Page 1

查询CS51220供应商

CS51220

Feed Forward Voltage

Mode PWM Controller

with Programmable

Synchronization

CS51220 is a single output PWM Controller with switching

frequency up to 500 kHz. The feed forward voltage mode control

provides excellent line regulation for wide input range. This PWM

controller has a synchronization output allowing programmable phase

delay. For overcurrent protection, the “soft hiccup” technique

effectively limits the output current with maximum flexibility. In

addition, this device includes such features as: soft start,

pulse–by–pulse current limit, programmable foldback current limit,

volt–second clamping, maximum duty cycle, overvoltage and

undervoltage protection, and synchronization input. The CS51220 is

available in 16 SO narrow surface mount package.

Features

• Constant Frequency Feed Forward Voltage Mode Control

• Programmable Pulse by Pulse Overcurrent Limit

• Programmable Foldback Overcurrent Limit with Delay

• Soft Hiccup Overcurrent Protection with Programmable Foldback

• Frequency Synchronization Output with Programmable Phase Delay

• Synchronization Input to Higher or Lower Frequency

• Direct Connection to External Opto Isolators

• Logic Gate Output Signal

• Accurate Volt–Second Clamping

• Programmable Soft Start

• Logic Input to Disable IC

• Line Overvoltage and Undervoltage Monitoring

• 3.3 V 3% Reference Voltage Output

http://onsemi.com

16

1

SO–16

D SUFFIX

CASE 751B

PIN CONNECTIONS AND

MARKING DIAGRAM

1

O

GND

CC

REF

SET

SENSE

UV

A = Assembly Location

WL, L = Wafer Lot

YY, Y = Year

WW, W = Work Week

CS51220

AWLYWW

16

SYNCOV

V

SD

SSV

COMPV

FFI

DISABLEI

SYNCIOV

C

T

Semiconductor Components Industries, LLC, 2002

January , 2002 – Rev. 6

ORDERING INFORMATION

Device Package Shipping

CS51220ED16

CS51220EDR16

1 Publication Order Number:

SO–16

SO–16 2500 Tape & Reel

48 Units/Rail

CS51220/D

Page 2

CS51220

R4

D3

10

MMSD4148T1

L1

T1

D4

MMSD4148T1

100

R13

OUT

V

6.8 µH

D5B

MBRB2535CTL

70:1

R15

10 k

36

R14

C12

100 pF

3.3 V @

T2

5.0 A

C17

R23

330 µF

10

20:5

RTN

V

C18

330 µF

D5A

MBRB2535CTL

C12

680 pF

O

R21

R16

U4

10

C10

Q1

DD

V

OUT

DD

INA

V

0.1 µF

40.2 k

C13

100 pF

MTB20N20E

OUT

GNDGND

NCP4414

NC

200 V

C15

R20

R22

0.022 µF

C14

2.21 k

R19

R17

24.3 k

3.92 k

182

100 pF

U3

R18

