Page 1

KAC-12040

f

4000 (H) x 3000 (V)

CMOS Image Sensor

Description

The KAC−12040 Image Sensor is a high-speed 12 megapixel

CMOS image sensor in a 4/3″ optical format based on a 4.7 mm 5T

CMOS platform. The image sensor features very fast frame rate,

excellent NIR sensitivity, and flexible readout modes with multiple

regions of interest (ROI). The readout architecture enables use of 8, 4,

or 2 LVDS output banks for full resolution readout of 70 frames per

second.

Each LVDS output bank consists of up to 8 differential pairs

operating at 160 MHz DDR for a 320 Mbps data rate per pair.

The pixel architecture allows rolling shutter operation for motion

capture with optimized dynamic range or global shutter for precise

still image capture.

Table 1. GENERAL SPECIFICATIONS

Parameter Typical Value

Architecture 5T Global Shutter CMOS

Resolution 12 Megapixels

Aspect Ratio 4:3

Pixel Size

Total Number of Pixels 4224 (H) × 3192 (V)

Number of Effective Pixels 4016 (H) × 3016 (V)

Number of Active Pixels 4000 (H) × 3000 (V)

Active Image Size 18.8 mm (H) × 14.1 mm (V)

Master Clock Input Speed 5 MHz to 50 MHZ

Maximum Pixel Clock Speed 160 MHz DDR LVDS, 320 Mbps

Number of LVDS Outputs 64 Differential Pairs

Number of Output Banks 8, 4, or 2

Frame Rate, 12 Mp 1−70 fps 10 bits

Charge Capacity 16,000 electrons

Quantum Efficiency

KAC−12040−CBA

KAC−12040−ABA

Read Noise

(at Maximum LVDS Clock)

Dynamic Range 73 dB, Rolling Shutter

Blooming Suppression > 10,000x

Image Lag 1.3 electron

Digital Core Supply 2.0 V

Analog Core Supply 1.8 V

Pixel Supply 2.8 V & 3.5 V

Power Consumption 1.5 W for 12 Mp @ 70 fps 10 bits

Package 267 Pin Ceramic Micro-PGA

Cover Glass AR Coated, 2-sides

NOTE: All Parameters are specified at T = 40°C unless otherwise noted.

4.7 mm (H) × 4.7 mm (V)

23.5 mm (Diagonal), 4/3″ Optical Format

1−75 fps 8 bits

40%, 47%, 45% (470, 540, 620 nm)

53%, 15%, 10% (500, 850, 900 nm)

3.7 e− rms, Rolling Shutter

−

25.5 e

rms, Global Shutter

56 dB, Global Shutter

www.onsemi.com

Figure 1. KAC−12040 CMOS Image Sensor

Features

• Global Shutter and Rolling Shutter

• Very Fast Frame Rate

• High NIR Sensitivity

• Multiple Regions of Interest

• Interspersed Video Streams

Applications

• Machine Vision

• Intelligent Transportation Systems

• Surveillance

ORDERING INFORMATION

See detailed ordering and shipping information on page 2 o

this data sheet.

© Semiconductor Components Industries, LLC, 2016

March, 2016 − Rev. 5

1 Publication Order Number:

KAC−12040/D

Page 2

KAC−12040

The image sensor has a pre-configured QFHD (4 × 1080p,

16:9) video mode, fully programmable, multiple ROI for

windowing, programmable sub-sampling, and reverse

readout (flip and mirror). The two ADCs can be configured

clamping, overflow pixel for blooming reduction, black-sun

correction (anti-eclipse), column and row noise correction,

and integrated timing generation with SPI control, 4:1 and

9:1 averaging decimation modes.

for 8-bit, 10-bit, 12-bit or 14-bit conversion and output.

Additional features include interspersed video streams

(dual-video), on-chip responsivity calibration, black

ORDERING INFORMATION

T able 2. ORDERING INFORMATION − KAC−12040 IMAGE SENSOR

Part Number Description Marking Code

KAC−12040−ABA−JD−BA Monochrome, Micro-PGA Package, Sealed Clear Cover Glass with AR

KAC−12040−ABA−JD−AE Monochrome, Micro-PGA Package, Sealed Clear Cover Glass with AR

KAC−12040−CBA−JD−BA Bayer (RGB) Color Filter Pattern, Micro-PGA Package, Sealed Clear Cover

KAC−12040−CBA−JD−AE Bayer (RGB) Color Filter Pattern, Micro-PGA Package, Sealed Clear Cover

1. Engineering Grade samples might not meet final production testing limits, especially for cosmetic defects such as clusters, but also possibly

column and row artifacts. Overall performance is representative of final production parts.

Coating (Both Sides), Standard Grade.

Coating (Both Sides), Engineering Grade.

Glass with AR Coating (Both Sides), Standard Grade.

Glass with AR Coating (Both Sides), Engineering Grade.

KAC−12040−ABA

Serial Number

KAC−12040−CBA

Serial Number

Table 3. ORDERING INFORMATION − EVALUATION SUPPORT

Part Number Description

KAC−12040−CB−A−GEVK Evaluation Hardware for KAC−12040 Image Sensor (Color). Includes Image Sensor.

KAC−12040−AB−A−GEVK Evaluation Hardware for KAC−12040 Image Sensor (Monochrome). Includes Image Sensor.

LENS−MOUNT−KIT−C−GEVK Lens Mount Kit that Supports C, CS, and F Mount Lenses. Includes IR Cut-filter for Color Imaging.

See the ON Semiconductor Device Nomenclature document (TND310/D) for a full description of the naming convention

used for image sensors. For reference documentation, including information on evaluation kits, please visit our web site at

www.onsemi.com

.

www.onsemi.com

2

Page 3

DEVICE DESCRIPTION

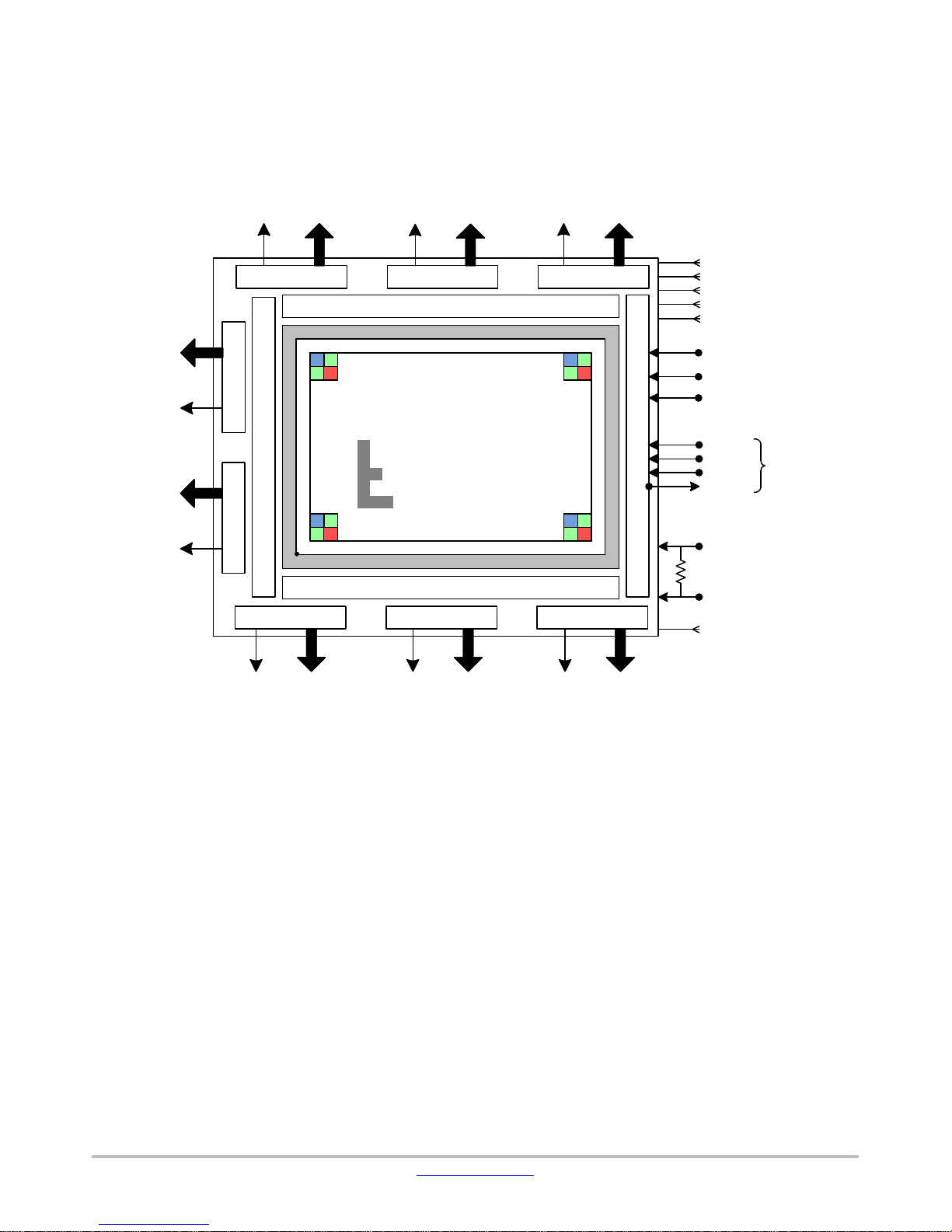

Architecture

KAC−12040

1D

0D

− 1D

0

− 0D

0

Clk1

Clk0

6

− 5D

0

5D

Clk7

Clk3

6

− 3D

0

3D

Clk5

LVDS Bank 3 LVDS Bank 5 LVDS Bank 7

Odd Row ADC, Analog Gain, Black-Sun Correction

88

6

B

G

R

G

8

B

G

4000 (H) y 3000 (V)

6

− 7D

0

7D

3.5 V

A

3.3 V

D

2.8 V

A

2.0 V

D

1.8 V

A

G

R

Chip Clock (2 Pins)

TRIGGER

RESETN

4.7 mm Pixel

104

8

8

104

CSN

SCLK

MOSI

6

Digital Gain/Offset, Noise Correction

LVDS Bank 0 LVDS Bank 1

(0, 0)

B

G

R

G

8

88

B

G

R

G

Timing Control, Sub-Sampling/Averaging

Even Row ADC, Analog Gain, Black-Sun Correction

MISO

ADC_Ref1

4.02 kW ±1%

ADC_Ref2

Serial

Peripheral

Interface

(SPI)

LVDS Bank 2 LVDS Bank 4 LVDS Bank 6

VSS 0 V

Clk2

6

− 2D

0

2D

6

Clk4

− 4D

0

4D

Figure 2. Block Diagram

Clk6

6

− 6D

0

6D

www.onsemi.com

3

Page 4

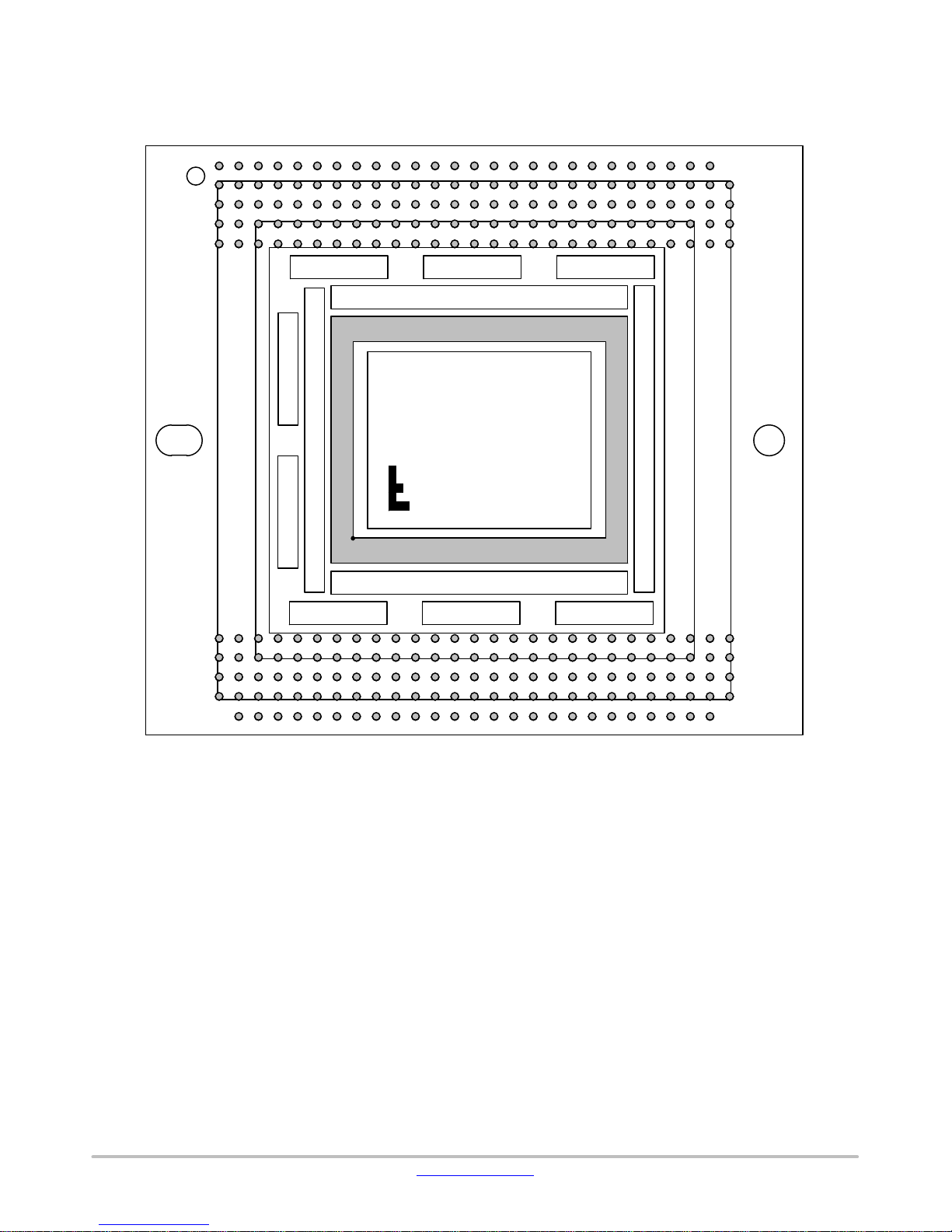

Physical Orientation

272625242322212019181716151413121110987654321

KAC−12040

A

B

C

D

E

LVDS Bank 3 LVDS Bank 5 LVDS Bank 7

LVDS Bank 0 LVDS Bank 1

LVDS Bank 2 LVDS Bank 4 LVDS Bank 6

Notes:

