Page 1

NCN5100 Arduinot Shield

Evaluation Board

User's Manual

EVBUM2715/D

INTRODUCTION

KNX [3] is a popular open home and building automation standard

ON Semiconductor has a series of transceivers that handle the low

level communication.

The NCN5100ASGEVB evaluation boards are Arduino-compatible

shields enabling rapid prototyping with a microcontroller of choice.

All external components necessary for operating the transceivers are

present on the shield. Plug it in a Arduino-compatible development kit

and start developing!

FEATURES

• Arduino Uno V3 compatible connectors

♦ Compatible with a wide variety of microcontroller development

boards

• Four on-board buttons/LEDs to build a dimmer application

• Available in UART- and SPI-version

♦ Fully KNX-compliant transceiver

• Easily get started with KNX

• Maximum bus current up to 40 mA

2

• Two high-efficiency DC-DC converters

♦ 3.3 V fixed output

♦ 1.2 V to 21 V variable output

• Integrated 20 V linear regulator output

1

.

www.onsemi.com

EVAL BOARD USER’S MANUAL

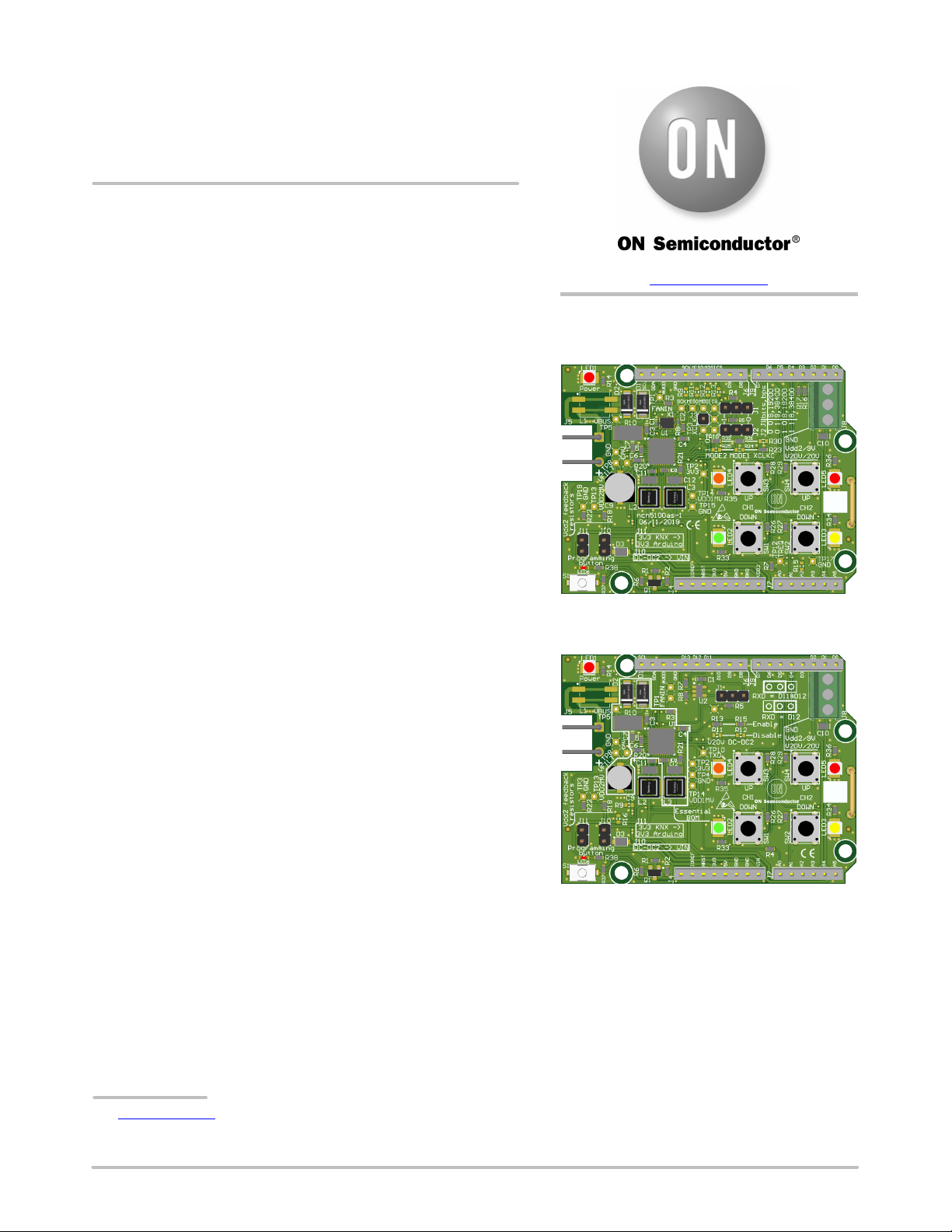

Figure 1. NCN5100AS-1 Evaluation Board

OVERVIEW

The NCN5100ASGEVB boards come in three variants containing

the NCN5110, NCN5121 and NCN5130 transceivers. The NCN5110

is a bit transceiver and all the timings are handled by the

microcontroller. Both the NCN5121 and NCN5130 also implement

the MAC layer, reducing the software development effort. All critical

timings are handled by the transceiver.

All transceivers include two high-effciency DC-DC converters. One

fixed converter generating 3.3 V, supplies the transceiver and other

optional peripherals such as a microcontroller. The second DC-DC

converter has an adjustable output voltage ranging from 1.2 V to 21 V

and can be used to supply peripherals such as, relays, a display, etc. ...

The Arduino shield form factor makes it easy to start developing;

just plug the shield into a compatible microcontroller board and start

coding. Thanks to the on-board buttons and LEDs, it is not necessary

to plug in additional shields to start testing. A simple dimmer

application can be set-up in no time with only the KNX

Arduino-shield.

1

https://my.knx.org

2

For the NCN5130 and NCN5110 version. The NCN5121 goes up to 24 mA.

© Semiconductor Components Industries, LLC, 2020

October, 2020 − Rev. 2

1 Publication Order Number:

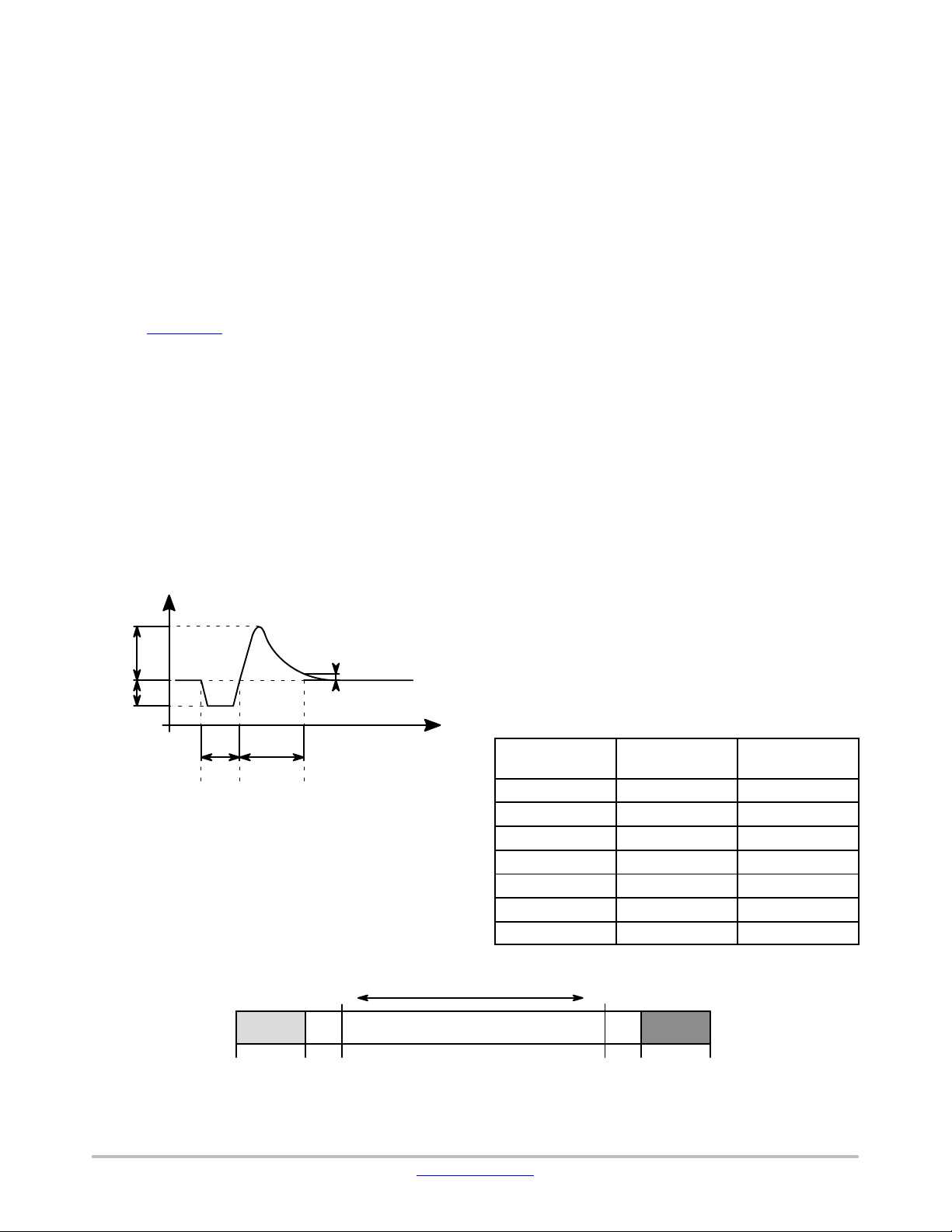

Figure 2. NCN5100AS-2 Evaluation Board

EVBUM2715/D

Page 2

EVBUM2715/D

Both the NCN5121 and NCN5130 come with an SPI and

UART communication interface. The latter is fully

TP-UART compatible, enabling the use of existing

compatible software.

The boards are 2 layer PCB’s with single-sided assembly,

demonstrating that it is possible to easily develop low-cost

applications.

EVALUATION BOARD OVERVIEW

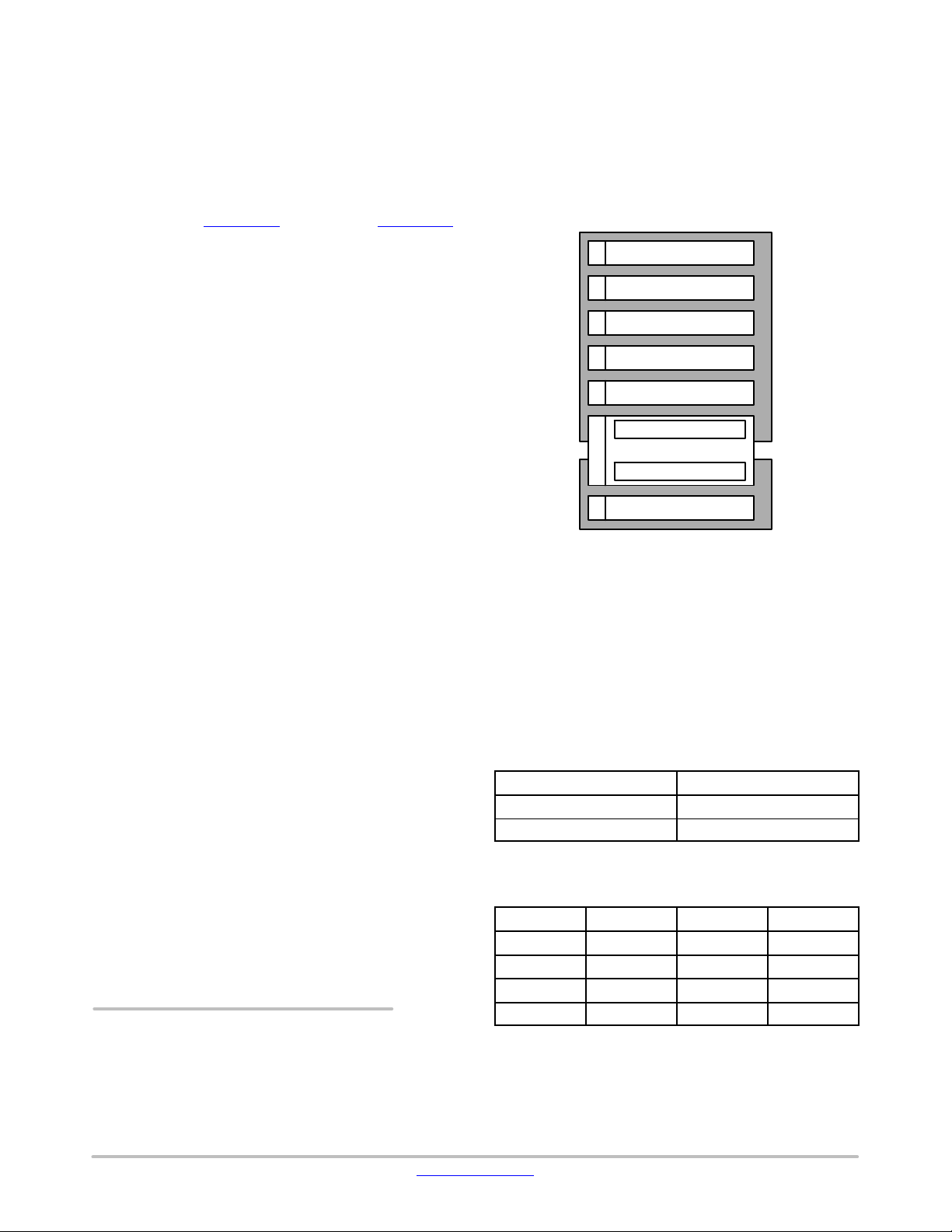

The main connectivity to the evaluation board is provided

through the Arduino V3 headers which can be seen in

Figure 1. This has the advantage that the board is compatible

with a wide variety of microcontroller development boards.

Refer to Appendix C

The KNX-Bus

, Table 6 for a list of tested platforms.

