Page 1

SERVICE MANUAL

MINIDISC RECORDER

MODEL MD-101A

MD-101A

Ref. No. 3703

112001

MINIDISC RECORDER

DISC LOADIING MECHANISM

INPUT

STANDBY / ON

STANDBY

DISPLAY

MDT

MGT, MGR

MULTI JOG

EDIT / NO YES

CD

DUBBING

REC

PUSH TO ENTER

MD

REC MODE

Silver models

120V AC, 60Hz

220-230V AC, 50/60Hz

STANDBY/ON

PLAY MODE

CONTINUE

RANDOM MEMORY

ABCDE

1

2345

FGHI J

6117

KLMNO

12

PQRST

16

17

UVWXY

21

22

Z

REPEAT A-B A.SPACE M.SCAN

>

25

/

?

REC

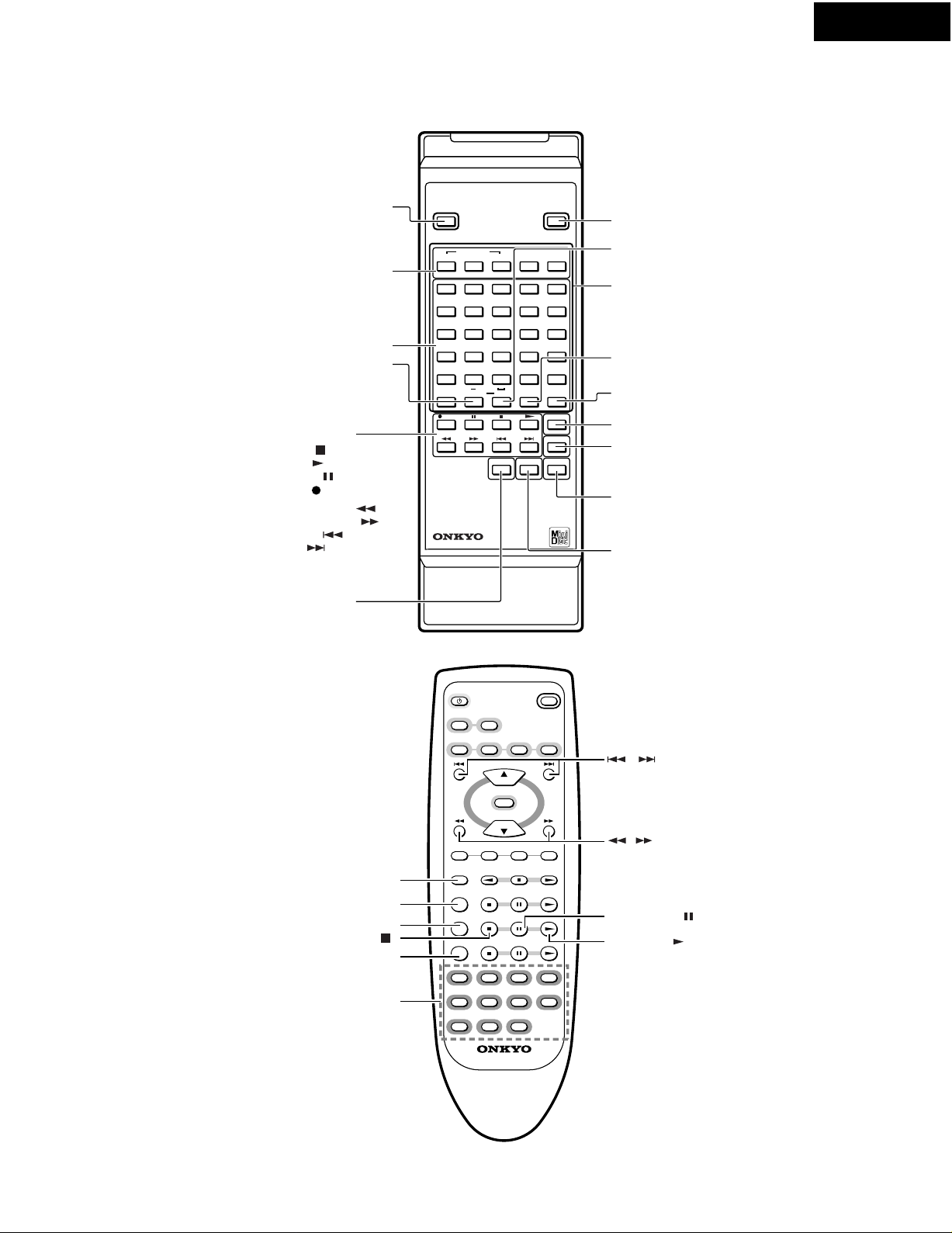

REMOTE CONTROLLER RC-

-

101

A

8

13

18

23

!

SCROLL DISPLAY

475

MD

EJECT

9

10

14

15

19

20

24

25

.,

(

CLEAR

ENTER

NAME

)

RC-475MD

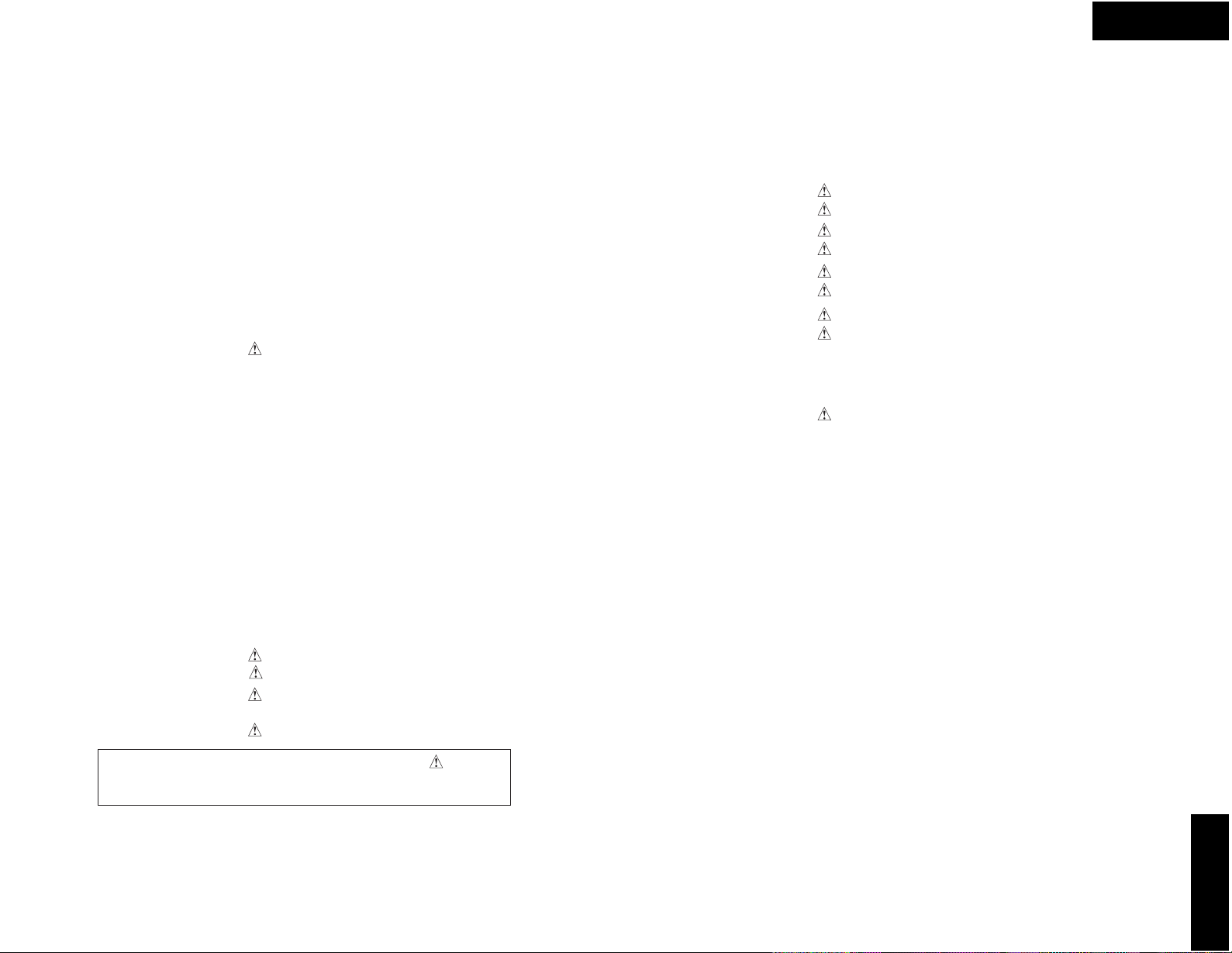

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

Page 2

SPECIFICATIONS

MD-101A

System

MiniDisc digital audio system

Recording system

Magnetic field modulation overwrite system

Signal read out system

Optical non-contact

Recording time

Stereo: Max. 80 min.

(when using MDW-80)

Mono : Max. 160 min.

(when using MDW-80)

Number of revolutions

About 400 - 900 rpm (constant linear velocity)

Error correction system

Advanced Cross Interleave Reed-solomon code

Sampling frequency

44.1 kHz

Number of channels

2 (stereo)

Frequency response

10 Hz - 20 kHz ( 0.5 dB)

Signal to noise ratio

100 dB or more when playing

Output level

2.0 volts r.m.s.

Power supply rating

AC 230-240 V, 50/60 Hz

AC 120 V, 60 Hz

Power consumption

13 watts (AC 230-240 V, 50/60 Hz)

15 watts (AC 120 V, 60 Hz)

Dimensions (W H D)

155 76 288.5 mm

Weight

2.3 kg

Specifications and features are subject to

change without notice.

Page 3

DISPLAY MESSAGES

MD-101A

Message

Auto Space

Blank Disc

Cannot Copy

Cannot Edit

Cannot Rec

CD Dub Fail

Complete

D. In Unlock

Disc Error

Disc Full

Full

Impossible

Mecha Error

Memory Full

Music Scan

Name Full

No Change

No Disc

No Track

Over

Protected

Retry Error

Signal Wait

Synchro Rec

TOC Reading

TOC Writing

TOC Error

Meaning

This message appears during the track intervals when A. Space is turned on.

A new recordable MD or a recordable MD without disc or track names is inserted.

An attempt was made to record copyright-protected material. An attempt was made to make a

second copy from a digitally dubbed MD

An attempt was made to edit the disc during MEMORY or RANDOM play or in recording standby

mode, or an attempt to edit a premastered disc was made.

An attempt was made to record onto a premastered (read-only) disc.

The CD dubbing operation could not be enabled. Check the connections. (An RI cable or audio

pin cable is not connected. "Digital In 1" is not selected as an input source, or the amplifier or CD

player is not turned on.)

Editing is complete.

The digital equipment (CD player, DAT, etc.) has not been connected properly. Otherwise, the

connected digital equipment is not operating properly.

The disc is abnormal (scratched or missing a TOC).

The disc is full.

An attempt was made to enter a character that exceeds the maximum character capacity.

The disc could not be edited.

An error occurred in the unit fs internal mechanism.

An attempt was made to record a 26th track.

Music Scan has started.

Number of characters has reached the limit for input to one MD.

The naming attempt failed.

There is no disc in the unit.

The inserted disc has a disc title but no tracks.

In pause mode (when playing is paused), the >>(Fast Forward) button was pressed to the end

of the disc.

The inserted disc is record-protected.

The recording attempt failed due to a consecutive disturbance or scratches on the MD.

The unit has entered Signal Wait mode.

Synchro recording has started.

The unit is reading the TOC from the MD.

The unit is writing the recorded or edited contents to the MD.

The writing of the recorded or edited contents failed. Something is wrong with the TOC.

