Page 1

VE-Tract Dual

Assembly Guide

AND9984

This document is intended to be a guide to assemble all

VE−Trac Dual family of modules. It covers the

specifications and requirements for a dual side cooler,

printed circuit boards, terminal connections and assembly.

Applies to the following parts.

Table 1.

NVG800A75L4DSC 750 V, 800 A, T2, HPS

NVG400A120L2SDSC 1200 V, 400 A, T2, HPS

Figure 1.

INTRODUCTION

In order to avoid unnecessary mechanical stress on the

VE−Trac

is important to follow the recommended specifications and

assembly order to install the power module into the end

application power converter. Proper assembly also ensures

good thermal and electrical performance for the power

module assembly.

module, its control leads or the power terminals, it

www.onsemi.com

APPLICATION NOTE

Since the product is only the power module, it should be

noted that this guide will use an example cooler design and

Printed Circuit Board (PCB) to explain the assembly

process. The user has the freedom to design their own

coolers and PCBs to meet their end application

requirements. But the assembly order and certain specific

requirements should be followed.

Recommended mounting order for the assembly:

1. Apply TIM to one side of the power module

2. Align and place power module on 1

cooler

3. Apply TIM to the other side of the power module

4. Align 2

cooler

5. Secure 1

power modules in between

6. Secure PCB to cooler or bracket

7. Solder PCB to power modules

HEATSINK/COOLER REQUIREMENTS

Power dissipated in the module must be effectively

removed from the module without exceeding the maximum

rated operating temperature of the module as specified in its

data sheet. In this section the general requirements for the

cooler is explained and in the following section the assembly

process is explained using an example reference cooler.

nd

half of the cooler to the 1st half of the

st

and 2nd halves of the cooler with the

st

half of the

Figure 2. VE−Trac Dual Power Module Showing

the Top and Bottom View

© Semiconductor Components Industries, LLC, 2019

March, 2021 − Rev. 2

General Specifications for the Cooler

• Dual side liquid cooling is necessary to enable the full

capability of the power module.

• It is necessary to use a thermal interface material between

the power module top and bottom area of the Direct Bond

Copper (DBC) to the cooler surface. It’s necessary to

ensure full coverage of the DBCs to the cooler.

• The specified flatness for the module for top and bottom

clamping area (see Figure 3) is specified as Max. Surface

flatness j 50 mm.

• Mating alignment feature must be included on the cooler

(see Figure 4).

1 Publication Order Number:

AND9984/D

Page 2

AND9984

Table 2. SPECIFICATIONS FOR THE COOLER

Max. Cooler

Roughness Rz [mm]

Clamping Area

RED + BLUE AREA 10 50 10 760 7

BLUE AREA 10 50 10 760 5.4

per ISO 4287

Min. Cooler Flatness

[per 100 mm]

per ISO 1101

Max. Step [mm]

per ISO 4287

Minimum

Clamping

Force [N]

Maximum

Clamping

Force [kN]

