Page 1

查询CS51227供应商

CS51227

Enhanced Voltage Mode

PWM Controller

The CS51227 is a fixed frequency, single output PWM controller

using feed forward voltage mode control. Feed forward control

provides superior line regulation and line transient response. This

PWM controller has been optimized for high frequency primary side

control operation. It has undervoltage lockout with 4.7 V start up

voltage and 75 µA start up current. One external capacitor can

program the switching frequency up to 1.0 MHz. The protection

features include pulse–by–pulse current limit with leading edge

blanking and thermal shutdown. The CS51227 is available in 8 lead

SO narrow surface mount package.

http://onsemi.com

8

1

SO–8

D SUFFIX

CASE 751

Features

• 1.0 MHz Frequency Capability

• 4.7 V Start–Up Voltage

• Fixed Frequency Voltage Mode Operation with Feed Forward

• Undervoltage Lockout

• 75 µA Start–Up Current

• Thermal Shutdown

• 1.0 A Sink/Source Gate Drive

• Pulse–By–Pulse Current Limit with Leading Edge Blanking

• 50 ns GATE Rise and Fall Time (1.0 nF Load)

• Maximum Duty Cycle Over 85%

• Programmable Volt–Second Clamp

PIN CONNECTIONS AND

MARKING DIAGRAM

1

GATE

SENSE

CT

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W = Work Week

ORDERING INFORMATION

Device Package Shipping

CS51227ED8 SO–8 95 Units/Rail

CS51227EDR8 SO–8

ALYW

8

51227

V

CC

GNDI

COMPFF

V

FB

2500 Tape & Reel