1. The center of the pixel array is aligned to the physical package center.

2. The region under the sensor die is clear of pins enabling the use of a heat sink.

3. Non-symmetric mounting holes provide orientation and mounting precision.

4. Non-symmetric pins prevent incorrect placement in PCB.

5. Letter “F” indicator shows default readout direction relative to package pin 1.

Figure 3. Package Pin Orientation − Top X-Ray View

AA

AB

AC

AD

AE

272625242322212019181716151413121110987654321

www.onsemi.com

4

Page 5

KAC−12040

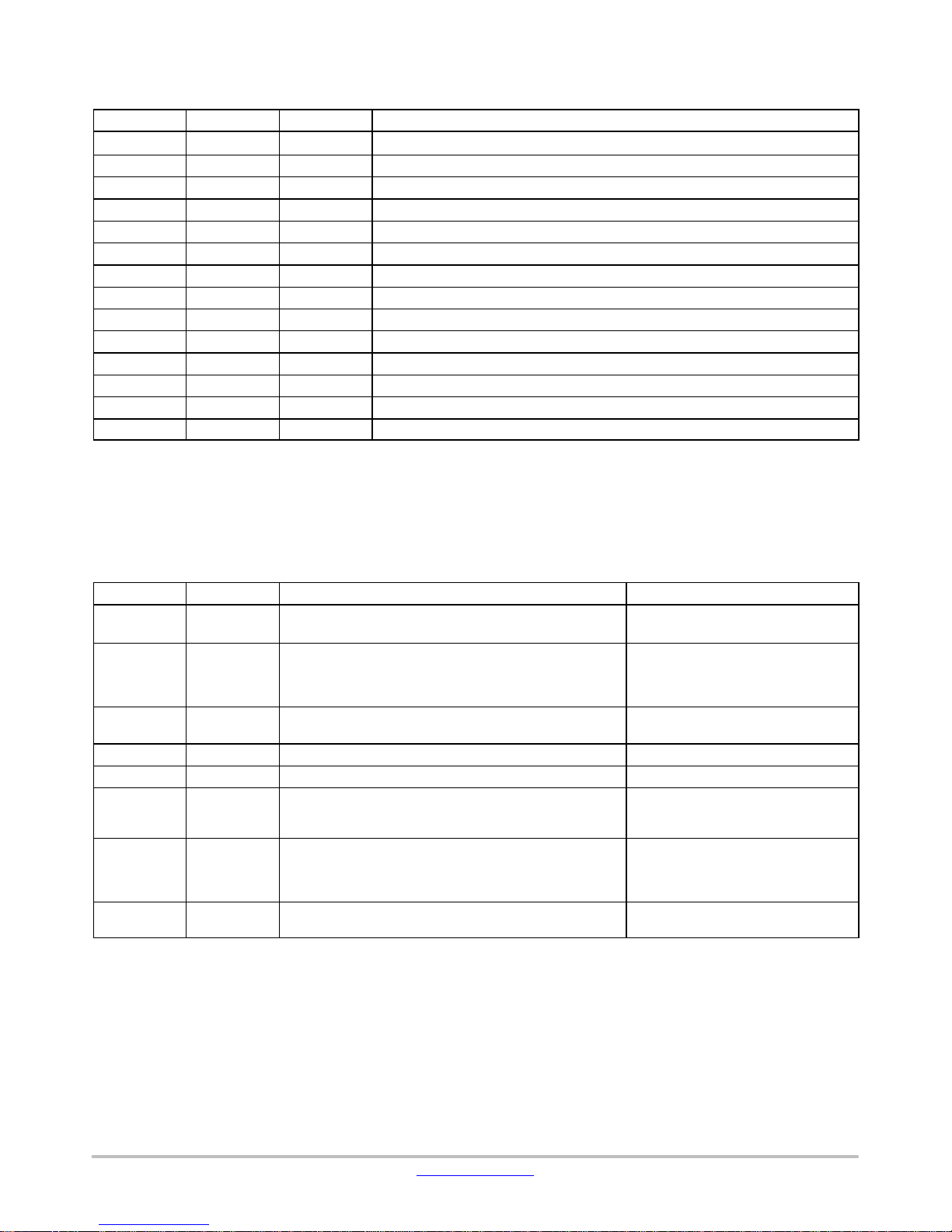

Table 4. PRIMARY PIN DESCRIPTION

Pin Name Type Description

AB09 RESETN DI Sensor Reset (0 V = Reset State)

E07 CLK_In1 DI Sensor Input Clk_In1 (45−50 MHz)

D08 CLK_In2 DI Sensor Input Clk_In2 (Connect to Clk1)

AB08 TRIGGER DI Trigger Input (Optional)

AA05 SCLK DI SPI Master Clock

AA08 MOSI DI SPI Master Output, Slave Input

AA07 MISO DO SPI Master Input, Slave Output

AA06 CSN DI SPI Chip Select (0 V = Selected)

AA14 ADC_Ref1 AO

AA15 ADC_Ref2 AO

AB07 MSO DO Mechanical Shutter Output Sync (Optional)

AB06 FLO DO Flash Output Sync (Optional)

E05 FEN DO Frame Enable Reference Output (Optional)

E06 LEN DO Line Enable Reference Output (Optional)

1. DI = Digital Input, DO = Digital Output, AO = Analog Output.

2. Tie unused DI pins to Ground, NC unused DO pins.

3. By default Clk_In2 should equal Clk_In1 and should be the same source clock.

4. The RESETN pin has a 62 kW internal pull-up resistor, so if left floating the chip will not be in reset mode.

5. The TRIGGER pin has an internal 100 kW pull down resistor. If left floating (and at default polarity) then the sensor state will not be affected

by this pin (i.e. defaults to ‘not triggered’ mode if floated).

6. All of the DI and DO pins nominally operate at 0 V → 2.0 V and are associated with the VDD_DIG power supply.

4.02 kW ±1% Resistor between Ref1 & Ref2

4.02 kW ±1% Resistor between Ref1 & Ref2

Table 5. POWER PIN DESCRIPTION

Name Voltage Pins Description

VDD_LVDS 3.3 V D C04, C05, C23, C24, D04, D24, E04, E24, AA04, AA24,

AB04, AB24, AC04, AC05 AC23, AC24

VDD_DIG 2.0 V D C18, C19, D18, D19, E18, AA18, AB18, AB19, AC18, AC19,

C20, C21, C22, D20, D21, D22, D23, E20, E21, E22, AA20,

AA21, AA22, AB20, AB21, AB22, AB23, AC20, AC21,

AC22, AB15, E08

AVDD_HV 3.5 V A C11, D11, E11, AA11, AB11, AC11, C10, D10, E10, AA10,

AB10, AC10

Vref_P 2.8 V A C13, D13, E13, AA13, AB13, AC13 Pixel Supply 2

AVDD_LV 1.8 V A C17, D16, D17, E17, AA17, AB16, AB17, AC17 Analog Low Voltage Supply

Vpixel_low 0 V E09 Pixel Supply 3. Combine with VSS for

VSS 0 V C12, C14, D12, D14, E12, AA12, AB12, AB14, AC12, AC14,

E15, D15, AA09, A02, A14, A26, B14, C03, C06, C25, D03,

D25, E03, E19, E23, E25, AA03, AA19, AA23, AA25, AB25,

AC03, AC06, AC25, AD14, AE02, AE14, AE26

No Connect NA A01, AC09, E14, E16, C09, D09, D05, D06, D07, AA16,

AB05

LVDS Output Supply

Digital Core Supply

Pixel Supply 1

normal operation. Can be pulsed for

Extended Dynamic Range Operation.

Sensor Ground Reference

Unused and test-only pins. These

pins must be floated.

