Page 1

EVBUM2277/D

KAI-2093 Image Sensor

Evaluation Timing

Specification

12-bit 20 MHz AFE

Altera Code Version Description

The Altera code described in this document is intended for

use in the KSC−1000 Timing Boar. The code is developed

specifically for use with the following system configuration:

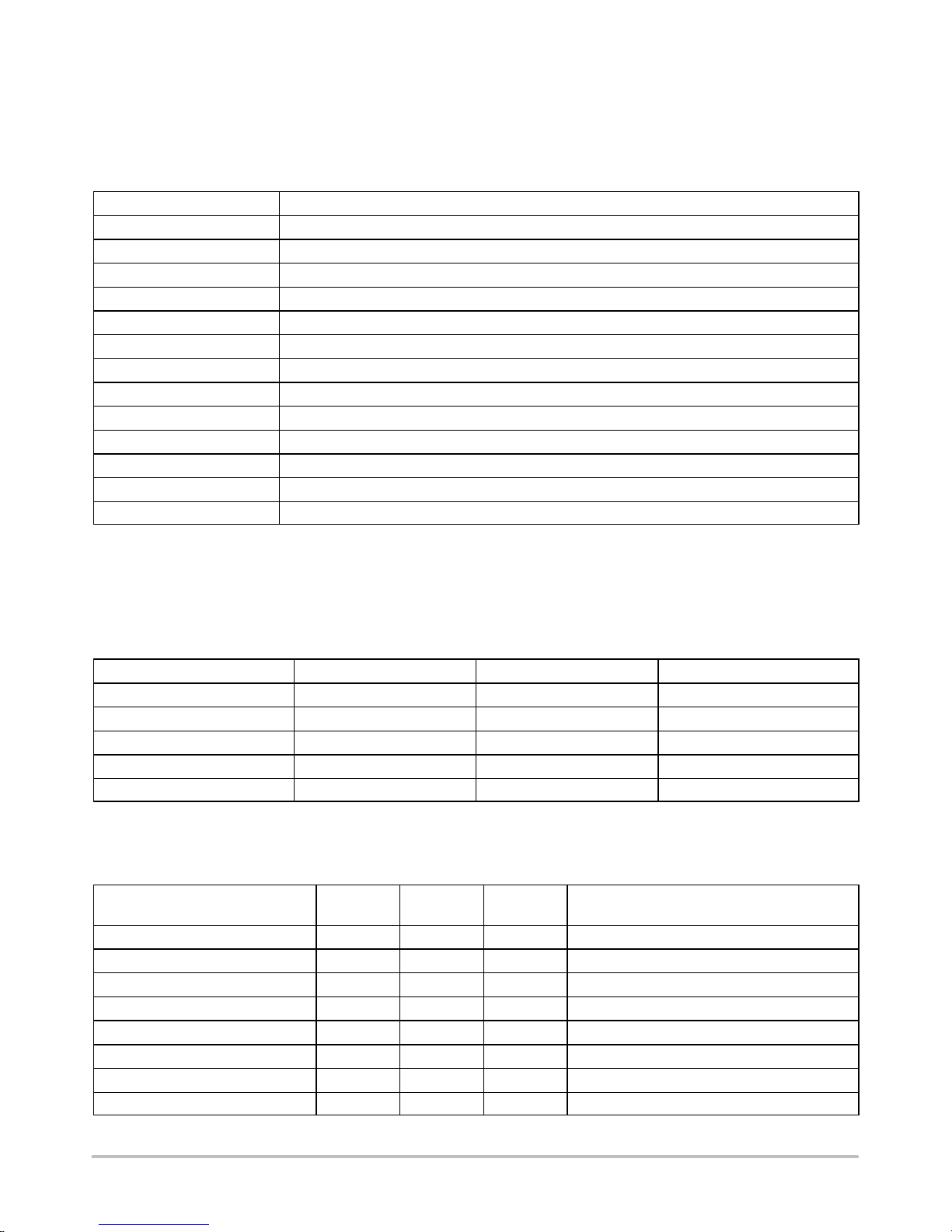

Table 1. SYSTEM CONFIGURATION

Evaluation Board Kit PN 4H0706

Timing Generator Board PN 3F5051 (AD9845A 20 MHz)

KAI−2001/KAI−2020/KAI−2093 CCD Imager Board PN 3F5121

Framegrabber Board National Instruments Model PCI−1424

The 3F5051 Timing Generator Board features the

KSC−1000 Timing Generator chip. The KSC−1000

provides all of the signals necessary for an imaging system

using Full Frame (KAF) or Interline (KAI) family of image

ALTERA CODE FEATURES/FUNCTIONS

The Altera Programmable Logic Device (PLD) serves as

a state machine, which performs a variety of functions.

Three basic functions are required, common to all CCD

image sensor configurations: serial input steering, AFE

default programming, and KSC−1000 default

programming. In addition, certain other functions specific t o

the KAI−2093 Image Sensor are implemented.

Serial Input Steering

The 3-wire serial interface enters the Timing Board

through the DIO Interface connector, and is routed to the

www.onsemi.com

EVAL BOARD USER’S MANUAL

sensors. It also provides the signals necessary for operation

of two analog front-end (AFE) chips, enabling independent

optimization of the AFE chips for dual channel readout

devices.

PLD. The Altera PLD decodes the addressing of the serial

input, and steers the datastream to the correct device.

The serial input must be formatted so that the Altera PLD

can correctly decode and steer the data to the correct device.

The serial interface can be used to dynamically change the

operating conditions of the AFE or KSC−1000 chips by

reprogramming the appropriate registers. Reprogramming

these registers through the serial interface will have no effect

on the default settings that are automatically programmed

into these devices on power-up or board reset.

Table 2. SERIAL INPUT DEVICE SELECT

Device Select DS[2..0] Serial Device

000 PLD

001 AFE1

010 AFE2

011 KSC−1000

100 (Not Used)

101 (Not Used)

110 (Not Used)

111 (Not Used)

© Semiconductor Components Industries, LLC, 2014

October, 2014 − Rev. 2

1 Publication Order Number:

EVBUM2277/D

Page 2

EVBUM2277/D

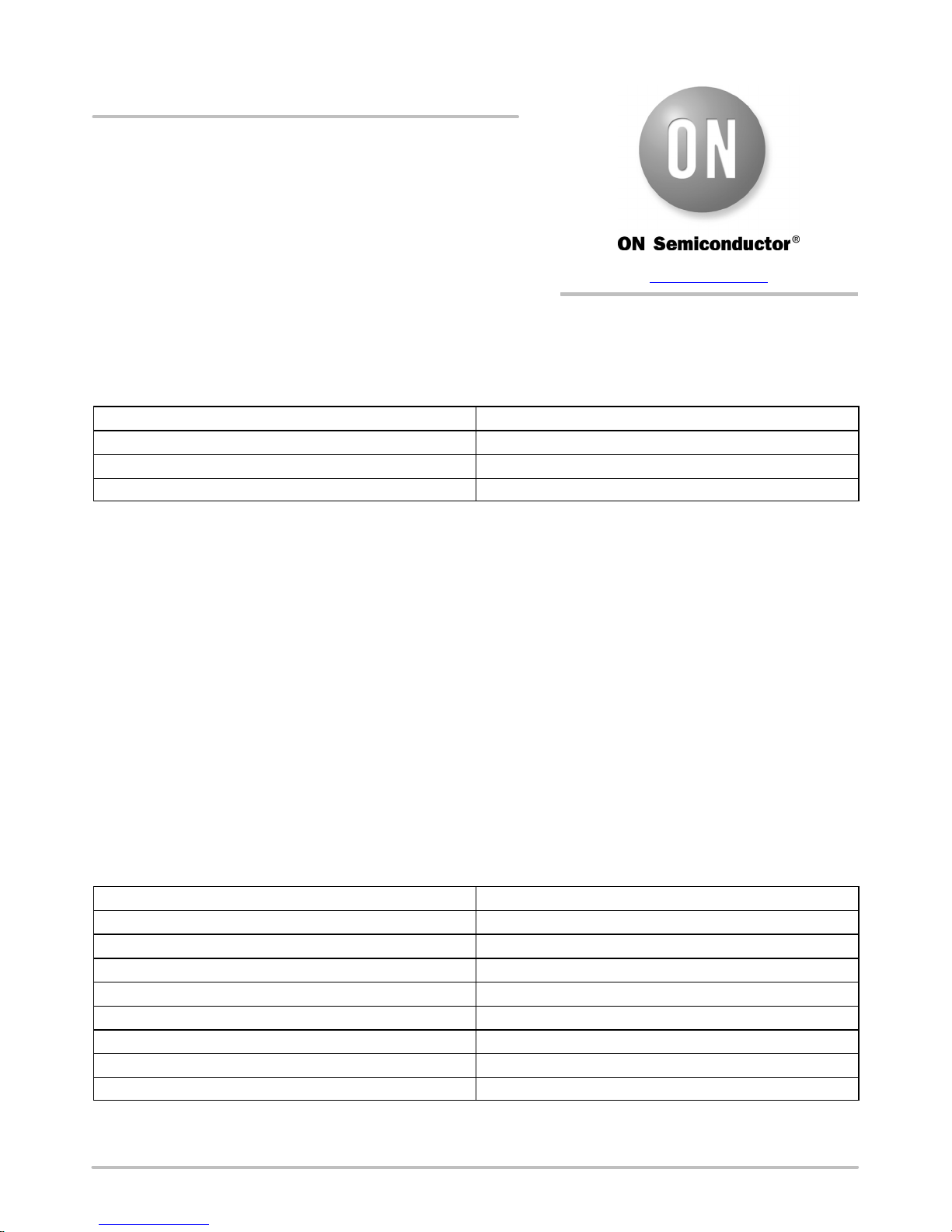

DS2

DS1

DS0

R/WA0A1A2A3 (or Test)D0D1D2D3

SLOAD_INPUT

SLOAD_xxx

SDATA_INPUT

SCLK_INPUT

(decoded PLD output)

Figure 1. Serial Input Timing

The first 3 bits in the datastream are the Device Select bits

DS[2..0], sent MSB first, as shown in Figure 1. The Device

Select bits are decoded as shown in Table 2.