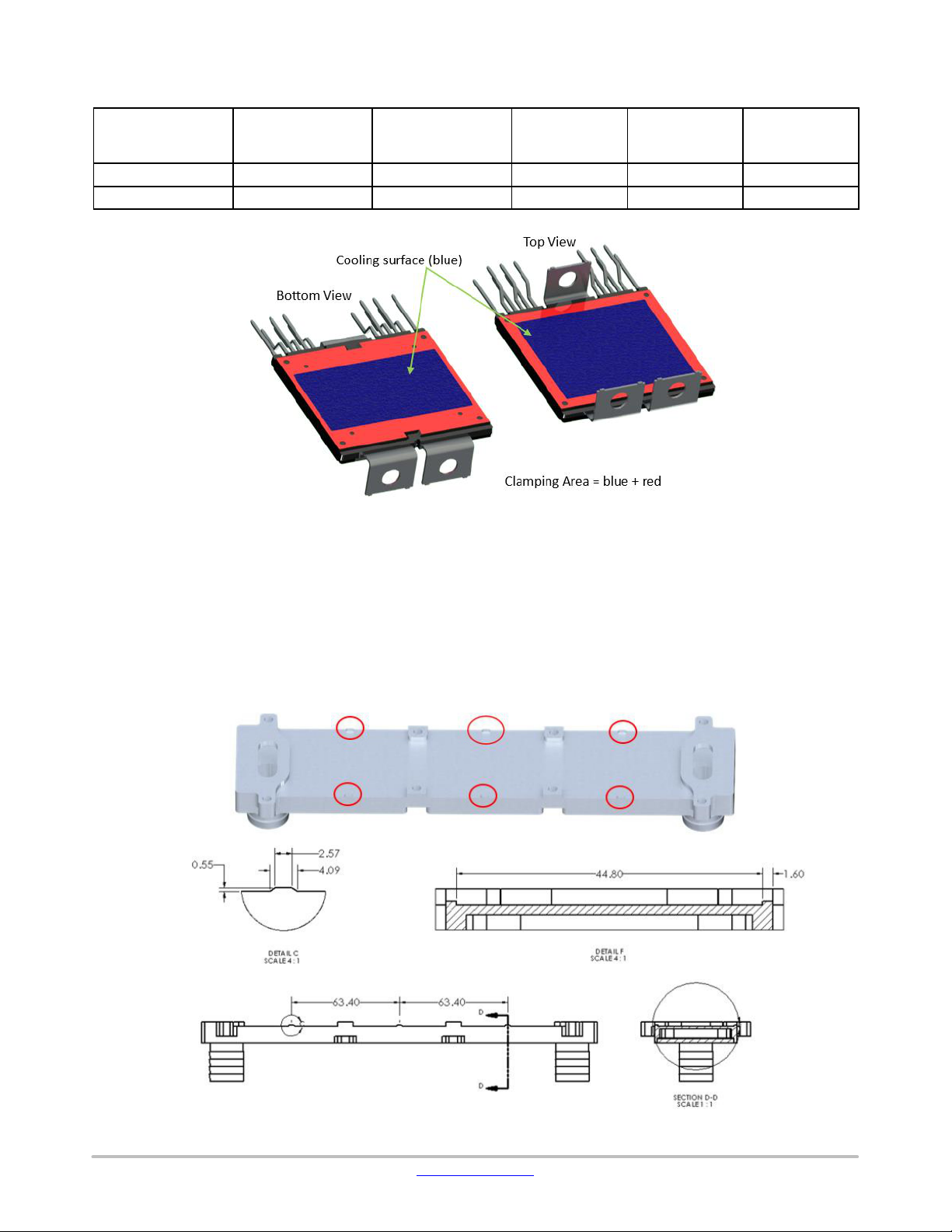

Figure 3. The Area Shown in Red is Where the Clamping Force Should Be Applied to Ensure Good Contact

In Figure 3 the cross sectional area where the clamping

force should be applied is shown in red and blue. It’s

important not to apply force on the DBC only (blue area),

since it can crack the DBC and damage the module. You can

also get cracked DBC if the specifications of the heatsink

flatness is not met. The blue area shown in Figure 3 is the

The cooler should also include the module alignment

features as shown in Figure 4. This protrusion feature has a

mating feature on the power module to control the module

orientation and spacing between the modules. Figure 4

shows the dimensions and spacing to be included for the

alignment features.

area that should be actively cooled to ensure optimal thermal

performance.