www.onsemi.com

5

Page 6

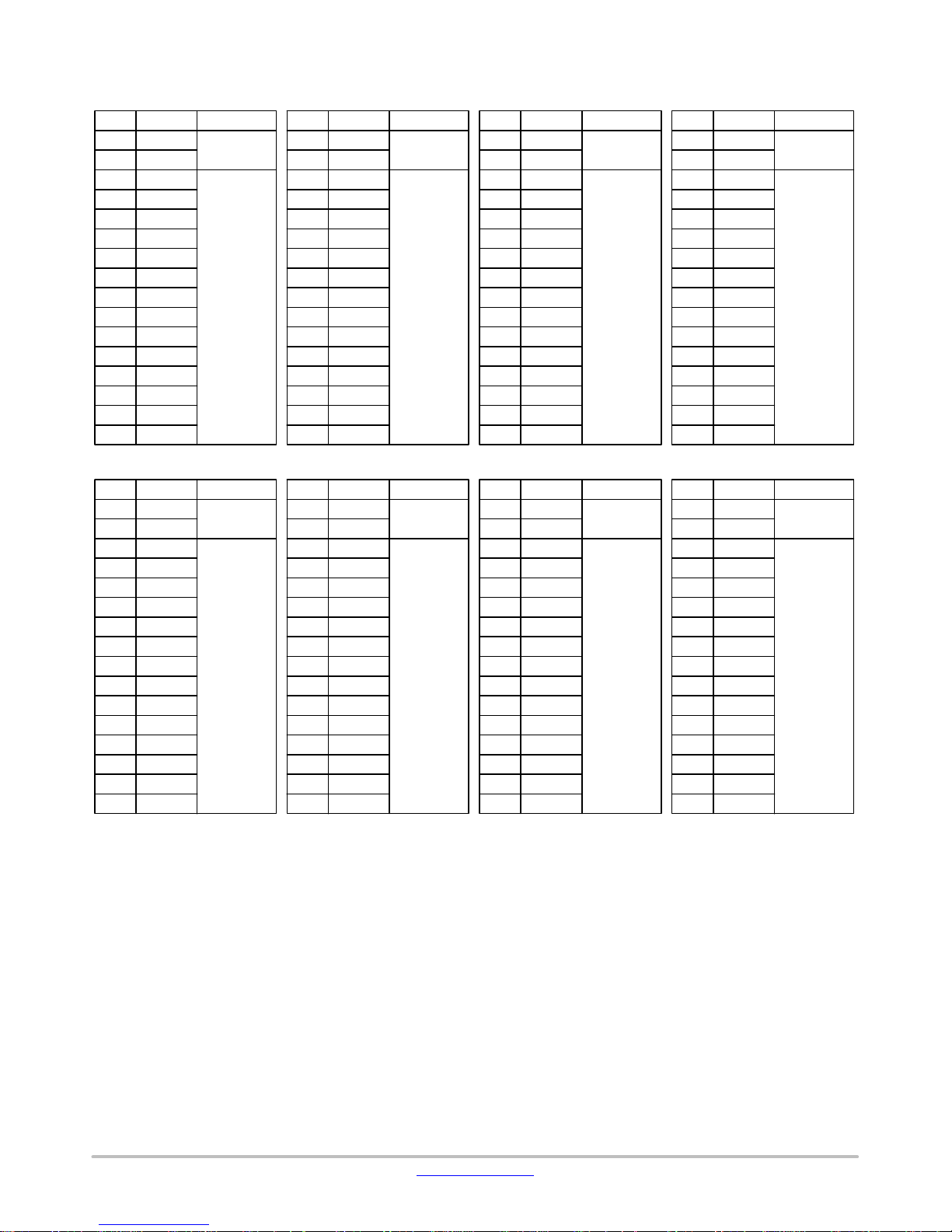

Table 6. L VDS PIN DESCRIPTION

KAC−12040

Pin Name Description

E01

1DCLK+

E02 1DCLK−

D01 1DATA0+

D02 1DATA0−

C01 1DATA1+

C02 1DATA1−

B01 1DATA2+

B02 1DATA2−

A03 1DATA3+

B03 1DATA3−

A04 1DATA4+

B04 1DATA4−

A05 1DATA5+

B05 1DATA5−

A06 1DATA6+

B06 1DATA6−

Pin Name Description

0DCLK+

AA01

AA02 0DCLK−

AB01 0DATA0+

AB02 0DATA0−

AC01 0DATA1+

AC02 0DATA1−

AD01 0DATA2+

AD02 0DATA2−

AE03 0DATA3+

AD03 0DATA3−

AE04 0DATA4+

AD04 0DATA4−

AE05 0DATA5+

AD05 0DATA5−

AE06 0DATA6+

AD06 0DATA6−

Bank 1

LVDS Clock

Bank 1

LVDS Data

Bank 0

LVDS Clock

Bank 0

LVDS Data

Pin Name Description

C07

3DCLK+

C08 3DCLK−

A07 3DATA0+

B07 3DATA0−

A08 3DATA1+

B08 3DATA1−

A09 3DATA2+

B09 3DATA2−

A10 3DATA3+

B10 3DATA3−

A11 3DATA4+

B11 3DATA4−

A12 3DATA5+

B12 3DATA5−

A13 3DATA6+

B13 3DATA6−

Pin Name Description

2DCLK+

AC07

AC08 2DCLK−

AE07 2DATA0+

AD07 2DATA0−

AE08 2DATA1+

AD08 2DATA1−

AE09 2DATA2+

AD09 2DATA2−

AE10 2DATA3+

AD10 2DATA3−

AE11 2DATA4+

AD11 2DATA4−

AE12 2DATA5+

AD12 2DATA5−

AE13 2DATA6+

AD13 2DATA6−

Bank 3

LVDS Clock

Bank 3

LVDS Data

Bank 2

LVDS Clock

Bank 2

LVDS Data

Pin Name Description

C15

5DCLK+

C16 5DCLK−

A15 5DATA0+

B15 5DATA0−

A16 5DATA1+

B16 5DATA1−

A17 5DATA2+

B17 5DATA2−

A18 5DATA3+

B18 5DATA3−

A19 5DATA4+

B19 5DATA4−

A20 5DATA5+

B20 5DATA5−

A21 5DATA6+

B21 5DATA6−

Pin Name Description

4DCLK+

AC15

AC16 4DCLK−

AE15 4DATA0+

AD15 4DATA0−

AE16 4DATA1+

AD16 4DATA1−

AE17 4DATA2+

AD17 4DATA2−

AE18 4DATA3+

AD18 4DATA3−

AE19 4DATA4+

AD19 4DATA4−

AE20 4DATA5+

AD20 4DATA5−

AE21 4DATA6+

AD21 4DATA6−

Bank 5

LVDS Clock

Bank 5

LVDS Data

Bank 4

LVDS Clock

Bank 4

LVDS Data

Pin Name Description

A22

7DCLK+

B22 7DCLK−

A23 7DATA0+

B23 7DATA0−

A24 7DATA1+

B24 7DATA1−

A25 7DATA2+

B25 7DATA2−

B27 7DATA3+

B26 7DATA3−

C27 7DATA4+

C26 7DATA4−

D27 7DATA5+

D26 7DATA5−

E27 7DATA6+

E26 7DATA6−

Pin Name Description

6DCLK+

AE22

AD22 6DCLK−

AE23 6DATA0+

AD23 6DATA0−

AE24 6DATA1+

AD24 6DATA1−

AE25 6DATA2+

AD25 6DATA2−

AD26 6DATA3+

AD27 6DATA3−

AC26 6DATA4+

AC27 6DATA4−

AB26 6DATA5+

AB27 6DATA5−

AA26 6DATA6+

AA27 6DATA6−

Bank 7

LVDS Clock

Bank 7

LVDS Data

Bank 6

LVDS Clock

Bank 6

LVDS Data

1. All LVDS Data and Clock lines must be routed with 100 W differential transmission line traces.

2. All the traces for a single LVDS Bank should be the same physical length to minimize skew between the clock and data lines.

3. In 2 Bank mode, only LVDS banks 0 and 1 are active.

4. In 4 Bank mode, only LVDS bank 0, 1, 2, and 3 are active.

5. Float the pins of unused LVDS Banks to conserve power.

6. Unused pins in active banks (due to ADC bit depth < 14) are automatically tri-stated to save power, but these can also be floated.

www.onsemi.com

6

Page 7

KAC−12040

IMAGING PERFORMANCE

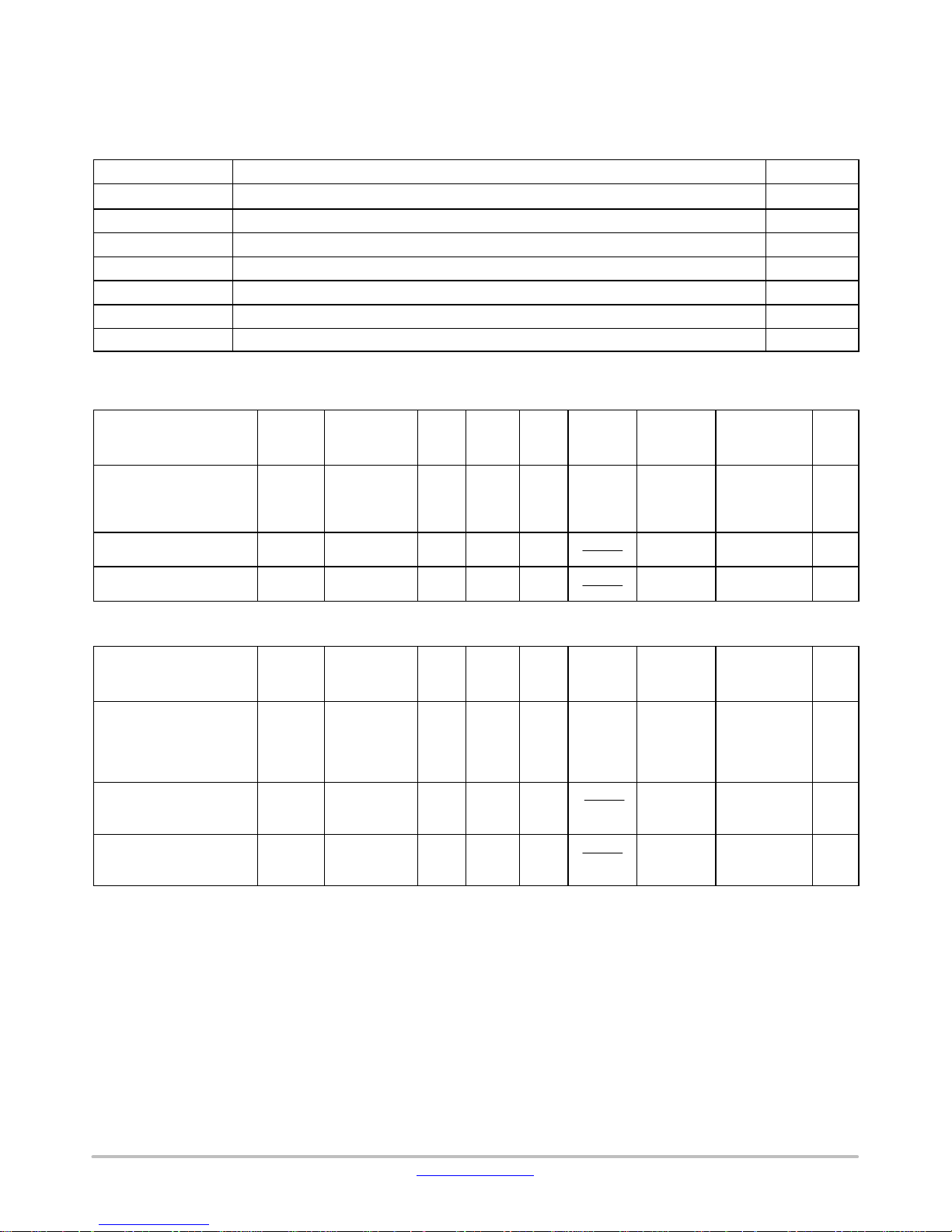

Table 7. TYPICAL OPERATIONAL CONDITIONS

(Unless otherwise noted, the Imaging Performance Specifications are measured using the following conditions.)

Description

Light Source Continuous Red, Green and Blue LED Illumination 1

Temperature Measured Die Temperature: 40°C and 27°C

Integration Time 16.6 ms (1400d LL, Register 0201h)

Readout Mode Dual-Scan, Global Shutter, 320 MHz, PLL2

Clamps Column/Row Noise Corrections Active, Frame Black Level Clamp Active

ADC Bit Depth 10 bit

Analog Gain Unity Gain or Referred Back to Unit Gain

1. For monochrome sensor, only green LED used.

T able 8. KAC−12040−ABA CONFIGURATION (MONOCHROME)

Wavelength

Description Symbol

Peak Quantum Efficiency

Green

NIR1

NIR2

Responsivity − 84 −

Responsivity − 7.0 −

QE

MAX

(nm)

550

850

900

Condition Notes

Temperature

Min. Nom. Max. Unit

−

−

−

53

15

10

−

−

−

% Design 27

ke

Lux @ s

V

Lux @ s

*

Sampling

Plan

Design 27 20

Design 27 21

Tested at

(5C)

Test

T able 9. KAC−12040−CBA CONFIGURATION (BAYER RGB)

Wavelength

Description Symbol

Peak Quantum Efficiency

Green

NIR1

NIR2

Responsivity Blue

Responsivity Blue

QE

MAX

(nm)

470

540

620

850

900

Green

Red

Green

Red

Min. Nom. Max. Unit

−

−

−

−

−

−

−

−

−

−

−

40

47

45

15

10

17

35

38

1.4

2.9

3.2

Sampling

Plan

−

−

−

−

−

−

−

−

−

−

−

% Design 27

*

ke

Lux @ s

V

Lux @ s

Design 27 20

Design 27 21

Temperature

Tested at

(5C)

Test

www.onsemi.com

7

Page 8

KAC−12040

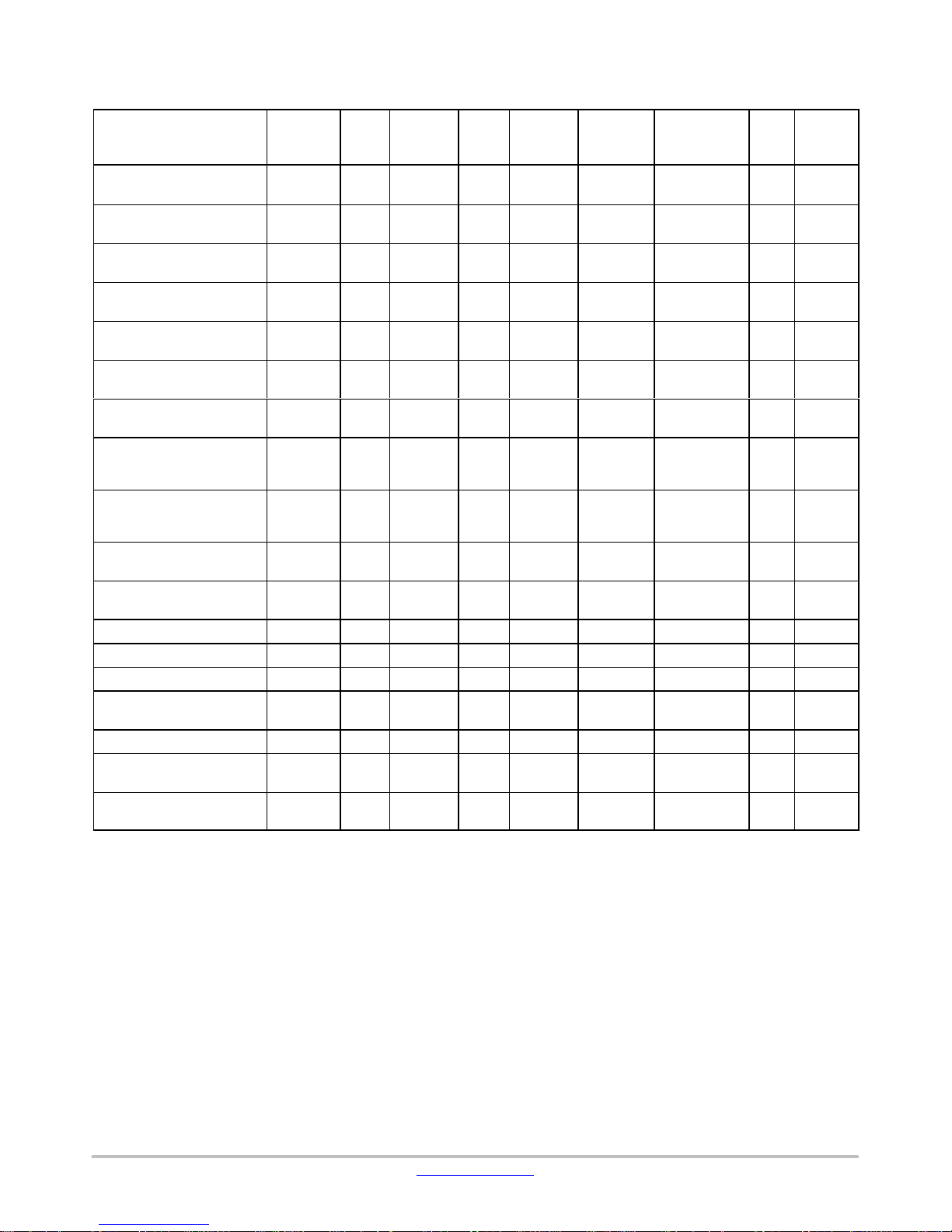

Table 10. PERFORMANCE SPECIFICATIONS ALL CONFIGURATIONS

Description Symbol Min. Nom. Max. Unit

Photodiode Charge

Capacity

PNe − 16 − ke

−

Sampling

Plan

Tested at

(5C)

Die 27, 40 16

Temperature

Test Notes

Read Noise ne−T −

Total Pixelized Noise −

Dynamic Range DR −

Column Noise C

Row Noise R

Dark Field Local

N

N

DSNU_flr −

Non-Uniformity Floor

Bright Field Global

PRNU_1 − 1.5 − % rms Die 27, 40 2 2

3.7 RS

−

25.5 GS

4.5 RS

−

28.3 GS

73 RS

−

56 GS

−

0.6 RS

−

3.0 GS

−

1.0 RS

−

5.0 GS

3.0 RS

−

21 GS

−

e− rms Die 27 8 1

−

−

e− rms Die 27 19 1

−

−

dB Die 27 1, 4

−

−

e− rms Die 27 9 1, 6

−

−

e− rms Die 27 10 1, 7

−

−

e− rms Die 27, 40 1 1, 5

−

Photoresponse

Non-Uniformity

Bright Field Global Peak to

PRNU_2 − 6.5 − % pp Die 27, 40 3 2

Peak Photoresponse

Non-Uniformity

Maximum Photoresponse

NL − 6.3 − % Die 27, 40 11 3

Non-Linearity

Maximum Gain Difference

DG

− 0.3 − % Die 27, 40 12 8

between Outputs

Photodiode Dark Current I

Storage Node Dark Current I

PD

VD

Image Lag Lag − 1.3 10

Black-Sun Anti-Blooming X

AB

− 4.6 70 e/p/s Die 40 13 9

− 1,200 5,000 e/p/s Die 40 14 5

−

−

−

12

> 10,000

−

W/cm

−

xllumSat

Design 27, 40 15

2

Design 27 7 14

Parasitic Light Sensitivity PLS − 730 − − Design 27 6 10

Dual-Video WDR −

Pulsed Pixel WDR

140 RS

−

120 GS

−

dB Design 27 1, 11,

−

− 100 − dB Design 27 12, 13

(GS Only)

1. RS = Rolling Shutter Operation Mode, GS = Global Shutter Operation Mode.

2. Measured per color, worst of all colors reported.

3. Value is over the range of 10% to 90% of photodiode saturation, Green response used.

4. Uses 20LOG (PNe / ne

−

T).

