Page 1

BLDC Motor Driver,

f

2

Single-Phase, 12 V

Advance Information

LV8314C

INTRODUCTION

Overview

The LV8314C is the driver for 12 V single phase BLDC motor. Its

target output duty−cycle can be set by input PWM duty−cycle. The

output duty−cycle curve setting can be stored to the internal

nonvolatile memory (NVM). In addition, lead−angle can also be

adjusted by the configuration saved in the internal NVM. The internal

NVM can be programmed by a dedicated GUI. Thus, it can drive

various kinds of motors at high efficiency and low noise.

Features

• Selectable Soft Start or Direct Output PWM Duty Control in Start−up

• Single−phase Full Wave Driver with Open-loop Output Duty Control

• Embedded Power FETs, Iomax [peak] = 1.0 A

• PWM Duty−cycle Input (7 kHz to 40 kHz)

• PWM Soft Switching Phase Transition

• Soft Switching Width Adjustment (Rise and Fall Individually)

• Soft PWM Duty−cycle Transitions (Changing the Target Output

Duty−cycle Gradually)

• Built−in Current Limit Function and Over Current Protection

Function

• Built In Thermal Protection Function

• Built−in Locked Rotor Protection and Automatic Recovery Function

• FG Signal Output Frequency Selectable (1 Time, 2 Times or

0.5 Times Hall Input Frequency)

• RD Signal Polarity Selectable

• FG or RD Signal Output Selectable

• Dynamic Lead Angle Adjustment with Respect to Rotation Speed

• Parameter Setting by SPI Communication

• Embedded EEPROM as NVM

• Parameter Setting to the NVM

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

Typical Applications

• Circulation Fan in Refrigerator

www.onsemi.com

14

1

TSSOP−14 WB

CASE 948G

MARKING DIAGRAM

14

LV83

14C

ALYW

1

LV8314C = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

PIN ASSIGNMENT

1

OUT1

2

PVCC

3

VCC

4

REG

5

VDD

6

IN1

7

IN2 FG

14

RF

13

TSL2

12

OUT

11

GND

10

TSL

9

PWM

8

This document contains information on a new product. Specifications and information

herein are subject to change without notice.

© Semiconductor Components Industries, LLC, 2020

January , 2021 − Rev. P5

1 Publication Order Number:

(Top view)

ORDERING INFORMATION

See detailed ordering and shipping information on page 26 o

this data sheet.