The KNX-bus consists of a twisted pair cable providing

both data and power. The voltage on the bus varies between

21 V to 32 V (V

in Figure 3). Communication on the bus

DC

is done at 9600 baud asynchronously. A logic one is

represented by the DC-level on the bus staying constant. For

a logic zero, the bus is pulled 3 V to 10 V below the DC-level

first. This is called the active pulse which has a duration of

typically 35 ms. Following immediately after is the

equalisation pulse. During this time, the voltage can swing

up to 13 V above the DC-level and will decay exponentially

in 69 ms.

V

BUS

V

eq

V

end

V

act

V

DC

Fan-in

Every device connected to the KNX-bus will draw current

from the bus to supply the application. The KNX standard

specifies the current should be limited to the real need. For

every KNX-device the maximum current draw is specified

in its datasheet according to the fan-in-model [1]. The

fan-in-model is used to determine how many devices can be

connected to one physical segment of the bus. All the

ON Semiconductor KNX transceivers contain a built-in

mechanism to keep the draw within the value specified in its

datasheet. This makes sure that the device complies with the

standard.

The fan-in pin sets the maximum current drawn from the

bus. The transceiver will actively keep the current below the

set limit.

Both transceivers (NCN5121 and NCN5130) have two

pre-defined fan-in modes. These can be selected by either

connecting the fan-in pin to GND or leaving it floating.

Leaving it floating, the maximum bus current is limited to

10 mA. Tied to GND the limit is set to 20 mA.

The NCN5130 also offers an external fan-in mode. In this

mode the current limit can be set linearly from 5 mA to

40 mA. This is achieved by connecting a resistor with

a value of 10 kW to 93.1 kW to the fan-in pin. The

fan-in-model [1] specifies discrete current classes. When

designing the application and defining the current

consumption, the next higher value of one of the classes

must be selected. According to section 3.3 of the KNX test

specification [2] the maximum allowed bus current

consumption for a fan-in-model of 10 mA is 12 mA. For

other fan-in models it is allowed to scale this value

accordingly. For example, a 20 mA fan-in-model allows to

draw 24 mA from the bus.

Active

Equalisation

pulse

35 ms

pulse

69 ms

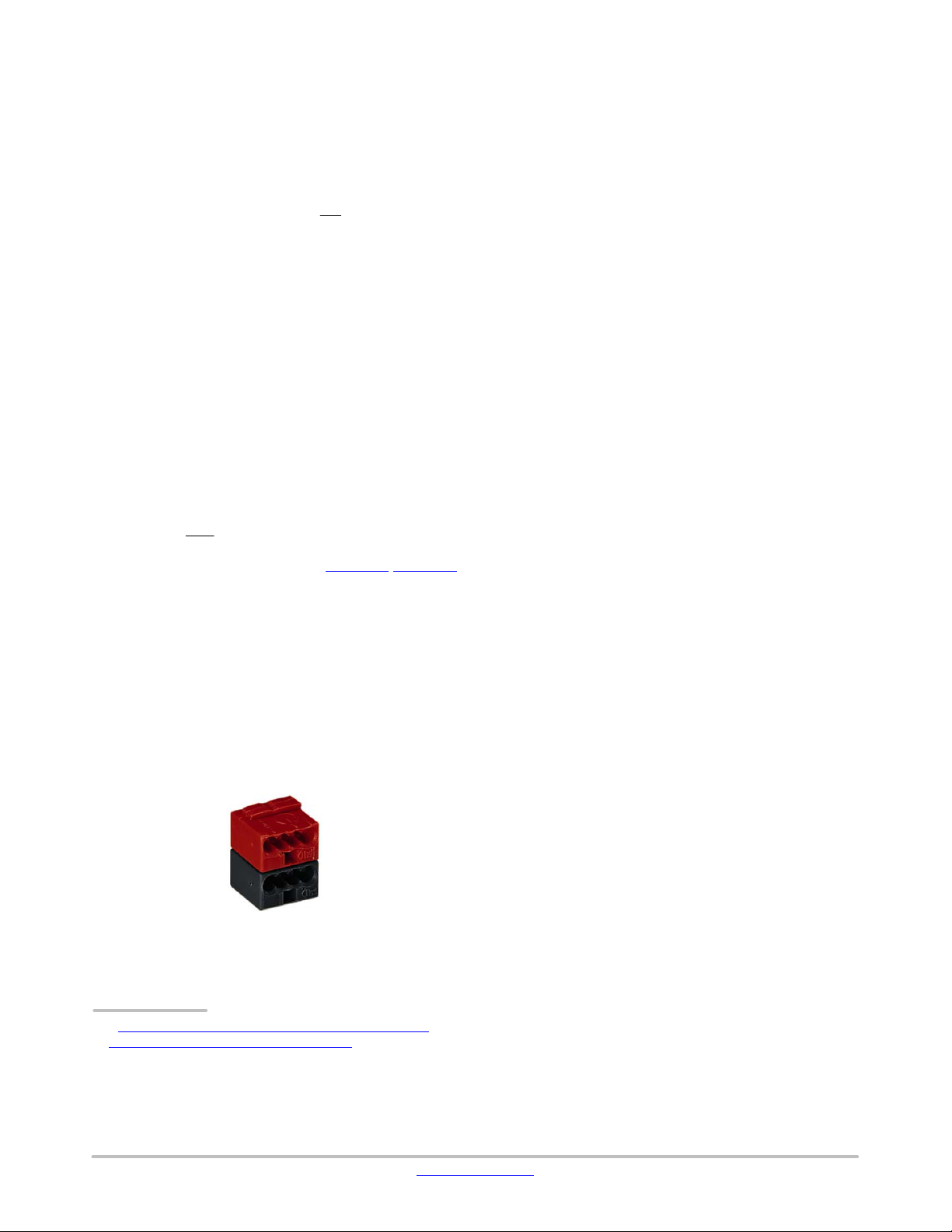

Figure 3. Waveform Seen on the Bus when

Transmitting a Logical Zero

Figure 3 shows a typical waveform on the bus

representing a logical zero.

2 k

40 mA

10 k

Figure 4. The Different Fan-in Settings

www.onsemi.com

20 mA 10 mA

Pre-defined

fan-in

R

3

0

t

Linear range

External fan-in

Only for NCN5130

Table 1. RECOMMENDED FAN-IN RESISTOR VALUES

1. According to the fan-in-model [1].

2

I

bus,lim

R

3

∞ 11.4 mA 10 mA

0 W

10 kW

13.3 kW

20 kW

42.2 kW

93.1 kW

(Typical Values)

5 mA

250 k93.1 k

22.3 mA 20 mA

43.9 mA 40 mA

33.0 mA 30 mA

22.1 mA 20 mA

10.7 mA 10 mA

5.1 mA 5 mA

Pre-defined

fan-in

∞

Current Class

(Note 1)

Page 3

EVBUM2715/D

A list of recommended fan-in resistor values can be found

in Table 1. For the listed resistor values, the corresponding

current limits are specified in the datasheet.

If a resistor value is used, other than the ones specified in

Table 1, the following formula can be used to calculate the

corresponding bus current limit:

Buffer Capacitor

I

bus,lim

+ 4 10*4)

434

R

A

3

(eq. 1)

Besides the maximum allowed current drawn from the

bus, the KNX standard also specifies at which rate the bus

current is allowed to change. This requirement introduces

the need for a large buffer capacitor. When the load current

changes abruptly this capacitor must deliver the required

energy. The KNX-transceiver will charge the capacitor

again after the load step using a fixed current slope.

According to the KNX test specification [2] a device with

a fan-in-model of 10 mA is allowed to change its current

draw from the bus with a slope of 0.5 mA/ms. Section 3.3

specifies that this can be increased accordingly with the

fan-in-model. The following formula can be used to

calculate the allowed bus current slope:

DI

bus

+ 0.05ńms @ I

Dt

fan−in−model

(eq. 2)

The datasheet (pages 18−19) of the NCN5121/NCN5130

describes how to dimension the buffer capacitor. The KNX

Family Efficiency Calculator

3

is a tool developed to help

customers with this dimensioning.

Common Mode Choke

If desired optionally a common mode choke such as the

Murata 50475C can be mounted on the footprint of L1. This

helps to block common mode disturbances, but in most

applications, this is not required.

Before soldering the choke on the foreseen footprint of

L1, the tracks shorting the component must be cut.

Figure 5. Wago 243−211 Terminal Block

3

https://www.onsemi.com/pub/Collateral/KNX%20FAMILY

%20EFFICIENCY%20CALCULATOR.XLSM

Power

The board is powered through the KNX-connector. These

two pins (KNX+/KNX- in Figure 9) mate with a typical

KNX terminal block such as the Wago 243−211, illustrated

in Figure 5. No additional connection is required as the

board will generate its own supply voltages. An input

voltage up to 30 V is tolerated. Using a standard KNX power

supply is the safest option as it generates the correct voltage

and has a built-in protection.

It is possible to use a laboratory supply, but be sure to

correctly set the output voltage to avoid damaging the board.

By using a laboratory power supply, it is not possible to send

messages on the KNX-bus. To enable communication on the

bus, a special choke must be placed between power supply

and development board. An example of such a choke is the

Siemens GAMMA Choke N 120/02.

To power the microcontroller development board there

are several options.

• Most modern microcontroller development boards can be

supplied through the 3V3-pin, this eliminates the need for

additional LDO’s, and lowers the overall power

consumption.

On the shield, there is always a 3.3 V supply present,

which is also used to supply the KNX transceiver. This

supply voltage can be routed to the 3V3-pin on the

Arduino headers by shorting J11 (Figure 6).

• Arduino-compatible development boards typically

accept a supply voltage of 7 V to 12 V, either through the

on-board DC-jack (if present) or the VIN-pin on the

headers.

The shield can supply the microcontroller through the

VIN-pin. When J10 is shorted (see Figure 6), the 9 V

generated by DC-DC2 is routed to the VIN-pin. In this

configuration, the whole system is supplied through the

KNX-bus and no additional power supplies are required.

• The microcontroller development board may be supplied

through an external supply. This occurs when debugging

the board through USB with the KNX-connector

disconnected. In this case remove both J10 and J11

(Figure 6).