The next bit in the datastream is the Read/Write bit (R/W).

Only writing is supported; therefore this bit is always LOW.

The definition of next four bits in the datastream depends

on the device being addressed with the Device Select bits.

For the KSC−1000 device, they are Register address bits

A[0..3], LSB first. For the AD9845A AFE, they are Register

Address bits A[0..2], LSB first, followed by a Test bit which

is always set LOW.

…

D4

Dn

The remaining bits in the bitstream are Data bits, LSB

first, with as many bits as are required to fill the appropriate

register.

AFE Default Initialization

Upon power up, or when the BOARD_RESET button is

pressed, the PLD programs the registers of the two AFE

chips on the T iming Generator Board to their default settings

via the 3-wire serial interface. See Table 9 for details.

The AD9845A AFE must be reprogrammed on power-up,

as it does not retain register settings when power is removed.

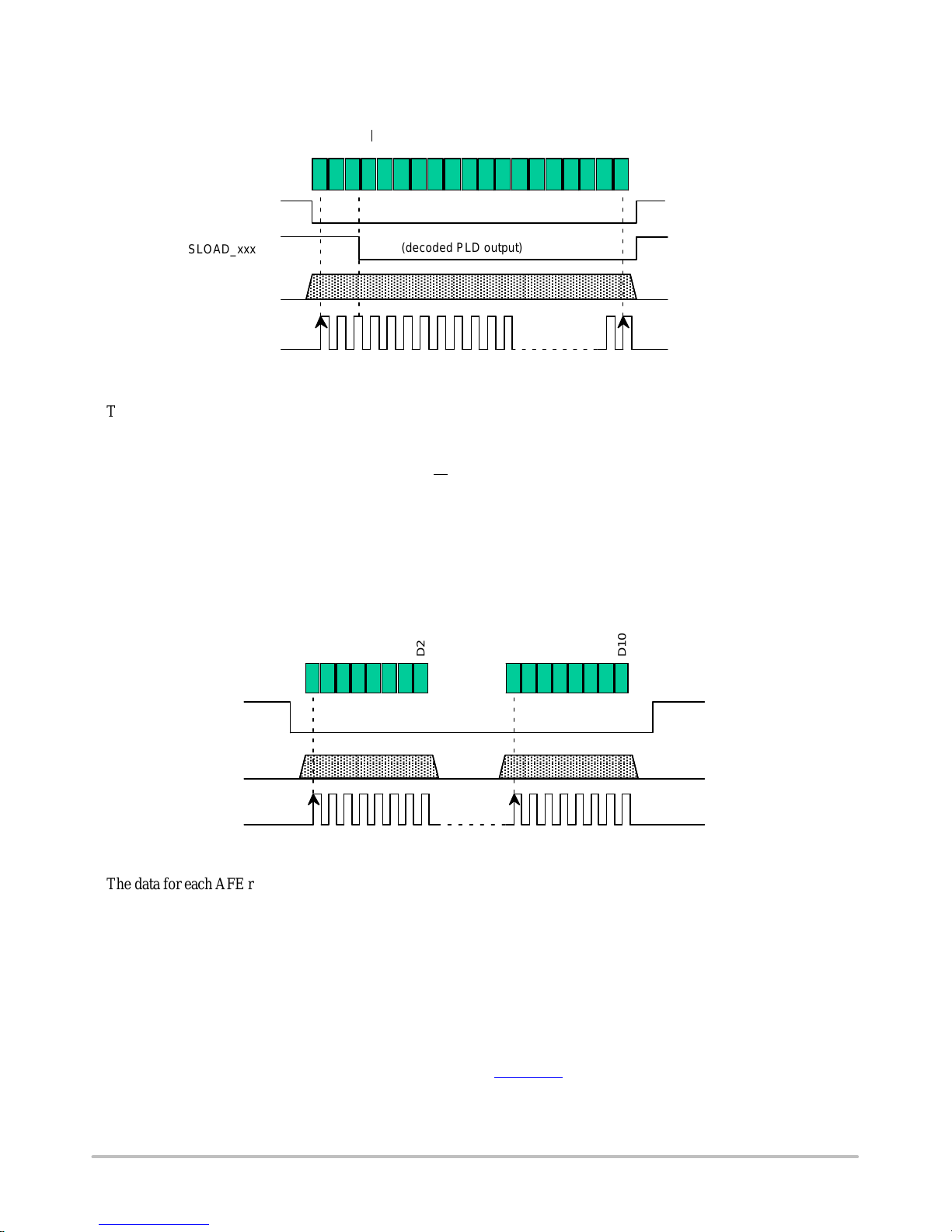

R/WA0A1A2TestD0D1

SLOAD_AFE_x

SDATA

SCLK

Figure 2. AFE Initialization Timing

D2

The data for each AFE register is formatted into two bytes

of data, as shown in Figure . The Read/Write bit is always

low, and the Address bits specify the register being

programmed, as shown in Table 9. Each byte is read into an

8-bit shift register, and is shifted out as a serial stream of

eight bits. Each register in the AFE is programmed in this

fashion until the entire AFE is programmed.

KSC−1000 Default Initialization

Upon power-up, or when the BOARD_RESET button is

pressed, the Altera PLD programs the registers of the

KSC−1000 chip on the AFE Timing Generator Board to

their default settings via the 3-wire serial interface.

D3

D4

D5D6D7D8D9

D10

The default setti ngs are selected by the user through the PLD

inputs SW[7..0] and DIO[15..0] (See Table 10 through

Table24 for details). The KSC−1000 must be

reprogrammed on power-up, as it does not retain register

settings when power is removed.

The KSC−1000 default settings automatically

programmed by the PLD allow the Evaluation Board Kit

user to operate the CCD image sensor with minimal

intervention and no programming. The default settings are

chosen to comply with the CCD device specification (See

References

). The registers, line tables and frame tables

described in this document also serve as examples for those

who wish to create their own KSC−1000 timing.

