Page 1

FT-3100 Transmitter

Inline Electromagnetic Flow Meter

Programming Guide

ONICON

Flow and Energy Measurement

Page 2

TABLE OF CONTENTS

1.0 INTRODUCTION .........................................................................................................................5

1.1 Purpose of this Guide ...................................................................................................................................... 5

1.2 Display and User Interface ............................................................................................................................. 5

1.3 Accessing the Programming Menus .......................................................................................................... 6

2.0 QUICK START MENU ..................................................................................................................6

2.1 MENU - QUICK START ..................................................................................................................................... 7

Empty Pipe Detector [E.P.Detect=ON] .................................................................................................... 7

Empty Pipe Threshold [R max=kohm XXXX] ......................................................................................... 7

Scaled Pulse Output 2 [Pls2=Gal X.XXXX] ............................................................................................. 7

Output 2 Pulse Duration [Tpls2=ms X.XXXX] ........................................................................................ 8

Analog Output 1 Full Scale Value [A1S=Gal/m XXXXXX] ................................................................. 8

3.0 MAIN MENU ............................................................................................................................... 9

3.1 MENU 1 - SENSOR ............................................................................................................................................ 9

Sensor Body Model [S.Model=XXX] ......................................................................................................... 9

Liner Material [Lining=XXXXXX] ...............................................................................................................10

Unit Type [U.type=XXXXXX] .......................................................................................................................10

Diameter [Diam.=XXX] .................................................................................................................................10

KA [KA=±XX.XXX] ..........................................................................................................................................10

KZ [KZ=±XXXX] ..............................................................................................................................................10

Empty Pipe Detector [E.P.Detect=ON] ..................................................................................................11

Empty Pipe Threshold [R max=kohm XXXX] .......................................................................................11

Electrode Cleaning [El. Cleaning=MIN] .................................................................................................11

Sensor Cable Length [S.cable=ft XXX] ...................................................................................................12

Alarm Delay Interval [S.err.delay=m XXX] ............................................................................................12

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.2 MENU 2 - UNITS .............................................................................................................................................13

Diameter Unit Type [Diam.=in] .................................................................................................................13

Remote Mount Cable Unit Type [S.cable=ft] ......................................................................................13

Flow Rate Unit Type [FR unit=IMPERIAL] .............................................................................................13

Pulse 1 Unit Type [Pl1 unit=IMPERIAL] ..................................................................................................14

Pulse 2 Unit Type [Pl2 unit=IMPERIAL] ...................................................................................................14

Total Forward Flow Totalizer Unit Type [T+ unit=IMPERIAL] ..........................................................14

Total Forward Flow Totalizer Units [T+ unit=Gal] ...............................................................................14

Total Forward Flow Totalizer Decimal Point Position [T+ D.P.=X] ................................................14

Partial Forward Flow Totalizer Unit Type [P+ unit=IMPERIAL] .......................................................14

Partial Forward Flow Totalizer Units [P+ unit=Gal] ............................................................................15

Partial Forward Flow Totalizer Decimal Point Position [P+ D.P.=X] .............................................15

Total Reverse Flow Totalizer Unit Type [T- unit=IMPERIAL] ............................................................15

Total Reverse Flow Totalizer Units [T- unit=Gal] .................................................................................15

Total Reverse Flow Totalizer Decimal Point Positiion [T- D.P.=X] .................................................15

Partial Reverse Flow Totalizer Unit Type [P- unit=IMPERIAL] .........................................................15

Partial Reverse Flow Totalizer Units [P- unit=Gal] ..............................................................................15

Partial Reverse Flow Totalizer Decimal Point Position [P- D.P.=X] ...............................................16

Temperature Unit Type [Temp. unit= °F] ................................................................................................ 16

Mass Units Enable [Mass units=OFF] ......................................................................................................16

Specic Gravity Coecient [Sg=kg/dm3 X.XXXX] ..............................................................................16

ONICON Incorporated 727.447.6140 Page 2 onicon.com

Page 3

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.3 MENU 3 - SCALES ...........................................................................................................................................17

Full Scale Flow Rate 1 [FS1= Gal/m XXX.X] ...........................................................................................17

Full Scale Flow Rate 2 [FS2 = Gal/m XXX.X] ..........................................................................................18

Scaled Pulse Output 1 [Pls1 = Gal X.XXXX] ...........................................................................................18

Output 1 Pulse Duration [Tpls1 = ms X.XXXX] .....................................................................................19

