Page 1

AMIS-42770

Dual High Speed CAN

Transceiver

General Description

Controller Area Network (CAN) is a serial communication protocol,

which supports distributed real−time control and multiplexing with h igh

safety level. Typical applications of CAN−based networks can be found

in automotive and industrial environments.

The AMIS−42770 Dual−CAN transceiver is the interface between

up to two physical bus lines and the protocol controller and will be

used for serial data interchange between different electronic units at

more than one bus line. It can be used for both 12 V and 24 V systems.

The circuit consists of following blocks:

• Two differential line transmitters

• Two differential line receivers

• Interface to the CAN protocol handler

• Interface to expand the number of CAN busses

• Logic block including repeater function and the feedback suppression

• Thermal shutdown circuit (TSD)

Due to the wide common−mode voltage range of the receiver inputs,

the AMIS−42770 is able to reach outstanding levels of electromagnetic

susceptibility (EMS). Similarly, extremely low electromagnetic

emission (EME) is achieved by the excellent matching of the output

signals.

Key Features

• Fully Compatible with the ISO 11898−2 Standard

• Certified “Authentication on CAN Transceiver Conformance (d1.1)”

• Wide Range of Bus Communication Speed (up to 1 Mbit/s in

Function of the Bus Topology)

• Allows Low Transmit Data Rate in Networks Exceeding 1 km

• Ideally Suited for 12 V and 24 V Industrial and Automotive

Applications

• Low EME: Common−mode−choke is No Longer Required

• Differential Receiver with Wide Common−mode Range (±35 V) for

High EMS

• No Disturbance of the Bus Lines with an Un−powered Node

• Prolonged Dominant Time−out Function Allowing Communication

Speeds Down to 1 kbit/s

• Thermal Protection

• Bus Pins Protected against Transients

• Short Circuit Proof to Supply Voltage and Ground

• This is a Pb−Free Device*

http://onsemi.com

SOIC 20

IC SUFFIX

CASE 751AQ

20

AMIS42770

ICAW−N

AWLYYWWG

1

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 2 of this data sheet.

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

© Semiconductor Components Industries, LLC, 2014

November, 2014 − Rev. 4

1 Publication Order Number:

AMIS−42770/D

Page 2

AMIS−42770

ORDERING INFORMATION

Part Number Package Shipping Configuration Temperature Range

AMIS42770ICAW1G SOIC−20 300

(Pb−Free, Green)

AMIS42770ICAW1RG SOIC−20 300

(Pb−Free, Green)

T able 1. TECHNICAL CHARACTERISTICS

Symbol Parameter Conditions Min. Max. Unit

V

CANHx

V

CANLx

V

o(dif)(bus_dom)

CM−range Input common−mode range for comparator Guaranteed differential receiver

V

CM−peak

V

CM−step

1. The parameters V

DC voltage at pin CANH1/2 0 < VCC < 5.25 V; no time limit −45 +45 V

DC voltage at pin CANL1/2 0 < VCC < 5.25 V; no time limit −45 +45 V

Differential bus output voltage in dominant state

Common−Mode peak See Figures 10 and 11 (Note 1) −1000 +1000 mV

Common−Mode step See Figures 10 and 11 (Note 1) −250 +250 mV

CM−peak

and V

guarantee low EME.

