Page 1

SYSTEM-30 BTU MEASUREMENT SYSTEM

LON Version

Installation and Operation Guide

0668-2 / 18337

For Software Version DD3.3S30 or higher.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727)442-5699

www.onicon.com • sales@onicon.com

05-14

Page 2

SAFETY INFORMATION

!

!

i

This meter was calibrated at the factory before shipment.

To ensure correct use of the meter, please read this manual thoroughly.

Regarding This Manual:

• This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without

ONICON’s written permission.

• ONICON makes no warranty of any kind with regard to this material, including, but

not limited to, implied warranties of merchantability and suitability for a particular

purpose.

• All reasonable effort has been made to ensure the accuracy of the contents of this

manual. However, if any errors are found, please inform ONICON.

• ONICON assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, ONICON

assumes no responsibility for any such harm owing to any defects in the product which

were not predictable, or for any indirect damages.

Safety Precautions:

The following general safety precautions must be observed during all phases of

installation, operation, service, and repair of this product. Failure to comply with these

precautions or with specic WARNINGS given elsewhere in this manual violates safety

standards of design, manufacture, and intended use of the product. ONICON Incorporated

assumes no liability for the customer’s failure to comply with these requirements. If this

product is used in a manner not specied in this manual, the protection provided by this

product may be impaired.

The following symbols are used in this manual:

Messages identied as “Warning” contain information regarding the personal safety of

individuals involved in the installation, operation or service of this product.

Messages identied as “Caution” contain information regarding potential damage to the

product or other ancillary products.

Messages identied as “Important Note” contain information critical to the proper operation

of the product.

WARNING

CAUTION

IMPORTANT NOTE

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION .............................................................................................................. 5

1.1 Purpose of this Guide ............................................................................................... 5

1.2 Typical SYSTEM-30 BTU MEASUREMENT SYSTEM ........................................... 5

1.3 Standard Features and Specications ..................................................................... 6

1.4 Working Environment .............................................................................................. 7

1.5 Warranty and Serial Number ................................................................................... 7

2.0 UNPACKING ..................................................................................................................... 8

2.1 Checking That You Have Received Everything ...................................................... 8

3.0 INSTALLATION ................................................................................................................ 9

3.1 Site Selection ............................................................................................................ 9

3.2 Mechanical Installation ......................................................................................... 10

3.2.1 Main Unit Installation .................................................................................. 10

3.2.2 Thermowell Installation .............................................................................. 11

3.2.3 Temperature Sensor Installation ................................................................. 11

3.3 Electrical Installation ............................................................................................. 13

3.3.1 Single Mode vs. Dual Mode Operation ....................................................... 13

3.3.2 Electrical Wiring .......................................................................................... 16

4.0 START UP & COMMISSIONING ..................................................................................... 17

4.1 Display and User Interface ....................................................................................... 17

4.2 Processor Start Up ................................................................................................... 17

4.3 Units and Multipliers ............................................................................................... 18

4.4 LonWorks Network Addressing ............................................................................... 19

4.4.1 LonWorks Network Addressing ................................................................... 19

4.5 Commissioning the System-30-LON ....................................................................... 19

4.5.1 Service Pin LED States ................................................................................... 19

4.6 LonWorks XIF Files ................................................................................................. 19

4.6.1 Output Network Variables ........................................................................... 19

4.6.2 Integer Format Output Network Variables .................................................. 20

4.6.3 Input Network Varables ............................................................................... 21

4.6.4 Node Object Network Variables ................................................................... 21

4.6.4.1 nviRequest ...................................................................................... 21

4.6.4.2 nvoStatus ........................................................................................ 22

4.6.5 Resetting Totals Via the Network ................................................................. 22

4.6.6 Rollover of Totals.......................................................................................... 23

4.7 Diagnostics ............................................................................................................. 24

4.7.1 Diagnostic Lights .......................................................................................... 24

4.8 Commissioning ........................................................................................................ 25

4.8.1 Commissioning Worksheet .......................................................................... 26

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 3

Page 4

APPENDIX A – DRAWINGS

A-1 TYPICAL SYSTEM INSTALLATION

A-2/A-3 THERMOWELL INSTALLATION

A-4 WIRING DIAGRAM AND SIGNAL CONNECTION BOARD

A-5 WIRING DIAGRAM FOR DIN CONNECTOR

A-6 LON BOARD

A-7 LONWORKS TWISTED PAIR NETWORK TERMINATION

A-8/A-9 INTEGER FORMAT OUTPUT NETWORK VARIABLES

A-10 CONDITIONS OF SALE

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 4

Page 5

SECTION 1.0: INTRODUCTION

!

SYSTEM-30 BTU MEASUREMENT SYSTEM WITH INTEGRAL

FLOW METER & TEMPERATURE SENSORS

INCORPORATED

WARNING

Only qualied service personnel should attempt to install or service this equipment. Serious

injury may result from the improper installation or use of this equipment.

1.1 PURPOSE OF THIS GUIDE

The purpose of this guide is to provide installation and commissioning procedures and basic

operating and servicing instructions for the ONICON SYSTEM-30 BTU MEASUREMENT

SYSTEM.