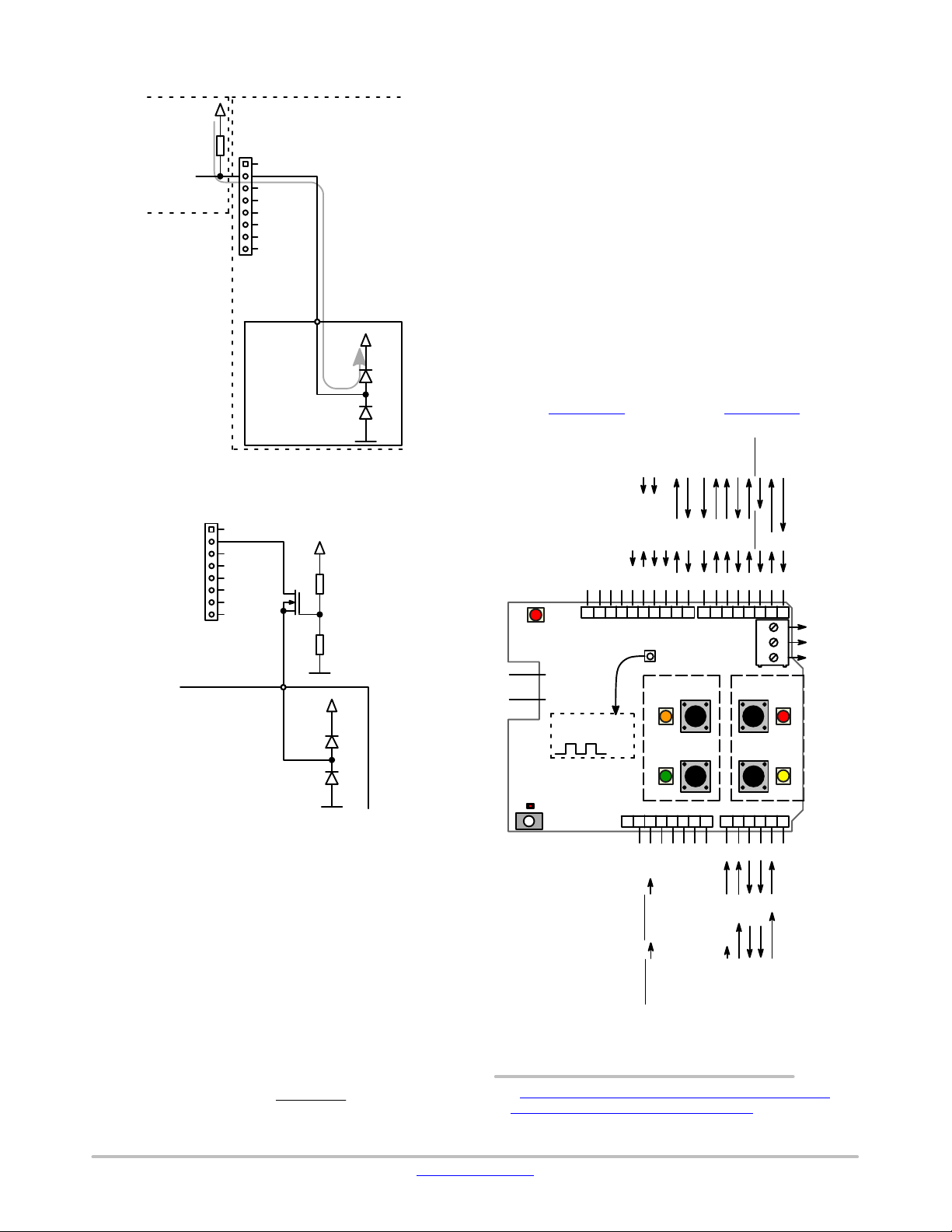

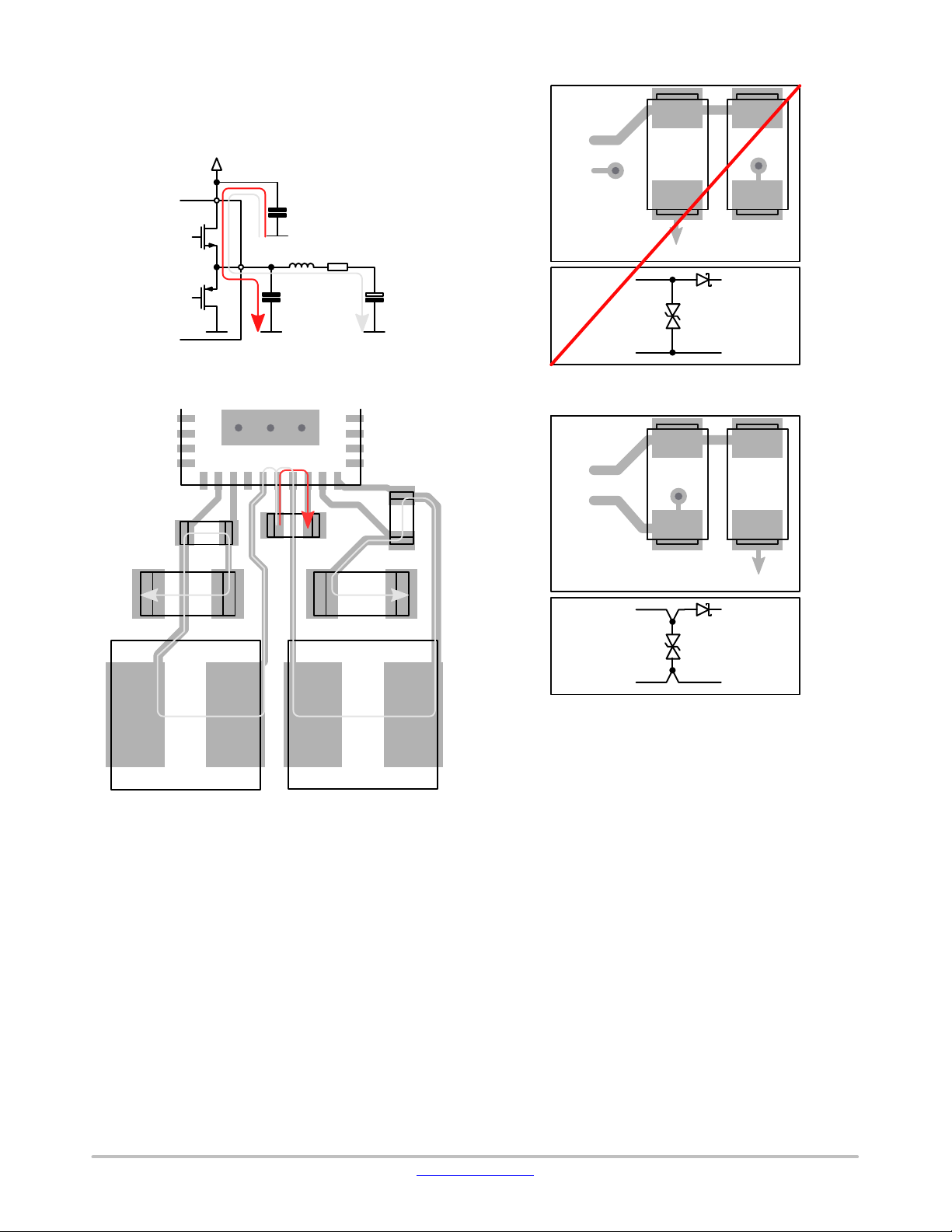

Debugging

During the development of the application code it is very

likely the microcontroller development board is powered

through the USB connection with the PC while debugging.

This introduces the risk that the KNX-transceiver is

powered through the reset line. Current can flow from the

NRST-output of the debugger into the RESETB-pin of the

transceiver through the internal ESD diodes as shown in

Figure 7. As a result, the NRST-line might be pulled low,

resetting the microcontroller. This makes it impossible to

debug the application.

www.onsemi.com

3

Page 4

EVBUM2715/D

To avoid this situation a transistor is added in series with

the NRST-line as shown in Figure 8. If the 3.3 V from the

KNX transceiver is absent, the transistor does not conduct,

and prevents current flow into the RESETB-pin. However,

if the 3.3 V supply is present, it is still possible for the KNX

transceiver to pull the NRST-line low. It is not necessary to

use this circuitry in the end application. In almost all

applications, the microcontroller will be powered from

the transceiver’s supply, and this situation will never

occur.

KNX power supplies are isolated. This means that the

KNX-ground is not connected to earth. On most

microcontroller development boards the ground connection

on the Arduino headers is connected to USB ground. The

USB ground on a PC is always connected to the earth

potential. So when connecting the development board to the

PC the KNX-ground is connected to the earth potential. This

might lead to the “pick-up” of interferences leading to

communication errors. To avoid these it is a good practice to

use an USB-isolator, such as the Olimex USB-ISO.

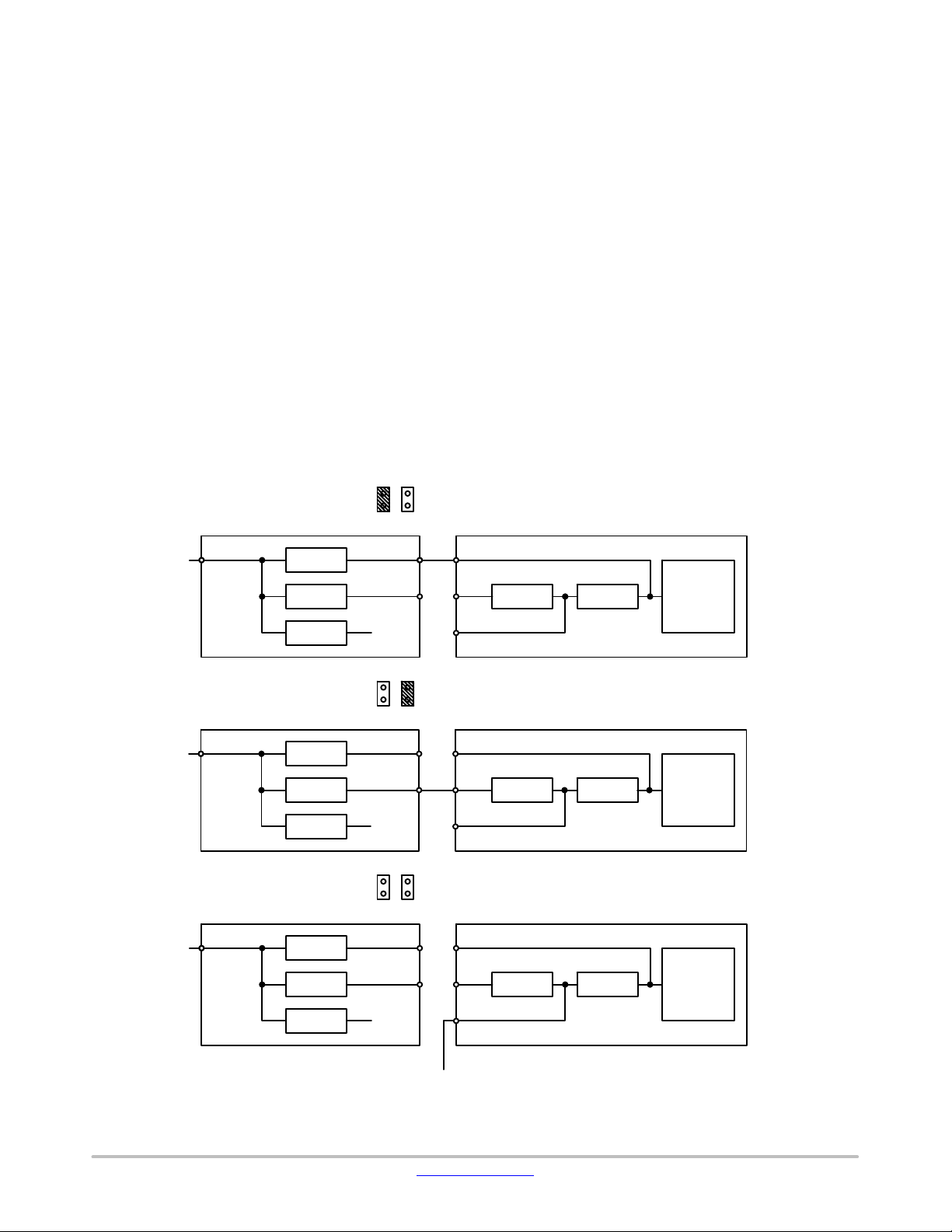

J11

J10

3V3 from DC−DC1 to 3V3

on the Arduino headers

NCN5100 evaluation board

KNX

DC−DC1

3.3 V

Powering External Circuitry

The transceiver’s 20 V LDO and DC-DC2 converter can

be used to power additional circuitry, e.g. a relay. When

additional shields are stacked, which take their power from

the VIN-pin, these can be powered by connecting DC-DC2

to the VIN-pin. This can easily be done by placing J10 as

shown in Figure 6.

If the additional circuitry is not a shield or if the shield is

powered in another way, the three pin screw terminal can be

used. Figure 9 shows the pin-out of this connector. It is also

possible to power additional circuitry using DC-DC1. This

converter delivers a fixed 3.3 V with a maximal output

current of 100 mA, ideal to supply, for example,

a microcontroller.

Arduino

3V3

NCN5100 evaluation board

KNX

NCN5100 evaluation board

KNX

DC−DC2

20 V LDO

DC−DC1

DC−DC2

20 V LDO

DC−DC1

DC−DC2

20 V LDO

1.2 to 21 V

20 V

J11

3.3 V

1.2 to 21 V

20 V

J11

3.3 V

1.2 to 21 V

20 V

VIN

USB 5 V

J10

9V from DC−DC2 to VIN

Arduino

3V3

VIN

USB 5 V

J10

Arduino motherboard

supplied externally

Arduino

3V3

VIN

USB 5 V

5 V LDO 3.3 V LDO MCU (3.3 V)

5 V LDO 3.3 V LDO MCU (3.3 V)

5 V LDO 3.3 V LDO MCU (3.3 V)

USB from PC

Figure 6. Jumper Settings for the Three Possible Supply Configurations

www.onsemi.com

4

Page 5

EVBUM2715/D

Arduino

Debugger

NCN5100 evalutation board

Vdd

NRST

RESETB

3V3

NCN5100

Figure 7. The Internal ESD Diodes Pulling the

NRST-line Low

NRST

3V3

Or use the KNX Family Efficiency Calculator

4

which can

be found on the ON Semiconductor website.

Inputs and Outputs

Arduino Header Pin-Out

Most of the buttons and LEDs are connected to digital pins

on the Arduino headers. Two of the buttons and one LED are

connected to analog input pins. This was done to keep the

2

I

C-pins free for other purposes. The same applies for the

TREQ-pin.

The SAVEB-pin is connected to a digital pin which has

interrupt capabilities. This is necessary to provide a signal

to the microcontroller as fast as possible indicating the bus

voltage is dropping.

All the LEDs are connected to PWM-capable pins,

allowing the application to dim the LEDs if desired.

A complete net list for the microcontroller connections is

given in Appendix A

, Table 4 and in Appendix B, Table 5.

NCN5110

RXD1

RXD2

SPI_MISO

SPI_MOSI

SPI_SCK

SPI_CS

SW3

LED4

SW3

LED4

SW1

SW1

LED2

LED2

SW4

LED3

SW4

LED3

SAVEB

LED5

SAVEB

LED5

TX

TX

RX

RX

NCN5121

NCN5130

R

1

560 W

Q

1

R

2

10 kW

RESETB

3V3

NCN5100

Figure 8. The Transistor Q1, Prevents Current Flow

when the 3.3 V is Not Present

Adjusting the DC-DC2 Output Voltage

DC-DC2 is adjustable and can be configured to generate

a voltage between 1.2 V to 21 V. This enables supplying

a very wide range of applications. By default, the output

voltage is set to 9 V. This makes it suitable to supply an

Arduino-compatible development board, which typically

accepts an input range of 7 V to 12 V.

To adjust the output voltage the values of the feedback

resistors must be changed. These are located at the bottom

left corner of the PCB, making them easily resolderable. The

required resistor values can be calculated from:

* 1.2

V

R18+ R22@

VDD2

1.2

(eq. 3)

AVDD

GND

D13

D12

D11

D10D9D8D7D6D5D4D3D2D1D0

CH1 CH2

SW3 SW4

LED4

SW1 SW2

LED2

GND

GND

VIN

A0

ANAOUT

TXD

NRST

IOREF

RESETB

RESETB

3V3

5V

A2

A1

SW2

TREQ

SW2

LED5

LED3

A3

A4

S1

LED6

S1

LED6

LED1

Power

KNX*

KNX+

XCLK

8 MHz / 16 MHz

Programming

button/LED

LED6

S1

D15

D14

Figure 9. Evaluation Board Connectivity

(KNX-Shield)

4

https://www.onsemi.com/pub/Collateral/KNX%20FAMILY

%20EFFICIENCY%20CALCULATOR.XLSM

Arduino

GND

9V

20V

Arduino

A5

NCN5121

NCN5130

NCN5110

www.onsemi.com

5

Page 6

EVBUM2715/D

User Buttons and LEDs

The shield has 4 on-board push buttons (SW1...4) and

4 LEDs (LED2...5) to enable the development of switching

apps in particular. For a dimmer application the four buttons

are split into two groups marked on the PCB as channel1 and

channel2 (CH1/CH2). The upper button in the channel is

used to dim up, whilst the other one is used for dimming

down. Refer to Appendix A

, Table 4 and Appendix B,

Table 5 to see how these are connected to the I/O pins of the

microcontroller.

It is possible to stack other shields containing I/Os which

are used for the end application. Remove R26−R29 and

R33−R36 if the buttons or LEDs conflict with the pin-out of

the other shields used.

Programming Push Button and LED

To assign an individual address to a device in

a KNX-network, the device must be put into programming

mode. The simplest way to do this is by pressing the

programming button (S1). LED6 indicates if the device is in

programming mode.

