t

SK6

C

450

for each driver.

500 pF

, tf, 10 ns.

r

PDH

PDL

V

O

from the longest t

from the longest t

1.5 V

t

t

PHZ

PLZ

0.1 VSS/R

L

0.1 V

SS/RL

V

in

1.5 V

t

PDH

90%

50%

V

out

10%

of the 4 drivers within a package.

PDH

of the 4 drivers within a package.

PDL

+3.0 V

1.5 V

0 V

t

PZH

VSS/R

VSS/R

L

L

t

PZL

0.5 VSS/R

0.5 VSS/R

L

L

+2.5 V

1.5 V

0 V

t

PDL

90%

50%

10%

t

r

t

f

Figure 5. Single–Ended Mode Rise/Fall Time and Data Propagation Delay

http://onsemi.com

6

Page 7

MC26LS30

5.0

4.0

3.0

2.0

, OUTPUT VOLTAGE (V)

OD

V

1.0

0

+100

+60

+20

-20

-60

, SHORT CIRCUIT CURRENT (mA)

SC

I

-100

Differential Mode

Mode = 0, VCC = 5.0 V

0.8 or

2.0 V

I

O

V

OD

, OUTPUT CURRENT (mA)

I

O

Figure 6. Differential Output Voltage

versus Load Current

Normally Low Output

Normally High Output

Differential Mode

Mode = 0, V

1.0

Vza, APPLIED OUTPUT VOLTAGE (V)

Figure 8. Short Circuit Current

versus Output Voltage

CC

= 5.0 V

40

Differential Mode

Mode = 0

Supply Current = Bias Current + Load Current

30

20

, BIAS CURRENT (mA)

B

VCC = 5.25 V

I

6050403020100

10

20

TOTAL LOAD CURRENT (mA)

1201008060040

Figure 7. Internal Bias Current

versus Load Current

+5.0

VCC = 0

0

-5.0

-10

-15

INPUT CURRENT A)

in

I

-20

6.05.04.03.02.00

-25

VCC = 5.0 V

Pins 2 to 4, 6, 7

-5.0 V VEE 0

Differential or

Single-Ended Mode

, INPUT VOLTAGE (V)

V

in

(Pin numbers refer to SO–16 package only.)

1513119.07.05.03.01.0-1.0

Figure 9. Input Current versus Input Voltage

4.5

4.0

3.5

, OUTPUT VOLTAGE (V)

OH

V

3.0

Single-Ended Mode

Mode = 1

VCC = 5.0 V, VEE = -5.0 V

Vin = 1

0

Figure 10. Output Voltage versus

I

, OUTPUT CURRENT (mA)

OH

Output Source Current

-3.25

-3.75

-4.25

, OUTPUT VOLTAGE (V)

OL

V

-4.75

-60-40-30 -50-20-10

0

http://onsemi.com

7

Single-Ended Mode

Mode = 1

VCC = 5.0 V, VEE = -5.0 V

Vin = 0

2010

I

, OUTPUT CURRENT (mA)

OL

Figure 11. Output Voltage versus

Output Sink Current

60504030

Page 8

MC26LS30

26

22

18

, BIAS CURRENT (mA)

B+

14

I

10

100

-20

-60

, SHORT CIRCUIT CURRENT (mA)

SC

I

-100

Single Ended Mode

Mode = 1

V

= 5.0 V, VEE = -5.0 V

CC

Supply Current = Bias Current + I

OH

Vin = LoVin = Hi

-80

I

OL

TOTAL LOAD CURRENT (mA)

Figure 12. Internal Positive Bias Current

versus Load Current

60

20

Single-Ended Mode

Mode = 1

VCC = 5.0 V, VEE = -5.0 V

Normally Low Output

Normally High Output

-2.0-4.0-6.0 2.0 4.0 6.0

V

, APPLIED OUTPUT VOLTAGE (V)

za

0

0

-5.0

-10

Vin = LoV

= Hi

in

, BIAS CURRENT (mA)