LV8314C/D

Page 2

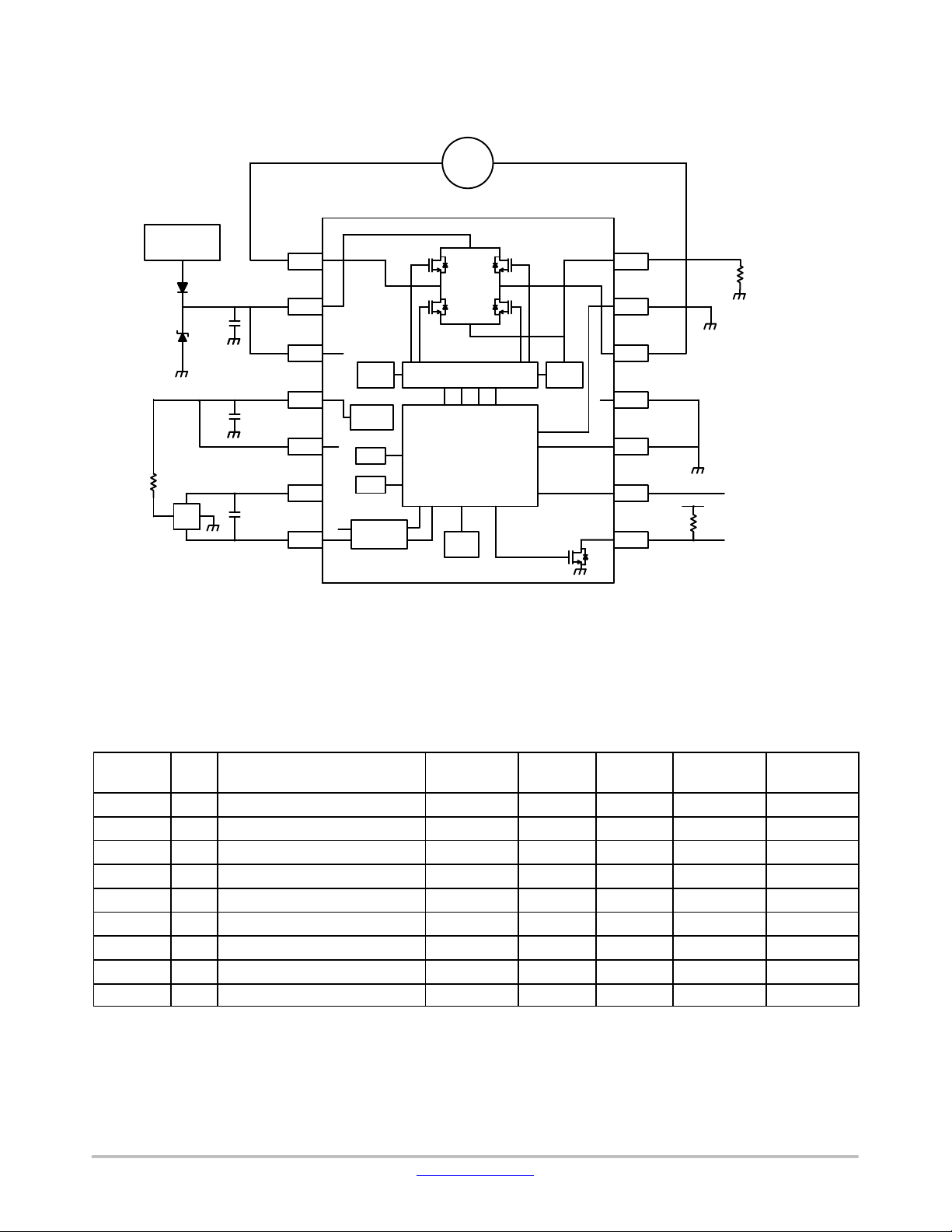

Application Diagram

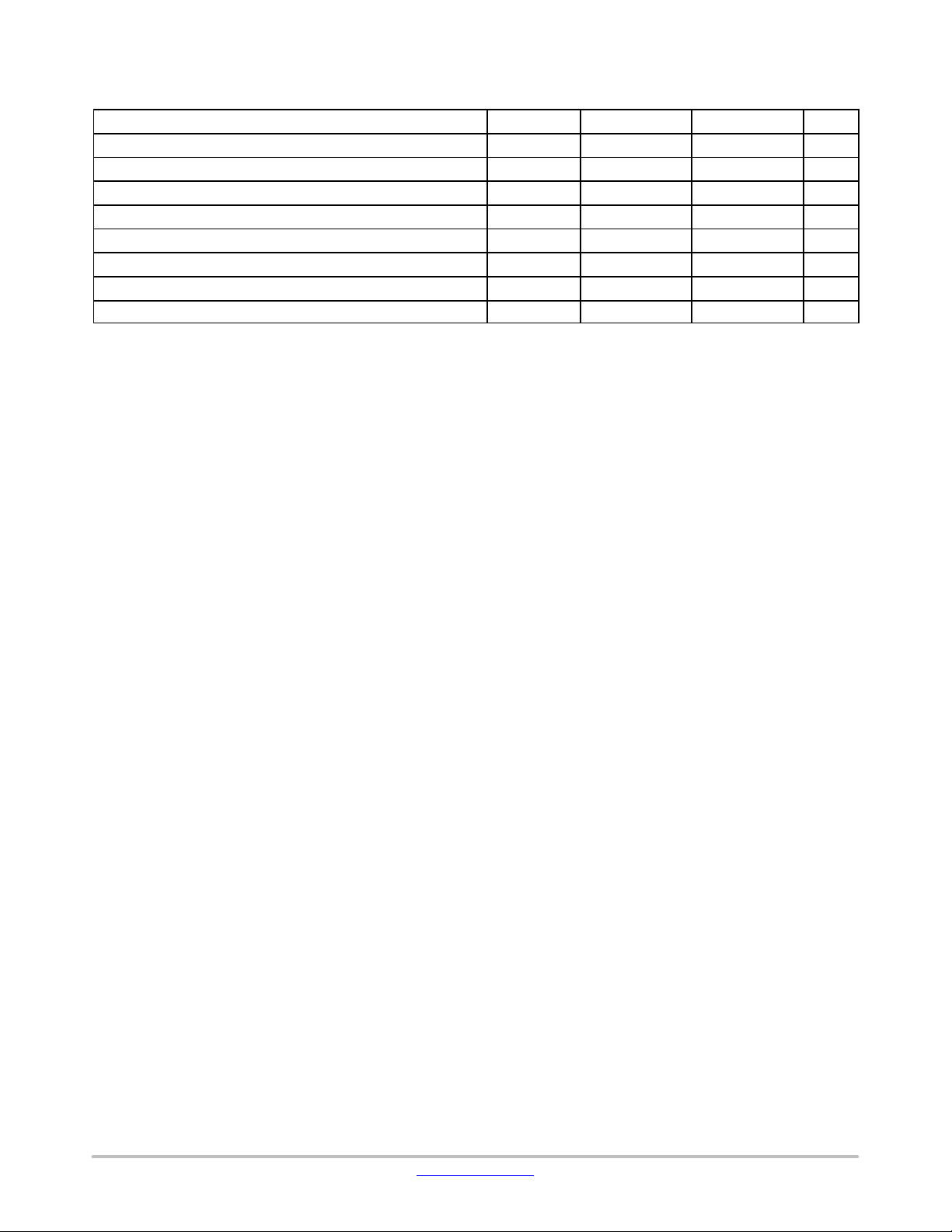

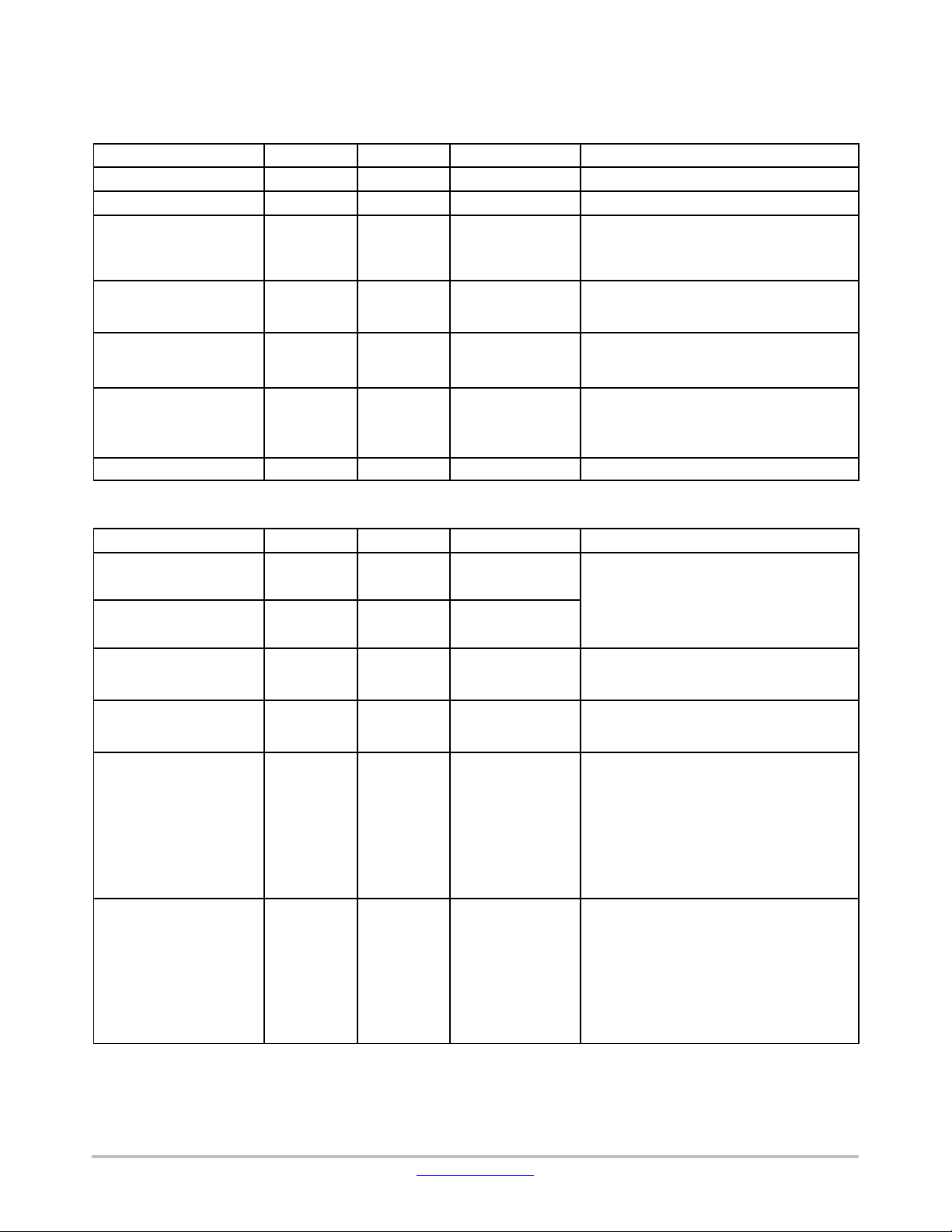

Table 1. EXTERNAL COMPONENT VALUE

Device

Qty

Description

Value

Tol

Footprint

Manufacture

Manufacture

D1

1

Anti−reverse connection diode

−

−

D2

1

Anti−abnormal boost Zener diode

−

−

C1

1

VCC bypass capacitor

10 mF / 50 V

10%

C2

1

REG bypass capacitor

1 mF / 25 V

10%

C3

1

Filter of system noise

0.1 mF / 16 V

10%

R1

1

Current limiter resistor for Hall

2 kW/ 1/4 W

5%

R2

1

FG pull−up resistor

10 kW/ 1/4 W

5%

R3

1

Sense resistor for CLM/OCP

200 mW/ ⅛ W

1%

T1

1

Hall element

−

−

Figure 1 shows the application diagram.

Power supply

voltage

D1

D2

( )

R1

T1

C1

C2

( )

C3

OUT1

PVCC

VCC

REG

VDD

IN1

IN2

1

2

3

4

5

6

7

Boot

strap

5 V

Regulator

UVLO

TSD

Hall

Comparator

LV8314C

M

Pre−Driver

Drive Control Logic

OSC

Current

limiter

RF

14

TSL2

13

OUT2

12

GND

11

TSL

10

PWM

9

FG

8

R3

Control (PWM) signal

Pull−up

R2

Rotation signal

Figure 1. Application diagram

The power supplies of the IC need to be decoupled

properly. This means that at least one external capacitor C1

must be connected in between GND and VCC, and one

external capacitor C2 between REG, VDD and GND.

External Components

Table 1 shows the external component list for the

application diagram.

Part Number

www.onsemi.com

2

Page 3

LV8314C

Table 2. TRUTH TABLE

IN1

IN2

Inner PWM State*

OUT1

OUT2

FG

Operation State

On

L

H

Drive mode

Off

LLRegeneration mode

On

H

LLDrive mode

Off

LLRegeneration mode

VCC and GND (VCC, GND)

The power supplies of the IC need to be decoupled

properly. The following three capacitors must be connected.

• Between VCC (pin 3) and ground as C1 in the application

diagram

• Between REG (VDD) and ground as C2

The Zener diode (D2) in Figure 1 is mandatory to prevent

the IC break down in case the supply voltage exceeds the

absolute maximum ratings due to the flyback voltage.

Hall−Sensor Input Pins (IN1, IN2)

Differential output signals of the hall sensor are connected

at IN1 and IN2. It is recommended that the capacitor (C3) is

connected between both pins to filter system noise. The

value of C3 should be selected properly depending on the

system noise. When a Hall IC is used, the output of the Hall

IC must be connected to the IN1 pin and the IN2 pin must be

kept in the middle level of the Hall IC power supply voltage

which should be corresponded to recommended operating

range.

L H

Command Input Pin (PWM)

This pin reads the duty−cycle of the PWM pulse which

controls rotational speed. The PWM input signal level is

supported from 2.8 V to 5.5 V. Linear voltage control is not

supported. The minimum pulse width is 200 ns.

Current Limiter Resistor for Hall (R1)

Hall output amplitude can be adjusted by R1.

The amplitude is proportional to Hall bias level VH for

particular magnetic flux density. VH is determined by the

following equation.

VH + VREG

ǒ

Rh ) R1

Ǔ

(eq. 1)

Rh

Where

VREG: REG pin voltage (5 V)

Rh: Hall resistance

However, it should be considered with Hall sensor

specification and Hall bias current. The bias current should

be set under 10 mA which is REG pin max current.

Hi−Z

H L

*Inner PWM state means the OUTPUT active period decided by inner control logic. Don’t match with PWM−pin input signal.

*Condition: Register “DRVMODE [1:0]” = 01

www.onsemi.com

3

Page 4

LV8314C

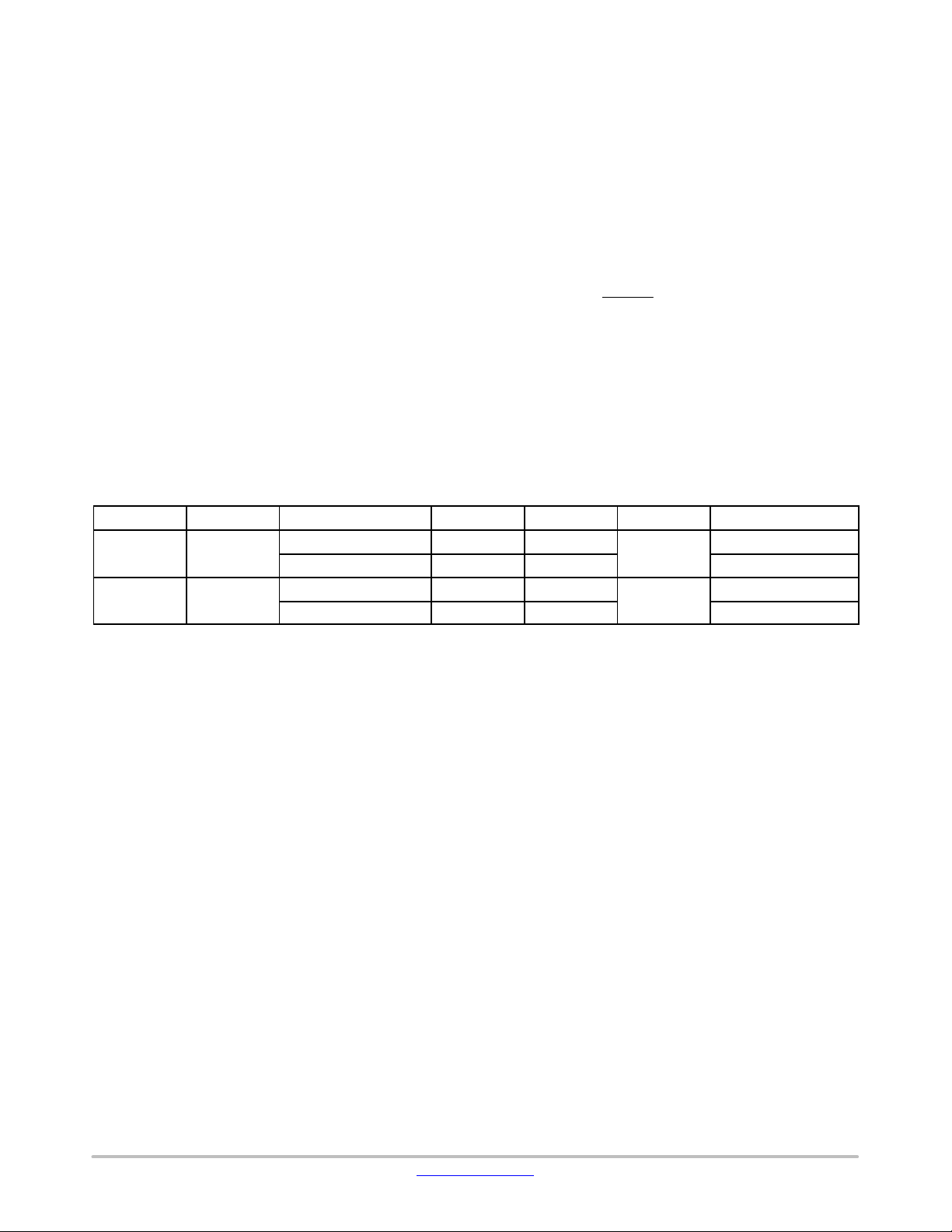

Table 3. ABSOLUTE MAXIMUM RATINGS

Parameter

Symbol

Conditions

Ratings

Unit

Maximum supply voltage

VCC

VCC pin

20

V

Maximum output voltage

V

OUT1/OUT2 pin

20

V

Maximum output current (Note 1)

I

OUT1/OUT2 pin

1.0

A

REG pin maximum output current

I

REG pin

10

mA

IN1/IN2 pin maximum input voltage

V

IN1/IN2 pin

5.5

V

PWM pin maximum input voltage

V

PWM pin

5.5

V

FG pin withstanding voltage

V

FG pin

20

V

FG pin maximum current

I

FG pin

7.5

mA

Allowable power dissipation (Note 2)

Pd

0.6

W

Operating temperature

TOP−40 to 105

C

Storage temperature

T

−55 to 150

C

Maximum junction temperature

Tj

150

C

Moisture Sensitivity Level (MSL) (Note 3)

MSL

1

Lead temperature soldering Pb−free versions (30 seconds or less)

T

255

C

ESD Human body Model: HBM (Note 5)

ESD

2500

V

Table 4. THERMAL CHARACTERISTICS

Parameter

Symbol

Value

Unit

Thermal Resistance, Junction−to−Ambient

R

193

C/W

Thermal Resistance, Junction−to−Case (Top)

R

11.6

C/W

SPECIFICATIONS

MAX

OUTMAX

OUTMAX

REGMAX

INMAX

PWMMAX

FGMAX

FGMAX

MAX

STG

MAX

°

°

°

(Note 4)

SLD

HBM

±

°

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. I

2. Specified circuit board: TBD

is the peak value of the motor supply current.