Page 4

SERVICE PROCEDURES

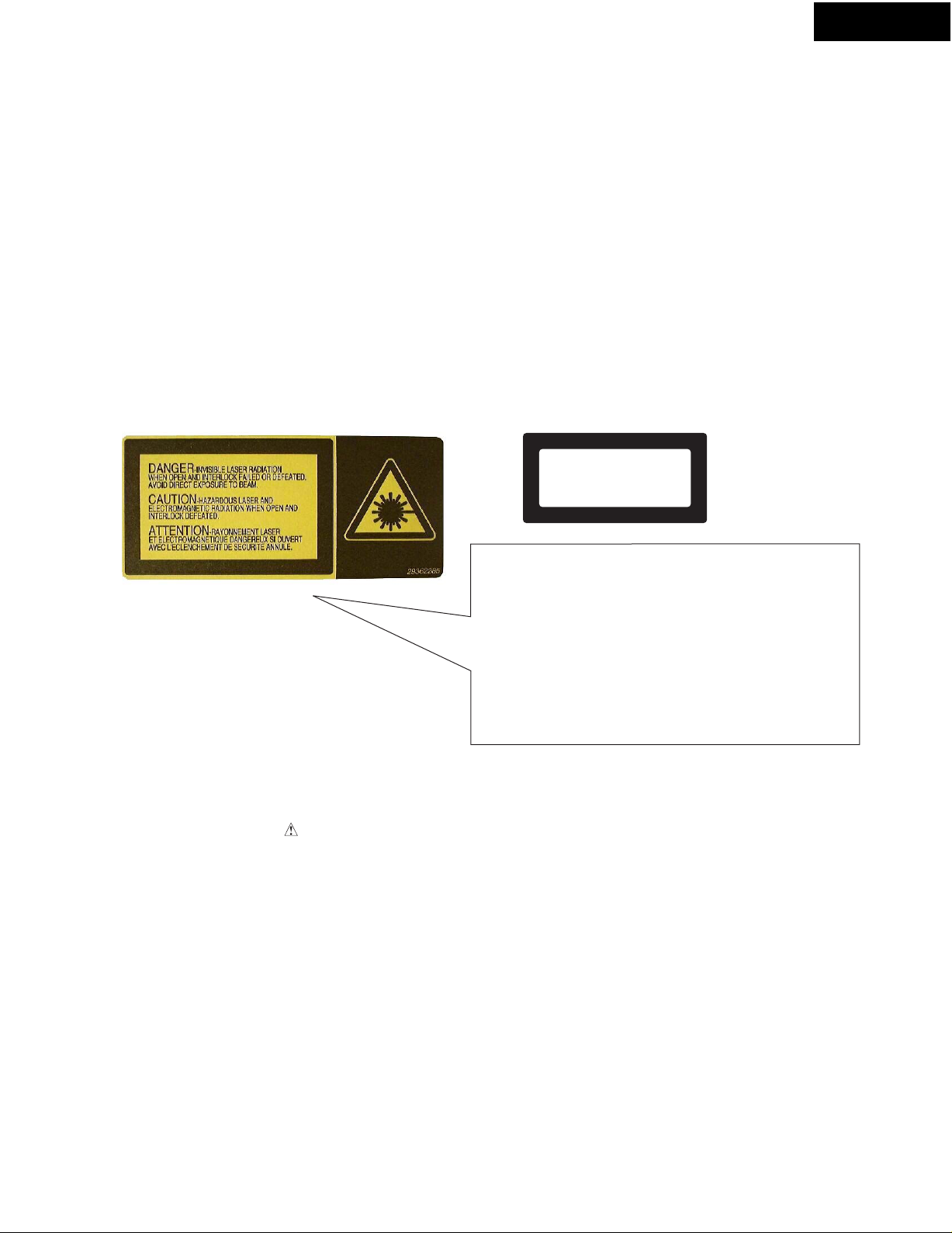

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

This set employs a laser. Therefore, be sure to follow

carefully the instructions below when servicing.

WARNING!!

SERVICE WARNING : DO NOT APPROACH THE

LASER EXIT WITH THE EYE TOO CLOSELY.

IN CASE IT IS NECESSARY TO CONFIRM LASER

BEAM EMISSION, BE SURE TO OBSERVE FROM

A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE

OPTICAL PICKUP BLOCK.

LASER W ARNING LABEL

The labels shown below are affixed.

1. Warning label

Laser Diode Properties

Material:

Wavelength:

Emission Duration:

Laser output:

2. Class 1 label

"CLASS 1 LASER

PRODUCT"

GaAS/GaAlAs

780 nm

Continuous

MAX. 7 mW

MD-101A

LUOKAN 1

LASERLAITE

KLASS 1

LASER APPARAT

SERVICE PROCEDURE

1. Replacing the fuses

REF. NO.

F901

[NOTE ]

<GT> : Asian model

<GR> : Chinese model

PART NO.

252074

2. To initialize the unit

(1) Connect the power supply cord in the wall socket.

(2) Press the STANDBY/ON button to turn the power source on.

(2) While hold down the YES button, press the DISPLAY button.

(4) Press the STANDBY/ON button.

(5) Disconnect the power supply cord.

DESCRIPTION

2A-SE-EAK, Fuse <GT, GR>

DANGER:

INVISIBLE LASER RADIATION WHEN OPEN AND

INTERLOCK FAILED OR DEFEATED. AVOID DIRECT

EXPOSURE TO BEAM.

CAUTION:

HAZARDOUS LASER AND ELECTROMAGNETIC

RADIATION WHEN OPEN AND INTERLOCK DEFEATED.

ATTENTION:

RAYONNEMENT LASER ET ELECTROMAGNETIQUE

DANGEREUX SI OUVERT AVEC L'ECLENCHEMENT

DE SECURITE ANNULE.

3. How to reset the unit compulsorily

Used when it becomes impossible to eject a disk.

Continues pressing the

STOP

button more than for 5 seconds.

Page 5

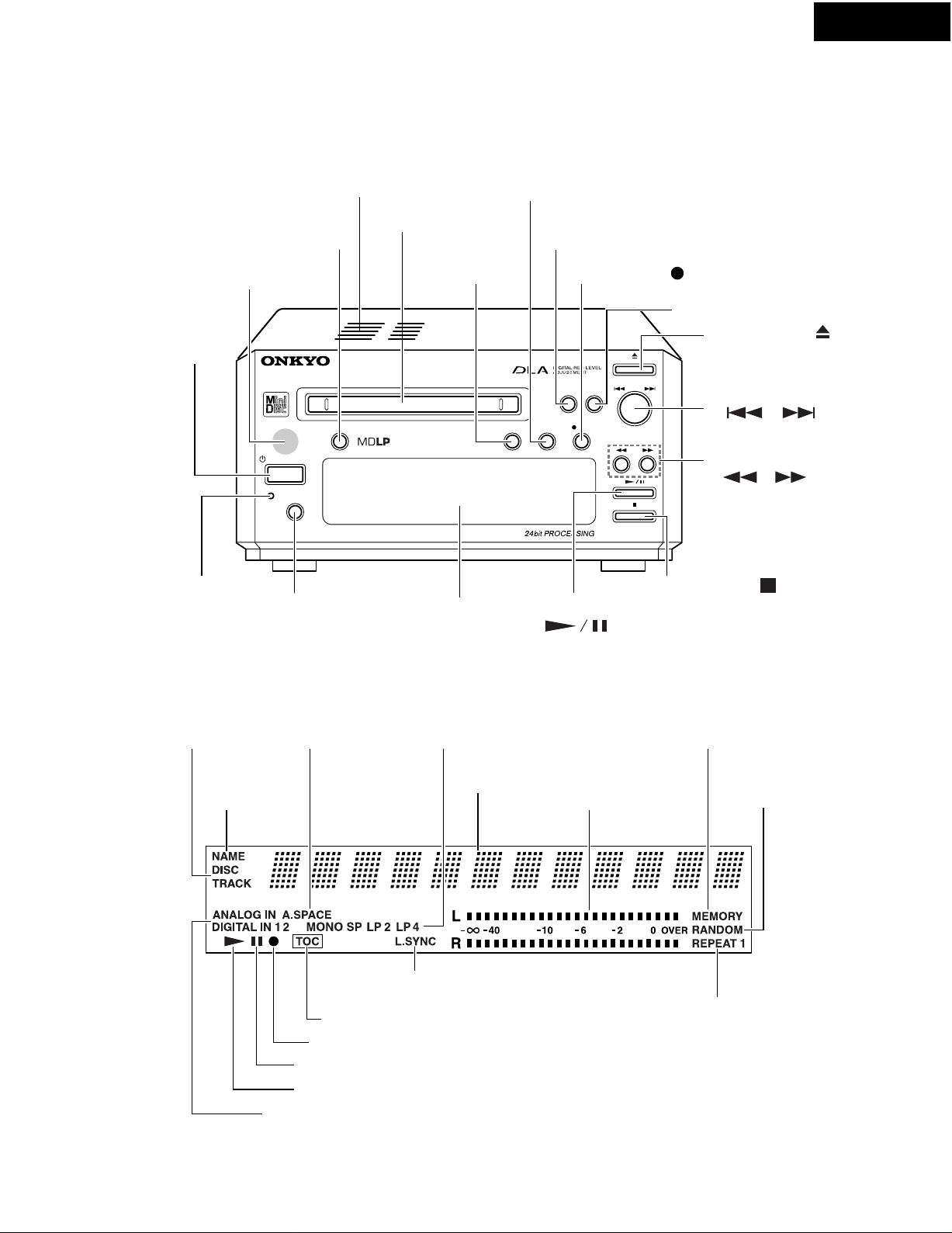

P ANEL VIEWS-1

FRONT PANEL

Ventilation

holes

MD-101A

CD DUBBING

button

Remote control

sensor

STANDBY/ON

button

STANDBY

indicator

INPUT

button

DISPLAY

button

Disc slot

REC MODE

button

Display

EDIT/NO

button

REC button

Play/Pause button

( )

( REC)

YES button

Eject button

MULTI JOG knob

( )

FF/FR button

( )

Stop button

( )

( )

DISPLAY

DISC/TRACK

indicator

NAME

indicator

Input setting indicator

A.SPACE

indicator

TOC indicator

REC indicator

PAUSE indicator

PLAY indicator

REC MODE

indicator

Time/Title

display

L.SYNC indicator

Peak level

meter

MEMORY

indicator

RANDOM

indicator

REPEAT/REPEAT1

indicator

Page 6

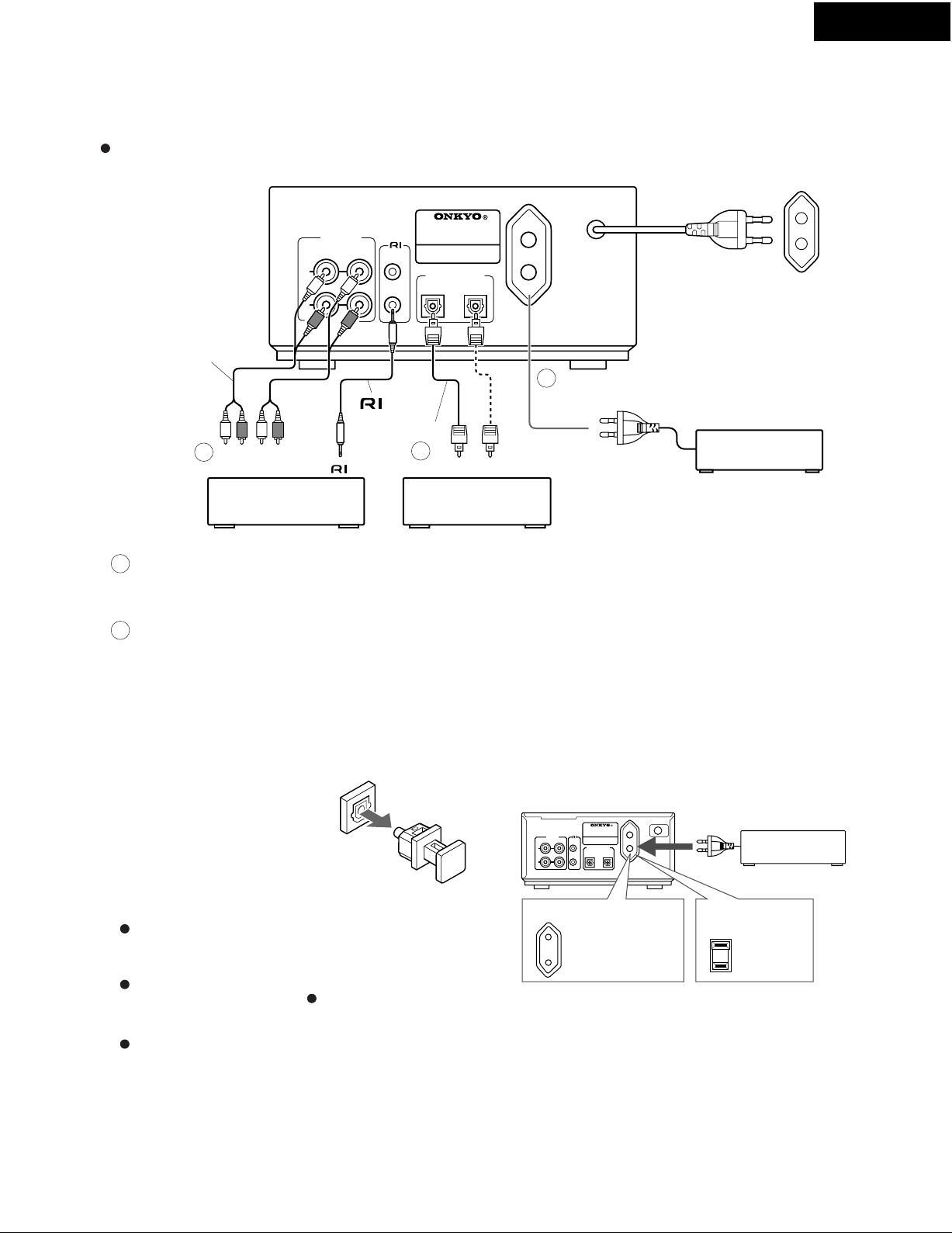

P ANEL VIEWS-2

CONNECTING TO THE OTHER COMPONENTS

This unit uses heat-sensitive parts. Do not place this unit on the Amplifier or Receiver.