B-

-15

I

Single-Ended Mode

Mode = 1

VCC = 5.0 V, VEE = -5.0 V

Supply Current = Bias Current + I

I

-2400 -160240 160 80

OH

-20

I

OL

OL

-80 -2400 -160240 160 80

I

OH

TOTAL LOAD CURRENT (mA)

Figure 13. Internal Negative Bias Current

versus Load Current

110

Normally Low Output

Normally High Output to Ground

020 85

T

, AMBIENT TEMPERATURE (°C)

A

40

60-20

+ (mA)

SC

-90

- (mA) I

-100

SC

I

-110

90

70

Single or Differential Mode

VCC = 5.0 V, VEE = -5.0 V or Gnd

50

-40

Figure 14. Short Circuit Current

versus Output Voltage

1.0 k

Single-Ended Mode

Mode = 1

µ, t

VCC = 5.0 V, VEE = -5.0 V

100

, RISE/FALL TIME ( s)t

10

f

r

1.0

10

Figure 16. Rise/Fall Time versus Capacitance

100

C

, CAPACITANCE (pF)

C

http://onsemi.com

8

Figure 15. Short Circuit Current

versus

Temperature

1.0 k

10 k

Page 9

MC26LS30

APPLICATIONS INFORMATION

(Pin numbers refer to SO–16 package only.)

Description

The MC26LS30 is a dual function line driver – it can be

configured as two differential output drivers which comply

with EIA–422–A Standard, or as four single–ended drivers

which comply with EIA–423–A Standard. The mode of

operation is selected with the Mode pin (Pin 4) and

appropriate power supplies (see Table 1). Each of the four

outputs is capable of sourcing and sinking 60 to 7 0 m A while

providing sufficient voltage to ensure proper data

transmission.

As differential drivers, data rates to 10 Mbaud can be

transmitted over a twisted pair for a distance determined by

the cable characteristics. EIA–422–A Standard provides

guidelines for cable length versus data rate. The advantage

of a differential (balanced) system over a single–ended

system is greater noise immunity, common mode rejection,

and higher data rates.

Where extraneous noise sources are not a problem, the

MC26LS30 may be configured as four single–ended drivers

transmitting data rates to 100 Kbaud. Crosstalk among wires

within a cable is controlled by the use of the slew rate control

pins on the MC26LS30.

Mode Selection (Differential Mode)

In this mode (Pins 4 and 8 at ground), only a +5.0 V supply

±5% is required at VCC. Pins 2 and 7 are the driver inputs,

while Pins 10, 11, 14 and 15 are the outputs (see Block

Diagram on page 1). The two outputs of a driver are always

complementary and the differential voltage available at each

pair of outputs is shown in Figure 6 for V

= 5.0 V. The

CC

differential output voltage will vary directly with VCC. A

“high” output can only source current, while a “low” output

can only sink current (except for short circuit current – see

Figure 8).

The two outputs will be in a high impedance mode when

the respective Enable input (Pin 3 or 6) is high, or if V

CC

1.1 V. Output leakage current over a common mode range of

± 10 V is typically less than 1.0 µA.

The outputs have short circuit current limiting, typically,

less than 100 mA over a voltage range of 0 to +6.0 V (see

Figure 8). Short circuits should not be allowed to last

indefinitely as the IC may be damaged.

Pins 9, 12, 13 and 16 are not normally used when in this

mode, and should be left open.

(Single–Ended Mode)

In this mode (Pin 4 ≥ 2.0 V) VCC requires +5.0 V, and V

EE

requires –5.0 V, both ±5.0%. Pins 2, 3, 6, and 7 are inputs for

the four drivers, and Pins 15, 14, 11, and 10 (respectively)

are the outputs. The four drivers are independent of each

other, and each output will be at a positive or a negative

voltage depending on its input state, the load current, and the

supply voltage. Figures 10 & 11 indicate the high and low

output voltages for V

= 5.0 V, and VEE = –5.0 V. The graph

CC

of Figure 10 will vary directly with VCC, and the graph of

Figure 11 will vary directly with VEE. A “high” output can

only source current, while a “low” output can only sink

current (except short circuit current – see Figure 14).