5. Photodiode dark current made negligible.

6. Column Noise Correction active.

7. Row Noise Correction active.

8. Measured at ~70% illumination.

9. Storage node dark current made negligible.

10.GSE (Global Shutter Efficiency) = 1 −1 / PLS.

11.Min vs Max integration time at 30 fps.

12.WDR measures expanded exposure latitude from linear mode DR.

13.Min/Max responsivity in a 30 fps image.

14.Saturation Illumination referenced to a 3 line time integration.

12

www.onsemi.com

8

Page 9

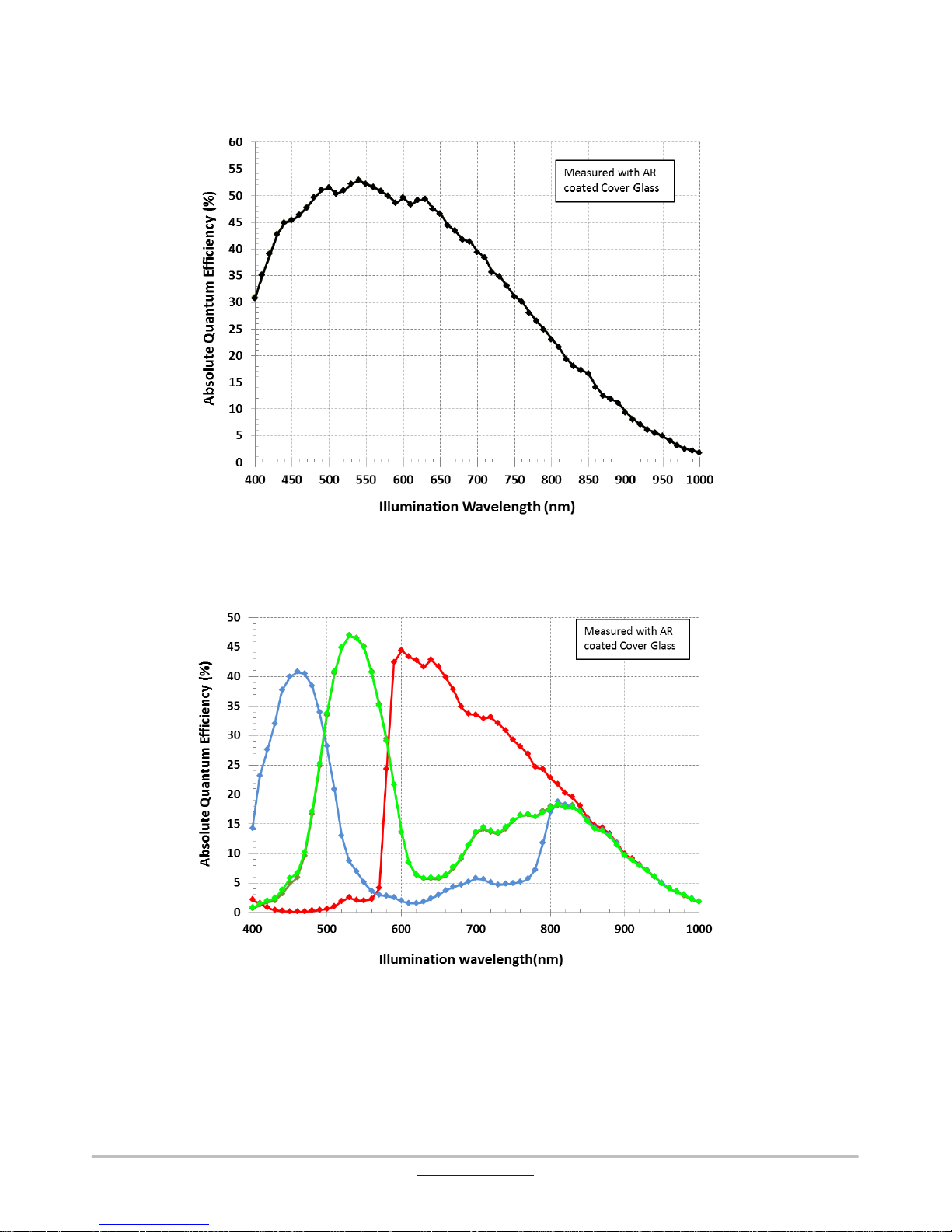

TYPICAL PERFORMANCE CURVES

KAC−12040

Figure 4. Monochrome QE (with Microlens)

Figure 5. Bayer QE (with Microlens)

www.onsemi.com

9

Page 10

KAC−12040

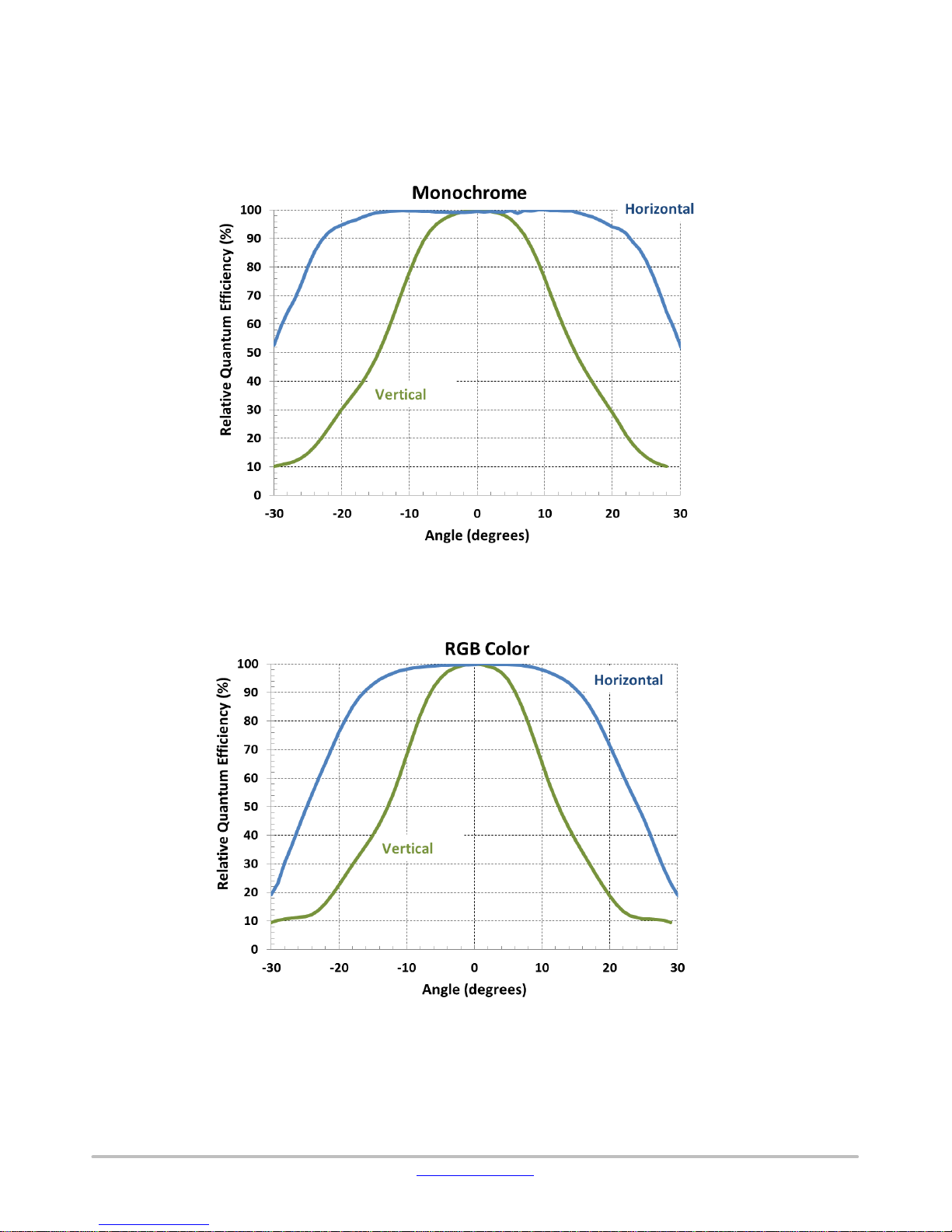

Angular Quantum Efficiency

For the curves marked “Horizontal”, the incident light angle is varied along the wider array dimension.

For the curves marked “Vertical”, the incident light angle is varied along the shorter array dimension.

Figure 6. Monochrome Relative Angular QE (with Microlens)

Figure 7. Bayer Relative Angular QE (with Microlens)

www.onsemi.com

10

Page 11

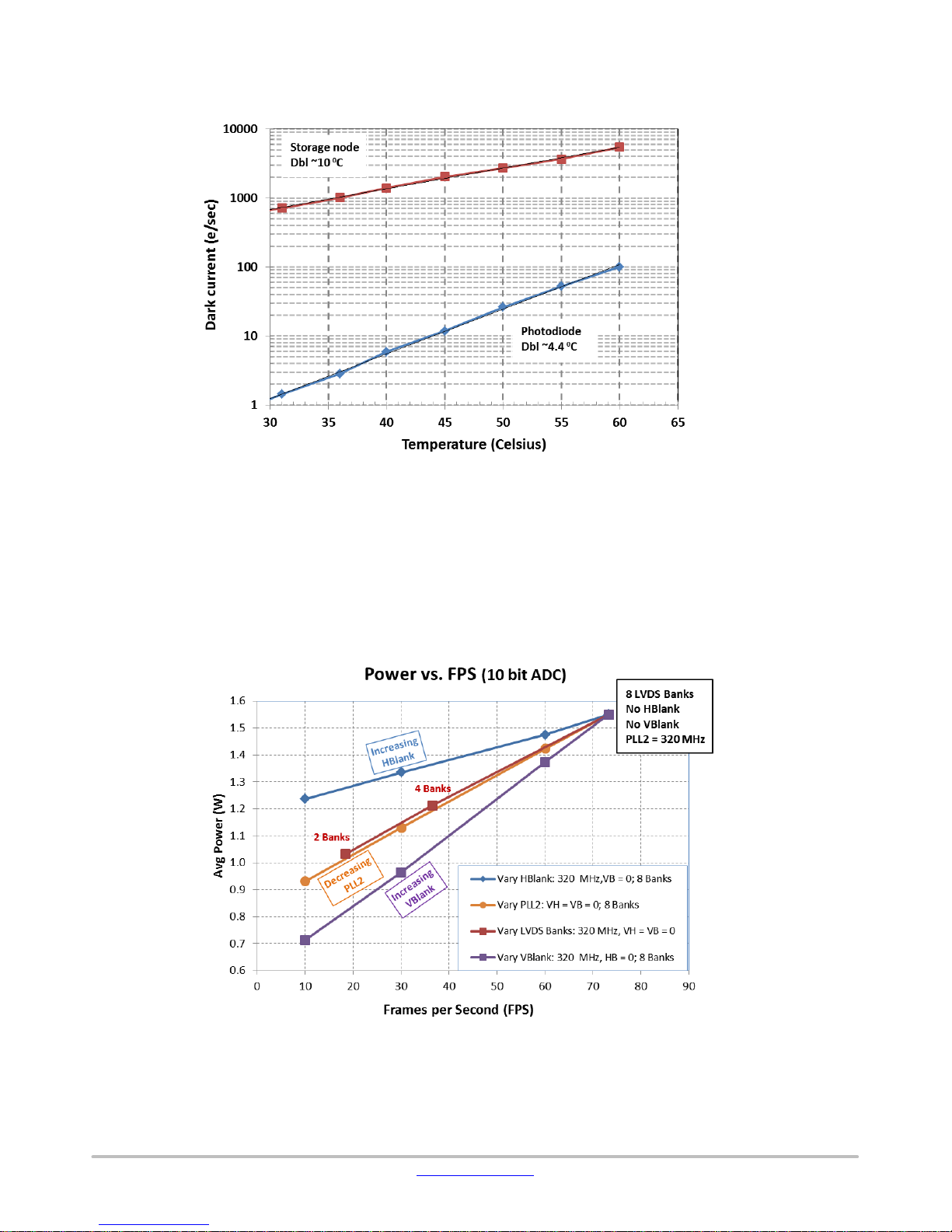

Dark Current vs. Temperature

NOTE: “Dbl” denotes an approximate doubling temperature for the dark current for the displayed temperature range.

KAC−12040

Figure 8. Dark Current vs. Temperature

Power vs. Frame Rate

The most effective method to use the maximum PLL2

speed (313 → 320 MHz) and control frame rate with

minimum Power and maximum image quality is to adjust

Vertical Blanking. (register 01F1h). Unnecessary chip

operations are suspended during Vertical Blanking

conserving significant power consumption and also

minimizing the image storage time on the storage node when

in Global Shutter Operation.

NOTE: The LVDS clock is ½ the PLL2 clock speed.