CM−step

VCC

12

38 / Tube −40°C to 125°C

1500 / Tape & Reel −40°C to 125°C

42.5 W < RLT < 60 W

1.5 3 V

−35 +35 V

threshold and leakage current

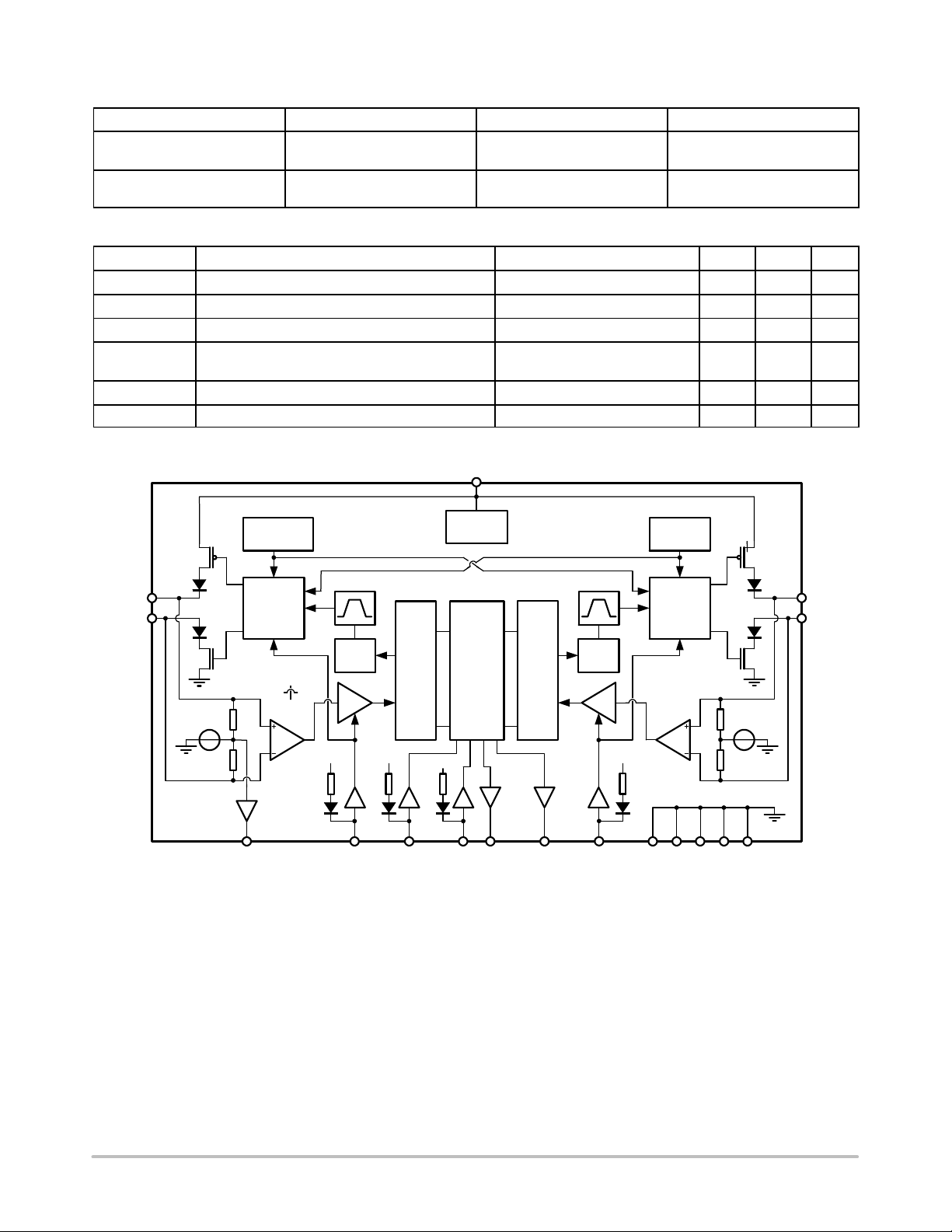

CANH1

CANL1

13

14

V

CC/2

−

R

R

i(cm)

i(cm)

+

shutdown

8

V

REF

Thermal

Driver

control

COMP

V

CC

Timer

10

ENB1

POR

AMIS−42770

Logic

Unit

Feedback Suppression

V

CC

V

CC

3792

4

Feedback Suppression

RintTx0Text

Figure 1. Block Diagram

Timer

ENB2

2x timer

clock

Driver

control

COMP

V

CC

5 6 15 16 17

19

CANH2

18

CANL2

R

i(cm)

V

CC/2

+

−

R

i(cm)

