Page 1

SYSTEM-20 BTU METER

Installation and Operation Guide

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699

2051-1 / 36985

For Software Version 0.1.15 and Higher

www.onicon.com • sales@onicon.com

03-18

Page 2

SAFETY INFORMATION

!

!

i

This meter was calibrated at the factory prior to shipment. To ensure correct use of the meter, please

read this manual thoroughly.

Regarding this Manual:

• This manual should be passed on to the end user.

• Before use, read this manual thoroughly.

• The contents of this manual may be changed without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without

ONICON’s written permission.

• ONICON makes no warranty of any kind with regard to this material, including, but not

limited to, implied warranties of merchantability and suitability for a particular purpose.

• All reasonable effort has been made to ensure the accuracy of the contents of this manual.

However, if any errors are found, please inform ONICON.

• ONICON assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, ONICON assumes

no responsibility for any such harm owing to any defects in the product which were not

predictable, or for any indirect damages.

Safety Precautions:

The following general safety precautions must be observed during all phases of installation,

operation, service, and repair of this product. Failure to comply with these precautions or

with specic WARNINGS given elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the product. ONICON Incorporated assumes no liability for

the customer’s failure to comply with these requirements. If this product is used in a manner

not specied in this manual, the protection provided by this product may be impaired.

The following symbols are used in this manual:

WARNING

Messages identied as “Warning” contain information regarding the personal safety of individuals

involved in the installation, operation or service of this product.

CAUTION

Messages identied as “Caution” contain information regarding potential damage to the product or

other ancillary products.

Messages identied as “Important Note” contain information critical to the proper operation of the

product.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 2

IMPORTANT NOTE

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION ...................................................................................................... 5

1.1 PURPOSE OF THIS GUIDE ........................................................................... 5

1.2 TYPICAL SYSTEM-20 BTU METER ............................................................. 5

1.3 STANDARD FEATURES AND SPECIFICATIONS ........................................ 5

1.4 ADDITIONAL REQUIRED HARDWARE ....................................................... 6

1.5 WORKING ENVIRONMENT ......................................................................... 6

1.6 WARRANTY & SERIAL NUMBER ................................................................ 7

2.0 UNPACKING ... .......................................................................................................... 7

2.1 CHECKING THAT YOU HAVE RECEIVED EVERYTHING .......................... 7

3.0 INSTALLATION ........................................................................................................ 8

3.1 SITE SELECTION ........................................................................................... 8

3.2 MECHANICAL INSTALLATION ................................................................... 9

3.2.1 Mounting the Enclosure ................................................................. 10

3.2.2 Thermowell Installation ................................................................. 11

3.2.2.1 Standard Thermowells ..................................................... 11

3.3.2.2 Hot Tap Thermowells ....................................................... 11

3.2.3 Temperature Sensor Installation .................................................... 13

3.2.3.1 ONICON Standard Temperature Sensor Installation ...... 13

3.3 POWER & SIGNAL WIRING CONNECTIONS ............................................ 15

4.0 SYSTEM-20 START UP & COMMISSIONING ...................................................... 16

4.1 START UP ..................................................................................................... 16

4.1.1 Single and Dual Mode Display Pages ............................................ 17

4.1.2 Additional Display Pages ............................................................... 17

4.2 COMMISSIONING ........................................................................................ 19

4.2.1 Commissioning Following Initial Power-up.................................. 19

4.3 SEALING THE METER ................................................................................ 22

5.0 DIAGNOSTIC FUNCTIONS ................................................................................... 22

6.0 BACnet

®

MS/TP ...................................................................................................... 23

6.1 BACnet® OBJECT TYPES ............................................................................. 23

6.2 PROTOCOL IMPLEMENTATION STATEMENT ........................................ 23

6.3 DEVICE OBJECT .......................................................................................... 24

6.4 ANALOG INPUT(S) ..................................................................................... 25

6.5 ANALOG VALUE(S) .................................................................................... 25

6.6 BINARY VALUE(S) ...................................................................................... 27

6.7 MULTI STATE VALUE .................................................................................. 28

6.8 TREND LOG MULTIPLE .............................................................................. 29

7.0 MODBUS

7.1 MODBUS

®

........................................................................................................ 30

®

MEMORY MAP ......................................................................... 31

7.2 DIAGNOSTIC FUNCTION CODE ................................................................. 38

7.3 REPORT SLAVE ID FUNCTION CODE ........................................................ 39

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 3

Page 4

APPENDIX A

A-1 SYSTEM-20 WIRING DIAGRAM

A-2 SYSTEM-20 WIRING TABLES

A-4 CHANGING RS485 SETTINGS OR METER PROGRAMMING AFTER

COMMISSIONING

A-5 SYSTEM-20 DRILLING TEMPLATE

A-6 OUTDOOR THERMOWELL ASSEMBLY

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 4

Page 5

SECTION 1.0: INTRODUCTION

!

ONICON

1.1 PURPOSE OF THIS GUIDE

The purpose of this guide is to provide installation and commissioning procedures, and basic

operating and servicing instructions for the ONICON System-20 BTU Meter.

WARNING

Only qualied service personnel should attempt to install or service this product. Serious injury

may result from the improper installation or use of this product.

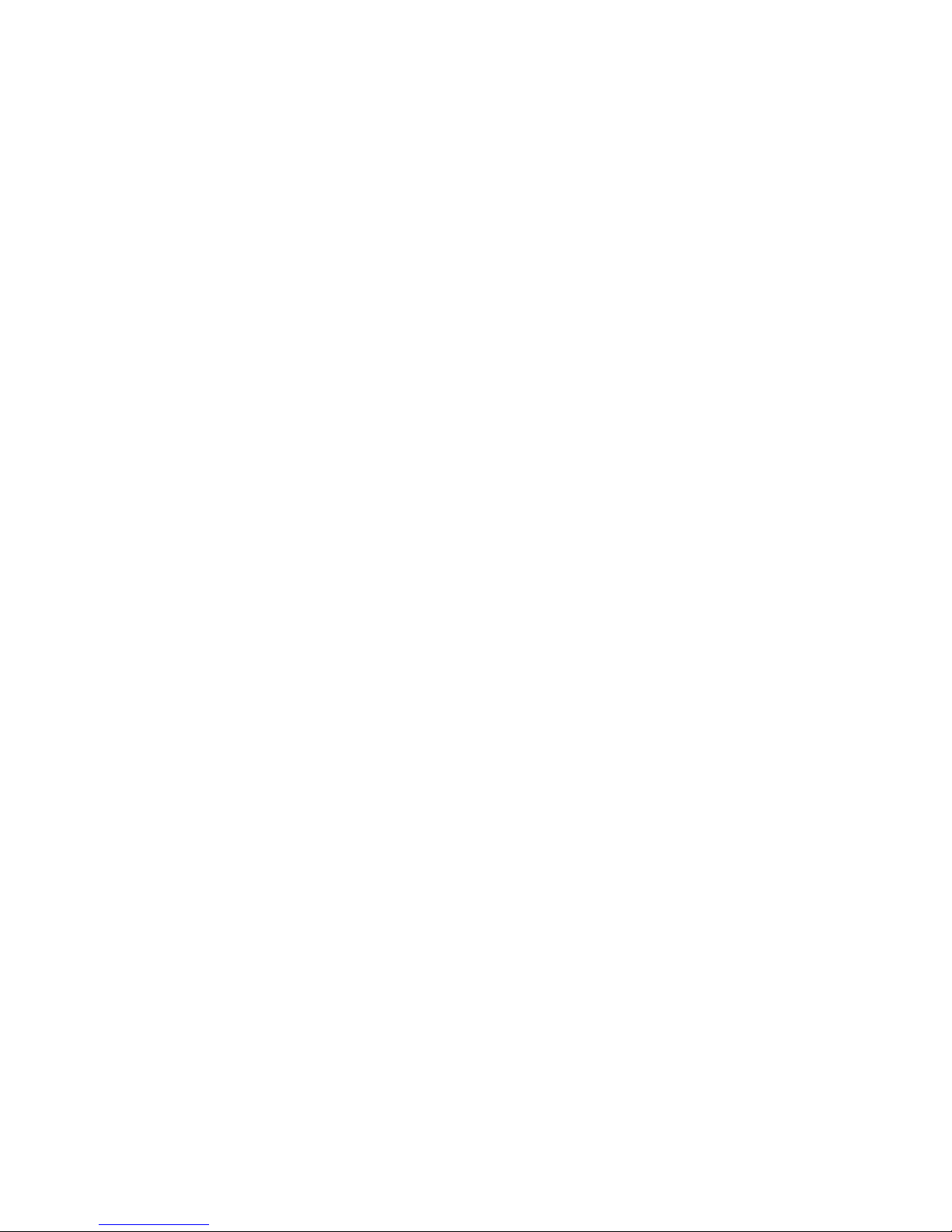

1.2 TYPICAL SYSTEM-20 BTU METER

ONICON’s System-20 is a true heat (Btu) computer, which accepts data from several sensors,

performs a series of computations with that data, and displays and/or transmits the results as an

indication of the amount of heat (Btus) being transferred per unit time or as a totalized amount.

ONICON F-3500

Flow Meter

(F-3500 must be

ordered separately)

Supply Temp

Sensor

Power / Output

24V AC/DC Power

RS-485

(BACnet or MODBUS)

3 Pulse Outputs

1 Analog Output

Up To Three

Pulse Inputs for

Water Meter

Gas Meter

Electric Meter

etc.

Made in the USA

SYSTEM-20

BTU METER

FLOW

Heat Exchanger

Supply

Return Temp

Sensor

Return

1.3 STANDARD FEATURES AND SPECIFICATIONS

• Single mode Btu calculations, in either the heating or cooling mode, are totalized, and

displayed.

• Two-pipe dual mode Btu calculations in both the heating mode and the cooling modes, are

totalized and displayed.

®

• A single isolated RS485 serial interface is provided for BACnet

MS/TP or MODBUS® RTU.

• Three eld congurable pulse outputs may be used for totalization, alarm indication and

mode status.

• Three auxiliary pulse inputs may be used to totalize data from external devices. This data

may also be transmitted via the network interface and viewed on the local display.