Figure 4. Alignment Feature to Be Included on the Bottom Half of the Cooler

www.onsemi.com

2

Page 3

AND9984

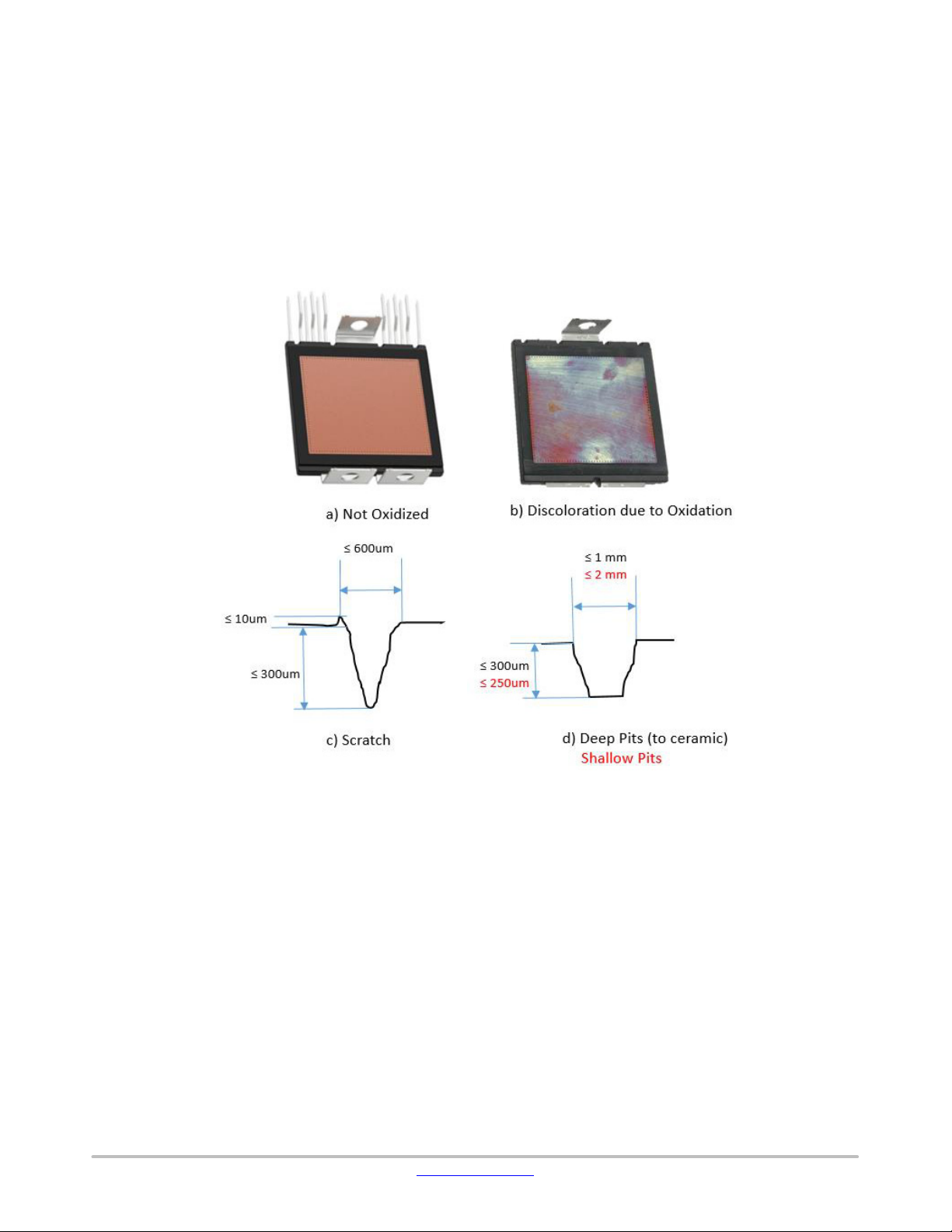

DBC Appearance

The cooling surfaces (DBC) as shown in Figure 3 can

sometimes appear to be discolored, scratched or pitted. The

discoloration is due to the copper on the DBC getting

oxidized due to prolonged exposure to air. The oxide layer

is thin (1.8 – 14 nm) and forms non−uniformly, resulting in

various shades of colors. The contribution of the copper

oxide layer to the thermal performance of the module is so

small that it has no effect on the Rth.j−f (junction to fluid) of

the module.

Other common issues seen on the DBC include scratches

and pitting. This can occur due to handling during assembly

or assembly rework. Figure 5 shows some examples of these

common issues and acceptable criteria for each type. Copper

oxide layer, scratches and pits within the acceptable criteria

have no impact on the electrical, thermal or isolation voltage

capability of the power module.

Figure 5. Different Acceptable Criteria of the Module DBC

Reference Cooler Design and Performance

The reference cooler design can be used as a guide by

customers to develop their own cooler designs. There is no

specific requirement to use this design for the cooler. The

thermal data shown in the data sheet for VE−Trac Dual

products are all measured using this reference cooler. The

www.onsemi.com

cooler can be designed in different ways as long as the

minimum requirements described in the previous section are

met and the proper trade−off consideration is given to the

thermal resistance/impedance, pressure drop and flow rates.

Reference design shown in Figure 6 should be considered as

an example.