GNDRx0

http://onsemi.com

2

Page 3

AMIS−42770

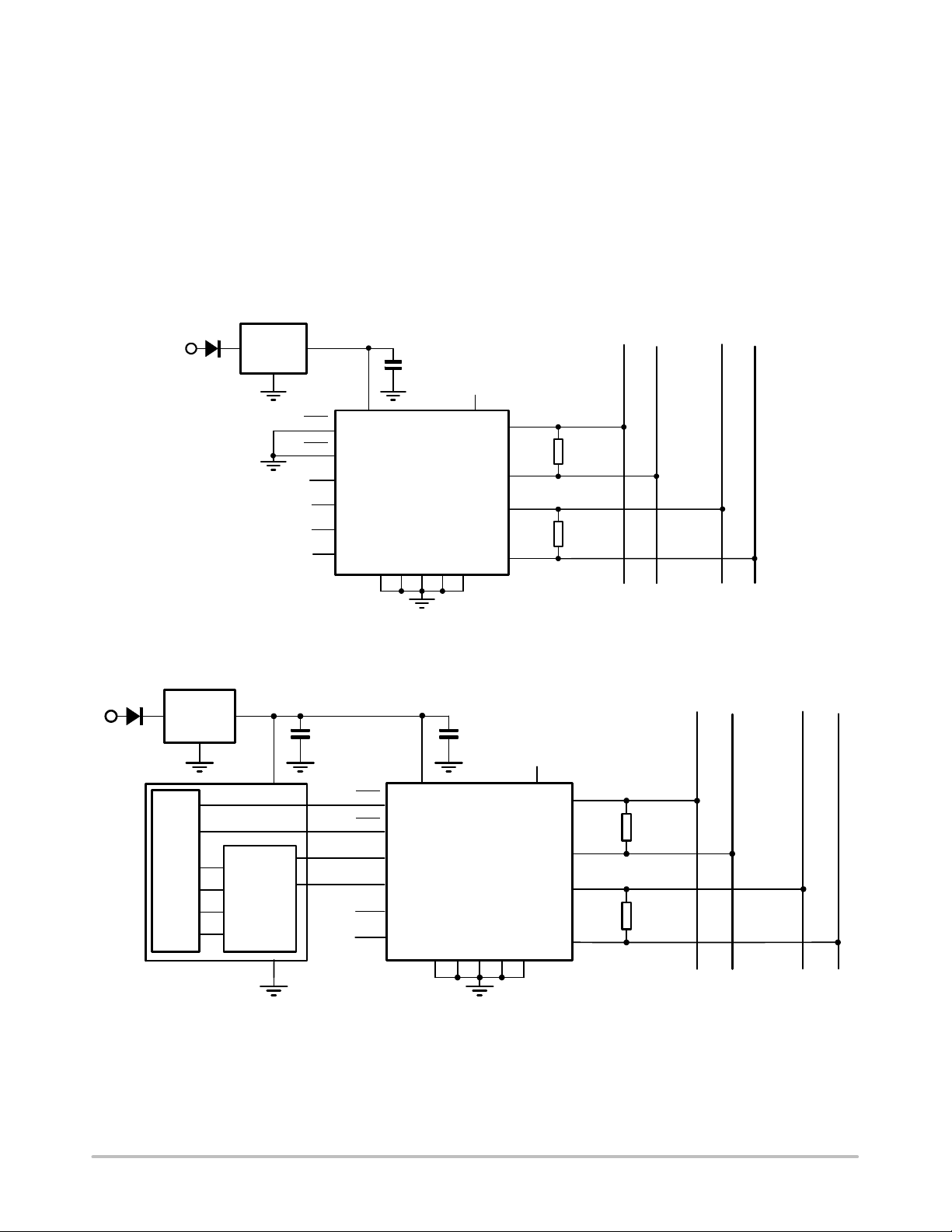

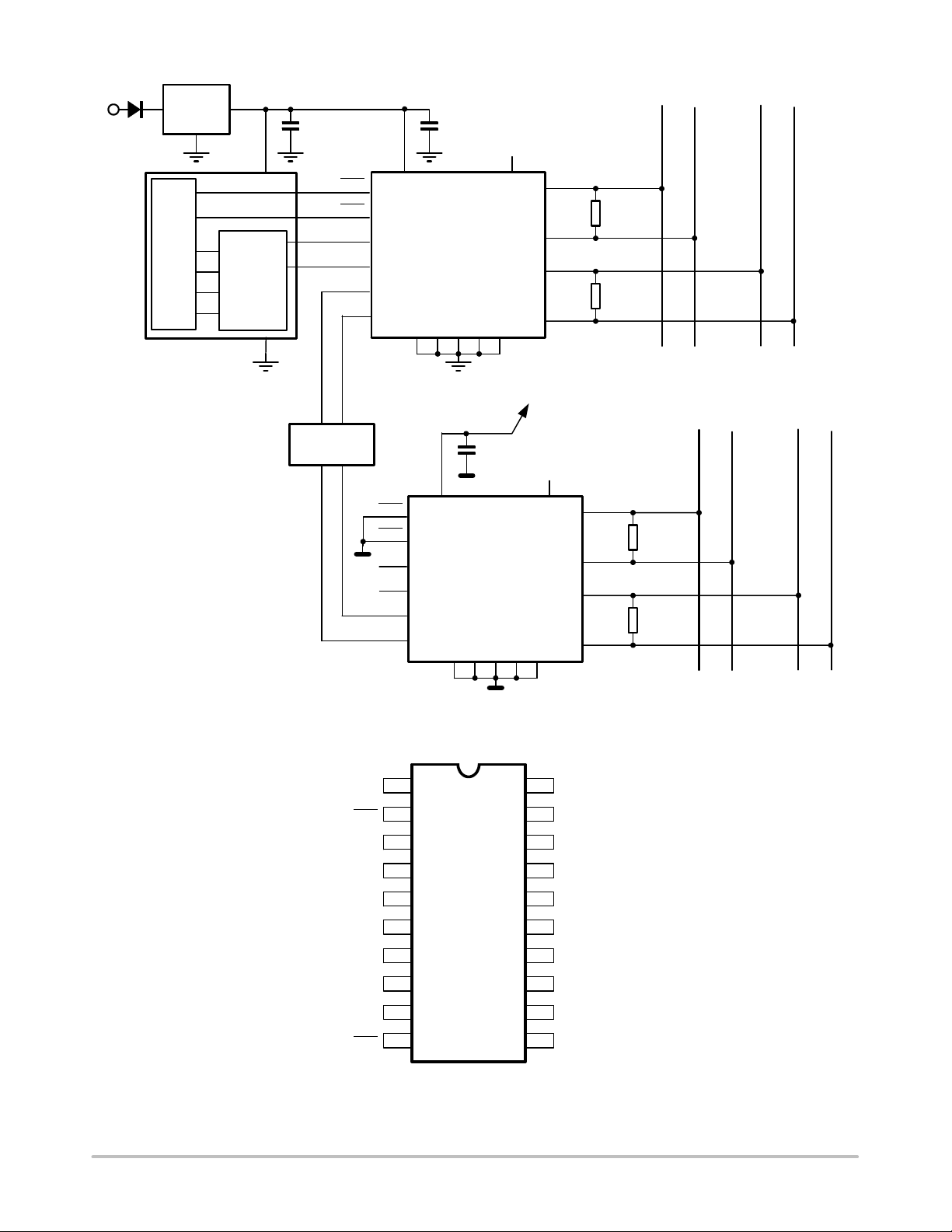

TYPICAL APPLICATION

Application Description

AMIS−42770 is especially designed to provide the link

between a CAN controller (protocol IC) and two physical

busses. It is able to operate in three different modes:

• Dual CAN

• A CAN−bus extender

• A CAN−bus repeater

Application Schematics

VBAT

5 V−reg

mC

VBAT

5 V−reg

VCC

CAN

controller

C

D

100 nF

EN1

EN2

Rx0

Tx0

Text

Rint

VCC

10

2

7

4

3

9

12

AMIS−42770

5

6 15 16 17

Vref

8

GND

13

14

19

18

CANH1

CANL1

CANH2

CANL2

R

60 W

R

60 W

Figure 2. Application Diagram CAN−bus Repeater

C

D

100 nF100 nF

AMIS−42770

5

6 15 16 17

Vref

8

GND

13

14

19

18

GND

C

D

VCC

10

12

2

7

4

3

9

EN1

EN2

Rx0

Tx0

Text

Rint

LT

LT

CANH1

CANL1

CANH2

CANL2

R

LT

60 W

R

LT

60 W

CAN BUS 2CAN BUS 1

CAN BUS 2CAN BUS 1

Figure 3. Application Diagram Dual−CAN

http://onsemi.com

3

Page 4

AMIS−42770

VBAT

5 V−reg

mC

VCC

CAN

controller

C

GND

OptoCoupler

D

Dual

EN1

EN2

Rx0

Tx0

Text

Rint

VCC

10

2

7

4

3

9

EN1

EN2

Rx0

Tx0

Text

Rint

12

AMIS−42770

5

6 15 16 17

VCC

10

2

7

4

3

9

C

D

100 nF100 nF

12

AMIS−42770

5

6 15 16 17

C

D

100 nF

Vref

8

GND

13

14

19

18

CANH1

CANL1

CANH2

CANL2

isolated +5

Vref

8

13

14

19

18

GND

R

LT

60 W

R

LT

60 W

CANH1

CANL1

CANH2

CANL2

R

LT

60 W

R

LT

60 W

CAN BUS 2CAN BUS 1

CAN BUS 4CAN BUS 3

Figure 4. Application Diagram CAN−bus Extender

NC

EN2

Text

Tx0

GND

GND

Rx0

Vref1

Rint

EN1

10

2

3

4

AMIS−42770

5

6

7

8

9

201

19

18

17

16

15

14

13

12

11

NC

CANH2

CANL2

GND

GND

GND

CANL1

CANH1

VCC

NC

Figure 5. Pin Out (top view)

http://onsemi.com

4

Page 5

AMIS−42770

Table 2. PIN DESCRIPTION

Pin Name Description

1 NC Not connected

2 ENB2 Enable input, bus system 2; internal pull−up

3 Text Multi−system transmitter Input; internal pull−up

4 Tx0 Transmitter input; internal pull−up

5 GND Ground connection (Note 2)

6 GND Ground connection (Note 2)

7 Rx0 Receiver output

8 V

9 Rint Multi−system receiver output

10 ENB1 Enable input, bus system 1; internal pull−up

11 NC Not connected

12 VCC Positive supply voltage

13 CANH1 CANH transceiver I/O bus system 1

14 CANL1 CANL transceiver I/O bus system 1

15 GND Ground connection (Note 2)

16 GND Ground connection (Note 2)

17 GND Ground connection (Note 2)

18 CANL2 CANL transceiver I/O bus system 2

19 CANH2 CANH transceiver I/O bus system 2

20 NC Not connected

2. In order to ensure the chip performance, all these pins need to be connected to GND on the PCB.

REF1

Reference voltage

FUNCTIONAL DESCRIPTION

Overall Functional Description

AMIS−42770 is specially designed to provide the link

between the protocol IC (CAN controller) and two physical

bus lines. Data interchange between those two bus lines is

realized via the logic unit inside the chip. To provide an

independent switch−off of the transceiver units for both bus

systems by a third device (e.g. the °C), enable−inputs for the

corresponding driving and receiving sections are provided.

As long as both lines are enabled, they appear as one logical

bus to all nodes connected to either of them.

The bus lines can have two logical states, dominant or

recessive. A bus is in the recessive state when the driving

sections of all transceivers connected to the bus are passive.

The differential voltage between the two wires is

approximately zero. If at least one driver is active, the bus

changes into the dominant state. This state is represented by

a differential voltage greater than a minimum threshold and

therefore by a current flow through the terminating resistors

of the bus line. The recessive state is overwritten by the

dominant state.

In case a fault (like short circuit) is present on one of the

bus lines, it remains limited to that bus line where it occurs.

Data interchange from the protocol IC to the other bus

system and on this bus system itself can be continued.

AMIS−42770 can be also used for only one bus system. If

the connections for the second bus system are simply left

open it serves as a single transceiver for an electronic unit.

For correct operation, it is necessary to terminate the open

bus by the proper termination resistor.

Logic Unit and CAN Controller Interface

The logic unit inside AMIS−42770 provides data transfer

from/to the digital interface to/from the two busses and from

one bus to the other bus. The detailed function of the logic

unit is described in Table 3.

All digital input pins, including ENBx, have an internal

pull−up resistor to ensure a recessive state when the input is

not connected o r i s a ccidentally interrupted. A d ominant s tate

on the bus line is represented by a low−level at the digital

interface; a recessive state is represented by a high−level.

Dominant state received on any bus (if enabled) causes a

dominant state on both busses, pin Rint and pin Rx0.

Dominant signal o n a ny o f the i nput p ins T x0 and T ext c auses

transmission of dominant on both bus lines (if enabled).