• A single eld congurable isolated analog output is provided for energy rate, ow rate or

temperature.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 5

Page 6

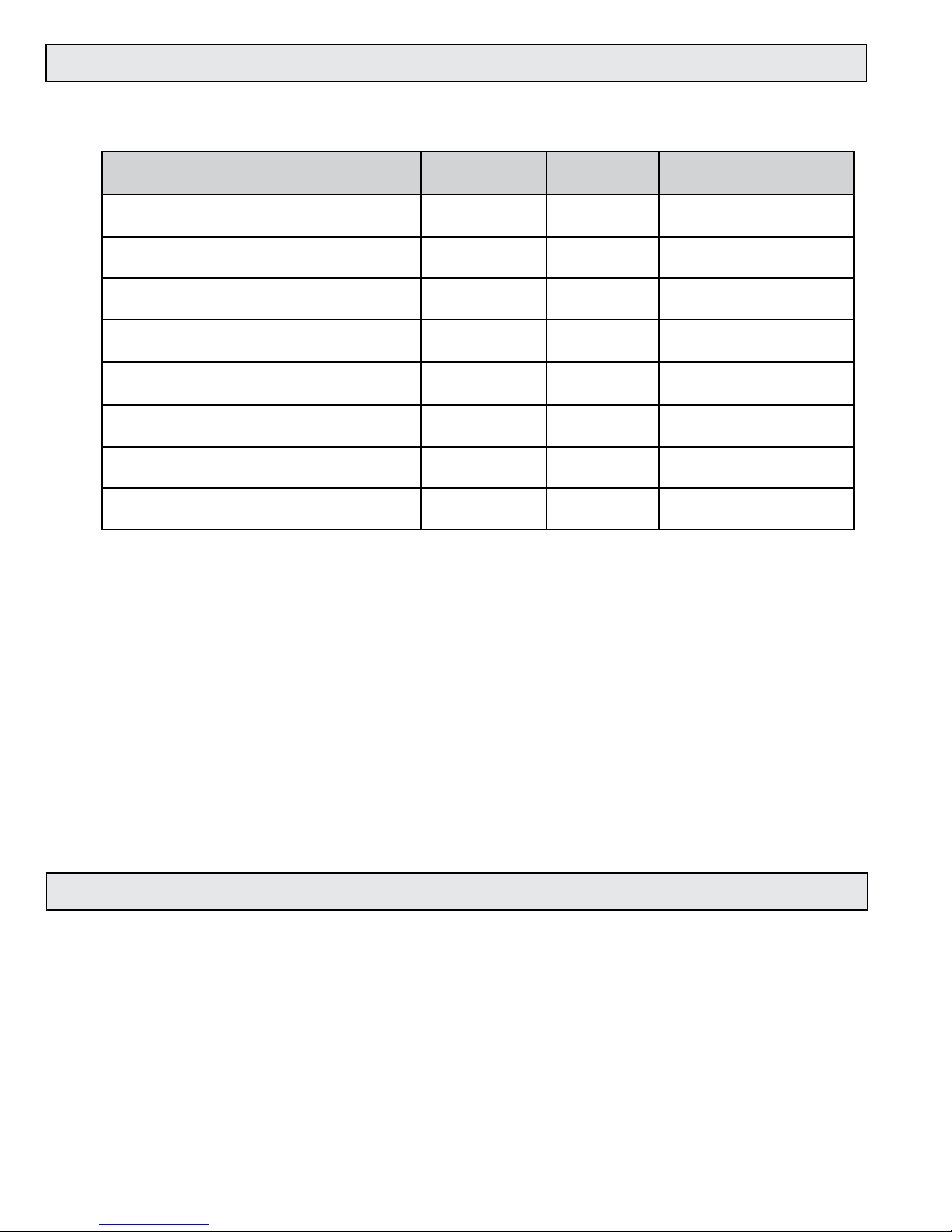

1.4 ADDITIONAL REQUIRED HARDWARE

The System-20 must be connected to a suitable volumetric ow meter and a matched pair of

temperature sensors in order to calculate and report heat data.

Flow Meter Model Line Sizes

F-1100 Single Turbine Insertion Flow

Meter

F-1200 Dual Turbin Insertion Flow Meter

F-1300 Inline Turbine Flow Meter

F-3500 Insertion Electromagnetic Flow

Meter

F-2600 Series Vortex Flow Meter

F-3000 Series Inline Electromagnetic Flow

Meters

F-4300 Clamp-on Ultrasonic Flow Meter

F-4600 Inline Ultrasonic Flow Meter

1 ¼" and larger 25

2 ½" and larger 15

¾" and 1" 25

1 ¼" and larger See manual

1" - 12" See manual

¼" and larger 5

2" and larger See manual

½" - 2 ½" See manual

Straight Run

Required

Notes

Can be used in 1" copper

lines

For use in higher

temperature applications

Please refer to ONICON’s ow meter literature, or contact ONICON for help in selecting the ow

meter that will best t your requirements.

Temperature/Sensors

ONICON Standard Temperature Sensors (32° – 200° F)

Pair of solid state temperature sensors with 0 – 20 mA outputs. Suitable for use with uid

temperatures up to 200° F.

Platinum RTD Temperature Sensors (32° – 250° F)

Pair of 4-wire 1000 Ω Platinum RTD temperature sensors. Suitable for use with uid temperatures

up to 250° F.

Please refer to ONICON’s System-20 product literature, or contact ONICON for help in selecting the

temperature sensors and thermowells that will best t your requirements.

1.5 WORKING ENVIRONMENT

The System-20 was designed for installation and use in typical domestic and commercial

environments that are free of corrosive liquids and fumes, direct liquid exposure, temperature

extremes and vibrations.

The System-20 may be installed outdoors in protected spaces away from direct sunlight, rain,

sleet or snow.

The operating ambient air temperature range is -13° F to 140° F. The electrical power should be

relatively clean, free of high frequency noise, large voltage transients, and protected from power

surges and brown outs.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 6

Page 7

1.6 WARRANTY & SERIAL NUMBER

Warranty

ONICON provides a 2-year warranty for this product. Certain exclusions apply. Please refer to

ONICON’s Conditions of Sale for details.

Serial Number

The serial number of your System-20 is located on the top and inside the enclosure. The serial

number is a unique identier for the product. Please have this number available when contacting

ONICON for assistance.

SECTION 2.0: UNPACKING

The System-20 is generally shipped in one package unless optional hardware or equipment is

ordered. (Thermowells may have been shipped in advance.)

2.1 CHECKING THAT YOU HAVE RECEIVED EVERYTHING

Please notify ONICON immediately if any of these items are missing.

• Standard Documentation Includes:

The System-20 BTU Meter Installation and Operation Guide

The System-20 Certicate of Calibration

• The System-20

Remove the System-20 from the shipping carton and inspect it for physical damage. Notify

the freight carrier and ONICON immediately if any items are damaged in transit. Save all

packaging.

Btu meters ordered with a ow meter and temperature sensors will be delivered congured

and programmed for use together as a system. The System-20 and the temperature sensor

serial numbers will match. The ow meter serial number will be shown on the certicate of

calibration and on the System-20 display.

• Temperature Sensors

If ordered, temperature sensors will generally be packed in the same carton with the

System-20. Inspect the sensors and cables for damage. Each sensor will have a label attached

with a serial number.

• Flow Meter

If ordered, the ow meter will be packaged in a separate carton. The ow meter ordered

with this Btu meter came complete with an instruction manual. Please refer to it for detailed

information regarding its installation, commissioning, and operation.

• Flow Meter & Temperature Sensor Installation Hardware

Installation hardware is ordered separately from the System-20, temperature sensors and ow

meter. Note that this hardware is frequently shipped in advance of the meter(s).

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 7

Page 8

SECTION 3.0: INSTALLATION

i

The System-20 BTU Meter should be installed by personnel with related knowledge and

experience in the heating, cooling, and uid metering elds. ONICON is available to assist with

technical recommendations and to provide guidance by telephone and/or e-mail during the

installation and commissioning process. On-site eld engineering, installation, and service are

also available at an additional cost. The installer should use good trade practices and must adhere

to all state and local building codes.

Before you begin, clean the external surfaces of all pipes at the installation sites so that they are

free of debris, foreign matter, solids, leak inhibitors, and chemically aggressive substances. Flush

the entire system so that it is free of ux, solder, pipe and tube cuttings and any other debris.

3.1 SITE SELECTION

Careful attention to the site selection for the system components will help ensure an accurate

energy measurement, help the installers with the initial installation, reduce start-up problems,

and make future maintenance easier. For example, do not install the ow meter where it will be

difcult for personnel to perform periodic maintenance. When selecting a site for mounting the

components, refer to Section 1.5: WORKING ENVIRONMENT, as well as the following:

IMPORTANT NOTE

Proper site selection is critical to the performance of this Btu meter. Both the ow sensor and

the temperature sensors must be properly located within the piping system in order to ensure an

accurate energy measurement.

• The System-20

Find an easily accessible location where eld wiring connections can be made and meter

readings can be taken from oor level. Mount the enclosure on a vibration free surface. Avoid

locations such as the plenum of a fan coil, heat exchanger or any housing that may contain

electric motors or other strong sources of electrical interference.

• The Flow Meter

When properly installed, the ow meter will only measure ow associated with that portion

of the piping system for which the energy measurement is being made. The ow meter may

be installed in either the supply or return line. Choose the location with the longest straight

run of unobstructed pipe. Please refer to the ow meter installation manual for specic

information regarding the straight run requirements for the ow meter.

• The Temperature Sensors

The two temperature sensors must be located so they accurately measure only the temperature

of the supply line entering and the return line leaving the portion of the piping system for

which the energy measurement is being made.

If possible, nd an easily accessible location where eld wiring connections can be made from

oor level. This will facilitate future service. Place the temperature sensors away from strong

sources of electrical noise that might affect the performance of the sensors.