Figure 9. Power vs. Frame Rate, 10 bit Mode

www.onsemi.com

11

Page 12

KAC−12040

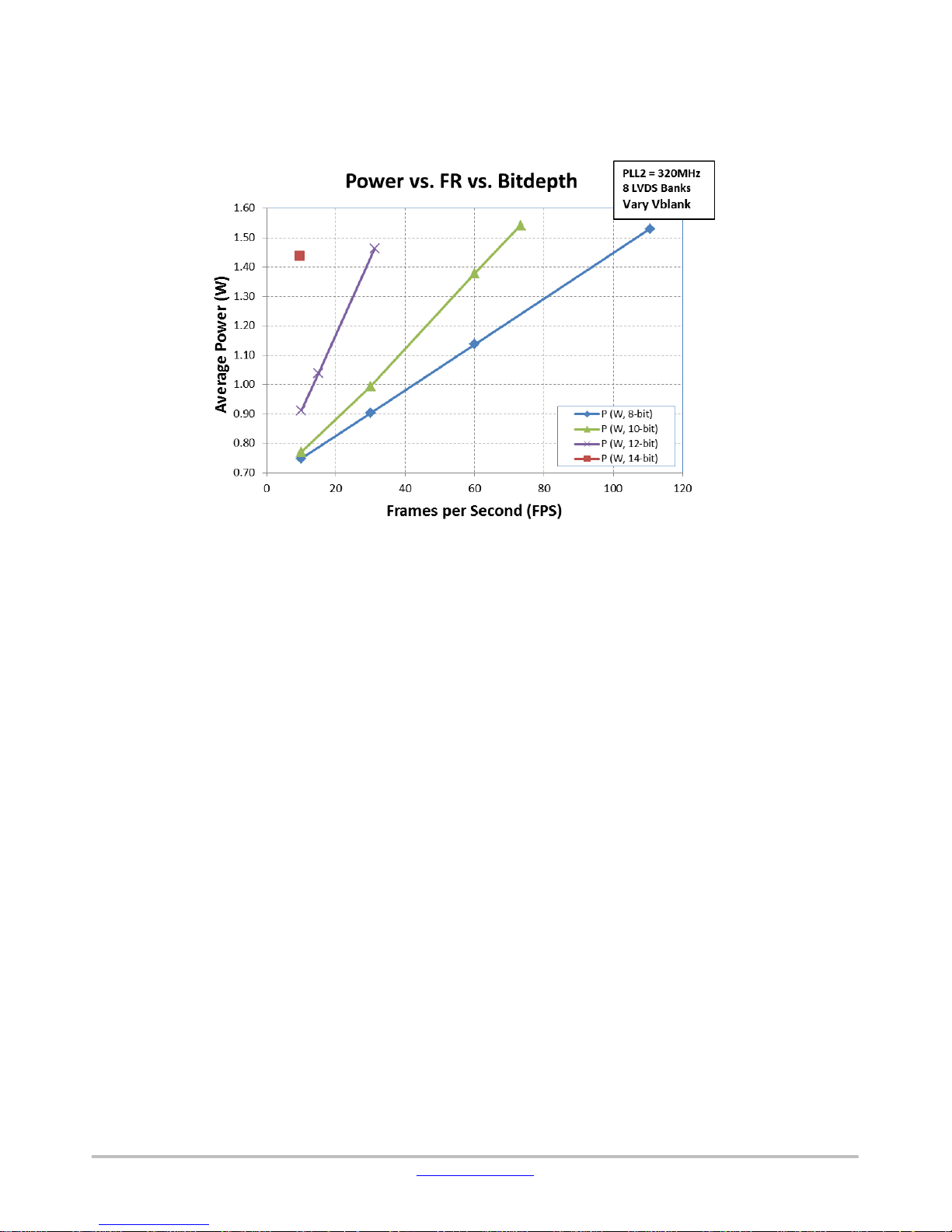

Power and Frame Rate vs. ADC Bit Depth

Increasing the ADC bit depth impacts the frame rate by

changing the ADC conversion time. The following figure

shows the power and Frame rate range for several typical

cases.

Figure 10. ADC Bit Depth Impact on Frame Rate and Power

www.onsemi.com

12

Page 13

KAC−12040

DEFECT DEFINITIONS

Table 11. OPERATION CONDITIONS FOR DEFECT TESTING

Description Condition Notes

Operational Mode 10 bit ADC, 8 LVDS Outputs, Global Shutter and Rolling Shutter Modes,

Pixels per Line 4,000

Lines per Frame 3,000

Line Time

Frame Time 13.9 ms

Photodiode Integration Time 33 ms

Storage Readout Time 13.9 ms

Temperature 40°C and 29°C

Light Source Continuous Red, Green and Blue LED Illumination 1

Operation Nominal Operating Voltages and Timing, PLL1 = 320 MHz, Wafer Test

1. For monochrome sensor, only the green LED is used.

Table 12. DEFECT DEFINITIONS FOR TESTING

Description Definition Limit Test Notes

Dark Field Defective Pixel 30°C

Bright Field Defective Pixel Defect ≥ ±12% from Local Mean 120 5 2, 5

Cluster Defect A group of 2 to 10 contiguous defective pixels, but

Column/Row Major Defect A group of more than 10 contiguous defective pixels

Dark Field Faint Column/Row Defect RS: 3 dn Threshold

Bright Field Faint Column/Row Defect RS: 12 dn Threshold

1. RS = Rolling Shutter, GS = Global Shutter.

2. For the color devices, all bright defects are defined within a single color plane, each color plane is tested.

3. Cluster defects are separated by no less than two good pixels in any direction.

4. Rolling Shutter Dark Field points are dominated by photodiode integration time, Global Shutter Dark Field defects are dominated by the

readout time.

5. The net sum of all bright and dark field pixel defects in rolling and global shutter are combined and then compared to the test limit.

Dual-Scan, Black Level Clamp ON, Column/Row Noise Corrections ON,

1× Analog Gain, 1× Digital Gain

8.7 ms

RS: Defect ≥ 20 dn

GS: Defect ≥ 180 dn

no more than 3 adjacent defects horizontally.

along a single column or row.

GS: 10 dn Threshold

GS: 18 dn Threshold

40°C

RS: Defect ≥ 30 dn

GS: Defect ≥ 240 dn

120 4 1, 4, 5

22 3

0

0 17 1

0 18 1

Defect Map

The defect map supplied with each sensor is based upon

testing at an ambient (29°C) temperature. All defective

pixels are reference to pixel (0, 0) in the defect maps. See

Figure 11 for the location of pixel (0, 0).

www.onsemi.com

13

Page 14

KAC−12040

TEST DEFINITIONS

Test Regions of Interest

Image Area ROI: Pixel (0, 0) to Pixel (4015, 3015)

Active Area ROI: Pixel (8, 8) to Pixel (3999, 2999)

Center ROI: Pixel (1958, 1458) to Pixel (2057, 1557)

Only the Active Area ROI pixels are used for performance and defect tests.

B

G

R

G

4000 (H) y 3000 (V)

4.7 mm Pixel

0,0

8,8

104

8

88

8

8

88

B

G

R

G

8

104

B

G

R

G

Figure 11. Regions of Interest

Test Descriptions

1) Dark Field Local Non-Uniformity Floor (DSNU_flr)

This test is performed under dark field conditions.

A 4 frame average image is collected. This image is

partitioned into 300 sub-regions of interest, each of which is

200 by 200 pixels in size. For each sub-region the standard

deviation of all its pixels is calculated. The dark field local

non-uniformity is the largest standard deviation found from

all the sub regions of interest. Units: e

−

rms (electrons rms).

2) Bright Field Global Photoresponse Non-Uniformity

(PRNU_1)

The sensor illuminated to 70% of saturation (~700 dn). In

this condition a 4 frame average image is collected. From

this 4 frame average image a 4 frame average dark image is

subtracted. The Active Area Standard Deviation is the

standard deviation of the resultant image and the Active

Area Signal is the average of the resultant image.

PRNU_1 + 100 @

Units : % rms

ǒ

Active Area Signal

Ǔ

Active Area Standard Deviation

3) Bright Field Global Peak to Peak Non-Uniformity

(PRNU_2)

This test is performed with the sensor uniformly

illuminated to 70% of saturation (~700 dn), a 4 frame

average image is collected and a 4 frame averaged dark

image is subtracted. The resultant image is partitioned into

300 sub regions of interest, each of which is 200 by

200 pixels in size. The average signal level of each sub

regions of interest (sub-ROI) is calculated.

The highest sub-ROI average (Maximum Signal) and the

lowest sub-ROI average (Minimum Signal) are then used in

the following formula to calculate PRNU_2.

PRNU_2 + 100 @

Units : % pp

ǒ

Active Area Signal

Ǔ

Max. Signal * Min. Signal

4) Dark Field Defect Test

This test is performed under dark field conditions.

The sensor is partitioned into 300 sub regions of interest,

each of which is 128 by 128 pixels in size. In each region of

interest, the median value of all pixels is found. For each

region of interest, a pixel is marked defective if it is greater

than or equal to the median value of that region of interest

plus the defect threshold specified in the Defect Definition

Table section.

5) Bright Field Defect Test

This test is performed with the imager illuminated to

a level such that the output is at approximately 700 dn.

The average signal level of all active pixels is found.

The bright and dark thresholds are set as:

Dark Defect Threshold = Active Area Signal ⋅ Threshold

Bright Defect Threshold = Active Area Signal ⋅ Threshold

The sensor is then partitioned into 300 sub regions of

interest, each of which is 128 by 128 pixels in size. In each

region of interest, the average value of all pixels is found.

For each region of interest, a pixel is marked defective if it

is greater than or equal to the median value of that region of

interest plus the bright threshold specified or if it is less than

www.onsemi.com

14

Page 15

KAC−12040

or equal to the median value of that region of interest minus

the dark threshold specified.

Example for bright field defective pixels:

• Average value of all active pixels is found to be 700 dn

• Lower defect threshold: 700 dn ⋅ 12% = 84 dn

• A specific 128 × 128 ROI is selected:

♦ Median of this region of interest is found to be

690 dn.

♦ Any pixel in this region of interest that is

≤ (690 − 84 dn) in intensity will be marked

defective.

♦ Any pixel in this region of interest that is

≥ (690 − 84 dn) in intensity will be marked

defective.

• All remaining 299 sub regions of interest are analyzed

for defective pixels in the same manner.

6) Parasitic Light Sensitivity (PLS)

Parasitic Light Sensitivity is the ratio of the light

sensitivity of the photodiode to the light sensitivity of the

storage node in Global Shutter. There is no equivalent

distortion in Rolling Shutter. A low PLS value can provide

distortion of the image on the storage node by the scene

during readout.

PLS +

GSE (Global Shutter Efficiency) is a related unit.

Detailed Method: Photodiode Responsivity:

The sensor is set in global shutter serial mode (integration

time not overlapping readout) and the FLO signal is used to

control a 550 nm normal incident (or large f# focused)

illumination source so that the sensor is illuminated only

during photodiode integration time (not illuminated during

readout time). The integration time is not critical but should

be large enough to create a measurable mean during this

time. A 16 frame-average illuminated photodiode image is

recorded. A 16 frame-average dark frame using the same

sensor settings is captured and is subtracted from the

illuminated image.

Detailed Method: Storage Node Responsivity:

The sensor is set to a special characterization mode where

the PD signal is discarded and does not impact the storage

node. A long total frame time (storage node exposure time)

is used to increase the storage node signal. A 16

frame-average dark frame is captured. The sensor is

illuminated by the same 550 nm incident light source used

for the photodiode responsivity. A 16 frame-average

illuminated photodiode image is recorded; the dark frame

image is subtracted from this. The integration time is not

critical but should be set such that a significant response is

detected, typically several orders of magnitude greater than

the photodiode integration time.

Photodiode Responsivity

Storage Node Responsivity

GSE +ǒ1 *

1

PLS

(UnitlessRatio)

Ǔ

%

7) Black-Sun Anti-Blooming

A typical CMOS image sensor has a light response profile

that goes from 0 dn to saturation (1023 dn for KAC−12040

in 10 bit ADC mode) and, with enough light, back to 0 dn.

The sensor reaching 0 dn at very bright illumination is often

called the “Black-sun” artifact and is undesirable. Black-sun

artifact is typically the dominant form of anti-blooming

image distortion. For the KAC−12040 the Black-sun artifact

threshold is measured at the onset of saturation distortion,

not at the point where the output goes to 0 dn. To first order

the onset of black-sun artifact for the KAC−12040 is not

proportional to the integration time or readout time.

The sensor is placed in the dark at unity gain and

illuminated with a 532 nm laser with the intensity of about

26 W/cm

2

at the center of the sensor. The laser is strong

enough to make the center of the laser spot below 1020 dn

without any ND filters. ND filters are added to adjust the

laser intensity until the signal in the region at the center of

the spot increases to > 1020 dn.

This illumination intensity at this ND filter is recorded

2

(W/cm

) as the Black-Sun Anti-blooming.

The ‘xIlumSat’ unit is calculated using and integration

time of 100 msec.

Exposing the sensor to very strong illumination for

extended periods of time will permanently alter the sensor

performance in that localized region.

8) Read Noise

This test is performed with no illumination and one line of

integration time. The read noise is defined as one standard

deviation of the frequency histogram containing the values

of all pixels after the excessively deviant pixels (± three

standard deviations) are removed.

9) Column Noise

After all rows are averaged together. Shading (low

frequency change wrt column address) is removed.

A frequency histogram is constructed of the resulting

column values. The column noise is the standard deviation

of the frequency histogram of the column values.

10) Row Noise

All columns are averaged together. Shading (low

frequency change wrt row address) is removed. A frequency

histogram is constructed of the resulting row values.

The row noise is the standard deviation of the frequency

histogram of the row values.

11) Maximum Photoresponse Non-Linearity

The photoresponse non-linearity is defined as the

deviation from the best fit of the sensor response using 70%

of saturation and zero signal as the reference points.

The different signal levels are determined by varying the

integration time. The sensor saturation level is (1023-dark

offset). The dark offset is subtracted from the image for the

following M

AVG

and L

AVG

.

www.onsemi.com

15

Page 16

KAC−12040

• The integration time is varied until the integration time

required to reach the 70% saturation is determined.

M

= the active array mean at the 70% saturation

AVG

integration time.

• The integration is set to 1/14 (5% exposure point).

= meant at the 5% exposure point.

L

AVG

• PRNL (@ 5% saturation) = ((L

AVG/MAVG

⋅ 100

12) Maximum Gain Difference between Outputs

The sensor contains two ADC and four channels of analog

data in its highest frame rate configuration. The sensor is

factory calibrated to reduce the gain differences between the

channels. The gain variations are manifest as a row oriented

pattern where every other row uses a different ADC. Using

triple scan read out mode, an additional two analog channels

are introduced resulting in a four row pattern. With one

channel (‘Top Ping’) used as the reference, the residual gain

difference is defined as:

Bottom Ping Row Average

ǒ

Top Ping Row Average

Top Pong Row Average

ǒ

Top Ping Row Average

Bottom Pong Row Average

ǒ

Top Ping Row Average

* 1Ǔ@ 100

* 1Ǔ@ 100

* 1Ǔ@ 100

13) Photodiode Dark Current

The photodiode dark current is measured in rolling shutter

read out mode using 105 ms integration time and an analog

gain = 8. The value is converted to electrons/pix/sec using

the formula:

Photodiode Dark Current + Aver. Signal (DN) @

where ‘average signal (DN)’ is the average of all pixels in

the sensor array, and ‘el-per-DN (gain=8)’ is measured on

each sensor using the photon transfer method.