1.0 K

U2

MOC213

TLV431ASNT1

R24

3.3 k

R3

10

C5

0.1 µF

U1

D2 15 V

R1

L2

100 k

C3

100 V

1.5 µF

36–72 V

1.0 µH

C1

0.2 µF

IN

V

100 V

R2

174 k

GND

Q2

MMFT1N10E

C4

C2

0.1 µF

MMSZ5245B

D1 9.1 V

MMSZ5239B

470 pF

500 V

CC

V

FF

V

SENSE

I

REF

R7

150 k

R5

10 k

O

SS

GND

SYNCI

SYNCO

CS51220

DISABLECOMP

ENABLE

SYNC IN

C7

1000 pF

R8

64.9 k

SYNC OUT

R11

510 k

R9

510 k

SET

OV

UV

I

VSDCTV

C8

390 pF

R6

7.5 k

C6

0.1 µF

R12

R10

11.8 k

15 k

C11

C9

1000 pF

1.0 µF

R23

220

R14

2.0 k

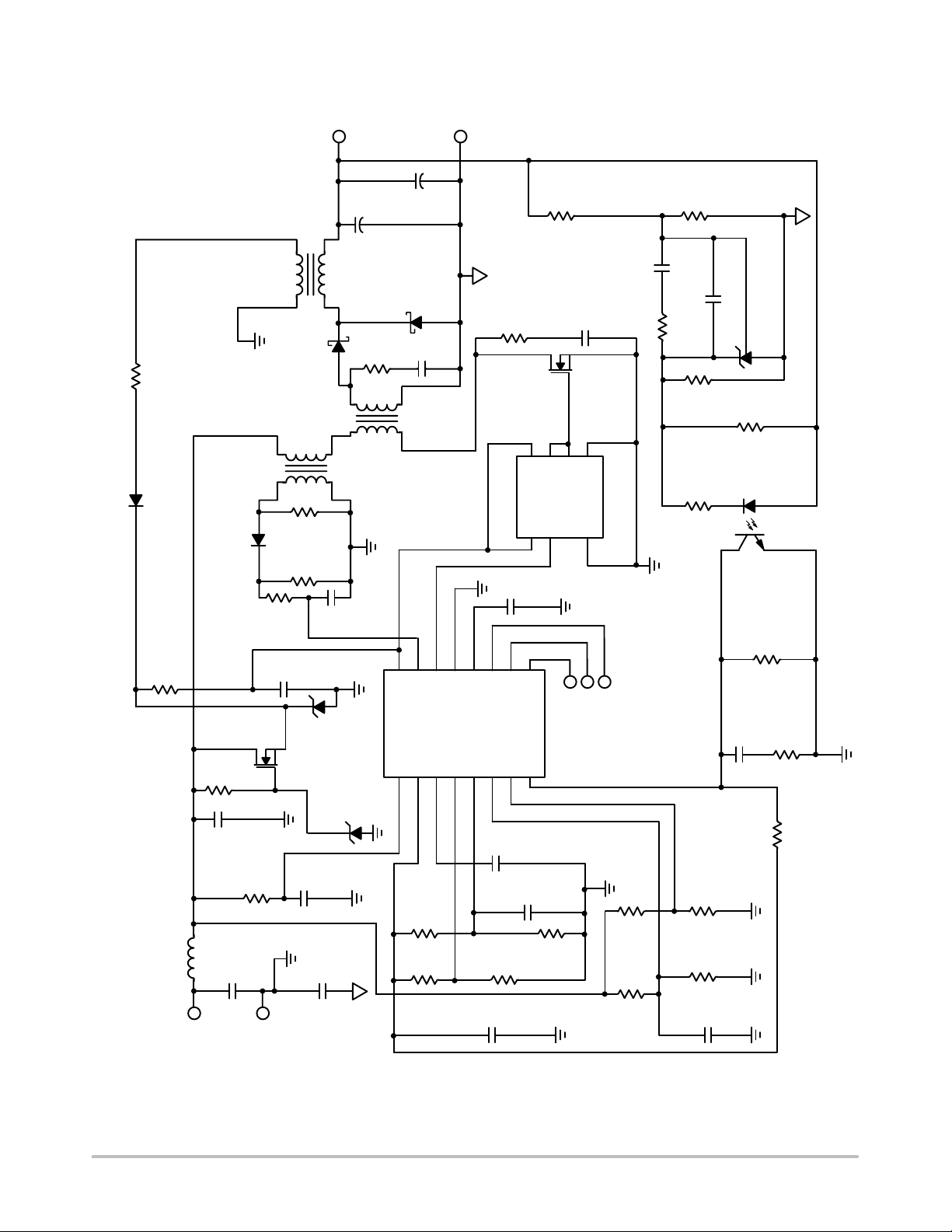

Figure 1. Application Diagram, 48 V to 3.3 V Converter

http://onsemi.com

2

Page 3

CS51220

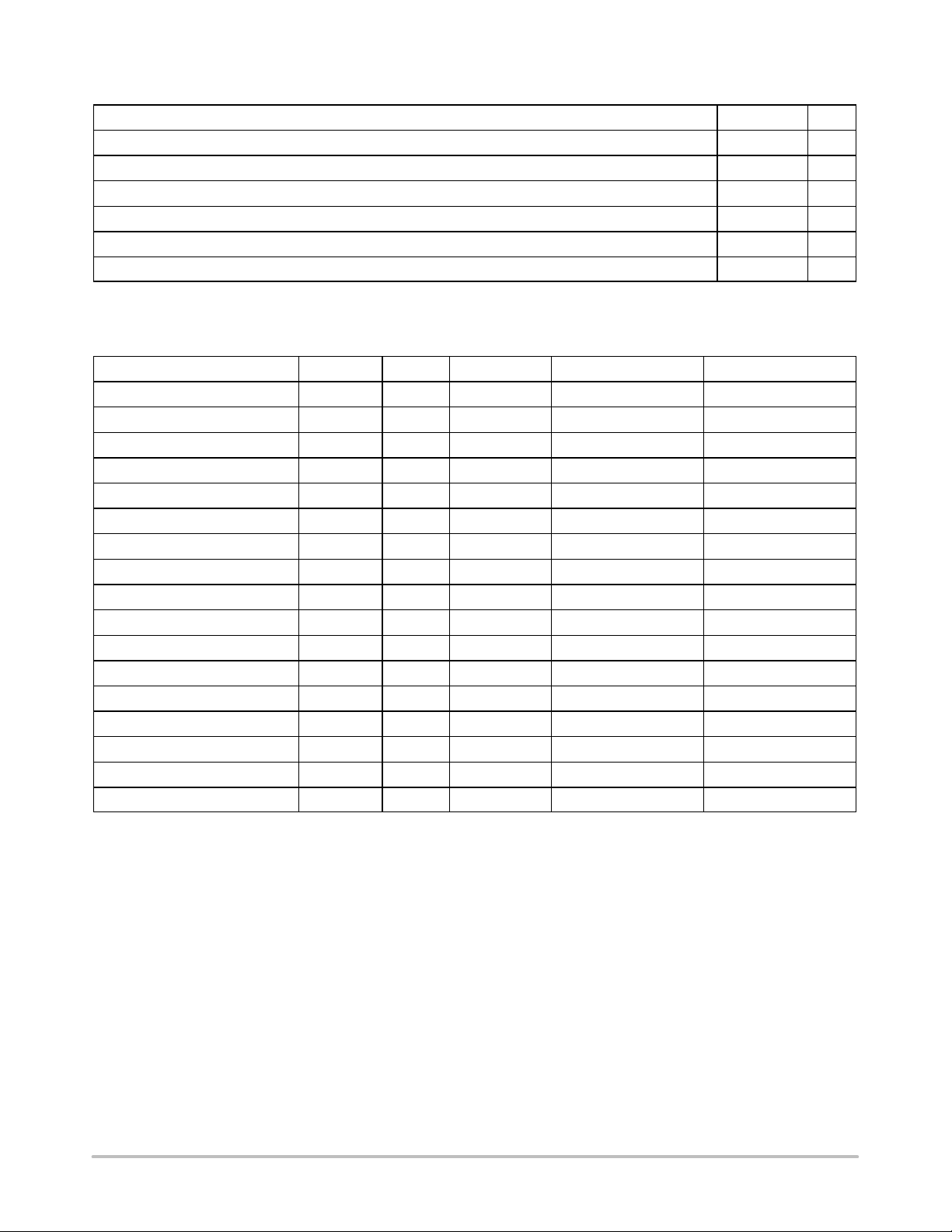

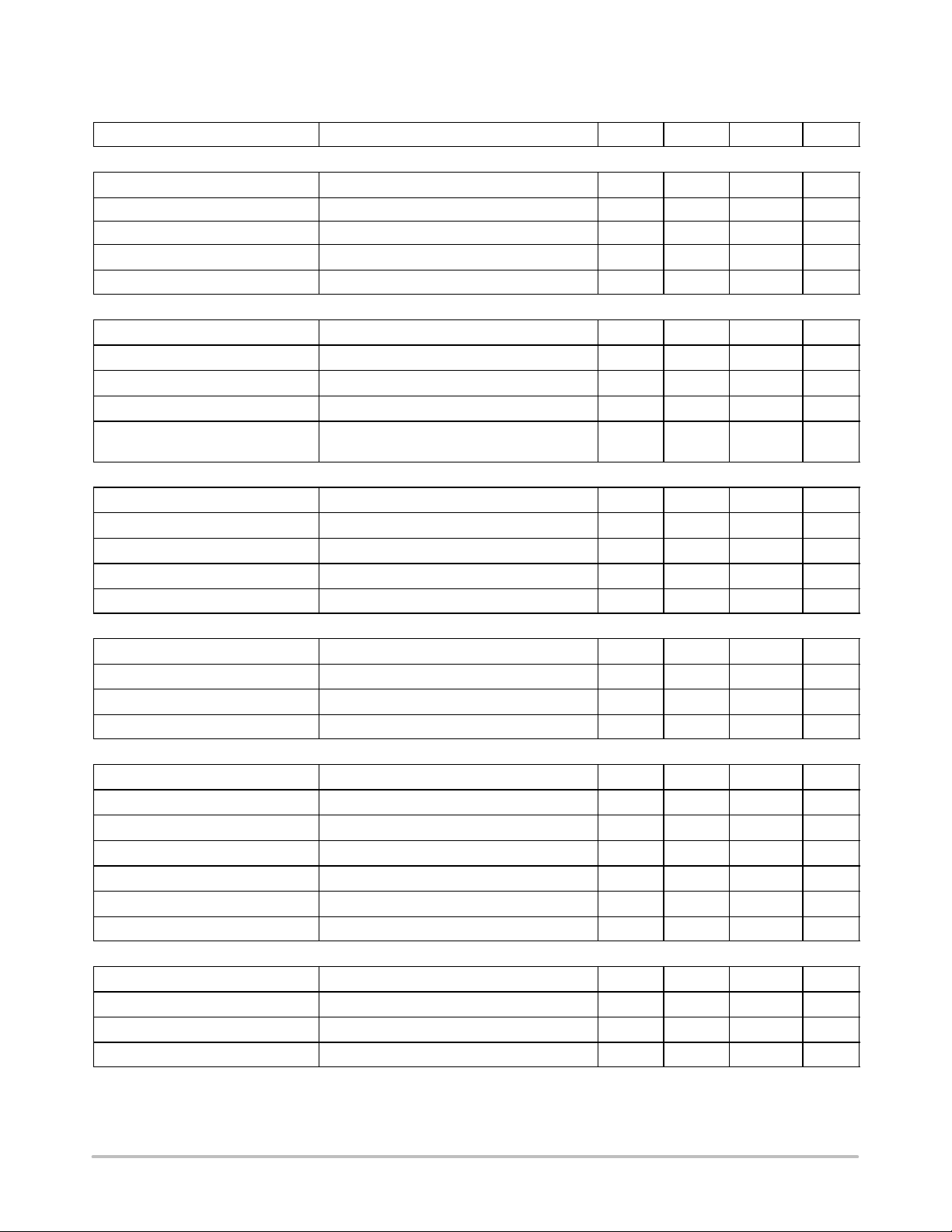

MAXIMUM RATINGS*

Rating Value Unit

Operating Junction Temperature, T

Storage Temperature Range, T

J

S

ESD Susceptibility (Human Body Model) 2.0 kV

Thermal Resistance, Junction–to–Case, R

Thermal Resistance, Junction–to–Ambient, R

Θ

JC

Θ

JA

Lead Temperature Soldering: Reflow: (SMD styles only) (Note 1) 230 peak °C

1. 60 second maximum above 183°C.

*The maximum package power dissipation must be observed.