One temperature sensor thermowell will need to be placed in the same pipe with the ow

meter. It must be located at least ve pipe diameters downstream of the ow meter leaving

enough clearance to remove either sensor from the pipe without interference from the other

sensor.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 8

Page 9

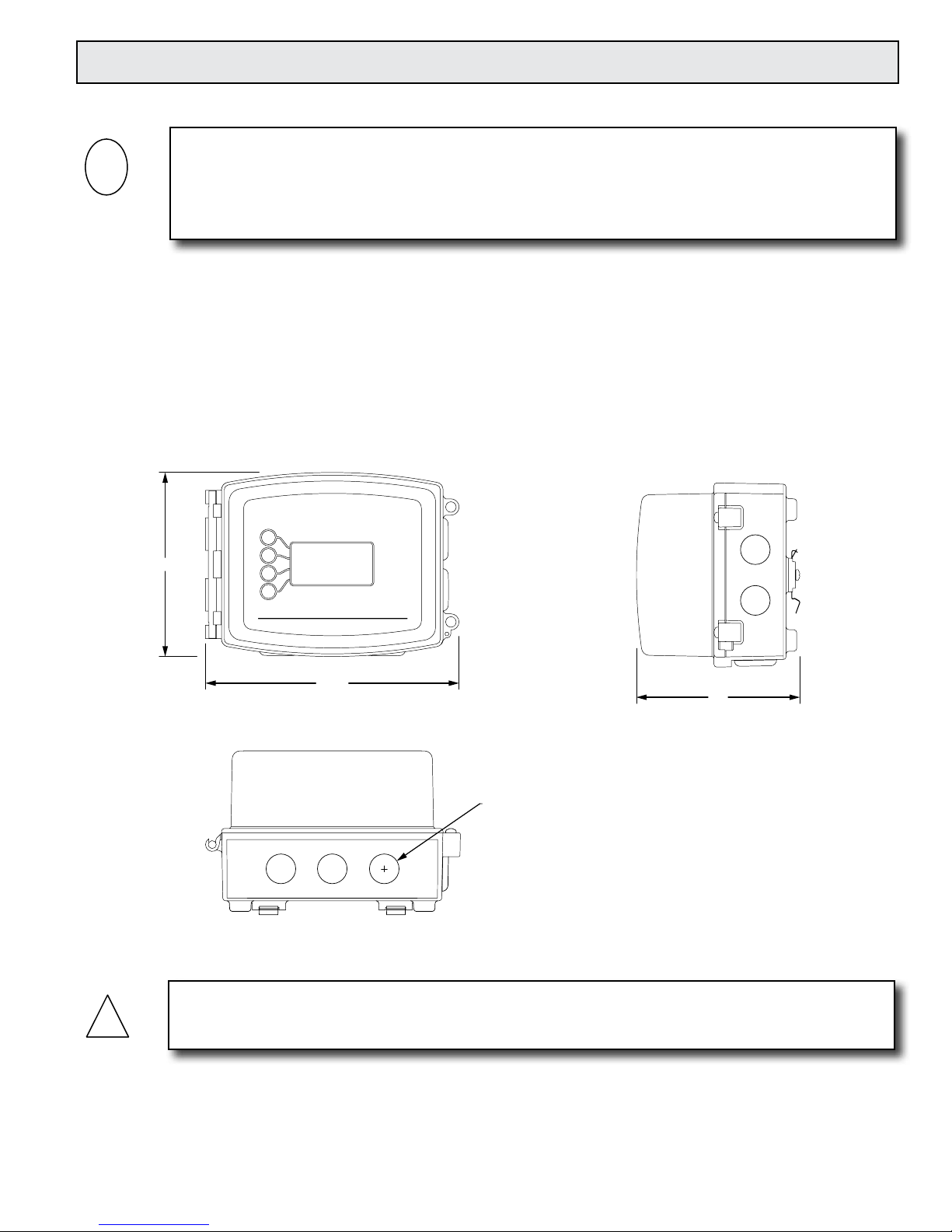

i

7 5/8"

5 1/2"

5"

∅ 0.875" 5pl

∅ 0.200" 4pl

SYSTEM-20

BTU METER

!

3.2 MECHANICAL INSTALLATION

IMPORTANT NOTE

The components of the ONICON System-20 BTU Measurement System must be congured,

programmed and installed together as a system. Mixing components from different systems may

result in signicant measurement errors.

• Find an easily accessible location where electrical connections can be made and meter

readings can be taken from the oor level.

• Mount the Btu meter on a vibration-free surface. Avoid sites such as the plenum of a fan coil,

heat exchanger, or other housings containing motors.

• The meter must be installed in protected spaces away from direct sunlight, rain, sleet or snow.

DO NOT drill holes in the enclosure. Use only the openings that are provided.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 9

CAUTION

Page 10

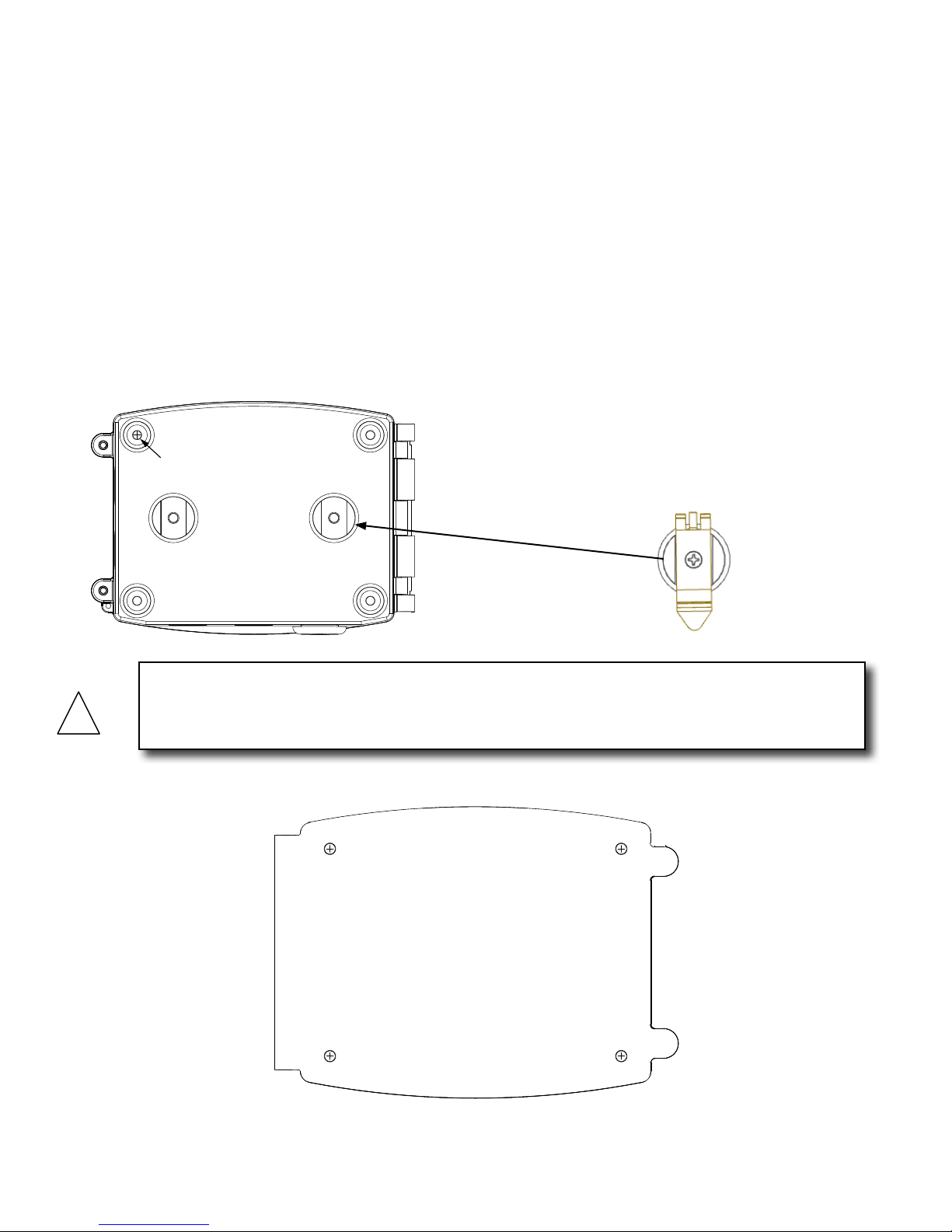

3.2.1 Mounting the Enclosure

!

Use four screws for mounting the Btu meter. The mounting surface must be structurally

sound and capable of withstanding a minimum weight of 40 lbs (18 kg).

Use the following screws for mounting.

• Four Machine screws - #10-24 X 1.5”

• Four Wood screws - No. 10 X 1.5”

• Four Concrete screws - 3/16” X 1.5” with ¼" maximum hex, Phillips or slot heads

Four mounting holes have been provided in the base of the enclosure shown below. Push

out the rubber seals by inserting the mounting screws. Use the drilling template provided

in Appendix 5 of this manual to drill the 4 holes required to mount the enclosure.

Mounting

Holes

A DIN rail mounting hardware kit has been

provided with this meter. Mount the DIN

rail clips as shown below.

CAUTION

DO NOT USE THE ENCLOSURE AS A TEMPLATE FOR DRILLING HOLES. Do not drill holes in

the enclosure. Use only the openings that are provided.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 10

Page 11

3.2.2 Thermowell Installation

i

!

It is important that no dirt or other foreign material be allowed into the thermowells as this could

affect the thermal response of the system.

3.2.2.1 Standard Thermowells

Standard thermowells are for new construction or scheduled shutdown. The

most common installation methods are shown below. Refer to Appendix A-6 for

thermal insulator installations. Consult ONICON for special applications.

IMPORTANT NOTE

NOTES: 1. Thermowell length varies with pipe size.