14) Storage Node Dark Current

The storage node dark current is measured in global

shutter read out mode using a special timing mode to prevent

the photodiode dark current from being transferred to the

storage node. In global shutter mode, the integration time of

the storage node is the time it takes to read out a frame. The

sensor analog gain is set to 2:

Storage Node Dark Current + Aver. Signal (DN) @

where ‘average signal (DN)’ is the average of all pixels in

the sensor array and ‘el-per-DN (gain=2)’ is measured on

each sensor using the photon transfer method.

15) Lag

Lag is measured as the number of electrons left in the

photodiode after readout when the sensor is illuminated at

70% of Photodiode Charge Capacity.

) ⋅ (14/1) −1)

el−per−DN (gain=8)

0.105 seconds

el−per−DN

0.138 seconds

(gain=2)

Analog gain is set to 8. With no illumination a 64 average

dark image is recorded (Dark_ref). The ‘el-per-DN’ is

measured using the photon transfer method.

Illumination is adjusted blink every other frame such that

the mean image output is 70% of the Photodiode Charge

Capacity for even frames, and with no illumination for odd

frames. A 64 frame average of Odd Dark Frames is recorded

as Dark_Lag.

Lag +(Dark_Lag * Dark_Ref)@ el−per−DN

Units : Electrons rms

16) Photodiode Charge Capacity

The sensor analog gain is reduced to < 1 to prevent ADC

clipping at 1023 dn. The ‘el-per-DN’ is measured using the

photon transfer method. The sensor is illuminated at a light

level ~1.5x the illumination at which the pixel output no

longer linearly changes with illumination level.

The Photodiode Charge Capacity is equal to the average

signal (DN) ⋅ el-per-DN. Units: electrons rms.

17) Dark Field Faint Column/Row Defect

A 4 frame average, no illumination image is acquired at

one line time of integration. Major defective pixels are

removed (> 5 Sigma). All columns or rows are averaged

together. The average of the local ROI of 128 columns or

rows about the column/row being tested is determined. Any

columns/rows greater than the local average by more than

the threshold are identified.

18) Bright Field Faint Column/Row Defect

A 4 frame average, 70% illumination image is acquired at

one line time of integration. Major defective pixels are

removed (> 5 Sigma). All columns or rows are averaged

together. The average of the local ROI of 128 columns or

rows about the column/row being tested is determined. Any

columns/rows greater than the local average by more than

the threshold are identified.

19) Total Pixelized Noise

This test is performed with no illumination and one line of

integration time. A single image is captured including both

T emporal a n d F i x e d P attern Noise (FPN). A spatial low pass

filter is applied to remove shading and deviant pixels

(± three standard deviations) are removed. The Total

Pixelized Noise is defined as one standard deviation of the

frequency histogram.

20) Responsivity ke

−

/lux-sec

This number is calculated by integrating the

multiplication of the sensor QE by the human photopic

response assuming a 3200K light source with a QT100 IR

filter. This is a sharp 650 nm cutoff filter. If the IR filter is

removed a higher response value will result.

21) Responsivity V/lux-sec

Voltage levels are not output from the sensor. This metric

uses the pixel output in volts at the ADC input for 1x Analog

Gain.

www.onsemi.com

16

Page 17

OPERATION

KAC−12040

This section is a brief discussion of the most common

features and functions assuming default conditions. See the

KAC−12040 User Guide for a full explanation of the sensor

operation modes, options, and registers.

Register Address

The last bit of any register address is a Read/Write bit.

Most references in this document refer to the Write address.

<2µ s

Slave Integration Mode

TRIG_WAIT

TRIGGER Active Edge

End of

acquisition

EXT_INT

TRIGGER Inactive Edge

<50µ s

<2µ s

<2µ s

End of acquisition AND

IDLE mode AND

No TRIGGER

All SPI reads are to an even address, all SPI writes are to an

odd address.

Sensor States

Figure 12 shows the sensor states, see the KAC−12040

User Guide for detailed explanation of the States.

RESET

<35µ s

STANDBY

CONFIG

IDLE

RUNNING

150µ s

WAKE−UP

(50 ms)

RUNNING mode OR

TRIGGER pin

<50µ s

RESETN low or

reset Reg 4060h

READOUT

Figure 12. Sensor State Diagram

www.onsemi.com

17

Page 18

KAC−12040

Encoded Syncs

To facilitate system acquisition synchronization the

KAC−12040 places synchronization words (SW) at the

beginning and at the end of each output row as indicated in

V Blanking Period

SOF

DataSOL

V Blanking Period

Line Length (LL)

Figure 13. Encoded Frame Syncs

Line Time

This Datasheet presumes the recommended startup script

that is defined in the KAC−12040 User Guide has been

applied. The KAC−12040 defaults to Dual-Scan mode. In

this mode the LVDS data readout overlaps the pixel readout

and ADC conversion time. The Pixel and ADC conversion

time are fixed (for 10 bit operation) and total ~8.66 ms.

The LVDS time will be dependent on the PLL2 frequency

selected. If the PLL2 < 313 MHz, then the LVDS data

readout will dominate the row time. For PLL2 > 313 MHz,

the Pixel + ADC will set the minimum Line Time. The Line

Time is not impacted by the selection of Rolling Shutter or

Global Shutter mode.

the following Figure 13. This is performed for each of the

8 LVDS output banks providing frame, line, and output

synchronization. See the KAC−12040 User Guide for

additional detail on LVDS and Encoded Sync output.

EOL

H Blanking Period

EOF

The KAC−12040 architecture always outputs two rows at

once, one row from the top ADC, and one from the bottom

ADC. Each ADC then divides up the pixel into 1 → 4

parallel pixel output LVDS Banks. The default is 4 output

banks per ADC for a total of 8 parallel pixel outputs to

minimize the LVDS data output time. Since the sensor

always outputs 2 rows at a time the timing and registers are

based on a Line Time (LT) or Line Length (LL) where one

LT = the time to readout 2 rows in parallel (one even row and

one odd row).

Figure 14. Default Line Time (Dual-Scan) with PLL2 = 320 MHz

Pixel n+1 10 bit ADC n+1

4.30 ms 4.36 ms

8 Bank LVDS Output n

LVDS Clock = 160 MHz

8.44 ms

Line n Time = Line Length Register (0201h) = 1400

8.75 ms

www.onsemi.com

18

Line

Wait

Page 19

KAC−12040

8.34 ms by Default (952 Line Times)

Frame Time

The frame time is defined in units of Line Time. 1 Line

Time unit = 2 output rows. To first-order the frame rate is not

directly impacted by selection of Global Shutter, Rolling

Shutter, Dual-Scan, or Tri-Scan.

The Frame Time is made up of three phases:

1. Integration Phase

2. Readout Phase

3. Frame Wait Phase (Vertical Blanking, V

Integration Phase Frame m Integration Phase Frame m+1 Integration Phase Frame m+2

Readout Phase Frame m Readout Phase Frame m+1

Single Frame of Video Overhead

Figure 15. Default Frame Time Configuration (Frame A)

13.80 ms by Default

Video Frame Time = Readout + Wait

BLANK

)

By default the Integration Phase overlaps the Readout and

Frame Wait Phases. If the Integration Phase is larger than the

Readout + Fram e Wait time, then the Integration Phase will

determine the video frame rate. Otherwise the frame rate

will be set by the Readout + Frame Wait time. In other words,

if the programmed integration time is larger than the

minimum readout time (and vertical blanking) then extra

vertical blanking will be added and the frame rate will slow

to accommodate the requested integration time.

Frame

Wait

13.79 ms by Default

(1576 Line Times)

If the Integration Phase is less than the Readout Phase then

the start of integration is automatically delayed to minimize

the storage time and dark current.

Frame

Wait

~0.01 ms

(1 Line Time)

Integration Phase Frame m

If the Readout Phase (+ V

Figure 16. Frame Time with Extended Integration Time

BLANKING

Integration Phase Frame m+1

Readout Phase Frame m

Video Frame Time = Integration Time

) is less than the

Integration Phase, then the readout occurs as soon the

integration is complete to minimize the storage time and

dark current.

Integration Phase Frame m+2

Frame

Wait

Readout Phase Frame m+1

Frame

Wait

See the KAC−12040 User Guide for detailed calculation

of the Integration Phase, Readout Phase, and Frame Wait.

To first-order the Readout Phase is equal to the number o f

rows ⋅ row_time.

www.onsemi.com

19

Page 20

KAC−12040

Integration of Next Frame Overlaps

Global Shutter Readout

Global Shutter readout provides the maximum precision

for freezing scene motion. Any motion artifacts will be

100% defined by an ideal integration time edge. Every pixel

in the array starts and stops integration at the same time.

Figure 17 illustrates a Global Shutter Frame readout

assuming the recommended Start-up Script defined in the

KAC−12040 User Guide (8 LVDS banks, Dual-Scan,

8.75 ms line time). The Frame W ait Phase is not shown due

to its small default size (1 LL) and for clarity.

Global Shutter readout mode is selected using Bits [1:0]

of Register 01D1h.

Images can be initiated by setting and holding the

TRIGGER input pin or by placing the sensor into

RUNNING mode by writing 03d to register 4019h. If the

TRIGGER input pin is true when at the start of the

integration time for the next frame then the sensor will

complete an additional frame integration and readout. In the

case shown in Figure 17 two frames will be output.

Integration Time = 8.33 ms

Row Address Axis

Time/Col Address Axis

Trigger Pin: True = 2.0 V

Figure 17. Illustration of Frame Time for Global Shutter Readout

Readout of Previous Frame

Frame Readout = 13.80 ms

Effective Frame Time (Video) = Readout Time

www.onsemi.com

20

Page 21

KAC−12040

Integration of Next Frame Overlaps

Rolling Shutter Readout

The KAC−12040 high speed Rolling Shutter readout

provides the maximum dynamic range while still providing

excellent motion capture. In Rolling Shutter the readout

more closely matches a film camera shutter. Each row of the

image receives the same integration time, but each row starts

and ends at a di fferent time as the shutter travels from the top

of the array to the bottom. In the Figure 18 frame time

illustration this ‘moving shutter’ displays as a sloped edge

for the blue pixel array region, just as the readout edge is

sloped.

The Figure 18 illustration shows a 2 frame output

sequence using the external TRIGGER pin.

Integration Time = 8.33 ms

Row Address Axis

Time/Col Address Axis

Trigger Pin: True = 2.0 V

Figure 18. Illustration of Frame Time for Rolling Shutter Readout

Readout of Previous Frame

Frame Readout = 13.80 ms

Effective Frame Time (Video) = Readout Time

Rolling Readout mode can be selected using Bits [1:0] of

Register 01D1h.

Images can be initiated by setting and holding the

TRIGGER input pin or by placing the sensor into

www.onsemi.com

RUNNING mode by writing 03d to register 4019h. If the

TRIGGER input pin is True when at the start of the

integration time for the next frame then the sensor will

complete an additional frame integration and readout.

21

Page 22

8 BANK LVDS DATA READOUT

KAC−12040

LVDS Banks

The KAC−12040 provides 8 parallel pixel banks, each

consisting of 8 LVDS differential pairs (7 data pairs + 1clock

pair). This allows the output of 8 pixels per LVDS clock

Bank 3 Bank 5 Bank 7

Pixel Array

2 Bank Mode

Bank 0 Bank 1

Bank 2 Bank 4 Bank 6

Bank 3 Bank 5 Bank 7

Bank 0 Bank 1

Bank 2 Bank 4 Bank 6

Figure 19. LVDS Bank Labeling

The number of output banks used is independent of the

ADC bit depth chosen. By default the KAC−12040 uses all

8 output banks for maximum frame rate. If technical

restrictions prevent the use of 8 LVDS banks, the sensor can

be programmed to use 4 or 2 banks, however this can result

in reduced frame rate and reduction of image quality. It is

recommended that 8 banks be used when possible. Only the

8 bank option is discussed in detail in this specification, see

the KAC−12040 User Guide for additional detail on 4 and 2

bank mode.

period. All 7 data pairs, of each bank, are used only in 14 bit

operation mode. By default only 5 data pairs are used for

10 bit mode (D4 → D0). The unused pairs are held in

low-power high impedance mode.

Bank 3 Bank 5 Bank 7

Pixel Array

4 Bank Mode

Bank 0 Bank 1

Bank 2 Bank 4 Bank 6

Pixel Array

8 Bank Mode

In order to minimize the L VDS clock rate (and power) for

a given data rate the pixels are output in DDR (Double Data

Rate) where the MSB is always sent first (on rising edge) and

the LSB second (falling edge) This is not programmable.

Ports per LVDS Bank

The MSB comes out first on the falling edge, followed by

the LSB on the net rising edge.

Table 13. NUMBER OF LVDS PAIRS (PORTS) USED VS. BIT DEPTH

Bit Depth Edge of DATA CLK Data0 Data1 Data2 Data3 Data4 Data5 Data6

14 bits

12 bits

10 bits

8 bits

Falling (MSB Nibble) D7 D8 D9 D10 D11 D12 D13

Rising (LSB Nibble) D0 D1 D2 D3 D4 D5 D6

Falling (MSB Nibble) D6 D7 D8 D9 D10 D11 HiZ

Rising (LSB Nibble) D0 D1 D2 D3 D4 D5 HiZ

Falling (MSB Nibble) D5 D6 D7 D8 D9 HiZ HiZ

Rising (LSB Nibble) D0 D1 D2 D3 D4 HiZ HiZ

Falling (MSB Nibble) D4 D5 D6 D7 HiZ HiZ HiZ

Rising (LSB Nibble) D0 D1 D2 D3 HiZ HiZ HiZ

www.onsemi.com

22

Page 23

KAC−12040

8 Bank Pixel Order

The KAC−12040 always processes two rows at a time.