Digital inputs Tx0 and Text are used for connecting the

internal logic’s of several IC’s to obtain versions with more

than two bus outputs (see Figure 4). They have also a direct

logical link to pins Rx0 and Rint independently on the EN1x

pins – dominant on Tx0 is directly transferred to both Rx0

and Rint pins, dominant on T ext is only transferred to Rx0.

http://onsemi.com

5

Page 6

AMIS−42770

Transmitters

The transceiver includes two t ransmitters, one f or each bus

line, and a driver control circuit. Each transmitter is

implemented as a push and a pull driver. The drivers will be

active if t he t ransmission o f a d ominant b it i s r equired. D uring

the transmission of a r ecessive bit all drivers are passive. The

transmitters have a built−in current limiting circuit that

protects the driver stages from damage caused by accidental

short circuit to either positive supply voltage or to ground.

Additionally a thermal protection circuit is integrated.

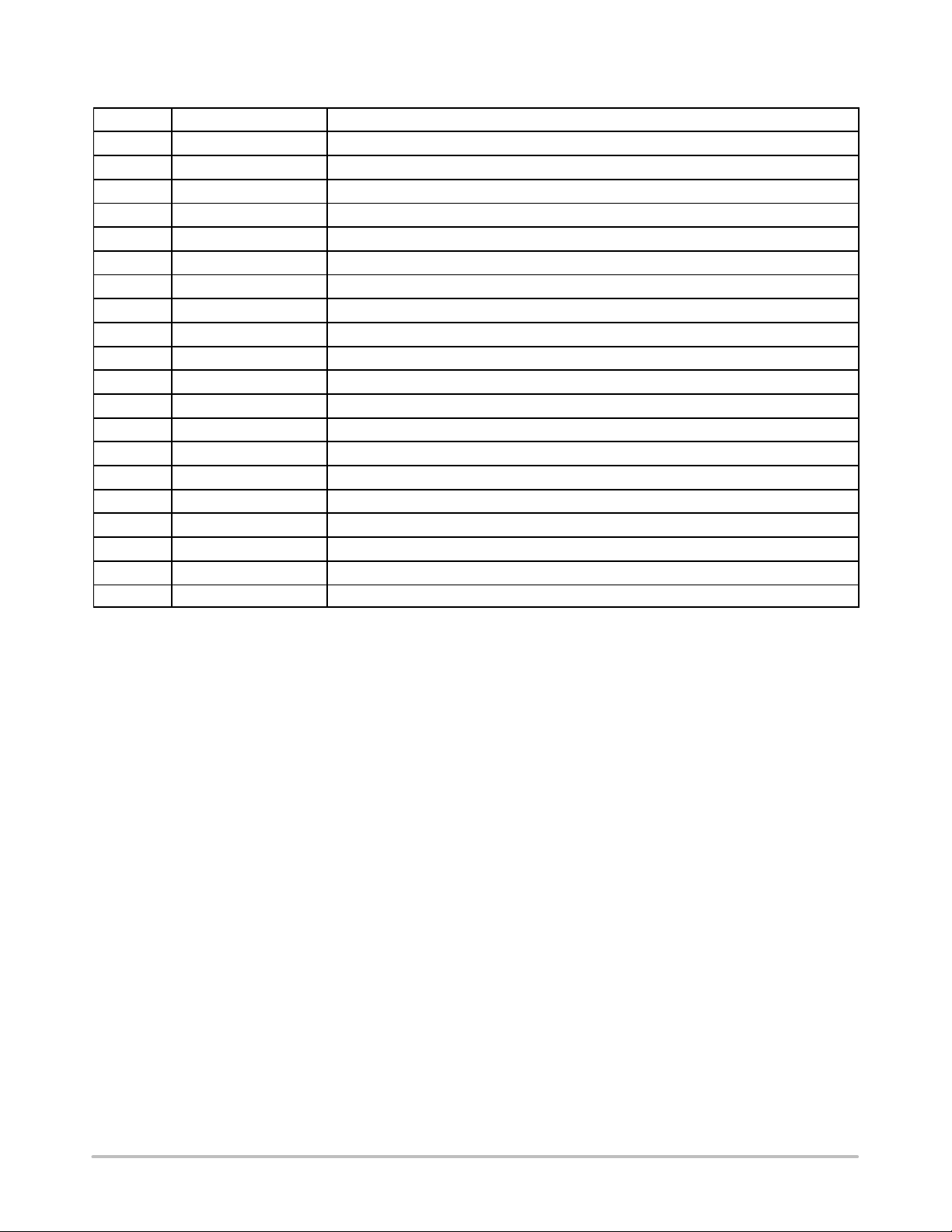

T able 3. FUNCTION OF THE LOGIC UNIT (bold letters describe input signals)