Connections

MINIDISC RECORDER

REMOTE

CONTROL

cable

MODEL NO. MD-101A

DIGITAL INPUT

12

2

OUT

CD player,

DAT deck, etc.

AC OUTLET

AC 220

-230 V

50 / 60 Hz

UNSWITCHED

100 W MAX.

3

Audio

connection

cable

LR LR

1

OUT IN

ANALOG

INPUT OUTPUT

L

R

Optical fiber

cable

Amplifier

MD-101A

To wall outlet

Connecting to the Amplifier

1

Connect the MD-101A to the MD (or TAPE)

jacks of your amplifier.

2

Connecting to the Digital Input

Terminals (DIGITAL INPUT 1, 2)

You can perform digital recording on the MD101A if a CD (Compact Disc) player or DAT

(Digital Audio Tape) deck equipped with a digital

(OPTICAL) output terminal is available. For digital

recording, you need to connect the equipment

to either DIGITAL INPUT 1 or 2 terminal using

the supplied optical cable.

These terminals can also

be used for connecting an

amplifier that is equipped

with a digital output

terminal.

Note

If you use DIGITAL INPUT 2 to connect an

amplifier, you will be unable to utilize the full

capabilities of the MD-101A.

If you attempt to perform digital recording using

a digital input terminal that is not connected,

"D.In Unlock " will appear.

Terminal protection caps are attached to the

DIGITAL INPUT terminals. Remove the cap for the

terminal you wish to use when connecting the

MD-101A to digital equipment. Replace the caps

if you are not using the DIGITAL INPUT terminals.

3

Connection to AC outlet

(UNSWITCHED)

The power cord of another unit can be connected

to this outlet.

Note

The shape, number, and total capacity of the AC

outlets may differ depending on the area in which

the unit is purchased.

230-240 V, 50/60 Hz model: Capacity is 100 W in

total.

120 V, 60 Hz model: Capacity is 120 W in total.

230-240V, 50/60Hz models

Capacity is

100 watts.

120V, 60Hz models

Capacity is

120 watts.

Page 7

REMOTE CONTROLLER

RC-475MD (supplied)

MD-101A

STANDBY/ON button

PLAY MODE buttons

CONTINUE buttons

RANDOM button

MEMORY button

Number buttons

REPEAT button

MD operation buttons

Stop button ( )

Play button (

Pause button (

Rec button (

)

)

REC)

Fast reverse button (

Fast forward button (

Down button ( )

Up button (

)

SCROLL button

STANDBY/ON

EJECT

EJECT button

PLAY MODE

CONTINUE

RANDOM MEMORY

ABCDE

1

2345

FGHI J

6117

KLMNO

PQRST

16

UVWXY

21

Z

>

25

/

REC

8

9

13

12

17

22

REPEAT A-B A.SPACE M.SCAN

?

14

18

19

23

24

!

SCROLL DISPLAY

.,

(

CLEAR

ENTER

NAME

10

15

20

25

)

)

A-B repeat button

Uppercase and

lower case letters,

symbols, and

numbers (1~10)

buttons

A.SPACE button

M.SCAN button

CLEAR button

ENTER button

NAME button

)

REMOTE CONTROLLER RC-

475

MD

DISPLAY button

RC-466S

(supplied with the R-801A)

Mode button (MODE)

Repeat button (REPEAT)

Clear button (CLEAR)

Stop button ( )

Scroll button (SCROLL)

Number buttons

STANDBY/ ON

CDR/PC

CD/ DVD

TAPE REW TAPE FF

SLEEP TIMER ENTER

MODE

REPEAT

CLEAR

SCROLL

1

5

9

ACOUSTIC

PRESENCE

TAPE

MD FM AM

U

L

O

V

UP

MUTING

DOWN

CLOCK

CD/DVD

CDR/PC

2

6

10/0

REMOTE CONTROLLER

INPUT SELECTOR

M

E

TAPE

MD

3

7

--/---

-

466S

RC

4

8

, button

, button

Pause button ( )

Play button ( )

Page 8

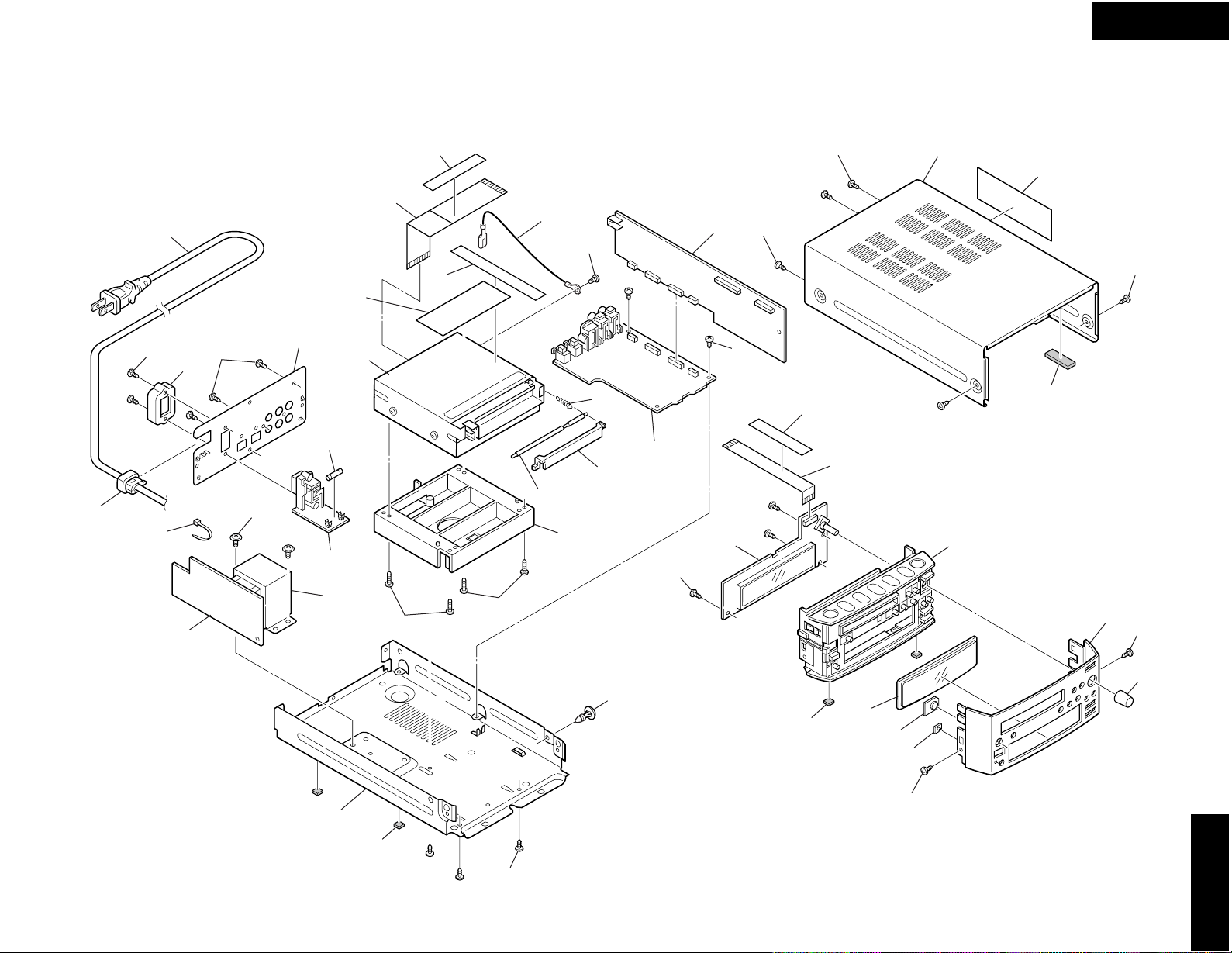

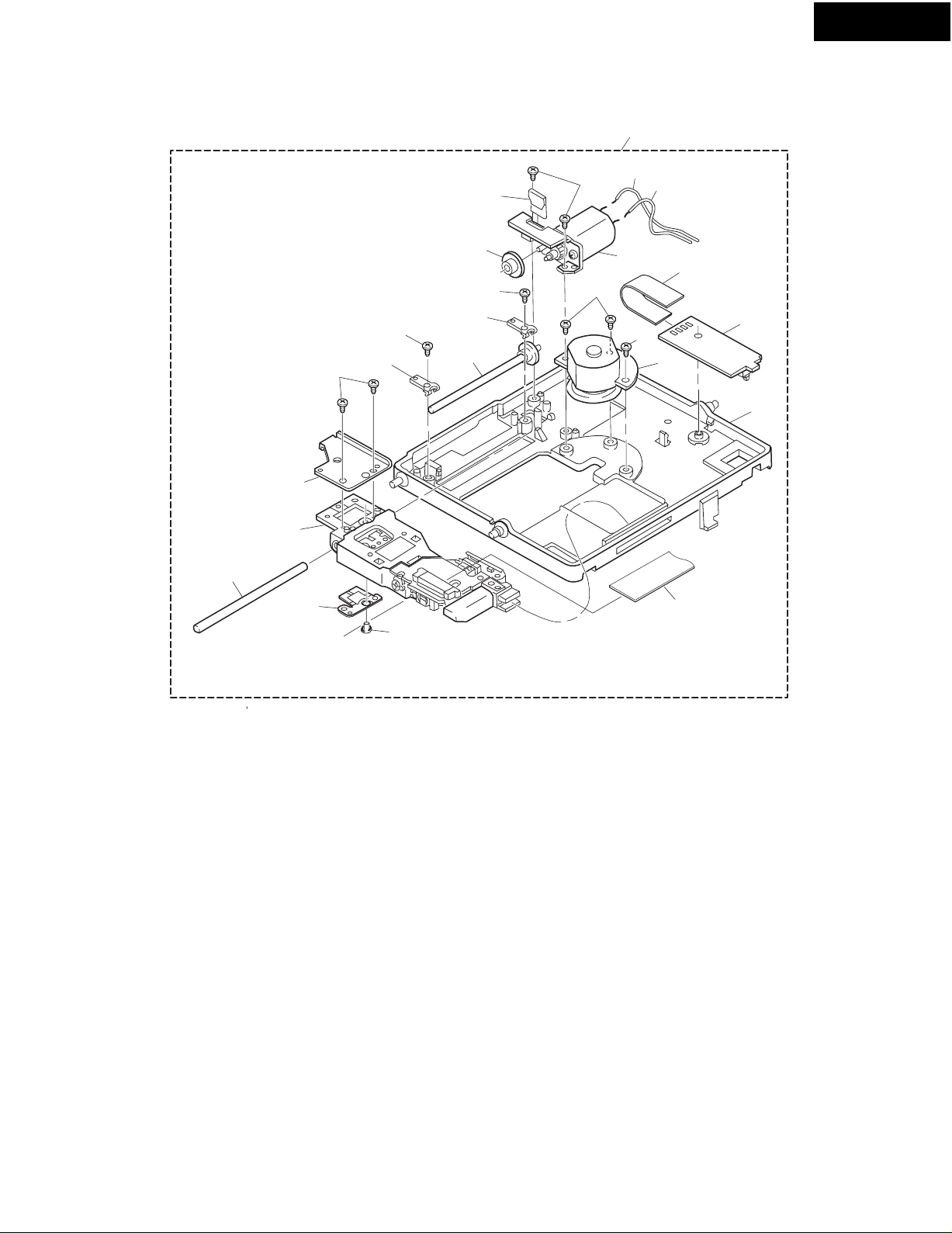

EXPLODED VIEW

MD-101A

19

P901

43

E801

46

43

17

41

F901

U5

47

Z1

P702

18

18

J10

Z5

23

U2

23

15

3

Z4

U1

Z3

8

U4

3

18

P801

21

44

23

24

1

U3

T901

5

11

15

15

27

3

39

13

11

31

32

33

3

MD-101A

3

Page 9

EXPLODED VIEW PARTS LIST

MD-101A

REF NO. PART NO. DESCRIPTION

1 27111252 Front bracket

3 838130088

5 27100411

8 27191159

11 28141489

13 27190503A

15 838430107

17 830440069

18 29110083

19 27300750

21 28184826

23 838930088

24 28141472A

27 27212354

31 28191944A

32 28191945

33 28198939

39 28325966

41 27122915

*

41 27122916 Rear panel <GT>

*

41 27122917 Rear panel <GR>

*

43 838430088

44 29362968

*

44 29360687

46 27191143

47 29362285

NOTE: THE COMPONENTS IDENTIFIED BY MARK ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE ONLY WITH PART NUMBER SPECIFIED.

[Notes]

This model may be produced in the case where it is manufactured in Malaysia, and Japan.

About the parts which have the mark on REF NO., part numbers differ by the case of the Malaysia production, and the case of

production of Japan.

When you exchange this part, check the manufacture place of the origin on the rear panel, and use the same parts.