3

Page 4

AND9984

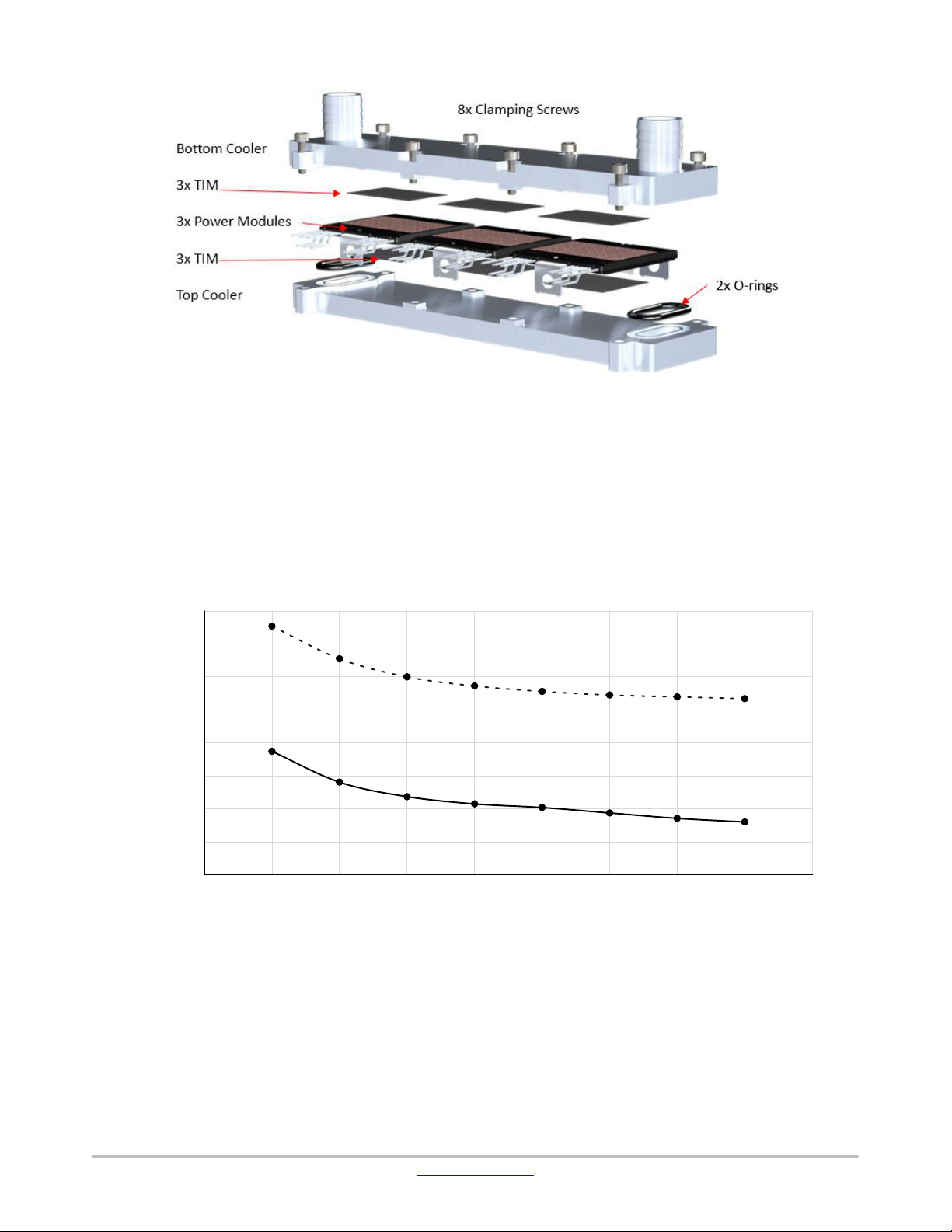

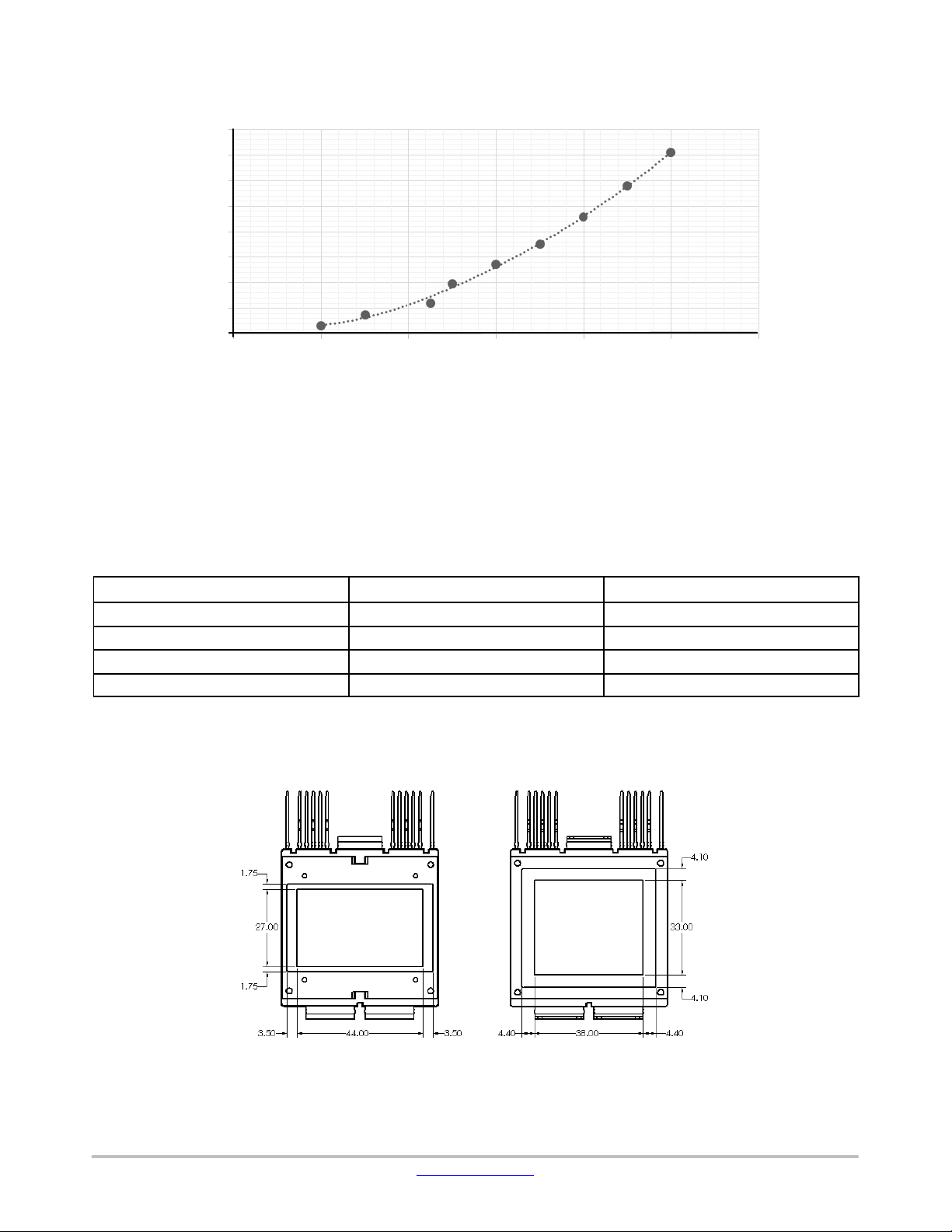

Figure 6. Example Cooler for Use with the VE−Trac Dual

The reference cooler uses a simple pin−fin design and is

optimized for thermal performance, pressure drop and cost.