EN1B

0 0 0 0 dominant dominant 0 0

0 0 0 1 dominant dominant 0 0

0 0 1 0 dominant dominant 0 1

0 0 1 1 recessive recessive 1 1

0 0 1 1 dominant (Note 3) dominant 0 0

0 0 1 1 dominant dominant (Note 3) 0 0

0 1 0 0 dominant recessive 0 0

0 1 0 1 dominant recessive 0 0

0 1 1 0 dominant recessive 0 1

0 1 1 1 recessive recessive 1 1

0 1 1 1 dominant (Note 3) recessive 0 0

0 1 1 1 recessive dominant (Note 3) 1 1

1 0 0 0 recessive dominant 0 0

1 0 0 1 recessive dominant 0 0

1 0 1 0 recessive dominant 0 1

1 0 1 1 recessive recessive 1 1

1 0 1 1 dominant (Note 3) recessive 1 1

1 0 1 1 recessive dominant (Note 3) 0 0

1 1 0 0 recessive recessive 0 0

1 1 0 1 recessive recessive 0 0

1 1 1 0 recessive recessive 0 1

1 1 1 1 recessive recessive 1 1

1 1 1 1 dominant (Note 3) recessive 1 1

1 1 1 1 recessive dominant (Note 3) 1 1

3. Dominant detected by the corresponding receiver.

Receivers

EN2B TX0 TEXT Bus 1 State Bus 2 State RX0 RINT

Two bus receiving sections sense the states of the bus

lines. Each receiver section consists of an input filter and a

fast and accurate comparator. The aim of the input filter is

to improve the immunity against high−frequency

disturbances and also to convert the voltage at the bus lines

CANHx and CANLx, which can vary from –12 V to +12 V,

to voltages in the range 0 to 5 V, which can be applied to the

comparators.

The output signal of the comparators is gated by the ENBx

signal. In the disabled state (ENBX = high), the output signal

of the comparator will be replaced by a permanently

The driver control circuit ensures that the drivers are

switched on and off with a controlled slope to limit EME.

The driver control circuit will control itself by the thermal

protection circuit, the timer circuit and the logic unit.

The enable signal ENBx allows the transmitter to be

switched off by a third device (e.g. the °C). In the disabled

state (ENBx = high) the corresponding transmitter behaves

as in the recessive state.

recessive state and does not depend on the bus voltage. In the

enabled state the receiver signal sent to the logic unit is

identical to the comparator output signal.

Time−out Counter

To avoid that the transceiver drives a permanent dominant

state on either of the bus lines (blocking all communication),

time−out function is implemented. Signals on pins Tx0 and

Text as well as both bus receivers are connected to the logic

unit through independent timers. If the input of the timer

stays dominant for longer than 25 ms (see parameter t

it is replaced by a recessive signal on the timer output.

dom

),

http://onsemi.com

6

Page 7

AMIS−42770

Feedback Suppression

The logic unit described in Table 3 constantly ensures that

dominant symbols on one bus line are transmitted to the

other bus line without imposing any priority on either of the

lines. This feature would lead to an “interlock” state with

permanent dominant signal transmitted to both bus lines, if

no extra measure is taken.

Therefore feedback suppression is included inside the

logic unit of the transceiver . This block masks−out reception

on that bus line, on which a dominant is actively transmitted.

The reception becomes active again only with certain delay

after the dominant transmission on this line is finished.

Power−on−Reset (POR)

While Vcc voltage is below the POR level, the POR

circuit makes sure that:

• The counters are kept in the reset mode and stable state

without current consumption

• Inputs are disabled (don’t care)

• Outputs are high impedant; only Rx0 = high−level

• Analog blocks are in power down

• Oscillator not running and in power down

• CANHx and CANLx are recessive

• VREF output high impedant for POR not released

Over Temperature Detection

A thermal protection circuit is integrated to prevent the

transceiver from damage if the junction temperature

exceeds thermal shutdown level. Because the transmitters

dissipate most of the total power, the transmitters will be

switched off only to reduce power dissipation and IC

temperature. All other IC functions continue to operate.

Fault Behavior

A fault like a short circuit is limited to that bus line where

it occurs; hence data interchange from the protocol IC to the

other bus system is not affected.

When the voltage at the bus lines is going out of the normal

operating range (−12 V to +12 V), the receiver is not allowed

to erroneously detect a dominant state.

Short Circuits

A current−limiting circuit protects the transmitter output

stage from damage caused by an accidental short−circuit to

either positive or negative supply voltage, although power

dissipation increases during this fault condition.

The pins CANHx and CANLx are protected from

automotive electrical transients (according to “ISO 7637”).

ELECTRICAL CHARACTERISTICS

Definitions

All voltages are referenced to GND. Positive currents

flow into the IC. Sinking current means that the current is

flowing into the pin. Sourcing current means that the current

is flowing out of the pin.

Table 4. ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Conditions Min. Max. Unit

V

CC

V

CANHx

V

CANLx

V

digIO

V

REF

V

tran(CANHx)

V

tran(CANLx)

V

esd(CANLx/CANHx)

V

esd

Latch−up Static latch−up at all pins (Note 6) 100 mA

T

stg

T

amb

T

junc

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

4. Applied transient waveforms in accordance with “ISO 7637 part 3”, test pulses 1, 2, 3a, and 3b (see Figure 6)

5. Standardized human body model (HBM) ESD pulses in accordance to MIL883 method 3015. Supply pin 8 is ±2 kV.

6. Static latch−up immunity: static latch−up protection level when tested according to EIA/JESD78.

7. Standardized charged device model ESD pulses when tested according to EOS/ESD DS5.3−1993.

Supply voltage −0.3 +7 V

DC voltage at pin CANH1/2 0 < VCC < 5.25 V; no time limit −45 +45 V

DC voltage at pin CANL1/2 0 < VCC < 5.25 V; no time limit −45 +45 V

DC voltage at digital IO pins (EN1B, EN2B,

Rint, Rx0, Text, Tx0)

DC voltage at pin V

Transient voltage at pin CANH1/2 (Note 4) −150 +150 V

Transient voltage at pin CANL1/2 (Note 4) −150 +150 V

ESD voltage at CANH1/2 and CANL1/2 pins (Note 5)