27122915-1 Rear panel <DT>

27122916-1 Rear panel <GT>

27122917-1 Rear panel <GR>

29362968-1

3TTB+8B, Self tapping screw

Chassis

Holder, M

Cushion, Reg

KGLS-8RF, Holder

3TTB+10S(BC), Self tapping screw

4TTC+6C(BC), Self tapping screw

TAPE(CROSS-16U)

Bushing, #2271

Top cover

3TTB+8B(UN), Self tapping screw

Cushion

Front panel

Clear plate

Clear plate, RE

Facet, S

Knob, JOG

Rear panel <DT>

3TTB+8B(BC), Self tapping screw

, CLASS1 SPEC, <GR>

Label

Label,

CLASS1 SPEC, <GR>

Label, CLASS-1 <GT>

Holder <GR>

Label, caution

MANUFACTURED IN MALAYSIA

MADE IN JAPAN

MANUFACTURED IN MALAYSIA

MADE IN JAPAN

MANUFACTURED IN MALAYSIA

MADE IN JAPAN

MANUFACTURED IN MALAYSIA

MADE IN JAPAN

*

REF NO. PART NO. DESCRIPTION

E801 260208 Binder, UL

P901 253336VOL or

253335HIT

P901

P901 253333VOL or

T901 2301545

J10 1F999013UL Faston AS

P702 2045291512

P801 204417023

F901 252074

U1 1H478598-1B

U2 1H478599-1B

U3 1H478500-1B

U4 1H478501-1B

U5 1H478502-1B

Z1 24650035 KMK-260EDN, MD Mechanism

Z3 24611665

Z4 24605828

Z5 24604139A

253337HIT or

253338VOL

253332HIT

2301554

1H478598-1C

1H478598-1D

1H478599-1C

1H478599-1D

1H478500-1C

1H478500-1D

1H478501-1C

1H478501-1D

1H478502-1C

1H478502-1D

AS-CEE or

AS-CEE, Power supply cord <GT>

AS-CCEE or

AS-CCEE, Power supply cord <GR>

AS-UC-2 or

AS-UC-2, Power supply cord <DT>

NPT-1424D, Power transformer <DT>

NPT-1424G, Power transformer <GT,GR>

NCFC5-291512, Flexible flat cable

NCFC4-17023, Flexible flat cable

2A-SE-EAK , Fuse <GT,GR>

NAAR-7298-1B, Main circuit PC board ass'y <DT>

NAAR-7298-1C, Main circuit PC board ass'y <GT>

NAAR-7298-1D, Main circuit PC board ass'y <GR>

NADG-7299-1B, Microprocessor PC board ass'y <DT>

NADG-7299-1C, Microprocessor PC board ass'y <GT>

NADG-7299-1D, Microprocessor PC board ass'y <GR>

NAPS-7300-1B, Power supply PC board ass'y <DT>

NAPS-7300-1C, Power supply PC board ass'y <GT>

NAPS-7300-1D, Power supply PC board ass'y <GR>

NADIS-7301-1B, Display PC board ass'y <DT>

NADIS-7301-1C, Display PC board ass'y <GT>

NADIS-7301-1D, Display PC board ass'y <GR>

NAETC-7302-1B, AC outlet PC board ass'y <DT>

NAETC-7302-1C, AC outlet PC board ass'y <GT>

NAETC-7302-1D, AC outlet PC board ass'y <GR>

Door

Spring

Shaft

NOTE:

<DT> : Taiwanese model only

<GT> : Asian model only

<GR> : Chinese model only

MD-101A

Page 10

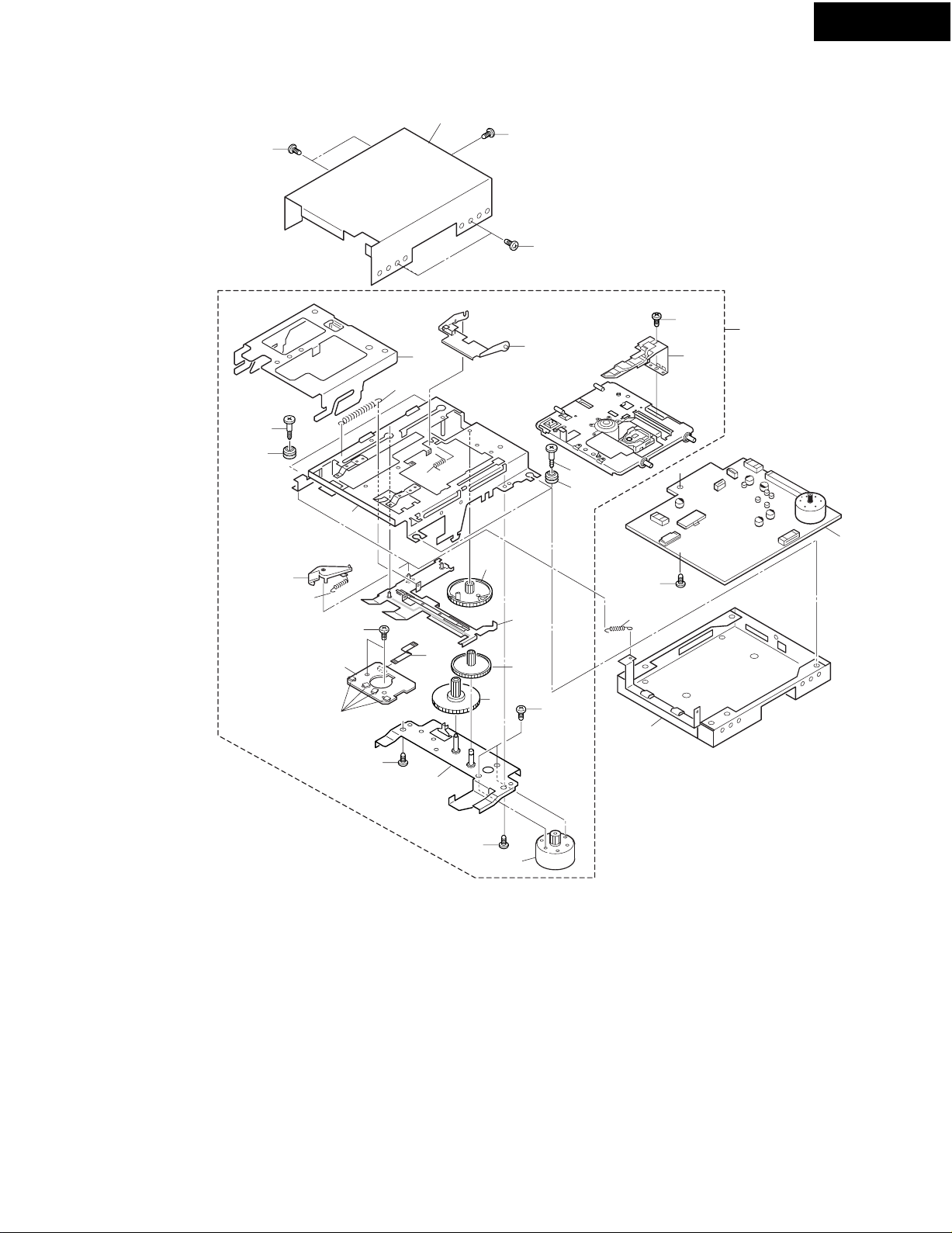

EXPLODED VIEWS OF MECHANISM-1

MD MECHANISM: KMK-260EDN

35

34

MD-101A

35

35

13

11

9

8

SW1-SW4

10

3

32

14

15

20

21

33

16

17

13

11

23

18

24

7

4

6

5

31

26

27

2

1

2

30

PARTS LIST

REF NO. PART NO. DESCRIPTIONREF NO.

10 --- Load Frame ass'y

11 2646-548-01 Insulator

13 2647-337-01 Screw, Step

14 --- Slide Frame

15 2646-559-02 Arm, head

16 2646-561-01 Spring, SP Tension

PART NO. DESCRIPTION

1 --- Motor Plate ass'y

2 7685-791-01 Screw +PTT2.6 x 5(S)

3 --- L-SW PC board

4 1792-100-21 Flexible flat cable(5 core)

5 2646-555-02 Gear(Relay B)

6 2646-554-01 Gear(Relay A)

7 X2646-726-1 Frame ass'y, slot

8 2646-563-01 Spring(Slot arm), Tension coil

9 2646-556-01 Slot Arm

17 2646-562-01 Spring, Tension coil

18 2646-560-02 Cam, mode

20 2627-529-01 Screw(+P1.7 x 2.5 Type2)

21 8620-021-71 MD Over write head

23 --- MD mount

24 7685-791-09 Screw(+PTT2.6 x 5 Type S)

26 2646-545-01 Spring(Door arm), Tension coil

27 --- Case(Lower)

30 X2626-328-1 Loading motor ass'y

31 7627-852-38 precision screw(+P1.7 x 1.8 Type 3)

32 7685-780-09 Screw +PTT2×3(S)

33 --- Loading ass'y

34 --- Case(Upper)

35 7621-259-25 Screw (+P2.6×4)

The mechanical parts with no part number

in the exploded views are not supplied.

Page 11

EXPLODED VIEW OF MECHANISM-2

MD MECHANISM: KMK-260EDN

MD-101A

69

65

64

68

66

63

57

51

67

58

56

57

52

51

51

59

55

53

54

71

61

59

60

62

70

PARTS LIST

REF. NO. PART NO. DESCRIPTION

51 3348-998-51 Pan tapping screw(M1.4×3.5)

52 2167-550-01 Plate(M), Pre load

53 --- Wire, SL motor lead

54 --- Wire, SL motor lead

55 X2162-145-1 Sled motor ass'y

56 2646-571-11 Gear(MD)

57 2167-551-01 Plate(M), main shaft fixed

58 X2162-144-1 Screw ass'y, lead

59 2646-358-11 Screw(B1.7 x 4)

60 X2162-143-1 Spindle motor ass'y

61 --- Mounted, PWD(D)SW

62 --- Chassis(M), mehanical

63 3039-041-01 Screw(M1.4 x 3)

64 2168-512-01 Plate, protection

65 2167-819-01 Shaft(M), guide

66 2647-338-01 Spring, rack

67 2627-529-01 Grip(1.7 x 2.5 type2)

68 8583-079-06 Optical pick up, KMS-260E

69 --- Deck ass'y, mechanical

70 1669-180-11 OP Flexible flat cable

71 1783-387-11 Flexible flat cable(7core)

The mechanical parts with no part number

in the exploded views are not supplied.

Page 12

EXPLODED VIEWS OF MECHANISM-3

MD MECHANISM: KMK-260EDN

MD-101A

MD Mount view

IC121

IC125

Test point-A

for adjustment

RF

VC

TE

IOP

I+3V

AGND

Side-A

IC171

IC201

D101

IC101

CN102

CN104

To over write head

CN110

Test point-B

for adjustment

RF

VC

TE

CN106

FE

IOP

I+3V

WP

CN103

Test point

(No use)

IC104

IC105

To main borad

IC301

D183

D181

To L-SW PCB

Side-B

Q162

Q102

Q101

IC103

Q103

X201

IC102

CN101

To pick-up unit

IC152

CN105

To D-SW PCB

Q182

Q181

IC181

Page 13

EXPLODED VIEWS OF MECHANISM-4

MD MECHANISM: KMK-260EDN

MD-101A

L-SW PC BOARD VIEW

SW1 SW2 SW3 SW4

CN107

The mechanical parts with no part number

PARTS LIST

REF. NO. PART NO. DESCRIPTION

IC101 8752-080-95 CXA2523AR, IC

IC102 1781-569-21 90M, oscillator

IC103 8729-903-10 FMW1-T-148, IC

IC104,IC105 8759-689-63 RH5RZ35CA-R1, IC

IC121 8752-404-64 CXD2662R, IC

IC125 8759-671-27 MSM51V4400E-70TS-K, IC

IC152 8759-574-24 BA5984FP-E2, IC

IC171 8759-640-39 BR24C02F-WE2, IC

IC181 8759-523-35 TC74ACT02FT(EL), IC

IC201 8752-926-12 CXP740010-060R, IC

IC301 6700-563-01 AK4552VT-E2, IC

Q101 8729-028-91 DTA144EUA-T106, Transistor

Q102 8729-026-53 2SA1576A-T106-QR, Transistor

Q103 8729-028-96 DTC114EUA-T106, Transistor

Q162 8729-101-07 2SB798-T1DK, Transistor

Q181 8729-018-75 2SJ278MY, Transistor

D101 223269R2 1SS355, Diode

D181,D183 8719-046-87 F1J6TP, Diode

Q182 8729-017-65 2SK1764KY, Transistor

X201 1767-179-31 12M, oscillator

CN101 1691-385-21 Connector, FFC/FPC(21P)

CN102 1778-461-11 Connector FFC/FPC(29P)

CN103,CN105,CN110 1779-345-11 Connector FFC/FPC(7P)

CN104 1778-283-11 Connector FFC/FPC(4P)

CN106 1779-353-21 Connector FFC/FPC(5P)

SW1-SW4 1771-092-21 Push switch (1key)

SW5 1771-327-11 Switch 2pin push(2key)

CN107 1785-242-21 Connector, FFC/FPC(5P)

CN108 1794-627-21 Connector, FFC/FPC(7P)

(MD mount section)

--- --- Mount, L SW

--- --- PWB, L SW

--- --- D SW mount

--- --- D SW PWB

in the exploded views are not supplied.