The data shown below in Figure 7 and Figure 8 should be

considered as typical performance of the cooler with three

750 V, 800 A VE−Trac Dual modules assembled using the

Rth,j−f vs. Flow rate, TF = 655C, 50/50 EGW

0,260

0,240

0,220

0,200

0,180

0,160

Rth,j−f (K/W)

0,140

0,120

0,100

02468101214

recommended thermal interface material and the assembly

process described later in the document. All measurements

were performed using 50/50 Ethylene Water Glycol mix at

65°C as the coolant. The maximum static withstand pressure

of the reference heatsink is 4 Bar.

FWD

IGBT

16 18

Flow Rate (LPM)

Figure 7. Thermal Performance Rth.j−f for IGBT and Diode at Coolant Temperature of 655C

www.onsemi.com

4

Page 5

AND9984

Pressure Drop (mBar) vs. Flowrate (LPM)

80

70

60

50

40

30

20

Pressure Drop (mBar)

10

0

0.0 2.0 4.0 6.0

Flowrate (LPM)

Figure 8. Pressure Drop versus Flow Rate for the Reference Heatsink Coolant @ 655C

8.0 10.0 12.0

Thermal Interface Material (TIM)

Use of an effective Thermal Interface Material is crucial

to achieving the best thermal performance. For VE−Trac

Dual assemblies we recommend using the Honeywell

PTM7000 die cut Phase Change Material at 200 mm

thickness. This material has been tested with the product and

used in all thermal measurements shown on the product data

sheet.

Table 3. CRITICAL PROPERTIES OF THE RECOMMENDED THERMAL INTERFACE MATERIAL (TIM)

Physical Properties

Thermal Conductivity W/m·K 6.5

Thermal Impedance @ No Shim °C.cm2/W 0.06

Specific Gravity g/cm

Volume Resistivity

The PTM7000 is also available in paste form to be used

with automated dispensing machines. Please refer to the

supplier for additional information on its handling and use.

Unit Honeywell PTM7000

3

W·cm

2.7

2.1x10

Figure 9 shows the size and positioning of the die cut

PTM7000 pad placement on the top and bottom cooling

areas of the VE−Trac power modules.

Figure 9. Recommended Size and Location of the TIM Pads for Bottom (left) and Top (right) Side

It is possible to use other TIM materials from other

suppliers in either pad or paste form. However, the new

www.onsemi.com

material will have to be characterized to determine its

performance and optimal method of use in assembly.

5

Page 6

AND9984

REFERENCE COOLER ASSEMBLY

The reference cooler described in the previous section is

used as example to explain the recommended assembly

process of the half−bridge VE−Trac Dual modules into a

STEP 1: Cooler placement in Jig

The bottom side cooler plate in inverter and placed in a jig. We refer to this side of the cooler plate as the bottom half, since it is contact

with bottom side of the power module. The recommended jig design is described below in detail. The purpose of the jig is to securely

hold the bottom half of the cooler plate while the power stack is being assembled.

3−phase power stack i.e. three power modules integrated

with a cooler. The complete assembly process is described

in the following steps:

Figure 10. Jig to Help Assemble the Power Module Stack to the Cooler

www.onsemi.com

6

Page 7

AND9984

STEP 2: TIM Application and Module placement

The TIM pads are aligned and placed as shown in Figure 9 to the bottom side (smaller DBC) of the power modules. The power module

with the TIM is then inverted and placed on the bottom cooler plate in the jig using the alignment features on the module and the cooler

plate to ensure proper orientation and placement.

STEP 3: TIM Application, O−ring and Cooler

The TIM pads are aligned and placed as shown in Figure 9 to the top side (larger DBC) of the power modules. Two O−rings are placed

as shown to seal the coolant flowing between the top and bottom cooler halves. The top cooler half is then visually aligned using the

eight mounting holes and placed on top of the three power modules as shown above.

www.onsemi.com

7

Page 8

The O−ring design for the reference cooler is shown

below in Figure 11:

Figure 11. O−ring Design for the Reference Dual Side Cooler

AND9984

For automotive applications it is typical to use double or

triple edge seal O−rings. In the above example a single edge

seal O−ring is shown as an example for the reference

STEP 4: Securing the Cooler Halves

heatsink. There are other heatsink designs that do not use

O−rings, but is instead welded or braized.

The stack assembly is now inverted bottom side up and secured using the eight screws. Heatsink secured using an ISO 4762 M4 x

0.7 mm Thread X 16 mm long Stainless Steel Socket Head Cap Screw in combination with a DIN 7980 M4 stainless steel split lock

washer. The screws are fastened in the order shown above in a 3 step torque sequence. First torque each screw in order shown to 10%

of the recommended torque value of 1 Nm. Second step is to torque each screw in order to 75% of recommended torque. The complete

assembly is then cured in an oven at 65°C for 30 minutes as recommended by the TIM supplier. Once cured and removed from the

oven, the screws are immediately torqued in order shown to the final recommended torque value of 1 Nm. The process can be different

for different types of TIM and heatsink designs.

www.onsemi.com

8

Page 9

AND9984

POWER TERMINAL CONNECTIONS

There are limited options to connect the module power

terminals to bus bars. The oxygen free copper power

terminals are tin plated and well suited for screw type

fastening.