OUTMAX

3. Moisture Sensitivity Level (MSL): IPC/JEDEC standard: J−STD−020A

4. For information, please refer to our Soldering and Mounting Techniques Reference Manual, SOLDERRM/D

http://www.onsemi.com/pub_link/Collateral/SOLDERRM−D.PDF

5. ESD Human Body Model is based on JEDEC standard: JESD22−A114

q

JA

Y

JT

°

°

Figure 2. Power Dissipation vs. Ambient Temperature Characteristics

www.onsemi.com

4

Page 5

LV8314C

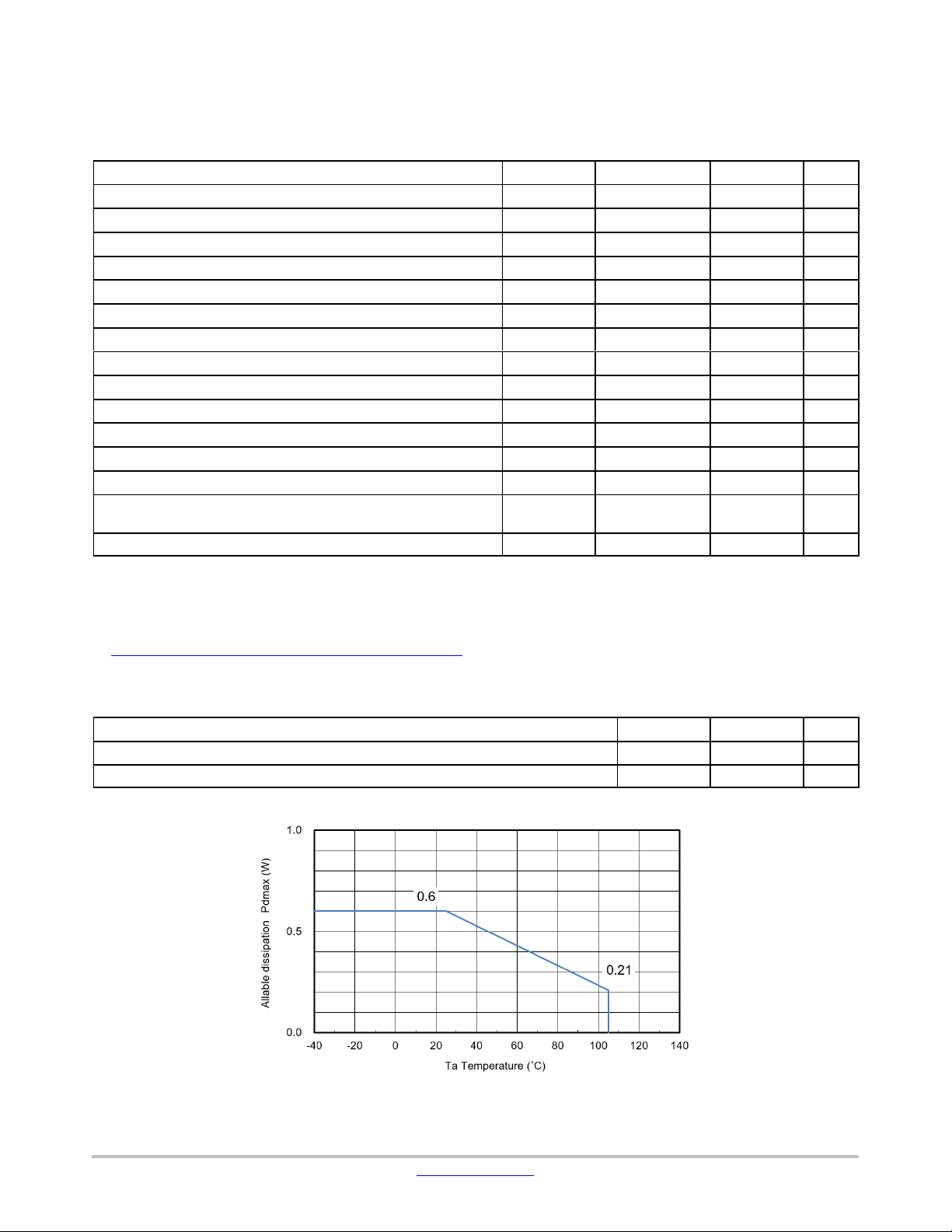

Table 5. RECOMMENDED OPERATING RANGES

Parameter

Symbol

Conditions

Value

Unit

VCC supply voltage

VCC

VCC pin

12

V

VCC operating supply voltage range1 (Note 6)

VCC

VCC pin

3.9 to 5.2

V

VCC operating supply voltage range2

VCC

VCC pin

5.2 to16

V

PWM input frequency range

F

PWM pin

7 to 40

kHz

PWM minimum input low/high pulse width

TW

PWM pin

200

ns

IN1 input voltage range

V

IN1 pin

0 to VDD

V

IN2 input voltage range

V

IN2 pin

0.3 to VDD * 0.6

V

Minimum RF resistor value

R_RFmin

0.20

TYP

OP1

OP2

PWM

PWM

IN1

IN2

W

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

6. When the VCC voltage is below 5.2 V, there are possibility to change the electric characteristics due to low VCC. However a motor keeps

rotation until to 3.9 V, normally.

www.onsemi.com

5

Page 6

Electrical Characteristics

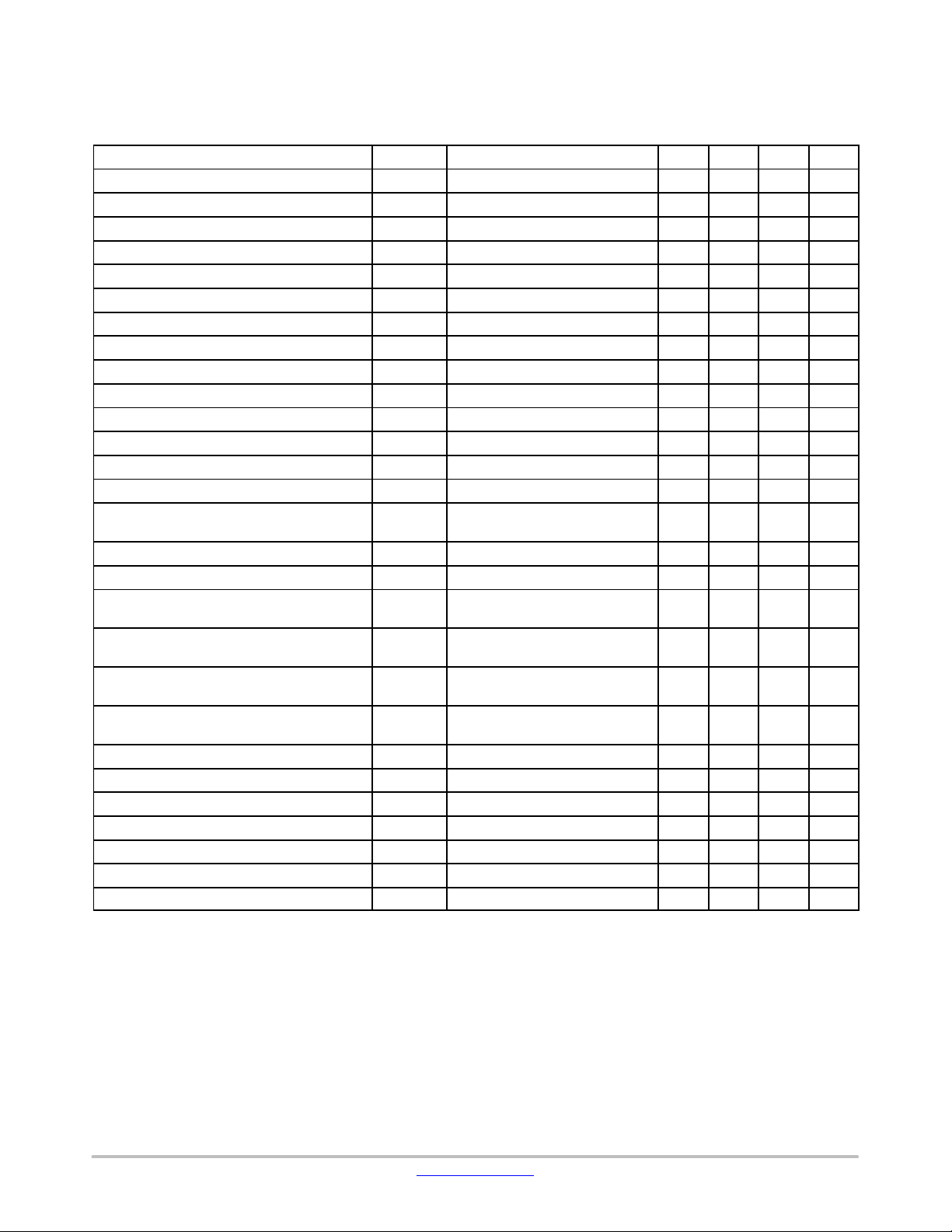

Table 6. ELECTRICAL CHARACTERISTICS (TA = 25

C, VCCOP = 12 V unless otherwise noted)

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

Circuit current

ICC−3.35mA

OUT1/OUT2 High−side on−resistance

R

= 0.3 A

−

0.4

0.8

OUT1/OUT2 Low−side on−resistance

R

IO = 0.3 A

−

0.4

0.8

OUT1/OUT2 PWM output frequency

f

−48−

kHz

PWM pin low level input voltage

V

−−0.7

V

PWM pin high level input voltage

V

2.8−−

V

PWM input resolution

−8−

Bit

PWM input bias current

I

VDD = 5.5 V, PWM = 0 V

142843

A

FG pin on−resistance

V

IFG = 5 mA

−−60

FG pin leak current

I

VCC = 16 V, VFG = 16 V

−−1

A

REG pin output voltage

V

4.7

5.0

5.3

V

REG pin output voltage load regulation

V

I

= −10 mA

−−50

mV

Lock−detection time1 (Note 7)

T

Under rotation

0.27

0.3

0.33

s

Lock−detection time2 (Note 8)

T

Start−up/Restart, LOCK_DET = 0

0.63

0.7

0.77

s

Lock−Stop release time1 from 1st to 4th off time

T

3.1

3.5

3.9

s

Lock−Restart on time (Note 8)

T

LOCK_DET = 0

0.63

0.7

0.77

s

Lock−Restart time ratio1 (Note 7)

R

(T

LOCK_DET = 0)

−5−

−

Lock−Stop release time2 as from 5th off time

T

12.51415.5

s

Lock−Restart time ratio2 as from 5th off time

R

(T

LOCK_DET = 0)

−20−

Thermal shutdown protection detection

T

150

180

−°C

Thermal shutdown protection detection

T

−40−°C

Over current detection voltage

I

135

150

165

mV

Current limiter1

I

CL_LVL = 1

657585

mV

Current limiter2

I

CL_LVL = 0

90

100

110

mV

Hall input bias current

I

IN1, IN2 = 0 V

−−1

A

Hall input sensitivity

V

40−−

mV

UVLO detection voltage

V

3.2

3.4

3.6

V

UVLO hysteresis voltage

V

0.1

0.2

0.4

V

LV8314C

°

(Note 8)

(Note 9)

(Note 9)

OH−ONIO

OL−ON

PWMO

PWML

PWMH

D

PWM

pwmin

FGL

FGLK

REG

D

REGLD

LD1

LD2

LRoff1

LRon

LR1

LRoff2

LR2

REG

LRoff1/TLRon,

LRoff2/TLRon,

W

W

m

W

m

D

OVC

D

uvdet

D

TSD

TSD

CL1

CL2

hin

m

hin

uv

temperature

hysteresis

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

7. When a motor rotates with below 50 rpm (phase change period over 0.3 s), lock protection will works. See Figure 20 for the detail.