D-SW PC BOARD VIEW

SW5

CN108

Page 14

BLOCK DIAGRAM

MD-101A

BLK

STB

CLK

DATA

36

42

41

Q802

SUB MICROPROCESSOR

FLTUBE CONTROLLER

TMP87C44U

1

301444 33

CS

CLK

DATA

RESET

OPERATION

KEYS

LED

LED

JOG-B

JOG-A

Q801 FL TUBE

WITH DRIVER IC

HCA-14SS02T

KEY1

KEY0

76

77

36

3

2

9

10

6

8

P402A

Q803

REMOTE

SENSOR

SPS-440-1

REMO61

MAIN MICROPROCESSOR

(SYSTEM CONTROL)

23

DIN1

DIN2

AC

AC

Q703,Q704

Q713,Q705

FILAMENT

ON/OFF

27 FILAMENT

Q701

UPD78F0058GC

131912

21

20

SYSDA(SDATARC)

Q709

STOP KEY RESET

MECLK(CLK)

MERESET

MECS(RCREQ)

PDOWN

641162

60

63

SYSOUT50

51

SYSIN

LINEMUTE49

MEMUTE(AMUTE)

MDREQ

MEDATA(SDATAMD)

Q706

BUFFER

MD MECHANISM

POWER CONTROL

Q702

LEVEL SHIFT

74HCU04

MDREQ

MEMUTE(AMUTE)

MEDATA(SDATAMD)

KMK-260EDN

Q903,Q904

DRIVER

+36V(Q801,Q802)

M+5V(MD MECHA)

H+5V(MD MECHA)

+5V(DIGITAL INPUT)

3.3V(MD MECHA)

(Q701,Q702,Q709,Q802)

Q707,Q708

MUTE DRIVER

RESET(Q701)

POFF(Q701)

+5V(MD MECHA)

+5V

+B(FILTER)

-B(FILTER)

L IN

R IN

L OUT

R OUT

Q901

D902,D913

Q711

BMR0101

Q905

7805

Q906

29M05

Q907

29M33

Q902

29M05

Q101(1/2)

Q101(2/2)

POWER TRANSFORMER

D901

Q203

Q204

Q405

OPT

ON/OFF

5V

T901

DIGITAL

INPUT 1

Q401

P402

Q403

BUFFER

74HCU04

Q201,Q205

MUTE

Q202,Q204

MUTE

C902

DIGITAL

INPUT 2

Q402

L901

P101

C901

RI

REMOTE

CONTROL

P701

L

INPUT

R

ANALOG

L

OUTPUT

R

AC OUTLET

P902

P901

AC IN

MD-101A

Page 15

MD-101A

A

SCHEMATIC DIAGRAMS

NADIS-7301

U4

DISPLAY PC BOARD

1

33

GND

34

GND

35

SUB_BLK

FL_STB36

GND

37

38

GND

39

GND

VDD40

FL_DATA41

FL_CLK42

GND

43

SUB_DATA

44

S-CLK

1

R805

2

100

28

31

32

GND

GND

GND

SUB_ACK29

SUB_STB 30

Q802

TMP87PH47U

GND

GND

GND

GND

CHECK

45678

3

2

R804

100

GND

GND

R803

100

GND

GND

F1A1F1B2F1C

3

2324252627

GND

GND

GND

GND

GND

GND

GND1 19

VAREF18

VASS[GND] 17

OSC2 16

OSC1 15

RESET14

TEST[GND]13

GND

GND

GND

GND

9

10

11

BCDEFGH

NOTE

.

THE COMPONENTS IDENTFIED

REPLACE ONLY

.

Q801

HCA-14SS02T

1

INB

5V5

2

INA

OUT4

3

10K

R824

22

21

20

12

1K

R801

473

C801

R80210K

104

C804

104

C811

JOGB

P801B

C814

104

X702

8.0MHZ

LED

C802

JOGA

102

5V

Q805

TC7S00FU

4.8

GND

FLCS

REMO

FLCLK

FLDATA

FLRESET

R813

C815

C816

KEY1F2KEY0

10K

S808

EJECT

223

223

F1

S807

C809104

+VDISP

FL_CLK34

FL_DI33

FL_DO32

1K

R827 1K

R826

C817

R814

1.8K

S814

DISPLAY

SLR-332

D801

STANDBY/ON

R825

33K

C810

104

223

FL_BLK36

FL_STB35

VDD137

VDD238

1K

R8291KR828

+36

MULTI JOG

R812

3.9K

R815

1K

S813

STANDBY/ON

R820

470

VSS139

D802

NP41

VSS240

R811

1.8K

S806

YES

R816

820

S812

INPUT

R821

UDZS5.6B

F2A42

F2B43

R819

470

F2C44

R8101KR809

S805

REC

R817

470

S811

REC_MODE

100

223

C806

REMO

470

R822

C807

R818

390

104

S810

C805

820

S804

FR

CD_DUB

+4.8

100/6.3

R808

470

FF

S803

KEY1

S809

PLAY

C812

EDIT/NO

R830

1K

R807

390

S802

STOP

/PAUSE

104

Q803

SPS-440-1-N

KEY0

S801

C813

104

VOLTAGE (MEASURED WITHVOLTMETER) IS

.

ELECTROLYTIC CAPACITORS (

.

ALL CAPACITORS ARE IN pF/50WV UNLESS OTHERWISE NOTED.

EX) 030 3pF 330 33pF 331 330pF

.

ALL RESISTORS ARE IN OHMS 1/4WATTS

.

THE THICK LINES ON PC BOARD ARE THE PRINTING SIDE OF THE PARTS.

EX) PRINTING SIDE

.

CIRCUIT IS SUBJECT TO CHANGE FOR IMPROVEMENT.

POWER SUPPLY PC BOARD

U1

NAAR-7298

Q904

2SB1068

Q905

MPC2905

+5.1

P903

78

GND34

OPTOFF23

K1 77

NC424

+36

Q705 KRA107S

R734

K0 76

XT1 73

VDD0[+5VD] 74

AVREF0[+5VE] 75

UPD78F0058GC

NC525

NC626

FILAMENT27

GND728

R707

R705

R703

+VDISP

10K

72

XT2

Q701

GND829

GND930 IC[VPP] 71

1K

1K

1K

Q713

KRC107S

X701

X1 70

GND1031

+36

5.0MHz

X2 69

VDD1[+5VB] 68

VSS1[GND12]33

GND1132

PDOWN

MECS

MERESET

MECLK

SYSDA

MEDATA

R737

R738 22K

65

64

66

67

GND32

MEMUTE

SUB_ACK

VSS0[GND34]

STBYLED36

GND1334

GND1435

GND1537

Q703

22K

2SD655

Q704

5VBK

5V

63

62

REQ

POFF

GND30

GND29

GND28

GND27

GND26

GND25 54

GND24 53

GND23

SYSIN 51

SYSOUT

LINEMUTE

GND22

GND21

GND20

GND19

CHKSIG

SCHECK

JAPAN

GND1638

GND1739

61

RESET

REMIN

METEST

GND1840

R708

1.8K

2SD655

+5

R728

60

59

58

57

56

55

52

50

49

48

47

46

45

44

43

42

41

R709

10K

1.8K

C701

473

R725 47K

R720 10K

R719 10K

R718 10K

R717 10K

R745

R710

1.8K

R743 10K

Q712

KRC104S

C708 223

R912

390

0

R711

1.8K

C702

R712

473

1.8K

C707

1/50

1SS352

D705

C922

104

C923

220/6.3

Q706

KRA107S

R726 330K

UDZS5.6B

Q711

BMR0101

OUT

R740 22K

D911

1SS352

D912

GP104003E

D702

1SS352

D701

10K

R723

To P402

R718: MGR,MGT,

MDT only

R745: MJJ only

VCC

R715

330

R739

4.7K

10K

R910

R716 10K

P402A

OPT OFF

C928

R909 470

473

D903

C909

R721

470

223

UDZS5.1B

R714

10K

6

78

GND

Q702

9

R713

330

R722

470

P903A

+5.8

4

5

74HCU04

101112

5.6V

3

+0.26

R729

3

2

10K

5

6

R730

2

13

C929

3

NADG-7299

U4

MICROPROCESSOR

P801A

JOGB

F2

F1

REMO

FLCLK

FLDATA

FLRESET

KEY0

KEY!

FLCS

LED

JOGA

5V

PC BOARD

R735

2.7K

R736

2.7K

REMO

4

R002

2.2K

R001

2.2K

FLASH0

FLASH1

RESET

5V

IC

P001

for

SOFT VERSION UP

R701

2.7K

R702

2.7K

5

1

GND

ROTEN12

ROTEN23

AVSS[GND]4

GND25

SUB_STB6

AVREF1[+5VA]7

SUB_RESET8

SUB_DATA9

SUB_CLK10

MEDA11

SYDA12

MECLK13

FLASH114

FLASH215

GND316

GND417

GND5

18

MERESET

19

20

MECS

R706 1K

R704 1K

SHUT

80

21

79

GND35

GND36

NC222

DOWN

DOUT

MGND2

DIN0

DIN1

M+5VB

MGND1

MD MECHANISM

CLK

M+5VA

HGND

SDATAMD

H+5V

SDATARC

RCREQ

Page 16

WITH PART

C910

+5.8

ARE CRITICAL FOR SAFETY.

MARKBY

NUMBER SPECIFIED.

ARE IN F/WV.

u

)

333 0.033uF

UNLESS OTHERWISE NOTED.

C920

D910

Q902

10/16

G

IO

MPC29M05

100/6.3

DCVOLTAGE.

+VDIS

D914

1SS352

22/16

C908

(NO INPUT SIGNAL)

Q901

KTD863

+36

4.7/50

UDZS18B

R905 100

R906 100

C913

D902

UDZS18B

D913

+10.2

22000/16

R904

R916

D904

D905

33K

C907

[NOTES]

MJJ : Japan model

MDT : Taiwanese model

MGR : Chinese model

MGT : Korean model

Q908

KRA107S

3.3K

47/50

D906

RS403M

Q909

KRC107S

C911

C906

MD-101A

AC OUTLET PC BOARD

U5

MGT

NAETC-7302

F901

T2AL250V

J1B J2B

+42

D901

GP104003E

C905

47/50

224

C904

R915

33K

JL901B

D901,D906-D909

RL1N4003

or GP104003E

334

C903 473

JL901A

F1

F2

AC2

GND

AC1

C951

473

NC

P902

T901

AC OUTLET

NAPS-7300

J1A

L901

C901

C902

C901,C902

MJJ

103Z

MDT

103M

MGR, MGT

472M

MJJ,MGR,MDT

NAETC-7302

P902

J1B

J2B

U3

POWER TRANSFORMER

PC BOARD

J2A

P901

AC OUTLET

AC IN

MJJ : 100V 50/60Hz

MGT,MGR : 230V 50/60Hzz

MDT : 120V 60Hz

R729

Q904

Q905

+5.1

10K

2

13

R907

IO

G

MPC2905

470/6.3

3

2

8

5

6

4

470

R730

1

Vcc

C929

100/6.3

22K

C917

1

Q709

NJM4565M

Q709

7

473

C925

C703

R908

1.5K

R917

1.5K

10/16

D703

1SS352

104

C926

L902

Q903

D704

1SS352

C927

10/16

R724

100

KRC107S

C706

Q710

KRC107S

R731

R732

Q708

1SS352

L903

L904

223

82K

100

C704

C705

470K

D706

+5.0

100/16

100/16

R744

Q707

KRA107S

L905

Q906

MPC29M05

IO

G

C918

470/6.3

KRA107S

MPC29M33

Q907

IO

G

+3.3

220/6.3

RI

POWER CONT

C919

P905

P905A

C914

2200/16

-11.0

C912

334

DIN0

DIN1

KRA107S

OPT OFF

Q405

C405

P402

To P402A

1.2K

R110

R105

390

(1/2W)

R106

390

(1/2W)

LIN

1.2K

R109

-2.8

D102

D101

R107

UDZ2.4B

UDZ2.4B

+2.8

1.8K

R108

1.8K

C106

C105

C103

22/50

22/50

C104

100/6.3

100/6.3

RIN

P906

P906A

LIN

RIN

R914

120 (1/2W)

R408

1K

R407

1K

R406 470

R405 470

74HCU04

223

1

NJM2100

7

Q101

8

Q101

9

10

11

12

13

Vcc

14

4

2

3

5

6

C403

C101

C102

104

C404

100/6.3

R401

R403

100K

R404

C932

BL02RN2-R62

R727

470

100K

473

100

R402

100

L701

LOUT

ROUT

Q403

GND

78

6

5

4

3

2

1

R101

18K

22K

101

R103

101

22K

R104

R102

18K

C709

101

C401

C402

C933

Q401

1

104

DIGITAL INPUT

OPTICAL

Q402

2

104

C710

P701

473

RI

C711

473

473

P101

L

INPUT

R

ANALOG

L

OUTPUT

R

P102

P102A

120

R913

1.5K

R221

D201

UDZS4.7B

R222 1.5K

(1/2W)