2. Use no additional bushings to ensure that tip of thermowell is inserted into ow stream.

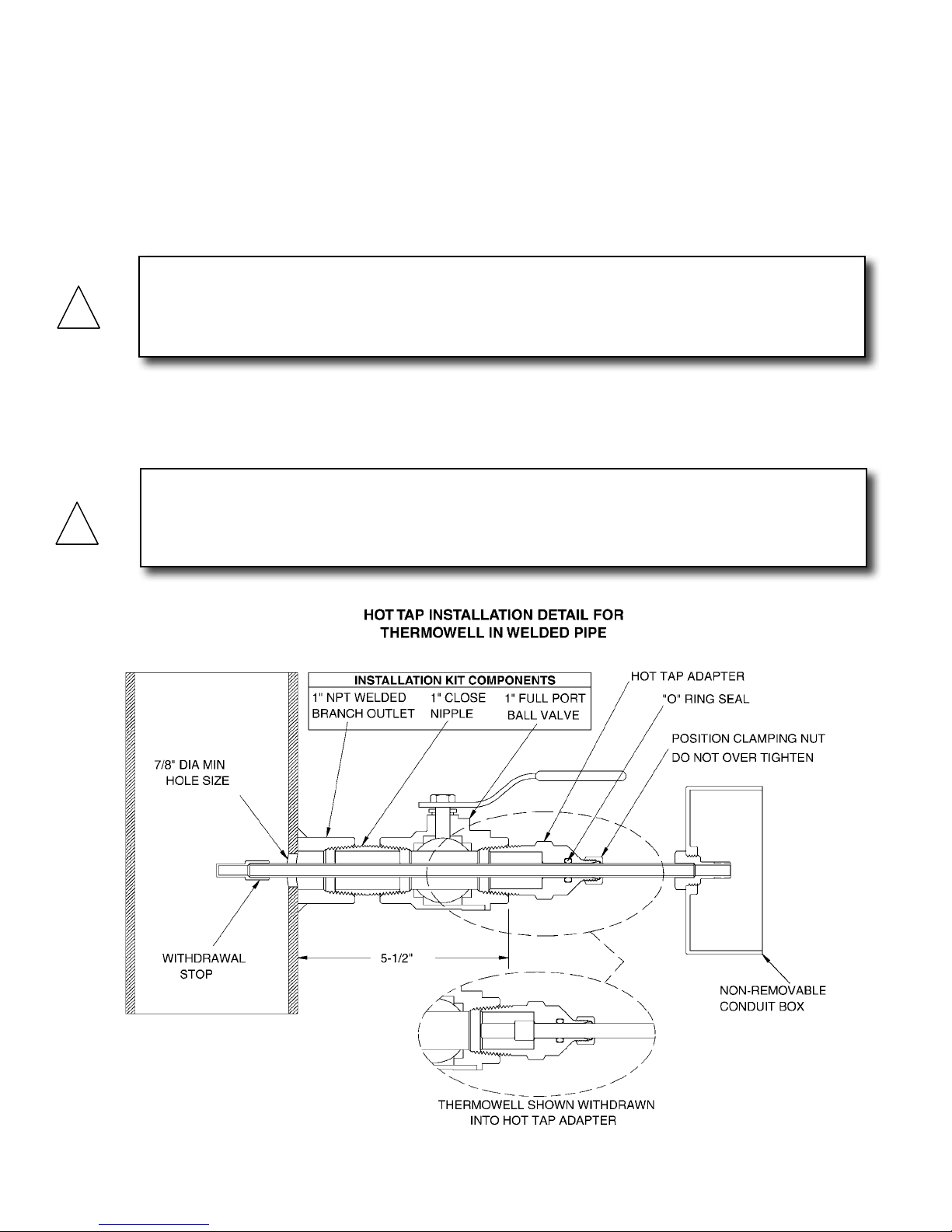

3.2.2.2 Hot Tap Thermowells

Hot tap thermowells are designed for retrot applications where it is not practical to

isolate and drain the pipe section prior to installation. The thermowell is installed

through a 1” full port ball valve as shown in the drawing on next page. A wet

tap drilling machine equipped with a

installation.

Install the valve assembly as shown in the drawing on the next page and then

drill the

been installed and the hole has been drilled, the thermowell can be inserted into

the ow stream without a system shutdown.

7/8” hole using the wet tap drilling machine. Once the valve assembly has

7/8” drill is required to perform this type of

WARNING

SYSTEM MAY BE UNDER HIGH PRESSURE. Be sure to hold the conduit box rmly by hand before

slowly loosening the position clamping nut when installing, adjusting or removing the thermowell.

Failure to do this will allow the pressure to suddenly and rapidly force the thermowell from the

pipe, potentially causing serious injury. The thermowell could also be damaged or break apart

causing a break in the water seal resulting in the loss of large amounts of water.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 11

Page 12

INSERTION OF THE HOT TAP THERMOWELL

!

!

1. Calculate the insertion force (lbs) required by multiplying the system pressure

(psig) by 0.11. The person inserting the thermowell should ensure adequate

footing for the force required prior to opening the valve.

2. After applying thread seal tape, thread the hot tap adapter into the valve.

Firmly grasp the wiring enclosure, loosen the position clamping nut, open the

valve, and carefully push the thermowell into the ow stream. Use the attached gauge to set the insertion depth.

CAUTION

Excessive vibration can damage the thermowell. Insert the thermowell to the proper depth using

gauge supplied as shown. Reduce the insertion depth as necessary if strong vibrations are felt

during insertion, making certain that the tip of the thermowell remains fully in the ow stream.

3. Carefully tighten the position clamping nut that is located at the top of the

1" NPT hot tap adapter tting. Do not release the wiring enclosure until the

position clamping nut has been tightened.

CAUTION

DO NOT OVER TIGHTEN THE POSITION CLAMPING NUT. If uid leaks, do not attempt to

correct by tightening this nut further. An internal o-ring seals the uid. Contact ONICON for

assistance in the event of a leak.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 12

Page 13

REMOVAL OF THE HOT TAP THERMOWELL

i

!

WARNING

Maintain a rm hold on the wiring enclosure until the thermowell is completely withdrawn and

the valve is closed.

1. System pressure will try to push the thermowell out of the ow stream when the

clamping nut is released. Be sure to establish safe footing prior to loosening the

clamping nut. The force pushing out against the thermowell is the same as the

insertion force.

2. Grasp the wiring enclosure rmly, holding the thermowell in the pipe and then

loosen the position clamping nut. Slowly withdraw the thermowell from the pipe.

3. After the thermowell is completely withdrawn, carefully close the isolation valve.

IMPORTANT NOTE

Rotating the thermowell as you slowly withdraw it through the valve will ensure that the lower

tip is fully withdrawn and completely free of the valve. If resistance is felt when closing the

valve, open valve fully and rotate the well as you pull it further out of the pipe.

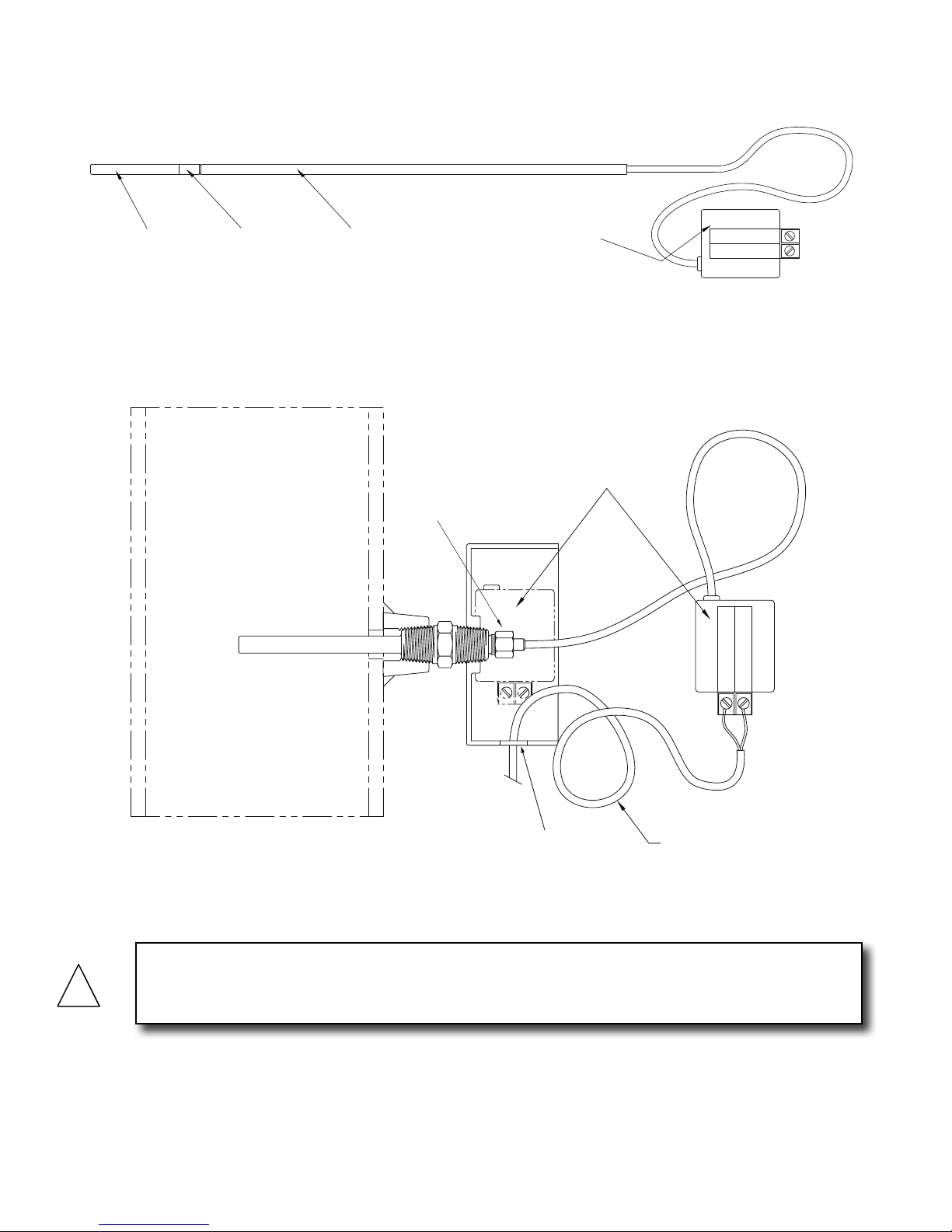

3.2.3 Temperature Sensor Installation

When ordered with the System-20, temperature sensors are factory matched and tagged

by serial number to a specic Btu meter. ONICON standard temperature sensors are also

designated and labeled as the SUPPLY or RETURN sensor and must be installed per these

labels.

3.2.3.1 ONICON Standard Temperature Sensor Installation

ONICON standard temperature sensors must be used as a pair to maintain

differential accuracy. They are also designated and labeled as the SUPPLY or

RETURN sensor and must be installed accordingly. To install, apply a thin coat

of thermal compound to the sensor tip area and insert it all the way into the

thermowell until it contacts the bottom of the cavity. Gently tighten the retainer

nut. DO NOT OVER TIGHTEN. The thermowell completely seals the plumbing

system without the retainer nut. The only purpose for the nut is to ensure that the

sensor tip will remain in contact with the bottom of the thermowell.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 13

Page 14

STANDARD THERMOWELL ASSEMBLY

FOR SYSTEM-10 BTU METER

SHOWN WITH TEMPERATURE SENSOR

TEMPERATURE

SENSOR

PLASTIC

END PIECE

SPACER SLEEVE

(Length varies with

thermowell length)

ELECTRONICS

MODULE

SUPPLY

S/N 123456

SIGNAL

(RED)

REFERENCE

(BLACK)

!

TEMPERATURE SENSOR

TEMPERATURE SENSOR INSTALLED IN THERMOWELL

PLACE ELECTRONICS

MODULE IN BOX AFTER

CONNECTING WIRES.

RETAINING NUT

(Do NOT Overtighten)

REFERNECE (BLACK)

SIGNAL

S/N 123456

SUPPLY

(RED)

PROVIDE #18-22 TWISTED

1/2” HOLE FOR

CONDUIT OR

STRAIN RELIEF

FITTING

SHIELDED PAIR. COIL ONE

FOOT OF EXTRA CABLE IN

CONDUIT BOX.