Output 1 Full Scale Frequency [Frq1 = Hz X.XXXXX] ........................................................................19

Scaled Pulse Output 2 [Pls2 = Gal X.XXXX] ...........................................................................................19

Output 2 Pulse Duration [Tpls2 = ms X.XXXX] .....................................................................................20

Output 2 Full Scale Frequency [Frq2 = Hz X.XXXXX] ........................................................................20

3.4 MENU 4 - MEASURE.......................................................................................................................................21

Flow Signal Damping [Damping=SMART] ............................................................................................21

Low Flow Cut-o [Cut-o = % XXX] ........................................................................................................22

Autorange [Autorange=OFF]......................................................................................................................22

High Immunity Input Filter [H.im.imp.=OFF] ........................................................................................22

3.5 MENU 5 - ALARMS ........................................................................................................................................23

Maximum Forward Flow Alarm Threshold [Max+ = Gal/m OFF] ................................................23

Maximum Reverse Flow Alarm Threshold [Max - = Gal/m OFF] .................................................23

Minimum Forward Flow Alarm Threshold [Min + = Gal/m OFF] ................................................23

Minimum Reverse Flow Alarm Threshold [Min - = Gal/m OFF] ..................................................24

Alarm Hysteresis Threshold [Hysteresis=%XXX] ................................................................................24

mA Output Value When in Alarm State [mA v.alarm=%XXX] .......................................................24

Frequency Output Value When in Alarm State [Hz v.alarm = %XXX} ........................................25

3.6 MENU 6 - INPUTS...........................................................................................................................................26

Total Forward Flow Totalizer Reset Enable [T+reset=ON] .............................................................26

Partial Forward Flow Totalizer Reset Enable [P+reset=OFF] .........................................................26

Total Reverse Flow Totalizer Reset Enable [T-reset=OFF] ...............................................................26

Partial Reverse Flow Totalizer Reset Enable [P-reset=OFF] ............................................................26

Disable Totalizers via Pulse Input [Meas. Lock=OFF] ....................................................................... 26

Activate Autozero Calibration via Pulse Input [Calibration=OFF] ...............................................27

Change Flow Range via Pulse Input [Range change=OFF] ...........................................................27

3.7 MENU 7 - OUTPUTS ......................................................................................................................................28

Digital Output 1 Function Select [Out1=XXXXXX] ............................................................................28

Digital Output 2 Function Select [Out2=XXXXXX] ............................................................................28

mA Output 1 Function & Scaling [Out mA1=4_20+/-] ...................................................................29

Analog Output 1 Full Scale Value [A1S=Gal/m XXXXXX] ...............................................................29

3.8 MENU 9 - DISPLAY .........................................................................................................................................30

Display Language [Language=GB] ..........................................................................................................30

Contrast Adjustment [Contrast=X] .........................................................................................................30

Display/User Interface Inactivity Time Interval [Disp. times=sXXX] ...........................................30

Display Refresh Frequency [D.rate=Hz X].............................................................................................30

Display Lock [Disp. lock=OFF]...................................................................................................................31

Enable Partial Totalizers [Part. tot.=OFF] ...............................................................................................31

Enable Negative Totalizers [Neg. tot. = OFF] ....................................................................................... 31

Enable Net Totalizers [Net tot.=OFF] .....................................................................................................32

Enable Quick Start Menu [Quick start=ON] ........................................................................................32

Default Display Page [Disp. fn = X] ..........................................................................................................33

ONICON Incorporated 727.447.6140 Page 3 onicon.com

Page 4

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.9 MENU 11 - FUNCTIONS ..............................................................................................................................34

Reset Total Forward (+) Totalizer [T + reset] .......................................................................................34

Reset Partial Forward (+) Totalizer [P + reset] ....................................................................................34

Reset Total Reverse (-) Totalizer [T - reset] ........................................................................................... 34

Reset Partial Reverse (-) Totalizer [P - reset] ........................................................................................34

Load Factory Default Sensor Body Settings [Load sens.f.def] ......................................................34

Load Factory Default Transmitter Settings [Load Conv.f.def] .......................................................34

3.10 MENU 12 - DIAGNOSTIC ............................................................................................................................35

Self Diagnostic Test [Self test] ................................................................................................................... 35

Test Display [Display test] ........................................................................................................................... 35

Simulate Flow Rate [Flow sim. = OFF] ...................................................................................................35

Firmware Information [Firmware info] ...................................................................................................35

Serial Number [S/N = XXXXXX] ................................................................................................................35