Even row decodes are sent to the bottom ADC and LVDS

output banks (0, 2, 4, 6). Odd rows are sent to the top ADC

and LVDS banks (1, 3, 5, 7). The ROI must be (and is

internally forced to) an even size and always starting on an

even row decode.

The rows are read out progressively left to right (small

column address to large). Eight pixels are sent out of the chip

at once, one pixel per LVDS bank per LVDS clock cycle.

Pixel Readout order:

1. Two rows are selected, the even row is sent to

the bottom ADC and the odd row to the top ADC.

2. Each ADC converts its row of pixel data at once

and stores the result in a line buffer.

3. At default settings there are 4 output LVDS banks

for each ADC.

Bank 3 Bank 5 Bank 7

4. Each LVDS Bank outputs one pixel per clock

cycle, so 4 pixels of each row are output each full

LVDS clock cycle, two rows in parallel for

8 pixels per clock cycle total.

5. The pixels are sent out from left to right

(low column number to high column number).

So the first 4 pixels are sent out on clock cycle 1,

and the next 4 pixels to the right are sent out on

clock cycle 2.

6. To conserve the number of wires per port,

the 10 bits per pixel are sent out DDR (Dual Data

Rate) over 5 ports. On the falling edge the upper

5 MSB bits are sent out, and on the rising edge the

lower 5 bits LSB are sent out. Completing one full

LVDS clock cycle and one set of eight pixels.

7

Row 2n +1

Row 2n

001122334455667

Bank 0 Bank 1

Bank 2 Bank 4 Bank 6

First CLK−DATA

Pulse

Figure 20. Pixel Readout Order Diagram

Table 14. PIXEL READOUT ORDER TABLE

LVDS Bank Row Pixel Number

Bank 0 2n (Even) 0 4 8 12 16

Bank 2 2n (Even) 1 5 9 13 17

Bank 4 2n (Even) 2 6 10 14 18

Bank 6 2n (Even) 3 7 11 15 19

Bank 1 2n+1 (Odd) 0 4 8 12 16

Bank 3 2n+1 (Odd) 1 5 9 13 17

Bank 5 2n+1 (Odd) 2 6 10 14 18

Bank 7 2n+1 (Odd) 3 7 11 15 19

LVDS Clock Cycle 1 2 3 4 5

Second CLK−DATA

Pulse

www.onsemi.com

23

Page 24

KAC−12040

De-Serializer Settings

Figure 21 shows the data stream of one LVDS bank for

10 bit resolution.

Data serialization is fixed at 2 cycle DDR for all bit depths.

Data output order is MSB first on the falling edge, and LSB

following on the rising edge.

Four pixel values per synchronization word are embedded

into the video stream per LVDS bank.

Dclk0

D0

Data0

Data1

Data2

Data3

Data4

D5

D0

SW1

D5

D0

D5

D1

D6

D1

D6

D2

D7

D2

D7

D3

D8

D3

D8

D4

D9

D4

D9

SW2 SW3 SW4 P0 P1 P2 P3 SW1 SW2 SW3 SW4PN−1 PN

D5

D6

D6

D7

D7

D8

D8

D9

D9

MSB LSB MSB

MSB LSB MSB

D0

D5

D0

D5

D1

D6

D1

D6

D2

D7

D2

D7

D3

D8

D3

D8

D4

D9

D4

D9

LSB MSB

LSB MSB

D0

D5

D0

D5

D1

D6

D1

D6

D2

D7

D2

D7

D3

D8

D3

D8

D4

D9

D4

D9

LSB MSB

LSB MSB

D0

D5

D0

D5

D1

D6

D1

D6

D2

D7

D2

D7

D3

D8

D3

D8

D4

D9

D4

D9

LSB MSB

LSB MSB

D0

D5

D0

D5

D1

D6

D1

D6

D2

D7

D2

D7

D3

D8

D3

D8

D4

D9

D4

D9

LSB MSB

LSB MSB

D5

D0

D5

D1

D6

D1

D6

D2

D7

D2

D7

D8

D3

D8

D3

D4

D9

D4

D9

LSB MSB

LSB MSB

D0

D5

D0

D5

D1

D6

D1

D6

D2

D7

D2

D7

D3

D8

D3

D8

D4

D9

D4

D9

LSB MSB

LSB MSB

The SOL/SOF synchronization words are sent out of each

LVDS bank before the first valid pixel data from that bank.

Each bank outputs all 4 syncs of the SOF or SOL.

And each of the active LVDS banks each output all 4 sync

codes for the EOL/EOF.

D0

D5

D0

D0

D1

D1

D2

D2

D3

D3

D4

D4

LSB

LSB

D5

D0

D5

D0

D6

D1

D6

D1

D7

D2

D7

D2

D8

D3

D8

D3

D9

D4

D9

D4

MSB LSB

MSB LSB

D5

D0

D5

D0

D6

D1

D6

D1

D7

D2

D7

D2

D8

D3

D8

D3

D9

D4

D9

D4

MSB LSB

MSB LSB

D0

D5

D6

D1

D6

D1

D7

D2

D7

D2

D3

D8

D3

D8

D9

D4

D9

D4

MSB LSB

MSB LSB

D5

D0

D5

D0

D6

D1

D6

D1

D7

D2

D7

D2

D8

D3

D8

D3

D9

D4

D9

D4

MSB LSB

MSB LSB

D5

D0

D5

D0

D6

D1

D6

D1

D7

D2

D7

D2

D8

D3

D8

D3

D9

D4

D9

D4

MSB LSB

MSB LSB

D5

D0

D5

D0

D6

D1

D6

D1

D7

D2

D7

D2

D8

D3

D8

D3

D9

D4

D9

D4

MSB LSB

MSB LSB

t

Synchronized Word on 10 bits Data on 10 bits

Figure 21. Data Stream of One LVDS Bank for 10 bits ADC Resolution

Synchronized Word on 10 bits

www.onsemi.com

24

Page 25

REGISTER DEFINITION

Table 15. REGISTER DEFINITION

16 bit

Write Address (Hex)

0001 420d Any Frame A Definition Frame A ROI y1

0009 2176d Any Frame A Definition Frame A ROI h1

0011 80d Any Frame A Definition Frame A ROI x1

0019 3856d Any Frame A Definition Frame A ROI w1

0021 0d Any Frame A Definition Frame A sub-ROI y2

0029 0d Any Frame A Definition Frame A sub-ROI h2

0031 0d Any Frame A Definition Frame A sub-ROI x2

0039 0d Any Frame A Definition Frame A sub-ROI w2

0041 0d Any Frame A Definition Frame A sub-ROI y3

0049 0d Any Frame A Definition Frame A sub-ROI h3

0051 0d Any Frame A Definition Frame A sub-ROI x3

0059 0d Any Frame A Definition Frame A sub-ROI w3

0061 0d Any Frame A Definition Frame A sub-ROI y4

0069 0d Any Frame A Definition Frame A sub-ROI h4

0071 0d Any Frame A Definition Frame A sub-ROI x4

0079 0d Any Frame A Definition Frame A sub-ROI w4

0081 0033d Any Frame A Definition Frame A Decimation

0089 0d Any Frame A Definition Frame A Video Blanking

0091 800d Any Frame A Definition Frame A Integration Lines

0099 0d Any Frame A Definition Frame A Integration Clocks

00A1 10d Any Frame A Definition Frame A Black Level

00A9 001Fh Any Frame A Definition Frame A Gain

00E9 0d Any Frame B Definition Frame B ROI y1

00F1 3016d Any Frame B Definition Frame B ROI h1

00F9 0d Any Frame B Definition Frame B ROI x1

0101 4016d Any Frame B Definition Frame B ROI w1

0109 0d Any Frame B Definition Frame B sub-ROI y2

0111 0d Any Frame B Definition Frame B sub-ROI h2

0119 0d Any Frame B Definition Frame B sub-ROI x2

0121 0d Any Frame B Definition Frame B sub-ROI w2

0129 0d Any Frame B Definition Frame B sub-ROI y3

0131 0d Any Frame B Definition Frame B sub-ROI h3

0139 0d Any Frame B Definition Frame B sub-ROI x3

0141 0d Any Frame B Definition Frame B sub-ROI w3

0149 0d Any Frame B Definition Frame B sub-ROI y4

0151 0d Any Frame B Definition Frame B sub-ROI h4

0159 0d Any Frame B Definition Frame B sub-ROI x4

0161 0d Any Frame B Definition Frame B sub-ROI w4

0169 033h Any Frame B Definition Frame B Decimation

0171 0d Any Frame B Definition Frame B Video Blanking

0179 800d Any Frame B Definition Frame B Integration Lines

0181 0d Any Frame B Definition Frame B Integration Clocks

0189 10d Any Frame B Definition Frame B Black Level

0191 001Fh Any Frame B Definition Frame B Gain

Default Value

Hex/Dec

KAC−12040

SPI State Group Register Name

www.onsemi.com

25

Page 26

Table 15. REGISTER DEFINITION (continued)

16 bit

Write Address (Hex)

01D1 CC11h CONFIG Only Config1

01D9 0000h CONFIG or IDLE Config2

01E1 000Ah CONFIG or IDLE Analog/Digital Power Mode

01E9 0000h CONFIG or IDLE Dual-Video Repetition

01F1 0d CONFIG or IDLE Vertical Blanking

01F9 1938d CONFIG or IDLE Fixed Frame Period

0201 1376d CONFIG or IDLE Line Length (LL)

0209 0028h CONFIG or IDLE ADC Bit Depth

0211 0000h CONFIG or IDLE FLO Edge

0219 0000h CONFIG or IDLE MSO Edge

0709 0000h Any CFA Feedback

0711 0000h Any Temperature Sensor FB

0719 0000h Any General Feedback

2059 0300h CONFIG Only Output Bank Select 1

2099 2877h CONFIG Only PLL1 Setting

20A1 0861h CONFIG Only PLL2 Setting

2449 0432h CONFIG Only Sub-LVDS Enable

2479 10ABh Any Column Clamp Threshold A

2481 20C7h Any Column Clamp Threshold B

2499 0011h CONFIG or IDLE Test Pattern Control 1

24A1 0220h CONFIG or IDLE Test Pattern Control 2

24B9 202d CONFIG Only Slope 1 Length

24C1 101d CONFIG Only Slope 2 Length

24C9 101d CONFIG Only Slope 3 Length

24D1 101d CONFIG Only Slope 4 Length

24D9 101d CONFIG Only Slope 5 Length

24E1 420d CONFIG Only Slope 6 Length

24E9 0083g CONFIG Only Slope 1/2 Gain

24F1 038Fh CONFIG Only Slope 3/4 Gain

24F9 0FBFh CONFIG Only Slope 5/6 Gain

2501 1F9Fh CONFIG Only Slope 7 Gain

2559 4804h Any Defect Avoidance Threshold

2561 0006h Any Defect Avoidance Enable

25C1 0003h CONFIG or IDLE Encoded Sync Config

25C9 000Ah CONFIG Only LVDS Power-Down

2619 000Bh CONFIG Only Output Bank Select 2

2D89 0000h CONFIG Only FLO/MSO Polarity

4001 4100h Any Chip Revision Code

4009 0011h Any Chip ID Code MSB

4011 0080h Any Chip ID Code LSB

4019 0000h Any Set Sensor State

4021 0000h CONFIG or IDLE OTP Address

Default Value

Hex/Dec

KAC−12040

SPI State Description

www.onsemi.com

26

Page 27

KAC−12040

Table 15. REGISTER DEFINITION (continued)

16 bit

Write Address (Hex)

4029 0000h CONFIG or IDLE OTP Write Data

4031 0000h CONFIG or IDLE Command_Done_FB

4041 0000h CONFIG or IDLE OTP Read Data

4061 0000h CONFIG or IDLE Soft Reset

NOTES: SPI State (the Sensor State from which the register can be set):

1. “Any”: Can be written from any state (including RUNNING).

2. “CONFIG or IDLE”: These registers can be changed in IDLE or CONFIG states.

3. “CONFIG Only”: Sensor must be in CONFIG state to set these registers.

4. Only Register 4018h and 4060h may be set when the sensor is in STANDBY state.

NOTES: Decimal, hexadecimal, binary values:

1. “b” denotes a binary number, a series of bits: MSB is on the left, LSB is on the right.

2. “h” or “hex” denotes a hexadecimal number (Base 16, 1−9, A−F). The letters in a hex number are always capitalized.

3. “d” denotes a decimal number.

4. Note that “0” and “1” are the same value in all number base systems and sometimes the base notation is omitted.

The KAC−12040 features an embedded microprocessor by Cortus.

Default Value

Hex/Dec

DescriptionSPI State

www.onsemi.com

27

Page 28

ABSOLUTE MAXIMUM RATINGS

KAC−12040

For Supplies and Inputs the maximum rating is defined as

a level or condition that should not be exceeded at any time.

degraded and may be damaged. Operation at these values

will reduce Mean Time to Failure (MTTF).

If the level or the condition is exceeded, the device will be

Table 16. SUPPLIES

Description Value

AVDD_LV, VDD_DIG −0.25 V; 2.3 V

AVDD_HV, Vref_P, VDD_LVDS −0.25 V; 4 V

DC Input Voltage at Any Input Pin −0.25 V; VDD_DIG + 0.25 V

Table 17. CMOS INPUTS

Parameter Symbol Minimum Typical Maximum Unit

Input Voltage Low Level V

Input Voltage High Level V

IL

IH

−0.3 − 0.35 VDD_DIG V

0.65 VDD_DIG − VDD_DIG + 0.3 V

www.onsemi.com

28

Page 29

KAC−12040

OPERATING RATINGS

Table 18. INPUT CLOCK CONDITIONS

Parameter Minimum Typical Maximum Unit

Frequency for Clk_In1 and Clk_In2 45 48 50 MHz

Duty Cycle for Clk_In1 and Clk_In2 40 50 60 %

RESETN 10 − − ns

TRIGGER Pin Minimum Pulse Width 20 − − ns

TRIGGER must be active at least 4 periods of PLL1 (~12.5 ns at 320 MHz) to start a capture cycle. The polarity of the active

level is configurable by SPI (Register 01D8h Bit 0), the default is active high (i.e. pin = VDD_DIG = trigger request).