CAUTION

DO NOT OVERTIGHTEN. The thermowell completely seals the plumbing system. Screwing in the

sensor just ensures that the sensor tip will remain in contact with the bottom of the thermowell.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 14

Page 15

System-20-BAC Enclosure Label

3.3 POWER AND SIGNAL WIRING CONNECTIONS

The System-20 is provided with three ¾" conduit openings along the bottom of the enclosure

for power and signal cables. Two openings are provided with knockout seals. The power cable

should enter the enclosure through the right hand opening. Do not remove the seals from

unused openings. To access the wiring connections, remove the two cover screws shown

below.

Pulse Inputs

Name TB2 Description

IN 1 (+) TB2-1

IN 1 (-) TB2-2

IN 2 (+) TB2-3

IN 2 (-) TB2-4

IN 3 (+) TB2-5

For use with open collector sinking

and dry contact outputs only

Input rating

Pulse duration: 50 ms minimum

Sinking current: 1 mA maximum

IN 3 (-) TB2-6

RS485 Termination Resistor

Name JMP1 Description

120 Ohm JMP1-1

120 Ohm JMP1-2

None JMP1-3

Jumper position 1 & 2 = 120

Ohm Termination

Jumper positions 2 & 3 = No

termination

RS485 (20 – 24 AWG wire)

Name TB1 Description

RS485 B (+) TB1-1

RS485 A (-) TB1-2

RS485 Common TB1-3

RS485 Unit Load = ¼

Recommended maximum

device per segment = 32

Shield TB1-4

Temperature (ONICON Standard Sensors)

Name TB5 Description

SUPTEMP (+) TB5-1

SUPTEMP (-) TB5-2

SHIELD TB5-3

RETTEMP (+) TB5-4

RETTEMP (-) TB5-5

Each sensor is individually

labeled as supply (SUP)

and return (RET) and

must be connected to the

appropriate terminals.

RTD Supply & RTD Return

Name TB6 & TB7 Description

(A) TB6-1 / TB7-1 RTD signal lead (A)

(A) TB6-2 / TB7-2

Compensation lead (A) not

used with 2-wire RTDs

(B) TB6-3 / TB7-3 RTD signal lead (B)

(B) TB6-4 / TB7-4

Compensation lead (B) not

used with 2-wire RTDs

Pulse Outputs

Name TB3 Description

OUT 1 (+) TB3-1

OUT 1 (-) TB3-2

OUT 2 (+) TB3-3

OUT 2 (-) TB3-4

OUT 3 (+) TB3-5

OUT 3 (-) TB3-6

TERMINATED UNTERMINATED

JMP1 RS485 LOAD

TB1 RS-485 TB2 PULSE IN TB3 PULSE OUT TB4 ANA OUT

1 2 3 4 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 4

RS485COM

RS485 -

RS485+

TB5 TEMPERATURE TB6 RTD SUP TB7 RTD RET TB8 TURB TB9 FLOWMETER

1 2 3 4 5 1 2 3 4 1 2 3 4 1 2 3 1 2 3 4 5

RETTEMP (+)

SHIELD

SUPTEMP (-)

SUPTEMP (+)

10/31/16

Opto coupled solid state relay output.

100 V maximum input voltage

30 Ω maximum ON resistance

80 mA maximum current

0.5 Hz maximum pulse rate

Pulse duration: Selectable 50, 100,

500 or 1000 ms

OUT1 (+)

IN 3 (-)

IN 3 (+)

IN 2 (-)

IN 2 (+)

IN 1 (-)

IN 1 (+)

SHEILD

(B)

(B)

(A)

(A)

(B)

(B)

(A)

(A)

RETTEMP (-)

2 4

2 4

2 4

WIRE

WIRE

2 4

WIRE

WIRE

AC/DC POWER IN AUX POWER OUT

!

24V ONLY

4-20 mACOM

4-20mAOUT

OUT 3 (-)

OUT 3 (+)

OUT2 (-)

OUT 2 (+)

OUT 1 (-)

FREQIN

4-20mA IN

24 VDC (=)

TURBCOM

TURB FREQ

24V TURB

1 2 3 4 5 6

24 V N (-)

24V L (+)

EARTH

24 V N (-)

24V L (+)

0-10VOUT

SIG COMM

2-wire / 4-wire RTS Selection Jumpers (4 places)

Name 2-4 Wire Description

2 JMP1-1

Select jumper positions 1

& 2 for 2-wire RTD

JMP1-2

4 JMP1-3

Select jumper positions 2

& 3 for 4-wire RTD

0-10 VCOM

24VDC (-)

EARTH

Cover Screws

Analog Output

Name TB4 Description

4-20 mA Out TB4-1

4-20 mA Common TB4-2

0-10 V Out TB4-3

0-10 V Common TB4-4

Turbine Flow Meter Input

Name TB8 Description

24 V TURB TB8-1

TURB FREQ TB8-2

TURB COMMON TB8-3 Isolated Common

Name TB9 Description

24 VDC (+) TB9-1

4-20 mA IN TB9-2

FREQ IN TB9-3

Signal Common TB9-4 Signal common only

24 VDC (-) TB9-5 24 VDC common

AC/DC POWER INPUT

Name Term # Description

24 V L (+) 1

24 V N (-) 2

EARTH 3

24 V L (+) 4

24 V N (-) 5

EARTH 6

4-20 mA maximum load

resistance 750 Ohms

Voltage output selectable as

0-10 V or 0-5 V

Isolated 24 VDC Supply, 100

mA maximum current

5-24 VDC, 500 Hz maximum

frequency

Flow Meter Input

24 VDC, 250 mA maximum

current

Loop power = TB9-1 & TB9-2 /

Active output = TB9-2 & TB9-4

5-24 VDC, 500 Hz maximum

frequency

20 – 28 V AC/DC, 50-60 Hz

500 mA DC input current

1A AC input current

Instrument earth

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 15

Page 16

SECTION 4.0: SYSTEM-20 START-UP AND COMMISSIONING

!

NEXT

SEL

More Totals

Meter Data

! Alarm

Diagnostic

EXIT

BACK

4.1 START-UP

When power is rst applied to the meter the display will be illuminated and the following start

screen will appear. Momentarily press SEL (select) to access the operating mode (User Screens)

display pages.

User Screens

Commissioning

NEXT

SEL

Verify that the meter is functional by stepping through the display pages and conrming the ow

rate and temperature data is within expected norms. Momentarily press NEXT or BACK to change

the displayed page. A complete list of the display pages is provided on the following pages.

BACK

NEXT

MENU

When reviewing the displayed data, note the factory programmed engineering units on each

display page (e.g. kBtu, gallons, kBtu/h, gpm, °F, etc.). Note any changes that may be necessary.

These will need to be made during commissioning.

Energy Total

!

Alarm Indication

!

0

Unit of Measure

kBtu

When reviewing the Supply and Return temperature display pages, note which one has the word

“FLOW” in the lower left corner of the page. This is an indication of the ow sensor location in

the piping system. Verify the actual location of the ow sensor in the piping system. It is critical

that the correct location (supply or return) be programmed into the meter.

During start-up and commissioning, the FLOW location must be properly identied as being

in the supply or return pipe of the heat exchange circuit. The sensor’s position must then be

programmed into the meter. Failure to do so will result in signicant errors in both the ow

and energy measurements.

To return to the commissioning mode from the user screens, momentarily press MENU.

The following page will appear. Momentarily press EXIT to return to the start screen.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 16

CAUTION

Page 17

4.1.1 Single and Dual Mode Display Pages

Single Mode Dual Mode

BACK

BACK

Run hours

NEXT

MENU

BACK

Auxiliary Input 3

NEXT

MENU

BACK

Auxiliary Input 2

NEXT

MENU

hours

Counts

Counts

Energy Total

NEXT

MENU

!

0

!

*

0

!

*

0

kBtu

!

0

BACK

NEXT

MENU

BACK

NEXT

MENU

BACK

NEXT

MENU

Volume Total

gallons x 1

Energy Rate

kBtu/h x 1

Volume Rate

!

0

!

0

!

0

gpm x 1

BACK

Run hours

NEXT

MENU

BACK

Auxiliary Input 3

NEXT

MENU

BACK

Auxiliary Input 2

NEXT

MENU

hours

*

Counts

*

Counts

BACK

Energy Total

NEXT

MENU

Mode 1

!

0

!

0

!

0

kBtu

!

0

BACK

NEXT

MENU

BACK

NEXT

MENU

BACK

NEXT

MENU

Energy Total

Mode 2

Volume Total

Mode 1

Volume Total

Mode 2

!

0

kBtu

!

0

gallons x 1

!

0

gallons x 1

BACK

NEXT

MENU

BACK

NEXT

MENU

Supply

Temperature

Deg F

Return

Temperature

Deg F

BACK

Auxiliary Input 1

NEXT

MENU

BACK

Delta Temperature

NEXT

MENU

Counts

0.0

Deg F

!

*

0

!

* Auxiliary input pages only appear when enabled.

0.0

0.0

0.0

BACK

NEXT

MENU

BACK

NEXT

MENU

BACK

NEXT

MENU

Energy Rate

kBtu/h x 1

Volume Rate

Supply

Temperature

!

0

!

0

gpm x 1

!

0.0

Deg F

!

BACK

!

!

Auxiliary Input 1

NEXT

MENU

BACK

Mode Status

NEXT

MENU

BACK

Delta Temperature

NEXT

MENU

*

Counts

Mode 2

0.0

Deg F

!

0

!

!