It is possible to customize the entering in programming

mode e.g. pushing two buttons simultaneously.

Microcontroller Clocking

NCN5130 and NCN5121 have the capability to deliver

a clock signal to the microcontroller. This clock signal is

available on the XCLK-pin of the transceiver and routed to

a 2.54 mm header pin on the shield (See Figure 9). Because

the Arduino headers do not foresee a dedicated pin to pass

clock signals, it is mandatory to route this signal manually

to the microcontroller. This is only necessary if it is desired

to use this signal to clock the microcontroller. In most cases

the microcontroller will be clocked from its internal

RC-oscillator or from an external crystal.

By default, the clock signal on the XCLK-pin is 16 MHz.

It can be changed to 8 MHz by tying the XSEL-pin to

ground: De-solder R23 and solder a 0 W resistor on the pads

of R30.

Digital Communication Interface

Both the NCN5121 and NCN5130 implement the mac

layer of the OSI model as shown in Figure 10. They will

handle the coding and decoding of messages, sending

acknowledges, etc... Critical low level timings such as the

duration of the active pulse are all managed by the

transceiver. The transceiver makes sure that the collision

avoidance

5

is handled correctly without any intervention by

the host controller. This greatly reduces the software

development effort. To communicate with the mac layer

both a UART- and SPI-interface are supported. Note that

5

CSMA/CA: Carrier-sense multiple access with collision

avoidance.

when the transceiver operates in SPI-mode it acts as the

master. The microcontroller must support slave mode in

order to be able to communicate with the transceiver. To

select in which mode the KNX-transceiver operates (UART

or SPI) the MODE2-pin is used. When tied to GND using

R32, the transceiver operates in UART-mode. Tying it to

V

using R25 puts the transceiver in SPI-mode.

DD1

7

6

5

4

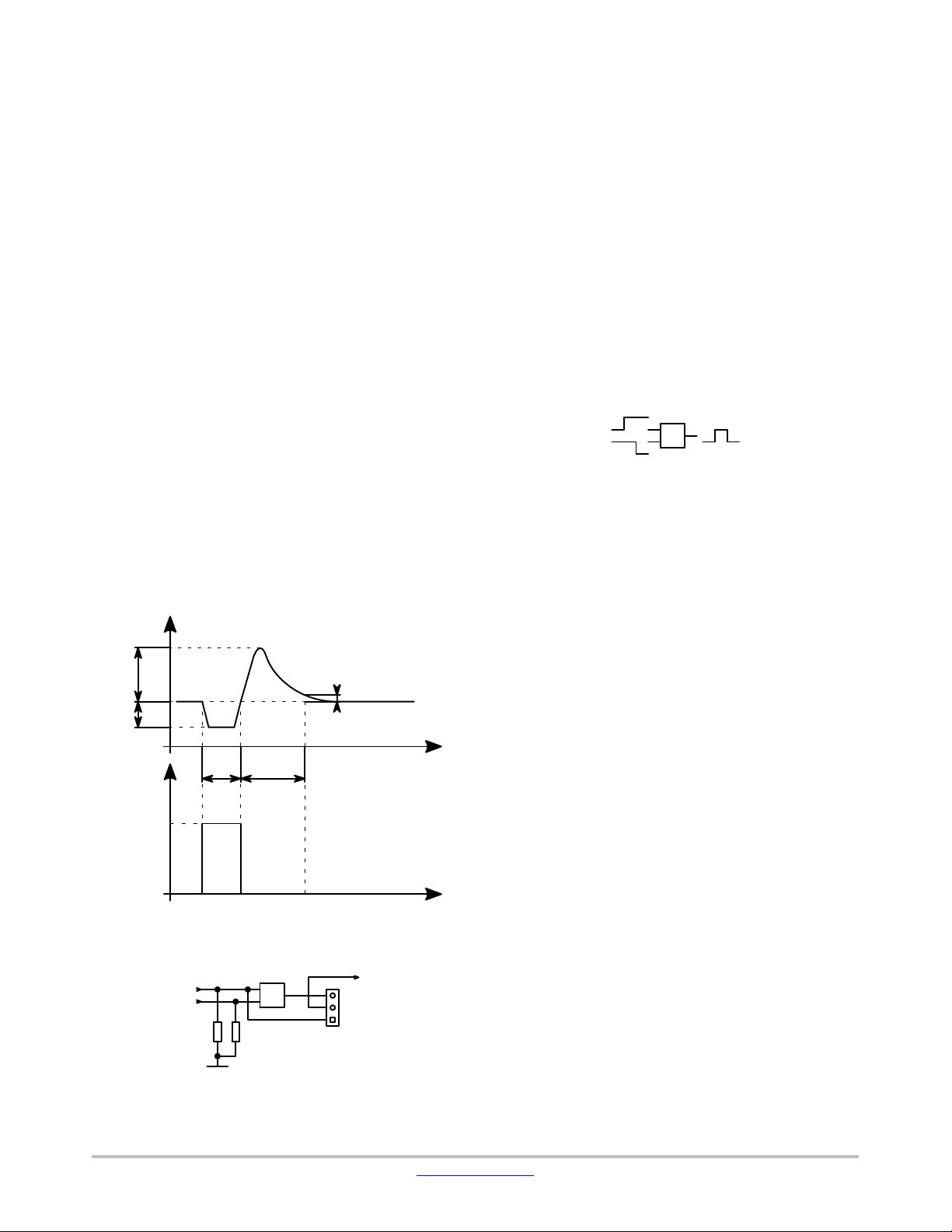

3

2

1

Figure 10. Placement of the Transceivers

Application layer

Presentation layer

Session layer

Transport layer

Network layer

Logic link control

Data link layer

Media access control

Physical layer

in the OSI Model

Host controllerNCN5121/30

560 W resistors protect the I/O lines going to the

microcontroller. Depending on which resistors are mounted

either the UART or the SPI-lines are connected. If desired it

is possible to transform a UART shield into SPI and vice

versa by soldering/de-soldering the resistors as listed in

Table 2.

Table 2. COMMUNICATION INTERFACE RESISTOR

MOUNTING OPTIONS

Communication Interface Resistor Mounted

UART R16, R17, R32

SPI R9, R11, R12, R13, R15, R25

Table 3. SELECT THE RIGHT BAUD RATE USING

J1/J2

J2 J1 Parity Bit Baud Rate

0 0 even 19 200 bps

0 1 even 38 400 bps

1 0 none 19 200 bps

1 1 none 38 400 bps

www.onsemi.com

6

Page 7

EVBUM2715/D

Selecting The Baud Rate

Jumpers J1 and J2 allow easy configuration of the baud

rate and parity. This is only used in UART-mode. In

SPI-mode, the communication speed is fixed to 500 kbps.

To make the UART-communication more robust, it is

possible to enable the transmission of an even parity bit with

every data byte. For the complete settings refer to the

silkscreen on the shield or to Table 3.

Analog Communication Interface

The NCN5110 transceiver doesn’t contain any digital

functionality, implementing only the physical layer of the

OSI model. Both the TXD- and RXD-lines are directly

connected to the KNX-transmitter/receiver.

Pulling the TXD high will make the transceiver drop the

bus voltage as shown in Figure 11. Once the transmit line is

pulled low again, the transceiver will put an equalisation

pulse on the bus. The duration the bus voltage stays by an

amount of V

below VDC, is determined by the

act

microcontroller. As a consequence the microcontroller is

also responsible for collision detection and avoidance. As

well as the encoding and decoding of messages, sending

acknowledges, etc... must be implemented in the

microcontroller, increasing the software complexity.

The RXD-line will become high when an active pulse is

detected on the bus. As the transceiver also receives the data

itself transmitted on the bus, this line will also become high

during transmission.

V

BUS

V

eq

V

end

V

act

Active

Equalisation

pulse

TXD

&

D12

D11

pulse

35 ms 69 ms

TXD/RXD

[V]

3.3

0

Figure 11. Communication with the NCN5110 and the

Corresponding Levels on the KNX-Bus

V

DC

t

t

Enable Interface

The timing of the pulses which drive the NCN5110 are

extremely time critical. Some microcontroller families have

special timer modes which can be used to generate the

correct pulses. Using these modes, would limit the use of the

software to a certain microcontroller family.

An AND port combines the signals coming from D11 and

D12. The schematic is shown in Figure 12. It provides

a mechanism to set and clear the transmit signal, without the

use of special timers only available in specific

microcontroller families.

Two timers can be used, one to generate a rising edge, the

other to generate a falling edge. Both signals are combined

to create the desired transmit signal as shown in Figure 13.

Both input pins of the AND port are pulled low. This

ensures that during the startup of the microcontroller, the

transceiver won’t transmit.

&

Figure 13. Combination of a Rising and Falling Edge

to Create the Transmit Signal

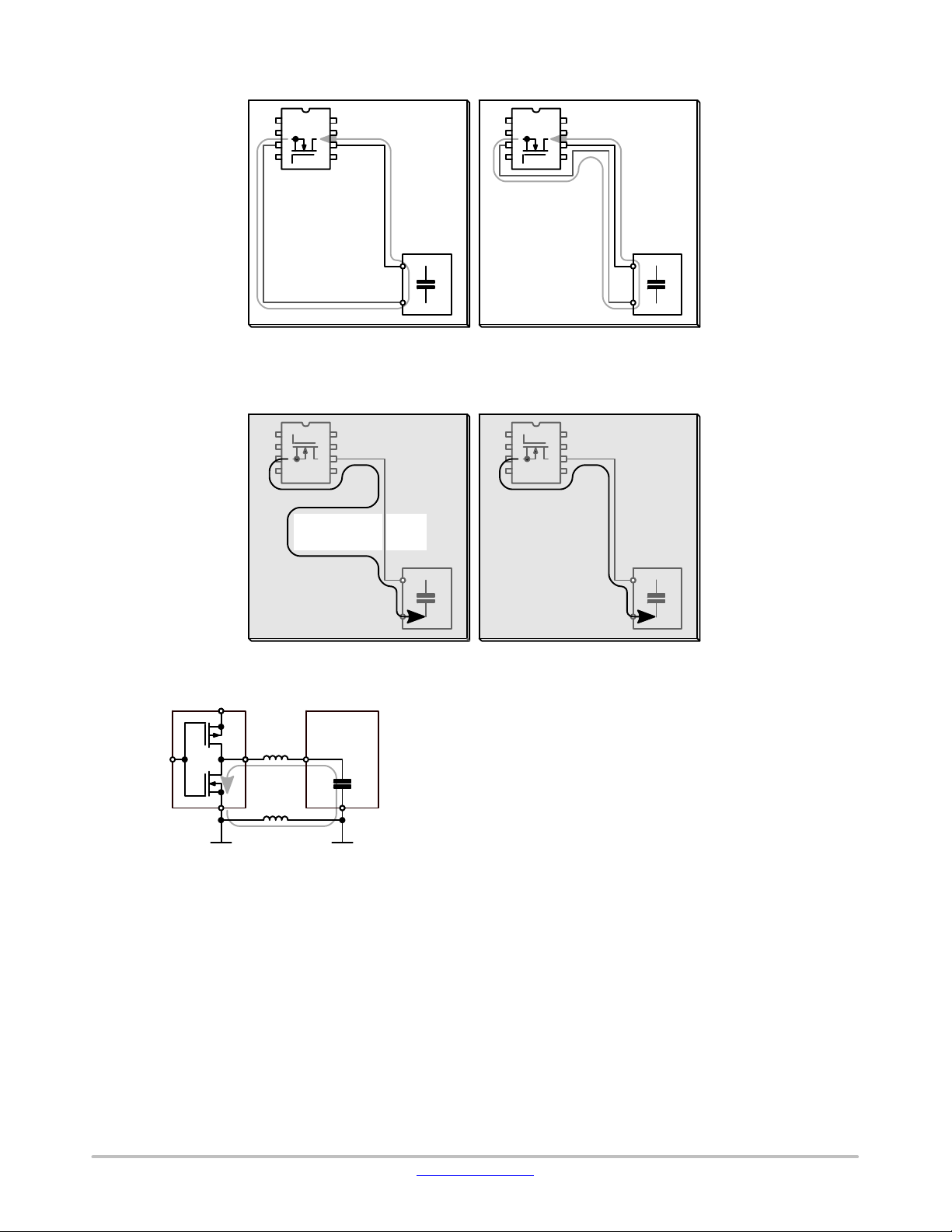

PCB LAYOUT GUIDELINES

When designing a PCB for the KNX-transceiver it is

important to take certain layout aspects into consideration.

The following good practices will help to improve the EMC

performance of the whole application. The Arduino shield

is a two-layer PCB, with the main ground plane on the

bottom layer. Empty space on the top layer is filled in with

ground copper, but this is not a ground plane.

DC-DC Converters

Electromagnetic interference is dominated by the DC-DC

converters. These converters switch at frequencies around

300 kHz. Without due consideration for PCB layout,

radiated emissions can become a serious issue.

Figure 16 shows an example schematic of an inverter

driving a capacitive load. The PCB tracks going to and

coming from the load will act as an inductor at high

switching frequencies. The return path can be the common

circuit ground, but this is not always the case!

When constructing the PCB layout it is very important to

pay attention to the signal return path.

The first situation in Figure 14 shows a single-layer

design. Here the signal and return path form a large loop,

which will act as an antenna at higher frequencies.

2 x 10 kW

Figure 12. An AND Port Can be Used to Combine the

Signals Coming from Two GPIO Pins

www.onsemi.com

7

Page 8

EVBUM2715/D

Single−layer design

Signal

Return

Single−layer optimized

Signal

Return

Figure 14. Optimizing the Return Path in a Single-layer Design

Dual−layer design

Signal

Dual−layer optimized

Signal

Return

Return

Figure 15. Optimizing the Return Path in a Dual-layer Design

Inverter Load

Signal

Z

PCB

Return

Z

PCB

Figure 16. Inverter Principle Schematic Showing

a Critical Current Loop

This layout can be improved significantly by routing the

signal and return path close to each other. They should be

routed as if they were a differential pair.