Semiconductor Components Industries, LLC, 2001

April, 2001 – Rev. 7

1 Publication Order Number:

CS51227/D

Page 2

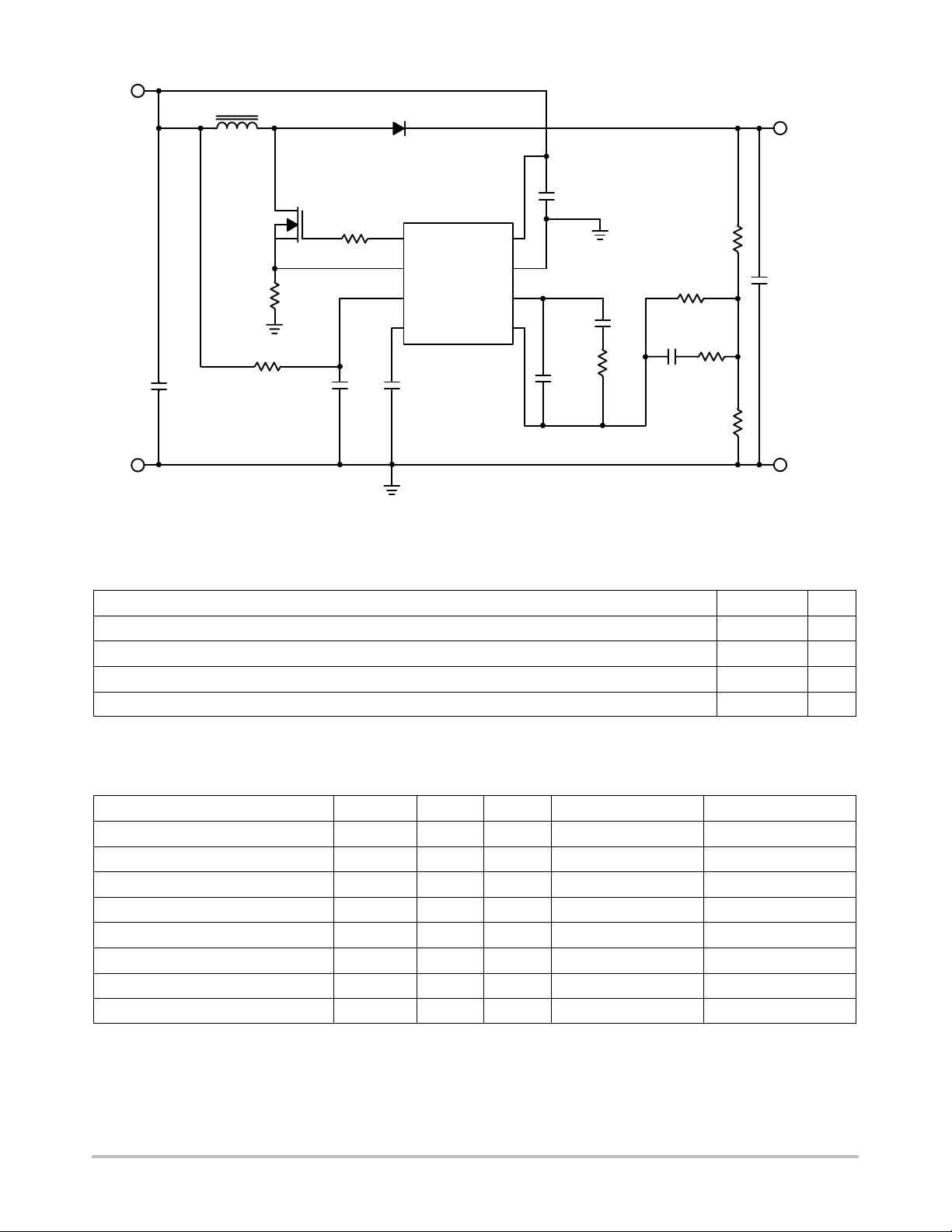

5.0 V

6.8 µH

FS70VSJ–03

0.1

B320DICT

GATE

CS51227

V

CC

12 V/ 2.0 A

0.1 µF

1.0 k

GND

COMP

CS51227

V

FB

2700 pF

100 pF

9.1 k

5.6 nF

51 k

+

22 µF × 4

300

+

22 µF × 2

9.31 k

0.025

330 pF1.0 nF

I

SENSE

FF

CT

110

GND

GND

Figure 1. Applications Diagram, 5.0 V to 12 V/2.0 A Boost Converter

MAXIMUM RATINGS*

Rating Value Unit

Operating Junction Temperature, T

Storage Temperature Range, T

J

S

ESD Susceptibility (Human Body Model) 2.0 kV

Lead Temperature Soldering: Reflow: (SMD styles only) (Note 1) 230 peak °C

1. 60 second maximum above 183°C.

*The maximum package power dissipation must be observed.

150 °C

–65 to +150 °C

MAXIMUM RATINGS

Pin Name Pin Symbol V

Gate Drive Output GATE 20 V –0.3 V 1.0 A Peak, 200 mA DC 1.0 A Peak, 200 mA DC

Current Sense Input I

Timing Capacitor CT 6.0 V –0.3 V 1.0 mA 10 mA

Feed Forward FF 6.0 V –0.3 V 1.0 mA 25 mA

Error Amp Output COMP 6.0 V –0.3 V 10 mA 20 mA

Feedback Voltage V

Power Supply V

Ground GND N/A N/A 1.0 A Peak, 200 mA DC N/A

SENSE

FB

CC

MAX

V

MIN

I

SOURCE

I

SINK

6.0 V –0.3 V 1.0 mA 1.0 mA

6.0 V –0.3 V 1.0 mA 1.0 mA

20 V –0.3 V 10 mA 1.0 A Peak, 200 mA DC

http://onsemi.com

2

Page 3

CS51227

ELECTRICAL CHARACTERISTICS: (–40°C < T

C

= 390 pF; unless otherwise specified.)