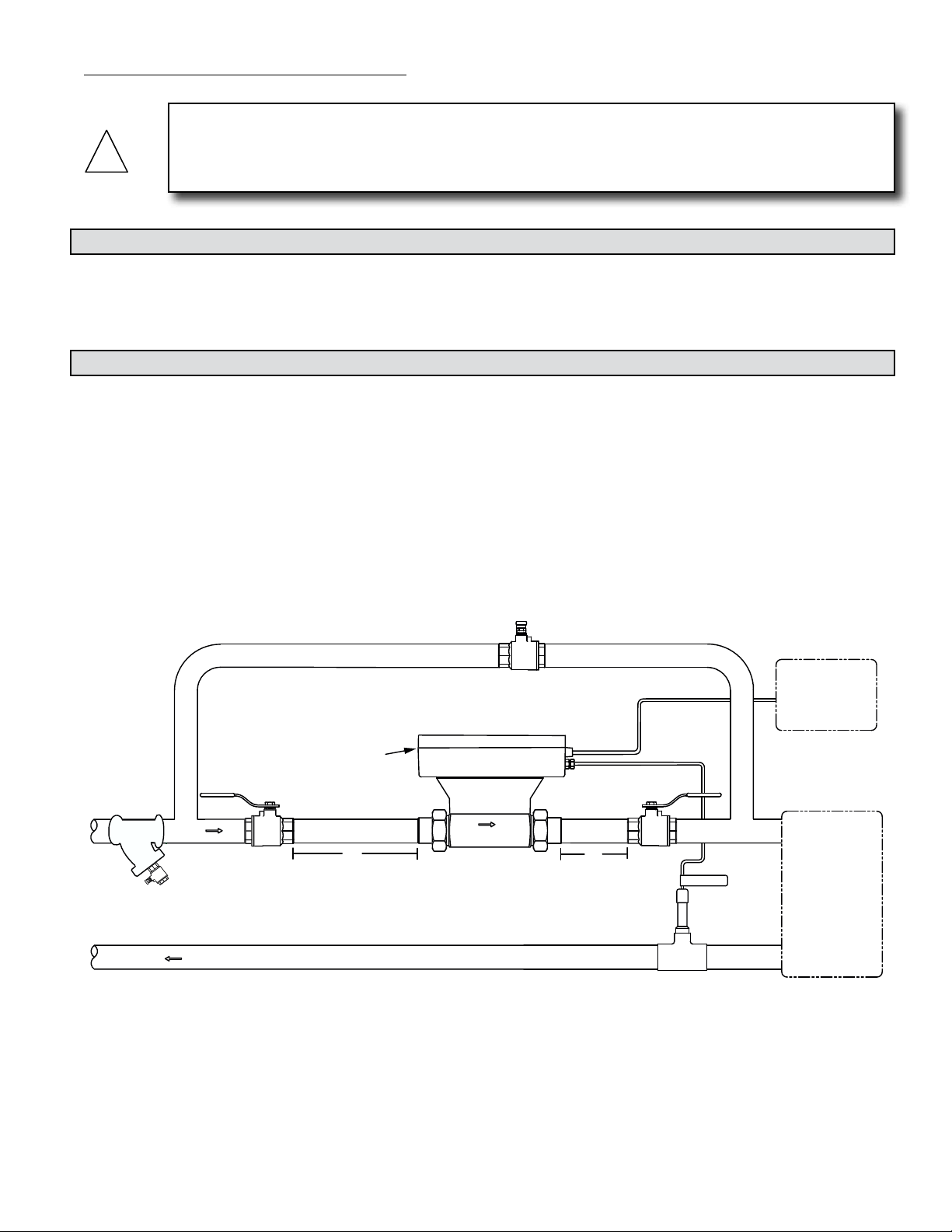

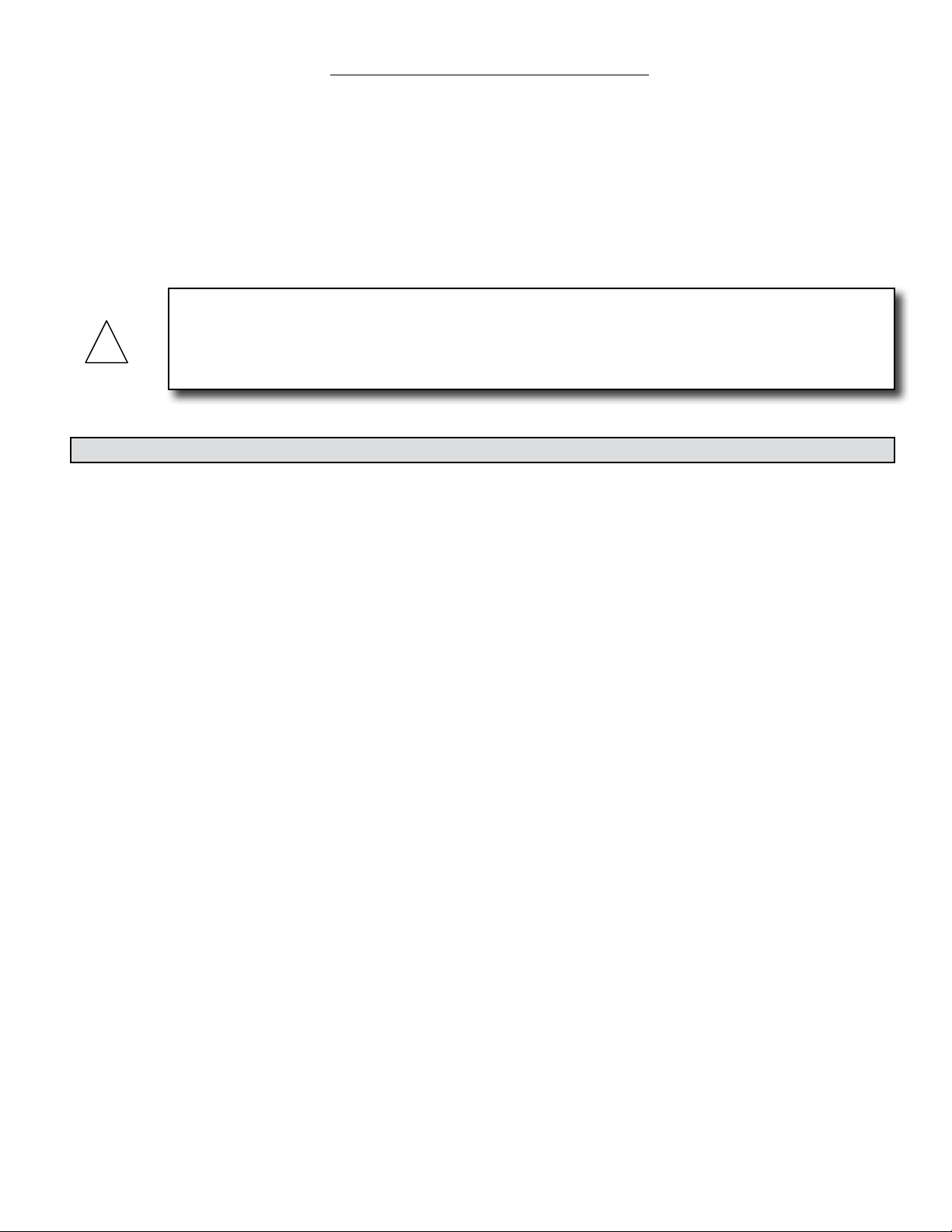

1.2 TYPICAL SYSTEM-30 BTU MEASUREMENT SYSTEM

ONICON’S System-30 is a true heat (Btu) computer, which accepts data from several sensors,

performs a series of computations with that data, and transmits the results as an indication of the

amount of heat (Btu’s) being transferred or as a totalized amount.

Y Strainer Upstream

Of Flow Meter

CHILLED WATER

RETURN

BYPASS VALVE

Normally Closed

DIAGNOSTIC

20"

LED’S

ISOLATION VALVE

FLOW

5"

ISOLATION VALVE

Normally Open

CHILLED WATER

SUPPLY

Normally Open

RETURN TEMP

CONTROL SYSTEM

CONTROL SYSTEM

LonTalk

BACnet MS/TP

NETWORK

NETWORK

24V AC/DC

24 VAC POWER

FAN COIL UNIT

OR

AIR HANDLING UNIT

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 5

Page 6

1.3 STANDARD FEATURES AND SPECIFICATIONS

• Single mode Btu calculations, in either the heating or cooling mode, are totalized and

reported.

• Two-pipe dual mode Btu calculations in both the heating mode and the cooling mode are

totalized and reported separately.

• Auxiliary pulse input for totalizing pulse outputs from external devices such as water or

gas meters.

GENERAL SPECIFICATIONS

CALIBRATION

Flow sensor and temperature sensors are individually

calibrated, followed by a complete system calibration.

Field commissioning is also available.

ACCURACY

Differential temperature accuracy ±0.15° F over

calibrated range

Computing non-linearity within ±0.05%

Flow sensor accuracy:

±0.5% OF READING at calibrated velocity

±1% OF READING from 3 to 30 ft/s (10:1 range)

±2% OF READING from 0.4 to 20 ft/s (50:1 range)

TEMPERATURE SENSORS

Solid state sensors are custom calibrated using N.I.S.T.

traceable temperature standards.

PROGRAMMING

Factory programmed for each specic application

MEMORY

Nonvolatile EEPROM memory retains all program parameters

and totalized values in the event of power loss.

OUTPUT SIGNALS

Isolated solid state dry contacts for mode 1 and mode

2 energy total

Contact rating: 100 mA, 50VDC maximum

Contact duration: 0.5, 1, 2 or 6 sec selectable

NETWORK INTERFACE

LonTalk

2-wire TP/FT-10F transceiver

OUTPUT SIGNALS

LONWORKS® Output Points: (TP/FT-10F)

Variable Description Units SNVT Name

Energy Total Btu SNVT_btu_f

Energy Rate Watts SNVT_power_f

Flow Rate Liters/Sec SNVT_ow_f

Supply Temperature °C SNVT_temp_f

Return Temperature °C SNVT_temp_f

Flow Total Liters SNVT_vol_f

Auxiliary Input No Units SNVT_count_f

BAUD RATE

78 kbps

INPUT SIGNALS

One isolated auxiliary pulse input for totalization

(Factory congurable for active pulse, open collector

sinking, open collector sourcing or dry contact pulses)

3 – 24V dc

50Hz maximum frequency

10msec minimum pulse duration

OPTIONAL LOCAL DISPLAY

Alphanumeric backlit LCD displays total energy, total, flow, energy

rate, flow rate, supply temperature and return temperature

Alpha: 16 characters, 0.2” high

Numeric: 6 digit, 0.4” high

MAINTENANCE

ONICON recommends periodic inspection and recalibration.

No other periodic maintenance is required.

TEMPERATURE RANGE

Liquid temperature range: 32° to 200°F

Ambient temperature range: 40° to 120°F

MECHANICAL

OVERALL DIMENSION:

9.25” L x 5” W x 6.5” H

TEMPERATURE THERMOWELL:

Brass thermowell (½” sweat or ¼” NPT)

ELECTRICAL

This equipment is intended for INSTALLATION

CATEGORY (OVERVOLTAGE CATEGORY) II

applications

INPUT VOLTAGE: 24 V ±10% AC 50/60 Hz or

24 V ±4 DC

INPUT CURRENT: 200 mA maximum

TERMINALS CONNECTIONS: Use 18-22 ga. Copper wire. Do

not exceed 4.5 in-lb (0.5 Nm) of torque when tightening.

WIRING:

CONDUIT: Use PVC jacketed copper cable with a wire Gauge

suitable for the length of run and required maximum current

carrying capacity. The installation must comply with all

local, state and federal codes.

PLENUM AREA: (without conduit) Use plenum rated

copper cable with a wire gauge suitable for the length of

run and required maximum current carrying capacity. The

installation must comply with all local, state and federal

building codes.

Note: Specications are subject to change without notice.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 6

Page 7

1.4 WORKING ENVIRONMENT

The SYSTEM-30 was designed for installation and use in typical commercial and residential

environments that are free of corrosive liquids and fumes, direct liquid exposure, heavy

condensation, and temperature extremes and vibrations.

The operating ambient air temperature range is 40° F to 120° F.

The electrical power should be relatively clean, free of high frequency noise, large voltage

transients, and protected from power surges and brown outs.

1.5 WARRANTY & SERIAL NUMBER

Warranty

ONICON’s 2-year “No-fault” warranty reduces start-up costs with extended coverage that

includes coverage for incidental damage during installation. Certain exclusions apply. See

our complete warranty statement for details.

Serial Number

The serial number of your SYSTEM-30 is located on the side of the enclosure. Serial

numbers are unique identiers that you should have available when contacting the factory

for assistance regarding your system.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 7

Page 8

SECTION 2.0: UNPACKING

Each SYSTEM-30 generally ships in one package. Inspect all packages immediately upon receipt.

Notify ONICON and the freight carrier if the shipment arrives with evidence of damage in transit.

2.1 CHECKING THAT YOU HAVE RECEIVED EVERYTHING

Standard Documentation

Enclosed with each SYSTEM-30 is a comprehensive documentation package that includes

the following items:

The SYSTEM-30 BTU MEASUREMENT SYSTEM Installation and Operation Guide

The System-30 Calibration Data Sheet

Please notify ONICON immediately if any items are missing.

The Main Unit

Remove the System-30 from the shipping carton and inspect it for physical damage.

Temperature Sensors

One temperature sensor is built-in to the body of the meter and the other is connected to

the main unit via a permanently attached cable. Inspect the free sensor and cable for

external damage.

Temperature Thermowell

A standard thermowell with installation hardware is packed with the main unit.

Mounting Hardware

The System-30 is supplied with two process connections to facilitate connection to the

piping system. A union with retaining nut makes up one end of each end piece. The

other end will either be a sweat tting for copper or a threaded nipple with male NPT

threads.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 8

Page 9

SECTION 3.0: INSTALLATION

!

The SYSTEM-30 BTU MEASUREMENT SYSTEM should be installed by experienced plumbers and

others with related knowledge and experience in the heating, cooling, and uid metering elds.

ONICON will be happy to assist with technical recommendations and to provide guidance by

telephone and/or mail. On-site eld engineering, installation, and/or service is also available at an

additional cost.

The installer should use good trade practices and adhere to all state and local building or other

applicable codes.

CAUTION

ONICON strongly recommends the use of a valved bypass and strainer in conjunction with the

installation of the System-30 to facilitate servicing and to protect the turbine assembly during

start-up.