Terminal Connection Options

The power terminal connections should be made to bus

bars are shown in Figure 12. An isolator with captured nuts

(see Figure 19) is used between the module terminal and

heatsink or chassis. The power module terminals go over the

isolator and the captive nuts and the bus bars over that and

a screw is used to fasten the bus bars to the module terminals.

Hardware shown:

Screw – DIN 439B M6 x 1 mm thread Thin Hex nut

Nut – ISO 7380 M6 x 1 mm thread x 8 mm long

Limitations

The mounting process should result is a system that will

limit the forces acting on the power terminals when secured

to the bus bars. Figure 13 shows the maximum allowed

forces and their axis on the module power terminal.

Figure 13. Force Limitations on the Power Terminal

in All Axis

PRINTED CIRCUIT BOARD (PCB) GUIDELINES

The general recommendation for the plated through holes

for the control pins are shown in Table 4 and Figure 14 shows

the recommended drill hole pattern. Depending on the

design of the PCB there are different methods to solder the

control pins to the PCB. Wave soldering or hand soldering

are the general practice for through−hole type (THT)

components.

Figure 12. Recommended Stack Up for Module

Power Terminal Connections

Figure 14. Recommended Drill−hole Pattern for the PCB

www.onsemi.com

9

Page 10

AND9984

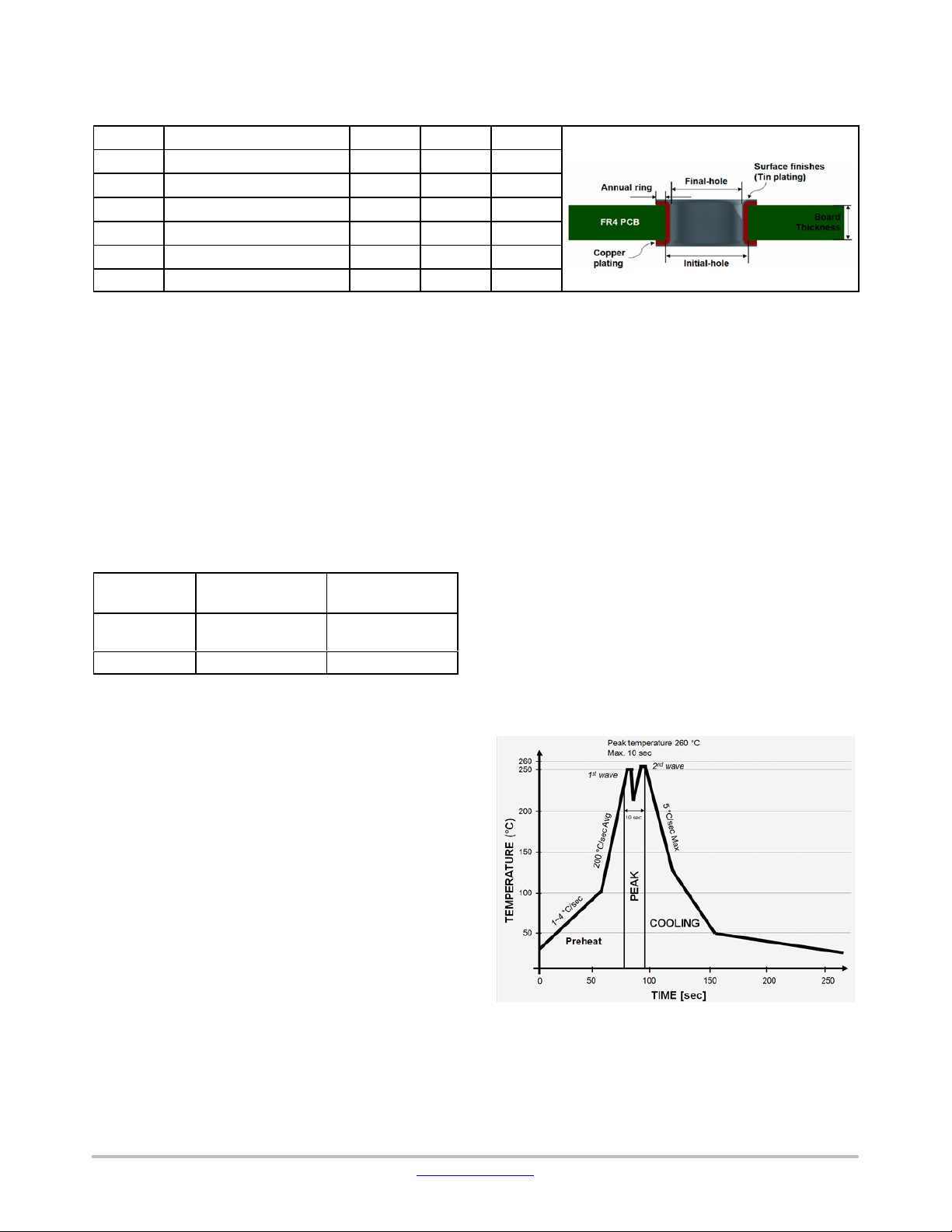

Table 4. SPECIFICATIONS FOR PLATED THROUGH HOLES ON PCB FOR THE SOLDERABLE MODULE CONTROL

PINS

# Description Min. Typ. Max.

1 Initial hole diameter (mm) 1.95 2.00 2.15

2

3

4 Final hole diameter (mm) − 1.85 −

5

6 PCB Thickness (mm) 0.8 1.6 −

Copper thickness in via (mm)