C915

+9.1

470/16

+4.3

473

C213

R741

220K

104

C214

R742

330K

C916

470/16

R229

R217

R218

R230

100

100K

100K

100

R219

R220

-9.5

-B

5

6

27K

27K

6

5

NJM4565M

Q203

R203

27K

C203

101

27K

R201

27K

R202

C204 101

R204 27K

Q204

NJM4565M

R205

R207

1.2K

822

822

R208

1.2K

470

C207

822

C208

822

NJM4565M

R209

1.5K

C209

C210

R210

1.5K

102

102

2

3

3

2

4

Q203

8

NJM4565M

8

Q204

4

R225

R211

R212

100K

100K

2.2K

R213

470

2.2K

R215

2SD655

2.2K

R216

R214

470

R226 2.2K

Q205

Q206

2SD655

C211

47/50

1

1

C212

47/50

MUTE

7

470

C205

C206

R206

7

R227

470

2SD655

R228

ROUT

LOUT

Q201

Q202

2SD655

470

H+5V

SDATARC

RCREQ

MDREQ

PWRCNT

5VB

3.3V

RESET

AMUTE

PDOWN

KMK-260EDN

5VA

LIN

SPL/XSPD

C930

104

RIN

GND1

ROUT

LOUT

AGND2

P702

AGND1

Page 17

PC BOARD CONNECTION DIAGRAM

MD-101A

AC IN

U5

NAETC-7302

AC outlet

PC board

AC-H AC-G

P901

U3

NAPS-7300

Power supply

PC board

J1A

J2A

J2B

J1B

DIGITAL INPUT

2

1

Q401

U1

P402

NAAR-7298

Main circuit PC board

P904

C913

JL901B

For MD

adjustment

Q402

RI

REMOTE

CONTROL

ANALOG

OUTPUT

Q906

Q905

Q902

INPUT

Q907

P102

P906

P905

P903

ROUT

GND

LOUT

GND

-11V

GND

GND

GND

+10.2V

GND

LIN

GND

RIN

RI

+3.3V

GND

-5.0V

POWER CONT

GND

+5.1V

GND

+5.1V

+36V

F1

F2

POFF

GND

+5.8V

P102A

P906A

U2

NADG-7299

Microprocessor

P905A

PC board

P903A

P702

T901

Power transformer

AC1

GND

JL901A

Remote sensor

GND

AC1

AC2F2F1

STANDBY/ON

Q803 NCDIS-7301

D801

DISPLAY

Q801

2

2

S814

STANBY/ON

S813

CN110

DOUT

MGND1

MGND2

S812

INPUT

1

FL tube

Sub microprocessor

CN102

CLK

DIN0

DIN1

M+5VB

M+5VA

HGND

SDATAMD

H+5V

SDATARC

RCREQ

MDREQ

KMK-260EDN

MD Mechanism

FLDATA

FLCLK

+VDISP

KEY1F2KEY0

F1

P801B

25137301

X702

Q802

LIN

RIN

5VA

5VB

PDOWN

PWRCNT

FLRESET

REMO

RESET

FLCS

GND

3.3V

AMUTE

SUB_ACK

GND

LP_MODE

5V

JOGA

LED

22

GND1

SPL/XSPD

JOGB

S810S811

CD_DUB

ROUT

U4

NADIS-7301

Display PC board

AGND2

NO

2

LOUT

S809

AGND1

P801B

REC

YES

222

S806

S805

2

Main microprocessor

S808

MULTI JOG

S807

S807

FR

FF

S803

2

S804

2 2

2

PLAY

S801

S802

STOP

XOPT-DIN1

Q701

X701

DIN2

GND

C922

P402A

P801A

P001

Page 18

MD-101A

A

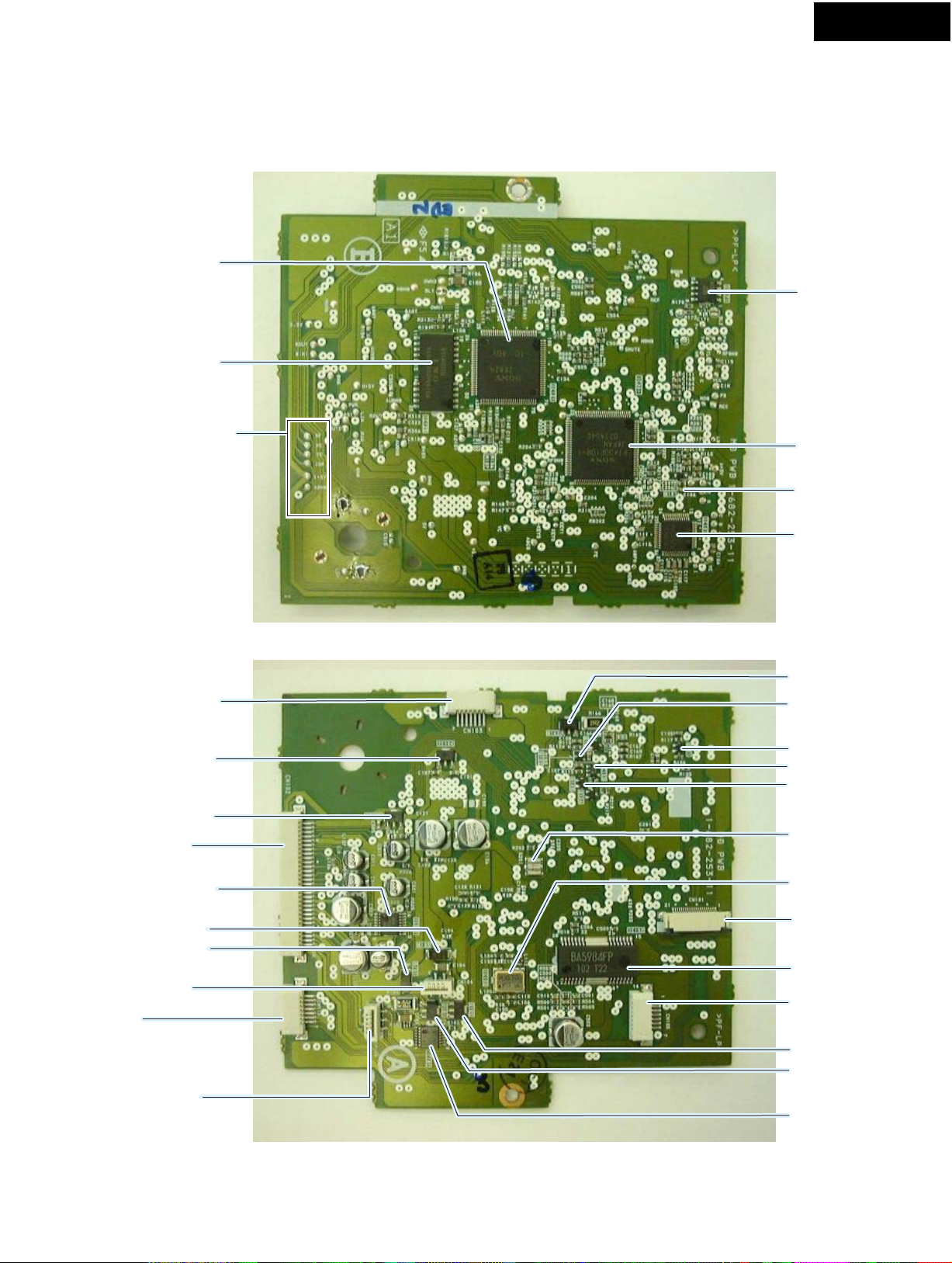

PRINTED CIRCUIT BOARD VIEWS-1

S808

J205

C812

R825

D802

R824

R829

EJ

PLAY

C801

R826

S803

2 2

R802

J203

R817

R828

P801B

J204

YES

222

S807

S807

FR

FF

2

2

S802

STOP

R801

C802

R821

R803

C814

S805

S804

S801

23

S806

7

J202

J201

2

REC

7

12

Q802

1

Soldering side

R522

C804

R525

R811

R521

R528

R523

R822

C809

C810

R818

C807

R527

R526

R524

C816

R809

R807

C815

R810

C813

R808

C811

R812

R813

2

C817

3

BCD

U4

DISPLAY PC BOARD

(NADIS-7301)

Component side

S810 S811

S809

2 2

2

7

J196

CD_DUB

7

J197

20

LP_MODE

E855

CUSHION

J191

15

R804

R805

1

Q805

44

R827

7

J187

J188

E854

CUSHION

R819

R814

S812

1

INPUT

Q801

NCDIS-7301

C806

J185

J184

R830

R820

25137301

J183

R815

X702

12

J189

12

J190

J186

Q801

R816

C805

Q803

J181

STANBY/ON

2

2

S814

DISPLAY

VCC

VOUT

S813

GND

D801

J200

J195

Q802

NO

12

J198

J199

J192

J193

J194

34

U3

POWER TRANSFORMER PC BOARD

(NAPS-7300)

Component side

AC-H AC-G

T901

C903

JL901A

L901

L901

C902

223 OR6

T901

U5

AC OUTLET

PC BOARD

P901

AC-GAC-H

C901

(NAETC-7302)

F901B F901A

15

4

J1B

J952

J951

15

F901

T2AL250V

25137302

NCETC-7302

J2B

J1A

J2A

NCPS-7300

1

25137300

P902

0

P902

Soldering side

C951

5

Page 19

MD-101A

A

PRINTED CIRCUIT BOARD VIEWS-2

U2

1

2

3

4

5

MICROPROCESSOR PC BOARD

(NADG-7299)

Component side

E851

Q206

PDOWN

MDREQ

SUB_ACK

REMO

FLCLK

KEY1

KEYO

LOUT

ROUT

DOUT

JOG

JOG

GND

-VB

E852

RIN

3.3V

SDA

SDA

CLK

DIN

DIN

C206

C210

LIN

5V

C212

J152

J151

J150

J149

J148

J147

J146

AGND

AGND

GND

SPL/XSPD

5V

AMUTE

RESET

PWRCNT

RCREQ

H+5V

HGND

M+5V

M+5V

MGND

MGND

J116

J114

J112

LED

5V

GND

FLCS

FLRECET

FLDATA

F2

F1

P801A

P001

P702

20

E853

22

C208

C204

J120

J117

J153

C929

J110

J159

12

12

12

15

J156

L904

J101

C205

L905

J130

L902

J129

L903

P402A

15

15

12

C211

C704

J115

J113

J157

J111

C209

J133

7

7

J121

J103

C214

C707

7

7

7

7

7

J162

J163

Q205

C207

C916

C203

7

C915

J158

20

J144

J145

C705

C925

C927

Q711

J137

J136

J135

J134

12 7

J124

C922

15

J118

J107

J102

777

J105

J106

20

J104

R913

J108

7

C916

C915

J143

J141

J125

J123

7

J154

20

7

7

J122

X701

J160

Q201

17

R914

J142

12712712

J139

J138

J131

12

7

Q202

P102A

12

J161

P906A

P905A

17

J140

P903A

7

J132

Q704

D912

C923

NCDG-7299

25137299

1

BCD

Soldering side

Q708

R742

Q703

J127

J128

J126

J119

D706

R206

R208

R210

R509

Q707

R214

R213

R211

R212

R205

R207

R209

R204

R218

8

Q204

R217

Q203

R219

R201

1

R229

R202

1

R220

R230

R508

Q709

8

R729 R730

D703

R731

R732

D704

C706

1

Q710

R740

D705

C930

C703

Q702

C928

R721R722

7

7

7

R503

R912

R735

R736

R701

R702

5V

J109

R704

R703

ICIC5V

R713

R709

R001R002

R708

8

C926

Q712

R716

14

1

R203

R715

R724

R215

C708

R744

Q702

R734

R216

R226

R741

R228

R227

R225

R222

R221

C213

D201

D903

C909

R910

R739

R909

R507

R743

R737

R738

21

R712

Q705

D702

Q706

R745

R720

R723

41

R707

C702

D911

R714

Q713

R505

R504

R506

R718

R717

R719

D701

R726

R725

C701

R728

61

80

Q701

1

Q701

R705

R706

R502

R711

R710

Page 20

MD-101A

A

PRINTED CIRCUIT BOARD VIEWS-3

U1

1

2

POWER SUPPLY PC BOARD

(NAAR-7298)

Component side

J924

P701

12

7

P102

C403

L701

R106

C106

J917

J922

J923

J921

J920

C101

C105

P402

C914

C914

R105

15

17

15

J918

25

C103

C104

C102

J916

P701

Q401

Q402

Q401

Q402

P101

P101

BCD

P904

C913

15

15

J912

Q907

7

J910

7

J908

C919

C918

7

J909

J911

D906

P905

7

JL901B

C911 C912

7

J906

Q905

Q906

J905

7

J904

C917

Q904

D901

17

J901

C910

C905

J903

C906

Q901

J902

Q902

C920

P903

C904

7

J907

C907

C908

7

J919

J914

1

J915

25137298A

NCAR-7298

P906

C913

J913

3

Soldering side

R403

1

7

R401

Q403

Q403

C401

R402

4

C933

C709

C710

C711

C932

R727

R404

C402

14

8

R501

C404

D102

R101

R103

R405

C405

Q405

Q101

R104

R406

D101

R408

R407

R915

R916

Q908

R904

R905

R906

D904

D905

R107

R109

1

R102

R108 R110

R917

D913

D902

R908

R907

Q909

D914

D910

5

Q903

Page 21

PRINTED CIRCUIT BOARD PARTS LIST-1

U1

MAIN CIRCUIT PC BOARD (NAAR-7298-1B/1C/1D)

CIRCUIT NO.