T

Characteristic

< 85°C, –40°C < TJ < 125°C, 4.7 V < VCC < 18 V

A

Test Conditions Min Typ Max Unit

Start/Stop Voltages

Start Threshold – 4.4 4.5 4.7 V

Stop Threshold – 3.2 3.8 4.2 V

Hysteresis Start – Stop 300 700 1400 mV

ICC @ Startup VCC < UVL Start Threshold – 38 75 µA

Supply Current

ICC Operating No Load – 10 16 mA

Overcurrent Protection

Overcurrent Threshold Ramp I

I

to GATE Delay VFB = 0.5 V (no blanking) – 60 125 ns

SENSE

SENSE

0.27 0.30 0.33 V

Error Amp

Reference Voltage VFB connected to COMP 1.234 1.263 1.285 V

VFB Input Current VFB = 1.25 V – 1.3 2.0 µA

Open Loop Gain Note 2 60 90 – dB

Unity Gain Bandwidth Note 2 1.5 2.5 – MHz

COMP Sink Current COMP = 1.4 V, VFB = 1.45 V 3.0 12 32 mA

COMP Source Current COMP = 1.4 V, VFB = 1.15 V 1.0 1.7 2.4 mA

COMP High Voltage VFB = 1.15 V 2.8 3.1 3.4 V

COMP Low Voltage VFB = 1.45 V 75 150 300 mV

PSRR Freq = 120 Hz, Note 2 60 85 – dB

Oscillator

Frequency Accuracy – 200 235 270 kHz

Max Duty Cycle – 85 90 95 %

Peak Voltage Note 2 1.99 2.05 2.11 V

Valley Clamp Voltage – 0.90 0.95 1.00 V

Valley Voltage Note 2 0.90 0.95 1.00 V

Discharge Current – 0.85 1.00 1.15 mA

Charge Current – 95 115 135 µA

Gate Driver

High Saturation Voltage VCC – V

Low Saturation Voltage V

GATE

, VCC = 10 V, I

GATE

, I

= 150 mA – 1.2 1.5 V

SINK

= 150 mA – 1.5 2.0 V

SOURCE

High Voltage Clamp – 11 13.5 16 V

Output UVL Leakage V

= 0 V – 1.0 50 µA

GATE

Rise Time 1.0 nF Load, VCC = 18 V, 1.0 V < VO < 9.0 V – 32 50 ns

Fall Time 1.0 nF Load, VCC = 18 V, 9.0 V < VO < 1.0 V – 25 50 ns

Max GATE Voltage @ UVL I

= 100 µA 0.4 0.7 1.5 V

LOAD

2. Guaranteed by design, not 100% tested in production.

http://onsemi.com

3

Page 4

CS51227

ELECTRICAL CHARACTERISTICS: (continued) (–40°C < T

C

= 390 pF; unless otherwise specified.)

T

< 85°C, –40°C < TJ < 125°C, 4.7 V < VCC < 18 V

A

Characteristic UnitMaxTypMinTest Conditions

Feed Forward (FF)

Discharge Voltage IFF = 2.0 mA – 0.3 0.7 V

Discharge Current FF = 1.0 V 2.0 16 30 mA

FF to GATE Delay – 50 75 125 ns

FF Max VOltage VFB = 1.15 V 1.7 1.8 1.9 V

Blanking

Blanking Time – 50 150 250 ns

COMP Blanking Disable Threshold VFB < 1.0 V 2.8 3.0 3.3 V

Thermal Shutdown

Thermal Shutdown

Note 3 125 150 180 °C

Thermal Hysteresis Note 3 5.0 10 15 °C

3. Guaranteed by design, not 100% tested in production.

PACKAGE PIN DESCRIPTION

PACKAGE LEAD #

SO–8

1 GATE External power switch driver with 1.0 A peak capability. Rail–to–rail output

2 I

3 FF PWM ramp.

4 CT Timing capacitor CT determines oscillator frequency.

5 V

6 COMP Error amplifier output.

7 GND Ground.

8 V

LEAD SYMBOL FUNCTION

occurs when the capacitive load is between 470 pF and 10 nF.

SENSE

FB

CC

Current sense comparator input.

Feedback voltage input. Connected to the error amplifier inverting input.