http://onsemi.com

2

Page 3

EVBUM2277/D

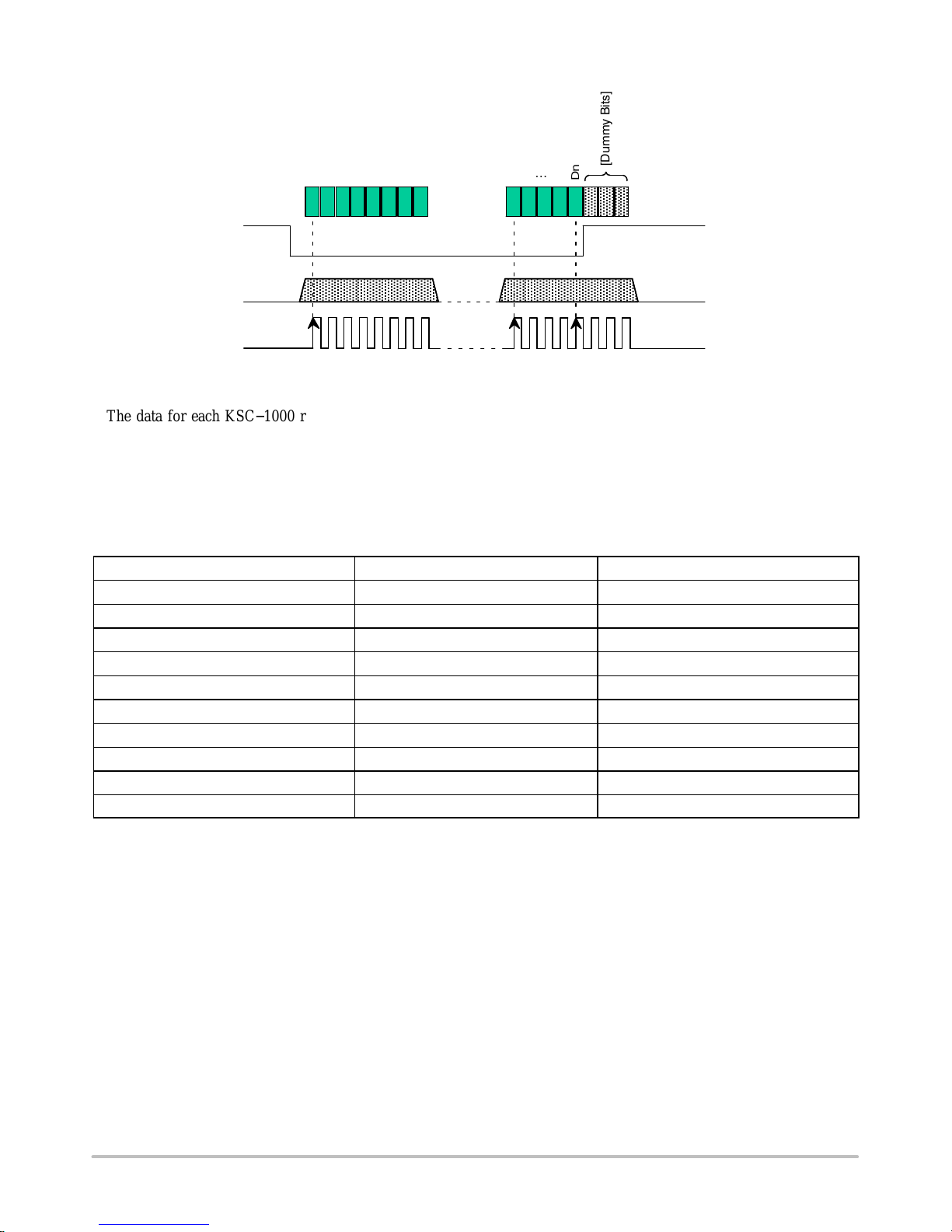

R/WA0A1A2A3D0D1

SLOAD_TG

SDATA

SCLK

Figure 3. KSC−1000 Initialization Timing

D2

The data for each KSC−1000 register is formatted into

bytes of data, as shown in Figure 3. The Read/Write bit is

always low, and the Address bits specify the register being

programmed, as shown in Table 3. Each byte is read into an

8-bit shift register, and is shifted out of the PLD as a serial

stream of eight bits. The last byte of data sent to a particular

T able 3. KSC−1000 REGISTERS

Register Address Register Description Data Bits

0 Frame Table Pointer 3

1 General Setup 202

2 General Control 2

3 INTG_STRT Setup 30

4 INTG_STRT Line 13

5 Signal Polarity 25

6 Offset 78

7 Width 65

8 Frame Table Access (Variable)

9 Line Table Access (Variable)

…

[Dummy Bits]

Dn

register may need to be padded with extra “dummy” bits;

the SLOAD_TG signal is brought HIGH at the appropriate

time so that the correct number of bits are streamed into each

register, and the extra bits are ignored. Each register in the

KSC−1000 is programmed in this fashion until the entire

device is programmed.

PLD State Machine

The Altera PLD contains a State Machine that parallels

the operation of the KSC−1000. The PLD controls the

KSC−1000 through the VD_TG output, and monitors

several of the KSC−1000 outputs, enabling it to track and

control the operation of the Timing Generator.

Remote Board Reset

The DIO14 input is used as a remote Board Reset control

line. The Altera PLD monitors this input, and when DIO14

goes HIGH, the ARSTZ (active low) output to the

KSC−1000 is asserted, disabling and clearing the timing

generator. When DIO14 goes LOW, the ARSTZ output is

de-asserted, and the Power-up/Board Reset initialization

sequence is executed. This allows programmable control of

the timing sequences to change the Electronic Shutter

position, for example.

Integration Clock

The Altera PLD uses the System Clock and an internal

counter to generate a 1 . 0ms-period clock. This clock is used

to generate an internal delay after power-up or Board Reset.

It may also be used to control precise integration times for

the image sensor.

Output Channel Control

PLD input SW0 is used to select one of the supported

operation modes: Full Field Single Output, and Full Field

Dual Output. When making a change to the switch settings,

the user must initiate a Board Reset for the change to take

http://onsemi.com

3

Page 4

EVBUM2277/D

effect, either by pressing the BOARD_RESET button (S1)

on the Timing Board, or by setting and resetting the Remote

Reset (DIO14) input.

Binning Control

PLD input SW2 is used to select between 2×2 Binning

Single Output, and normal operation (no binning). When

making a change to the switch settings, the user must initiate

Integration & Electronic Shutter Control

In the Full Field Timing Modes, PLD inputs DIO[11..7]

may be used to select the integration time. See T able 25 for

a Board Reset for the change to take effect, either by pressing

the BOARD_RESET button (S1) on the Timing Board, or

by setting and resetting the Remote Reset (DIO14) input.

timing details. In general, when making a change to the

DIO[11..7] settings, the user must initiate a Board Reset for

the change to take effect, either by pressing the

BOARD_RESET button (S1) on the Timing Board, or by

setting and resetting the Remote Reset (DIO14) input.

Video Mux Switch

The PLD input SW6 controls the Video Mux Switch,

which steers either CCD output VoutL or VoutR to the

auxiliary video output connector J1.

ALTERA CODE I/O

Inputs

The Altera PLD has multiple inputs that may be used to

control certain functions. The inputs include: user selectable

switches SW[7..0] on the Timing Board; remote digital

inputs DIO[15..0] and a 3-wire serial interface through

Timing Board connector J7; Timing Board signals;

and various outputs from the KSC−1000 Timing Generator.

Table 4. ALTERA INPUTS

Symbol

POWER_ON_DELAY The Rising Edge of this Signal Clears and Re-initializes the PLD

SYSTEM_CLK 40 MHz Clock, 2X the Desired Pixel Clock Rate

PIXCLK NI1424 20 MHz Pixel Rate Clock from the KSC1000TG (Not Used)

SW0 HIGH = Dual Output, Full Image, LOW = Single Output, Full Image

SW1 (Not Used, Must be LOW)

SW2 Binning Mode: HIGH = 2 x 2 Binning, Single Output, LOW = No Binning

SW3 (Not Used)

SW4 (Not Used)

SW5 (Not Used)

SW6 Video Mux Switch Control: HIGH = VoutR, LOW = VoutL

SW7 (Not Used)

DIO[6..0] (Not Used)

DIO[11..7] Integration Control (See Table 24)

DIO12 (Not Used)

DIO13 (Not Used)

DIO14 Remote Board Reset (HIGH Activates ARSTZ, Falling Edge Activates BOARD_RESET)

SLOAD_INPUT 3-wire Serial Interface LOAD Signal Input

SDATA_INPUT 3-wire Serial Interface DATA Signal Input

SCLOCK_INPUT 3-wire Serial Interface CLOCK Signal Input

LINE_VALID Used to Monitor KSC−1000

FRAME_VALID Used to Monitor KSC−1000

AUX_SHUT (Not Used for KAI−2093 Operation)

INTG_START Used to Monitor KSC−1000

The KSC−1000 outputs are monitored by the PLD to control

auxiliary timing functions, and keep the KSC−1000 and

Altera PLD synchronized. The remote digital inputs

DIO[15..0] are optional, and are not required for KAI−2093

operation, but may be used to control integration time and

remote triggering.

Description

http://onsemi.com

4

Page 5

EVBUM2277/D

Outputs

The Altera PLD outputs include: the 3-wire serial

interface; control signals to the KSC−1000;

the INTEGRATE signal used for external monitoring and

Table 5. ALTERA OUTPUTS

Symbol

PLD_OUT0 KAI−2093 Video MUX Control

PLD_OUT1 (Not Used for KAI−2093 Operation)

PLD_OUT2 (Not Used for KAI−2093 Operation)

GIO[2..0] (Not Used for KAI−2093 Operation)

SLOAD_AFE_1 Serial Load Enable, Ch1 AD9845A AFE

SLOAD_AFE_2 Serial Load Enable, Ch2 AD9845A AFE

SLOAD_TG Serial Load Enable, KSC−1000

SDATA 3-wire Serial Interface DATA Signal Output

SCLOCK 3-wire Serial Interface CLOCK Signal Output

INTEGRATE High During CCD Integration Time

HD_TG (Not Used for KAI−2093 Operation)

VD_TG Control Signal to KSC−1000

ARSTZ Asynchronous Reset to KSC−1000 (from DIO14)

synchronization; the PLD[2..0] signals which are auxiliary

Imager Board control bits; and the GIO[2..0] bits which are

used for PLD monitoring and testing.