MAXIMUM RATINGS

Pin Name Pin Symbol V

Gate Logic Output V

Current Sense Input I

Timing Capacitor C

O

SENSE

T

MAX

20 V –0.3 V 100 mA 100 mA

6.0 V –0.3 V 10 mA 10 mA

6.0 V –0.3 V 10 mA 10 mA

Feed Forward FF 6.0 V –0.3 V 10 mA 100 mA

Error Amp Output COMP 6.0 V –0.3 V 10 mA 10 mA

Feedback Voltage V

FB

6.0 V –0.3 V 10 mA 10 mA

Sync Input SYNCI 20 V –0.3 V 10 mA 10 mA

Power Down Input DISABLE 20 V –0.3 V 10 mA 10 mA

Undervoltage UV 6.0 V –0.3 V 10 mA 10 mA

Overvoltage OV 6.0 V –0.3 V 10 mA 10 mA

Current Set I

SET

6.0 V –0.3 V 10 mA 10 mA

Soft Start SS 6.0 V –0.3 V 10 mA 10 mA

Power Supply V

CC

20 V –0.3 V 10 mA 50 mA

Sync Output SYNCO 20 V –0.3 V 100 mA 100 mA

Reference Voltage V

Sync Delay V

REF

SD

6.0 V –0.3 V Internally Limited 10 mA

6.0 V –0.3 V 1.0 mA 1.0 mA

Ground GND N/A N/A 50 mA N/A

V

MIN

I

SOURCE

150 °C

–65 to +150 °C

28 °C/W

115 °C/W

I

SINK

http://onsemi.com

3

Page 4

CS51220

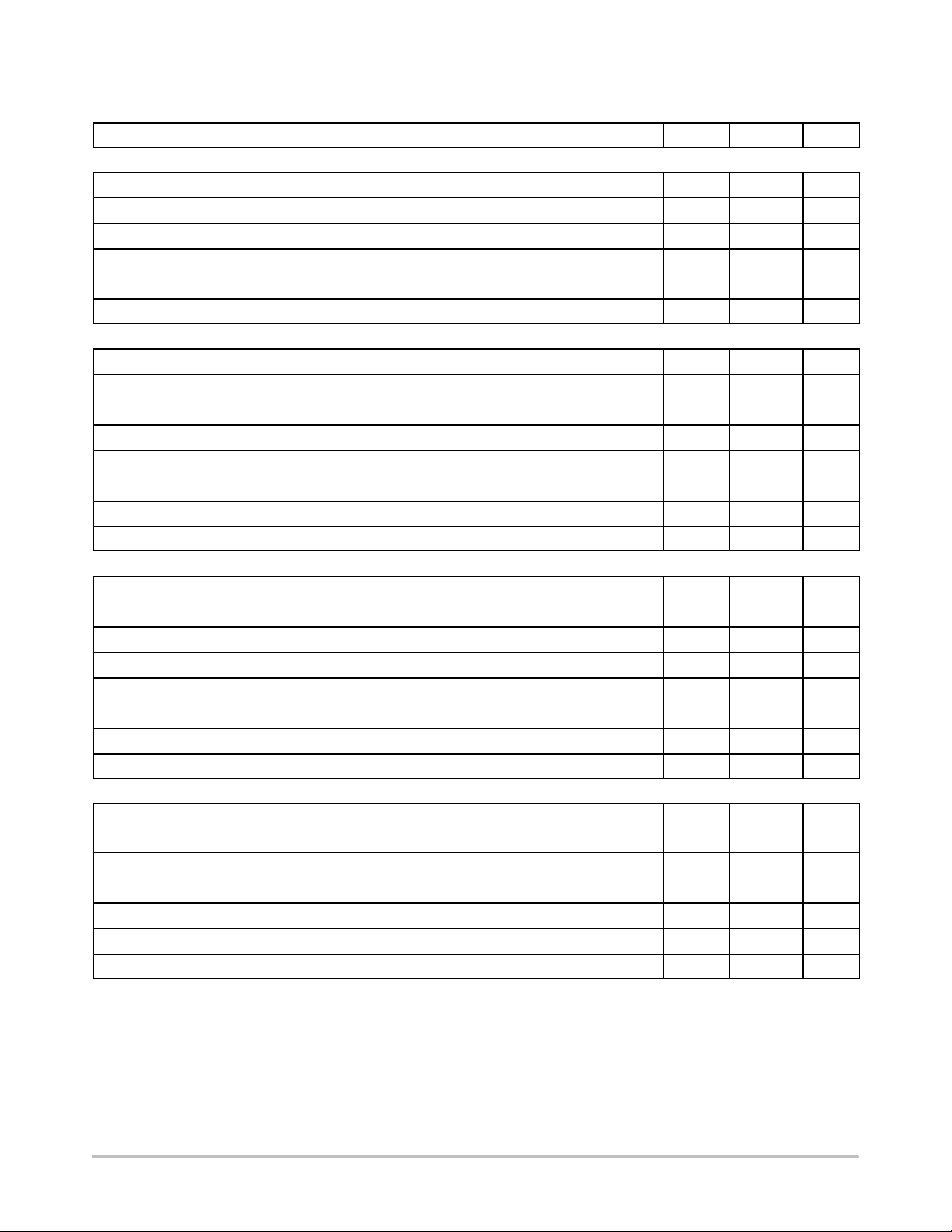

ELECTRICAL CHARACTERISTICS (–40°C < T

< 85°C; –40°C < TJ < 125°C; 4.7 V < VCC < 16 V; CT = 390 pF; unless

A

otherwise specified.)

Characteristic

Test Conditions Min Typ Max Unit

Supply Voltage/Current

Start Threshold – 4.0 4.4 4.7 V

Stop Threshold – 3.3 3.8 4.1 V

Hysteresis Start – Stop 400 600 1000 mV

ICC @ Startup VCC < UVL Start Threshold – – 500 µA

ICC Operating, Low V

ICC Operating, High V

CC

CC

4.7 V < VCC < 10 V – – 7.5 mA

10 V < VCC < 16 V – – 9.0 mA

Reference Voltage

Total Accuracy 0 mA < I

Line Regulation I

REF

Load Regulation 0 mA < I

< 2.0 mA 3.2 3.3 3.4 V

REF

= 2.0 mA – 6.0 20 mV

< 2.0 mA, VCC = 8.0 V – 6.0 15 mV

REF

Operating Life Shift T = 1000 Hrs., Note 2 – 4.0 20 mV

Fault Voltage – 2.8 2.95 3.1 V

V

OK Voltage – 2.9 3.05 3.2 V

REF

V

OK Hysteresis – 50 100 150 mV

REF

Current Limit V

= 2.5 V 2.0 25 65 mA

REF

Oscillator

Frequency Accuracy – 223 266 309 kHz

Temperature Stability Note 2 – 8.0 – %

Max Frequency Note 2 500 – – kHz

Duty Cycle – 80 85 90 %

Peak Voltage Note 2 1.9 2.0 2.1 V

Valley Voltage Note 2 0.85 0.90 0.98 V

Discharge Current VCT = 1.5 V 0.70 0.85 1.05 mA

Charge Current VCT = 1.5 V 127 150 183 µA

Synchronization

SYNCI Input Threshold f

SYNCI Input Resistance V

= 500 kHz 1.0 2.0 3.0 V

SYNC

= 0.5 50 150 250 kΩ

SYNC

Minimum Sync Frequency Reduction of nominal frequency. 25 – – %

Minimum Input Sync Pulse Width – – – 200 ns

SYNCO Output High R

= 5.0 k, VCC = 8.0 V 5.0 6.5 7.5 V

SYNCO

SYNCO Output Low Sink 1.0 mA, VSD = 2.5 V – 0.2 0.4 V

SYNCO Delay Time VCT = 1.5 V, Toggle V

SD

100 200 300 ns

2. Guaranteed by design. Not tested in production.

http://onsemi.com

4

Page 5

CS51220

ELECTRICAL CHARACTERISTICS (continued) (–40°C < T

< 85°C; –40°C < TJ < 125°C; 4.7 V < VCC < 16 V; CT = 390 pF; unless

A

otherwise specified.)

Characteristic UnitMaxTypMinTest Conditions

Output (continued)