Metallization (Sn) in via (mm)

Annular ring (mm)

25 − −

10 − −

200 − −

Manual Soldering

The recommended conditions for manual soldering are

listed in Table 5. Considering the glass transition

temperature (Tg) of the package mold resin and the thermal

withstand capability of internal chips, the temperature of the

terminal root part should be kept below 150°C. Iron tip

should touch the lead terminal keeping certain distance from

the package mold body. Manual soldering is not

recommended for mass production as it may be difficult to

control the amount of solder applied and the time and

temperature of the soldering step.

Table 5. SPECIFICATIONS FOR MANUAL SOLDERING

CONDITIONS

Single Side Circuit

Parameter

Iron tip

temperature

Soldering time 2 – 6 seconds 4 – 10 seconds

Wave Soldering

Board

385 ± 10°C 420 ± 10°C

Double/Multi−layer

Circuit Board

Assembles are placed on a carrier belt and run the

soldering process to contact the wave solder. The wave

soldering process typically uses a thermal profile which

consists of four stages: solder fluxing, preheating zone,

solder wave and cooling zone. Solder flux is either sprayed

or foamed into the components. Then goes to the preheating

zones, normally by convention, where the flux is activated.

The assembly then goes to wave soldering and slowly cooled

down. Key elements such as preheat ramp rate, conveyor

speed, peak temperature and time forms a wave solder

profile. Wave soldering profile should be optimized in the

assembly site since it strongly depends on the equipment

condition and the material type used in application. A typical

soldering profile and conditions is illustrated in Figure 15

and recommended specifications are shown in Table 6 for

different solder types.

Preheat: Preheat is required to avoid any possible thermal

stress due to overheating. Preheat temperatures and the

preheating time should be set according to the flux

specification. Too high a temperature and too long a duration

may break down the flux activation systems which can cause

unintentional shorts. On the other hand, too low a preheat

temperature setting may cause skips or unwanted residues

left on the PCB. Ramp up rate between 1~4°C per second is

suggested in the preheat zone.

Wave soldering: Dual−wave soldering is the most

common method. The 1st wave which has turbulent wave

crest ensures wetting of all the landing pads, allowing the

molten solder to find its way to all joints on the PCB. The 2nd

wave, which has a laminar flow, drains the excess solder

from the board after the 1st wave thus removing the solder

bridges. It is recommended that maximum soldering

temperature up to 260°C for 10 sec is maintained to establish

a good quality of the solder joint and to avoid package

damage by thermal shock.

Cooling: Gradually cool the processed board down. A

cool down rate between 1 − 5°C/s is recommended in

general.

Figure 15. Typical Dual Solder Profile

www.onsemi.com

10

Page 11

AND9984

Table 6. RECOMMENDED WAVE SOLDERING CONDITIONS

Profile Feature SnPb Eutectic Assembly Pb−Free Assembly

Average ramp up rate ~200°C/sec ~200°C/sec

Preheat ramp up rate Typical 1 − 2, max 4°C/sec Typical 1 − 2, max 4°C/sec

Final preheat temp. ~130°C ~130°C

Peak wave soldering temperature max 235°C, max 10 sec max 260°C, max 10 sec

Ramp down rate 5°C/sec max 5°C/sec max

Solder Inspection

Monitoring the soldering quality is essential, since

abnormal solder joints are potential risks for failures.

IPC−A−610 (DE) standard specifies the soldering quality

criteria for soft soldering. For the examination of a solder

joint, visual or X−ray inspection and automatic optical

inspection are suitable evaluation methods.

Figure 16 shows the recommended final position of a

4−layer PCB (1.6 mm) relative to the edge of the power

module. The minimum recommended space from the edge

of the module to the PCB surface is 10mm spacing. Moving

it closer will likely bend the control pins. Likewise, the

maximum distance between the module edge and PCB

surface should be 18.38 mm. It is generally recommended

that the distance between the PCB and the module edge be

kept as short as possible for optimal performance.

Table 7. CREEPAGE AND CLEARANCE

Parameter Value

Clearance Power Terminal – Power Terminal 3.4 mm

Clearance Power Terminal – Signal Pin 3.1 mm

Clearance Signal Pin – Signal Pin 3.0 mm

Clearance signal pin – Ref. cooler 10.2 mm

Clearance power terminal – ref. cooler 7.0 mm

Creepage Power Terminal – Power Terminal 6.2 mm

Creepage Signal Pin – Signal Pin 5.8 mm

Creepage Power Terminal – Signal Pin 5.9 mm

Creepage Power Terminal – ref. cooler 5.22 mm

Creepage signal pin – ref. cooler 5.22 mm

Table 7 summarizes the creepage and clearance distances

between the various pins of the module and also between the

reference cooler to the different module pins. Figure 17

illustrates the various distances noted in Table 7. Great care

should be taken not to violate the minimum clearance and

creepage requirements when assembling the power module

to heatsinks and using fasteners to secure cables or bus bars

to the module terminals.