8. When a motor can’t rotate for the time which is set by the register named LOCK_DET after start−up, lock protection will work. See Figure 21

for the detail.

9. When the locked rotor state continues for long time, lock stop period changes as from 5th off time. See Figure 21 for the detail.

www.onsemi.com

6

Page 7

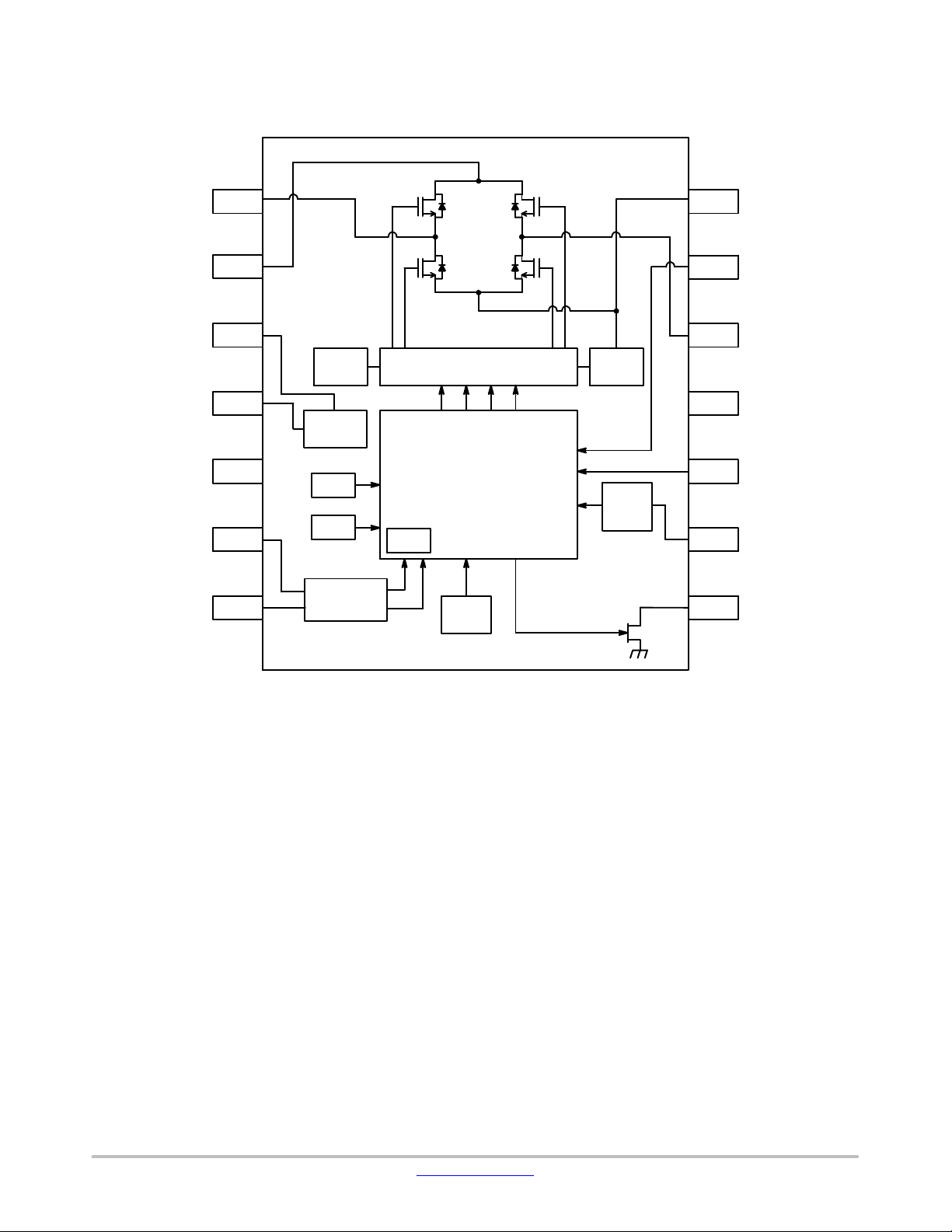

Block Diagram

Figure 3 shows the functional block diagram of LV8314C.

OUT1

1

LV8314C

RF

14

PVCC

VCC

REG

VDD

IN1

IN2

2

3

Boot

strap

4

5 V

Regulator

5

6

7

UVLO

TSD

Hall

Comparator

NVM

Pre−Driver

Drive Control Logic

OSC

Current

limiter

Duty

Cycle

Counter

TSL2

13

OUT2

12

GND

11

TSL

10

PWM

9

FG

8

Figure 3. Block Diagram

www.onsemi.com

7

Page 8

Pin Description

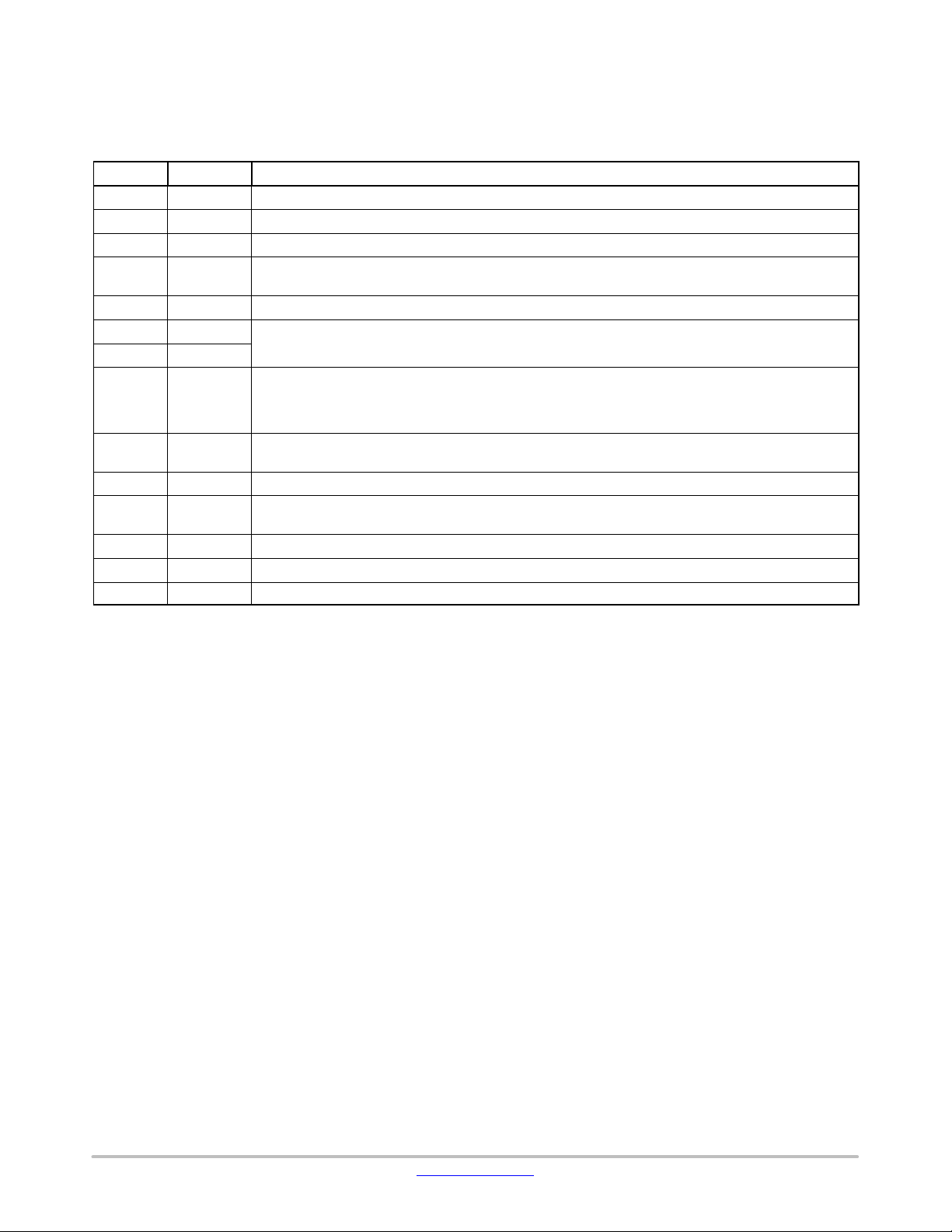

Table 7. PIN LIST AND FUNCTION

Pin No.

Pin Name

Description

1

OUT1

Motor drive output pin. This pin is connected to the built−in power MOSFET

2

PVCC

Power supply pin for built−in power MOSFET

3

VCC

Power supply for internal circuit, ex. Pre−driver, charge−pump

4

REG

5.0 V regulator output. This voltage acts as a power source for oscillator, protection circuits, and so on.

5

VDD

Power supply pin for both digital and analog circuits. This pin must be connected to REG pin

6

IN1

7

IN2

8FGThe FG (frequency generator) output controls the motor electrical rotational speed (FG output

9

PWM

Rotational control signal input pin. The rotational speed is controlled by duty−cycle of the pulse and is

10

TSL

Test mode pin. This pin connect to GND typically

11

SGND

Internal circuit ground pin When short to GND, FG pin is serial in/out. When short to REG, PWM pin is

12

OUT2

Motor drive output pin. This pin is connected to the built−in power MOSFET

13

TSL2

Test mode pin. This pin connect to GND typically

14

RF

Sense resistor voltage input for current limit/over current protection

Table 7 shows the pin list and their functions.

The maximum load current of REG is 10 mA. Be sure not to exceed this maximum current

Hall sensor input pin. The differential outputs of the hall sensor need to be connected to IN1 and IN2 each.

synchronizes with the Hall sensor signal). The FG pin is an open drain output. Recommended pull up

resistor is 1 kW to 100 kW. Leave the pin open when not in use. FG pin can be selected from 2 times, 0.5

times FG and RD. switching by bit setting of Reg. 0x0027 “TACHSEL”

proportional to the duty−cycle ratio.