Table 19. OPERATING TEMPERATURE

Description Symbol Minimum Maximum Unit

Operating Temperature (Note 1) T

1. Under conditions of no condensation on the sensor.

Table 20. CMOS IN/OUT CHARACTERISTICS

Parameter Symbol Minimum Typical Maximum Unit

Output Voltage Low Level V

Output Voltage High Level V

Input Hysteresis Voltage V

Pull-up Resistor Value for RESETN Pin R

Pull-down Resistor Value for TRIGGER Pin R

Current on ADC_REF Pin I

OL

OH

TH

PU

PD

ADC_REF

OP

− − 0.45 V

VDD_DIG − 0.45 − − V

− 0.25 −

62 − −

100 − −

− 100 −

−40 80 °C

kW

kW

mA

www.onsemi.com

29

Page 30

KAC−12040

Table 21. SUPPLIES

Parameter

LVDS IO Supply VDD_LVDS 3.15 3.30 3.63 V

Pixel High Voltage Supply AVDD_HV 3.40 3.50 3.60 V

Pixel Low Voltage Supply Vref_P 2.71 2.80 2.88 V

Analog Power Supply AVDD_LV 1.71 1.80 1.89 V

Digital Power Supply VDD_DIG 1.90 2.00 2.10 V

AVDD_HV − Vref_P − 0.5 − V

Power in STANDBY State − 10 − mW

Current in STANDBY State

VDD_LVDS

AVDD_HV

AVDD_LV

Vref_P

VDD_DIG

Power in CONFIG State − 330 − mW

Current in CONFIG State

VDD_LVDS

AVDD_HV

AVDD_LV

Vref_P

VDD_DIG

Power in IDLE State − 410 − mW

Current in IDLE State

VDD_LVDS

AVDD_HV

AVDD_LV

Vref_P

VDD_DIG

Power in RUNNING State − 1.5 − W

Current in RUNNING State

VDD_LVDS in Standard LVDS Mode

VDD_LVDS in Sub-LVDS Mode

AVDD_HV

AVDD_LV

Vref_P

VDD_DIG

1. Voltages relative to VSS. Current measurements made in darkness.

2. PLL2 = 320MHz, Max frame rate (i.e., no row or frame wait time). These average power values will decrease at lower frame rate either from

reduced PLL2 or low power state during Line and Frame blanking.

3. Sub-LVDS active.

Symbol Minimum Typical Maximum Unit

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

< 0.5

< 0.5

< 0.5

< 0.5

4

< 0.5

< 0.5

< 0.5

< 0.5

145

< 0.5

20

< 0.5

< 0.5

145

164

104

74

12

26

396

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

mA

mA

mA

mA

www.onsemi.com

30

Page 31

SPI (SERIAL PERIPHERAL INTERFACE)

KAC−12040

The SPI communication interface lets the application

system to control and configure the sensor. The sensor has

an embedded slave SPI interface. The application system is

the master of the SPI bus.

T able 22.

Sensor I/O

Name

CSN I SPI Chip Select − Active low, this input activates the slave interface in the sensor.

SCK I SPI Clock − Toggled by the master.

MISO O SPI Master Serial Data Input − Slave (sensor) serial data output.

MOSI I SPI Master Serial Data Output − Slave (sensor) serial data input.

Direction

Description

T able 23.

Parameter

SPI SCK 5 25 50 MHz

Duty Cycle on SPI SCK 40 50 60 %

Minimum Typical Maximum Unit

Clock Polarity and Phase

CPOL (Clock POLarity) and CPHA (Clock PHAse) are

commonly defined in SPI protocol such as to define SCK

clock phase and polarity. The KAC−12040 defaults to

expecting the master to be configured with CPOL = 1

(the base value of the clock is VDD_DIG) and CPHA = 1

(data is valid on the clock rising edge).

CSN

SCK

MOSI

MISO

…

…

X

X

…

…

X

X

Figure 22. CPOL = 1 and CPHA = 1 Configuration

www.onsemi.com

31

Page 32

SPI Protocol

KAC−12040

Byte 0 Byte 1 Byte 2 Byte 3

CSN

CSN

Sclk

MOSI

Sclk

MOSI

Byte 0 Byte 1 Byte 2 Byte 3

8 Cycles 8 Cycles 8 Cycles 8 Cycles

16 Bit

Address Word

MSB

8 Cycles 8 Cycles 8 Cycles 8 Cycles

16 Bit

LSB

Address Word

MSB

Figure 23. SPI Write Byte Order

LSB MSB LSB

Data to Write

16 Bit

MISO

Figure 24. SPI Read Byte Order

Wait Time

1.5 ms

There is a delay during readback between presenting the

address to be read on the MOSI and being able to read the

register contents on the MISO. This delay is not the same for

all registers. Some are available immediately, some require

a longer fetch time. The 1.5 ms shown in Figure 15 is the

maximum time to fetch a register’s value when in CONFIG

state (the recommended state for changing registers). Some

registers can be adjusted during RUNNING state (see the

Register Summary on page 25). If performing a readback

during RUNNING state, the delay could be as long as 4.5 ms

depending on when in the row the request was sent and the

sensor’s microcontroller activity at that moment.

Note that readback does not provide the actual register

value being used, but reflects the next value to be used. All

www.onsemi.com

16 Bit

Data to Write

MSB LSB

new register writes are placed in a shadow memory until

they can be updated into the active memory. This active

memory update occurs at the start of the next frame or upon

entering the state listed in the Register Summary table on

page 25. Register reads access this shadow memory not the

active memory. For instance if the sensor is in RUNNING

mode and you adjust the LL in register 200h. You can read

back and confirm that your register change was received by

the sensor; however, the LL will not change since register

200h can only be changed in CONFIG state. If you change

the sensor state to CONFIG and then back to RUNNING,

then the new LL will take effect.

32

Page 33

SPI Interface

KAC−12040

CS

T

CS_SETUP

SCK

T

SETUP

MOSI

X

T

OUT_DELAY_CSN

MISO

Table 24. SPI TIMING SPECIFICATION

Symbol

T

CYCLE

T

SETUP

T

HOLD

T

CS_SETUP

T

CS_HOLD

T

OUT_DELAY_CSN

T

OUT_DELAY

…

T

T

CYCLE

CS_HOLD

…

T

HOLD

MSB

T

OUT_DELAY

MSB

MSB−1

Figure 25. SPI Timing Chronogram

Minimum Value Maximum Value Unit

20 200 ns

− 2.9 ns

0.8 − ns

− 2.5 ns

0.1 − ns

3.1 4.7 ns

4.9 8.7 ns

www.onsemi.com

33

Page 34

LVDS INTERFACE

KAC−12040

The data output can be configured to follow standard

TIA/EIA−644−A LVDS specification or a low power mode

compatible with common Sub-LVDS definition used in

FPGA industry. (Please refer to the KAC−12040 User Guide

for more information).

Unless otherwise noted, min/max characteristics are for

T = −40°C to +85°C, output termination resistance

RL = 100 W ±1%, Typical values are at VDD_LVDS =

3.3 V.

Use register 2449h to select standard or Sub-LVDS. This

document assumes that Sub-LVDS is active for all power

measurements. Standard LVDS can increase the average

power consumption as much as 200 mW in the case of

minimum horizontal and vertical blanking.

Table 25. ST ANDARD LVDS CHARACTERISTICS

Parameter

Differential Output Voltage VOD 250 355 450 mV

VOD Variation between Complementary Output States

Common Mode Output Voltage VOCM 1.235 1.259 1.275 V

VOCM Variation between Complementary Output States

High Impedance Leakage Current IOZD −1 − 1

Output Short Circuit Current:

When D+ or D− Connected to Ground

When D+ or D− Connected to 3.3 V

Output Capacitance CDO − 1.3 − pF

Maximum Transmission Capacitance Load Expected

(for 260 MHz LVDS Clock)

Symbol Minimum Typical Maximum Unit

DVOD

DVOCM

IOSD

−20 − 20 mV

−25 − 25 mV

2.9

12.25

− − 10 pF

−

−

4.3

30.47

mA

mA

Table 26. SUB-LVDS CHARACTERISTICS

Parameter

Differential Output Voltage V

VOD Variation between Complementary Output States

Common Mode Output Voltage V

VOCM Variation between Complementary Output States

High Impedance Leakage Current I

Output Short Circuit Current:

When D+ or D− Connected to Ground

When D+ or D− Connected to 3.3 V

Output Capacitance C

Maximum Transmission Capacitance Load Expected

(for 260 MHz LVDS Clock)

Symbol Minimum Typical Maximum Unit

140 180 220 mV

−5 − 5 mV

0.88 0.90 0.92 V

−10 − 10 mV

−1 − 1

1.4

10.21

− 1.3 − pF

− − 10 pF

−

−

2.2

30.47

mA

mA

DV

DV

I

OD

OD

OCM

OCM

OZD

OSD

DO

T able 27.

Parameter Minimum Typical Maximum Unit

LVDS_CLK 50 160 160 MHz

Duty Cycle on LVDS_CLK − 50 − %

www.onsemi.com

34

Page 35

In-Block LVDS Timing Specification

Ideal Sample Times = Center of Data

The tables below give LVDS timing specifications for no

data de-skew applied and with data de-skewing applied.

Data

AA AACC

Clock

BBBB

Figure 26. LVDS Timing Chronogram

KAC−12040

Table 28. IN-BLOCK LVDS TIMING SPECIFICATION (Data Transition Uncertainty − No De-Skew Applied)

Parameter

A 360 ps Max Data Transition Uncertainty (Skew + Jitter)

B LVDS Clock Period/4 1/4 LVDS Clock Period = 1/2 PLL2 Period

C C = B − A Minimum Receiver Setup/Hold Time Sample Window

KAC−12040 Example at Maximum PLL2 Speed

(320 MHz):

LVDS Clock Frequency = PLL2/2 = 160 MHz

LVDS Clock Period = 6250 ps

B = LVDS Clock Period/4 = 1563 ps

Value Description

If the sampling window is too small the PLL2 can be

reduced to increase the window (parameter C).

Alternatively, the majority of the transition uncertainty is

potential skew between the 7 data lines. Using de-skewing

can remove 350 ps from the uncertainty window.

C = B – A = 1563 – 360 = 1203 ps

Table 29. IN-BLOCK LVDS TIMING SPECIFICATION (Data Transition Uncertainty − Data De-Skewing Applied)

Parameter

A 10 ps Max Data Transition Uncertainty (Jitter)

B LVDS Clock Period/4 1/4 LVDS Clock Period = 1/2 PLL2 Period

C C = B − A Minimum Receiver Setup/Hold Time Sample Window

Value Description

KAC−12040 Example at Maximum PLL2 Speed

(320 MHz):

LVDS Clock Frequency = PLL2/2 = 160 MHz

LVDS Clock Period = 6250 ps

B = LVDS Clock Period/4 = 1563 ps

C = B – A = 1563 – 10 = 1553 ps

Table 30. INTER-BLOCK LVDS TIMING SPECIFICATION

Parameter Minimum Typical Maximum Unit

Inter-Block Skew − 6 12 LVDS Clock Period

www.onsemi.com

35

Page 36

KAC−12040

STORAGE AND HANDLING

Table 31. STORAGE CONDITIONS

Description Symbol Minimum Maximum Unit Notes

Storage Temperature T

Humidity RH 5 90 % 2

1. Long-term storage toward the maximum temperature will accelerate color filter degradation.

2. T = 25°C. Excessive humidity will degrade MTTF.

ST

−40 80 °C 1

For information on ESD and cover glass care and

cleanliness, please download the Image Sensor Handling

and Best Practices Application Note (AN52561/D) from

www.onsemi.com

.

For information on soldering recommendations, please

download the Soldering and Mounting Techniques

Reference Manual (SOLDERRM/D) from

www.onsemi.com

.

For quality and reliability information, please download

the Quality & Reliability Handbook (HBD851/D) from

www.onsemi.com.

For information on device numbering and ordering codes,

please download the Device Nomenclature technical note

(TND310/D) from www.onsemi.com

.

For information on Standard terms and Conditions of

Sale, please download Terms and Conditions

www.onsemi.com

.

from

www.onsemi.com

36

Page 37

MECHANICAL INFORMATION

Completed Assembly

KAC−12040

Notes:

1. See Ordering Information for marking code.

2. No materials to interfere with clearance through package holes.

3. Imaging Array is centered at the package center.

4. Length dimensions in mm units.

Figure 27. Completed Assembly (1 of 5)

www.onsemi.com

37

Page 38

KAC−12040

Figure 28. Completed Assembly (2 of 5)

www.onsemi.com

38

Page 39

KAC−12040

Figure 29. Completed Assembly (3 of 5)

www.onsemi.com

39

Page 40

KAC−12040

Figure 30. Completed Assembly (4 of 5)

Figure 31. Completed Assembly (5 of 5)

www.onsemi.com

40

Page 41

KAC−12040

P

al

MAR (Multi-Layer Anti-Reflective Coating) Cover Glass

Notes:

1. Units: IN [MM]

2. A-Zone Dust/Scratch Spec: 10 mm Maximum

3. Index of Refraction: 1.5231

Figure 32. MAR Cover Glass Specification

ON Semiconductor and the are registered trademarks of Semiconductor Components Industries, LLC (SCILLC) or its subsidiaries in the United States and/or other countries.

SCILLC owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of SCILLC’s product/patent coverage may be accessed

at www.onsemi.com/site/pdf/ Patent− Marking.pdf . S CILLC reserves t he right to m ake changes wit hout further notice to any products h erein. SCILLC makes no warranty, representation

or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and