3.1 SITE SELECTION

Careful attention to the site selection for the system components will help the installers with the

initial installation, reduce start-up problems, and make future maintenance easier. For example,

do not install the System-30 or its temperature sensor where it will be difcult for personnel to

perform periodic maintenance and calibration. When selecting a site for mounting the system

components, consider the criteria under Section 1.4, WORKING ENVIRONMENT, as well as the

following:

The Main Unit

Choose the location (supply or return) with the longest straight, unobstructed run. Ideally,

the location chosen should allow for at least 20 diameters of unobstructed straight run

upstream of the meter and at least 5 diameters of unobstructed straight run downstream.

If both the supply and return have adequate straight run conditions, locate the meter in the

supply.

The location must be accessible to facilitate service and recalibration.

The Temperature Sensor

The remote temperature sensor should be located in an accessible location. This will

facilitate any on-site service.

Place the temperature sensor away from sources of electrical noise that might interfere

with the temperature sensor signal.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 9

Page 10

3.2 MECHANICAL INSTALLATION

SYSTEM-30 BTU MEASUREMENT SYSTEM WITH INTEGRAL

FLOW METER & TEMPERATURE SENSORS

INCORPORATED

!

3.2.1 Main Unit Installation

BYPASS VALVE

Normally Closed

DIAGNOSTIC

LED’S

Y Strainer Upstream

Of Flow Meter

CHILLED WATER

RETURN

ISOLATION VALVE

CHILLED WATER

SUPPLY

Normally Open

FLOW

20"

ISOLATION VALVE

Normally Open

5"

RETURN TEMP

Installing the meter body

1. Make sure the unions are free of nicks or scratches on either end of the ow

meter body and on the process connections.

2. Spray the union faces with a silicone spray or apply a thin coat of beeswax to enhance

seating. Do not use paste thread sealant on union faces.

3. Orient the ow arrow on the meter with the direction of ow.

4. Recommended torques for union seal: 70 ft/lbs minimum

5. Make sure alignment of pipe does not put lateral stress on either joint.

CONTROL SYSTEM

CONTROL SYSTEM

LonTalk

BACnet MS/TP

NETWORK

NETWORK

24 VAC POWER

24V AC/DC

FAN COIL UNIT

OR

AIR HANDLING UNIT

Process

Connection

Unions

Process

Connection

CAUTION

Before you attempt to use the BTU measurement system, isolate the main unit, open the bypass

and ush the entire system so that it is free of ux, solder, pipe and tube cuttings and any other

free moving particles.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 10

Page 11

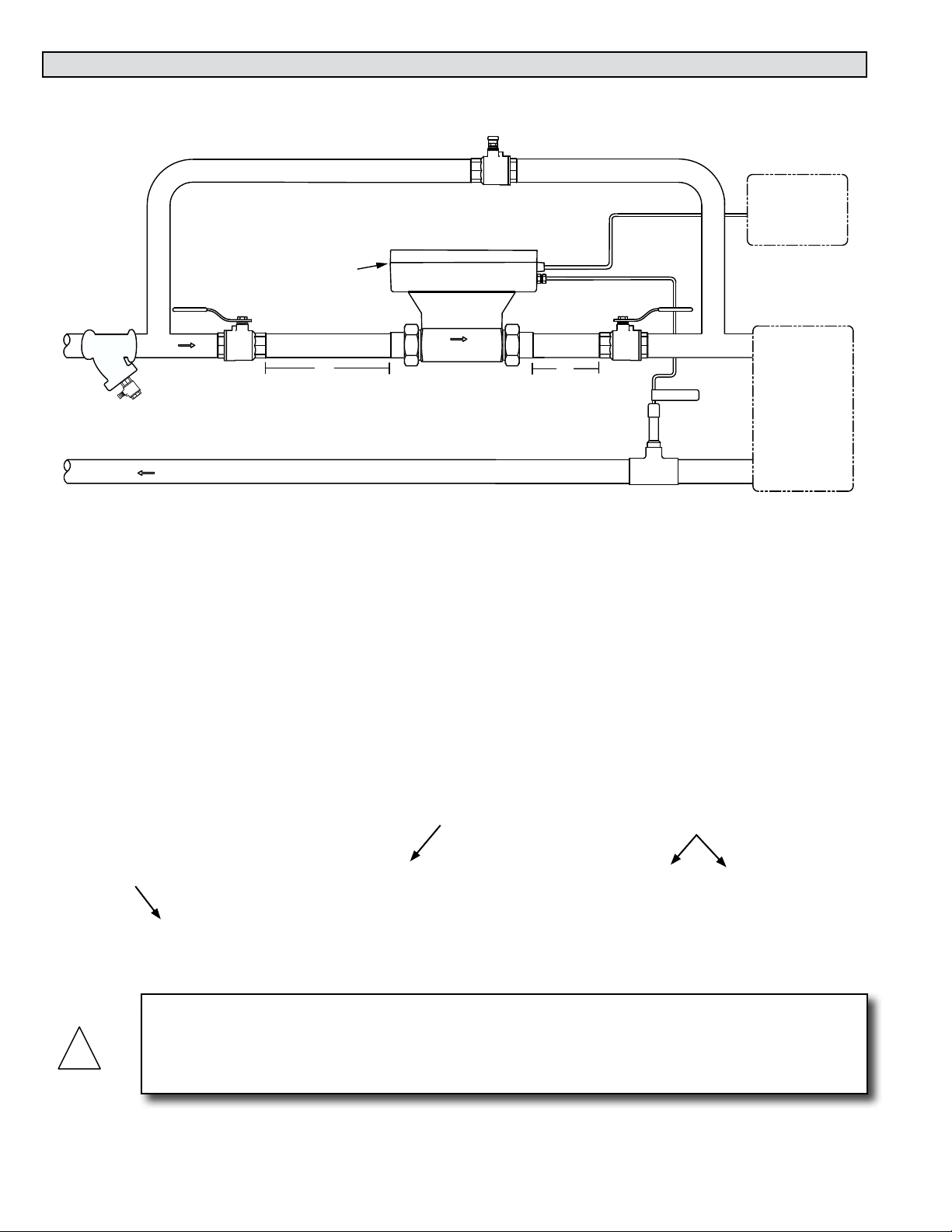

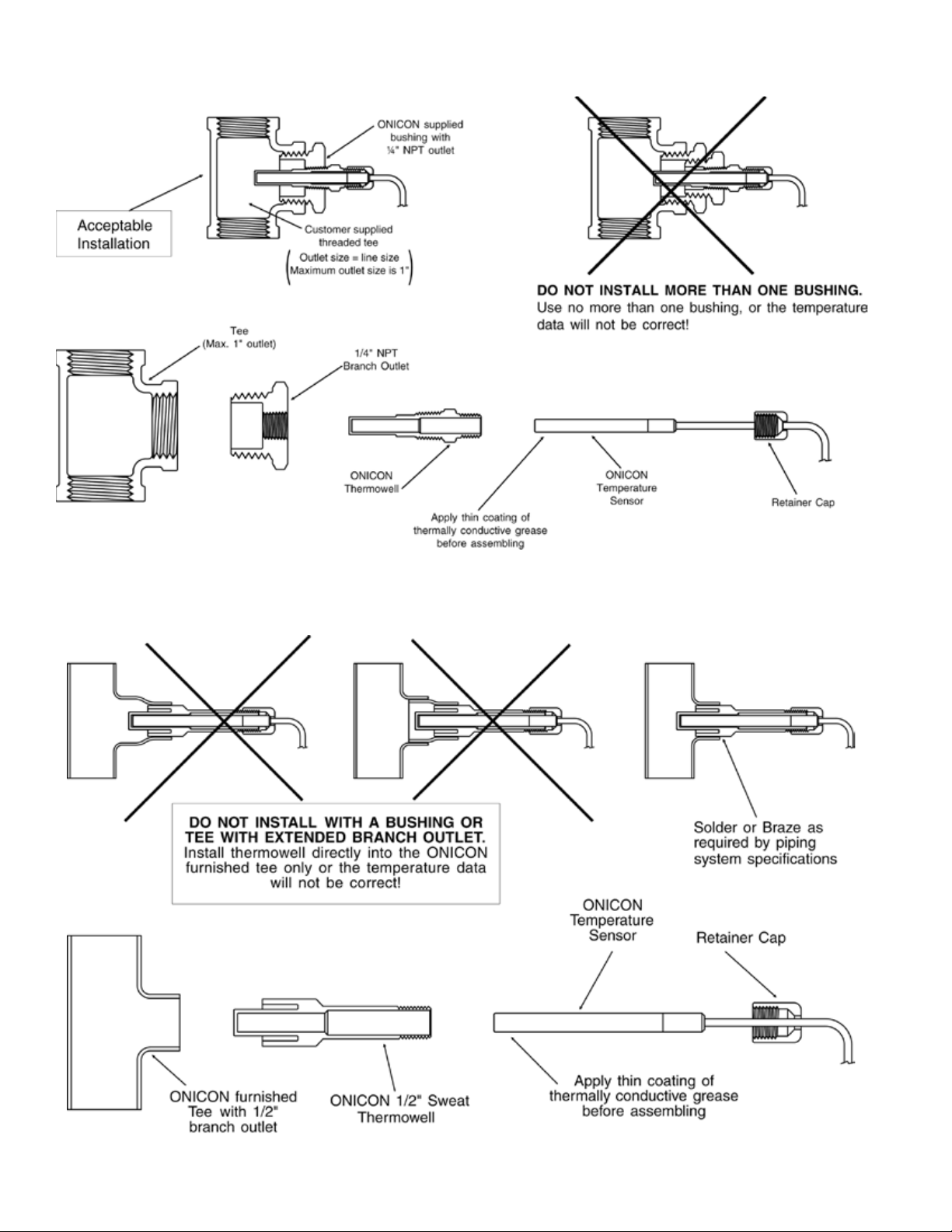

3.2.2 Thermowell Installation

!

i

IMPORTANT NOTE

It is important that no dirt or other foreign material be allowed into the thermowell as this could

affect the thermal response of the system.