Figure 16. PCB Position to Module

SYSTEM ASSEMBLY REQUIREMENTS

The VE−Trac Dual represents a new standard for

packaging power modules for high power applications. It

offers many possibilities for designing more compact power

converters, but there are certain minimum requirements that

must be met to ensure optimal performance.

Creepage and Clearance Requirements

All VE−Trac Dual modules comply with the required

creepage and clearance distances as summarized in the table

below. The module offers basic isolation, pollution degree

2 and a Comparative Tracking Index (CTI) value > 600.

www.onsemi.com

Figure 17. Illustration of Creepage and Clearance

Distances

11

Page 12

AND9984

In order to increase the creepage and clearance between

the cooler and the pins it is necessary to use an isolator. The

and nut has reduced the distance between the high potential

power terminal and the grounded metal cooler.

issue is illustrated in Figure 18. The addition of the screw

Figure 18. Illustration of the Clearance Issue when Using Fasteners to Secure the Power Module Terminals

There are several methods to overcome this clearance

issue depending on your cooler design. However, one of the

methods is discussed as an example. This method captures

the nuts in a floating isolator as shown in the figure below.

integration of the DC link capacitor. The goal is to minimize

the parasitic inductance between the power module and the

bus capacitor. High parasitic inductance will impact the

switching losses of the power modules. Again, there are

multiple options for integrating a DC link and far less critical

is the integration of the output current sensors. Two example

methods are illustrated.

The first example is the Horizontal Integration Concept −

It integrates the DC bus capacitor (from SBE) below the

power stack (power modules + cooler). The DC link uses a

laminated bus structure to connect the power terminals on

the module to the bus capacitor as shown in Figure 20. It uses

a 3−pak, off the shelf hall−effect current sensor from LEM

(HAH3DR 900−S00) with copper AC bus bars. This concept

Figure 19. Using a Floating Isolator with Captured

Nuts is a Potential Solution

positions the gate driver board over the power stack and

cable harness to connect the driver output to a daughter

board that is soldered on to the power module. This design

DC Link, Current Sensor and Gate Driver Integration

Another critical design area that can also impact

primarily meant for evaluation and offers flexibility and

ease in probing signals during evaluations.

performance of the converter system is the mechanical

Figure 20. Horizontal Concept for Integration

The front isometric view of the horizontal concept

(Figure 21) shows how the phase current sensor is integrated

with the power stack. It also shows how the module interface

www.onsemi.com

board is connected to the power module and then a cable is

used to connect the interface board to the driver board on top

of the power module cooler.

12

Page 13

AND9984

Figure 21. Front Isometric View of the Horizontal Integration Concept

The second example is the Vertical Integration Concept

and it is suited for paralleling the VE−Trac Dual modules to

develop high power converters. This concept orients the

power modules vertically and allows the modules to be

stacked in multiples of three to create a compact and scalable

high power inverter. Figure 22 illustrates this concept in

more detail with the parallel integration of 6 (2 modules per

phase) VE−Trac Dual modules. It uses a single large PCB for

driver and controller and the power stack is attached via

screws to the PCB. The large DC bus capacitor from SBE is

located behind the stack with DC link snubber capacitors

attached very close to the paralleled power modules. In this

example concept hall−effect current sensors from LEM

(HAH1DRW 1100−S) are directly attached to the AC bus

bars.

Figure 22. Vertical and Scalable Integration Concept

www.onsemi.com

13

Page 14

AND9984

VISUAL MARKINGS

The product has a number of visual markings to enable

traceability of the materials. It’s important to link the

traceability from the chip to the inverter to maintain an

effective traceability chain.

Figure 23. Traceability Markings on the Power Module

Table 8. EXPLANATION OF MARKINGS

Marker Description

Company Logo ON Semiconductor Logo

2D Code 1 Assembly Lot Number + S/N

2D Code 2 P/N+ Assy. Lot Number + Site & Date

Code + Tool ID + S/N

Site and Date Code Assembly location (XX) and date code

(YWW)

Lot Code Last 3 digits of lot number

S/N Number 7 digit Serial number

P/N Number 7 Character Product part number

Storage and Shipping

Transporting and storing the modules requires care to

avoid extreme shock, vibration and environments. The

Traceability and Identification

Figure 23 and Table 8 together describe all the visual

markings on the module and provide an explanation of the

markers.

recommended storage conditions for the module according

to IEC 60721−3−1, class 1K2 should be followed and

storage time should not exceed two years from

manufactured date code. Below is a summary of the

recommended storage parameters:

Table 9. STORAGE SPECIFICATIONS

Parameter Value Unit

Maximum air temperature 40 °C

Minimum air temperature +5 °C

Maximum relative humidity 85 %

Minimum relative humidity 5 %

Condensation Not Allowed

Precipitation Not Allowed

Icing Not Allowed

VE−Trac is trademark of Semiconductor Components Industries, LLC (SCILLC) or its subsidiaries in the United States and/or other countries.

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

14

Loading...

Loading...