Supply voltage.

http://onsemi.com

4

Page 5

V

CC

4.7 – 18 V

CT

V

FB

COMP

FF

1.263 V

EAMP

+

–

+

–

+

–

UV Lockout

Start/Stop

OSC

3.0 V

CS51227

3.3 V

V

OK

REF

V

= 3.3 V

REF

3.1 V

PWM

COMP

+

–

Blank

Disable

1.8 V

+

–

G2

–+–

SRQ

V

REF

Thermal

Shutdown

Q

G1

Low Sat

Gate Driver

GATE

13.5 V

GND

FF Discharge

0.3 V

I

SENSE

150 ns

Blank

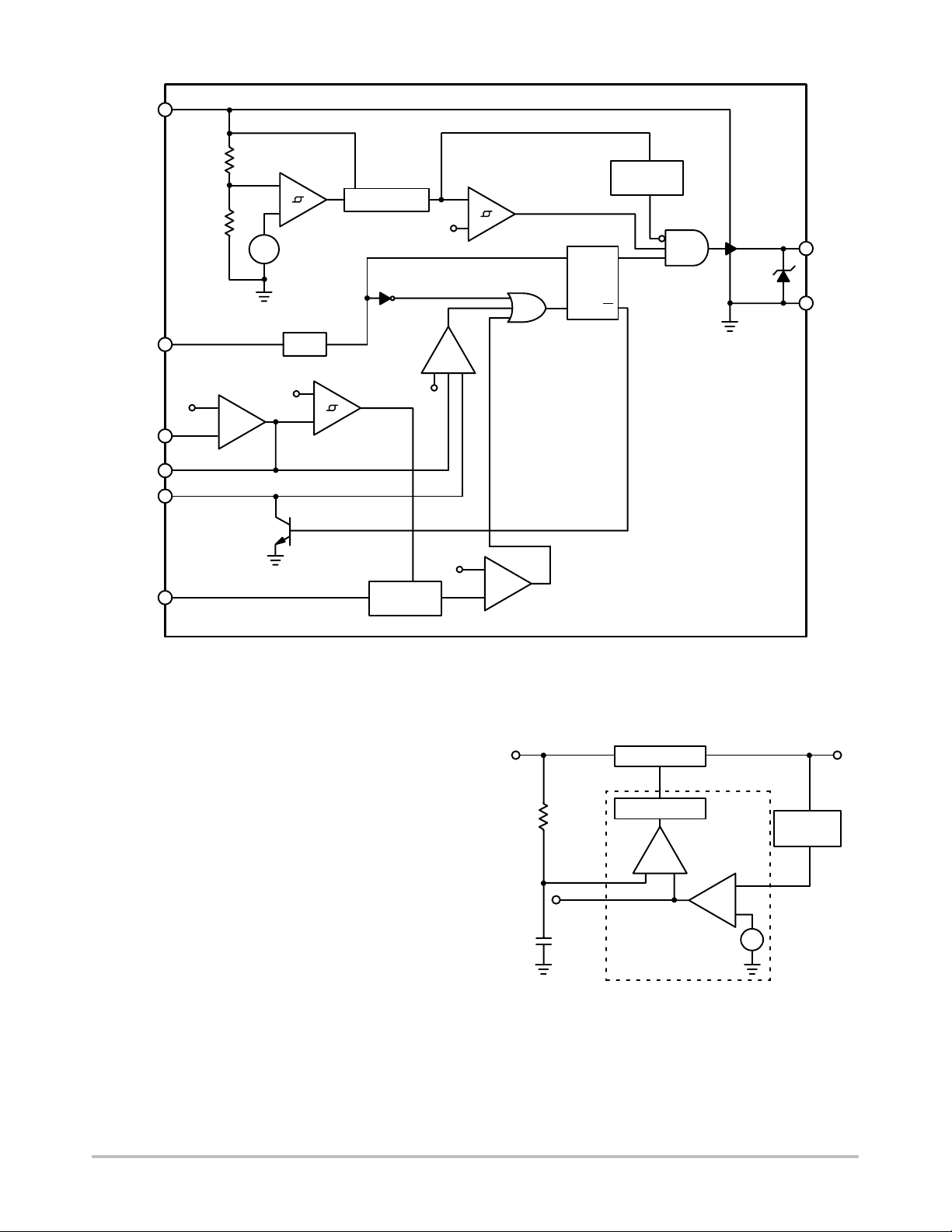

Figure 2. Block Diagram

THEORY OF APPLICATION

THEORY OF OPERATION

Feed Forward Voltage Mode Control

In conventional voltage mode control, the ramp signal is

fixed and often generated by the oscillator. The output

voltage is the only feedback path for regulation against load

and line variations. Feed forward voltage mode uses the

ramp signal driven by the input line, as shown in Figure 3.

Therefore, the ramp signal responds immediately to line

change. At the start of each switch cycle, the FF pin

capacitor is charged up through a resistor connected to the

input line. Meanwhile, the Gate output is turned on to drive

an external power switching device. When the FF pin

voltage reaches the error amplifier output V

COMP

, the PWM

comparator turns off the Gate and the FF pin capacitor is

quickly discharged by an internal current source.