High Saturation Voltage VCC – VO, V

Low Saturation Voltage VO – GND, I

Pull Down Resistance I

= 100 µA 25 50 75 kΩ

SINK

= 10 V, I

CC

= 100 µA – 0.7 1.0 V

SINK

= 100 µA – 1.4 2.0 V

SOURCE

Rise Time VCC = 10 V, 1.0 V < VO < 6.0 V; 50 pF load – 35 80 ns

Fall Time VCC = 10 V, 1.0 V < VO < 6.0 V; 50 pF load – 25 50 ns

Feed Forward

Discharge Voltage IFF = 2.0 mA 0.25 0.35 0.45 V

Discharge Current FF = 1.0 V 2.0 10 30 mA

FF to VO Delay Connect VO to FF, Measure min. pulse width. 50 75 150 ns

FF Clamp Voltage – 1.15 1.3 1.45 V

COMP Switch Off Voltage VFF = 0.2 V, Ramp down V

VFF = 0.2 V, Ramp down V

COMP

COMP

–40°C

0.8

1.4

1.4

1.6

1.7

1.7

Overcurrent Protection

Overcurrent Comparator DC Offset – 180 200 215 mV

I

Attenuation ∆V

SENSE

I

Input Resistance ∆V

SENSE

I

to GATE Delay V

SENSE

I

Foldback Sink Current I

SET

/∆V

ISET

ISENSE

= 0 V 40 82 150 kΩ

ISENSE

= 0.5 V 50 100 175 ns

ISET

= 0.5 V, SS = 1.5 V and I

SET

= 0.5 V 12 15 18 µA

SENSE

0.9 0.94 0.98 V/V

External Voltage Monitors

Overvoltage Threshold OV pin increasing 1.9 2.0 2.1 V

OV Hysteresis Current OV = 2.15 V 10 12.5 15 µA

Undervoltage Threshold UV pin decreasing 0.95 1.00 1.05 V

UV Hysteresis – 25 75 125 mV

Soft Start

Charge Current SS = 1.5 V 35 50 65 µA

Discharge Current SS = 1.5 V, UV = 1.5 V 4.0 5.0 7.0 µA

OC Delay Discharge Current SS = 2.85 V, I

SET

= 0.5, I

= 0.5 V 35 50 65 µA

SENSE

SS Clamp Voltage – 2.7 2.9 3.1 V

Discharge Voltage – 0.25 0.3 0.35 V

Soft Start Fault Voltage OV = 2.5 V or UV = 0.85 V – 0.1 0.2 V

Hiccup Delay Discharge Voltage – 0.08 0.1 0.12 V

Disable

DISABLE Input Threshold – 1.0 2.0 3.0 V

DISABLE Input Resistance V

DISABLE Operation Current, Low V

DISABLE Operation Current, High V

CC

CC

4.7 V < VCC < 10 V – – 800 µA

10 V < VCC < 16 V – – 1600 µA

= 0.5 V 50 150 250 kΩ

DISABLE

V

V

http://onsemi.com

5

Page 6

PACKAGE PIN #

16 Lead SO Narrow

1 V

2 GND Ground.

3 V

4 V

5 I

6 I

7 OV Overvoltage protection monitor.

8 UV Undervoltage protection monitor.

9 C

10 SYNCI By applying sync pulses to this pin, the IC can be synchro-

CS51220

PACKAGE PIN DESCRIPTION

PIN SYMBOL FUNCTION

O

CC

REF

SET

SENSE

T

Logic output connecting to external gate driver.

Supply Voltage.

3.3 V reference voltage output.

Voltage at this pin sets pulse–by–pulse overcurrent thresh-

old. When the I

time, a sink current is generated at this pin. Along with exter-

SENSE

exceeds I

SET

nal resistors, this current provides a foldback overcurrent

threshold. The sink current is disabled periodically for restart.

Current sense input for overcurrent protection.

Timing capacitor CT determines oscillator frequency.

nized to frequencies ranging from 25% slower to several

times faster than the internal oscillator frequency.

for a sustained period of

11 DISABLE Disable mode input pin. A voltage greater than 3.0 V turns off

the whole IC.

12 FF Feed forward input for PWM ramp. This pin allows external

connection to make the ramp adjustable to the input line.

13 COMP This pin carries feedback error signal from an external ampli-

fier. Internally, it connects to the PWM controller.

14 SS A capacitor is connected to this pin for Soft Start and soft

hiccup timing.

15 V

SD

The voltage at this pin programs the delay of the SYNCO

output in reference to the internal oscillator.

16 SYNCO Sync output.

http://onsemi.com

6

Page 7

V

CC

DISABLE

I

SENSE

I

SET

COMP

GND

FF

SYNCO

V

SD

SYNCI

C

CS51220

UVL Comparator

+

-

+

–

X0.94

+

–

200 mV

+

I

LIM

-

Ifoldback

1.3 V

SS

MIN

-

+

PWM COMP

OSC

T

= 3.3 V

V

REF

OC

Soft

Hiccup

CLK

RESET DOMINANT

S

R

-

+

V

REF

SS

Discharge

SS low

SS

Q

COMP

3.1 V

Off

SS

Clamp

RQ

Fault

Latch

Q

S

SET DOMINANT

-

+

OV COMP

UV COMP

SS low

SS

COMP

-

+

Charge

SS

Discharge

+

2.0 V

1.0 V

0.3 V

V

REF

SS

OV

UV

V

O

Figure 2. Block Diagram

http://onsemi.com

7

Page 8

CS51220

APPLICATIONS INFORMATION

THEORY OF OPERATION

Feed Forward Voltage Mode Control

Conventional voltage mode control uses a fixed ramp

signal for pulse width modulation, typically utilizing the

oscillator output as the ramp signal. Since the only feedback

signal comes from the output, this results in inferior line

regulation and audio susceptibility. A significant

improvement in line regulation and line transient response

can be achieved using Feed Forward Voltage Mode Control,

implemented using the CS51220 controller.

The enhancement comes from generating the ramp signal

using a pull–up resistor from the FF pin to the line voltage

and a capacitor to ground. The slope of the ramp then

depends on the line voltage. At the start of each switch cycle,

the capacitor connected to the FF pin is charged through the

resistor connected to the input voltage. Meanwhile, the V

pin goes high to turn on a power mosfet through an external

gate driver. When the rising FF pin exceeds the COMP input

pin, as driven through the regulation feedback loop, VO goes

low and turns off the external switch. Simultaneously, the FF

capacitor is quickly discharged and set for the next switching

cycle.

Overall, both input and output voltages control the

dynamics of the duty cycle. As illustrated in Figure 3, with

a fixed input voltage the output voltage is regulated solely

by the error amplifier. For example, an elevated output

voltage pulls down the COMP pin through an external error

amplifier. This in turn causes duty cycle to decrease. On the

another hand, if the input voltage varies, the slope of the FF

pin ramp reacts correspondingly and immediately. As an

example shown in Figure 4, when the input voltage goes up,

the slope of the ramp signal increases, which reduces duty

cycle and counteracts the change. For line variations, feed

forward control requires less response from the error

amplifier, which improves the transient speed and DC

regulation.

V

OUT

COMP

FF

V

IN

C

T

V

O

Figure 3. Pulse Width Modulated by the Output

Voltage with a Constant Input Voltage

O

V

IN

COMP

FF

V

OUT

C

T

V

O

Figure 4. Pulse Width Modulated by the Input Voltage

with a Constant Output Voltage

The feed forward feature can also be employed for

volt–second clamp, which limits the maximum product of

input voltage and switch on time. This clamp is used in

circuits, such as forward and flyback converters, to prevent

the transformer from saturating. Calculations used in the

design of the volt–second clamp are presented in the Design

Guidelines section on page 12.

http://onsemi.com

8

Page 9

CS51220

V

Power Up and Fault Conditions

CC

During power up, an undervoltage lockout comparator

monitors V

entire IC), until the VCC voltage reaches its start threshold.