ESD voltage at all other pins (Note 5)

Storage temperature −55 +155 °C

Ambient temperature −40 +125 °C

Maximum junction temperature −40 +150 °C

REF

(Note 7)

(Note 7)

−0.3 VCC + 0.3 V

−0.3 VCC + 0.3 V

−4

−500

−2

−250

+4

+500

+2

+250

kV

kV

V

V

http://onsemi.com

7

Page 8

AMIS−42770

Table 5. THERMAL CHARACTERISTICS

Symbol Parameter Conditions Value Unit

R

th(vj−a)

R

th(vj−s)

DC CHARACTERISTICS

T able 6. DC AND TIMING CHARACTERISTICS

(VCC = 4.75 to 5.25 V; T

Symbol

SUPPLY (pin VCC)

I

CC

PORL_VCC Power−on−reset level on V

DIGITAL INPUTS (Tx0, Text, EN1B, EN2B)

V

IH

V

I

IH

I

IL

C

DIGITAL OUTPUTS (pin Rx0, Rint)

I

oh

I

ol

REFERENCE VOLTAGE OUTPUT (pin V

V

REF

V

REF_CM

BUS LINES (pins CANH1/2 and CANL1/2)

V

o(reces)(CANHx)

V

o(reces)(CANLx)

I

o(reces) (CANHx)

I

o(reces) (CANLx)

V

o(dom) (CANHx)

V

o(dom) (CANLx)

V

o(dif) (bus)

I

o(sc) (CANHx)

I

o(sc) (CANLx)

Thermal resistance from junction to ambient in SO20 package In free air 85 K/W

Thermal resistance from junction to substrate of bare die In free air 45 K/W

= −40 to +150°C; RLT = 60 W unless specified otherwise.)

junc

Parameter Conditions Min. Typ. Max. Unit

Supply current, no loads on digital outputs, both busses enabled

CC

High−level input voltage 0.7 x V

IL

Low−level input voltage −0.3 − 0.3 x V

High−level input current VIN = V

Dominant transmitted

Recessive transmitted

CC

45 137.5

2.2 4.7 V

CC

− V

−5 0 +5

Low−level input current VIN = 0 V −75 −200 −350

i

Input capacitance Not tested − 5 10 pF

High−level output current V

Low−level output current V

)

REF1

Reference output voltage

Reference output voltage for

full common mode range

Recessive bus voltage at pin

CANH1/2

Recessive bus voltage at pin

CANL1/2

Recessive output current at

pin CANH1/2

Recessive output current at

pin CANL1/2

Dominant output voltage at pin

CANH1/2

Dominant output voltage at pin

CANL1/2

Differential bus output voltage

(V

CANHx

− V

CANLx

)

Short circuit output current at

pin CANH1/2

Short circuit output current at

pin CANL1/2

= 0.7 x V

o

= 0.3 x V

o

−50 mA < I

−35 V <V

−35 V <V

V

= VCC; no load 2.0 2.5 3.0 V

Tx0

V

= VCC; no load 2.0 2.5 3.0 V

Tx0

−35 V < V

0 V < V

−35 V < V

0 V < V

V

V

V

= 0 V; dominant;

Tx0

42.5 W < R

V

= VCC; recessive;

TxD

V

= 0 V;V

CANHx

V

= 36 V; V

CANLx

CC

CC

< +50 mA

VREF

< +35 V;

CANHx

< +35 V

CANLx

< +35 V;

CANHx

< 5.25 V

CC

< +35 V;

CANLx

< 5.25 V

CC

= 0 V 3.0 3.6 4.25 V

Tx0

= 0 V 0. 5 1.4 1.75 V

Tx0

< 60 W

LT

no load

= 0 V −45 −70 −120 mA

Tx0

= 0 V 45 70 120 mA

Tx0

−5 −10 −15 mA

5 10 15 mA

0.45 x V

0.40 x V

CC

CC

0.50 x V

0.50 x V

CC

CC

−2.5 − +2.5 mA

−2.5 − +2.5 mA

1.5 2.25 3.0 V

−120 0 +50 mV

19.5

CC

0.55 x V

0.60 x V

CC

CC

CC

mA

V

V

mA

mA

V

V

http://onsemi.com

8

Page 9

AMIS−42770

T able 6. DC AND TIMING CHARACTERISTICS

(VCC = 4.75 to 5.25 V; T

Symbol UnitMax.Typ.Min.ConditionsParameter

BUS LINES (pins CANH1/2 and CANL1/2)

V

i(dif)(th)

V

ihcm(dif) (th)

V

i(dif) (hys)

R

i(cm)(CANHx)

R

i(cm) (CANLx)

R

i(cm)(m)

R

i(dif)

C

i(CANHx)

C

i(CANLx)

C

i(dif)

I

LI(CANHx)

I

LI(CANLx)

V

CM−peak

V

CM−step

THERMAL SHUTDOWN

T

j(sd)

TIMING CHARACTERISTICS (see Figures 8 and 9)

t

d(Tx−BUSon)

t

d(Tx−BUSoff)

t

d(BUSon−RX)

t

d(BUSoff−RX)

t

d(ENxB)

t

d(Tx−Rx)

t

dom

t

d(FBS)

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

= −40 to +150°C; RLT = 60 W unless specified otherwise.)