LV8314C

serial in and FG pin is for serial out

NOTE: Characteristic values comply with the conditions in Table 6. “ELECTRICAL CHARACTERISTICS”.

www.onsemi.com

8

Page 9

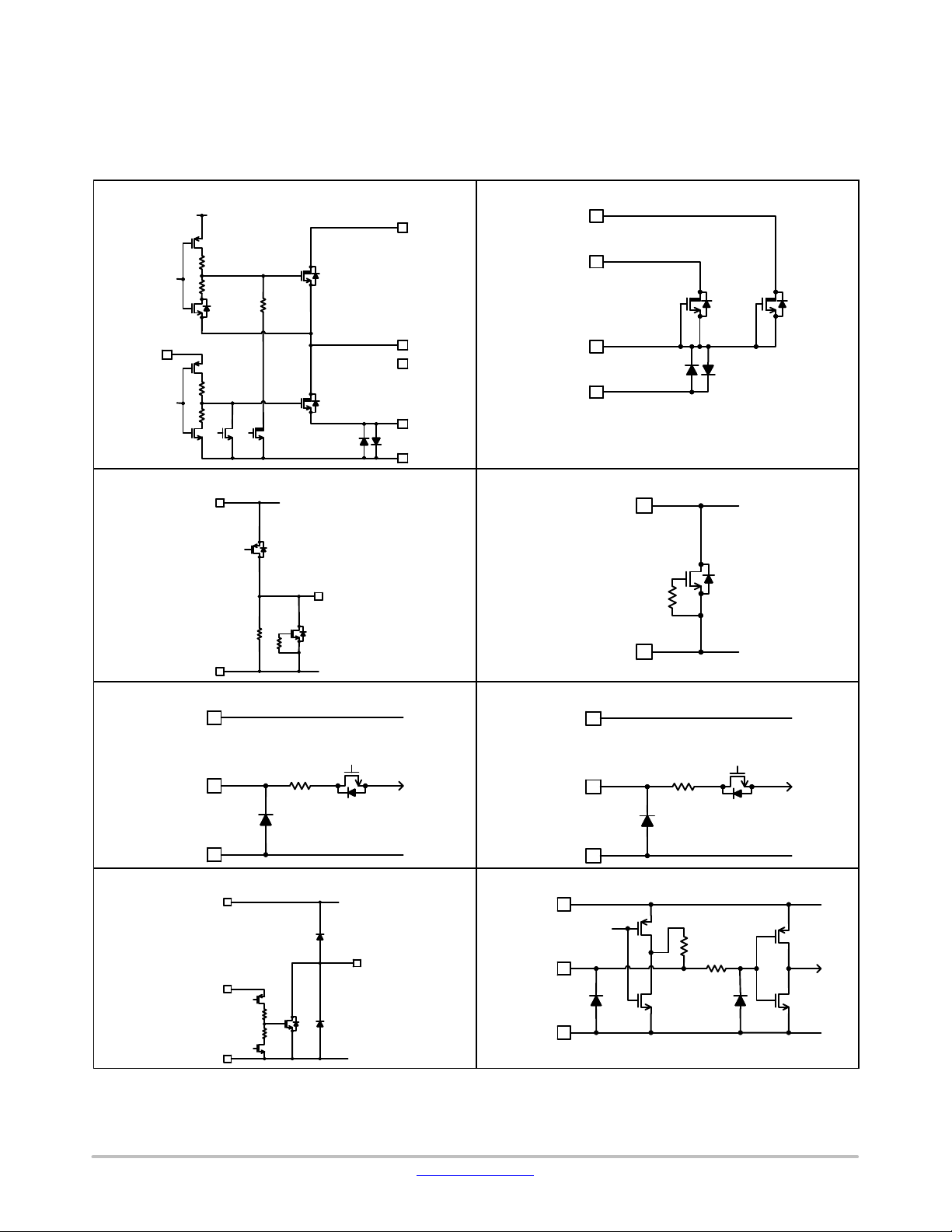

Simplified Equivalent Circuits

Table 8. PIN EQUIVALENT CIRCUIT

OUT1, OUT2

PVCC, VCC/SGND

(OUT +4.5 V)

PVCC

REG

VDD

VCC

IN1

IN2

VDD

FG

PWM

VCC

Table 6 shows the pin information. The pull−up/down

resistor and diode path are included.

PVCC

LV8314C

VCC

VDD

SGND

IN1

REG

OUT1

OUT2

RF

SGND

SGND

RF

VDD

SGND

VDD

IN2

SGND

VDD

SGND

FG

SGND

VDD

Low

200 kW

PWM

SGND

www.onsemi.com

9

Page 10

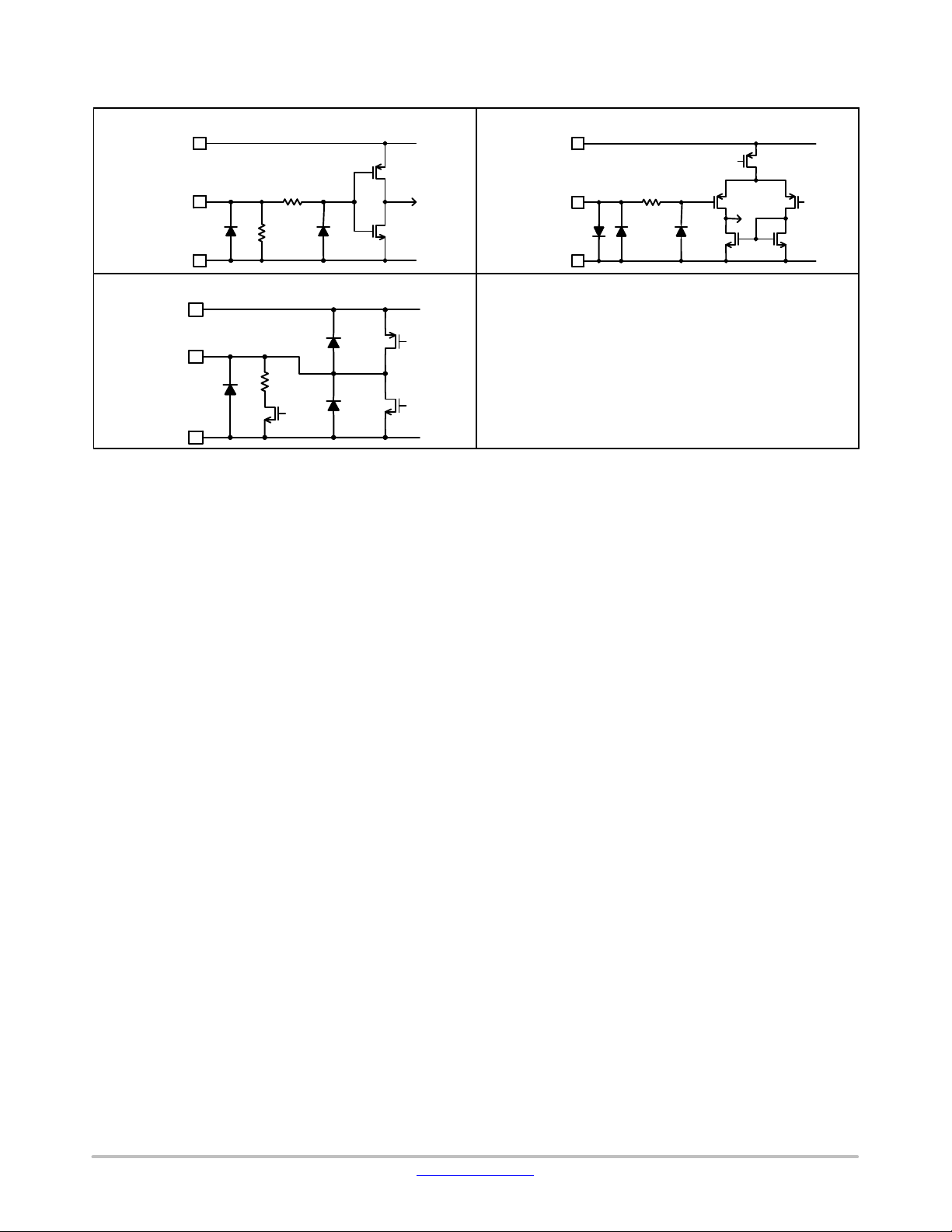

T

able 8. PIN EQUIVALENT CIRCUIT (continued)

TSL

RF

VDD

VDD

TSL2

VDD

LV8314C

TSL

SGND

TSL2

SGND

RF

200 kW

SGND

200 kW

High

www.onsemi.com

10

Page 11

LV8314C

Table 9. SOFT START END DUTY−CYCLE

SSTART_SEL

End Duty−cycle

0

24% output duty−cycle

1

54% output duty−cycle

Table 10. SOFT START DURATION TIME

INCTIM

Duration Time (s)

[1]

[0]

SSTART_SEL = 0

)

SSTART_SEL = 1

)

0

0

0.002

0.10

0

1

0.50

0.50

1

0

1.00

1.00

1

1

2.00

2.00

OPERATION DESCTIPTION

The LV8314C has various functions and parameters

which are defined by built−in registers. Refer to the Register

map and description page for the detail.

Spin−up Sequence

To spin−up a motor, power is applied to VCC pin and the

appropriate input PWM signal (see “DUTY_L” and

“DUTY_S” setting description in section “Steady rotation”)

is applied to PWM pin. The LV8314C starts driving the

motor whose current direction is determined by the Hall

sensor signal.

To avoid the unnecessary rush current, the “soft start”

mode is provided, which gradually increases output

duty−cycle. After the soft start mode, LV8314C goes to

steady rotation mode. The detail of the soft start mode and

steady rotation mode are described in the sections below.

If a motor already rotates at the power on in faster speed

than 304 rpm, the soft start mode is skipped and goes to

steady rotation mode immediately.

Soft Start

For soft start mode, the duty−cycle ramp up profile is

defined by the initial duty−cycle, slope, and exit condition.

The initial duty−cycle is fixed and it starts from 4%. The

slope is programmable. It is determined by registers

“SSTART_SEL” and “INCTIM”. The duty−cycle is

increased up to the end duty−cycle “SSTART_SEL” for

duration time “INCTIM”. The end duty−cycle is selectable

at 24% or 54% (see Table 9). The duration time can be

selected from 0.002 s to 2.0 s (see Table 10). The exit

condition means it’s in the state of either the duty−cycle

reaches “SSTART_SEL”. Soft start operation requires at

least 8 electrical cycles (4 mechanical cycles in case of 4

poles single phase motor) independent on the exit condition.

(End Duty−cycle = 24%

(End Duty−cycle = 54%

Figure 4 shows the image of soft start mode.

Figure 4. The Image of Soft Start Exit by End Duty−cycle

www.onsemi.com

11

Page 12

LV8314C

As the blue curve shown in Figure 4, the output

duty−cycle in the soft start mode starts from 4% of the output

duty. Then the output duty−cycle is increased to the end

duty−cycle linearly, which is shown by yellow circle. After

that, LV8314C goes to the steady rotation mode.

Figure 5 is the example of the duration time in case of

“SSTART_SEL = 1”.

Figure 5. Example: The Image of Soft Start

Duration Time in Case of SSTART_SEL = 1

Steady Rotation

The motor speed is defined by the output duty−cycle

which is controlled by input PWM pin.

The input PWM frequency range is 7 kHz − 40 kHz. The

output frequency is fixed to 48 kHz and it is not related to

input PWM frequency. Figure 6 shows the output

duty−cycle control profile which is relationship between

input PWM duty−cycle and the target output duty−cycle.

Registers to determine this relationship are;

TAG_L (Address 0x0100 D [7:1]): Minimum output

duty−cycle

TAG_H (Address 0x0101 D [7:1]): Maximum output

duty−cycle

DUTY_L (Address 0x0102 D [6:1]): Minimum input

duty−cycle

DUTY_H (Address 0x0103 D [6:1]): Maximum input

duty−cycle

FULL (Address 0x0108 D [2]): Output duty−cycle selection

at input duty−cycle over DUTY_H

DUTY_S (Address 0x0108 D [3]): Output duty−cycle

selection at input duty−cycle under DUTY_L

The detail of each register will be explained later.

Figure 6. Target Output Duty−cycle Control Profile

TAG_L/TAG_H: Minimum/Maximum Target Output

Duty−cycle Setting

The minimum output duty−cycle is set by “TAG_L” and

the maximum output duty−cycle is set by “TAG_H” within

the range of DUTY_L and DUTY_H. (See Figure 7.)