Description

System Timing Conditions

Table 6. SYSTEM TIMING

Description Symbol Time Notes

System Clock Period T

Unit Integration Time U

Power Stable Delay T

Default Serial Load Time T

Integration Time T

CCD Timing Conditions

Table 7. CCD TIMING

Description

H1, H2, RESET Period T

VCCD Delay T

VCCD Transfer Time T

HCCD Delay T

Vertical Transfer Period V

Horizontal Pixels H

Vertical Pixels V

Line Transfer Time T

KAI−2093 TIMING CONDITIONS

sys

int

pwr

sload

int

Pixel

Symbol Time

pix

VD

VCCD

HD

period

PIX

PIX

L

50.0 ns 1 20 MHz Clocking of H1, H2, RESET

50.0 ns 1 Delay after Hclks Stop

1.75 ms

1.55 ms

3.35 ms

100.80 ms

1220 1214 CCD Lines + 6 Overclock Lines

104.15 ms

Counts

35 V2 Rising Edge to V2 Falling Edge

31 Delay before Hclks Resume

67 V

2016 1992 CCD Pixels + 24 Overclock Pixels

2083 TL = Vperiod + HPIX

25.0 ns 40 MHz System Clock

1.0 ms Generated by PLD

100 ms Typical

2.06 ms Typical

Operating Mode Dependent

Notes

= T

period

VD

+ T

VCCD

+T

HD

http://onsemi.com

5

Page 6

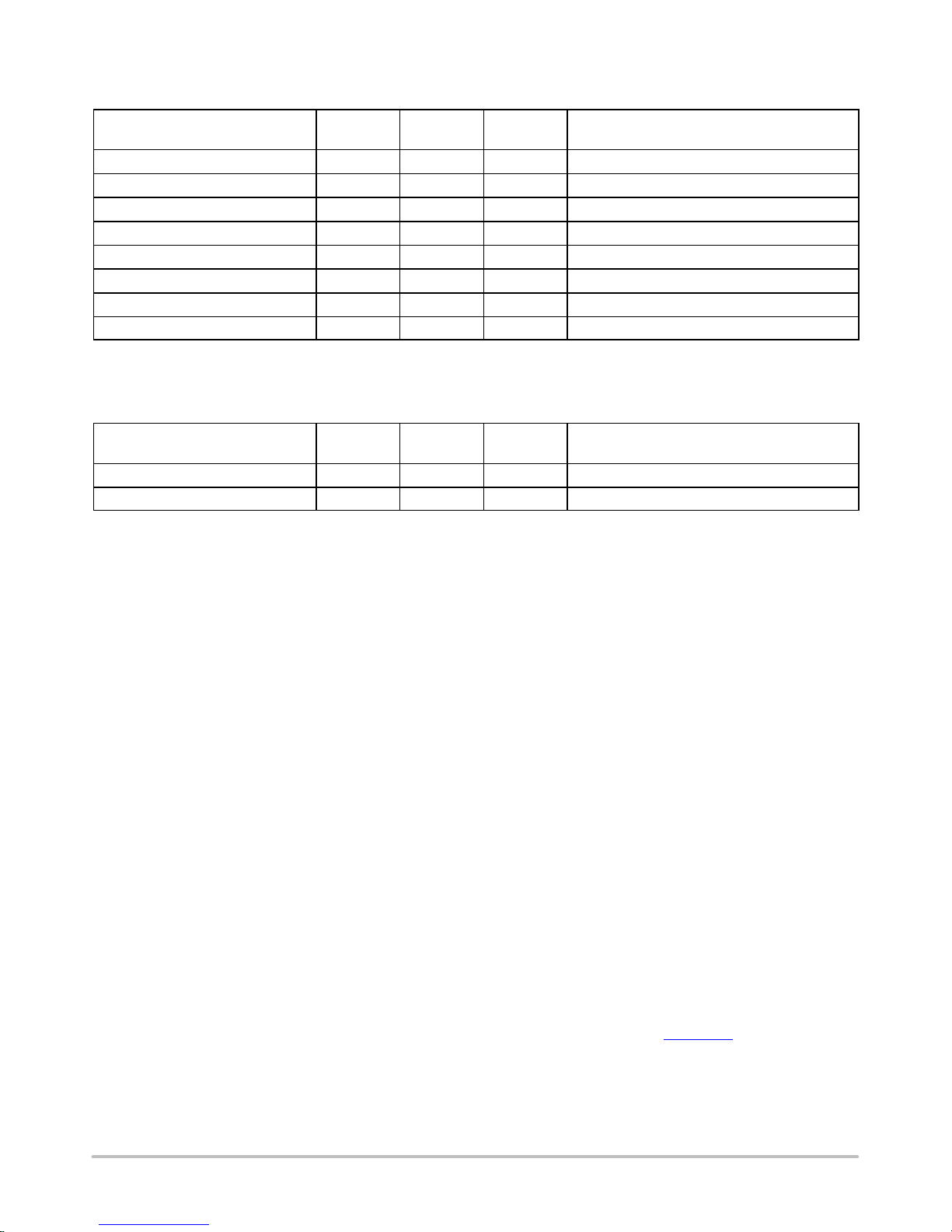

Table 7. CCD TIMING (continued)

Description Notes

VCCS Pedestal Time T

Photodiode Transfer Time TV

Photodiode Delay T

Photodiode Frame Delay T

Photodiode Transfer Period T3PT

Shutter Pulse Setup T

Shutter Pulse Time T

Shutter Pulse Delay T

PCI−1424 Timing Conditions

Table 8. PCI−1424 TIMING

Description Symbol Time

PIX Period T

FRAME Time T

3P

3rd

3D

3FD

EL

S

SD

PIX

FRAME

EVBUM2277/D

Pixel

TimeSymbol

25.05 ms

12.30 ms

20.00 ms

85.50 ms

142.85 ms

1.50 ms

10.0 ms

1.50 ms

50.0 ns 1 20 MHz Clocking of DATACLK Sync Signal

127.2 ms 2,544,117 T

Counts

501

246 V2 3rd Level

400

1710 Delay before 1st Line Transfer

2857 T

30

200

30

Pixel

Counts

FRAME

3PT

= T

= T3P + T

* ((V

PIX

V3rd

Notes

period

+ T3D + T

+ H

PIX

) * V

3FD

PIX

+ T

3PT

)

MODES OF OPERATION

The following modes of operation are available to the

user:

Electronic Shutter Modes

The Evaluation Board electronic shutter circuitry

provides a method of precisely controlling the image

exposure time without any mechanical components. Charge

may be cleared from the CCD photodiodes at some time

during the readout of the previous frame. This allows

integration times of less than one frame time, to compensate

for high light exposures that would otherwise saturate the

CCD.

In Free-Running Mode, the default integration time can be

set from 1× to 1/8× frame time via the digital inputs

DIO[11..7] (See Table 14 and Table 25). When changing the

POWER-ON/BOARD RESET INITIALIZATION

When the board is powered up, the Board Reset button is

pressed, or the Remote Rest (DIO14) is toggled, the Altera

PLD is internally reset. When this occurs, state machines in

the PLD will first serially load the initial default values into

the AFE registers, then will load the KSC−1000 frame

tables, line tables, and registers.

Upon completion, the KSC−1000 will be ready to proceed

according to its programmed configuration. In the

background, the Altera PLD monitors the activity of the

integration time, the user must initiate a Board Reset for the

change to take effect, either by pressing the

BOARD_RESET button (S1) on the Timing Board, or by

setting and resetting the Remote Reset (DIO14) input.

Black Clamp Mode

One of the features of the AD9845A AFE chip is an

optical black clamp. The black clamp (CLPOB) is asserted

during the CCD’ s dark pixels and is used to remove residual

offsets in the signal chain, and to track low frequency

variations in the CCD’s black level. The location of these

pulses is fixed in the default KSC−1000 settings, but can be

adjusted dynamically through the 3-wire serial interface.

The default settings are shown in Table 11.

3-wire Serial Interface, and monitors and interacts with the

KSC−1000.

AFE Register Default Settings

On power-up or board reset, the AFE registers are

programmed to the default levels shown in T able 9. See the

AD9845A specifications (References

) for details of the

AFE registers.

http://onsemi.com

6

Page 7

EVBUM2277/D

Table 9. DEFAULT AD9845A AFE REGISTER PROGRAMMING

Register

Address

0 Operation 128

1 VGA Gain

2 Clamp 96 The Output of the AD9845A will be Clamped to Code 96 during the CLPOB Period

3 Control 8 CDS Gain Enabled

4, 5, 6, 7 PXGA Gain 43 Corresponds to a PXGA Stage Gain of 0.0 dB

Description

(KAI−2093)

Value

(decimal)

340 Corresponds to a VGA Stage Gain of 9.9 dB

Notes

KSC−1000 Timing Generator Default Settings

On power-up or board reset, The KSC−1000 is

programmed to the default settings as detailed in Table 10

through Table 24. See the KSC−1000 Device Specification

(References

) for details of the KSC−1000 registers.

Register 0: Frame Table Pointer

Register 0 contains the Frame Table Pointer, which

instructs the KSC−1000 to perform the timing sequence

defined in that table. Frame Table 0 is used for Free-Running

Single Channel and Dual Channel modes, and Frame

Table 1 is used for Single Channel 2×2 Binning mode.

The default setting depends on the position of SW2.

Table 10. REGISTER 0 DEFAULT SETTING

Register Entry Data (Normal Mode) Data (Binning 2y2)

Frame Table Address 0 1

Register 1: General Setup

The default settings written to Register 1 depend on the

position of SW0 on the Timing Board, used to select

between 1-channel and 2-channel operation.

Table 11. REGISTER 1 DEFAULT SETTING

Register Entry

Pixels Per Line[0..12] 2016 1008

Line Valid Pixel Start[0..12] 9 9

Line Valid Pixel Quadrature Start[0..1] 0 0

Line Valid Pixel End[0..12] 2004 1007

CLPOB1_Pix_Start[0..12] 1982 1000

CLPOB1_Pix_End[0..12] 1992 1004

CLPOB2_Pix_Start[0..12] 0 0

CLPOB2_Pix_End[0..12] 0 0

CLPDM1_Pix_Start[0..12] 6 22

CLPDM1_Pix_End[0..12] 16 30

CLPDM2_Pix_Start[0..12] 0 0

CLPDM2_Pix_End[0..12] 0 0

PBLK_Pix_Start[0..12] 2002 1001

PBLK_Pix_End[0..12] 1 1

RG_Enable 1 1

H6_Enable 0 0

H4_Enable 1 1

H5_ Enable 0 0

SH2_Enable 1 1

SH4_Enable 1 1

Data (1-channel) Data (2-channel)

http://onsemi.com

7

Page 8

EVBUM2277/D

Table 11. REGISTER 1 DEFAULT SETTING (continued)

Register Entry Data (2-channel)Data (1-channel)