The outputs will be in a high impedance mode only if

V

1.1 V. Changing VEE to 0 V does not set the outputs

CC

to a high impedance mode. Leakage current over a common

mode range of ±10 V is typically less than 1.0 µA.

The outputs have short circuit current limiting, typically

less than 100 mA over a voltage range of ±6.0 V (see Figure

14). Short circuits should not be allowed to last indefinitely

as the IC may be damaged.

Capacitors connected between Pins 9, 12, 13, and 16 and

their respective outputs will provide slew rate limiting of the

output transition. Figure 16 indicates the required capacitor

value to obtain a desired rise or fall time (measured between

the 10% and 90% points). The positive and negative

transition times will be within ≈ ±5% of each other. Each

output may be set to a different slew rate if desired.

Inputs

The five inputs determine the state of the outputs in

accordance with Table 1. All inputs (regardless of the

operating mode) have a nominal threshold of +1.3 V, and

their voltage must be kept within a range of 0 V to +15 V for

proper operation. If an input is taken more than 0.3 V below

ground, excessive currents will flow, and the proper

operation of the drivers will be affected. An open pin is

equivalent to a logic high, but good design practices dictate

that inputs should never be left open. Unused inputs should

be connected to ground. The characteristics of the inputs are

shown in Figure 9.

Power Supplies

VCC requires +5.0 V, ±5%, regardless of the mode of

operation. The supply current is determined by the IC’s

internal bias requirements and the total load current. The

internally required current is a function of the load current

and is shown in Figure 7 for the differential mode.

In the single–ended mode, V

must be –5.0 V, ±5% in

EE

order to comply with EIA–423–A standards. Figures 12 and

13 indicate the internally required bias currents as a function

of total load current (the sum of the four output loads). The

discontinuity at 0 load current exists due to a change in bias

current when the inputs are switched. The supply currents

vary ≈ ± 2.0 mA as V

and VEE are varied from 4.75 V

CC

to 5.25 V.

Sequencing of the supplies during power–up/

power–down is not required.

Bypass capacitors (0.1 µF minimum on each supply pin)

are recommended to ensure proper operation. Capacitors

reduce noise induced onto the supply lines by the switching

action of the drivers, particularly where long P.C. board

tracks are involved. Additionally, the capacitors help absorb

http://onsemi.com

9

Page 10

MC26LS30

transients induced onto the drivers’ outputs from the

external cable (from ESD, motor noise, nearby computers,

etc.).

Operating Temperature Range

The maximum ambient operating temperature, listed as

+85°C, is actually a function of the system use (i.e.,

specifically how many drivers within a package are used)

and at what current levels they are operating. The maximum

power which may be dissipated within the package is

determined by:

T

T

where R

P

Dmax

= package thermal resistance which is typically:

JA

θ

Jmax

R

A

JA

120°C/W for the SOIC (D) package,

T

= max. allowable junction temperature (150°C)

Jmax

TA = ambient air temperature near the IC package.

1) Differential Mode Power Dissipation

For the differential mode, the power dissipated within the

package is calculated from:

PD [(VCC VOD) IO] (each driver) (VCC IB)

where: VCC= the supply voltage

VOD= is taken from Figure 6 for the known

value of I

I

= the internal bias current (Figure 7)

B

O

As indicated in the equation, the first term (in brackets) must

be calculated and summed for each of the two drivers, while

the last term is common to the entire package. Note that the

term (VCC –VOD) is constant for a given value of IO and does

not vary with VCC. For an application involving the

following conditions:

TA = +85°C, IO = –60 mA (each driver), VCC = 5.25 V, the

suitability of the package types is calculated as follows.