Standard Thermowell

The most common installation methods are shown below. Consult the factory for

special applications.

3.2.3 Temperature Sensor Installation

The temperature sensor is factory matched and permanently attached to the BTU

MEASUREMENT SYSTEM. Sensors from different Btu meters cannot be used without

being returned to the factory for recalibration.

Apply a thin coat of thermally conductive grease to the temperature sensor, and gently

insert the temperature sensor all the way into the thermowell until it contacts the bottom

of the cavity. Gently tighten the retainer cap. DO NOT OVER TIGHTEN. The thermowell

completely seals the plumbing system without the retainer cap. The only purpose of the

cap is to keep the sensor from losing contact with the bottom of the thermowell cavity.

CAUTION

Cable length is specied at time of order. This is three wire shielded plenum rated cable.

Altering the cable length will affect calibration. Do not change the cable length without

consulting ONICON.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 11

Page 12

THERMOWELL INSTALLATION IN THREADED PIPE TEES

THERMOWELL INSTALLATION IN COPPER TEE

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 12

Page 13

THERMOWELL INSTALLATION IN WELDED PIPE

i

3.3 ELECTRICAL INSTALLATION

All user supplied conduit ttings, junction boxes, etc. are to be installed as required by all

applicable building codes.

IMPORTANT NOTE

The System-30-LON BTU Meter is designed with one internal (Temp1) and one remote (Temp 2)

temperature sensor. If the meter body is located in the supply pipe then the internal temperature

sensor will indicate the supply temperature and the remote sensor will indicate the return

temperature. This relationship will reverse if the meter body is located in the return pipe. The

location of the meter will also affect the logic used to determine mode 1 and mode 2 operations

for dual mode applications. Single mode energy measurements are absolute measurements and

are not effected by polarity of the Delta t.

3.3.1 Single Mode (4 Pipe) Vs. Dual Mode (2 Pipe) Operation

ONICON System 30 BTU Meters may be congured for single or dual mode applications.

Single and dual mode is a reference to the piping system and not the meter itself. Single

mode (4 pipes) applications are those that always have the same relationship between the

supply and return pipe temperatures. In dual mode (2 pipes) applications the polarity of

the temperature differential (Delta t) reverses; often on a seasonal basis.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 13

Page 14

It is often desirable to totalize the amount of energy transferred in each mode in separate registers.

0333-2

1500 North Belcher Road, Clearwater, FL 33765 • Tel (727) 447-6140 • Fax (727) 442-5699

www.onicon.com • sales@onicon.com

01-13-09

For these applications, ONICON BTU meters may be congured for dual mode operation. In this

conguration, the meter will measure and totalize energy in separate registers based on the

polarity of the Delta t.

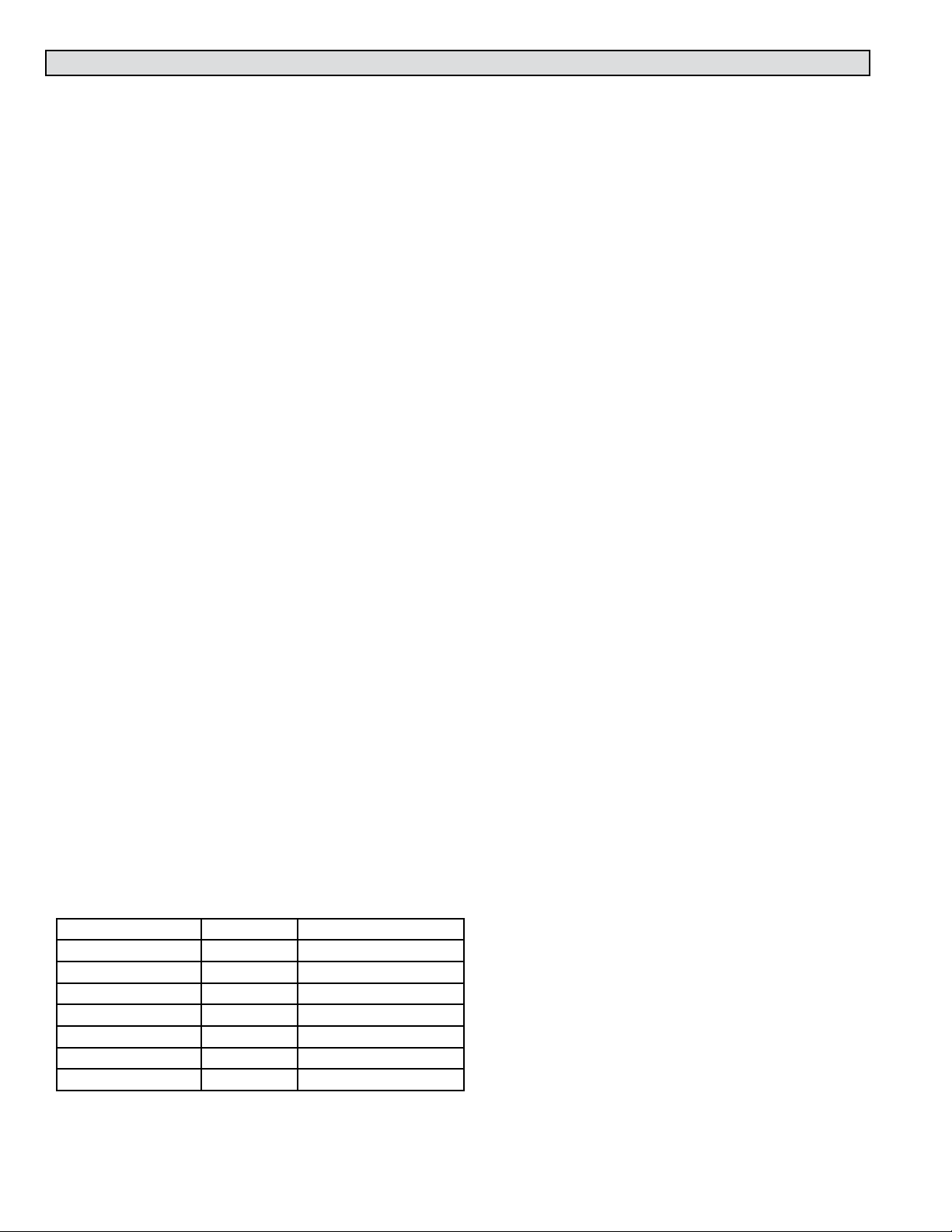

The drawings and tables below illustrate the relationship between meter location, temperature

sensor and mode of operation.

Temperature Sensor/ Mode of Operation Relationship with Meter in Supply Line

Supply Temp Temperature 1 Sensor (Internal Sensor)

Return Temp Temperature 2 Sensor (External Sensor)

Mode 1 Total Heating (Supply Temp > Return Temp)

Mode 2 Total Cooling (Supply Temp < Return Temp)

CONTROL SYSTEM

LonTalk

NETWORK

24V AC/DC

NETWORK

BACnet MS/TP

24 VAC POWER

CONTROL SYSTEM

OR

FAN COIL UNIT

AIR HANDLING UNIT

Normally Closed

BYPASS VALVE

Normally Open

ISOLATION VALVE

5"

FLOW

LED’S

DIAGNOSTIC

Normally Open

ISOLATION VALVE

20"

SUPPLY

CHILLED WATER

RETURN TEMP

Of Flow Meter

Y Strainer Upstream

RETURN

CHILLED WATER

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 14

Page 15

Temperature Sensor/ Mode of Operation Relationship with Meter in Return Line

Supply Temp Temperature 2 (External Sensor)

Return Temp Temperature 1 (Internal Sensor)

Mode 1 Total Cooling (Supply Temp < Return Temp)

Mode 2 Total Heating (Supply Temp > Return Temp)

NORMALLY CLOSED

CONTROL SYSTEM

LonTalk

NETWORK

24V AC/DC

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 15

Page 16

3.3.2 Electrical Wiring

!

Connect all Btu meter signal outputs to terminal strip TB1 and/or TB4 (optional

communication output) as shown below. Then connect the 24 V AC/DC input power to

terminal strip TB1. The standard SYSTEM-30 is congured for 24 V AC 50/60 Hz

operation or 24 V DC operation. Do not connect the 24 V AC/DC source until all other

signal connections have been made and veried.

Aux Pulse Input

LON connections

}

}

4

-

+

5

1

Not used

2

3

TB4

CAUTION

Only qualied service personnel should make connections between the System-30-LON BTU

Meter and the user’s external equipment. ONICON assumes no responsibility for damaged caused

tot he external equipment as a result of an improper installation.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 16

24V AC/DC

}

Btu Mode 1Contact

-

2

3

}

4

+

1

TB1

5

Analog Output

}

6

Btu Mode 2 Contact

}

7

-

+

8

Page 17

SECTION 4.0: START UP AND COMMISSIONING

4.1 DISPLAY AND USER INTERFACE (If display ordered)

The System 30 may be ordered from the factory with an optional display and user interface.

The display consists of 2 lines of alphanumeric characters. Line 1 indicates the current value

while the bottom line identies the engineering units and multiplier values that apply to the

current value displayed on line 1. In the example shown the current value is 3864, the

engineering units are Btu’s and the multiplier is 10,000. This would be read as 38,640,000 Btu’s.

The user interface consists of 3 pushbutton switches. These 3 switches allow the user to operate

the display and program the meter.

When operating in the run mode, the scroll button

advances the display from one parameter to the next.

A total of up to 11 different operating parameters may

be available for display depending on whether the

meter is being used in a single mode or dual mode

application.

When operating in the run mode, the reset button (if

enabled) allows the user to reset volume and energy

totals.

The program button is not functional in the run mode.

4.2 PROCESSOR START-UP

When power is applied to the BTU Meter alphanumeric characters appear on the two lines of

the display, indicating the meter is operating. Press and release the SCROLL button on the front

panel. Observe the display cycle to the next display page.