BACK

Return

Temperature

NEXT

MENU

Deg F

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 17

Page 18

4.1.2 Additional Display Pages

NEXT

MENU

Low Flow

Alarm

NEXT

MENU

0

Reset Count

NEXT

MENU

0

Max 200

Flow Count

BACK

EXIT

BACK

EXIT

BACK

EXIT

Diagnostics

NEXT

MENU

Flow Meter

Serial Number

NEXT

MENU

NEXT

MENU

HH:MM:SS

Current Time

NEXT

MENU

App:

Boot:

Versions

NEXT

MENU

0

Serial Number

BACK

EXIT

BACK

EXIT

BACK

EXIT

BACK

EXIT

BACK

EXIT

Meter Data

NEXT

MENU

YYYY/MM/DD

Manuafacture Date

NEXT

MENU

Current Date

BACK

EXIT

BACK

EXIT

YYYY/MM/DD

Alarms

Alarm Mesages

Flow Temp Open

Low Flow

Low Supply Temp

Low Return Temp

dt< Minimum

Temperature Sensor

Serial Number

Single Mode

More Totals

EXIT

YTD Energy

BACK

NEXT

MENU

EXIT

User Energy Total

BACK

NEXT

MENU

EXIT

Prev. Yr Volume

BACK

NEXT

MENU

0

KBtu

0

gallons

YTD Energy & Volume Totals reset at

12:01 AM on January 1st

Prev. Yr. Energy & Volume Totals update at

12:01 AM on January 1st

0

kBtu

EXIT

BACK

NEXT

MENU

EXIT

BACK

NEXT

MENU

YTD Volume

gallons

Prev. Yr Energy

kBtu

Dual Mode

More Totals

EXIT

YTD Energy

BACK

NEXT

MENU

Mode 1

EXIT

User Energy Total

0

0

BACK

NEXT

MENU

Mode 2

EXIT

User Energy Total

BACK

NEXT

MENU

Mode 1

EXIT

Prev. Yr Volume

BACK

NEXT

MENU

Mode 2

EXIT

Prev. Yr Volume

BACK

NEXT

MENU

Mode 1

0

kBtu

0

kBtu

0

gallons

0

gallons

kBtu

0

EXIT

YTD Energy

BACK

NEXT

MENU

Mode 2

EXIT

YTD Volume

BACK

NEXT

MENU

Mode 1

EXIT

YTD Volume

BACK

NEXT

MENU

Mode 2

EXIT

Prev. Yr Energy

BACK

NEXT

MENU

Mode 1

0

kBtu

0

gallons

0

gallons

0

kBtu

User Energy Totals reset via MODBUS

Meter Data

Diagnostics

EXIT

Prev. Yr Energy

BACK

NEXT

MENU

Mode 2

kBtu

0

Alarms

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 18

Page 19

NEXT

Meter Factor

XX.XXX

EXIT

BACK

NEXT

BACK

EDIT

EXIT

Full Scale

Maximum Flow

XXXX

NEXT

BACK

EDIT

EDIT

0 - 9999999

EXIT

Flow Damping

1

1 - 32

NEXT

BACK

EDIT

Pulses per units

% of maximum flow

EXIT

Flow Input Source

Frequency

NEXT

BACK

EDIT

EXIT

Flow Input Source

4-20Ma

NEXT

BACK

EDIT

EXIT

Energy Units

kBtu x 1

Select Units

NEXT

BACK

EDIT

EXIT

Energy Multiplier

EXIT

Energy Rate

kBtu/h x 1

Select Units

NEXT

BACK

EDIT

NEXT

BACK

EDIT

NEXT

Energy Rate Multiplier

kBtu/h x 1

EXIT

BACK

EXIT

Energy Damping

1

NEXT

BACK

EDIT

EDIT

1 - 32

kBtu x 1

X.X

NEXT

Mode

Single

EXIT

BACK

N

EXT

BACK

EDIT

Single/Dual/BiDirectional

EDIT

EXIT

Flow Multiplier

NEXT

Volume Multiplier

gal x 1

EXIT

BACK

NEXT

BACK

EDIT

EXIT

Flow Units

gpm x 1

NEXT

BACK

EDIT

EDIT

Select Units

gpm x 1

NEXT

Medium

Water

EXIT

BACK

EDIT

EXIT

Flow Rate Units

gpm x 1

Select Units

NEXT

BACK

EDIT

NEXT

Flow 20mA

XXXX

EXIT

BACK

EXIT

Low Flow Cutoff

X.X

NEXT

BACK

EDIT

EDIT

% of maximum flow

EXIT

Flow Damping

1

1 - 32

NEXT

BACK

EDIT

0 - 9999999

EXIT

Meter Volume Units

gallons

Se

lect Units

NEXT

BACK

EDIT

EXIT

Low Flow Cutoff

EXIT

Volume Units

gallons

Select Units

Units of Measure Settings

4.2 COMMISSIONING

The last step in the installation process is commissioning the meter. Commissioning is a two-step

process. The rst step is to review the mechanical installation to conrm that the ow sensor and

temperature sensor(s) are properly located in the piping system. The second step is a review of

the meter program settings. Both steps must be completed in order to nish the installation. A

simple commissioning checklist is shown below. A copy of this may be found online at

www.onicon.com/system20.html.

Commissioning Checklist

Part 1 Mechanical Installation

Conrm that the system components are

installed in the correct locations (Sec. 1.5 & 3.1).

Conrm that the ow sensor is properly installed

and correctly oriented with respect to ow

direction (ow meter manual).

Part 2 Programming

Conrm that the ow sensor location in the

piping system (supply or return) is programmed

into the meter (Sec. 4.1 & 4.2.1).

Verify that the Units of Measure Settings in the

meter are correct (Sec. 4.1 & 4.2.1).

Conrm that there are no alarm indications and

the meter is functional (Sec. 4.1.2 & 5.0).

4.2.1 Commissioning Following Initial Power-up

During initial power-up, the display pages will appear when the

commissioning option is selected. The settings shown below allow

the installer to set MODBUS

®

or BACnet® parameters, the ow

EXIT

BACK

NEXT

EDIT

sensor location (supply or return pipe) and the date and time. If

the factory pre-programmed engineering units for ow, energy and

temperature are correct, press SAVE to exit commissioning once

the correct date has been set. Momentarily press NEXT if you wish

access the remaining commissioning mode display pages shown

on the following pages.

Protocol

None

Initial Power-up

Short Commissioning

Protocol

EXIT

BACK

Modbus

NEXT

EDIT

Modbus Address

EXIT

BACK

NEXT

EDIT

Baud Rate

EXIT

BACK

NEXT

EDIT

Parity

EXIT

BACK

NEXT

EDIT

Odd Even None

Stop Bits

EXIT

BACK

NEXT

EDIT

1

0 - 247

19200

None

1

1 2

Short Commissioning

Set Meter

EXIT

BACK

Next to complete Install

settings.

or adjust

NEXT

Protocol

EXIT

BACK

BACnet

NEXT

EDIT

BACnet Address

EXIT

BACK

NEXT

EDIT

0 - 127

Instance Number

EXIT

BACK

57017

NEXT

EDIT

0 - 4194302

Baud Rate

EXIT

BACK

NEXT

EDIT

Max Master

EXIT

BACK

NEXT

EDIT

2 - 127

Set Time

EXIT

BACK

HH:MM:SS

NEXT

EDIT

Set Date

EXIT

BACK

YYYY:MM:DD

NEXT

EDIT

Meter Location

EXIT

BACK

Return

NEXT

EDIT

Flow Meter

EXIT

Serial Number

BACK

NEXT

XXXXXX

EDIT

Location Tag

EXIT

BACK

NEXT

EDIT

Set Meter

EXIT

NEXT edits units of

BACK

measure

NEXT

SAVE completes install

SAVE

with current settings

1

38400

2

Text

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 19

Page 20

Continued From Previous Page

Supply Temperature

20mA

Return Temperature

4mA

Return Temperature

20mA

EXIT

Temperature Sensor

Type

1k Ohm RTD

NEXT

BACK

EDIT

NEXT

X

EXIT

BACK

EXIT

XXX

NEXT

BACK

EDIT

EDIT

EXIT

Supply Temperature

4mA

X

NEXT

BACK

EDIT

EXIT

Temperature Sensor

Type

Scalable

NEXT

BACK

EDIT

EXIT

XXX

NEXT

BACK

EDIT

Flow Input Source

EXIT

BACK

NEXT

EDIT

Flow Damping

EXIT

BACK

NEXT

EDIT

Flow Rate Units

EXIT

BACK

NEXT

EDIT

Select Units

Flow 20mA

EXIT

BACK

NEXT

EDIT

0 - 9999999

Low Flow Cutoff

EXIT

BACK

NEXT

EDIT

% of maximum flow

4-20Ma

1 - 32

gpm x 1

XXXX

X.X

Units of Measure Settings

Energy Units

Mode

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

1

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

Single

Single/Dual/BiDirectional

Medium

Water

Flow Input Source

Frequency

Flow Damping

1 - 32

Meter Volume Units

gallons

Select Units

Meter Factor

XX.XXX

Pulses per units

Full Scale

Maximum Flow

XXXX

0 - 9999999

Low Flow Cutoff

X.X

% of maximum flow

Volume Units

gallons

Select Units

1

EXIT

BACK

NEXT

EDIT

Select Units

Energy Multiplier

EXIT

BACK

NEXT

EDIT

Energy Rate

EXIT

BACK

kBtu/h x 1

NEXT

EDIT

Select Units

Energy Rate Multiplier

EXIT

BACK

NEXT

EDIT

Energy Damping

EXIT

BACK

NEXT

EDIT

kBtu x 1

kBtu x 1

kBtu/h x 1

1 - 32

1

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 20

Volume Multiplier

EXIT

BACK

NEXT

EDIT

Flow Units

EXIT

BACK

NEXT

EDIT

Select Units

Flow Multiplier

EXIT

BACK

NEXT

EDIT

gal x 1

gpm x 1

gpm x 1

Page 21

Units of Measure Settings Continued

Continued From Previous Page

Temperature Sensor

EXIT

Type

BACK

1k Ohm RTD

NEXT

EDIT

Temperature Sensor

EXIT

Type

BACK

NEXT

EDIT

Supply Temperature

EXIT

4mA

BACK

NEXT

EDIT

Supply Temperature

EXIT

20mA

BACK

NEXT

EDIT

Return Temperature

EXIT

4mA

BACK

NEXT

EDIT

Scalable

XXX

Temperature

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

X

X

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

EXIT

BACK

NEXT

EDIT

Deg F

Select Units

Temperature Sensor

Serial Number

XXXXXX

Temperature Sensor

Type

ONICON

Supply Temperature

Offset

+0.000

Supply Temperature

Slope

10.000

Return Temperature

Offset

+0.000

Pulse Output 1

EXIT

BACK

Energy Total

NEXT

EDIT

Select Type

Pulse Output 2

EXIT

BACK

Volume Total

NEXT

EDIT

Select Type

Pulse Output 3

EXIT

BACK

NEXT

EDIT

Select Type

Pulse Duration

EXIT

BACK

NEXT

EDIT

Volume Pulse Scaling

EXIT

BACK

NEXT

EDIT

elect Multiplier

S

EXIT

Analog Output

BACK

Energy Rate

NEXT

EDIT

500 ms

S

elect Type

Alarm

x 1

Return Temperature

EXIT

20mA

BACK

NEXT

EDIT

XXX

Return Temperature

EXIT

Slope

BACK

NEXT

EDIT

Configure Auxiliary

EXIT

Input 1

BACK

NEXT

EDIT

Auxiliary Input

EXIT

Label 1

BACK

NEXT

EDIT

Configure Auxiliary

EXIT

Input 2

BACK

NEXT

EDIT

Auxiliary Input

EXIT

Label 2

BACK

NEXT

EDIT

Configure Auxiliary

EXIT

Input 3

BACK

NEXT

EDIT

10.000

Pulse

Counts

Pulse

Counts

Pulse

Analog Volts Signal

EXIT

BACK

NEXT

EDIT

Analog Output Max

EXIT

BACK

NEXT

EDIT

Energy Rate - kBtu/h

Analog Output Min

EXIT

BACK

NEXT

EDIT

Energy Rate - kBtu/h

Set Meter

BACK

Press NEXT edit units

of measure

NEXT

SAVE completes install

with current settings

EDIT

0 - 10V

S

elect Signal

2000

0

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 21

EXIT

BACK

NEXT

EDIT

Auxiliary Input

Label 3

Counts

Page 22

4.3 SEALING THE METER

Once commissioning is complete, install the security seal.