The power dissipated is:

PD [3.0V 60 mA 2] (5.25 V 18 mA)

PD 454 mW

The junction temperature calculates to:

TJ 85°C (0.454 W 120° CW) 139°C for the

SOIC package.

Since the maximum allowable junction temperature is not

exceeded in any of the above cases, either package can be

used in this application.

2) Single–Ended Mode Power Dissipation

For the single–ended mode, the power dissipated within

the package is calculated from:

P

[(

D

I

O

(

IB V

(

VCC V

CC

OH

)(

)](

IB V

each driver

EE

)

)

The above equation assumes IO has the same magnitude

for both output states, and makes use of the fact that the

absolute value of the graphs of Figures 10 and 11 are nearly

identical. IB+ and IB– are obtained from the right half of

Figures 12 and 13, and (V

Figure 10. Note that the term (V

– VOH) can be obtained from

CC

– VOH) is constant for a

CC

given value of IO and does not vary with VCC. For an

application involving the following conditions:

TA = +85°C, IO = –60 mA (each driver), VCC = 5.25 V,

V

= –5.25 V, the suitability of the package types is

EE

calculated as follows.

The power dissipated is:

(

P

24 mA 5.25 V

D

[

60 mA 1.45 V 4.0

PD 490 mW

)(

3.0 mA 5.25 V

]

)

The junction temperature calculates to:

TJ 85°C (0.490 W 120° CW) 144°C for the

SOIC package.

Since the maximum allowable junction temperature is not

exceeded in any of the above cases, either package can be

used in this application.

http://onsemi.com

10

Page 11

MC26LS30

SYSTEM EXAMPLES

(Pin numbers refer to SO–16 package only.)

Differential System

An example of a typical EIA–422–A system is shown in

Figure 17. Although EIA–422–A does not specifically

address multiple driver situations, the MC26LS30 can be

used in this manner since the outputs can be put into a high

impedance mode. It is, however, the system designer’s

responsibility to ensure the Enable pins are properly

controlled so a s t o p revent t wo d rivers o n t he s ame c able f rom

being “on” at the same time.

The limit on the number of receivers and drivers which

may be connected on one system is determined by the input

current of each receiver, the maximum leakage current of

each “off” driver, and the DC current through each

terminating resistor. The sum of these currents must not

exceed the capability of the “on” driver (≈60 mA). If the

cable is of any significant length, with receivers at various

points along its length, the common mode voltage may vary

along its length, and this parameter must be considered when

calculating the maximum driver current.

The cable requirements are defined not only by the AC

characteristics and t he d ata r ate, b ut also by t he D C r esistance.

The maximum resistance must be such that the minimum

voltage across any receiver inputs is never l ess t han 2 00 m V.

The ground terminals of each driver and receiver in Figure

17 must be connected together by a dedicated wire (or the

shield) in the cable to provide a common reference. Chassis

grounds or power line grounds should not be relied on for

this common connection as they may generate significant

common mode differences. Additionally, they usually do

not provide a sufficiently low impedance at the frequencies

of interest.

Single–Ended System

An example of a typical EIA–423–A system is shown in

Figure 18. Multiple drivers on a single data line are not

possible since the drivers cannot be put into a high

impedance mode. Although each driver is shown connected

to a single receiver, multiple receivers can be driven from a

single driver as long as the total load current of the receivers

and the terminating resistor does not exceed the capability

of the driver (≈60 mA). If the cable is of any significant

length, with receivers at various points along its length, the

common mode voltage may vary along its length, and this

parameter must be considered when calculating the

maximum driver current.

The cable requirements are defined not only by the AC

characteristics and the data rate, but also by the DC

resistance. The maximum resistance must be such that the

minimum voltage across any receiver inputs is never less

than 200 mV.