Select the SUPPLY TEMP Page. Note the displayed temperature. Conrm that it is in the

expected range. Now select the RETURN TEMP page. Again note the displayed temperature.

Conrm that it is also in the correct range.

Select the FLOW RATE page. Note the displayed ow rate. Conrm that the ow rate value is in

the correct range.

Successively pressing the SCROLL button will cycle the display through the run mode pages

summarized in the tables on the next page.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 17

Page 18

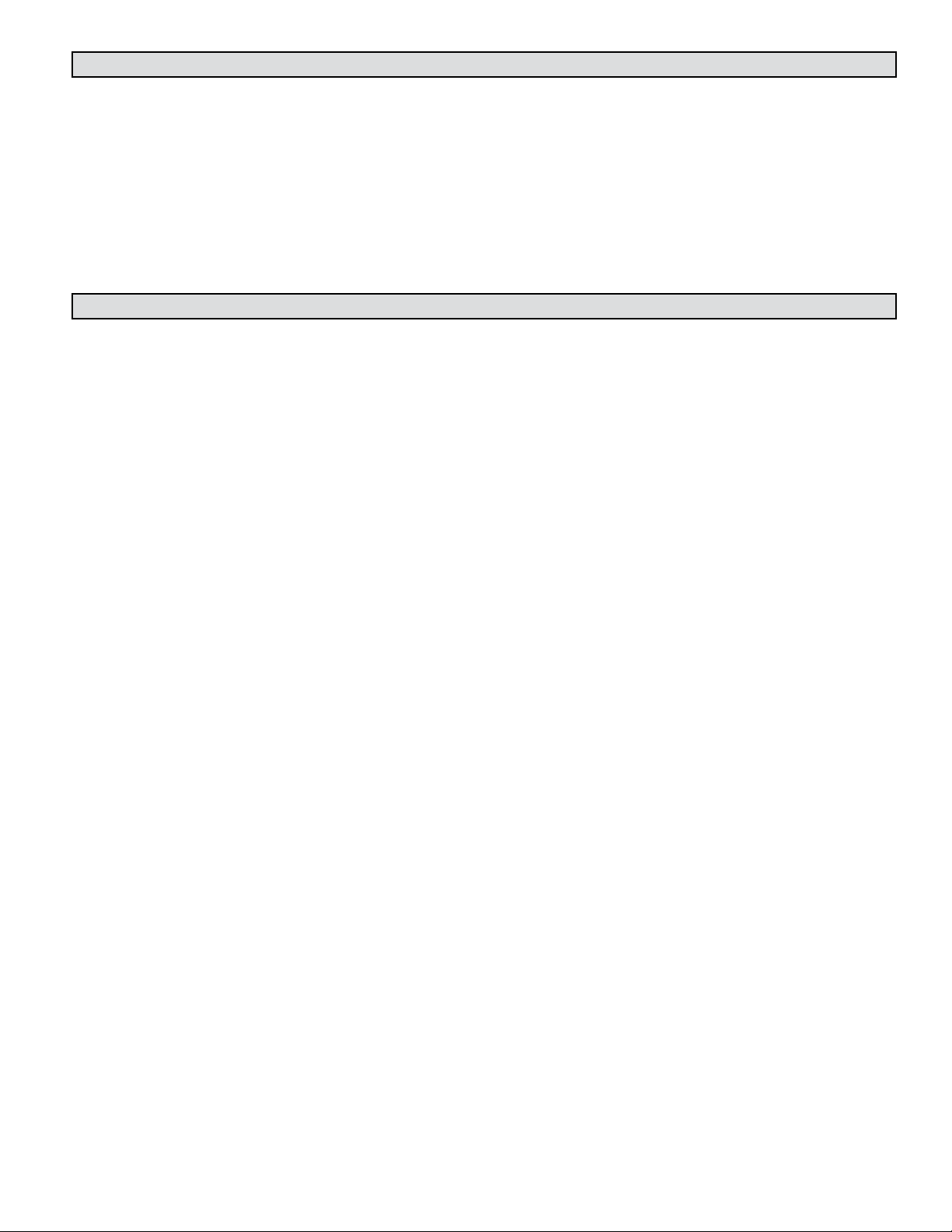

Single Mode Operation

SINGLE MODE BTU METERS – RUN MODE DISPLAY PAGES

PAGE No. DISPLAY NAME SELECTABLE UNITS

1

2

3

4

5

6

7

8

9

Dual Mode BTU Meters

PAGE No. DISPLAY NAME SELECTABLE UNITS

1

2

3

4

5

6

7

8

9

10

11

The operating mode, measurement units and multipliers are programmed into the Btu

meter at the factory. These settings may be re-programmed in the eld. Please contact

ONICON technical support personnel for assistance, if changes are required.

ENERGY TOTAL BTU, TONHR or KWHR

FLOW TOTAL GAL, LITER, METERS

ENERGY RATE BTU/HR, TONS, KW

FLOW RATE GPM, GPH, MGD, L/SEC, L/MIN, L/HR,

METERS

INTRN TEMPERATURE DEG F, DEG C

EXTRN TEMPERATURE DEG F, DEG C

Di3 PULSE TOTAL

ALARM STATUS

SERIAL NUMBER

DUAL MODE BTU METERS – RUN MODE DISPLAY PAGES

MODE 1 ENERGY TOTAL BTU, TONHR or KWHR

MODE 1 FLOW TOTAL GAL, LITER, METERS

MODE 2 ENERGY TOTAL BTU, TONHR or KWHR

MODE 2 FLOW TOTAL GAL, LITER, METERS

ENERGY RATE BTU/HR, TONS or KW

FLOW RATE GPM, GPH, MGD, L/SEC, L/MIN, L/HR,

INTRN TEMPERATURE DEG F, DEG C

EXTRN TEMPERATURE DEG F, DEG C

Di3 PULSE TOTAL

ALARM STATUS NOT APPLICABLE

SERIAL NUMBER NOT APPLICABLE

COUNTS or TEXT ENTRY

NOT APPLICABLE

NOT APPLICABLE

METERS

COUNTS or TEXT ENTRY

3

/HR

3

/HR

3

3

3

4.3 DISPLAY AND PULSE OUTPUT UNITS AND MULTIPLIERS

The units and multipliers are programmed prior to delivery. Contact ONICON’s technical support

personnel for assistance in changing units or multipliers.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 18

Page 19

4.4 LONWORKS NETWORK ADDRESSING

The Btu meter contains two microprocessors, the heat computer board processor and the Echelon

TP/FT-10F transceiver with its Neuron processor. The TP/FT-10F transceiver is located on the

LON board. The two processors communicate with each other using a serial channel. This serial

channel device address is xed at 017 and cannot be changed.

4.4.1 LonWorks Network Addressing

Every Neuron processor has a unique 48 bit address kown as the Neuron ID. This address

is generally used as the Node ID. It is combined with the Domain ID and Subnet ID to form

the device address. In most installations, the device address is created dynamically by the

network.

4.5 COMMISSIONING THE SYSTEM-30-LON

Pressing the Service Pin on the LON board (see Appendix 6) generates a service pin message

on the network. The message contains the Neuron ID and the standard program identier

(SPID). The network conguration tool then maps the System-30-LON Neuron ID into the

domain/subnet/node ID addressing scheme for the network, creating the device address.

4.5.1 Service Pin LED States

The yellow service pin LED indicates the status of the Lon Talk network connection.

• LED blinking at ½ Hz rate indicates that the meter is in an decommissioned state.

• LED off indicates that the meter is commissioned and operating normally.

4.6 LONWORKS XIF FILES

Each System-30-LON BTU Meter is shipped with a diskette or CD containing the XIF le. It also

contains the Neuron executable le in various formats and documentation describing the

network variables in detail.

4.6.1 Output Network Variables

The System-30-LON BTU Meter transmits data to the network using Standard Network

Variable Types (SNVTs). Volume ow rate, and volume total are provided in oating point

format.

Display operating mode and mode status information is provided in ASCII character format.

The oating point output network variables are described in the table on the next page.

Column 1 contains a brief description of the network variables. Column 2 contains the

network variable names. Column 3 contains the Lon SNVTs used for each variable.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 19

Page 20

FLOATING POINT OUTPUT NETWORK VARIABLES

Description Variable Name SNVT Name Engineering Units Valid Range

Flow (volume) rate nvoVolRateLf SNVT_ow_f Liters/Sec 0 to 10

Flow (volume) total -1 nvoVol1Lf SNVT_vol_f Liters 0 to 10

Flow (volume) total -2 nvoVol2Lf SNVT_vol_f Liters 0 to 10

Supply temperature nvoSupplyTempf SNVT_temp_f ° C -17.778 to 148.889

Return temperature nvoReturnTempf SNVT_temp_f ° C -17.778 to 148.889

Energy rate nvoEnrRateWf SNVT_power_f Watts 0 to 10

*Displayed energy rate nvoDispEnrRatef SNVT_count_f *See note 0 to 10

Energy total -1 nvoBTU1f SNVT_BTU_f Btu 0 to 10

*Displayed energy total-1 nvoDispEnergy1f SNVT_count_f *See note 0 to 10

Energy total-2 nvoBTU2f SNVT_BTU_f Btu 0 to 10

*Displayed energy total-2 nvoDispEnergy2f SNVT_count_f *See note 0 to 10

Auxiliary pulse input (Di3) nvoAuxIn1 SNVT_count_f None 0 to 10

* These network variables transmit energy rate and total data exactly as it is displayed on the

optional System-30 front panel display (If ordered). The value transmitted will not include any

multiplier associated with displayed total.

12

12

12

12

12

12

12

12

12

12

The ASCII character status output network variables are described in the table below.

Column 1 contains a brief description of the network variables. Column 2 contains the

network variable names. Column 3 contains the Lon SNVT used for each variable.