+

I

LIM

–

V

IN

R

COMP

C

FF

Power Stage

GATE

Latch & Driver

PWM

Error

Amplifier

–

+

Figure 3. Feed Forward Voltage Mode Control

+

–

Feedback

Network

FB

V

OUT

http://onsemi.com

5

Page 6

CS51227

V

OUT

V

COMP

FF

V

IN

C

T

GATE

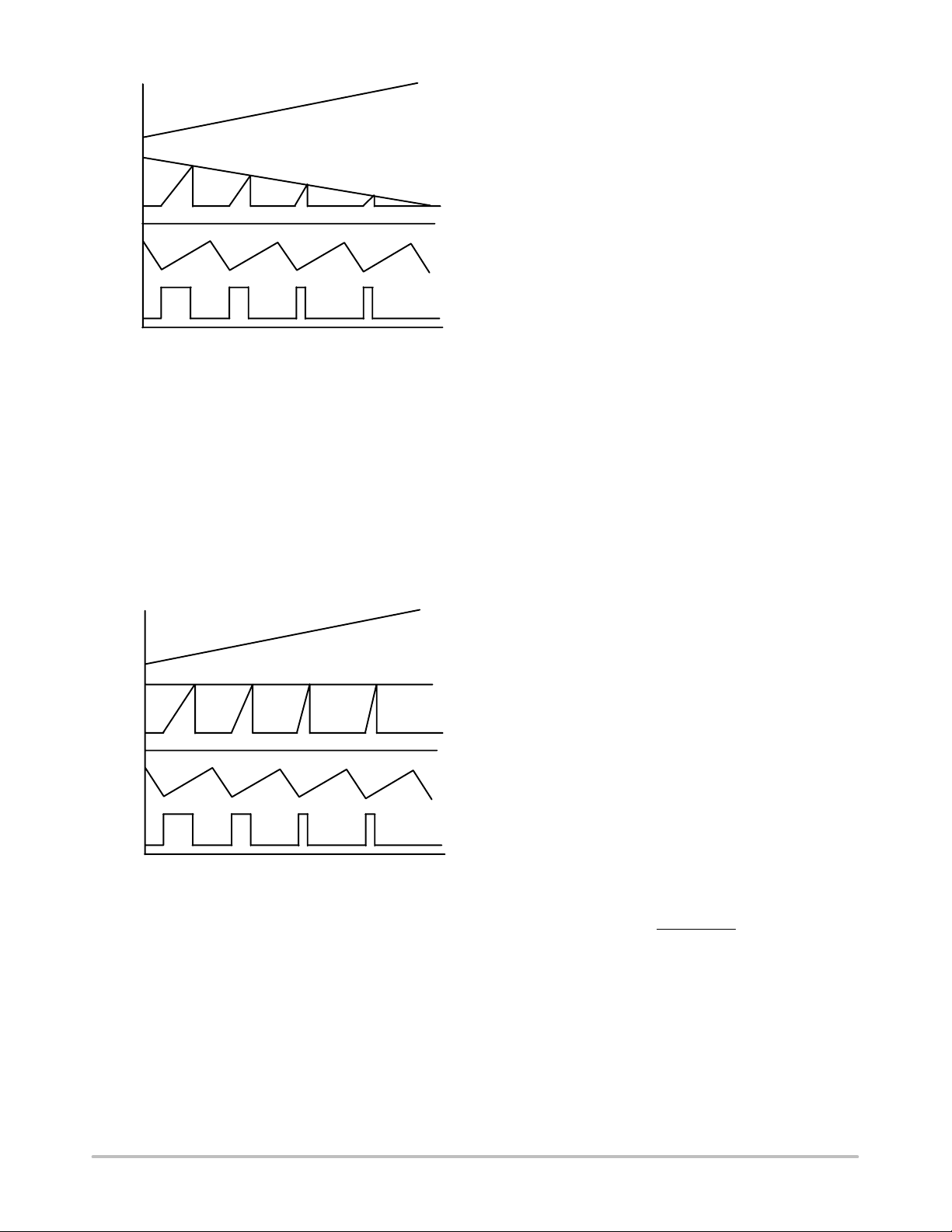

Figure 4. Pulse Width Modulated By Output

Current With Constant Input Voltage

Overall, the dynamics of the duty cycle are controlled by

both input and output voltages. As shown in Figure 4, an

elevated output voltage reduces V

through the error

COMP

amplifier. This in turn decreases the duty cycle and corrects

the deviation of the output voltage. For line variation, the

ramp signal responds immediately, which provides much

improved line transient response. The delay associated with

the power stage and feedback path has been totally avoided.

As an example, shown in Figure 5, when the input line goes

up, the slope of the ramp signal increases, reducing duty

cycle to counteract the change.

V

OUT

V

COMP

FF

V

IN

C

T

GATE

Figure 5. Pulse Width Modulated By Input

Voltage With Constant Output Voltage

The feed forward feature can also be employed to

implement volt–second clamping, which limits the

maximum product of input voltage and turn on time. This

clamp is used in circuits, such as Forward and Flyback

converters, to prevent the transformer from saturating. The

calculation for volt–second clamping is presented in the

Design Guidelines section.