The ground terminals of each driver and receiver in

Figure 18 must be connected together by a dedicated wire

(or the shield) in the cable so as to provide a common

reference. Chassis grounds or power line grounds should not

be relied on for this common connection as they may

generate significant common mode differences.

Additionally , they usually do not provide a sufficiently low

impedance at the frequencies of interest.

Additional Modes of Operation

If compliance with EIA–422–A or EIA–423–A Standard

is not required in a particular application, the MC26LS30

can be operated in two other modes.

1) The device may be operated in the differential mode

(Pin 4 = 0) with VEE connected to any voltage between

ground and –5.25 V. Outputs in the low state will be

referenced to VEE, resulting in a differential output voltage

greater than that shown in Figure 6. The Enable pins will

operate the same as previously described.

2) The device may be operated in the single–ended mode

(Pin 4 = 1) with V

connected to any voltage between

EE

ground and –5.25 V. Outputs in the high state will be at a

voltage as shown in Figure 10, while outputs in a low state

will be referenced to V

Termination Resistors

EE

.

Transmission line theory states that, in order to preserve

the shape and integrity of a waveform traveling along a

cable, the cable must be terminated in an impedance equal

to its characteristic impedance. In a system such as that

depicted in Figure 17, in which data can travel in both

directions, both physical ends of the cable must be

terminated. Stubs leading to each receiver and driver should

be as short as possible.

In a system such as that depicted in Figure 18, in which

data normally travels in one direction only, a terminator is

theoretically required only at the receiving end of the cable.

However, if the cable is in a location where noise spikes of

several volts can be induced onto it, then a terminator

(preferably a series resistor) should be placed at the driver

end to prevent damage to the driver.

Leaving off the terminations will generally result in

reflections which can have amplitudes of several volts above

V

or several volts below ground or VEE. These

CC

overshoots/undershoots can disrupt the driver and/or

receiver, create false data, and in some cases, damage

components on the bus.

http://onsemi.com

11

Page 12

En

MC26LS30

R

TTL

En

R

DTTLTTL

TTL

DR

T

En

TTL

D

En

TTL

D

R

T

En

D

TTL

TTL

R

NOTES:

1. Terminating resistors R

should be located at the physical ends of the cable.

T

2. Stubs should be as short as possible.

3. Receivers = AM26LS32, MC3486, SN75173 or SN75175.

4. Circuit grounds must be connected together through a dedicated wire.

TTL

R

En

TTL

R

TTL

D

Twisted

Pair

TTL

TTL

TTL

TTL

D

D

D

D

MC26LS30

Figure 17. EIA–422–A Example

C

C

R

T

C

C

R

T

C

C

R

T

C

C

R

T

+

-

+

-

+

-

+

R

-

TTLR

TTLR

TTLR

TTL

AM26LS32, MC3486, SN75173, or SN75175

Figure 18. EIA–423–A Example

http://onsemi.com

12

Page 13

–T–

–A–

16 9

–B–

18

G

K

C

SEATING

PLANE

D

16 PL

0.25 (0.010) A

M

S

B

T

S

MC26LS30

PACKAGE DIMENSIONS

SO–16

D SUFFIX

CASE 751B–05

ISSUE J

8 PLP

M

0.25 (0.010) B

M

S

X 45

R

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

DIM MIN MAX MIN MAX

F

J

A 9.80 10.00 0.386 0.393

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

INCHESMILLIMETERS

http://onsemi.com

13

Page 14

Notes

MC26LS30

http://onsemi.com

14

Page 15

Notes

MC26LS30

http://onsemi.com

15

Page 16

MC26LS30

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 Toll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (Mon–Fri 2:30pm to 7:00pm CET)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (Mon–Fri 2:00pm to 7:00pm CET)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (Mon–Fri 12:00pm to 5:00pm GMT)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

Toll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

http://onsemi.com

16

MC26LS30/D

Page 17

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...