Q101

Q401,Q402

Q403

Q902,Q906

Q905

Q907

Q405,Q908

Q901

Q903,Q909

Q904

D101,D102

D901

D902,D913

D904,D905,D914

D906

L701

C103,C104

C105,C106,C910

C904

C905,C906

C907

C908

C911,C912

C913

C914

C917,C918

C919

C920

R105,R106

P101

P701

JL901B

P102

P402

P903

P905,P906

Q902A

Q905A

Q906A

Q902B,Q906B

PART NO.

ICs

22240608R1

24120083 or

24120086

222740046R2TO

22278005ENE

22278005DNE

22278033ENE

Transistors

2216480R2 or

2216350R2

2211853 or

2216605 or

2216604

2216470R2 or

2216340R2

2212855 or

2212853

Diodes

224490240R2

22380260 or

22380035

224551800R2

223234R2 or

223269R2

22380022F or

22380271F or

22380285F

Coil

230906

Capacitors

354782209

354721019

374722244

354784709

354780479

354742209

374723344

3504348

354742229S

354724719

354722219

354741009

Resistors

443523914

Jacks

25045594

25045601

Socket

25050271

Plugs

25055804

25055149

25055702

25055705

Others

27160484

27160472

27160227

82143010

DESCRIPTION

NJM2100M

GP1FA550RZ

GP1FA551RZ

TC74HCU04F

MPC29M05HF

MPC2905HF

MPC29M33HF

DTA114YKA or

KRA107S

2SD667-C or

KTD863-GR or

KTD863-Y

DTC114YKA or

KRC107S

2SB1068-U or

2SB1068-K

UDZ2.4B

RL1N4003 or

GP104003E

UDZS18B

1SS352 or

1SS355

RBV402 or

D3SBA20 or

RS403M

BL02RN2-R62, EMI filter

CE04W50V-22uF, Elect.

CE04W6.3V-100uF, Elect.

ECQ-V50V-224J, Plastic

CE04W50V-47uF, Elect.

CE04W50V-4.7uF, Elect.

CE04W16V-22uF, Elect.

ECQ-V50V-334J, Plastic

CE69W16V-22000M(LQ), Elect.

CE04W16V-2200uF, Elect.

CE04W6.3V-470uF, Elect.

CE04W6.3V-220uF, Elect.

CE04W16V-10uF, Elect.

RS1/2WBJ-390 ohm

NPJ-4PDWR405

NPJ-2PDB409

NSCT-7P99

NPLG-4P760

NPLG-5P133

NPLG-6P658

NPLG-9P661

RAD-153

RAD-141

(RAD-076), Heat sink

3P+10FN(BC), Pan head screw

MD-101A

NOTE:

<DT> : Taiwanese model only

<GT> : Asian model only

<GR> : Chinese model only

NOTE : THE COMPONENTS IDENTIFIED BY MARK

ARE CRITICAL FOR RISK OF FIRE AND

ELECTRIC SHOCK. REPLACE ONLY WITH

PART NUMBER SPECIFIED.

Page 22

PRINTED CIRCUIT BOARD PARTS LIST-2

MICROPROCESSOR PC BOARD (NADG-7299-1B/1C/1D)

U2

CIRCUIT NO.

Q203,Q204,Q709

Q701

Q702

Q711

Q201,Q202

Q205,Q206

Q703,Q704

Q705,Q706,Q707,Q708

Q710,Q713

Q712,Q804

D201

D701

D702-D706

D903

D910-D911

D912

L902-L905

X701

C101,C102,C203,C204

C205-C208

C209,C210

C211,C212

C214

C403,C929

C704,C705

C707,C808

C915,C916

C922

C923

C925,C927

R913,R914

P904

P102A

P402A

P702

P801A

P903A

P905A,P906A

E852,E853

E854,E855

Q905

PART NO.

ICs

22241383R2

22241670R3

222740046R2TO

22241210

Transistors

2211705 or

2211706

2211705 or

2211706

2216350R2 or

2216480R2

2216470R2 or

2216340R2

2214770R2 or

2216210R2

Diodes

224550470R2

224550560R2

223234R2 or

223269R2

224550510R2

223234R2 or

223269R2

22380260 or

22380035

Coils

230906

Oscillator

3010343

Capacitors

374721015

374728224

374721024

354784709

374721044

354721019

354741019

354780109

354744719

3000120

354722219

354741009

Resistors

443521214

Terminal

25060140

Sockets

25051526

2009990681UL

25052523 or

25052329

25052317 or

25052511

25051231

25051234

Others

27190540-1

28141471

82143010

DESCRIPTION

NJM4565M-D

MPD780056GC-038-8BT

TC74HCuF04F

BMR-0101D

2SD655-E or

2SD655-F

2SD655-E or

2SD655-F

KRA107S or

DTA114YKA

DTC114YKA or

KRC107S

DTC144EK or

KRC104S

UDZS4.7B

UDZS5.6B

1SS352 or

1SS355

UDZS5.1B

1SS352 or

1SS355

RL1N4003 or

GP104003E

BL02RN2-R62, EMI filter

CSTS0500MG06, Ceralock

ECQ-B50V-101K, Plastic

ECQ-B50V-822J, Plastic

ECQ-B50V-102J, Plastic

CE04W50V-47uF, Elect.

ECQ-V50V-104J, Plastic

CE04W6.3V-100uF, Elect.

CE04W16V-100uF, Elect.

CE04W50V-1uF, Elect.

CE04W16V-470uF, Elect.

FMC0H104Z, Super

CE04W6.3V-220uF, Elect.

CE04W16V-10uF, Elect.

RS1/2WBJ-120 ohm

NTM-1S68, Terminal

NSCT-4P1313

NSAS-10P0947

NSCT-29P2420 or

NSCT-29P2226

NSCT-17P2214 or

NSCT-17P2408

NSCT-6P1021

NSCT-9P1024

(CLAMP)

Cushion

3P+10FN(BC), Pan head screw

MD-101A

NOTE:

<DT> : Taiwanese model only

<GT> : Asian model only

<GR> : Chinese model only

NOTE : THE COMPONENTS IDENTIFIED BY MARK

ARE CRITICAL FOR RISK OF FIRE AND

ELECTRIC SHOCK. REPLACE ONLY WITH

PART NUMBER SPECIFIED.

Page 23

PRINTED CIRCUIT BOARD PARTS LIST-3

POWER SUPPLY PC BOARD (NAPS-7300-1B/1C/1D)

U3

CIRCUIT NO.

L901

C901,C902

P901A

JL901A

DISPLAY PC BOARD (NADIS-7301-1B/1C/1D)

U4

CIRCUIT NO.

Q801

Q803

Q802

Q805

D801

D802

X702

C805

S807

S801-S814

P801B

PART NO.

Coil

231287

Capacitors

3300030

3300031

Plug

25055675

Holder

25051111

PART NO.

FL Tube

212220

Remote sensor

241339

ICs

22241671R3

22241158R2

Diode

225338

224550560R2

Oscillator

3010341

Capacitor

355721019

Rotary encoder

25065621

Push switches

25035699

Socket

25052354 or

25052538

DESCRIPTION

NCH-3567, Choke coil

DE1307E472M-KH, IS <GT,GR>

DE1607F103M-KH, IS <DT>

NPLG-2P631

NSCT-7P898, Wire holder

DESCRIPTION

HCA-14SS02T

SPS-440-1-N

TMP87C447uF-3GC6

TC7S00FuF

SLR-332VR, LED

UDZS5.6B

CSTLS800MG56, Ceralock

CE04W6.3V-100uF, Elect.

EC11E18244, Rotaly encoder

NPS-111-S662

NSCT-17P2251 or

NSCT-17P2435

MD-101A

AC OUTLET PC BOAD (NAETC-7302-1B/1C/1D)

U5

CIRCUIT NO.

F901A, F901B

P902

PART NO.

Fuse holders

25052133

Sockets

25051637

25051990

25052611

DESCRIPTION

NSCT-1P2031 <GT,GR>

NSCT-2P1424 <GT>

NSCT-2P1777 <DT>

NSCT-2P2508, AC Outlet <GR>

NOTE:

<DT> : Taiwanese model only

<GT> : Asian model only

<GR> : Chinese model only

NOTE : THE COMPONENTS IDENTIFIED BY MARK

ARE CRITICAL FOR RISK OF FIRE AND

ELECTRIC SHOCK. REPLACE ONLY WITH

PART NUMBER SPECIFIED.

Page 24

FL TUBE VIEW

Q801:HCA-14SS02T

12G 11G 10G 9G 8G 7G 5G6G 4G 3G 2G 1G

ARTIST

MD-101A

CD-RW SKIP ON

FINALIZE

13Ga 13Gd13Gc13Gb

5

6

7

ARTIST

8

9

10

11

14Ga 14Gd14Gc14Gb

13G

(13G)

CD

23

-R W

24 25 26

SKIP ON

27

19 20 21 22

FINALIZE

16

17 18

14 15

12 13

(14G)

28 27 26 25 24 23 22 21 20 19 18 17

29

30

14G

(12G - 1G)

1 2 3 4 5

6 7 8 9 10

11 12 13 14 15

16 17 18 19 20

21 22 23 24 25

26 27 28 29 30

31 32 33 34 35

31

35

34

16 15 14 13 12 11 10 9 8 7 6 5

33

32

Page 25

MICROPROCESSOR CONNECTION DIAGRAM

MD MECHANISM

KMK-260EDN

P DOWN

RCREQ

RESET

SDATARC

MULTI JOG

EJECT

STANDBY

DISPLAY

FL BLK 36

FL STB 35

FL CLK 34

FL DI 33

Q801

FL TUBE with

built-in driver IC

HCA-14SS02T

F2

F1

/ON

PUSH

INPUT

Q805

CLK

a

b

d

c

e

RECYES

FR

FF

CD

REC

DUBBING

MODE

33 SUB BLK

36 FL STB

42 FL CLK

41 FL DATA

EDIT/NO

SUB_ACK 29

SUB_STB 30

RESET 14

SUBDATA 44

Q802

SUB

MICROPROCESSOR

TMP87C447uF-3GC6

Q704

Q703

PLAY

/PAUSE

STOP

SCLK 1

+36V

(+VDISP)

Q705

Q713

FL Tube Filament

to Power supply Circuit

+5 V

f

e

d

c

b

f

a

A MUTE

MDREQ

Q702

1

9

10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

BUFFER

74HCV04

2

3

8

5

12

11

GND

ROTEN1

ROTEN2

AVSS

NU

SUB_STB

AVREF1

SUB_RESET

SUB_DATA

SUB_CLK

MEDA

SYSDA

MECLK

FLASH1

FLASH2

MU

NU

NU

MERESET

MECS

4

6

13

80797877767574737271606968676665646362

NUNUNU

SHUT_DOWNNUOPT OFFNUNUNUFILAMENTNUNUNUNUNUVSS1NUNU

21222324252627282930313233343536373839

L IN

R IN

L OUT

R OUT

D IN1

Q711

BNR0101

RESET

5.0 MHz

OSC

X2

VSS0

VDD1

D IN2

SUB_ACK

RESET

NU

ME MUTE

K1

SDATA MD

+5 V

K0

POWER

SUPPLY

CIRCUIT

+5 V

VDD0

AVREF0

NU

Q709

BUFFER

XT2

IC(VPP)

X701

X1

Q701

MAIN MICROPROCESSOR

MPD780056GC-033-8BT

[NOTES]

NU: NO USED

STBY_LEDNUNUNUNU

Q712

POFF

Rch

Q710

61

REQ

REMIN

LINE MUT

Rch

RESET

RESET

NU

NU

NU

NU

NU

NU

NU

NU

SYS IN

SYS OUT

NU

NU

NU

NU

CHKSIG

CHECK

JAPAN

METEST

40

Q203(2/2)

+3.3 V

Q708

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

Q101(1/2)

BUFFER AMP

Q203(1/2)

4

6

Q707

BUFFER

74HCU04

3

512

Q205

Vcc

2

14

1

13

+4.8 V

Q403

+5 V

Q803

REMOTE

SENSOR

Q706

BUFFER

+5 V

INITIALIZE

Setup of the destination

R718,R745

MUTE

Q201

Q404

OPT OFF

Rch

Rch

+5 V

P101

L

R

L

R

Q401

Q402

P701

+4.8 V

STANDBY/ON

LED

MD-101A

INPUT

ANALOG

OUTPUT

1

DIGITAL

INPUT

OPTICAL

2

RI

REMOTE

CONTROL

MD-101A

Page 26

MICROPROCESSOR TERMINAL DESCRIPTIONS-1

Q701: MPD780056GC-033-8BT (MAIN MICROPROCESSOR)

MD-101A

PIN NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

FUNCTION FUNCTION

Not used. (Connect to ground)

NOT USED (GND)

ROTEN1

ROTEN2

AVSS

NOT USED

SUB STB

AVREF1

SUB RESET

SUB DATA

SUB CLK

MEDA

SYDA

MECLK

FLASH1

FLASH2

NOT USED(GND)

I

Pulse input terminal from rotary encoder (MULTI JOG).