Powering the IC & UVL

The internal logic monitors the supply voltage to ensure

the controller has enough operating headroom. The V

REF

block provides power to the controller’s logic. The

V

REF(OK)

and flags a fault if V

comparator monitors the internal 3.3 V V

falls below 3.1 V.

REF

REF

line

The Undervoltage Lockout (UVL) comparator has two

voltage references; the start and stop thresholds. During

power–up, the UVL comparator disables V

REF

(which

in–turn disables the entire IC) until the controller reaches its

VCC start threshold. During power–down, the UVL

comparator allows the controller to operate until the V

CC

stop threshold is reached. The CS51227 requires only 50 µA

during startup. During low VCC and abnormal operation

conditions, the output stage is held at a low level, low

impedance state.

Current Sense and Over Current Protection

The I

pulse current limit. When the I

pin monitors the switch current for pulse by

SENSE

pin voltage exceeds the

SENSE

internal threshold (0.3 V typical), the current limit

comparator immediately turns off the Gate signal. The Gate

will then stay off for the remainder of the cycle. Various

techniques, such as using current sensing resistor or current

transformer, a re w idely a dopted t o g enerate the c urrent s ignal.

The current sense signal is prone to leading edge spikes

caused by switching transitions. A RC low–pass filter can

effectively reduce the spikes a nd avoid p remature t riggering.