In most circuit designs, the return path for most signals is

the common circuit ground. For these circuits using a twoor four-layer PCB with the main ground on the bottom- or

inner-layer is the recommended choice. It simplifies the

layout work and makes it much easier to create optimal

return paths.

Still care has to be taken during the design, as it is easy to

overlook common mistakes. Figure 15 shows a situation

where there is a slot in the ground plane. The return path now

goes around the slot creating a slot antenna.

Ideally the bottom ground plane should never be

interrupted.

Figure 17 shows the current loops for the two DC-DC

converters on the Arduino shield. All the components on the

shield are placed and routed to minimize the loop surface

areas.

When the DC-DC converter switches on its top transistor,

the instantaneous current spike is drawn from the small

100 nF capacitor C8. As these current spikes are short, they

will have a high frequency. So the most critical loop, is the

current flowing from C8 into the parasitic capacitance at

V

as shown in red. To keep this loop very small, C8 must

SW

be placed as close as possible to the VIN-pin. If possible,

place it right next to it as in Figure 18.

Keeping all the tracks on the top layer avoids any

disruptions in the bottom ground layer and resistance/

inductance being added by vias. The two grey arrows show

the larger current loops created by the DC-DC converter.

These should also be kept as short as possible to minimize

radiated emissions. Figure 18 shows the optimal layout,

used on the shield, to keep these loops small.

www.onsemi.com

8

Page 9

EVBUM2715/D

The larger buffer capacitor C9 can be placed further away

from the VIN-pin, as long as the small ceramic capacitor C8

is placed very close to it.

Vin

C8

KNX+

KNX*

D1

D2

L3

Cpar

R21

C12

Vsw

Figure 17. Schematic Showing the DC-DC Converter

Current Loops

VDD2

C11

R20

VDD2MC

VSS2

VSW2

VIN

VSW1

VSS1

C8

VDD1

VDD1M

R21

C12

To VBUS

D1

D2

Figure 19. Wrong Layout for the TVS Diode

D2

KNX+

KNX*

D1

To VBUS

D1

D2

L2

L3

Figure 18. DC-DC Converter Current Loops on the

Arduino Shield

TVS Diode

It is important to optimize the layout of the Transient

Voltage Suppression (TVS) diode in order to effectively

protect the transceiver against surges. When a surge occurs,

the TVS diode must clamp the voltage to a level which

doesn’t damage the transceiver. To achieve this, the series

resistance should be as low as possible.

This can be done by connecting KNX-directly to the TVS

diode before being routed to the rest of the PCB ground as

shown in Figure 20. This ensures that the current path to the

TVS has the lowest resistance and no transient current will

flow to the transceiver.

Figure 20. Optimal Layout for the TVS Diode

GETTING STARTED

The Arduino shield comes with demo software developed

by Tapko Technologies GmbH. The software includes

a demo version of KAIstack which runs on

a STM32F103-NUCLEO board. This software contains all

the necessary software components to connect to the

KNX-bus and comes with a variety of demo applications.

The demo version of KAIstack can be used to start

developing custom application software.

The following limitations apply to the demo version:

• Limited to 16 group addresses, 16 associations and 16

communication objects instead of 255.

• Application interface objects have been removed.

• The rout-count is set to zero in the network layer, limiting

the application use to only one line.

• There are no repetitions on the transport layer.

• It is not possible to change the individual address of the

device through ETS.

• Only one derivative is supported.

www.onsemi.com

9

Page 10

EVBUM2715/D

Prerequisites

Listed below are all the components needed to construct

a small KNX-network with the NCN5100ASGEVB.

• KNX power supply (including a choke).

• USB-KNX interface to communicate with ETS on the

PC.

• A demo version of ETS.

• STM32F103-NUCLEO board to plug the shield into.

• Any version of the NCN5100ASGEVB.

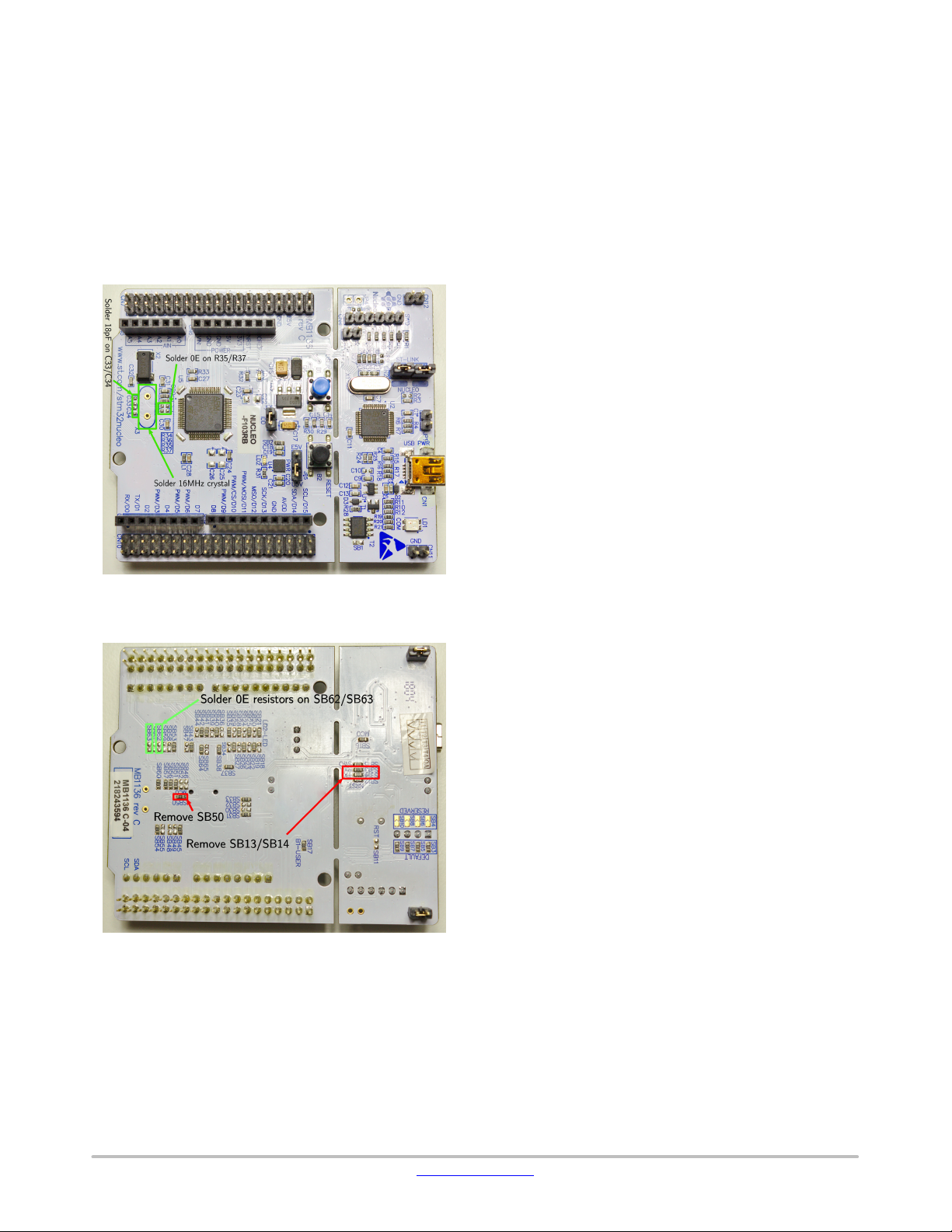

Figure 21. Hardware Modifications on the Top Side of

the Nucleo Board

To meet the timing requirements to communicate on the

KNX-bus, it is mandatory to have a more accurate clock than

the on provided by the internal RC-oscillator of the

microcontroller. Two options are suggested below.

Placing a Crystal

Mount a crystal in the X3 footprint on the Nucleo board.

This crystal must have a frequency of 16 MHz. For the

recommended value of the loading capacitors C33/C34,

refer to the datasheet of the crystal. A good crystal is the

9B-16.000MEEJ-B, which needs loading capacitors of

18 pF.

To get the crystal working on the Nucleo board the

following configuration is required (Figures 21 and 22):

• Place 0 W resistors at R35 and R37.

• Solder the loading capacitors on C33 and C34.

• Remove the 0 W resistor at SB50.

• Solder the crystal on X3.

Apply An External Clock

The second option is to use an external clock.

Use the XCLK-output of the KNX-transceiver as a clock

input for the microcontroller. By tying the XCLKC-pin

high/low a clock frequency of 16 MHz or 8 MHz can be

selected. By default on the Arduino shield, the XCLKC-pin

is pulled high, meaning a clock signal of 16 MHz is present

on the XCLK-pin. This method has the advantage that the

complete application only needs one crystal.

To use the XCLK-output as a clock signal, the following

configuration is required:

• Place a 0 W resistor at SB55.

• Remove the 0 W resistor from SB50.

• Connect the XCLK-pin on the Arduino shield to pin 29 of

CN7 on the Nucleo board. Do this using a wire which is

as short as possible.

UART Communication

On the Nucleo board the USART2 interface is by default

used to communicate with the on-board ST-LINK. This

means that it is not possible to use D0 and D1 on the Arduino

headers for UART communication, as they are not

connected.

To enable UART communication on the Arduino headers

execute the following steps (Figures 21 and 22):

• Remove the 0 W resistors from SB13 and SB14.

• Mount 0 W resistors at SB62 and SB63.

Figure 22. Hardware Modifications on the Bottom

Side of the Nucleo Board

Hardware Modifications

To get started with the demo software, a NCN5110,

NCN5121 or NCN5130 Arduino shield is required in

combination with a STM32F103-NUCLEO board. In order

to get the software running on the microcontroller, a couple

of hardware modifications are required.

www.onsemi.com

These steps will disable the communication between the

microcontroller and the ST-LINK. Then it is no longer

possible to use the Virtual COM-port on the Nucleo board.

To keep using the Virtual COM-port, connect another

USART peripheral to the ST-LINK. USART3 is a possible

candidate which can be used by connecting two wires as

follows:

• Connected pin 1 of CN7 (PC10-USART3_TX) to the RX

pin on CN3.

10

Page 11

EVBUM2715/D

• Connected pin 2 of CN7 (PC11-USART3_RX) to the TX

pin on CN3.

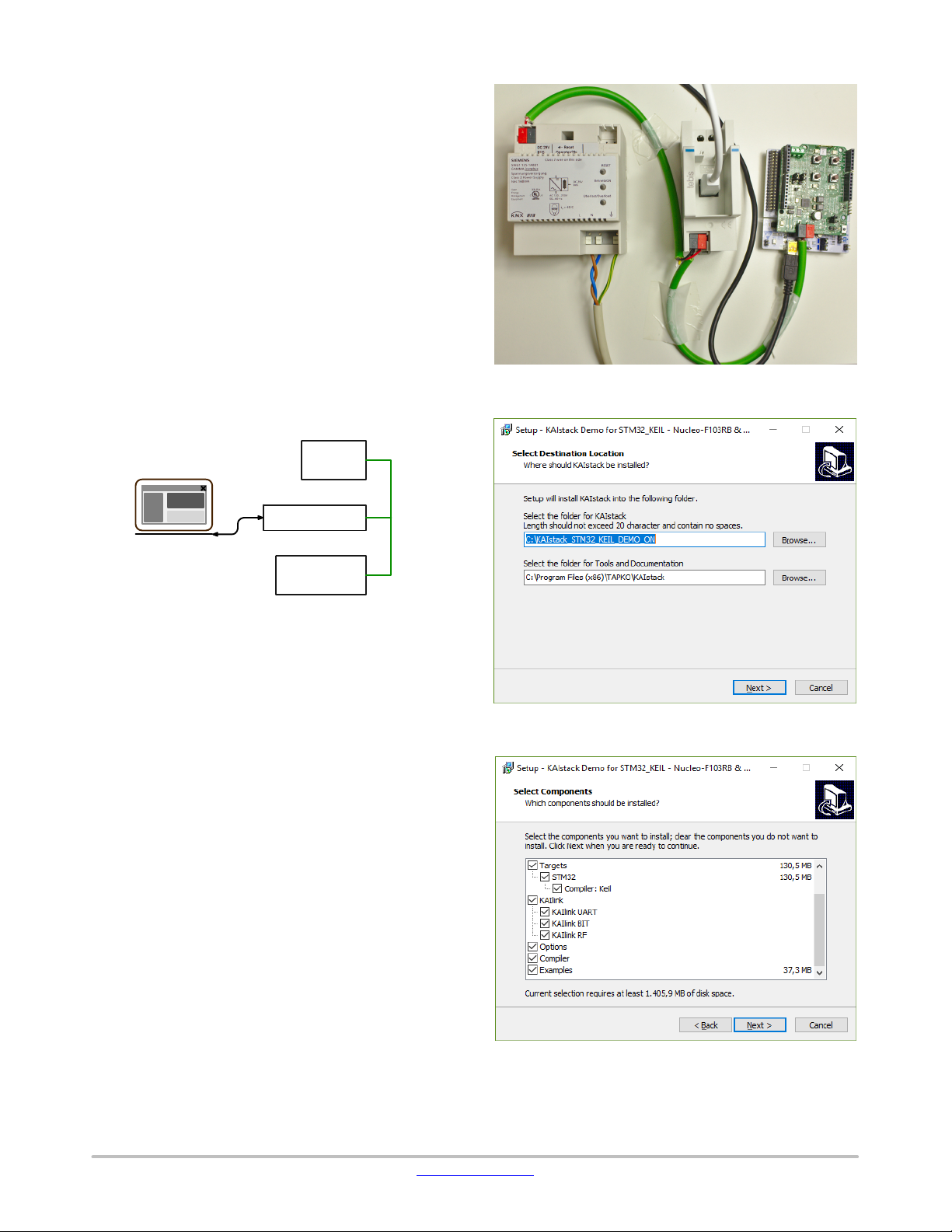

Setting Up A Network

Once the STM32F103-NUCLEO board is ready, a small

network can be set up to get started with the

NCN5100ASGEVB.