DATACLK1_Enable 1 1

DATACLK2_Enable 1 1

PIXCLK_Enable 1 1

H3_Enable 1 1

H1_Enable 1 1

H2_Enable 1 1

SH1_Enable 1 1

SH3_Enable 1 1

H6 24 mA Output Enable 0 0

H4 24 mA Output Enable 0 0

H5 24 mA Output Enable 0 0

RG 24 mA Output Enable 0 0

SH2 24 mA Output Enable 0 0

SH4 24 mA Output Enable 0 0

DATACLK1 24 mA Output Enable 0 0

DATACLK2 24 mA Output Enable 0 0

H3 24 mA Output Enable 0 0

H1 24 mA Output Enable 0 0

H2 24 mA Output Enable 0 0

SH1 24 mA Output Enable 0 0

SH3 24 mA Output Enable 0 0

DLL Frequency Range Select 8 8

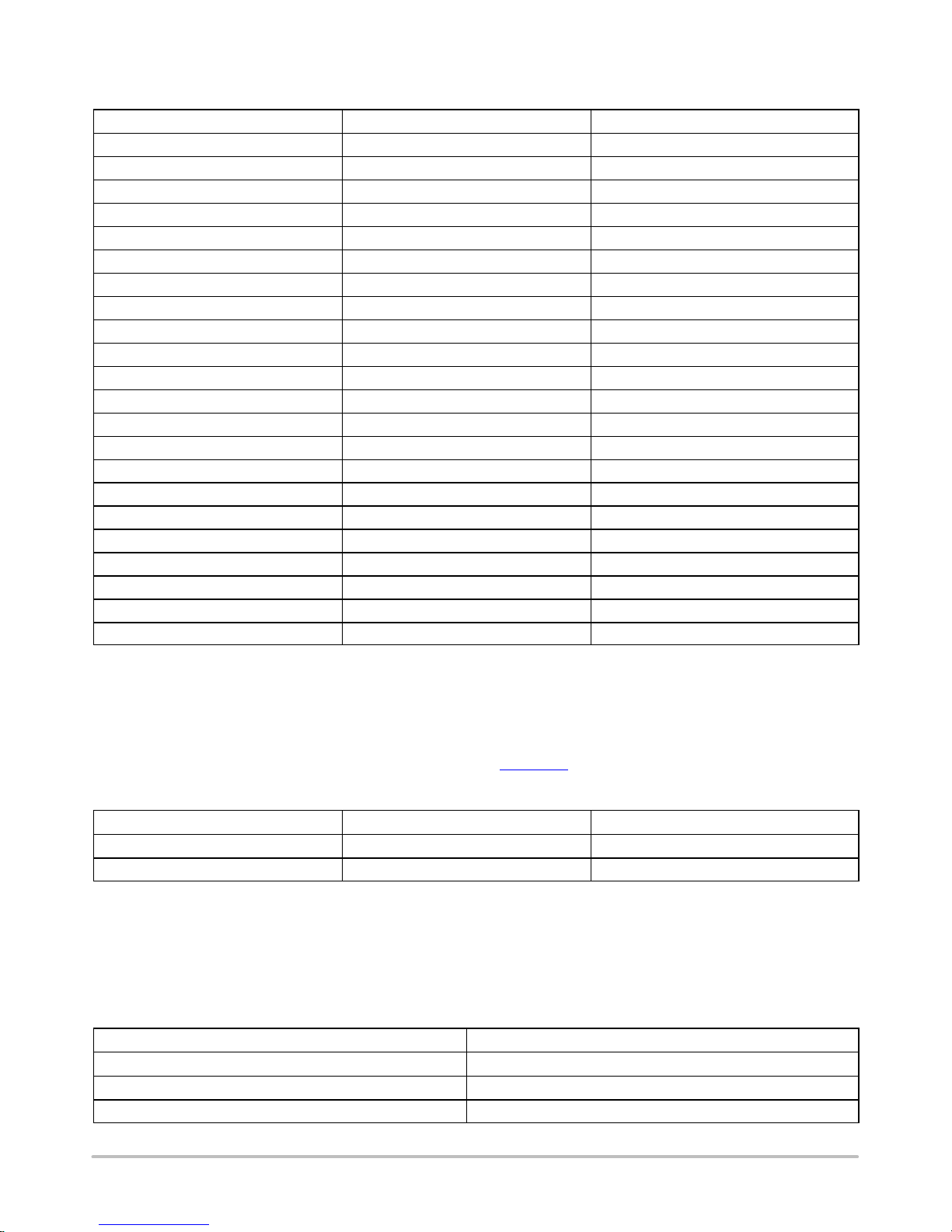

Register 2: General Control

Register 2 controls the Power Management and

Operation state of the KSC−1000. The Low Power Mode is

not used on the KAI−2093, so this bit is always LOW.

The Memory Table Mod e b i t i s u s e d t o halt execution of the

KSC−1000 timing sequences and to enable programming of

Table 12. REGISTER 2 SETTINGS

Register Entry Program Mode Execution Mode

Low Power Enable 0 0

Memory Table Mode 0 1

Register 3: INTG_START Setup

The default settings written to Register 3 establish the

setup, pulsewidth, and hold timing of the Electronic Shutter

pulse. The Shutter Pulse may occur on a particular line, as

controlled by Register 4, or may be asserted by setting the

Table 13. REGISTER 3 DEFAULT SETTING

Register Entry Data

Electronic Shutter Setup Clocks[0..9] 30

Electronic Shutter Pulse Width[0..9] 200

Electronic Shutter Hold Clocks[0..9] 30

the registers. The KSC−1000 Initialization sequence begins

with setting the Memory Table Mode bit in Register 2 to

Program Mode, and ends by setting the bit to Execution

Mode. See the KSC−1000 Device Specification

(References

) for more details.

“Force INTG_STRT ” bit in the Frame Table (Register 8). In

either case, the Electronic Shutter Pulse occurs before the

vertical clocking interval of the Frame Table entry

(Figure 12).

http://onsemi.com

8

Page 9

EVBUM2277/D

Register 4: INTG_START Line

Short integration times may be controlled through use of

the Electronic Shutter. The default setting written to

Register 4 controls the line number on which the Electronic

Shutter will occur . The DIO[11..7] inputs are used to control

the Integration time, by selecting pre-programmed line

numbers, as shown in Table 14.

In Free-Running Mode, the Electronic Shutter pulse

occurs during the previous frame readout. The line number

Table 14. REGISTER 4 DEFAULT SETTING

DIO[11..7] Frame/Flush Integration

0 1 2040 (Default – No Pulse)

1 1/8 966

2 1/4 828

3 3/8 690

4 1/2 552

5 5/8 414

6 3/4 276

7 7/8 138

> 7 See Table25 2040 (No Pulse)

values are chosen to allow integration times adjustable in

increments of one-eighth the Frame or Flush time.

If the line number is greater than the number of lines

specified in a Frame Table (Register 8), the Electronic

Shutter will not occur. This is the method used to turn the

Shutter off ; i n t h i s c ase, the integration time is controlled by

a counter in the Altera PLD (See Table 25).

Integrate Start Pulse Line Number[0..12]

Free-Running Mode

Register 5: Signal Polarity

The default settings written to Register 5 depend on the

position of SW0 on the Timing Board, used to select

between 1-channel and 2-channel operation.

Table 15. REGISTER 5 DEFAULT SETTING

Register Entry 1-channel 2-channel Evaluation Board Signal Name

H6_IDLE_VAL 0 0 (Not Used)

H3_IDLE_VAL 1 1 H1A

H4_IDLE_VAL 0 0 H2A

H1_IDLE_VAL 1 0 H2B

H5_IDLE_VAL 0 0 (Not Used)

H2_IDLE_VAL 0 1 H1B

RG_IDLE_VAL 1 1 RESET

SH2_IDLE_VAL 1 1 SHP1

SH1_IDLE_VAL 1 1 SHP2

SH4_IDLE_VAL 1 1 SHD1

SH3_IDLE_VAL 1 1 SHD2

DATACLK1_IDLE_VAL 1 1 ADCLK (to AFEs)

DATACLK2_IDLE_VAL 0 0 DATACLK (to Framegrabber)

CLPOB_IDLE_VAL 1 1 CLPOB

CLPDM_IDLE_VAL 1 1 CLPDM

AMP_ENABLE_IDLE_VAL 0 0 AMP_ENABLE

FRAME_VALID_IDLE_VAL 0 0 FRAME_VALID

LINE_VALID_IDLE_VAL 0 0 LINE_VALID

INTEGRATE_START_IDLE_VAL 0 0 INTG_START/VES

V1_IDLE_VAL 0 0 V3RD

V2_IDLE_VAL 0 0 (Not Used)

http://onsemi.com

9

Page 10

EVBUM2277/D

Table 15. REGISTER 5 DEFAULT SETTING (continued)

Register Entry Evaluation Board Signal Name2-channel1-channel

V3_IDLE_VAL 0 0 V2

V4_IDLE_VAL 1 1 V1

V5_IDLE_VAL 0 0 (Not Used)

V6_IDLE_VAL 0 0 FDG

Register 6: Pixel-Rate Signal Offset

The default settings written to Register 6 depend on the

position of SW0 on the Timing Board, used to select

between 1-channel and 2-channel operation.

Table 16. REGISTER 6 DEFAULT SETTING

Data

Register Entry

H6_OFFSET[0..5] 0 0 (Not Used)

H3_OFFSET[0..5] 32 32 H1A

H4_OFFSET[0..5] 29 29 H2A

H1_OFFSET[0..5] 33 31 H2B

H5_OFFSET[0..5] 0 0 (Not Used)

H2_OFFSET[0..5] 31 33 H1B

RG_OFFSET[0..5] 0 0 RESET

SH2_OFFSET[0..5] 31 31 SHP1

SH1_OFFSET[0..5] 31 31 SHP2

SH4_OFFSET[0..5] 63 63 SHD1

SH3_OFFSET[0..5] 63 63 SHD2

DATACLK1_OFFSET[0..5] 42 42 ADCLK (to AFEs)

DATACLK2_OFFSET[0..5] 0 0 DATACLK (to Framegrabber)

(1-channel)

Data

(2-channel)

CCD Signal Name

Register 7: Pixel-Rate Signal Width

The default settings written to Register 7 depend on the

position of SW0 on the Timing Board, used to select

between 1-Channel and 2-Channel operation.