I

I

Negative power supply input terminal for D/A converter.

I

Not used.

I

Output terminal of tip selection for serial communication with sub microprocessor.

O

Reference voltage input terminal for D/A converter.

---

Reset signal output terminal to sub microprocessor.

O

O

Serial data output terminal to sub microprocessor.

Clock output terminal for serial communication to sub microprocessor.

O

Serial data input terminal from MD mechanism.

I

Serial data output terminal to MD mechanism.

O

Clock output terminal for the serial communication with MD mechanism.

O

Input terminal for writing at the time of flash microprocessor use.

I

I

Not used. (Connect to ground)

I

I

I

MERESET

MECS

SHUT DOWN

NOT USED (OPEN)

OPT OFF

NOT USED (OPEN)

Reset output terminal for MD mechanism.

O

Signal output terminal for serial communication with MD mechanism.

O

Power failure detected signal output terminal to MD mechanism.

O

Not used. (Open)

O

Output terminal for control of the optical digital input.

O

Not used. (Open)

O

O

O

FILAMENT

NOT USED( GND)

Output terminal for filament control of FL tube.

O

Not used. (Connect to ground)

I

I

I

I

I

VSS1

NOT USED (GND)

Negative power supply input terminal. (Connect to ground)

I

Not used. (Connect to ground)

I

I

STBYLED

NOT USED (GND)

Output terminal for control of STANDBY/ON LED.

O

I

Not used. (Connect to ground)

I

I

I

PIN NO.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

METEST

JAPAN

CHECK

CHKSIG

NOT USED (GND)

LINEMUTE

SYSOUT

SYSIN

NOT USED (GND)

RESET

REMIN

REQ

POFF

ME MUTE

NOT USED (GND)

SUB ACK

VSS0 (GND)

VDD1

X2

X1

IC (VPP)

XT2 (OPEN)

XT1

VDD0

AVREF0

K0

K1

NOT USED (GND)

I/OI/O

DESCRIPTIONDESCRIPTION

The input terminal for test mode setup of MD mechanism.

I

Input terminal for carrying out initial setting of the destination

I

Input terminal for setting up the check mode of the program

I

Signal output terminal for check of program.

O

Not used. (Connect to ground)

I

I

I

I

Output terminal for muting circuit control

O

System control (RI) signal output terminal.

O

System control (RI) signal input terminal.

I

Not used. (Connect to ground)

I

I

I

I

I

I

I

I

Input terminal of system reset.

I

Input terminal of the remote control signal from the remote sensor.

I

Signal input terminal for communication with MD mechanism.

I

Input terminal of power failure detected signal.

I

Muting signal input terminal from MD mechanism.

I

Not used. (Connect to ground)

I

Signal input terminal of the completion of serial data reception from the sub microcomputer

I

Negative power supply input terminal of the port part.

---

Positive power supply input terminal.

--O

Connection terminal of the oscillation element of main system clock. (5MHz)

I

Internal connection terminal.

I

O

Sub system clock oscillation element connection terminal.

I

Positive power supply input terminal of port section.

---

Reference voltage input terminal of A/D converter.

I

I

Input terminal from operation keys. (Inputs by A/D conversion.)

I

I

Not used. (Connect to ground)

I

I

MD-101A

Page 27

MICROPROCESSOR TERMINAL DESCRIPTIONS-2

Q802: TMP87C447uF-3GC (SUB MICROPROCESSOR)

MD-101A

PIN NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

FUNCTION DESCRIPTION

SUB_CLK

NOT USED

NOT USED

NOT USED

CHECK

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

TEST

RESET

OSC1

OSC2

GND

WAREF

NOT USED

NOT USED

NOT USED

NOT USED

I/O

I

Input terminal of serial data clock from main microprocessor.

---

Not used. (Connect to ground)

---

---

Check terminal.

O

Not used. (Connect to ground)

---

---

---

---

---

---

--I

Test terminal.

Input terminal of system rest.

I

I

Connection terminal of the oscillation element.

O

---

Negative power supply input terminal of A/D converter.

---

Reference voltage input terminal of A/D converter.

Not used. (Connect to ground)

---

---

---

---

PIN NO.

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

FUNCTION DESCRIPTION

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

SUB_ACK

SUB_STB

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

FL STB

NOT USED

NOT USED

NOT USED

VDD

FL DATA

FL_CLK

NOT USED

SUB_DATA

---

Not used. (Connect to ground)

---

---

---

---

--O

Output terminal which gives the completion notice of data receipt to main microcomputer.

Input terminal of the STB signal from the main microcomputer

I

---

Not used. (Connect to ground)

---

---

---

--O

Output terminal of the STB signal to the FL display driver IC.

---

Not used. (Connect to ground)

---

---

--O

Output terminal of the serial data to the FL display driver IC.

Output terminal of the serial clock to the FL display driver IC.

O

---

Not used. (Connect to ground)

I

Input terminal of the serial data from the main microprocessor.

MD-101A

Page 28

ADJUSTMENT PROCEDURES-1

The necessity for adjustment

necessary

Adjustment item

Adjustment of Temperature Compensation Offset

1

Adjustment of laser power

2

Check of laser power

3

Adjustment of Traverse (EF balance)

4

Check of error rate in high reflectance disk

5

6

Check of error rate in low reflectance disk

7

Adjustment of focus Bias

8

Check of focus bias

unnecessary

Pickup unit

The exchanged parts

Parts on MD

mount,

and Motors

Mechanical

parts

MD-101A

REMARKS

When an error rate is worse than

the standard value, perform this

work.

Notes in adjustment

1. Laser of pickup

In case adjust, don't look at the laser of the pickup unit.

You have fear of loss of eyesight.

2. Perform adjustment using test mode.

3. Perform adjustment as the indicated turn.

4. After adjustment should cancel test mode.

Equipment required for adjustment

1. Measuring instrument

Name

Laser power meter

Optical sensor

Oscilloscope

Digital volt meter

2. T est disk

Name

MO disk

High reflectance disk

Manufactured

LEADER

LEADER

Manufactured

Description

LPM-8010

LP-8010-02

Frequency range is 40MHz or more.

The calibration of the probe is performed.

Description

Standard disk for recording/play back

A-BEX TMD-381

3. JIG

Name

Extended JIG

Flexible flat cable

0J12

0F001

DetailsPart No.

PC board

FFC socket

1mm pitch, 7 cores

Part No. NCJIG-0J12

Part No. 25052307

Page 29

ADJUSTMENT PROCEDURES-2

Explanation in test mode

1. How to test mode to enter

(1) Connect the power supply cord in the wall socket.

(2) While hold down the YES button, press the DISPLAY button

at standby state.

(3) Release only the DISPLAY button, with press the YES button.

(4) Press the STANDBY button, with press the YES button.

(5) Release the STANDBY/ON and the YES simultaneously.

FL Display

TEMP ADJUST

Time chart

YES

DISPLAY

STANDBY

MD-101A

push

release

push

release

push

2. How to cancel test mode

Disconnect the power supply cord from the wall socket.

release

3. Cautions on Test Mode Use

Don't use the disk which you must not eliminate in test mode.

Push the EJECT button after pressing the EDIT/NO button, when taking out disk in test mode.

4. Basic operation in Test Mode

Cancel

EDIT/NO YES

MULTI JOG

Enter

PUSH TO ENTER

5. Selection Method in Test Mode

Display

EDIT/NO

Cancel

JOG PUSH

YES

In the test mode.

Select the test mode.

Adjustment

TEMP ADJUST

LDPWR ADJUST

LDPWR CHECK

LOAD CHECK

SLEVEL CHECK

EFBAL ADJUST

FBIAS ADJUST

FBIAS CHECK

CPLAY MODE

CREC MODE

EEP MODE

POINT ADJUST

Record of the fiducial point of temperature data.

Laser power adjustment

Check the laser power

Check the loading operation.

Check the lens of the pickup.

Traverse (EF balance) adjustment

Focus bias adjustment

Check the focus bias adjustment

Continuous play back mode

Continuous recoding mode

Data memorized in non-volatile memory

Setting the access point on CREC and CPLAY mode.

Page 30

ADJUSTMENT PROCEDURES-3

Preparation of adjustment

1. Make the extended JIG and connection.

Connect to the MD mechanism

Extended JIG (KIT)

Part No.0J12

Flexible flat cable

Part No. 0F001

Socket

Part No.25052307

Jumper wire

MD-101A

PC board

Part No.NCJIG-0J12

Connect to the

CN110

on the MD mechanism.

back side view

2. Setting the WP terminal.

Be sure to do this work before adjustment.

An adjustment value cannot be set up unless you do this work.

(An adjustment value is not memorized by EEP ROM on MD mount.)

Extended JIG

0J12

WP

Connect to the

P000A

on the JIG.

Attach the wire to required point

so that it may be easy to connect

measuring instrument etc.

Connect the the chassis earth

Page 31

ADJUSTMENT PROCEDURES-4

The adjustment method

1

Adjustment of temperature compensation value

[NONE]

(1) Perform circumference temperature in the 22 to 28 degrees state.

(2) Adjust, after exchanging D101, and the temperature of this part turns into the

same temperature as circumference temperature.

[CONNECTION]

(1) Connect to extended jig and the unit.

(2) Short-circuit WP terminal on the extended jJIG and the chassis ground.

MD-101A

(Refer to setting WP)

FL Display

[Adjustment]

(1) Select the TEMP ADJUST in the test mode.

(2) Press the JOG knob.

(3) Press the JOG knob.

TEMP ADJUST

TEMP=&&

TEMP=&&SAVE

TEMP ADJUST

Page 32

ADJUSTMENT PROCEDURES-5

Adjustment of laser power

2

[Preparation]

(1) Connect digital volt meter to I+3V and IOP on Extended JIG.

(2) Set the optical sensor to laser power meter.

(3) Loading of the optical sensor to the unit.

Extended JIG

Part No. 0J12

MD-101A

Digital volt meter

To MD

mechanism

[Adjustment]

(1) Turns the JOG knob, and select the

LDPWR ADJUST mode.

(2) Press the JOG button .

(3) Turn the JOG knob, adjust so that reading

of the laser power meter becomes 0.86 to 0.92mW.

[Note]

Do the work to (5)-(7) within 15 seconds.

Since continuation luminescence of the 7mW laser power is carried out, if it is left for a long time,

the pickup will deteriorate.

(4) Press the JOG knob.

(5) Turn the JOG knob, adjust so that reading

of the laser power meter becomes 6.9 to 7.1mW.

I+3V

IOP

FL Display

LDPWR ADJUST

LD 0.9mW $XX

LD 0.9mW $XX

LD SAVE $XX

LD 7.0mW $XX

(6) Press the JOG knob.

LD SAVE $XX

3

Check of laser power

LD 7.0mW $XX

LD 0.9mW $XX

(1) Press the EDIT/NO button .

(2) Turns the JOG knob, and select the

LDPWR CHECK mode.

(3) Press the JOG button .

(4) Checks that reading of laser power meter is

0.85mV to 0.91mW.

(5) Press the JOG button .

(6) Checks that reading of laser power meter is

6.9 mV to 7.1 mV.

(7) Read the value (V) of digital bolt meter.

Calculate laser current (I) from the value(V).

I (mA)= V / 1(ohm)

Check that the laser current is -10 to +10%

of range of the display value of the pickup unit (Fig-1).

(8) Press the EDIT/NO button after check.

(9) Press the EJECT button and takes out

the optical sensor

(10) Remove the digital volt meter from JIG.

LDPWR ADJUST

LDPWR CHECK

LD 0.9mW $XX

LD 7.0mW $XX

Fig-1

KMS2606

19311

C0526

52.6 mA

LDPWR CHECK

Page 33

ADJUSTMENT PROCEDURES-6

Adjustment of traverse (EF balance)

4

[Preparation]

(1) Connect oscilloscope to TE and VC on Extended JIG.

[NOTE]

Do not connect the VC to the GND of the unit.

(2) Loading the MO disk to the unit.

Extended JIG

Part No. 0J12

MD-101A

Oscilloscope

To MD mechanism

[Adjustment]

(1) Turns the JOG knob, and select for the display

of FL tube to be set to EFBAL ADJUST.

(2) Press the JOG button .

(3) Turn the JOG knob, adjust so that reading

of the waveform currently observed with the

oscilloscope should be as follows.

TE