However, the low p ass f ilter will i nevitably c hange t he s hape

of the current pulse and also add cost. The CS51227 has

built–in leading edge blanking circuitry that blocks out the

first 150 ns (typ) of each current p ulse. T his f eature r emoves

the leading edge spikes without altering the current

waveform. Blanking is d isabled w hen the C OMP p in v oltage

exceeds 3.0 V (typ). This feature reduces the minimum duty

cycle during an output short or overload condition.

DESIGN GUIDELINES

Programming Oscillator Frequency

The switching frequency is set by the capacitor connected

to the C

pin. The CT pin voltage oscillates between 1.0 V

T

and 2.0 V. The ratio of the charge and discharge currents sets

the maximum duty cycle to be 90%. Use the following

equation to select C

,

T

C

T

9.027 10

7

f

s

where:

fs = Switching frequency

CT = Capacitance in pF

http://onsemi.com

6

Page 7

CS51227

When CT is less than 100 pF, parasitic capacitance

associated with the CT pin s tarts t o i mpact frequency a ccuracy.

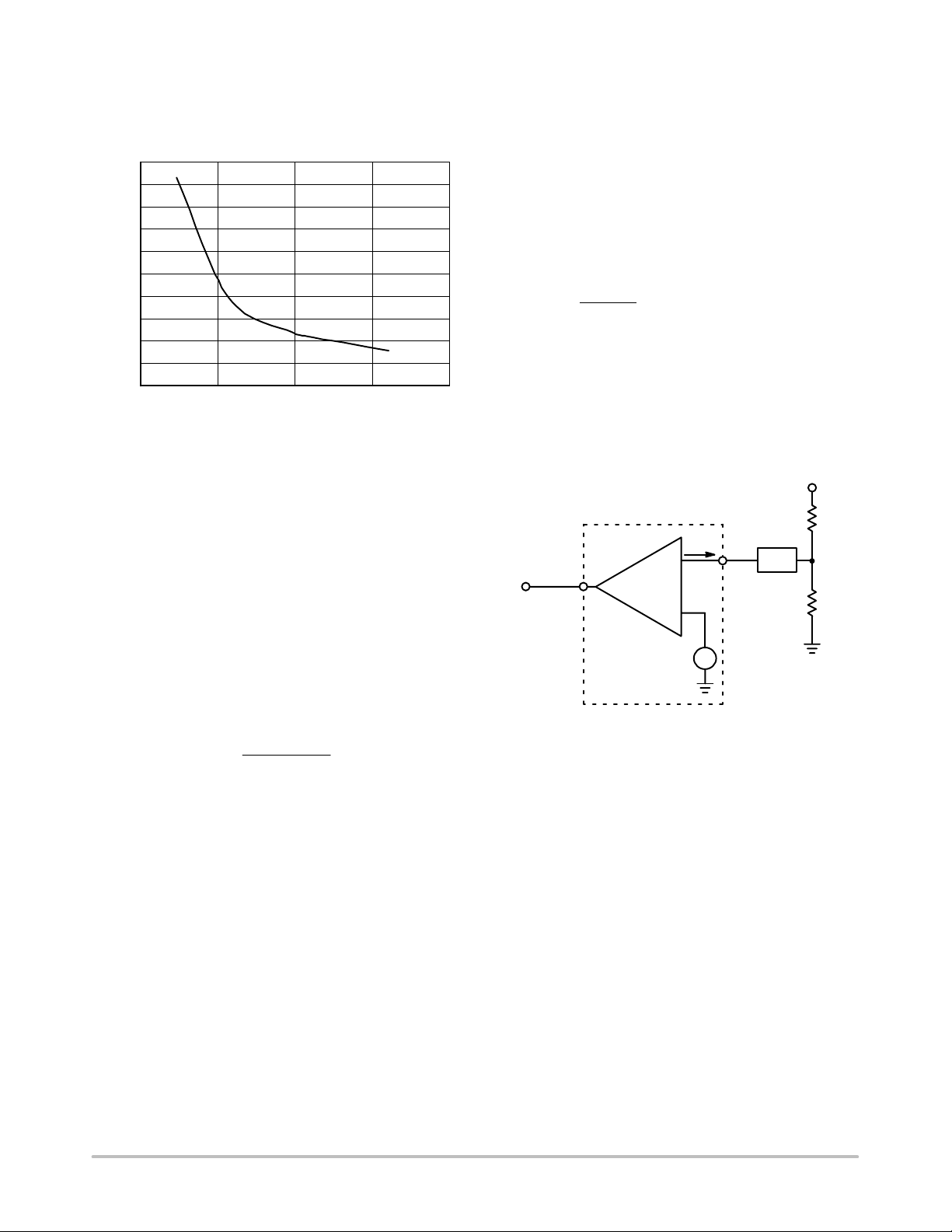

Figure 6 shows typical oscillator frequency vs. CT value.

1000

900

800

700

600

500

400

300

200

Oscillator Frequency (kHz)

100

0

0 200 400 600 800

(pF)

C

T

Figure 6. Typical Performance Characteristics:

Oscillator Frequency vs. C

Component Selection for Feed Forward Ramp

T

FF discharge voltage and FF maximum voltage limit the

maximum voltage rise on the FF pin to 1.5 V typical. This

provides the volt–second clamp feature when the FF pin is

driven by the i nput l ine. I f t he l ine v oltage i s m uch g reater t han

the FF pin voltage, the charge current is approximately equal

to V

/R where R is the resistor connecting the FF pin and

IN

input line. The voltage second clamp then has the form of:

VIN TON 1.5 R C

FF

One can select RCFF to prevent magnetic devices from

saturating.

In a buck or forward converter, the error amplifier output

V

is equal to:

COMP

V

T

V

COMP

OUT

N R C

S

FF

0.3V

where:

N = Transformer turns ratio (use 1 for buck converter)

T

= Switching period

S

This equation shows that the error amplifier output is