SECTION 5.0: DIAGNOSTIC FUNCTIONS

The ONICON System-20 has self diagnostic functions that continually monitor key operating

parameters. A list of the alarm messages is shown below.

Install Security

Seal Here

Displayed Message Description

System Fault This message indicates a hardware malfunction. The meter will not

calculate energy in this state.

Dt< Minimum This is a warning message that the delta temperature is low.

Empty Pipe The pipe is empty.

Flow RTD Open The SUPPLY temperature sensor in the ow body is reading open.

The meter will not calculate energy in this state.

Flow RTD Short The SUPPLY temperature sensor in the ow body is reading as a short

circuit. The meter will not calculate energy in this state.

Remote RTD Open The remote RETURN temperature sensor is reading open. The meter

will not calculate energy in this state.

Remote RTD Short The remote RETURN temperature sensor is reading as a short circuit.

The meter will not calculate energy in this state.

Low Flow The ow reading is below the minimum ow threshold of the meter

(e.g. 0.03 gpm for ½” meter). The meter will not calculate energy in

this state.

High Flow This is a warning message that the ow reading is above the

maximum ow rate of the meter (e.g. 15 gpm for ½” meter).

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 22

Page 23

SECTION 6.0: BACnet® MS/TP

BACnet® MS/TP, serial interface connections are connected at terminal block TB1.

Transceiver: 2-wire, half-duplex (1/4 unit load)

BACnet® address (MAC address) range: 1 - 255 (Default: 017)

Device Instance: 0 - 4,194,303 (Default: 57017)

Baud rate: 9600, 19200, 38400 or 76800 (Default: 38400)

Termination: 120 Ω or none (Default: none)

Biasing: None

Flow control: None

6.1 BACnet® OBJECT TYPES

BACnet® Object Type and Number of Objects Implemented

Device 1

Analog Input 10

Analog Value 34

Binary Value 12

Multi-State Object 1

Trend Log Multiple 1

6.2 PROTOCOL IMPLEMENTATION STATEMENT

BACnet® Protocol Revision: 10

Device Prole (Annex L): BACnet® Application Specic Controller (B-ASC)

MS/TP master (Clause 9), baud rate(s): 9600, 19200, 38400 & 76800

Device Address Binding: No

BBMD support registration by Foreign Devices: No

Character Set Supported: ANSI X3.4

BACnet® Interoperability Building Blocks Supported (Annex K):

Data Sharing - ReadProperty-B (DS-RP-B)

Data Sharing - ReadProperty Multiple - B (DS-RPM-B)

Data Sharing - WriteProperty-B (DS-WP-B)

Data Sharing - WriteProperty Multiple - B (DS-WPM-B)

Device Management - Dynamic Device Binding - B (DM-DDB-B)

Device Management - Dynamic Object Binding - B (DM-DOB-B)

Device Management - DeviceCommunicationControl-B (DM-DCC-B)

Device Management - Time Synchronization - B (DM-TS-B)

Device Management - UTC Time Synchronization - B (DM-UTC-B)

Trending - View and Modify Multiple Values - I - B (T-VMMV-I-B)

Standard Object Types Supported:

Device Object Binary Value Object

Analog Input Object Multi-State Value

Analog Value Object Trend Log Multiple

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 23

Page 24

6.3 DEVICE OBJECT

Property Default Value Read-only or

Writable

Object Identier 57017 Writable 0-4,194,303

Object Name System-20-XXXXXX Read-only

Object Type Device Read-only

System Status Operational Read-only

Vendor Name ONICON Inc. Read-only

Model Name System-20 Read-only

Firmware Rev. 000.000.000 Read-only

Location Customer Location Writable 32 char. Max

Description Customer Description Writable 32 char. Max

Protocol Version 1 Read-only

Protocol Revision 10 Read-only

Services Supported Read property, Read property multiple, Write

property, Write property multiple, Read

range, Who-has, I have, Who-is, I-am, Device

communications control, Time synchronization,

UTC time synchronization

Object Types Supported Analog input, Analog value, Binary input, Device,

Multi-state value, Trend log multiple

Object List (Device, 57017), (analog input, 1 – 10),

(analog value, 1 – 24), (binary value, 1 – 10),

(trend log multiple, 1), (multi-state value, 1)

Max ADPU Length 480 Read-only

Local Time Device current time Read-only

Local Date Device current date Read-only

UTC Offset -300 Writable

Daylight Savings Status False Writable

APDU Time-out 6000 Read-only

# of APDU Retries 3 Writable

Max Master 127 Read-only

Device Address Binding N/A Read-only Active

Database Revision 1 Read-only

Read-only

Read-only

Read-only

Comment

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 24

Page 25

6.4 ANALOG INPUT(S)

Property Default Value Read-only or Writable

Object Identier Analog input 1 to 10 Read-only

Object Name Various Read-only

Object Type Analog-input Read-only

Present Value REAL Writable

Description Analog-input,# Name Read-only

Status Flags (F,F,F,F) Read-only

Event State Normal Read-only

Reliability No-fault-detected Read-only

Out-of-Service FALSE Writable

Update interval 100 Read-only

Units Various Read-only

Min-Present-Value -1000000000 Read-only

Max-Present-Value 1000000000 Read-only

Resolution 0.000001 Read-only

Objects List

Object Identier Function

Analog input 1 Energy rate

Analog input 2 Volume rate

Analog input 3 Supply temperature

Analog input 4 Return temperature

Analog input 5 Delta temperature

Analog input 6* Peak energy rate

Analog input 7* Average delta temp

BACnet Engineering Units for Analog Inputs (Defaults)

Energy rate: kBtu/h, tons, kW or MW

Volume rate: gpm, l/s, ft3/m or m3/h

Temperature: °F or °C

* Time interval set by Trend Log Object

6.5 ANALOG VALUE(S)

Property Default Value Read-only or Writable

Object Identier Analog value 1 to 24 Read-only

Object Name Various Read-only

Object Type Analog-value Read-only

Present Value REAL Writable

Description Analog-value,# Name Read-only

Status Flags (F,F,F,F) Read-only

Event State normal Read-only

Reliability No-fault-detected Read-only

Out-of-Service FALSE Writable

Units Various Read-only

Priority Array {NULL, NULL, NULL, NULL, NULL, NULL, NULL, NULL,

NULL, NULL, NULL, NULL, NULL, NULL, NULL, NULL}

Relinquish Default 0 Read-only

Read-only

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 25

Page 26

Analog Value Objects

Object Identier Function

Analog value 1 Single mode energy total

Analog value 2 Mode 1 energy total

Analog value 3 Mode 2 energy total

Analog value 4 Single mode Y-T-D energy total

Analog value 5 Mode 1 Y-T-D energy total

Analog value 6 Mode 2 Y-T-D energy total

Analog value 7 Single mode previous year energy total

Analog value 8 Mode 1 previous year energy total

Analog value 9 Mode 2 previous year energy total

Analog value 10 Single mode user dened energy total

Analog value 11 Mode 1 user dened energy total

Analog value 12 Mode 2 user dened energy total

Analog value 13 Single mode incremental energy total

Analog value 14 Mode 1 incremental energy total

Analog value 15 Mode 2 incremental energy total

Analog value 16 Single mode volume total

Analog value 17 Mode 1 volume total

Analog value 18 Mode 2 volume total

Analog value 19* Single mode Y-T-D volume total

Analog value 20* Mode 1 Y-T-D volume total

Analog value 21* Mode 2 Y-T-D volume total

Analog value 22* Single mode previous year volume total

Analog value 23 Mode 1 previous year volume total

Analog value 24 Mode 2 previous year volume total

Analog value 25 Single mode user dened volume total

Analog value 26 Mode 1 user dened volume total

Analog value 27 Mode 2 user dened volume total

Analog value 28 Single mode incremental volume total

Analog value 29 Mode 1 incremental volume total

Analog value 30 Mode 2 incremental volume total

Analog value 31 Aux pulse input 1 total

Analog value 32 Aux pulse input 2 total

Analog value 33 Aux pulse input 3 total

Analog value 34 Run hours

* Time interval set by Trend Log Object

BACnet Engineering Units for Analog Values (Defaults)

Energy: kBtu, MBtu, ton-hours, kJ, MJ, kWh or MWh

Volume: gallons, liters, ft3 or m3

Auxiliary pulse inputs: No units (counts)

Run hours: Hours

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 26

Page 27

6.6 BINARY VALUE(S)

Property Default Value Read-only or Writable

Object Identier Binary value 1 to binary value 10 Read-only

Object Name Various Read-only

Object Type Binary-value Read-only

Present Value 0 Writable

Description Binary-value,# Name Read-only

Status Flags (F,F,F,F) Read-only

Event State Normal Read-only

Reliability No-fault-detected Read-only

Out-of-Service FALSE Writable

Elapsed Active Time Various Read-only

Priority Array (NULL, NULL, NULL, NULL, NULL, NULL,

NULL, NULL, NULL, NULL, NULL, NULL,

NULL, NULL, NULL, NULL)