Connecting Power

There are several options to power the Nucleo board.

Refer to Section Power for all the possible configurations.

To get started, remove the jumpers J10 and J11 from the

Arduino shield and place JP5 on the Nucleo in the U5V

position. This way the microcontroller will be powered from

the USB port while the KNX-transceiver is powered from

the KNX-bus.

To power the complete solution from the KNX-bus, place

J10 on the Arduino shield and JP5 in the E5V position on the

Nucleo.

Figure 24. Picture of the Practical Setup

ETS

KNX−PSU

USB−KNX interface

NCN5100GEVB

Figure 23. Minimal Network Setup

KNX bus

UART Communication

The demo software from Tapko communicates with the

transceiver at 19.2 kb/s using an even parity bit. Place J1 and

J2 in the ‘0’-position to select the correct communication

speed.

Building The Network

A minimal network setup consists of a KNX power

supply, KNX USB-interface and the NCN5100ASGEVB.

This setup is displayed in Figure 23. The KNX

USB-interface is used to configure the NCN5100ASGEVB

through ETS and to send and receive messages.

After setting up the network, connect the USB coming

from the KNX USB-interface and the Nucleo to the PC. The

physical hardware setup is now complete.

Installing The Software

The microcontroller demo software can be found on the

ON Semiconductor website [5]. Download the software,

unpack it and execute the installer.

The installer will first ask in which folders to install the

software. The first folder will contain KAIstack, the

compiler, software examples and the documentation. In the

second installation folder, some additional tools and the

documentation for KAIstack are installed.

Figure 25. Selection of the Installation Folders

Figure 26. Select which Components to Install

www.onsemi.com

11

Page 12

EVBUM2715/D

Figure 27. Folder Structure of the KAIstack

Installation

Next, the installer gives the option to select which

components to install. It is recommended to leave

everything selected. When clicking on Next, a summary is

given of what will be installed.

Install the software and open the installation folder where

KAIstack is installed. The folder structure will look like the

one shown in Figure 27.

In the appl_example folder, many examples of application

programs can be found. Refer to the documentation included

with the installation on how to modify the software

examples to your needs.

Building and Loading The Software

The folder structure of the first application example

1in1out 07B0 is shown in Figure 28.

Two folders named dummy and tmp contain some

temporary files necessary to compile the program. These

files can be ignored.

The ETS_DB folder contains an ETS-project, that will be

used later on to configure the NCN5100ASGEVB. The

folder named 1_IN_OUT_07B0 contains all the files

necessary to get started in the KNX manufacturer tool. They

can be used to create a catalog entry, product database, etc...

KEIL m Vision IDE. The necessary files are located in the

workspace folder. For more information refer to the

documentation included with the installation.

Lastly there are two batch files included in the folder.

These can be used to build and rebuild the application.

To get started with the previously built setup, one of the

example projects must be loaded in the microcontroller.

Compile the 1in1out_07B0 example by executing the

rebuild.cmd batch file. A command window will pop-up

showing the progress of the compilation process. It will

display a message, as shown in Figure 29 once the

compilation is finished. Now the output folder contains

a .hex file, which can be loaded in the microcontroller.

To program the microcontroller, the

STM32CubeProgrammer tool is used. Open the program

after downloading and installing the latest version. In the

tool click on Open File and select the generated .hex file.

Once it is loaded in the tool, click on the Download button

to load it in the microcontroller. A window saying File

download complete should pop up, as shown in Figure 30.

Now the KNX-device is ready and the network can be

configured.

Figure 29. Output Window of the Compilation

Process

Figure 28. Folder Structure of an Application

Example

The final output files generated by the compiler are placed

in the output folder. The binary that must be loaded in the

microcontroller can be found there.

The application program specific source and header files

are located in the src folder. A file named project.h contains

all the project specific settings.

These projects are all compiled using the ARM KEIL

compiler. It is possible to open the example projects in the

www.onsemi.com

Figure 30. Program the Nucleo Using the

STM32CubeProgrammer

12

Page 13

EVBUM2715/D

Figure 31. Import the ETS-project Included with the Demo Application

Figure 32. The 1-in 1-out ETS-project

ETS Configuration

Configuring a KNX-network is done through ETS. ETS

is a PC tool used by certified KNX-installers to set up

a network. To get started, only the basics are explained here.

For more information, refer to the official

KNX-documentation [4].

The ETS project that is included with the demo

application has to be imported. Click on the import button

shown in Figure 31. Now select the Test Project

1_IN_1_OUT_07B0.knxproj File in the ETS DB folder.

When the import is finished the project will appear in the

Projects pane. Double click on the project to open it.

Because ETS is an installer tool, it is possible to create

complete building structures. This makes it easy to keep

a good overview of the whole installation and to make

modifications in the future. This building structure is created

in the Buildings pane on the left.

The NCN5100ASGEVB device can be found under

Dynamic Folders → Not assigned to a room. To be able to

use and configure it, it has to be assigned to a room first.

A room can not exist on it’s own and must be created inside

a building. To create a building, click on the word Buildings

and then Add Buildings. Once the building is created, right

click on it and select Add → Rooms to create a room.

To assign NCN5100ASGEVB to the room just created,

click on the Not assigned to a room folder and drag the

device into the room. After the device is linked to a room, an

individual address must be assigned to it.

The individual address has a fixed format, and is chosen

in such a way that it reflects it’s position in the network. It

is only used for programming the device. For more

information on this topic, refer to the official

KNX-documentation [4].

The Tapko demo stack doesn’t support changing the

individual address. So the device must be given the fixed

individual address 1.5.8 as shown in Figure 33. Click on the

device in the Buildings panel so that the Properties panel

opens on the right. Under the settings tab the individual

address can be found.

Figure 33. Assigning an Individual Address to the

NCN5100ASGEVB

www.onsemi.com

13

Page 14

EVBUM2715/D

Now the group addresses have to be assigned in order for

the device to communicate on the bus. Refer to the official

KNX-documentation [4] for more information on how the

communication system with group addresses works. Click

on the device in the Buildings panel and go to it’s Group

Objects tab, as shown in Figure 34. It will show all the

supported group objects and the group addresses which are

assigned to it. The assigned group addresses will be blank.

To assign a group address to a group object, right click on it

and select Link with.... A window as shown in Figure 35 will

pop up. In this window, select New. In this tab a new group

address can be created which will be immediately assigned

to the group object. Assign group address 0/0/2 to the bit

group object and 0/0/1 to the switch group object. Give them

both an appropriate name. The switch group object is used

to send a bit value on the bus every time the button SW3 is

pressed. The bit group object is used to control LED3 on the

shield.

It is possible to review and adjust the group

addresses/names in the Group Addresses panel (Workplace

→ Open New Panel).

Figure 35. Assign a New Group Address

Now the complete project has been configured and should

look like Figure 34. This configuration can now be loaded

in the NCN5100ASGEVB. Make sure that the USB-KNX

interface is connected to the PC. Right click on the device in

ETS and select Download → Full download.

Figure 34. The ETS-project after Completing

the Set Up

Figure 37. The Group Monitor Showing the Group Communication on the Bus

Figure 36. Downloading the Full Configuration in the

NCN5100ASGEVB

www.onsemi.com

14

Page 15

EVBUM2715/D

ETS will now ask to press the programming button on the

NCN5100ASGEVB. It can be found on the lower left corner

of the shield. After pressing the button, the LED above will

light up. Now ETS will start the download process.

Once the download has finished, open the Diagnostics

panel by clicking on the Diagnostics button on the top menu

bar. In this panel it is possible to monitor what happens on

the network and control the network through the USB-KNX

interface. Press the Start button to start monitoring the

network.

Now every time button SW3 on the shield gets pressed

a message is sent on the bus by the NCN5100ASGEVB. The

Diagnostics panel shows who is sending the message, what

group address is being sent and what value. The value should

toggle between On and Off every time the button is pressed.

It is possible to send messages on the bus through the

Diagnostics panel to control one of the LEDs on the shield.

In the Group Address field enter 0/0/2.

When pressing the Read button, the USB-KNX interface

sends a read request on the bus for group object 0/0/2. The

NCN5100ASGEVB will respond with the current state of

LED3, which is Off.

In the Value field enter 1. When the Write button is

pressed, the USB-KNX interface sends group object 0/0/2

on the bus with the value On. LED3 on the shield should now

light up. When pressing the Read button again the device

will now respond with On.

BIBLIOGRAPHY

Standards

[1] The KNX Standard v2.1 − KNX Hardware

Requirements and Tests − Part 4−1: Safety

and Environmental Requirements − General.

KNX, 2013.

[2] The KNX Standard v2.1 − System Conformance Testing − Part

8−2−2: Medium Dependant Layers Tests − TP1 Physical and

Link Layer Tests.

KNX, 2013.

Internet

[3] KNX Association. 2020, accessed January 28, 2020. url:

https://www.knx.org

[4] KNX Training Centres. 2020, accessed January 28, 2020. url:

https://www.knx.org/knx−en/

for−professionals/community/training−centres/

index.php.

[5] Wired connectivity solutions. 2020, accessed

January 28, 2020. url: https://www.onsemi.com/

PowerSolutions/segment.do?method=subSolution&

segmentId=IoT&solutionId=19116&subSolutionId=

19126.

.

APPENDIX A − MICROCONTROLLER NET LIST NCN5100AS-1

Table 4. MICROCONTROLLER PINS LIST

Pin Arduino Headers Connected to Function MCU Pin Direction

D0/RX SDO/TXD UART receive line IN

D1/TX SDI/RXD UART transmit line OUT

D2 SAVEB Save data indication IN

D3/PWM LED5 CH2 Red up button LED OUT

D4 SW4 Up button CH2 IN

D5/PWM LED3 CH2 Yellow down button LED OUT

D6/PWM LED2 CH1 Green down button LED OUT

D7 SW1 Down button CH1 IN

D8 SW3 Up button CH1 IN

D9/PWM LED4 CH1 Orange up button LED OUT

D10/CS CSB/UC1 SPI chip select IN

D11/MOSI SDO/TXD SPI MOSI IN

D12/MISO SDI/RXD SPI MISO OUT

D13/SCK SCK/UC2 SPI clock IN

A0 ANAOUT Analog multiplexer output IN (analog)

A1 SW2 Down button CH2 IN

A2 TREQ Transmission request OUT

A3 LED6 Programming LED OUT

A4 S1 Programming button IN

www.onsemi.com

15

Page 16

EVBUM2715/D

APPENDIX B − MICROCONTROLLER NET LIST NCN5100AS-2

Table 5. MICROCONTROLLER PINS LIST

Pin Arduino Headers Connected to Function MCU Pin Direction

D3/PWM LED5 CH2 Red up button LED OUT

D4 SW4 Up button CH2 IN

D5/PWM LED3 CH2 Yellow down button LED OUT

D6/PWM LED2 CH1 Green down button LED OUT

D7 SW1 Down button CH1 IN

D8 SW3 Up button CH1 IN

D9/PWM LED4 CH1 Orange up button LED OUT

D11 RXD2 Data input NCN5110 OUT

D12 RXD1 Data input NCN5110 OUT

A0 TXD Data output NCN5110 IN

A1 SW2 Down button CH2 IN

A3 LED6 Programming LED OUT

A4 S1 Programming button IN

www.onsemi.com

16

Page 17

Table 6. TESTED PLATFORMS

Manufacturer Development Board Microcontroller

STMicroelectronics NUCLEO−F103RB STM32F103RB

Cypress CY8CKIT−044 CY8C4247AZI−M485

Waveshare XNUCLEO−F103RB STM32F103RB

EVBUM2715/D

APPENDIX C − LIST OF TESTED PLATFORMS

www.onsemi.com

17

Page 18

UART-version

8

7

6

5

Place this as close

4

3

2

1

C2

10pF

as possible to the chip!

16MHz

X1

FA−238

1 3

2 4

10pF

C1

XTAL1 XTAL2

XTAL oscillator

GND GND

R1

3V3

A A

9−bit, 19200bps

9−bit, 38400bps

8−bit, 19200bps

8−bit, 38400bps

110

0

010

1

UC1 UC2

Use these to select the baud rate and

parit bit in UART mode.

123

J2

UC2

3V3

3V3

GND

10k

R5

SCK/UC2CS/UC1

123

UC1

J1

Arduino headersArduino headers

GND

10k

R4

Baud rate/parity bit select

C4

3V3

GND

0ER8

1

J3

TP3

XCLK

XCLK

XSEL

XTAL2

XTAL1

D2

RESETB

FANIN

TP1

FANIN

R3

GND

10k

R2

560E

1

ANAOUT

10k

3V3

TP2

C3

3V3

0ER7

0ER6

GND

2

3

Q1

NDS355AN

EVBUM2715/D

APPENDIX D − NCN5130ASGEVB

Red

LED1

750E

R14

3V3

Power LED

123456789

SCL/D15

SDA/D14

Populate for

100nF

U1

31

32

33

34

35

36

37

38

39

40

100nF

Place diode and TVS as close

as possible to the common mode choke!