Table 17. REGISTER 7 DEFAULT SETTING

Data

Register Entry

H6_WIDTH[0..4] 16 16 (Not Used)

H3_WIDTH[0..4] 13 13 H1A

H4_WIDTH[0..4] 18 18 H2A

H1_WIDTH[0..4] 13 18 H2B

H5_WIDTH[0..4] 16 16 (Not Used)

H2_WIDTH[0..4] 18 14 H1B

RG_WIDTH[0..4] 8 8 RESET

SH2_WIDTH[0..4] 14 14 SHP1

SH1_WIDTH[0..4] 14 14 SHP2

SH4_WIDTH[0..4] 14 14 SHD1

SH3_WIDTH[0..4] 14 14 SHD2

DATACLK1_WIDTH[0..4] 31 31 ADCLK (to AFEs)

DATACLK2_WIDTH[0..4] 16 16 DATACLK (to Framegrabber)

(1-channel)

Data

(2-channel)

CCD Signal Name

http://onsemi.com

10

Page 11

EVBUM2277/D

Register 8: Frame Tables

Several Frame Tables are written by default to the

KSC−1000 Frame T able registers, but only one Frame Table

is active at one time, as determined by the Frame Table

Pointer (Register 0). Frame Table 0 is used for

Free-Running Single Channel and Dual Channel modes, and

Table 18. FRAME TABLE 0 DEFAULT SETTING

Bit Location Frame Table Data

0 Check and Increment Line Counter 1 0 0 0

1 Clear Line Counter 0 1 1 1

2 Force INTG_STRT 0 0 0 0

3:4 Horizontal Binning Factor 0 0 0 0

5 HCLK_V Enable 0 0 0 0

6 LINE_VALID Enable 1 0 0 0

7 FRAME_VALID Enable 1 0 0 0

8 Video Amplifier Enable 0 0 0 0

9 AFE Clock Enable 1 1 1 1

10 CLPDM2 Enable 0 0 0 0

11 CLPDM1 Enable 1 0 0 0

12 CLPOB2 Enable 0 0 0 0

13 CLPOB1 Enable 1 0 0 0

14 PBLK Enable 1 0 0 0

15 Pblk_Idle_Val 1 1 1 1

16 Flag 0 1 0 0

17:29 Count 1104 0 1 0

30:32 Address 2:0 0 4 1 0

33 Address 3 0 0 0 0

− Mnemonic ELT0 ExLTNVD 4 ELT 1 JMPFT 0

Frame Table 1 is used for Single Channel 2×2 Binning

mode. Note that the last row in Table 18 and Table 19 are the

mnemonics associated with the Flag, Count, and Address

bits. See the KSC−1000 Device Specification (References

for more details.

FT0 Entry

0 1 2 3

)

Table 19. FRAME TABLE 1 DEFAULT SETTING

Bit Location Frame Table Data

0 Check and Increment Line Counter 1 0 0 0

1 Clear Line Counter 0 1 1 1

2 Force INTG_STRT 0 0 0 0

3:4 Horizontal Binning Factor 1 0 0 0

5 HCLK_V Enable 0 1 0 0

6 LINE_VALID Enable 1 0 0 0

7 FRAME_VALID Enable 1 0 0 0

8 Video Amplifier Enable 0 0 0 0

9 AFE Clock Enable 1 1 1 1

10 CLPDM2 Enable 0 0 0 0

11 CLPDM1 Enable 1 0 0 0

12 CLPOB2 Enable 0 0 0 0

FT1 Entry

0 1 2 3

http://onsemi.com

11

Page 12

EVBUM2277/D

Table 19. FRAME TABLE 1 DEFAULT SETTING (continued)

Bit Location

Bit Location

13 CLPOB1 Enable 1 0 0 0

14 PBLK Enable 1 0 0 0

15 Pblk_Idle_Val 1 1 1 1

16 Flag 0 1 0 0

17:29 Count 552 0 1 0

30:32 Address 2:0 3 2 1 1

33 Address 3 0 0 0 0

− Mnemonic ELT0 ExLTNVD 5 ELT 1 JMPFT 1

Register 9: Line Tables

There are five Line Tables written by default to the

KSC−1000 Line T able registers. Line Table 0 is the normal

Line Transfer sequence. See Figure 4.

Table 20. LINE TABLE 0 DEFAULT SETTING

CCD Signal Line Table Data Name

FDG V6 0 0 0 0 0 0 0

V1 V4 0 0 1 0 0 0 0

V2 V3 0 1 1 1 0 0 0

V3RD V1 0 0 0 0 0 0 0

Frame Table Data

Frame Table Data

Count[0..12] 1 3 30 2 30 1 0

HCLK_H Enable 0 0 0 0 0 1 0

V5 0 0 0 0 0 0 0

V2 0 0 0 0 0 0 0

FT1 Entry

3210

LT0 Entry

0 1 2 3 4 5 6

Line T able 1 is the normal Photodiode Transfer sequence

that transfers charge from all the photodiodes to the vertical

registers. See Figure 5.

Table 21. LINE TABLE 1 DEFAULT SETTING

CCD Signal

FDG V6 0 0 0 0 0 0 0 0

V1 V4 0 0 0 1 0 0 0 0

V2 V3 0 1 1 1 1 1 0 0

V3RD V1 0 0 1 1 1 0 0 0

Line Table Data Name

Count[0..12] 1 500 6 240 1 400 1310 0

HCLK_H Enable 0 0 0 0 0 0 0 0

V5 0 0 0 0 0 0 0 0

V2 0 0 0 0 0 0 0 0

0 1 2 3 4 5 6 7

http://onsemi.com

LT1 Entry

12

Page 13

EVBUM2277/D

Line Table 2 is the Integration sequence. The vertical

clocks are not active, and the Horizontal register is

continually flushed of charge. See Figure 6.

Table 22. LINE TABLE 2 DEFAULT SETTING

CCD Signal Line Table Data Name

Count[0..12] 1 0

HCLK_H Enable 1 0

FDG V6 0 0

V5 0 0

V1 V4 0 0

V2 V3 0 0

V2 0 0

V3RD V1 0 0

LT2 Entry

0 1

Line Table 3 is the Binning Mode Line Transfer sequence.

Two V1 and V2 pulses occur during each Vertical clocking

interval, followed by Horizontal Register readout. See

Figure 7.

Table 23. LINE TABLE 3 DEFAULT SETTING

LT3 Entry

CCD Signal Line Table Data Name

Count[0..12] 1 1 30 1 30 1 30 1 30 0

HCLK_H Enable 0 0 0 0 0 0 0 0 1 0

FDG V6 0 0 0 0 0 0 0 0 0 0

V5 0 0 0 0 0 0 0 0 0 0

V1 V4 0 0 1 0 0 0 1 0 0 0

V2 V3 0 1 1 1 0 1 1 1 0 0

V2 0 0 0 0 0 0 0 0 0 0

V3RD V1 0 0 0 0 0 0 0 0 0 0

0 1 2 3 4 5 6 7 8 9

Line Table 4 is an Integration sequence. Neither the

Vertical clocks nor the Horizontal clocks are active. See

Figure 8.

Table 24. LINE TABLE 4 DEFAULT SETTING

LT4 Entry

CCD Signal Line Table Data Name

Count[0..12] 1 0

HCLK_H Enable 0 0

FDG V6 0 0

V5 0 0

V1 V4 0 0

V2 V3 0 0

V2 0 0

V3RD V1 0 0

0 1

http://onsemi.com

13

Page 14

EVBUM2277/D

KAI−2093 TIMING

Line Table 0 (Line Transfer)

Line Table 0 is the Line Transfer timing sequence that

transfers one entire row of charge toward the horizontal

register. V1 and V2 are asserted, with overlap adjustability

to compensate for the clock driver rise and fall times. Charge

VMID

V1_CCD

VLOW

is moved down the vertical CCD registers, and the last row

of charge is dumped into the horizontal register. The VCCD

clocking interval is followed by the Horizontal clocks,

which shift one line out through the output amplifier(s).

VMID

V2_CCD

HCLK_ENABLE

H1A_CCD

H2A_CCD

LT0 Entry

0 1 2 3 5

1 3 30 2 130Pix Counts

Symbol

T

VD

T

VCCD

Figure 4. Line Table 0 Default Timing

Line Table 1 (Diode Transfer)

Line Table 1 is the Photodiode Transfer timing, in which

the V2 clock 3

HCLK_ENABLE

rd

-level shifts charge from all the photodiodes

V1_CCD

V2_CCD

VLOW

VHIGH

(not to scale)

VLOW

4

T

HD

into the vertical CCD registers. The V1 and V2 clocks have

overlap adjustability to compensate for the clock driver rise

and fall times.

VMID

VMID

VLOW

H1A_CCD

H2A_CCD

LT1 Entry

0 1 2 3 4 5 6

1 500 6 240 1 400 1310Pix Counts

Symbol

T

3P

T

V3rd

(not to scale)

T

Figure 5. Line Table 1 Default Timing

http://onsemi.com

14

3D

T

3FD

Page 15

EVBUM2277/D

Line Table 2 (Integration)

Line Table 2 is the Integration timing sequence, during

which the Vertical clocks are inactive and the Horizontal

V1_CCD

(Vclks not active)

V2_CCD

HCLK_ENABLE

H1A_CCD

H2A_CCD

LT2 Entry

Pix Counts

(not to scale)

Figure 6. Line Table 2 Default Timing

Line Table 3 (Binning Mode Line Transfer)

Line Table 3 is the Binning Mode Line Transfer sequence,

during which the Vertical clocks are asserted twice per line.