Column 4 contains the ASCII single characters that may be transmitted by the meter

along with a description of what they indicate.

ASCII STATUS OUTPUT NETWORK VARIABLES

Description Variable Name SNVT Name Valid ASCII Characters*

Meter operating

mode indicator

nvoMeterMode SNVT_char_ascii

S = Single mode (83)

D = Dual mode (68)

B = Bidirectional mode (66)

N = Communication lost (78)

Mode status

indicator

nvoModeStatus SNVT_char_ascii

Z = Communication restored waiting for

update (90)

H = Heating mode (mode 1) (72)

C = Cooling mode (mode 2) (67)

* Systems that are not set to decode ASCII characters will display the decimal equivalent.

These values are shown in parentheses.

4.6.2 Integer Format Output Network Variables

ONICON provides rate and total data to the network in integer format for systems that

cannot accept the oating point data. Refer to Appendices A-8 and A-9 for information on

the use of integer format SNVTs.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 20

Page 21

4.6.3 Input Network Variables

The System-30-LON BTU Meter receives remote commands to reset totals from the

network using Standard Network Variable Types (SNVTs). The input network variables are

in ASCII format. They are used to zero the ow, energy and auxiliary pulse totals

transmitted in the output variables listed in section 1.7.1.

The ASCII character reset input network variables are described in the table below.

Column 1 contains a brief description of the network variables. Column 2 contains the

network variable names. Column 3 contains the Lon SNVT used for each variable. Column

4 contains the ASCII single characters that must be transmitted to the meter along with a

description of what they indicate.

ASCII RESET INPUT VARIABLES

Description Variable Name SNVT Name Valid Characters*

Reset Energy-1 nviResetBTU1a SNVT_char_ascii

Reset Volume-1 nviResetVol1a SNVT_char_ascii

Reset Energy-2 nviResetBTU2a SNVT_char_ascii

Reset Volume-2 nnviResetVol2a SNVT_char_ascii

Write an ASCII 1 (49) to reset the

selected total. Once the total has

reset, change the value to back to

ASCII 0 (48).

Reset Auxin1 (Di3) nviResetAuxIn1a SNVT_char_ascii

*Systems that are not set to decode ASCII characters will use and display the decimal

equivalent. These values are shown in parentheses.

4.6.4 Node Object Network Variables

The System-30 LON BTU Meter node object utilizes one output network variable and one

input network variable. These are described in the table below.

NODE OBJECT NETWORK VARIABLES

Description Variable Name SNVT Name

Node object control input nviRequest SNVT_obj_request

Node object response output nvoStatus SNVT_obj_status

4.6.4.1 nviRequest

Five input variable requests have been implemented. These are listed in the table

on the next page. Three of the requests are mandatory functions. They are

Normal, Update Mask and Report Mask. The other two are used to reset totals in

the Btu meter. They are Reset and Clear Reset.

The requests can be used on the node object or on selected function blocks. The

tables on the next page describe the requests and the function blocks associated

with totals in the Btu meter.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 21

Page 22

NODE OBJECT REQUESTS

Node Object

Requests

Function

Blocks

Affected

Comments

RQ_NORMAL 0-27 This request clears the status registers. Function block 0 clears

all function block status registers. Selecting function blocks 1- 27

only clears the selected status register.

RQ_UPDATE_MASK 0-27 This request updates the selected status register.

RQ_REPORT_MASK 0-27 This request displays the available Object Status functions.

RQ_RESET 0, 3, 6, 17,

21, 27

This request zeroes the various ow, energy and auxiliary pulse

totals. If the Object ID 0 request RQ_RESET is selected then all

totals are cleared. If the Object ID of 3, 6, 17, 21 or 27 RQ_RESET

is selected then only the appropriate total is cleared.

RQ_CLEAR_RESET 0, 3, 6, 17,

21, 27

This request clears reset status ags. Object ID of 0 clears all

“reset_complete” ags. Object IDs 3, 6, 17, 21, 27: Clears the

selected “reset_complete” ags.

SELECT FUNCTION BLOCKS, BTU METER TOTALS & BTU METER OPERATING MODES

Functional

Block

3 Flow (volume) - 1 Heat or Cool Heating Forward Flow

6 Flow (volume) - 2 Inactive Cooling Reverse Flow

17 Energy-1 Heat or Cool Heating Forward Flow

21 Energy-2 Inactive Cooling Reverse Flow

27 Auxiliary Pulse (Di3) Active Active Active

Btu Meter Total

Single Dual Bidirectional

Btu Meter Operating Mode

4.6.4.2 nvoStatus

Six status object functions are mechanized to report status information to

the network. These are listed in the table below. The table also lists

function blocks associated with each status ag.

nvoStatus Object Functions Functional Blocks

object_id All

invalid_id All

invalid_request All

comm_failure 0

report_mask All

reset_complete 0, 3, 6, 17, 21, 27

4.6.5 Resetting Totals via the Network

Totals are held in non-volatile memory within the Btu meter. Each total (ow, energy or

auxiliary input) has a corresponding output variable that transmits the information from

the meter to the network. There are two ways to remotely reset totals in the display. This

can be done using individual input variables to command the display to reset specic

totals or it can be done using the nviRequest variable. Using nviRequest allows you to

reset each total individually or all totals simultaneously with one command. See sections

1.7.3 and 1.7.4.1 for specic instructions on how to reset totals.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 22

Page 23

4.6.6 Rollover of Totals

The totals stored in the ow Btu meter memory will roll over to zero when the maximum

count is exceeded. When this occurs, the network totals will also roll over to zero. The

point at which the rollover occurs is a function of the displayed engineering units and

multipliers programmed into the System-30.

The examples below show the rollover point in the engineering units transmitted by the

network variable (SNVT) for common totals shown on the System-30-LON BTU Meter.

VOLUME TOTAL

System-10 BTU Meter

Engineering Units

Gallons X 100 SNVT_vol_f – Liters 3,785,411,621 Liters

Liters X 1000 SNVT_vol_f – Liters 9,999,999,000 Liters

M³ X 1 SNVT_vol_f – Liters 9,999,999,000 Liters

ENERGY TOTAL

System-10 BTU Meter

Engineering Units

Btu X 10k SNVT_Btu_f – Btu 99,999,990,000 Btu

kWhr X 10 SNVT_Btu_f – Btu 341,214,065,900 Btu

Tonhr X 1 SNVT_Btu_f – Btu 119,999,998,000 Btu

System-10 BTU

Meter

Multiplier

System-10 BTU

Meter

Multiplier

LonWorks SNVT and

Transmitted

Engineering Units

LonWorks SNVT and

Transmitted

Engineering Units

Maximum Total Transmitted

Over the Network

Maximum Total Transmitted

Over the Network

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 23

Page 24

4.7 DIAGNOSTICS

The ONICON System-30 BTU MEASUREMENT

SYSTEM uses a microprocessor to calculate

energy. Factory programmed settings provide

energy total outputs in accordance with the

customer’s application data. An optional

isolated analog output for energy rate, ow rate

or delta T may also be available. Refer to the

Btu meter calibration sheet for a complete listing

of factory settings. These settings cannot be

changed in the eld. Contact ONICON factory

service personnel if changes to the calibration

are required.

The System-30 is equipped with diagnostic

indicator lights that conrm the operation of

the microprocessor and its input circuitry.

Please contact the ONICON factory service personnel if either of the diagnostic lights

indicate a potential problem with the operation of the BTU MEASUREMENT SYSTEM.

4.7.1 Diagnostic Lights

Energy

Located on the end of main unit opposite the cable connection is a red LED labeled Btu.

This LED will ash as energy is transferred.

Liquid Flow

Located on the end of main unit opposite the cable connection is a red LED labeled FLOW.

This LED will ash at a rate that is proportional to the liquid ow rate. An unlit LED

indicates no ow signal.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 24

Page 25

4.8 COMMISSIONING

Please read all installation instructions carefully before proceeding. Wiring diagrams are located

in the appendix. A worksheet for checking off these steps and recording measured values is

located on the following page.

1. Conrm main unit

location and adequate

straight pipe run to

achieve desired results

In order to proceed with the following steps, the System-30 must be operating and connected to the control

system. There must also be ow in pipes. Flow signal readings should be taken while holding the ow rate

constant if possible, otherwise, take the various output readings as quickly as possible.

2. Conrm correct supply

voltage

3. With the HVAC system

active, verify that the

diagnostic LED’s for

FLOW and BTU are

both ashing.

The following steps require a multi-meter with the ability to measure DC voltage as well as DC frequency in hertz.

Remove the six screws that secure the cover to the main unit and carefully lift the cover off.

4. Check temperature

readings for T1, T2

and the differential

temperature

Is the main unit located in the correct location as required by the plans?

Is the meter correctly oriented with respect to ow direction?

Compare actual straight pipe upstream and downstream of the main unit location

to the recommended distances identied in this installation manual. Note: This

manual is very conservative and assumes the worst-case pipe obstructions; contact

ONICON’s technical support department to discuss specics of your application

Verify that the correct supply voltage is available at the System-30 signal cable

connections. The System-30 BTU MEASUREMENT SYSTEM operates from 24 V

AC/DC.

The LED’s are located on the exterior of the main unit on the end opposite from the

cables.

Set multi-meter for 2 to 4 volt range

T2: (TB2) Measure DC volts between terminals 2(+) and 3(-)

T3: (TB3) Measure DC volts between terminals 2(+) and 3(-)

Delta T: (TB2-TB3) Measure DC volts between terminals 2 and 2

The relationship between voltage and temperature is 10 mV/degree F.

Multiply the reading in volts by 100 to obtain degrees F.

Compare the calculated temperatures to expected values and to the values shown

on the network.

5. Check ow signal

6. Check Energy Total

Output (BTU Output

Mode 1 and/or Mode 2)

End of standard commissioning. Please contact ONICON’s technical service department at (727)447-6140 with

any questions.