Relinquish Default 0 Read-only

Binary Value Objects

Object Identier Description Notes

Binary value 1 Mode indication 0 = mode 1, 1 = mode 2

Binary value 2 Location 0 = supply, 1 = return

Binary value 3 Single mode user energy total reset 1 = reset total

Binary value 4 Mode 1 user energy total reset 1 = reset total

Binary value 5 Mode 2 user energy total reset 1 = reset total

Binary value 6 Single mode user volume total reset 1 = reset total

Binary value 7 Mode 1 user volume total reset 1 = reset total

Binary value 8 Mode 2 user volume total reset 1 = reset total

Binary value 9 Aux total 1 reset 1 = reset total

Binary value 10 Aux total 2 reset 1 = reset total

Binary value 11 Aux total 3 reset 1 = reset total

Binary value 12 Flow direction 1 = reverse ow

Read-only

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 27

Page 28

6.7 MULTI STATE VALUE

Property Default Value Read-only or Writable

Object Identier Multi state value 1 Read-only

Object Name Meter Status Read-only

Object Type Multi-state-value Read-only

Present Value 1 Writable

Description Multi-state-value,# Name Read-only

Status Flags (F,F,F,F) Read-only

Event State Normal Read-only

Reliability No-fault-detected Read-only

Out-of-Service FALSE Writable

Number of States 11 Read-only

State Text Normal, Low Supply Temperature,

High Supply Temperature, Low Return

Temperature, Delta T< Minimum, High

Energy Rate, Low Signal Quality, Comm

Error, Low Supply Voltage, System Fault

Relinquish Default 0 Read-only

Read-only

Multi-state Object

Object Identier Description Notes

Multi-state value 1 Reports the operating status of the meter

1 = Normal

2 = Low Supply Temperature

3 = High Supply Temperature

4 = Low Return Temperature

5 = High Return Temperature

6 = Delta T < Minimum

7 = High Energy Rate

9 = Comm error

10 = Low Supply Voltage

11= System Fault

Numeric values indicate meter

status.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 28

Page 29

6.8 TREND LOG MULTIPLE

Property Default Value Read-only or Writable

Object Identier Trend log multiple 1 Read-only

Object Name Log Data Read-only

Object Type Trend-log-multiple Read-only

Description Trend-log-multiple,# Name Read-only

Status Flags (F,F,F,F) Read-only

Event State Normal Read-only

Reliability No-fault-detected Read-only

Enable TRUE Writable

Log Device Property Read-only

Logging Type POLLED Read-only

Log Interval 90000 Writable

Stop When Full FALSE Read-only

Buffer Size 480 Read-only

Log Buffer Read-only

Record Count 0 Writable

Total Record Count 0 Read-only

Trend log Multiple Object

Object Identier Description Notes

Trendlog Multiple 1 Logs the following BACnet objects:

Peak energy rate

Average delta temp

Incremental energy total mode 1

Incremental energy total mode 2

Incremental volume total mode 1

The log buffer holds 120 records

and then rolls over with the rst in

as rst out.

The logging interval can be set from

30 seconds to 1 hour via BACnet.

The default interval is 15 minutes.

Incremental volume total mode 2

Meter status (multi-state object)

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 29

Page 30

SECTION 7.0: MODBUS

MODBUS®, serial interface connections are connected at terminal block TB1.

Transceiver: 2-wire, half-duplex (1/4 unit load)

MODBUS® address range: 1 - 247 (Default: 017)

Data format: 8 bit

Stop Bits: 1

Parity: None (Default), Odd, or Even

Byte Order: ABCD

Baud rate: 4800, 9600, 19200, 38400, 57600, 76800 or 115200 (Default: 9600)

Termination: Jumper selectable 120Ω resistor (See page 15)

Biasing: None

Engineering Units Abbreviation Engineering Units Abbreviation

Energy Rate Energy Total

Btu per hour x 1,000 kBtu/hr Btu x 1,000 kBtu

Tons Tons Btu x 1,000,000 MBtu

Watts x 1,000 kW Ton-hour TonHr

Watts x 1,000 x

1,000,000

Volume Rate (Flow) Watt-hours x 1,000 kWHr

Gallons per minute GPM Volume Total

Liters per second L/s Gallons Gal

Cubic feet per minute ft3/min Liters Liters

Cubic meters per hour m

Temperature Cubic Meters m

Degrees Fahrenheit ºF

Degrees Celsius ºC

Velocity (Flow velocity, Fluid speed of sound)

Feet per second ft/s

Meters per second m/s

MW Joules x 1,000,000 MJ

3

/hr Cubic Feet ft

3

3

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 30

Function Codes Supported:

01 - Read Coil(s)

02 - Read Discreet Input(s)

03 - Read Holding Register(s)

04 - Read Input Register(s)

05 - Write Single Coil

06 - Write Single Register

08 - Diagnostic

15 - Write Multiple Coils

16 - Write Multiple Registers

17 - Report Slave ID

Page 31

7.1 MODBUS MEMORY MAP

Register

Address

1 Reset User Dened Energy

Description Register

Type

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Data

Range

Over

Range

Read/Write Comments

Total - Single Mode

2 Reset User Dened Energy

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Total - Mode 1

3 Reset User Dened Energy

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Total - Mode 2

4 Reset User Dened Volume

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Total - Single Mode

5 Reset User Dened Volume

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Total - Mode 1

6 Reset User Dened Volume

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Total - Mode 2

7 Reset Aux Input Total -

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Input 1

8 Reset Aux Input Total -

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Input 2

9 Reset Aux Input Total -

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Input 3

10 Reset Aux Input Total - All

Coil NA NA Read/Write Turn coil ON (1) to reset total on System-20.

Inputs

11 Aux Output 1 Coil NA NA Read/Write

12 Aux Output 2 Coil NA NA Read/Write

13 Aux Output 3 Coil NA NA Read/Write

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0)once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil to OFF (0) once reset is complete.

Turn coil ON (1) to latch Aux I/O # 1 closed. Turn

coil to OFF (0) to latch I/O # 1 open. Aux I/O #

1 must have been congured as an output at the

factory, and programmed for "MODBUS Coil" in

the commissioning menu.

Turn coil ON (1) to latch Aux I/O # 2 closed. Turn

coil to OFF (0) to latch I/O # 2 open. Aux I/O #

2 must have been congured as an output at the

factory, and programmed for "MODBUS Coil" in

the commissioning menu.

Turn coil ON (1) to latch Aux I/O # 3 closed. Turn

coil to OFF (0) to latch I/O # 3 open. Aux I/O #

3 must have been congured as an output at the

factory, and programmed for "MODBUS Coil" in

the commissioning menu.

Register

Address

10001 Mode Indication Discreet Input 0-1 NA Read

10002 Location Discreet Input 0-1 NA Read

10003 Mode Single Dual Discreet Input 0-1 NA Read

Register

Description Register Type Data Range Over

Range

Read/

Write

Only

Only

Only

Comments

1- Indicates heating mode

2- Indicates cooling mode

1- Indicates heating mode;

2- Indicates cooling mode

1- Indicates meter congured as

single mode; 2- indicates meter

congures as dual mode

Description Register Type Register Type Comments

Address

30001 Energy Rate - kBtu/hr Input Register Floating Point Register (1 of 2)

30002 Energy Rate - kBtu/hr Input Register Floating Point Register (2 of 2)

30003 Energy Rate - Tons Input Register Floating Point Register (1 of 2)

30004 Energy Rate - Tons Input Register Floating Point Register (2 of 2)

30005 Energy Rate - kW Input Register Floating Point Register (1 of 2)

30006 Energy Rate - kW Input Register Floating Point Register (2 of 2)

30007 Energy Rate - MW Input Register Floating Point Register (1 of 2)

30008 Energy Rate - MW Input Register Floating Point Register (2 of 2)

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 31

Page 32

30009 Volume Rate - GPM

30010 Volume Rate - GPM

30011 Volume Rate - L/s

30012 Volume Rate - L/s

30013 Volume Rate - ft3/min

30014 Volume Rate - ft3/min

30015 Volume Rate - m3/hr

30016 Volume Rate - m3/hr

Input Register

Input Register

Input Register

Input Register

Input Register

Input Register

Input Register

Input Register

Floating Point Register (1 of 2)

Floating Point Register (2 of 2)

Floating Point Register (1 of 2)

Floating Point Register (2 of 2)

Floating Point Register (1 of 2)

Floating Point Register (2 of 2)

Floating Point Register (1 of 2)

Floating Point Register (2 of 2)

30017 Flow Temperature - °F Input Register Floating Point Register (1 of 2)

30018 Flow Temperature - °F Input Register Floating Point Register (2 of 2)

30019 Flow Temperature - °C Input Register Floating Point Register (1 of 2)

30020 Flow Temperature - °C Input Register Floating Point Register (2 of 2)

30021 Remote Temperature - °F Input Register Floating Point Register (1 of 2)

30022 Remote Temperature - °F Input Register Floating Point Register (2 of 2)

30023 Remote Temperature - °C Input Register Floating Point Register (1 of 2)

30024 Remote Temperature - °C Input Register Floating Point Register (2 of 2)

30025 Delta Temperature - °F Input Register Floating Point Register (1 of 2)

30026 Delta Temperature - °F Input Register Floating Point Register (2 of 2)

30027 Delta Temperature - °C Input Register Floating Point Register (1 of 2)

30028 Delta Temperature - °C Input Register Floating Point Register (2 of 2)

Temperature measured

by RTD in ow meter

location

Temperature measured

by RTD in ow meter

location

Temperature measured

by RTD in ow meter

location

Temperature measured

by RTD in ow meter

location

Temperature measured

by remote RTD

Temperature measured

by remote RTD

Temperature measured

by remote RTD

Temperature measured

by remote RTD

30029

30030

30031

30032

30033

30034

30035

30036

30037

30038

30039

30040

30041

30042

30043

30044

30045

Energy Total - Single Mode - kBtu

Energy Total - Single Mode - kBtu

Energy Total - Single Mode - MBtu

Energy Total - Single Mode - MBtu

Energy Total - Single Mode - TonHr

Energy Total - Single Mode - TonHr

Energy Total - Single Mode - MJ

Energy Total - Single Mode - MJ

Energy Total - Single Mode - kWHr

Energy Total - Single Mode - kWHr

Energy Total - Mode 1 - kBtu

Energy Total - Mode 1 - kBtu

Energy Total - Mode 1 - MBtu

Energy Total - Mode 1 - MBtu

Energy Total - Mode 1 - TonHr

Energy Total - Mode 1 - TonHr

Energy Total - Mode 1 - MJ

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

Input Register Floating Point Register (2 of 2)

Input Register Floating Point Register (1 of 2)

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

System-20-BTU Meter Installation and Operation Guide 03/18 - 2051-1 / 36985 Page 32

Page 33

30046

30047

30048

30049

30050

30051

30052

30053

30054

30055

30056

30057

30058

30059

30060

30061

30062

30063

30064

30065

30066

30067

30068

30069

30070

30071

30072

30073

30074

30075

30076

30077

30078

30079

30080

30081

30082

30083

30084

30085

30086

30087

30088

30089

30090

30091

Energy Total - Mode 1 - MJ