Figure 7. Max/Min Speed Setting

Do not set the maximum output duty−cycle setting

(TAG_H) less than the minimum output duty−cycle setting

(TAG_L).

www.onsemi.com

12

Page 13

LV8314C

DUTY_L/DUTY_H: Minimum/Maximum Input Duty−cycle

Setting

The range of PWM input duty−cycle can be set by the

registers “DUTY_L” and “DUTY_H” whose range is 0 to

100%. The equation of resolution is;

DUTY_L

D

+

min

max

DUTY_H

+

D

Where D

D

Do not set “DUTY_H” less than “DUTY_L”.

Figure 8 shows the relationship between input duty−cycle

and target output duty−cycle. TAG_L/TAG_H define the

start and end points of the output duty−cycle curve and the

value between (DUTY_L, TAG_L) and (DUTY_H,

TAG_H) are interpolated linearly.

49.8 [%]

63

49.8 ) 50.2 [%]

63

is minimum input duty−cycle

min

is maximum input duty−cycle

max

(eq. 2)

(eq. 3)

Figure 9. Max Speed Function Setting

DUTY_S: Speed Selection at Input Duty−cycle under

DUTY_L

For the behavior at input duty−cycle which is under

DUTY_L, the register “DUTY_S” provides two options.

DUTY_S = 0 i s t o keep the speed specified by “TAG_L” and

DUTY_S = 1 is to go to 0% output duty−cycle as shown in

Figure 10.

Figure 8. Input Duty−cycle Setting

FULL: Speed Selection at Input Duty−cycle over

DUTY_H

For the behavior at input duty−cycle which is over

DUTY_H, the register “FULL” provides two options.

FULL = 0 is to keep the speed specified by “TAG_H” and

FULL = 1 is to go to 100% output duty−cycle−cycle as

shown in Figure 9.

www.onsemi.com

Figure 10. Min Speed Function Setting

13

Page 14

LV8314C

Table 11. RATE OF CHANGE FOR OUTPUT DUTY

PWM_ROC

Rate of Change for Output Duty [%]

0

0.2% per 128 pulses

1

0.2% per 256 pulses

2

0.2% per 512 pulses

3

Change immediately to the target

Output Duty−cycle Transitions

When PWM i nput duty cycle changes, output PWM tar get

duty changes along with input and output characteristics

setting. The rate that actual output duty−cycle changes is set

by the register “PWM_ROC”. Actual output duty−cycle

transfers gradually to the target according to the rate which

is defined by PWM_ROC as shown in Table 11. In addition,

this register setting is effective not only in changing the input

duty−cycle but also in changing the mode from Start−up to

normal.

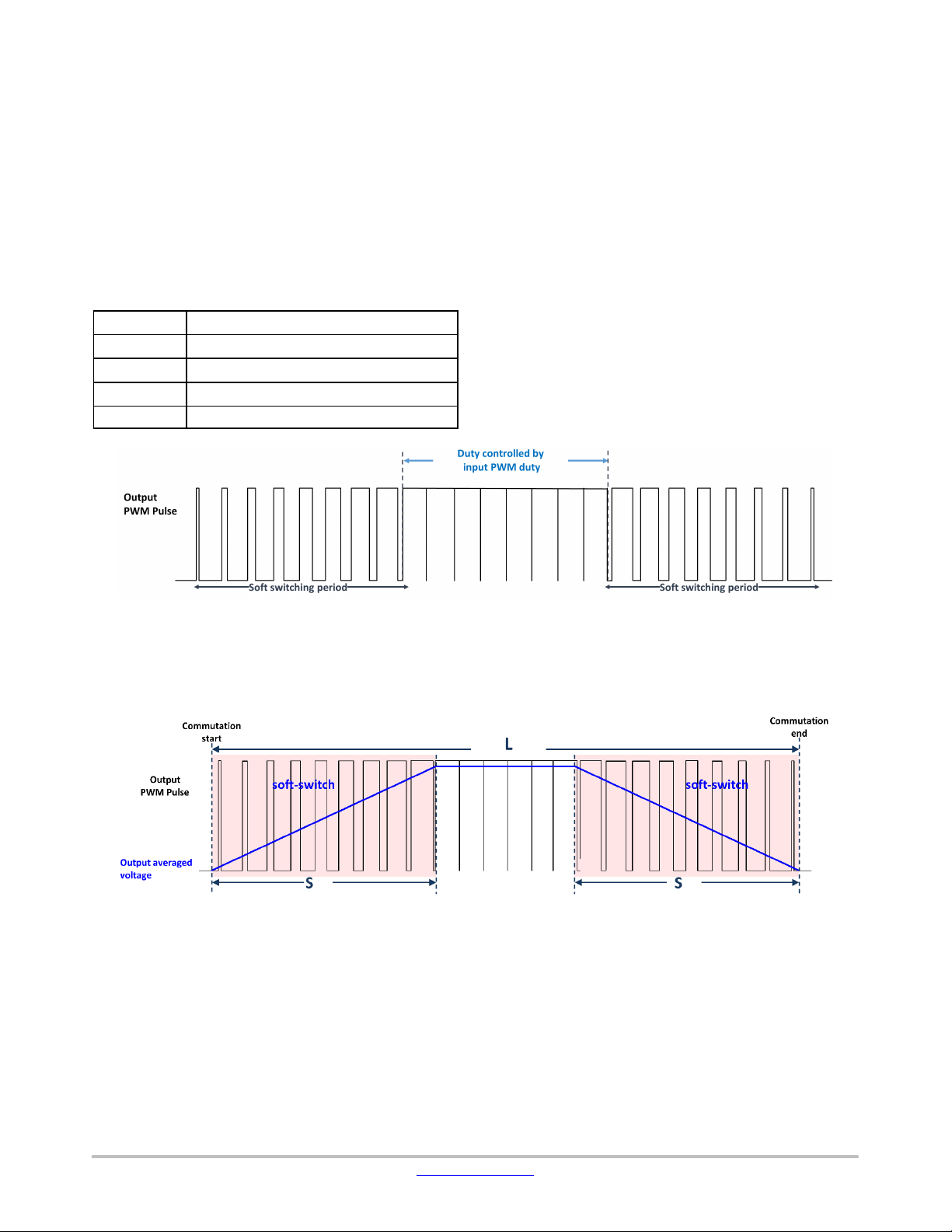

Output Waveform

The output pulse signal is about 0 V − VCC. The duty

before commutation change decreases gradually to 0% and

the duty after commutation change increases gradually to

the duty level controlled by speed control function by

built−in function called soft−switch. This state is shown in

Figure 11 as a schematic view.

Figure 11. Output Waveform Image

Soft−Switch Setting

Figure 12 shows the soft switch image. Due to the

soft−switch, the averaged output voltage can has the slope.

Rise

Rise Fall

Figure 12. L (Length) and S (Soft−Switch) Image

Fall

www.onsemi.com

14

Page 15

LV8314C

Table 12. SOFT−SWITCH PERIOD ADJUSTMENT

SSWHIGH_F

S/L Ratio

SSWHIGH_F

S/L Ratio

0

2.9%

8

26.4%

1

5.9%

9

29.3%

2

8.8%

10

32.2%

3

11.7%

11

35.2%

4

14.6%

12

38.1%

5

17.6%

13

41.0%

6

20.5%

14

43.9%

7

23.4%

15

46.9%

The soft switch period in beginning of commutation is

called “Rise soft−switch” and in end of commutation is

called “Fall soft−switch”. The LV8314C can adjust both soft

switch periods independently as the ratio of L and S shown

in Figure 12. “SSWHIGH_F” and “SSWLOW_F” define

the period of “Rise soft−switch” and “SSWHIGH” and

“SSWLOW” define the period of “Fall soft−switch”. These

soft switch periods are defined by equation 4.

Soft switch period [%] +

S

100

L

(eq. 4)

Where:

S is soft−switch period

L is one commutation period

SSWHIGH_F and SSWHIGH are for the maximum

output duty−cycle defined by TAG_H and SSWLOW_F and

SSWLOW are for the minimum output duty−cycle defined

by TAG_L. All register have 4bits and Table 12 shows the

adjustable values.

SSWLOW_F

SSWHIGH

SSWLOW

SSWLOW_F

SSWHIGH

SSWLOW

Once these registers are set, the ratio of soft−switch in

other speed settings is as shown in Figure 13.

SSWLOW_F or SSWLOW setting value

SSWHIGH_F = SSWLOW_F or

SSWHIGH = SSWLOW

SSWHIGH_F or SSWHIGH setting value

Figure 13. The Relationship between Soft−Switch

and Speed

FG Output

FG signal output is decided by the Hall signal cross point.

The relationship between motor speed and FG frequency in

the state “T ACHSEL = 0” represents the following equation.

p

fFG[Hz] +

60

N

2

(eq. 5)

Where N: Motor speed [rpm] and p: Number of Pole

Figure 14 shows the timing chart of the hall sensor output

and the FG output.

Figure 14. Timing Chart of Output

www.onsemi.com

15

Page 16

Output signal in FG pin can be selected by setting the

Table 13. TYPE OF OUTPUT SIGNAL IN FG PIN

TACHSEL

Output Signal in FG Pin

0

FG signal as shown in Figure 14

1

2 times frequency of FG signal

2

one half the frequency of FG signal

3

RD signal (The polarity is decided by RD_INV

register “TACHSEL” as shown in Table 13 and Figure 15.

register)

Figure 15. FG Signal vs. TACHSEL Setting

LV8314C

When TACHSEL is set to 1 or 2, FG signal starts from

LOW in POR regardless of rotor position as shown in

Figure 16. Note that in some cases FG signal cannot keep the

Figure 16. FG State by TACHSEL Setting

50% duty−cycle when the rotation restarts from the stop or

the rotation speed changes suddenly as shown in Figure 17.

IN1<IN2: FG=H

Figure 17. FG Duty−cycle

www.onsemi.com

16

Page 17

LV8314C

Table 14. LEAD−ANGLE ADJUSTMENT

DL_RESO

Lead−Angle

Range of

0

0.70

0−10.5

1

0.35

0−5.25

Lead−Angle Setting

In the output, the output current delays from the output

voltage because of the inductance of motor coil. The output

current which flows in a motor coil generates torque for the

motor and the torque is maximized by the synchronization

of output current with the BEMF phase. Therefore, this

delay decreases an efficiency of motor rotation. It is

generally increased in proportion to the rotational speed.

The LV8314C can cancel the delay by earlier

commutation than the Hall sensor signal as shown in

Figure 18. This phase adjustment is called the “lead−angle”.

In Figure 18, when the output voltage VOUT1 and the

output current IOUT1 in black are changed to the waveform

in red after the lead−angle adjustment and it is the most

optimum commutation timing.

Figure 18. The Relationship between the Lead−Angle and the Delay of Output Current

The relationship between output duty−cycle and

lead−angle is shown in Figure 19. The optimum lead−angle

will vary by the motor characteristics so it is necessary to

adjust the lead−angle based on the motor in use.