Hysteresis prevents “chattering” caused by the source

impedance of the VCC supply. V

using the Disable input pin, which is active high. An internal

pull–down resistor ensures the IC will start up if the Disable

pin is allowed to float. In V

output stage is held low by the output pull–down resistance.

After V

cause fault mode:

1. The 3.3 V V

2. The OV pin rises above overvoltage threshold, or

3. The UV pin falls below undervoltage threshold.

Fault detection will cause the VO output to go low and the

SS pin to discharge. The UV and OV inputs are typically

used to monitor the input line voltage. The undervoltage

comparator has a built–in hysteresis voltage, while the

hysteresis for the OV comparator is programmable through

a current sourced from the pin when above the threshold, and

the equivalent external resistance. The fault condition can

only be reset after the SS pin has been completely discharged

and all faults have been removed.

After a fault is removed or upon initial startup, the SS pin

charges at a rate determined by an internal charge current

and an external capacitor. The rising voltage on the SS pin

will override the regulation feedback voltage on the COMP

pin and clamp the duty cycle, helping to reduce any in–rush

current during startup. The duration of the Soft Start is

typically set with a capacitor from 0.01 µF to 0.1 µF.

Overcurrent Protection

The CS51220 uses the “soft hiccup” technique to provide

an adjustable and predictable overcurrent limit. By choosing

external component values the designer can select

pulse–by–pulse current limit, soft hiccup current limit or

hard hiccup limit.

Normal pulse–by–pulse current limit can be obtained by

selecting the I

and disables V

CC

turns on, there are three conditions that can

REF

is below regulation,

REF

resistor values for a low Thevenin

SET

, (which in turn disables the

REF

can also be disabled

REF

or Disable lockout mode, the

CC

resistance to the I

pin. However with normal

SET

pulse–by–pulse current limit, the secondary currents during

short circuits may be several times the maximum output

current.

Soft hiccup limit can be obtained by setting the I

SET

resistor values for a higher thevenin resistance. During

overcurrent conditions, the I

level will fold back, after a

SET

short delay , to reduce the pulse by pulse threshold. If desired,

the short circuit current can be chosen to be equal to or even

less than the maximum output current. During soft hiccup

the circuit will periodically disable the foldback and attempt

to restart.

Hard hiccup limit can be obtained by setting the I

resistor values so that the I

pin is held below 200 mV

SET

during foldback. During overcurrent conditions, the I

SET

SET

level will fold back, after a short delay, preventing any gate

pulses. When the SS capacitor is completely discharged, the

circuit will attempt restart. This configuration provides the

lowest power dissipation during short outputs.

The circuit functions can be best described by discussing

the block diagram and illustrations of expected waveforms.

Actual waveforms, values and circuit configurations from a

design will be used. The design is from the 5.0 V supply of

a dual synchronized converter.

The current is monitored with a voltage at the I

The I

signal i s s lightly a ttenuated D C s hifted b y 2 00 m V,

SENSE

SENSE

pin.

and is c ompared w ith the t hreshold v oltage p rogrammed b y the

voltage at the I

pin. If the current signal reaches the

SET

threshold voltage, the overcurrent comparator resets the V

latch and t erminates the VO pulse. T he o vercurrent c omparator

has a maximum common mode input voltage of 1.8 V.

However, an I

voltage b elow 1 .0 V i s d esirable f or r educing

SET

the comparator’s propagation delay. During initial turnon of

the power supply, normal pulse–by–pulse overcurrent control

is used to protect the power supply switches. This is

accomplished by comparing the voltage at the I

the voltage at t he I

pin and using this to limit the duty factor

SET

SENSE

input to

of VO, the gate drive signal. This current limit control is

maintained until the SS voltage reaches 2.9 V.

O

http://onsemi.com

9

Page 10

CS51220

The block diagram of the soft hiccup circuit is shown in

Figure 5. When o vercurrent o ccurs a nd t he S S i s a bove 2 .9 V,

the OC pulses set the OC latch. The output of the OC latch

turns on the O C d elay d ischar ge c urrent t o r amp d own t he S S

voltage. This SS discharge ramp down is at a rate of 50 µA

while the SS voltage is a bove 2 .8 V. The level between 2.9 V

and 2.8 V is called the hiccup delay discharge voltage. The

time to cross this voltage creates a short delay. This delay is

useful so that a quick transient overcurrent condition can be

controlled and still allow the s upply t o r eturn i mmediately t o

normal operation. After reaching t he h iccup d elay discharge

voltage, the SS current is reduced to 5.0 µA and t he I

foldback current is turned on at 15 µA. It is the I

foldback current that adjusts the I

new lower I

current limit level. See Figure 6 for

SENSE

level to establish a

SET

SET

SET

details.

SS

OC

CLK

SS low

2.9 V

2.8 V

+

–

Peak COMP

Reset

Trig

One Shot

–

+

Delay COMP

N00C

S

Q

R

OC Latch

ON

SS

Discharge

Foldback

The NOOC or SS low (VSS < 0.3 V) signal can reset OC

latch at any time. This event turns off I

foldback and

SET

allows the recharging of the SS capacitor. Therefore, the IC

allows the power supply to restart periodically or after the

overcurrent condition is cleared. The OC latch can not be se t

until the SS capacitor is fully charged.

To implement “hard hiccup” which disables the V

completely when the SS voltage is ramping down, select a

resistor value greater than 3.3 V/I

saturate the internal I

current source. Since the saturation

SET

voltage is less than the DC shift applied to the I

for R1 in Figure 6, and

SET

SENSE

signal,

the OC comparator output is always high and in turn keeps

the VO low. Figure 7 demonstrates the interactions among

the voltage of SS, I

and internal signal OC. Figure 8

SET

further describes the specifications associated with the soft

hiccup. The ratio among the charge time, delay time and

discharge time is given at the bottom of Figure 8.

2.9 V

2.8 V

0.3 V

I

SET

SS

O

Figure 5. The Block Diagram of the Soft

Hiccup Operation

A circuit monitors the OC pulses. If the OC pulses cease

for 50 µs, the NOt–OverCurrent (NOOC) signal is

generated. This NOOC signal resets the OC Latch and

allows the SS capacitor to charge back up allowing the

output to reestablish regulation.