junc

Differential receiver threshold

voltage

Differential receiver threshold

voltage for high common−

mode

Differential receiver input voltage hysteresis

Common−mode input resist-

−5 V < V

−5 V < V

see Figure 7

−35 V < V

−35 V < V

see Figure 7

−35 V < V

−35 V < V

see Figure 7

CANLx

CANHx

CANLx

CANHx

CANL

CANH

< +12 V;

< +12 V;

< +35 V;

< +35 V;

< +35 V;

< +35 V;

0.5 0.7 0.9 V

0.3 0.7 1.05 V

50 70 100 mV

15 26 37

KW

ance at pin CANH1/2

Common−mode input resist-

15 26 37

KW

ance at pin CANL1/2

Matching between pin CANH1/2

and pin CANL1/2 common−

V

CANHx

= V

CANLx

−3 0 +3 %

mode input resistance

Differential input resistance 25 50 75

Input capacitance at pin

CANH1/2

Input capacitance at pin

CANL1/2

Differential input capacitance V

Input leakage current at pin

CANH1/2

Input leakage current at pin

CANL1/2

Common−mode peak during

V

= VCC; not tested 7.5 20 pF

Tx0

V

= VCC; not tested 7.5 20 pF

Tx0

= VCC; not tested 3.75 10 pF

Tx0

VCC < PORL_VCC;

−5.25 V < V

CANHx

VCC < PORL_VCC;

−5.25 V < V

CANLx

< 5.25 V

< 5.25 V

−350 170 350

−350 170 350

See Figure 11 −1000 1000 mV

KW

mA

mA

transition from dom → rec or

rec → dom

Difference in common−mode

See Figure 11 −250 250 mV

between dominant and recessive state

Shutdown junction temperature 150 °C

Delay Tx0/Text to bus active 40 85 120 ns

Delay Tx0/Text to bus inactive 30 60 115 ns

Delay bus active to Rx0/Rint 25 55 115 ns

Delay bus inactive to Rx0/Rint 65 100 145 ns

Delay from EN1B to bus act-

100 200 ns

ive/inactive

Delay from Tx0 to Rx0/Rint

15 pF on the digital output 4 10 35 ns

and from Text to Rx0

(direct logical path)

Time out counter interval 15 25 45 ms

Delay for feedback suppres-

sion release

5+

t

d(BUSon−RX)

300 ns

http://onsemi.com

9

Page 10

Measurement Set−ups and Definitions

Schematics are given for single CAN transceiver.

+5V

AMIS−42770

100 nF

Tx0

Vref

CANH1

8

13

CANL1

14

CANH2

19

CANL2

18

6151617

5

GND

Text

Rint

Rx0

EN1 EN2

VCC

3

9

4

7

10

12

AMIS−42770

2

Figure 6. Test Circuit for Automotive Transients

V

RxD

Hysteresis

0,5

0,9

Figure 7. Hysteresis of the Receiver

1 nF

1 nF

V

i(dif)(hys)

Transient

Generator

High

Low

+5 V

100 nF

Vref

8

13

14

19

18

5

6151617

GND

Tx0

Text

Rint

Rx0

VCC

12

3

9

4

7

EN1 EN2

10

AMIS−42770

2

Figure 8. Test Circuit for Timing Characteristics

CANH1

CANL1

CANH2

CANL2

R

LT

60 W

R

LT

60 W

C

LT

100 pF

C

LT

100 pF

http://onsemi.com

10

Page 11

V

CANHx−BUS

V

=

DIFF

V

CANHx

− V

CANLx

Tx0

Text

5 V

0,7 V

V

CANHx

V

CANLx

CC

0,3 V

AMIS−42770

CC

dominant

+5 V

Gen

0 V

Rx0

Rint

t

d(Tx−Rx)

t

d(Tx−BUSon)

Text

Rint

Tx0

Rx0

0,9 V

0,3 V

CC

VCC

12

3

9

AMIS−42770

4

7

2

10

EN1 EN2

0,9 V

PD(H)

t

d(Tx−Rx)

t

d(Tx−BUSoff)

0,7 V

0,5 V

CC

t

t

d(BUSon−Rx)

Figure 9. Timing Diagram for AC Characteristics

100 nF

Vref

CANH1

8

13

CANL1

14

CANH2

19

CANL2

18

5

6151617

GND

6.2 kW

6.2 kW

30 W30 W

47 nF

0,3 V

10 nF

CC

Spectrum Anayzer

0,5 V

t

d(BUSoff−Rx)

Active Probe

recessive

0,7 V

CC

Figure 10. Basic Test Set−up for Electromagnetic Measurement

http://onsemi.com

11

Page 12

AMIS−42770

CANHx

CANLx

recessive

V

CM−peak

V

= 0.5*

CM

(V

CANHx

+ V

CANLx

)

V

CM−peak

Figure 11. Common−mode Voltage Peaks (see Measurement Set−up Figure 10)

Company or Product Inquiries

For more information about ON Semiconductor’s products or services visit our Web site at http://www.onsemi.com.

V

CM−peak

http://onsemi.com

12

Page 13

MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SOIC 20 W

CASE 751AQ−01

ISSUE O

DATE 19 JUN 2008

DOCUMENT NUMBER:

DESCRIPTION:

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

98AON30891E

SOIC 20 W

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

www.onsemi.com

Page 14

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

◊

www.onsemi.com

1

Loading...

Loading...