Figure 19. Lead−angle Curve Image

The LV8314C can set the lead−angle at maximum target

output duty−cycle (TAG_H) and at minimum target output

duty−cycle (TAG_L) by “DLDEG_H” and “DLDEG_L”

individually. These parameters have 4 bits. The direction of

lead−angle is defined by the MSB bit of “DLDEG_H” and

“DLDEG_L”. When they are set to “0”, the direction of

lead−angle is the behind, it means the output voltage

commutation is slower than the Hall sensor signal. When

they are set to “1”, the direction is the advance, it means the

output voltage commutation is earlier than the Hall sensor

signal, that is, the output voltage commutation is earlier than

the Hall sensor signal. The adjustable range and the

resolution are determined by “DL_RESO” setting as shown

in Table 14.

Resolution

°

°

Lead−Angle

°

°

The lead−angles are expressed in the following equations.

L

+ Res DLDEGH[deg]

max

L

+ Res DLDEGL[deg]

min

(eq. 6)

(eq. 7)

where:

Lmax: lead−angle at maximum target output duty−cycle

(TAG_H)

www.onsemi.com

17

Page 18

LV8314C

Table 15. UVLO TRUTH TABLE

Input

Output

IN1

IN2

OUT1

OUT2

LHL

Hi−Z

HLHi−Z

L

Table 16. RD SIGNAL

Normal Rotation

Lock Rotation

RD_INV = 0

Low

High

RD_INV = 1

High

Low

Lmin: lead−angle at minimum target output duty−cycle

(TAG_L)

Res: The resolution of lead−angle defined by “DL_RESO”

Once DLDEG_H and DLDEG_L are set, the lead−angle

in other output duty−cycle is set to interpolated and

extrapolated value according to the output duty−cycle, even

though the output duty−cycle is defined by FULL = 1.

Protections

The LV8314C has the following protection functions.

• TSD (Thermal Shut Down)

• UVLO (Under Voltage Lock Out)

• Lock protection

• CLM (Current Limiter)

• OCP (Over Current Protection)

When the TSD, OCP or Lock protection works, all of the

internal FETs are turned off. When UVLO or CLM works,

the output PWM is off and the motor goes to re−circulation

mode with asynchronous operation.

Thermal Shutdown Protection (TSD)

When LV8314C junction temperature rises to 180°C,

TSD will activate and turns off high−side and low−side

Power FET. Therefore, OUT1 and OUT2 will become high

impedance and the coil current will shut off. When it falls

under 140°C, TSD will is deactivated and motor will start to

rotate.

Under Voltage Lock Out (UVLO)

When VCC voltage goes to low level (3.4 V(typ)), UVLO

will active and stop the motor. VCC voltage is recovered to

above detection voltage (3.4 V(typ)) plus hysteresis voltage

(0.2 V(typ)).

The TRUTH TABLE of Operating State with UVLO is as

shown in Table 15.

Lock Detection and Lock Protection

When the motor is locked, the heat is continuously

generated because the LV8314C keeps trying to rotate the

motor.

The lock protection works to prevent such a heat

generation by turning OUT1 and OUT2 into high impedance

and shutting off the motor current. When a motor is locked

in the steady rotation mode and the L V8314C doesn’t detect

the FG edge for more than 0.3 s which is equivalent to

50 rpm, the lock protection works (Figure 20).

The lock protection signal can be output from FG pin by

setting the register “TACHSEL”. In this mode, the RD signal

goes to “High”, though it is “Low” at motor starts when

“RD_INV” is sets to 0. Table 16 shows the behavior of RD

signal.

When the motor restarts and IC detects 4 phase changes

at least (depends on rotation speed), the RD signal goes to

“Low”.

Figure 20. Timing Chart of the Lock Protection

www.onsemi.com

18

Page 19

LV8314C

Table 17. STAND−BY PERIOD FOR FG

LOCK_DET

Stand−by Period for FG [s]

0

0.7

1

1.0

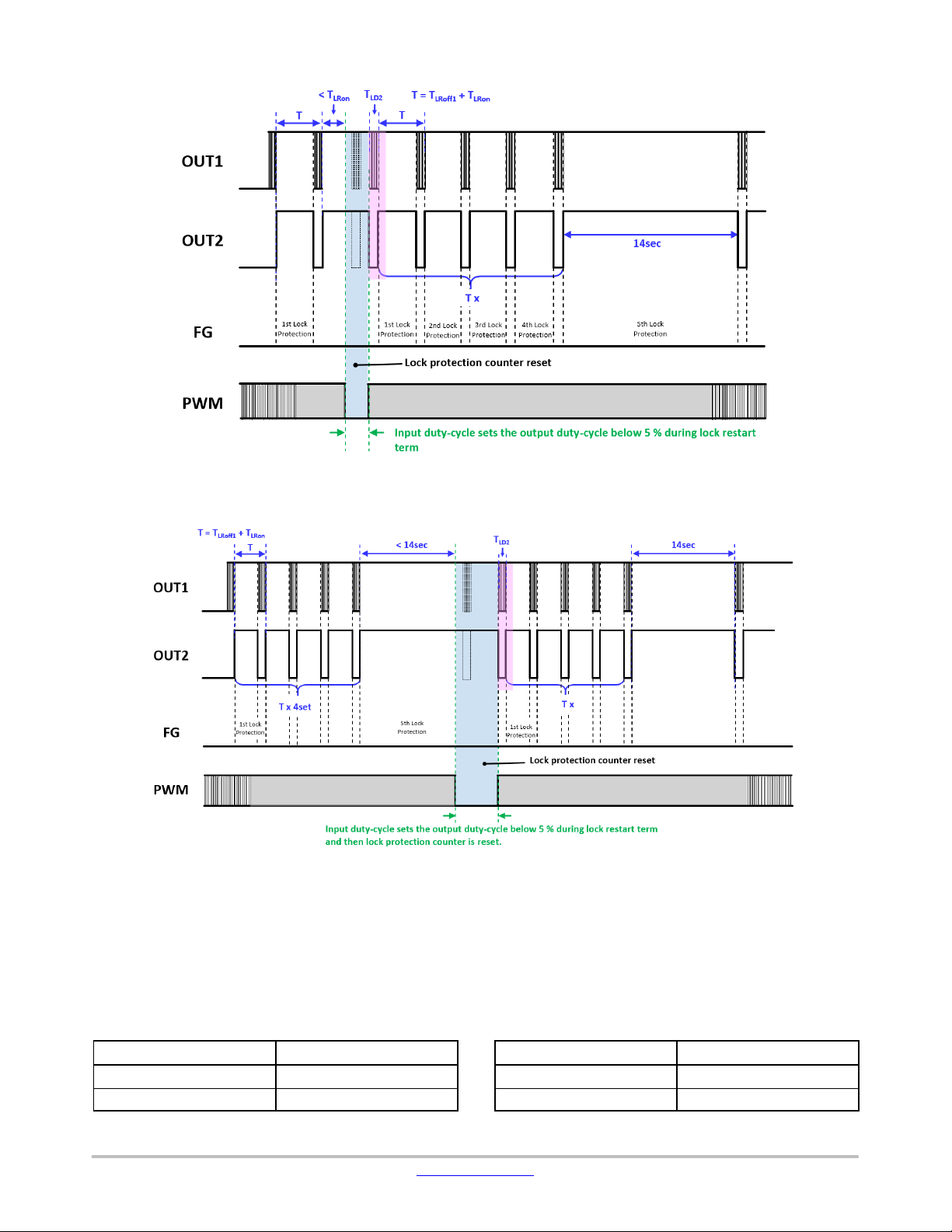

Figure 21. The Relationship between Protection Time and the Number of Protection Times

Figure 21 shows the relationship between protection

period and the number of protection times. The 1st to 4th

protection period take 3.5 s and 5th and subsequent

protection period takes 14 s.

After the period of motor lock protection, the LV8314C

tries to rotate the motor and stand−by for FG edge for a

certain period defined by “LOCK_DET” as shown in

Table17.

To reset the lock protection mode, low duty−cycle to set

output PWM duty below 5% must be applied to the PWM

input signal. T o retry the motor rotation, proper duty−cycle

must be applied to the PWM input signal.

These protection periods and the number of protection

times are applied in accordance with the internal counter. If

the duty−cycle to set output PWM duty below 5% is input

during lock protection period, the lock protection counter

will keep to count the protection period and the protection

state is not changed. Figure 22 shows this counter behavior.

www.onsemi.com

19

Page 20

LV8314C

Figure 22. Lock Protection Counter Continues During Lock Protection Period

The lock protection period is changed by the condition of

output signal. If the duty−cycle to set output PWM duty

below 5% is input and the output signals are disappeared

during the restart period in lock protection period, the

www.onsemi.com

counter is reset and the lock protection counter will activate

from the initial state starting from PWM Pos−Edge and the

protection period will start from 1

st

time as shown in

Figure 23 and Figure 24.

20

Page 21

LV8314C

Table 18. CLM THRESHOLD LEVEL

CL_LVL

CLM Threshold Level

0

100 mV

1

75 mV

Table 19. CLM MASK TIME

OCP_MASK

CLM Mask Time [ms]

0

0.511.0

Figure 23. Lock Protection Counter Reset During Motor Restart after 3.5 s Lock Protection Period

Figure 24. Lock Protection Counter Reset During Motor Restart after 14 s Lock Protection Period

Current Limiter (CLM)

When the coil current becomes large, CLM will activate

and then output will be in the re−circulation state. The

current is monitored by RF pin and the threshold can be

selectable by “CL_LVL” as shown in Table 18.

While CLM is active, synchronous rectification of the

output becomes disabled. “OCP_MASK” sets the masking

time to ignore upper and lower FET’s reverse recovery.

Table 19 shows the mask time.

www.onsemi.com

21

Page 22

LV8314C

Overcurrent Protection (OCP)

OCP monitors the coil current by RF pin and if it becomes

larger than 150 mV even if CLM is activated, OCP works to

prevent the device or motor from breakdown. OCP

operation is to turn OUT1 and OUT2 into high impedance

and to shut off the motor current.

This function has also the mask time same as CLM

function shown in Table 19.

Register called “OCP_LAT_CLR” allows to select

behavior when OCP is activated. One is to keep the motor

stopped until the next power on sequence, and the other one

is to activate Lock protection mode.

Nonvolatile Memory

The L V8314C has internal nonvolatile memory which can

store register values which define various parameters and

settings. The stored register values will be reloaded at POR

shown as Figure 25.

The LV8314C Evaluation kit can support NVM

programming. For the detail, please see the EVK user guide

“EVBUM2735−D”.

Figure 25. Image of the Internal Register and Nonvolatile Memory

SPI Communication

The LV8314C allows SPI communication. Through

provided the Evaluation kit, various parameter registers can

be accessed. For the detail, please see EVK user guide

“EVBUM2735−D”.

www.onsemi.com

22

Page 23

REGISTER MAP

Table 20. GENERIC STRADDLE TABLE

Register

D7D6D5D4D3D2D1

D0

0x0000

0xAA10101010

0x0001

0x5501010101

0x0002

0x0000

RECALC_

RELOAD_

0x0003

0x00

RELOAD

0x0004

0x00

RECALC

0x0005

0x18

Identification Number

0x0100

0x00

TAG_L[7:1]

0

0x0101

0xFE

TAG_H[7:1]

0

0x0102

0x00

0

DUTY_L[6:1]

0

0x0103

0xFF

1

DUTY_H[6:1]

1

0x0104

0x90

DLDEG_H[4:1]

DLDEG_L[4:1]

0x0105

0x8F

SSWHIGH_F[3:0]

SSWLOW_F[3:0]

0x0106

0x8F

SSWHIGH[3:0]

SSWLOW[3:0]

0x0107

0x56

PWM_ROC[1:0]

TACHSEL[1:0]

RD_INV

SSTART_

INCTIM[1:0]

0x0108

0xA5

DLDEG_

DLDEG_

DL_RESO

PWMIN_

DUTY_S

FULL

CL_LVL

DRV

0x0109

0x20

PWMAV[1]

PWMAV[0]

LOCK_EN

LOCK_

OCP_

OCP_

0x010A

0x000000

0

0x010B

0x00

Reserved

0

0x010C

0x00

ON_INTERNAL

0x010D

0x0000

Register Map

Internal register map can be classified into four types as

shown in Table 20.