For an equivalent circuit shown in Figure 6, the I

SET

current reduces the overcurrent threshold and sets the new

threshold at

V

I(SET)

(3.3 I

I

SET

SET

I

SET

R1)

V

REF

Pin

R1

R2

Figure 6. The Voltage Divider Used at the I

Pin Allows the I

Foldback Current to

SET

Reduce the Overcurrent Threshold

R2

(R1 R2)

SET

OC

50µs

Figure 7. Illustrative Waveforms of the

Soft Hiccup Operation

Charge Voltage

Charge

Current

Discharge Voltage

26

OC Delay

Dischage

Current

Dischage

Current

1 250

Figure 8. The SS Pin Voltage Under Ramp

Up and Overcurrent Condition and

Associated Specifications.

Hiccup Delay

Discharge Voltage

http://onsemi.com

10

Page 11

CS51220

The effect of the soft hiccup can be observed in Figure 9,

which shows the o utput v oltage a s l oad i ncreases. T he o utput

is maintained a t t he r egulation v alue o f 5 .0 V u ntil i t g oes i nto

current limit. At the point of overcurrent inception (A), the

current limit level changes to a lower level (B). The

switchback to a lower current limit level can be seen as the

bottom curve in Figure 9.

6

5

4

3

2

Output Voltage (V)

1

0

0

B

2

Load Current (A)

Figure 9. Overcurrent In a 5.0 V Output

Converter Using Soft Hiccup

46

A

A typical overload scenario is shown in Figure 10. The top

trace is the voltage on the Soft Start (SS) pin. The initial high

discharge rate can be seen transitioning to a 40 ms discharge

period. During this period the I

establishes a lower

SET

current limit level. The bottom trace shows the output

current. The initial current spike is the output capacitors

discharging. The next level around 4.0 A is the short circuit

current level set by the I

current. The output then turns

SET

off allowing the current to reduce to a level that does not

cause overcurrent pulses. This releases the SS pin to ramp

back up. During ramp up, the output is still shorted as noted

by the 8.0 A current level. When SS reaches the 2.9 V level,

the short is again recognized and I

is turned back on

SET

shifting the short circuit current level.

Figure 10. Over–Load Current and

Soft Start Waveforms

The middle trace is a digitizing ‘scope trace of the current

sense line. The scope interprets the voltages as an average

voltage. This voltage is actually a narrow duty cycle peak

voltage representing the peak current level in the switching

transistor. The a ctual p eak v oltages c an b e s een i n the F igure

11. The peaks are 0 .85 V a t f ull l oad, r educing t o 0 .6 V p eak

at the reduced short circuit level. The 1.1 V peak is the full

short circuit c urrent w hile S S r amps b ack u p. T he 0 .32 V l evel

is the normal load resistance, while I

is still o n. T he 1.0 V

SET

surge is created by ramp up into a normal 5.0 A load and

followed by the 0.85 V at normal load.

Peak Detect Setting

Figure 11. Over–Load Current and

I

Voltage

SENSE

Oscillator and Synchronization

The switching frequency is programmable through a

capacitor connected to the CT pin. When the CT pin voltage

reaches peak voltage (2.0 V), the internal discharge current

discharges the C

capacitor and VO stays low. When the C

T

voltage declines to valley voltage (0.9 V), the current source

toggles to char ge current and ramps up the CT pin. This starts

a new switching cycle. The duty cycle of the oscillator

determines the maximum PWM duty cycle.

The switching frequency of the IC can be synchronized to

an external frequency presented to the SYNCI pin. When

pulses with amplitude over SYNCI input threshold are

detected, the C

capacitor and the V

pin immediately ramps down the external

T

pin is forced low. A new switching

O

cycle begins when the CT pin reaches valley voltage. During

synchronization, the oscillator charge current is reduced by

80 µA, while discharge current is increased by 80 µA. This

effectively slows down the internal oscillator to avoid any

race condition with the sync frequency. As a result, the sync

frequency can be either higher or lower than the internal

oscillator frequency. CS51220 is able to synchronize up to

500 kHz and down to 25% below C

frequency. The

T

maximum duty cycle clamp is raised to 92% in

synchronization mode. The original oscillator frequency is

restored upon the removal of sync pulses.

T

http://onsemi.com

11

Page 12

CS51220

Figure 12. Synchronization Input Timing

Figure 12 shows the sync input from one CS51220 into

another. The delay between receiving the sync input and the

start of the next switching cycle is 423 ns. This delay must

be taken into account when establishing the total delay

between two regulators.

The SYNCO p in p rovides o utgoing s ynchronization p ulses

whose delay c an b e p rogrammed b y s etting t he v oltage o n t he

V

pin. The feature allows two converters to run at

SD

interleaved phases. This implementation significantly

reduces the input ripple, and thus the number of input

capacitors. The phase delay is achieved by turning on

SYNCO output only a fter the C

voltage. Therefore, the phase delay varies linearly with the

VSD voltage. The SYNCO output is reset during the falling

edge of the CT pin. For minimum phase delay ( ~ 2 40 n s ), t ie

the VSD pin to the ground. To entirely disable the SYNCO

output, connect the V

pin to V

SD

The waveform in Figure 13 shows the CT ramp crossing

the VSD voltage set at 1.41 V.

pin v oltage r eaches t he V

T

.

REF

SD

The desired effect on the input ripple is illustrated in

Figure 14. This is the input current for two power converters

operating from a 36 V line.

Figure 14. Input Current Ripple with

Different Overlap Conditions

The top waveform in Figure 14 is the input current with

the two supplies operating out of phase. The next down

shows the same supplies but with both conduction times

occurring simultaneously. The greatly increased ripple

current can be observed. The last two waveforms are the two

converters shown individually when operating out of phase.

DESIGN GUIDELINES

Program Volt–Second Clamp

Feed forward voltage mode control provides the

volt–second clamp which clamps the product of the line

voltage and switch on time. For t he c ircuit s hown i n F igure 1 5,

the charging c urrent o f t he CFF ca n b e c o nsi dere d as a constant

current equal to VIN/R

, provided VIN is much greater than

FF

the FF pin voltage. Then the volt–second clamp provided by

CS51220 is given by

VINT

ON(MAX)

1.0RFFC

FF

Figure 13. Synchronization Output Timing

The delay from the point of crossing to the output of the

sync signal is 240 ns. The time for the sync out voltage is

measured at the +2.0 V level, which is the level that triggers

the next CS51220.

http://onsemi.com

V

IN

RFF

FF Pin

CFF

Figure 15. An RC Network Provides Both

Volt–Second Clamp and Feed Forward Control

Select the time constant of the FF pin RC network to

provide desirable volt–second clamp.