Set multi-meter for DC hertz, voltage range > 15 volts.

The test points for ow are located next to the reset button.

GPM = Frequency in Hz X 60

Meter Factor in ppg (refer to calibration tag for meter factor)

Compare the calculated ow rate to expected values and to the values shown on

the network.

Set multi-meter for ohms

Mode 1: Measure ohms between terminals 3 and 4

Mode 2: Measure ohms between terminals 5 and 6

Conrm that the voltage changes state (low to high or high to low) each time the

controls system register records a new energy total.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 25

Page 26

4.8.1 Commissioning Worksheet

Please read all installation instructions carefully prior to proceeding with these steps.

Wiring diagrams are located in the appendix. Use the following worksheet for checking

off the commissioning steps and recording measured values:

STEP TEST / MEASUREMENT S/N: S/N: S/N: S/N:

1. Meter location

2.

3.

4.

5.

6.

TROUBLESHOOTING GUIDE FOR ONICON SYSTEM-30 BTU MEASUREMENT SYSTEMS

NOTE: Also refer to the COMMISSIONING GUIDE located on the preceding pages.

REPORTED PROBLEM: POSSIBLE SOLUTIONS:

No Flow Signal/ Energy

Signal

(While hydronic system

is active)

Displayed Flow Rate too

high or too low

Displayed Temperature

too high or too low vs.

expected values.

Device is not

communicating with the

Lon Talk network.

Communications with

the Lon Talk network is

intermittent.

For technical assistance, contact ONICON Incorporated at (727) 447-6140.

Supply voltage veried

Verify diagnostic LED’s

are ashing

Note and record

temperature readings for

T1, T2 & delta T

Note and record ow rate

Conrm contact closure

output operation for

Mode 1 & Mode 2

• Verify 24 VAC / VDC supply voltage to the System-30.

• Verify correct wiring to the System-30 (see wiring diagram).

• Check turbine for clogging due to debris.

• If none of the above, double check hydronic system to

ensure that ow is really present in the line.

• NOTE: Flow meter function cannot be veried by blowing on the turbine.

The sensing system requires a conductive liquid to operate.

• Verify that System-30 isolation valves are fully open and

bypass valve is fully closed (if bypass is used).

• Check turbine(s) for debris.

• Verify supply voltages.

• Verify that thermowell is inserted into the ow stream and

that the temperature sensor is completely inserted into the

thermowells.

• What is the state of the service pin LED?

• Is it ashing? A ashing service pin LED indicates that the Lon module

has not been commissioned. (See Appendix A-6)

• Is it off? A service pin LED that is off indicates that the Lon module is

commissioned and operating normally.

• Is the network properly terminated? The Lon TP/FT bus can be

terminated in 2 different ways.

• A single RC lter can installed at any point on a free topology network.

A dual termination scheme is used with 2 RC lters installed at the

ends of bus networks. (Refer to the Appendix A-7 for details.)

• What type of cable is used to wire the network? TP/FT networks

should only use twisted shielded pair cable. (Belden 85102 or equiv.)

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 26

Page 27

APPENDIX A – DRAWINGS

A-1 TYPICAL SYSTEM INSTALLATION

A-2/A-3 THERMOWELL INSTALLATION

A-4 WIRING DIAGRAM AND SIGNAL CONNECTION BOARD

A-5 WIRING DIAGRAM FOR DIN CONNECTOR

A-6 LON BOARD

A-7 LONWORKS TWISTED PAIR NETWORK TERMINATION

A-8/A-9 INTEGER FORMAT OUTPUT NETWORK VARIABLES

A-10 CONDITIONS OF SALE

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page 27

Page 28

OR

4-12-04

1500 North Belcher Road, Clearwater, FL 33765 • Tel (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

24V AC/DC POWER

CONTROL SYSTEM

LonWorks OUTPUT

BTU PULSE OUTPUT

24V AC/DC POWER

CONTROL SYSTEM

FAN COIL UNIT

AIR HANDLING UNIT

INCORPORATED

RETURN TEMP

Normally Open

ISOLATION VALVE

5”

BYPASS VALVE

Normally Closed

FLOW

20”

FLOW METER & TEMPERATURE SENSORS

Normally Open

SYSTEM-30 BTU MEASUREMENT SYSTEM WITH INTEGRAL

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-1

ISOLATION VALVE

SUPPLY

CHILLED WATER

of Flow Meter

Y Strainer Upstream

RETURN

CHILLED WATER

Page 29

specifications.

1500 North Belcher Road, Clearwater, FL 33765 • Tel (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

3-1-99

with piping system

Weld in accordance

Retainer Cap

Sensor

ONICON

Temperature

IN WELDED PIPE

THERMOWELL INSTALLATION

DO NOT OVER-TIGHTEN THERMOWELL.

Thermowell has a thin wall for better temperature

measurement and can be damaged by over-tightening.

branch outlet

1/4” NPT welded

drill 5/8” hole through pipe

If piping specifications permit,

before assembling.

Apply thin coating of

thermally conductive grease

ONICON

Thermowell

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-2

Page 30

required by piping

1500 North Belcher Road, Clearwater, FL 33765 • Tel (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

07-18-01

2050-0082

Solder or braze as

Retainer Cap

Sensor

ONICON

Temperature

before assembling

Apply thin coating of

thermally conductive grease

IN COPPER TEES

ALTERNATE THERMOWELL INSTALLATION

Install thermowell directly into the

ONICON furnished tee only or the

temperature data will not be correct!

DO NOT INSTALL WITH A BUSHING OR

TEE WITH EXTENDED BRANCH OUTLET.

Thermowell

ONICON 1/2” Sweat

Tee with 1/2”

branch outlet

ONICON furnished

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-3

Page 31

System-30 Signal Connection Board

Aux Pulse Input

LON connections

}

3

4

}

-

+

5

1

Not used

2

TB4

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-4

24V AC/DC

}

Btu Mode 1Contact

-

2

3

}

4

+

1

TB1

5

Analog Output

}

}

6

Btu Mode 2 Contact

7

-

+

8

Page 32

3-06

1500 North Belcher Road, Clearwater, Florida 33765 Tel (727) 447-6140 Fax (727) 442-5699

www.onicon.com E-mail: sales@onicon.com

INCORPORATED

ISOLATED SOLID STATE

MODE 1 ENERGY TOTAL -

ISOLATED SOLID STATE

DRY CONTACT

MODE 2 ENERGY TOTAL -

DRY CONTACT

Di3 AUXILIARY PULSE INPUT

RED 24VAC

SYSTEM-30 with DIN CONNECTOR WIRING DIAGRAM

BLACK COMMON

GRAY

VIOLET

ORANGE

WHITE

DIN

CONNECTOR

GREEN +

BROWN -

BLUE ISOLATED OUTPUT

YELLOW ISOLATED COMMON

BYPASS VALVE

Normally Closed

Normally Open

ISOLATION VALVE

RETURN TEMP

FLOW

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-5

Page 33

TB3

TB2

System-30 LON Board

LON Reset and

Power LED

Service Pin

and LED

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-6

Page 34

LONWORKS TWISTED PAIR NETWORK TERMINATION

LonWorks Twisted Pair Network Termination

(Recommended Cable: Belden 85102 or equiv.)

Free Topology Network (Single Termination)

C1

100 uf electrolytic

+

R1

52.3 Ohm

+

C2

100 uf electrolytic

Connect across Lon

bus at any point.

Bus Network (Dual Termination)

C1

100 uf electrolytic

+

R1

105 Ohm

Connect across Lon network

at each end of the bus.

+

C2

100 uf electrolytic

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-7

Page 35

INTEGER FORMAT OUTPUT NETWORK VARIABLES

Integer format output variables are limited to 2 bytes of data. For this reason, the maximum number that

can be transmitted in this format is 65,535. Values for both rate and total data from the Btu meter will often

exceed this limit. For this reason, energy rate data is scaled and energy totals are transmitted in segments

using multiple variables. This is explained in detail below.

Volume and Energy Rate Variables

The integer output network variables for volume and energy rate are described in the table below. Column

1 contains a brief description of the network variables. Column 2 contains the network variable names.

Column 3 contains the Lon SNVTs used for each variable. Column 4 contains the engineering units and

column 5, the valid range for each variable. Please note that while the oating point variable for energy

rate is transmitted in Watts, the integer network variable is transmitted in kW to ensure that the maximum

rate never exceeds the register capacity.

Integer Output Network Variables

Description Variable Name SNVT Name Engineering Units Valid Range

Flow (volume) rate nvoVolRateLi SNVT_ow Liters/Sec 0 to 65535

Mode status indicator nvoModeStatus SNVT_char_ascii

Supply temperature nvoSupplyTempi SNVT_temp_p ° C -17.778 to 260.0

Return temperature nvoReturnTempi SNVT_temp_p ° C -17.778 to 260.0

Delta temperature nvoDeltaTempi SNVT_temp_diff_p ° C -327.68 to 327.66

Energy rate nvoEnrRateKWi SNVT_power_kilo KWatts 0 to 65535

Volume and Energy Total Variables

The integer output network variables for volume and energy total are described in the table below. Column

1 contains a brief description of the network variables. Column 2 contains the network variable names.

Column 3 contains the Lon SNVTs used for each variable. Column 4 contains the engineering units and

column 5, the valid range for each variable.

Please note that while the oating point variable for volume total is transmitted in liters, the integer

network variable for volume total is transmitted in kLiters. This is done to increase the maximum total

that can be transmitted via the integer variable. Total(s) must be reset before the accumulated value

exceeds 6553.5 kliters using nviResetVol1a and/or nviResetVol2a. If this is not done, nvoVol1KLi and/or

nvoVol2KLi will over range and continue to indicate 6,553.5 kliters (1,731,252 gallons) until the

System-10’s internal total rolls over to zero.