independent of the input voltage. Therefore, the system does

not rely on the error amplifier to respond to line variations.

This excludes the delay associated with the error amplifier.

The line regulation is also greatly improved because both

error amplifier and ramp signal can contribute to DC

regulation.

Select Feedback Voltage Divider

As shown in Figure 7, the voltage divider output feeds the

FB pin which connects to the inverting input of the error

amplifier. The non–inverting input of the error amplifier is

connected to a 1.263 V reference voltage. The FB pin has an

input current which has to be taken into account for accurate

output voltage programming. The following equation can be

used to calculate the R1 and R2 value:

R2

R1 R2

V

OUT

1.263

∇

where ∇ is the correction factor

Ri R1R2 Ier

∇

Ri = DC resistance between the FB pin and the voltage

divider output, as shown in Figure 7.

Ier = FB pin input current, 1.3 µA typical.

V

OUT

R1

Ier

–

COMP

Figure 7. The Feedback Voltage Divider Design Has

to Consider the Error Amplifier Input Current

Thermal Management

Error

Amplifier

1.263 V

+

FB

Ri

R2

+

–

The CS51227 will enter thermal shutdown when the

junction (die surface) temperature exceeds 150°C, typical.

10°C typical thermal hysteresis will prevent part cycling, or

a “chattering” startup near the shutdown temperature.

Junction temperature is a function of the ambient

temperature, thermal resistance of the die and package, and

the power dissipated by the package and leads.

http://onsemi.com

7

Page 8

–Y–

–Z–

CS51227

PACKAGE DIMENSIONS

SO–8

D SUFFIX

CASE 751–07

–X–

A

58

B

1

S

0.25 (0.010)

4

G

C

SEATING

PLANE

0.10 (0.004)

H

D

0.25 (0.010) Z

M

Y

SXS

ISSUE V

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE MOLD

PROTRUSION.

M

M

Y

K

N

X 45

M

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL IN

EXCESS OF THE D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

PACKAGE THERMAL DATA

Parameter

R

Θ

JC

R

Θ

JA

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

Typical 45 °C/W

Typical 165 °C/W

SO–8 Unit

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

CS51227/D

8

Loading...

Loading...