12

Page 13

CS51220

Program Oscillator Frequency

CS51220 requires an external capacitor to program the

oscillator frequency. The internally trimmed

charge/discharge current determines the maximum duty

cycle. The capacitor for a required switching frequency f

can be calculated by:

13400

CT

95

f

S

where:

= Timing capacitance is in pF

C

T

fS = Switching frequency is in kHz

Figure 16 shows the relationship of CT and fS.

600

550

500

450

400

350

300

Frequency (kHz)

250

200

150

100

100 300 400 500 600

200

CT (pF)

Figure 16. Operating Frequency

Synchronized Dual Converters with Soft Hiccup and

Feed Forward

The circuits shown in Figures 17 and 18 illustrate typical

applications for a dual output supply using independent but

synchronized converters. These circuits demonstrate the use

S

of the soft hiccup, feed forward, volt–second control and

synchronization features of the CS51220.

In Figure 17, the feed forward circuit has a volt–second

constant of 8 2 V / µs. This would limit the duty factor to 0.51

at 48 V input. With a turns ratio of 4:1 on the power

transformer and 48 V input, a duty factor of 0.46 is required

for 5.0 V output. This converter serves as the master

synchronization generator. The voltage on the V

establishes the delay as it is compared to the ramp generated

on the CT pin.

Adjustable synchronization allows the conduction time

for the two converters to be adjusted so that they are not on

at the same time. This greatly reduces the ripple current from

the 48 V source.

In Figure 18, the feed forward circuit has a volt–second

constant of 6 3 V / µs. This would limit the duty factor to 0.39

at 48 V input. With a turns ratio of 4:1 on the power

transformer and 48 V input, a duty factor of 0.33 is required

for 3.3V output.

SD

pin

http://onsemi.com

13

Page 14

CS51220

IN

V

TP1

R23

D2

10

MMSD4148T1

L1

T1

D1

MMSD4148T1

R12

100

R11

OUT

V

6.8 µH

D5B

MBRB2535CTL

T2

70:1

R10

10 k

36

C6

5.0 V @

5.0 A

100 pF

C11

R15

330 µF

10

TP2

C9

330 µF

D5A

MBRB2535CTL

C12

680 pF

20:5

RTN

O

V

40.2 k

OUT

GNDGND

NCP4414

NC

C36

C10

TP3

200 V

100 pF

1000 pF

C14

R18

0.022 µF

10 k

R20

R48

R16

13.3 k

1.25 V

C13

3.92 k

182

100 pF

U3

R17

U2

TLV431ASNT1

1.0 K

MOC213

R13

U4

R19

10

Q2

IRF634S

DD

V

OUT

DD

INA

V

C7

0.1 µF

TP4

BST1

GND

R22

10

C2

0.1 µF

U1

D3 15 V

R1

L2

100 k

C1

100 V

1.5 µF

36–72 V

1.0 µH

C16

0.2 µF

IN

V

Q1

MMFT1N10E

MMSZ5245BT1

D4 9.1 V

MMSZ5239BT1

R6

174 k

100 V

C5

C37

470 pF

0.1 µF

500 V

CC

V

FF

V

SENSE

I

REF

R4

150 k

R2

10 k

O

SS

GND

SYNCI

SYNCO

CS51220

DISABLECOMP

SET

OV

UV

I

VSDCTV

C4

390 pF

C38

1000 pF

C3

7.5 k

0.1 µF

R5

64.9 k

R3

SYNC

ENABLE1

R21

R7

511 k

511 k

SYNC IN

R9

R8

11.8 k

15 k

C35

1000 pF

C18

1000 pF

R14

2.0 k

Figure 17. Additional Application Diagram, 5.0 V Output Converter

Used As Sync Master for the Dual Converter

http://onsemi.com

14

Page 15

CS51220

TP5

R38

D6

10

MMSD4148T1

L3

T3

D7

MMSD4148T1

100

R34

OUT

V

6.8 µH

D8B

MBRB2535CTL

70:1

R36

10 k

36

R35

C23

3.3 V @

T4

100 pF

5.0 A

C26

R39

330 µF

10

TP6

C27

330 µF

D8A

MBRB2535CTL

C25

680 pF

20:5

RTN

O

V

R44

R40

U4

10

V

V

C21

DD

DD

Q3

MTB20N20E

OUT

INA

0.1 µF

40.2 k

OUT

GNDGND

NCP4414

NC

C28

200 V

100 pF

TP7

C29

R43

R45

0.022 µF

2.21 k

R47

R41

24.3 k

C30

2.21 k

182

100 pF

U7

R42

U6

MOC213

C24

1.0 µF

TLV431ASNT1

1.0 K

R48

220

BST1

36–72 V

R37

10

C22

0.1 µF

U5

C32

100 V

1.5 µF

R24

137 k

IN

V

GND

C31

470 pF

CC

V

FF

SENSE

I

REF

R27

150 k

R25

10 k

O

V

SS

GND

VSDCTV

SYNCI

CS51220

SET

UV

I

R26

SYNCO

DISABLECOMP

OV

C20

390 pF

5.11 k

C19

0.1 µF

C39

1000 pF

R28

64.9 k

ENABLE2

SYNC OUT

SYNC

R31

R29

511 k

511 k

R32

R30

C33

11.8 k

15 k

1000 pF

R49

R33

3.3 k

TP8

2.0 k

Figure 18. Additional Application Diagram, 3.3 V Output

Converter Synchronized to the 5.0 V Converter

http://onsemi.com

15

Page 16

CS51220

PACKAGE DIMENSIONS

SO–16

D SUFFIX

CASE 751B–05

ISSUE J

–T–

–A–

16 9

–B–

18

G

K

C

SEATING

PLANE

D

16 PL

0.25 (0.010) A

M

S

B

T

S

8 PLP

0.25 (0.010) B

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

M

S

X 45

R

F

J

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 9.80 10.00 0.386 0.393

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

INCHESMILLIMETERS

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan 141–0031

Phone: 81–3–5740–2700

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

CS51220/D

16

Loading...

Loading...