A separate integer SNVT is also available to transmit ow totals in liters. This variable is only used in

special small pipe applications as the maximum total it can accumulate is only 65,535 liters (17,312

gallons) before it must be reset.

Energy totals are handled in a slightly different way. The oating point variable for energy total is

transmitted in Btu but the integer network variable for energy total is MBtu. This total will over range at

65,535 MBtu. The internal total stored in the Btu meter will not roll over until it exceeds 99,999.99 MBtu.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-8

Page 36

INTEGER FORMAT OUTPUT NETWORK VARIABLES

(continued)

In order to prevent the loss of data nvoMegaBTU1i and/or nvoMegaBTU2i must be reset before the

accumulated value exceeds 65,535 MBtu.

A second variable is available for energy totals. It is kBtu. This variable will roll over to zero whenever

the accumulated value exceeds 65,535 kBtu. This variable has been provided to accommodate small pipe

applications where MBtu is not appropriate. The two energy variables (MBtu and KBtu) can be combined

to produce a total with resolution to 1000 Btu (1kBtu). Programming for this calculation is given below.

Integer Output Network Variables

Description Variable Name SNVT Name Engineering Units Valid Range

* Flow (volume) total -1 nvoVol1Li SNVT_vol Liters 0 to 65535

Flow (volume) total -1 nvoVol1KLi SNVT_vol KLiters 0 to 6553.5

* Flow (volume) total -2 nvoVol2Li SNVT_vol Liters 0 to 65535

Flow (volume) total -2 nvoVol2KLi SNVT_vol KLiters 0 to 6553.5

Energy total -1 nvoKiloBTU1i SNVT_btu_kilo KBtu 0 to 65535

Energy total -1 nvoMegaBTU1i SNVT_btu_mega MBtu 0 to 65535

Energy total -2 nvoKiloBTU2i SNVT_btu_kilo KBtu 0 to 65535

Energy total -2 nvoMegaBTU2i SNVT_btu_mega MBtu 0 to 65535

* Special small pipe volume total variables

Totalizing Using Both the MBtu and KBtu Variables Combined

MBtu (Btu x 1,000,000) is value in nvoMegaBTU1i (or nvoMegaBTU2i)

KBtu (Btu x 1,000,000) is value in nvoKiloBTU1i (or nvoKiloBTU2i)

Combined total = MBtu x 1000 + X

Where X = KBtu - [int (KBtu/1000) x 1000]

Example:

nvoMEGABTU1i present value = 4006 MBtu

nvoKILOBTU!i present value = 6200 KBtu

Combined total = (4006 x 1000) + (6200 - [int(6200/1000) x 1000])

Combined total = 4006000 + (6200 - 6000)

Combined total = 4006200 KBtu

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-9

Page 37

1. ACCEPTANCE: The following Conditions of Sale apply to all sales of ONICON’s products. These provisions shall apply even

CONDITIONS OF SALE

if ONICON fails to object to provisions appearing on, incorporated by, referenced in, or attached to Buyer’s purchase order

form. Buyer’s acceptance of delivery of ONICON’s products constitutes its acceptance of these Conditions of Sale.

2. DELIVERY AND TITLE: All product shipments are Ex Works shipping point and title passes to the Buyer at the time ONICON

delivers the merchandise to the carrier. Risk of loss or damage to the product passes to the Buyer at the time ONICON delivers

the product to the carrier. The Buyer immediately upon receipt should inspect all shipments, and should there be any evidence of

damageorlossintransit,Buyermustleclaimsortracersuponcarrier.ONICONwillassistintracingshipmentsuponrequest.

3. LIMITED WARRANTY: ONICON warrants that for a period of two (2) years following the date of original shipment of an

ONICONproduct:(i)theproductwillconformtoONICON’sstandardwrittenspecicationsapplicabletosuchproductineffect

onthedateofBuyer’sorder,orasmodiedbyONICON’squotationorBuyer’spurchaseorderacceptedbyONICON,(ii)the

product will be free from defects in workmanship, and (iii) that ONICON has title to the product prior to shipment to the Buyer;

provided, however, that the warranties provided herein shall be void and may not apply in the event Buyer misuses or

damages a product, including, but not limited to, any use by the Buyer of a product for an application other than one of a type

approved by ONICON. ONICON’s sole liability and Buyer’s sole remedy for any breach of the foregoing warranty is for

ONICON to repair or replace, at ONICON’s option, any defective product that is returned to ONICON during the warranty

period. EXCEPT AS MAY BE SPECIFICALLY AGREED BY ONICON IN WRITING IN RELATION TO EACH SALE, NO

OTHER WARRANTIES SHALL APPLY, WHETHER EXPRESSED, IMPLIED OR STATUTORY, AND THERE SHALL BE NO

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

4. REMEDIES: ONICON’s OBLIGATION UNDER THE FOREGOING WARRANTIES IS LIMITED SOLELY TO REPAIR OR

REPLACEMENT, AT ONICON’s OPTION, OF DEFECTIVE OR NONCONFORMING PRODUCTS. ONICON SHALL NOT BE

LIABLE FOR CONSEQUENTIAL, INDIRECT, PUNITIVE, INCIDENTAL, OR SPECIAL DAMAGES WHETHER FOUND ON

CONTRACT, TORT OR ANY OTHER THEORY OF LAW. No products shall be returned to ONICON without its prior consent

and transportation and insurance costs shall be prepaid. Any repair or replacement of ONICON’s products under the foregoing

warranty will be at no charge to the Buyer provided such repair is done at the ONICON factory or authorized service center.

ONICON products that are repaired or replaced under this warranty will be returned to Buyer via the same method of shipment

use to return the product to ONICON. Repair or replacement of ONICON products is conditioned upon ONICON’s

acknowledgement of any alleged defect or nonconformance during the warranty period and issuance of a Return

Authorization number. All product returns must reference the Return Authorization number on the outside of the shipping

carton and on any paperwork referencing the return.

5. PRICES AND PAYMENT TERMS: The prices set forth in the most recent quote or acknowledgement as applicable, supersede

allpreviouspricesorquotations.Allquotationsaresubjecttochangeorwithdrawalwithoutnoticeexceptasmaybespecically

noted on the face of the quotation. The prices shown do not include sales, excise or government charges payable by ONICON to

Federal, State, or local authority. Any such tax or charge now or hereafter imposed upon the sale or shipment of the products

under this contract will be added to the purchase price. Buyer agrees to reimburse ONICON for such tax or charge or provide

ONICONwithanacceptableexemptioncerticate.Paymentofinvoiceswillbedue30daysfromthedateofshipmentofthe

products contained therein. In the event that payment of an invoice is not received by the invoice due date, ONICON will assess

a late fee not to exceed 1.5% per month or 18% per year, or the maximum allowableby law whichever is lower.

6. CANCELLATION: Buyer may cancel its order, or any part of it, by sending written notice of cancellation to ONICON and

payingareasonablecancellationfeeasdeterminedbyONICON.Thereasonablecancellationfeewillreect,amongother

factors,theexpensesalreadyincurredandcommitmentsmadebyONICON,salesandadministrativecostsandprotas

determined by ONICON. If Buyer received a reduced price based on the quantity of products ordered, but has not purchased

the applicable quantity at the time of cancellation, Buyer will pay the price it would have paid had ONICON’s sale price been

based on the quantity actually purchased.

7. CHANGES:IfBuyermakesanychangesinitsdrawings,designs,orspecicationsapplicableinanycontractwithONICON

that cause an increase or decrease in the cost of performance of the contract, or if such changes result in rework or obsolescence, an

equitable adjustment shall be made to the contract. Such changes are subject to ONICON’s prior written consent.

8. EXCUSABLEDELAY:ONICONshallundernocircumstanceberesponsibleforfailuretollanyorderororderswhendueto:res,

oods,riots,strikes,freightembargoesortransportationdelays,shortageoflabor,inabilitytosecurefuel,materialsupplies,orpower

at current price or on account of shortages thereof, acts of God or of the public enemy, any existing or future laws or acts of the

FederalorStateGovernment(includingspecically,butnotexclusively,andorders,rulesorregulationsissuedbyanyofcialor

agency of any such government) affecting the conduct of ONICON’s business with which ONICON in its judgment and discretion

deems it advisable to comply as a legal or patriotic duty, or due to any cause beyond ONICON’s reasonable control.

9. PATENTS: ONICON shall defend all suits or proceedings brought against Buyer or its customers arising from claimed

infringements of any patent, trademark, service mark or copyright for any product furnished by ONICON and shall indemnify it

againstallcosts,fees,anddamagesontheconditionBuyerpromptlynotiesONICONinwritingandprovidesinformationand

assistance to enable ONICON to conduct the defense, provided that ONICON shall have no such obligation in case of

infringement resulting from ONICON’s conformance to special requirements of Buyer. If ONICON is not able to settle any such

suit or proceeding on acceptable terms, ONICON may, at its option, require return of the infringing product and refund the

purchase price to Buyer less a reasonable allowance for depreciation or use.

10. FAIR LABOR STANDARDS ACT: ONICON represents that all products delivered under this contract are furnished in

accordance with the applicable provisions of the Fair Labor Standards Act as amended.

11. APPLICABLE LAW: This document and any resulting contract shall be governed by and construed in accordance with the

laws of the State of Florida. The courts of the State of Florida and the federal courts located in Florida shall have jurisdiction

and venue with respect to litigation to this contract. In the event of litigation, the prevailing party shall be entitled to recover

attorney’s fees and costs from the non-prevailing party, including appellate attorney’s fees.

12. MODIFICATIONS: These Conditions of Sale along with the prices, quantities, delivery schedules and other provisions and

instructions in applicable quotations by ONICON or Buyer’s purchase orders accepted by ONICON shall constitute the entire

agreementbetweenONICONandBuyerpertainingtoanyresultingcontract.Theycanbemodiedonlyinwriting.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

System-30 BTU Measurement System LON 05/14 - 0668-2 / 18337 Page A-10

Loading...

Loading...