VMID

V1_CCD

V2_CCD

VLOW

VLOW

clocks are running continuously. This sequence runs until

Integration is complete, signaled by the assertion of the

VD_TG signal from the Altera PLD.

VMID

VLOW

0

1

This effectively sums two pixels’ worth of charge into each

Horizontal CCD pixel. After the binning line transfer,

the Horizontal clocks are run in Binning Mode.

VMID

HCLK_ENABLE

H1A_CCD

H2A_CCD

LT3 Entry

Pix Counts

Symbol

0 1 2 3 8

1 1 30 1 3030

T

H

T

VCCD

4 5

30 1

T

VCCD

(not to scale)

Figure 7. Line Table 3 Default Timing

Line Table 4 (Trigger Hold)

Line T able4 is a sequence one pixel time in length, used

when the KSC−1000 is waiting to be triggered by the Altera

V1_CCD

V2_CCD

HCLK_ENABLE

H1A_CCD

H2A_CCD

LT4 Entry

Pix Counts

(Vclks not active)

(Hclks not active)

(not to scale)

6

7

1

T

VCCD

T

HD

PLD. Neither the Vertical clocks nor the Horizontal Clocks

are active during this sequence.

VMID

VLOW

(LOW)

HMID

HLOW

0

1

Figure 8. Line Table 4 Default Timing

http://onsemi.com

15

Page 16

EVBUM2277/D

Frame Table 0 Sequence

Frame Table 0 contains the Free-Running (video mode)

timing sequence used to continuously read out all rows of the

CCD. The sequence begins with the Line Transfer sequence,

followed by the Timed Integration sequence. When

Altera PLD KSC−1000TG

State Machine Sequence Frame Table 0 Sequence

integration is complete, the Altera PLD asserts the VD_TG

signal to the KSC−1000. This initiates the Photodiode

transfer, and the cycle repeats with the next Line Transfer

sequence.

V_TRANSFER

TIMED_

INTEGRATION

DIODE_

TRANSFER

Wait for

FRAME_VALID

(falling edge)

Yes

DIO[11..7] =

{1,2,...7}?

No

Set INTEGRATE

Wait for INT ctr

Issue VD_TG

Reset INTEGRATE

Wait for FRAME_VALID

(rising edge)

Set INTEGRATE

on INTG_START

(falling edge)

FRAME_VALID

INTG_START

VD_TG

Shutter?

INTG_START

FRAME_VALID

Issue

Jump to FT0 Entry 0

Execute LT0

(LINE XFR)

Count = 1214

Execute LT5

Wait for VD_TG

Execute LT1

(DIODE XFR)

Count = 1

Count = 1

ENTRY 0

ENTRY 1

ENTRY 2

ENTRY 3

Figure 9. Free-Running Mode Timing Sequence

http://onsemi.com

16

Page 17

V1_CCD

V2_CCD

H1A_CCD

H2A_CCD

CLPOB1

PBLK

INTEGRATE

VD_TG

FRAME_VALID

LINE_VALID

EVBUM2277/D

FT0 Entry

Line Table

Counts

PLD STATE

0

0

1104

V_TRANSFER

(not to scale)

Figure 10. Frame Table 0 Default Timing

Frame Table 1 Sequence

Frame Table 1 contains the 2×2 Binning Mode timing

sequence used to sum the charge collected in four photosites

into one CCD pixel. The sequence is identical to that of

V1_CCD

V2_CCD

H1A_CCD

H2A_CCD

CLPOB1

PBLK

INTEGRATE

VD_TG

FRAME_VALID

LINE_VALID

1

4

x

TIMED_INTEGRATION

2

1

1

DIODE_TRANSFER

Frame Table 0, except that the Vertical Clocks are asserted

twice per line, which dumps charge from two vertical CCD

pixels into each Horizontal register CCD pixel.

FT1 Entry

Line Table

Counts

PLD STATE

Electronic Shutter Timing

The electronic shutter timing is controlled by the values in

Register 3 of the KSC−1000. There are two methods of

actuating the Electronic Shutter pulse: by setting the

Integrate Start Pulse Line Number value in Register 4 so

that the pulse occurs on a specific line, or by setting the

Force INTG_START bit in a Frame Table entry. In either

case, the Electronic Shutter pulse setup, width, and hold

times are determined by the values in Register 3. The shutter

0

0

610

V_TRANSFER

(not to scale)

1

5

x

TIMED_INTEGRATION

Figure 11. Frame Table 1 Default Timing

sequence is inserted before the specified line, causing that

particular line time to be extended accordingly.

If the Integrate Start Pulse Line Number value in

Register 4 is set to 0, the Electronic Shutter will occur

immediately following the Diode Transfer sequence, before

the first line is read out. If the Integrate Start Pulse Line

Number value is greater than the number of vertical lines in

the Frame T able, there will be no Electronic Shutter. This is

the method used to disable the Electronic Shutter.

http://onsemi.com

17

2

1

1

DIODE_TRANSFER

Page 18

V1_CCD

V2_CCD

EVBUM2277/D

VSUB

H1A_CCD

H2A_CCD

Reg3 Entry

setup width hold

30 200 30Pix Counts

(not to scale)

Figure 12. Electronic Shutter Timing

Horizontal Timing

Figure 13 depicts the basic theoretical relationship

between the pixel-rate clocks to the CCD, the Video output

of the CCD, and the pixel-rate clocks to the AFE.

Vpix

VOUT_CCD

RESET_CCD

H2A_CCD

Vsat

Start of Integration

(Line Table 0)

Tr

Tpix

H1A_CCD

SHP

SHD

DATACLK

Figure 13. Horizontal Timing

Binning Mode Horizontal Timing

In order to sum the charge from two Horizontal CCD

pixels into one, the Reset clock is suspended on alternating

Horizontal clock cycles. In this way, two pixels of charge are

dumped onto the floating diffusion of the output amplifier

before this node is reset to VRD, the Reset Drain voltage.

See the KAI−2093 Device Specification (References

) for

further details.

In order to correctly convert the output amplifier voltage

to digital data, the AFE clocks must be adjusted accordingly.

The Clamp pulse (SHP) samples the output after the Reset

pulse has been issued, but before the Horizontal clocks have

Tshp

Tshd

moved charge onto the floating diffusion. The Sample pulse

(SHD) samples the output after two Horizontal clock cycles

have moved two charge packets onto the floating diffusion.

The DATACLK then clocks the AFE to perform the

conversion.

The KSC−1000 has the capability of implementing the

Horizontal Timing necessary to bin up to four pixels. This

feature is controlled by setting bits 3:4 of the active Frame

Table (Register 8) in the KSC−1000. Figure 14 depicts the

basic theoretical relationship between the pixel-rate clocks

to the CCD, the Video output of the CCD, and the pixel-rate

clocks to the AFE in 2× Horizontal Binning Mode.

http://onsemi.com

18

Page 19

EVBUM2277/D

The Altera PLD default KSC−1000 settings contain 2×2

Binning Mode timing in Frame Table 2 (See Figure 11). In

order to activate the 2×2 Binning Mode, the Frame Table

VOUT_CCD

Tr

RESET_CCD

H2A_CCD

Tpix

H1A_CCD

SHP

SHD

DATACLK

Figure 14. Binning Mode Horizontal Timing

Pointer (Register 0) must be changed to a value of 2. This is

done by setting SW2 HIGH and pressing the

BOARD_RESET button (S1 on the Timing Board).

Tshp

Tshd

Integration & Shutter Timing

Free-Running Mode

The default Integration Time in Free-Running Mode is

approximately one Frame Time, or the time between Frame

Transfers, during which the photodiodes are collecting

charge (Figure 16). This time may be decreased by use of the

Electronic Shutter (Figure 17), and may be increased by

lengthening the Frame Time (Figure 18). The user may

control the Integration Time through the DIO connector bits

DIO[11..7]. This connector is optional, and when

disconnected, all bits are pulled LOW. The available

pre-programmed Integration Times are detailed in Table 25.

The Electronic Shutter is controlled by changing the

Integrate Start Pulse Line Number value of the KSC−1000

Register 4. The Altera PLD has 8 pre-programmed Shutter

settings, controlled through the DIO[11..7] bits, as shown in

Table14 and Table 25. These settings result in Integration

times of one Frame T ime or less, in increments of 1/8 of the

Frame T ime (See Figure 17). When the Integrate Start Pulse

Line Number value is set to 2040, the Shutter is never

pulsed, as this value exceeds the number of lines in a frame

(Figure 16 and Figure 18). Either the BOARD_RESET

switch must be pressed, or the Remote Reset (DIO14) must

be toggled, after changing the DIO[11..7] bits in order for the

change to the KSC−1000 to take effect.