9V

3V3S

IOREF

1234567

J4

10

AVDD

GND

SCK/D13

MISO/D12

PWM/MOSI/D11

PWM/CS/D10

PWM/D9D8D7

560ER9

560ER11

560ER12

560ER13

SPI

TP4

SCK/UC2

CS/UC1

TP7

GND

CS/UC1

SCK/UC2

MOSI/TXD

TREQ

MODE2

MISO/RXD

25

30

26

29

27

24

28

TREQ

VDDD

VSSD

SDI/RXD

CSB/UC1

SCK/UC2

SDO/TXD

XCLK

XSEL

XTAL2

XTAL1

SAVEB

RESETB

FANIN

ANAOUT

VDDA

VSSA1VBUS22TXO3CCP4CAV5VBUS16CEQ17CEQ28VFILT9V20V

VBUS

TXO

CAV

CCP

CEQ1

GND

C6

27ER10

47nF, 50VC5220nF, 50V

TP5

VBUS

D1

SS16T3G

CAV TP8

TP6

L1

1 2

4 3

KNX−

KNX+

J5

KNX−Bus

MBR0530T

D3

NRST

5VS

VIN

8

Power

MODE1

CEQ2

VFILT

J6

TP9

TRIG

22

MODE123MODE2

VFILT

GND

B B

GND

VLMS30J1L2−GS08

Mode select

1234567

MISO/RXD

TP10

XCLKC

21

TRIG

XCLKC

10

V20V

SMAJ40CA

D2

J7

PWM/D6

PWM/D5D4PWM/D3D2TX/D1

MOSI/TXD

TP11

TRIG

VDD1M

VDD1

VSS1

VSW1

VIN

VSW2

VSS2

VDD2

VDD2MC

VDD2MV

1μF, 50V

C10

100μF, 35V

C9

100nF

C8

100nF

C7

560ER15 TREQ

A0A1A2A3A4

12345

Populate for

UART

NCN5130

20

19

18

17

16

15

14

13

12

11

50V

50V

TP12

TREQ

Populate

for SPI

A5

6

560ER16

TP14

TP13

GND

8

RX/D0

560ER17

3V3

VDD1MV

GND GND

VDD2MV

J8

TP17

GND

TP16

GND

GND

TP15

TP19

GND

Analog in

J9

VDD2

123

3V3

3V3

3V3

C12

10μF

GND

GND

TP18

1E

R21

L3

L2

1E

R20

130k

R18

10μF

C11

GND

GND

691214110003

GND

GND

GND

GND

R19

GND GND

User buttons and LEDs

Figure 38. Schematic

2 x 220 uH, 0.4 A

R22

3V3S

3V3S

3V3S

3V3S

CH1 CH2

R25

R24

R23

GND

20k

Populate for SPI

0E

MODE2MODE1

0E

0E

XCLKC

3V3S

Supply select

9V

GND

10k

R29

PWM/D3PWM/D5PWM/D6 PWM/D9

10k

R27

10k

R28

10k

R26

−

11

Revision

Sheet ofA3

8

Size

Populate for UART

0E

R32

0E

R31

0E

R30

1

2

J11

1

2

J10

SW4

D4D7 D8

Red

LED5

750E

R36

SW2

A1

Yellow

LED3

560E

R34

SW3

Orange

LED4

750E

R35

SW1

Green

LED2

680E

R33

C C

UART

SPI 500kpbs

GND

0

0

10

Select the desired communication mode

GND

TREQ MODE1MODE2

TREQ

0

GND

In this configuration DC−DC2 will generate 9V

and supply the microcontroller board through

the VIN pin on the Arduino headers.

In this configuration the 3,3V generated by DC−DC1

is connected to the 3V3 pin on the Arduino headers.

Make sure your micrcontroller board can be directly

J10 J11

VLMS30J1L2−GS08

VLMA3100−GS08

VLMO30L1M2−GS08

VLMC3100−GS08

J10 J11

GND

GND

GND

GND GNDGND GND

3V3S

R37

A3

GND

Prog

ON Semiconductor — Energy Management Products

1

8MHz

16MHz

Default

1

XLCKC01

XCLK frequency selection

supplied through the 3V3 pin. Else you could damage it!

S1

10k

A4

1

2

Red

LED6

680E

R38

KPT−1608EC

D D

Tijl Schepens

A: NCN5130−UART

KNX Arduino shield

Design

Board ncn5100as−1

Variant

GND GND

Programming button/LED

7

17/10/2019

Date

6

5

4

3

2

1

www.onsemi.com

18

Page 19

Table 7. BILL OF MATERIALS UART-VERSION

Designator

J1 1 WR−PHD 2.54 mm THT Pin Header, 3p 61300311121

J2 1 WR−PHD 2.54 mm THT Pin Header, 3p 61300311121

J3 1 WR−PHD 2.54 mm THT Pin Header, 1p 61300111121

J4 1 Board-To-Board Connector, 2.54 mm,

Qty Description Value Part Number

8 Contacts, Receptacle, Through Hole, 1 Rows

EVBUM2715/D

SSQ−110 −03−G−S

J6 1 Board-To-Board Connector, 2.54 mm,

J7 1 Board-To-Board Connector, 2.54 mm,

J8 1 Serie 2141 − 3.50 mm Horizontal Entry Modular

J9 1 Board-To-Board Connector, 2.54 mm,

L2 1 SMT Power Inductor WE−LQFS, size 4828,

L3 1 SMT Power Inductor WE−LQFS, size 4828,

Q1 1 N-Channel Logic Level Enhancement Mode

J10, J11 2 WR−PHD 2.54 mm THT Pin Header, 2p

R6, R7, R8, R23,

R31, R32

C10 1 Capacitor

D1 1 Schottky Rectifier, Singel 60 V, 1 A,

R20, R21 2 Resistor

LED3 1 LED, Yellow, SMD, 2 mA, 2.2 V, 594 nm 2 mA, 2.2 V, 594 nm VLMA3100−GS08

R19 1 2 (1 x 2) Position Shunt Connector

LED4 1 LED, Orange, SMD, 2.4 mm, 2 mA, 1.8 V,

LED2 1 LED, Green, SMD, 2.4 mm, 2 mA, 1.9 V, 575

C11, C12 2 Capacitor

R2, R3, R4, R5,

R26, R27, R28,

R29, R37

10 Contacts, Receptacle, Through Hole,

1 Rows

6 Contacts, Receptacle, Through Hole, 1 Rows

with Rising Cage Clamp WR−TBL, 3 pin

8 Contacts, Receptacle, Through Hole, 1 Rows

220 mH, 0.4 A

220 mH, 0.4 A

Field Effect Transistor, 30 V, 1.7 A, −55°C to

150°C, 3-Pin SOT−3, RoHS, Tape and Reel

6 Resistor

DO−214AC, 2 Pins, 720 mV

Non-Insulated 0.400 in (10.16 mm) Gold

609 nm

nm

9 Resistor

0 W

1 mF, 50 V

1 A / 720 mV / 60 V SS16T3G

1 W

2 pins D3082−05

2.4 mm, 2 mA, 1.8 V,

609 nm

2.4 mm, 2 mA, 1.9 V,

575 nm

10 mF

10 W

SSQ−110 −03−G−S

SSQ−106−03−G−S

691214110003

SSQ−108−03−G−S

74406043221

74406043221

NDS355AN

RC0603JR−070RL

GCM21BR71H105KA03L

RC0603FR−071RL

VLMO30L1M2−GS08

VLMC3100−GS08

C3216X7R1E106K160AE

CRCW060310K0FKEA

C1, C2 2 Capacitor 10 pF C0402C100J5GACTU

SW1, SW2, SW3,

SW4

X1 1 Crystal Oscillator, 16 MHz, Low Profile SMD,

R22 1 Resistor

R10 1 Resistor

U1 1 Transceiver for KNX Twisted Pair Networks 40 pins NCN5130MNTWG

4 Switch 12 V, 50 mA MCDTS6−3N

3.2 mm 2.5 mm, 30 ppm, 12.5 pF, 50 ppm,

FA−238 Series

16 MHz to 60 MHz /

Load: 12.5 pF /

Stability: 30 ppm /

Tolerance: 50 ppm

20 W

27 W

Q22FA23800181 FA−238

CRCW060320K0FKEA

352027RJT

www.onsemi.com

19

Page 20

EVBUM2715/D

Table 7. BILL OF MATERIALS UART-VERSION (continued)

Designator Part NumberValueDescriptionQty

D2 1 SMAJ40CA − TVS Diode, TRANSZORB SMAJ

Series, Bidirectional, 40 V, 64.5 V, DO−214AC,

2 Pins

C5 1 Capacitor 47 nF, 50 V CGA3E2X7R1H473K080AA

C9 1 Capacitor

S1 1 6.0 x 3.8 mm SMD J−Bend WS−TASV

C3, C4 2 Capacitor 100 nF CC0402KRX7R7BB104

C8 1 Capacitor 100 nF, 50 V VJ0603Y104KXACW1BC

C7 1 Capacitor 100 nF, 50 V VJ0603Y104KXACW1BC

R18 1 Resistor

C6 1 Capacitor 220 nF, 50 V CGA3E3X7R1H224K080AB

R1, R16, R17, R34 4 Resistor

LED6 1 Surface Mount Chip LED, Red 0603, Red KPT−1608EC

R33, R38 2 Resistor

R14, R35, R36 3 Resistor

J5 1 Male connector for WAGO 243−211 Pitch: 5.75 mm /

LED1, LED5 2 LED, Red, 2.4 mm, 636 nm, 1.8 V, 2 mA,

18 mcd

D3 1 Surface Mount Schottky Power Rectifier Uf = 430 mV,

40 V, 400 W SMAJ40CA

100 mF, 35 V

100 mW, 250 V (AC)

130 W

560 W

680 W

750 W

Diameter:1 mm / 100 V /

6 A

Red, 1.8 V, 2 mA VLMS30J1L2−GS08

If = 500 mA, Ur = 30 V

EEEFT1V101AP

434 123 025 816

CRCW0603130KFKEA

CRCW0603560RFKEA

CRCW0603680RFKEA

CRCW0603750RFKEA

13.14.125

MBR0530T1G

www.onsemi.com

20

Page 21

SPI-version

8

7

6

5

4

3

2

1

10pF

C2

Place this as close

as possible to the chip!

16MHz

FA−238

1 3

2 4

10pF

C1

XTAL1 XTAL2

XTAL oscillator

3V3

9−bit, 19200bps

9−bit, 38400bps

8−bit, 19200bps

8−bit, 38400bps

110

0

010

1

UC1 UC2

Use these to select the baud rate and

parit bit in UART mode.

123

UC2

J2

3V3

10k

R5

SCK/UC2CS/UC1

123

UC1

J1

3V3

10k

R4

Baud rate/parity bit select

GND

0ER8

1

J3

X1

FANIN

TP1

GND GND

10k

R3

GND

0ER7

0ER6

GND

10k

R2

2

560E

R1

1

3

Q1

A A

GND

GND

3V3

TP3

XCLK

TP2

3V3

3V3

NDS355AN

3V3

Power LED

123456789

SCL/D15

SDA/D14

AVDD

GND

SCK/D13

MISO/D12

PWM/MOSI/D11

Arduino headersArduino headers

100nF

C4

U1

31

32

XCLK

33

XSEL

XTAL2

34

XTAL1

35

D2

36

37

RESETB

FANIN

38

ANAOUT

39

40

100nF

C3

J4

PWM/CS/D10

560ER9

560ER11

560ER12

560ER13

Populate for

SPI

SCK/UC2

TP4

GND

CS/UC1

SCK/UC2

MOSI/TXD

MISO/RXD

30

26

29

28

27

VDDD

VSSD

SDI/RXD

CSB/UC1

SCK/UC2

SDO/TXD

XCLK

XSEL

XTAL2

XTAL1

SAVEB

RESETB

FANIN

ANAOUT

VDDA

VSSA1VBUS22TXO3CCP4CAV5VBUS16CEQ17CEQ28VFILT9V20V

TXO

CAV

CCP

GND

27ER10

47nF, 50VC5220nF, 50V

TP5

VBUS

D1

SS16T3G

Place diode and TVS as close

as possible to the common mode choke!

1 2

KNX−

KNX+

J5

9V

D3

3V3S

IOREF

NRST

5VS

VIN

1234567

8

EVBUM2715/D

Red

LED1

750E

R14

10

J6

PWM/D9D8D7

TP9

TP7

CS/UC1

TREQ

MODE1

MODE2

TRIG

24

22

25

TREQ

MODE123MODE2

VFILT

VBUS

CEQ1

CEQ2

C6

VFILT

TP6

CAV TP8

L1

4 3

KNX−Bus

MBR0530T

GND

Power

B B

MISO/RXD

TP10

XCLKC

21

TRIG

XCLKC

10

V20V

SMAJ40CA

D2

J7

VLMS30J1L2−GS08

1234567

PWM/D6

PWM/D5D4PWM/D3D2TX/D1

Populate for

MOSI/TXD

TRIG

TP11

NCN5130

VDD1M

20

VDD1

19

VSS1

18

VSW1

17

VIN

16

VSW2

15

VSS2

14

VDD2

13

VDD2MC

12

VDD2MV

11

1μF, 50V

C10

100μF, 35V

C9

50V

100nF

C8

50V

100nF

C7

TP12

560ER15 TREQ

Populate

A0A1A2A3A4

12345

GND

560ER16

UART

TP14

TP13

GND

TREQ

for SPI

A5

6

8

RX/D0

560ER17

3V3

VDD1MV

GND GND

VDD2MV

J8

TP17

GND

TP16

GND

GND

TP15

TP19

GND

Analog in

J9

VDD2

123

1E

1E

C12

10μF

130k

R18

10μF

C11

691214110003

GND

GND

GND

GND

R19

Mode select

TP18

GND GND

Populate for SPI

0E

R25

3V3

0E

R24

3V3

0E

R23

3V3

GND

3V3S

GND

GND

R21

L3

L2

Supply select

2 x 220 uH, 0.4 A

R20

9V

20k

R22

GND

GND

R29

3V3S

PWM/D3PWM/D5PWM/D6 PWM/D9

R27

3V3S

R28

3V3S

R26

3V3S

CH1 CH2

User buttons and LEDs

Populate for UART

MODE2MODE1

XCLKC

GND

10k

10k

10k

10k

−

11

Revision

Sheet ofA3

8

Size

7

Tijl Schepens

UART

0E

R32

GND

0E

R31

GND

0E

R30

GND

1

2

J11

1

2

J10

SW4

D4D7 D8

Red

LED5

750E

R36

SW2

A1

Yellow

LED3

560E

R34

SW3

Orange

LED4

750E

R35

SW1

Green

LED2

680E

R33

C C

SPI 500kpbs

0

0

10

Select the desired communication mode

TREQ MODE1MODE2

0

TREQ

1

8MHz

XLCKC01

XCLK frequency selection

In this configuration DC−DC2 will generate 9V

and supply the microcontroller board through

the VIN pin on the Arduino headers.