Read Only

Read/Write, User defined registers to be written to nonvolatile memory

Read/Write

Write only (Auto clear)

Address Initial

LV8314C

H[0]

L[0]

INV

SEL

DET

EN

LAT_CLR

(0)

EN

MODE

MASK

Registers in the black cells do not exist. Therefore, these

registers cannot be written and the read values are always

zero. The bits with numeric values (0 or 1) must remain

as−is.

There are some register addresses which contain both the

bits stored in NVM and the bits not stored in NVM. Confirm

the bit types to save the data to NVM.

www.onsemi.com

23

Page 24

Register Description

T able 21. REGISTER ADDRESS 0x0000−0x0005 Register Description 1

Function

Address

Bits

Register Name

Description

Fixed register 1

0x0000

[7:0]

−

Data of 0xAA are stored. (Read only)

Fixed register 2

0x0001

[7:0]

−

Data of 0x55 are stored. (Read only)

Enable re−calculation

0x0002

[1]

RECALC_EN

This register enable re−calculation of Speed/

Register re−loading

0x0002

[0]

RELOAD_EN

This register enables data reloading from NVM.

Register re−loading

0x0003

RELOAD

When this bit is set to 1, data reloading from NVM

Trigger of re−calculation

0x0004

[0]

RECALC

When this bit is set to 1, re−calculation of Speed/

Device ID

0x0005

[7:0]

ID_NUMBER

Data of device ID are stored. (Read only)

Table 22. REGISTER ADDRESS 0x0100−0x0109 Register Description 2

Function

Address

Bits

Register Name

Description

Minimum speed setting

0x0100

[7:1]

TAG_L

s.

Maximum speed setting

0x0101

[7:1]

TAG_H

Minimum input duty cycle

0x0102

[6:1]

DUTY_L

These registers set minimum input duty−cycle.

Maximum input duty cycle

0x0103

[6:1]

DUTY_H

These registers set maximum input duty−cycle.

Lead−angle setting at

0x0104

[3:0]

DLDEG_L

This register adjusts lead−angle at rotational

Lead−angle setting at

0x0104

[7:4]

DLDEG_H

This register adjusts lead−angle at rotational

LV8314C

Lead Angle/Soft SW setting.

0: Disable

1: Enable

(memory to register)

(memory to register)

setting

setting

[0]

0: Disable

1: Enable

is executed while RELOAD_EN is set to 1.

This register is auto clear type.

Lead Angle/Soft SW setting is executed while

RECALC_EN is set to 1.

This register is auto clear type.

These registers set minimum/maximum output

duty−cycle.

000 0000: 0%

111 1111: 100%

Also 111 1110 and 111 1111: 100%

*Refer to the section “Steady Rotation” for detail

00 0000: Duty 0%

11 1111: Duty 49.3%

00 0000: Duty 50.4%

11 1111: Duty 100%

minimum speed

maximum speed

0x0108

0x0108

[6]

[7]

www.onsemi.com

speed set by TAG_L.

0000: 0°,

1111: −5.25 or −10.5°

(DLDEG_L[4] = 0)

0000: 0°,

1111: +5.25 or +10.5°

(DLDEG_L[4] = 1)

*Refer to register of “DL_RESO” description.

speed by TAG_H.

0000: 0°,

1111: −5.25 or −10.5°

(DLDEG_H[4] = 0)

0000: 0°,

1111: +5.25 or +10.5°

(DLDEG_H[4] = 1)

*Refer to register of “DL_RESO” description.

24

Page 25

LV8314C

T

Soft switch width setting at

0x0105

[7:4]

SSWHIGH_F

Soft switch width of top is set at rotational speed

Soft switch width setting at

0x0105

[3:0]

SSWLOW_F

Soft switch width of top is set at rotational speed

Soft switch width setting at

0x0106

[7:4]

SSWHIGH

Soft switch width of tail is set at rotational speed

Soft switch width setting at

0x0106

[3:0]

SSWLOW

Soft switch width of tail is set at rotational speed

Increment Ratio of the Output

0x0107

[7:6]

PWM_ROC

This register sets the increment ratio of the

FG/RD select

0x0107

[5:4]

TACHSEL

This register sets FG pin function.

RD polarity select

0x0107

[3]

RD_INV

RD polarity select at RD output by TACHSEL

Soft start end duty−cycle

0x0107

[2]

SSTART_SEL

This register sets Soft start end duty−cycle.

Soft start release time

0x0107

[1:0]

INCTIM

This register sets the soft start duration time.

Lead angle resolution select

0x0108

[5]

DL_RESO

This register sets the lead angle resolution and

Speed control slope invert

0x0108

[4]

PWMIN_INV

Control slope polarity for input duty−cycle is

able 22. REGISTER ADDRESS 0x0100−0x0109 Register Description 2 (continued)

Function DescriptionRegister NameBitsAddress

maximum speed

minimum speed

maximum speed

minimum speed

duty−cycle

set by TAG_H.

0000: 2.9% equivalency of one commutation

period.

1111: 46.9% equivalency of one commutation

period.

set by TAG_L.

0000: 2.9% equivalency of one commutation

period.

1111: 46.9% equivalency of one commutation

period.

set by TAG_H.

0000: 2.9% equivalency of one commutation

period.

1111: 46.9% equivalency of one commutation

period.

set by TAG_L.

0000: 2.9% equivalency of one commutation

period.

1111: 46.9% equivalency of one commutation

period.

output−duty.

00: 0.2% per 128 pulses

01: 0.2% per 256 pulses

10: 0.2% per 512 pulses

11: Change immediately to target output

duty−cycle

00: FG output (1 times hall frequency)

01: FG output (2 times hall frequency)

10: FG output (0.5 times hall frequency

11: RD output (Polarity is decided by RD_INV

register)

register.

0: Low in rotation, High in lock protection

1: High in rotation, Low in lock protection

0: 24% output duty−cycle

1: 54% output duty−cycle

*Refer to the section “Soft Start” for details.

width.

0: 0.70° per DLDEG register, adjustment

width is ±10.5°

1: 0.35° per DLDEG register, adjustment

width is ±5.25°

changed.

0: Normal mode (Low duty−cycle is low speed

rotation)

1: Invert mode (Low duty−cycle is high speed

rotation)

www.onsemi.com

25

Page 26

LV8314C

T

Minimum speed setting 2

0x0108

[3]

DUTY_S

This register sets the speed when input

Maximum speed setting 2

0x0108

[2]

FULL

This register defines the output behavior when

CLM threshold level select

0x0108

[1]

CL_LVL

This register sets current limiter threshold level.

Sync/Async drive select

0x0108

[0]

DRVMODE

This register selects synchronous/asynchronous

Input PWM average setting

0x0109

[5:4]

PWMAV

The number of times to perform averaging for

Lock protection enable

0x0109

[3]

LOCK_EN

This register selects enable or disable of the lock

r

Standby period for FG pulse

0x0109

[2]

LOCK_DET

This register sets standby period for FG pulse in

Condition to enter Lock

0x0109

[1]

OCP_LAT_CLR

This register selects the status when OCP is

Mask time for reverse

0x0109

[0]

OCP_MASK

This register sets the masking time to ignore the

e

ORDERING INFORMATION

Device Order Number

Specific Device Marking

Package Type

Shipping

†

LV8314CGR2G

LV8314C

TSSOP−14

2500 / Tape & Reel

able 22. REGISTER ADDRESS 0x0100−0x0109 Register Description 2 (continued)

Function DescriptionRegister NameBitsAddress

duty−cycle is less than DUTY_L.

0: Fixed speed set by DUTY_L

1: Fixed output duty−cycle of 0%

input PWM is greater than the duty cycle set by

DUTY_H.

0: Fixed speed set by TAG_H

1: Fixed duty cycle of 100% with soft switch

0: 100 mV

1: 75 mV

drive.

0: High−side switching is PWM. Low−side

switching is asynchronous

1: High−side switching is PWM. Low−side

switching is synchronous

input PWM duty cycle.

00: Averaged 4 times

01: Averaged 8 times

10, 11: Not averaged

protection function.

0: Lock protection disable

1: Lock protection enable

Please set it to 0 for normal use. To set to 1 is fo

test use only.

in Lock protection

Protection mode in OCP

active

recovery time setting

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

Lock protection.

0: 0.7 s

1: 1.0 s

activated.

0: The motor stops until next power on

sequence

1: The IC goes to “Lock Protection mode”

reverse recovery for both high−side and low−sid

Power FET.

0: 0.5 ms

1: 1.0 ms

(Pb−Free)

www.onsemi.com

26

Page 27

TSSOP−14 WB

0.10 (0.004)

P

−T−

SEATING

PLANE

LV8314C

PACKAGE DIMENSIONS

CASE 948G

ISSUE C

14X REFK

S

U

T

S

N

0.25 (0.010)

U0.15 (0.006) T

S

2X L/2

0.10 (0.004) V

14

M

8

M

L

PIN 1

IDENT.

1

S

U0.15 (0.006) T

A

−V−

B

N

−U−

F

7

DETAIL E

K

K1

J

J1

SECTION N−N

C

D

G

H

DETAIL E

SOLDERING FOOTPRINT

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD

FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH OR GATE BURRS SHALL NOT

EXCEED 0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE

INTERLEAD FLASH OR PROTRUSION.

INTERLEAD FLASH OR PROTRUSION SHALL

NOT EXCEED 0.25 (0.010) PER SIDE.

5. DIMENSION K DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.08 (0.003) TOTAL

IN EXCESS OF THE K DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. TERMINAL NUMBERS ARE SHOWN FOR

REFERENCE ONLY.

7. DIMENSION A AND B ARE TO BE

DETERMINED AT DATUM PLANE −W−.

INCHESMILLIMETERS

−W−

DIM MIN MAX MIN MAX

A 4.90 5.10 0.193 0.200

B 4.30 4.50 0.169 0.177

C −−− 1.20 −−− 0.047

D 0.05 0.15 0.002 0.006

F 0.50 0.75 0.020 0.030

G 0.65 BSC 0.026 BSC

H 0.50 0.60 0.020 0.024

J 0.09 0.20 0.004 0.008

J1 0.09 0.16 0.004 0.006

K 0.19 0.30 0.007 0.012

K1 0.19 0.25 0.007 0.010

L 6.40 BSC 0.252 BSC

M 0 8 0 8

____

7.06

1

0.65

PITCH

14X

0.36

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor ’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

14X

1.26

DIMENSIONS: MILLIMETERS

UBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

◊

www.onsemi.com

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

27

Loading...

Loading...