The Integration time is controlled by the Altera PLD. In

Free-Running mode, the KSC−1000 waits for a trigger

signal (VD_TG) before beginning the Diode Transfer

sequence (See Figure 16). The Altera PLD issues this trigger

pulse when the Integration Counter has reached

a pre-programmed value, as shown in Table 25. The

Integration counter is clocked by an internally-generated

1 ms clock. The default value of 0 means that the VD_TG

trigger is issued on the next rising edge of the 1 ms clock

after the frame readout is complete. A value greater than 0

adds that many milliseconds to the Integration Time,

allowing Integration times greater than 8 seconds

(Figure 18).

http://onsemi.com

19

Page 20

EVBUM2277/D

Table 25. PROGRAMMED INTEGRATION TIMES

DIO[11..7] Int Count Free-Run Mode Reg4 Entry Free-Run Mode Tint(s)

0 (Default) 0 2040 (No Shutter) 0.115

1 0 966 0.014

2 0 828 0.029

3 0 690 0.043

4 0 552 0.057

5 0 414 0.072

6 0 276 0.086

7 0 138 0.101

8 1 2040 (No Shutter) 0.116

9 3 2040 (No Shutter) 0.118

10 5 2040 (No Shutter) 0.120

11 10 2040 (No Shutter) 0.125

12 25 2040 (No Shutter) 0.140

13 50 2040 (No Shutter) 0.165

14 70 2040 (No Shutter) 0.185

15 100 2040 (No Shutter) 0.215

16 200 2040 (No Shutter) 0.315

17 300 2040 (No Shutter) 0.415

18 400 2040 (No Shutter) 0.515

19 500 2040 (No Shutter) 0.615

20 600 2040 (No Shutter) 0.715

21 700 2040 (No Shutter) 0.815

22 800 2040 (No Shutter) 0.915

23 900 2040 (No Shutter) 1.015

24 1000 2040 (No Shutter) 1.115

25 2000 2040 (No Shutter) 2.115

26 3000 2040 (No Shutter) 3.115

27 4000 2040 (No Shutter) 4.115

28 5000 2040 (No Shutter) 5.115

29 6000 2040 (No Shutter) 6.115

30 7000 2040 (No Shutter) 7.115

31 8000 2040 (No Shutter) 8.115

http://onsemi.com

20

Page 21

EVBUM2277/D

V1_CCD

V2_CCD

VES (shutter)

INTEGRATE

1ms Clock

VD_TG

FRAME_VALID

LINE_VALID

FT0 Entry

Line Table

Counts

DIO[11..7]

Figure 15. Programmed Integration Times

1 2 11041103

Shutter Line = 2040 (No shutter pulse)

Integration Count = 0

0

0

1104

1

4

x

2

1

1

0

(not to scale)

Figure 16. Free-Running Mode Default Integration Timing

http://onsemi.com

21

Page 22

V1_CCD

V2_CCD

VES (shutter)

INTEGRATE

1ms Clock

VD_TG

FRAME_VALID

LINE_VALID

1 2 3 4 5 965

EVBUM2277/D

966 11041103

Integration Count = 0

FT0 Entry

Line Table

Counts

DIO[11..7]

V1_CCD

V2_CCD

VES (shutter)

INTEGRATE

1ms Clock

VD_TG

FRAME_VALID

LINE_VALID

FT0 Entry

Line Table

Counts

DIO[11..7]

0

0

1104

1

4

x

2

1

1

1 (Shutter Line = 966)

(not to scale)

Figure 17. Free-Running Mode Integration Timing with Shutter

(no shutter)

Integration Count = 3

0123

0

0

1104

1

4

x

9

(not to scale)

2

1

1

Figure 18. Free-Running Mode Extended Integration Timing

http://onsemi.com

22

Page 23

EVBUM2277/D

BOARD INTERFACE CONNECTOR SIGNAL MAP

For reference, the board interface timing signals from the

3F5051 Timing Board to the 3F5121 Imager Board are

shown in Table 26. Note that the power connections are not

shown here.

Table 26. TIMING BOARD/IMAGER BOARD SIGNAL MAP

KSC−1000 Timing Board

KSC−1000

Signal Name

V5 TIMING_OUT0 1/2 1/2

INTG_START TIMING_OUT1 5/6 5/6 IMAGER_IN11 VES

V6 TIMING_OUT2 9/10 9/10 IMAGER_IN10 FDG

V1 TIMING_OUT3 13/14 13/14 IMAGER_IN9 V3RD

V2 TIMING_OUT4 17/18 17/18 IMAGER_IN8

V3 TIMING_OUT5 21/22 21/22 IMAGER_IN7 V2

V4 TIMING_OUT6 25/26 25/26 IMAGER_IN6 V1

RG TIMING_OUT7 29/30 29/30 IMAGER_IN5 RESET

H1 TIMING_OUT8 33/34 33/34 IMAGER_IN4 H2B

H4 TIMING_OUT9 37/38 37/38 IMAGER_IN3 H2A

H2 TIMING_OUT10 41/42 41/42 IMAGER_IN2 H1B

H3 TIMING_OUT11 45/46 45/46 IMAGER_IN1 H1A

H6 TIMING_OUT12 51/52 51/52

H5 TIMING_OUT13 55/56 55/56

AMP_EN TIMING_OUT14 59/60 59/60 IMAGER_IN0 AMP_ENABLE

SCLOCK TIMING_OUT15 63/64 63/64 IMAGER_IN15

SDATA TIMING_OUT16 67/68 67/68 IMAGER_IN14

PLD_OUT2 TIMING_OUT17 71/72 71/72 IMAGER_IN13

PLD_OUT0 TIMING_OUT18 75/76 75/76 IMAGER_IN12 VIDEO_SWITCH

PLD_OUT1 TIMING_OUT19 79/80 79/80

LVDS Interface

Signal Name

3F5051 J6 Pins 3F5121 J1 Pins

KAI−2093 Imager Board

LVDS Interface

Signal Name

Imager Board

Signal Name

http://onsemi.com

23

Page 24

EVBUM2277/D

VIDEO SIGNAL PATH

The entire video signal path through the Imager Board and

Timing Board is represented in Figure 19. The individual

blocks are discussed in the Imager Board User Manual and

the Timing Board User Manual.

The hardware gain for the entire pre-AFE signal path can

be calculated by multiplying the gains of the individual

stages:

0.96 1.25 0.5 1.25 + 0.75

+15V

VOUT_CCD

CCD

Emitter−Follower

Av = ~0.96

+5V

−

+

−5V

Op−Amp Buffer

Av = 1.25

(eq. 1)

The gain of the hardware signal path is designed so that the

saturation output voltage of the KAI−2093 CCD will not

overload the AFE input. The AFE default PXGA gain is set

at 1.0 (0.0 dB), and the default VGA gain is set to maximize

the dynamic range of the AFE (See Table 9 and References

Timing BoardImager Board

+5V

Coax Cable

(75ohm, terminated)

Av = 0.5

−

+

−5V

Op−Amp Buffer

Av = 1.25

Analog

Front End

AFE (2-stage

prog. gain)

Digital

Out

).

Figure 19. Video Signal Path Block Diagram

WARNINGS AND ADVISORIES

When programming the T iming Board, the Imager Board

must be disconnected from the Timing Board before power

is applied. If the imager Board is connected to the Timing

Board during the reprogramming of the Altera PLD, damage

to the Imager Board will occur.

Purchasers of a O NSemiconductor Evaluation Board Kit

may, at their discretion, make changes to the Timing

ORDERING INFORMATION

Please address all inquiries and purchase orders to:

Truesense Imaging, Inc.

1964 Lake Avenue

Rochester, New York 14615

Phone: (585) 784−5500

E-mail: info@truesenseimaging.com

Generator Board firmware. ON Semiconductor can only

support firmware developed by, and supplied by, Truesense

Imaging. Changes to the firmware are at the risk of the

customer.

ON Semiconductor reserves the right to change any

information contained herein without notice. All

information furnished by ON Semiconductor is believed to

be accurate.

http://onsemi.com

24

Page 25

EVBUM2277/D

P

al

REFERENCES

[1] KAI−2093 Device Specification

[2] KAI−2001/KAI−2020/KAI−2093 Imager Board

User Manual

[3] KAI−2001/KAI−2020/KAI−2093 Imager Board

Schematic

[4] KSC−1000 Timing Generator Board User Manual

[5] KSC−1000 Timing Generator Board Schematic

[6] Analog Devices AD9845A Product Data Sheet

(20, 24, 28, 30 MHz operation)

ON Semiconductor and the are registered trademarks of Semiconductor Components Industries, LLC (SCILLC) or its subsidiaries in the United States and/or other countries.

SCILLC owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of SCILLC’s product/patent coverage may be accessed

at www.onsemi.com/site/pdf/ Patent− Marking.pdf . S CILLC reserves t he right to m ake changes wit hout further notice to any products h erein. SCILLC makes no warranty, representation

or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets

and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each

customer application by customer’s technical e xperts. SCILLC does not convey any license u nder its patent rights nor the rights of others. SCILLC p roducts a re n ot d esigned, i ntended,

or authorized for use as components in systems intended for surgic al i mplant into the body, or other applications intended t o s upport o r s ust ain life, or for any other application in which

the failure of the SCILLC product could create a situation where personal injury or death may occur. Should Buyer purchase or use SCILLC products for any such unintended or

unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, em ployees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable at torney f ees a r ising o ut o f, d irectly o r indirectly, any claim o f personal injury or death associated w ith s uch u nintended o r u nauthorized u se, e ven if such claim

alleges that SCILLC was negligent r egarding the design o r manuf acture o f t he p art. SCILLC is a n E qual O pportunity/Af firmative Ac tion Employer. This literature is subject to all a pplicable

copyright laws and is not for resale in any manner.

UBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

http://onsemi.com

25

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your loc

Sales Representative

EVBUM2277/D

Loading...

Loading...