In this configuration the 3,3V generated by DC−DC1

is connected to the 3V3 pin on the Arduino headers.

Make sure your micrcontroller board can be directly

supplied through the 3V3 pin. Else you could damage it!

J10 J11

VLMS30J1L2−GS08

VLMA3100−GS08

VLMO30L1M2−GS08

VLMC3100−GS08

J10 J11

GND

GND

GND

GND GNDGND GND

10k

R37

A4

GND

3V3S

1

A3

680E

R38

Prog

16MHz

Default

1

Red

LED6

D D

B: NCN5130−SPI

Design

Board ncn5100as−1

Variant

ON Semiconductor — Energy Management Products

KNX Arduino shield

S1

2

GND GND

KPT−1608EC

Programming button/LED

17/10/2019

Date

6

5

4

3

2

1

Figure 39. Schematic

www.onsemi.com

21

Page 22

Table 8. BILL OF MATERIALS SPI-VERSION

Designator

J3 1 WR−PHD 2.54 mm THT Pin Header, 1p 61300111121

J4 1 Board-To-Board Connector, 2.54 mm,

Qty Description Value Part Number

8 Contacts, Receptacle, Through Hole, 1 Rows

EVBUM2715/D

SSQ−110 −03−G−S

J6 1 Board-To-Board Connector, 2.54 mm,

J7 1 Board-To-Board Connector, 2.54 mm,

J8 1 Serie 2141 − 3.50 mm Horizontal Entry Modular

J9 1 Board-To-Board Connector, 2.54 mm,

L2 1 SMT Power Inductor WE−LQFS, size 4828,

L3 1 SMT Power Inductor WE−LQFS, size 4828,

Q1 1 N-Channel Logic Level Enhancement Mode

J10, J11 2 WR−PHD 2.54 mm THT Pin Header, 2p

R6, R7, R8, R23,

R25, R31

C10 1 Capacitor

D1 1 Schottky Rectifier, Singel 60 V, 1 A,

R20, R21 2 Resistor

LED3 1 LED, Yellow, SMD, 2 mA, 2.2 V, 594 nm 2 mA, 2.2 V, 594 nm VLMA3100−GS08

R19 1 2 (1 x 2) Position Shunt Connector

LED4 1 LED, Orange, SMD, 2.4 mm, 2 mA, 1.8 V,

LED2 1 LED, Green, SMD, 2.4 mm, 2 mA, 1.9 V,

C11, C12 2 Capacitor

R2, R3, R26, R27,

R28, R29, R37

C1, C2 2 Capacitor 10 pF C0402C100J5GACTU

SW1, SW2, SW3,

SW4

X1 1 Crystal Oscillator, 16 MHz, Low Profile SMD,

R22 1 Resistor

R10 1 Resistor

U1 1 Transceiver for KNX Twisted Pair Networks 40 pins NCN5130MNTWG

D2 1 SMAJ40CA − TVS Diode, TRANSZORB SMAJ

C5 1 Capacitor 47 nF, 50 V CGA3E2X7R1H473K080AA

10 Contacts, Receptacle, Through Hole, 1

Rows

6 Contacts, Receptacle, Through Hole, 1 Rows

with Rising Cage Clamp WR−TBL, 3 pin

8 Contacts, Receptacle, Through Hole, 1 Rows

220 mH, 0.4 A

220 mH, 0.4 A

Field Effect Transistor, 30 V, 1.7 A, −55°C to

150°C, 3-Pin SOT−3, RoHS, Tape and Reel

6 Resistor

DO−214AC, 2 Pins, 720 mV

Non−Insulated 0.400 in (10.16 mm) Gold

2.4 mm, 2 mA, 1.8 V,

609 nm

2.4 mm, 2 mA, 1.9 V,

575 nm

7 Resistor

4 Switch 12 V, 50 mA MCDTS6−3N

3.2 mm 2.5 mm, 30 ppm, 12.5 pF, 50 ppm,

FA−238 Series

Series, Bidirectional, 40 V, 64.5 V, DO−214AC,

2 Pins

0 W

1 mF, 50 V

1 A / 720 mV / 60 V SS16T3G

1 W

2 pins D3082−05

609 nm

575 nm

10 mF

10 W

16 MHz to 60 MHz /

Load: 12.5 pF /

Stability: 30 ppm /

Tolerance: 50 ppm

20 W

27 W

40 V, 400 W SMAJ40CA

SSQ−110 −03−G−S

SSQ−106−03−G−S

691214110003

SSQ−108−03−G−S

74406043221

74406043221

NDS355AN

RC0603JR−070RL

GCM21BR71H105KA03L

RC0603FR−071RL

VLMO30L1M2−GS08

VLMC3100−GS08

C3216X7R1E106K160AE

CRCW060310K0FKEA

Q22FA23800181 FA−238

CRCW060320K0FKEA

352027RJT

www.onsemi.com

22

Page 23

EVBUM2715/D

Table 8. BILL OF MATERIALS SPI-VERSION (continued)

Designator Part NumberValueDescriptionQty

C9 1 Capacitor

S1 1 6.0 x 3.8 mm SMD J−Bend WS−TASV

C3, C4 2 Capacitor 100 nF CC0402KRX7R7BB104

C8 1 Capacitor 100 nF, 50 V VJ0603Y104KXACW1BC

C7 1 Capacitor 100 nF, 50 V VJ0603Y104KXACW1BC

R18 1 Resistor

C6 1 Capacitor 220 nF, 50 V CGA3E3X7R1H224K080AB

R1, R9, R11, R12,

R13, R15, R34

LED6 1 Surface Mount Chip LED, Red 0603, Red KPT−1608EC

R33, R38 2 Resistor

R14, R35, R36 3 Resistor

J5 1 Male connector for WAGO 243−211 Pitch: 5.75 mm /

LED1, LED5 2 LED, Red, 2.4 mm, 636 nm, 1.8 V, 2 mA,

D3 1 Surface Mount Schottky Power Rectifier Uf = 430 mV,

7 Resistor

18 mcd

100 mF, 35 V

100 mW, 250 V (AC)

130 W

560 W

680 W

750 W

Diameter: 1 mm / 100 V /

6 A

Red, 1.8 V, 2 mA VLMS30J1L2−GS08

If = 500 mA, Ur = 30 V

EEEFT1V101AP

434 123 025 816

CRCW0603130KFKEA

CRCW0603560RFKEA

CRCW0603680RFKEA

CRCW0603750RFKEA

13.14.125

MBR0530T1G

www.onsemi.com

23

Page 24

UART-version

8

7

6

5

Place this as close

4

3

2

1

C2

10pF

as possible to the chip!

16MHzX1FA−238

1 3

2 4

10pF

C1

XTAL1 XTAL2

XTAL oscillator

GND GND

R1

3V3

A A

9−bit, 19200bps

9−bit, 38400bps

8−bit, 19200bps

8−bit, 38400bps

110

0

010

1

UC1 UC2

Use these to select the baud rate and

parit bit in UART mode.

123

J2

UC2

3V3

3V3

GND

10k

R5

SCK/UC2CS/UC1

123

UC1

J1

Arduino headersArduino headers

GND

10k

R4

Baud rate/parity bit select

C4

3V3

GND

0ER8

1

J3

TP3

XCLK

XCLK

XSEL

XTAL2

XTAL1

D2

RESETB

FANIN

FANIN

TP1

R3

GND

10k

R2

560E

1

ANAOUT

0E

3V3

TP2

C3

3V3

0ER7

0ER6

GND

2

3

Q1

NDS355AN

EVBUM2715/D

APPENDIX E − NCN5121ASGEVB

Red

LED1

750E

R14

3V3

Power LED

123456789

SCL/D15

SDA/D14

Populate for

100nF

U1

31

32

33

34

35

36

37

38

39

40

100nF

Place diode and TVS as close

as possible to the common mode choke!

9V

3V3S

IOREF

1234567

J4

10

AVDD

GND

SCK/D13

MISO/D12

PWM/MOSI/D11

PWM/CS/D10

PWM/D9D8D7

560ER9

560ER11

560ER12

560ER13

SPI

SCK/UC2

TP4

TP7

CS/UC1

GND

CS/UC1

SCK/UC2

MOSI/TXD

TREQ

MODE2

MISO/RXD

25

30

26

29

24

27

28

TREQ

VDDD

VSSD

SDI/RXD

CSB/UC1

SCK/UC2

SDO/TXD

XCLK

XSEL

XTAL2

XTAL1

SAVEB

RESETB

FANIN

ANAOUT

VDDA

VSSA1VBUS22TXO3CCP4CAV5VBUS16CEQ17CEQ28VFILT9V20V

CCP

CEQ1

VBUS

TXO

CAV

GND

C6

27ER10

47nF, 50VC5220nF, 50V

TP5

VBUS

D1

SS16T3G

CAV TP8

TP6

L1

1 2

4 3

KNX−

KNX+

J5

KNX−Bus

D3

MBR0530T

NRST

5VS

VIN

8

Power

MODE1

CEQ2

VFILT

J6

TP9

TRIG

22

MODE123MODE2

VFILT

GND

B B

MISO/RXD

TP10

XCLKC

21

TRIG

XCLKC

10

V20V

SMAJ40CA

D2

J7

VLMS30J1L2−GS08

1234567

PWM/D6

PWM/D5D4PWM/D3D2TX/D1

Populate for

MOSI/TXD

TP11

TRIG

NCN5121

VDD1M

20

VDD1

19

VSS1

18

VSW1

17

VIN

16

VSW2

15

VSS2

14

VDD2

13

VDD2MC

12

VDD2MV

11

1μF, 50V

C10

100μF, 35V

C9

50V

100nF

C8

50V

100nF

C7

TP12

560ER15 TREQ

Populate

A0A1A2A3A4

12345

GND

560ER16

UART

TP14

TP13

GND

TREQ

for SPI

A5

6

8

RX/D0

560ER17

3V3

VDD1MV

GND GND

VDD2MV

J8

TP17

GND

TP16

GND

GND

TP15

TP19

GND

Analog in

J9

VDD2

123

1E

1E

10μF

C12

130k

R18

10μF

C11

691214110003

GND

GND

GND

GND

R19

Mode select

TP18

GND GND

3V3

3V3

3V3

GND

GND

R21

L3

L2

R20

GND

GND

User buttons and LEDs

2 x 220 uH, 0.4 A

R22

3V3S

3V3S

3V3S

3V3S

CH1 CH2

R25

R24

R23

GND

20k

Populate for SPI

0E

MODE2MODE1

0E

0E

XCLKC

3V3S

Supply select

9V

GND

10k

R29

PWM/D3PWM/D5PWM/D6 PWM/D9

10k

R27

10k

R28

10k

R26

−

11

Revision

Sheet ofA3

8

Size

Populate for UART

0E

R32

0E

R31

0E

R30

1

2

J11

1

2

J10

SW4

D4D7 D8

Red

LED5

750E

R36

SW2

A1

Yellow

LED3

560E

R34

SW3

Orange

LED4

750E

R35

SW1

Green

LED2

680E

R33

C C

UART

SPI 500kpbs

GND

0

0

10

Select the desired communication mode

GND

TREQ MODE1MODE2

TREQ

0

GND

In this configuration DC−DC2 will generate 9V

and supply the microcontroller board through

the VIN pin on the Arduino headers.

In this configuration the 3,3V generated by DC−DC1

is connected to the 3V3 pin on the Arduino headers.

Make sure your micrcontroller board can be directly

J10 J11

VLMS30J1L2−GS08

VLMA3100−GS08

VLMO30L1M2−GS08

VLMC3100−GS08

J10 J11

GND

GND

GND

GND GNDGND GND

3V3S

R37

A3

GND

Prog

ON Semiconductor — Energy Management Products

1

8MHz

16MHz

Default

1

XLCKC01

XCLK frequency selection

supplied through the 3V3 pin. Else you could damage it!

S1

10k

A4

1

2

Red

LED6

680E

R38

KPT−1608EC

D D

Tijl Schepens

C: NCN5121−UART

KNX Arduino shield

Design

Board ncn5100as−1

Variant

GND GND

Programming button/LED

7

21/11/2019

Date

6

5

4

3

2

1

Figure 40. Schematic

www.onsemi.com

24

Page 25

EVBUM2715/D

Table 9. BILL OF MATERIALS UART-VERSION

Designator

J1 1 WR−PHD 2.54 mm THT Pin Header, 3p 61300311121

J2 1 WR−PHD 2.54 mm THT Pin Header, 3p 61300311121

J3 1 WR−PHD 2.54 mm THT Pin Header, 1p 61300111121

J4 1 Board-To-Board Connector, 2.54 mm,

J6 1 Board-To-Board Connector, 2.54 mm,

J7 1 Board-To-Board Connector, 2.54 mm,

J8 1 Serie 2141 − 3.50 mm Horizontal Entry Modular

J9 1 Board-To-Board Connector, 2.54 mm,

L2 1 SMT Power Inductor WE−LQFS, size 4828,

L3 1 SMT Power Inductor WE−LQFS, size 4828,

Q1 1 N-Channel Logic Level Enhancement Mode

J10, J11 2 WR−PHD 2.54 mm THT Pin Header, 2p

R3, R6, R7, R8,

R23, R31, R32

C10 1 Capacitor

D1 1 Schottky Rectifier, Singel 60 V, 1 A,

R20, R21 2 Resistor

LED3 1 LED, Yellow, SMD, 2 mA, 2.2 V, 594 nm 2 mA, 2.2 V, 594 nm VLMA3100−GS08

R19 1 2 (1 x 2) Position Shunt Connector

LED4 1 LED, Orange, SMD, 2.4 mm, 2 mA, 1.8 V,

LED2 1 LED, Green, SMD, 2.4 mm, 2 mA, 1.9 V,

C11, C12 2 Capacitor

R2, R4, R5, R26,

R27, R28, R29,

R37

C1, C2 2 Capacitor 10 pF C0402C100J5GACTU

SW1, SW2, SW3,

SW4

X1 1 16 MHz to 60 MHz /

R22 1 Resistor

R10 1 Resistor