Working Time [WT = XXXX:XX:XX:XX] ...................................................................................................35

ONICON Incorporated 727.447.6140 Page 4 onicon.com

Page 5

SECTION 1.0: INTRODUCTION

FT-3100 TRANSMITTER PROGRAMMING GUIDE

1.1 PURPOSE OF THIS GUIDE

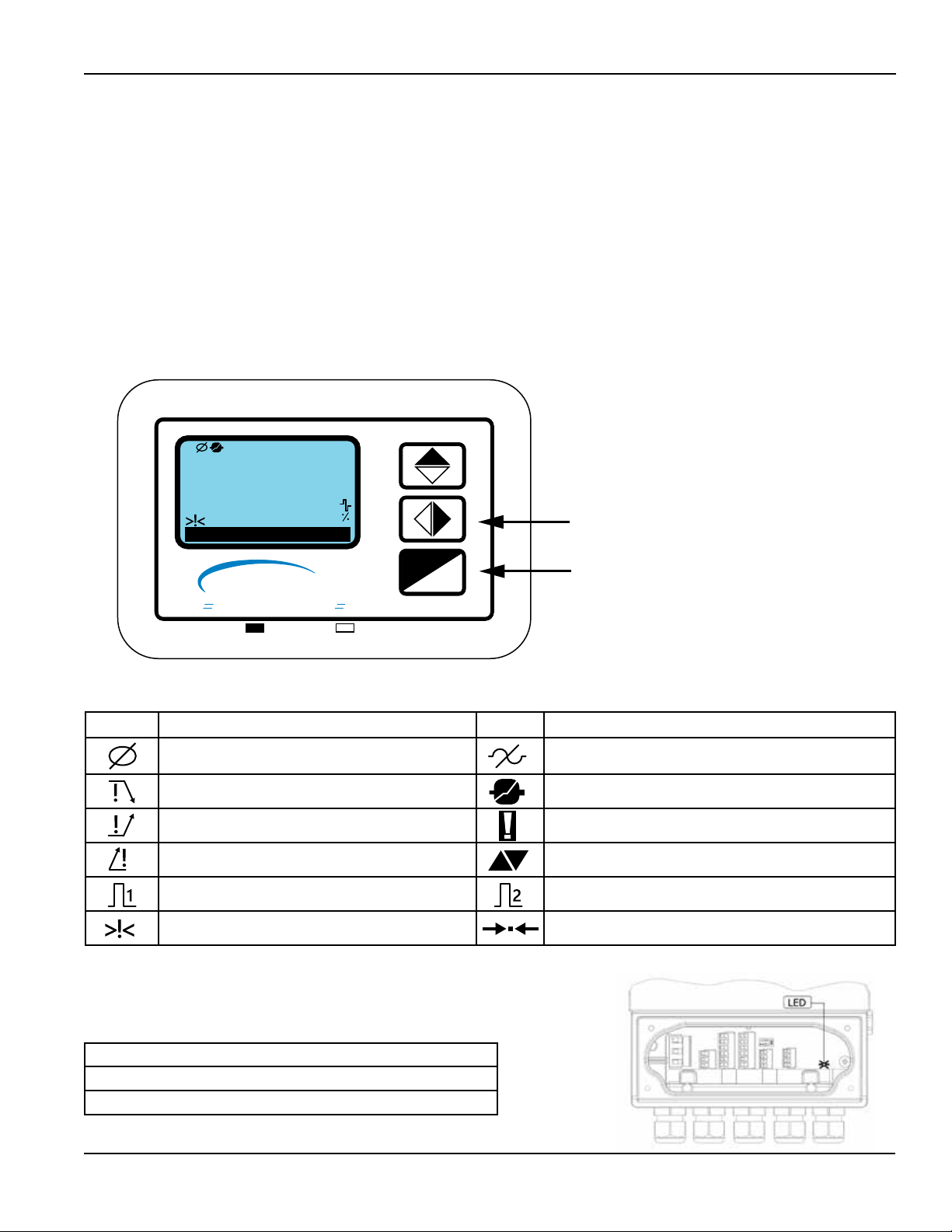

1.2 DISPLAY AND USER INTERFACE

Gal/m

2 ALARM(S)

ONICON

Flow and Energy Measurement

+0.00

SHORT PUSH LONG PUSH

The purpose of this guide is to provide programming information for the FT-3100

transmitter congured with the following options:

• One (1) analog output

• Two (2) digital outputs

• One (1) digital input

It does not include information on serial communications or data logging.

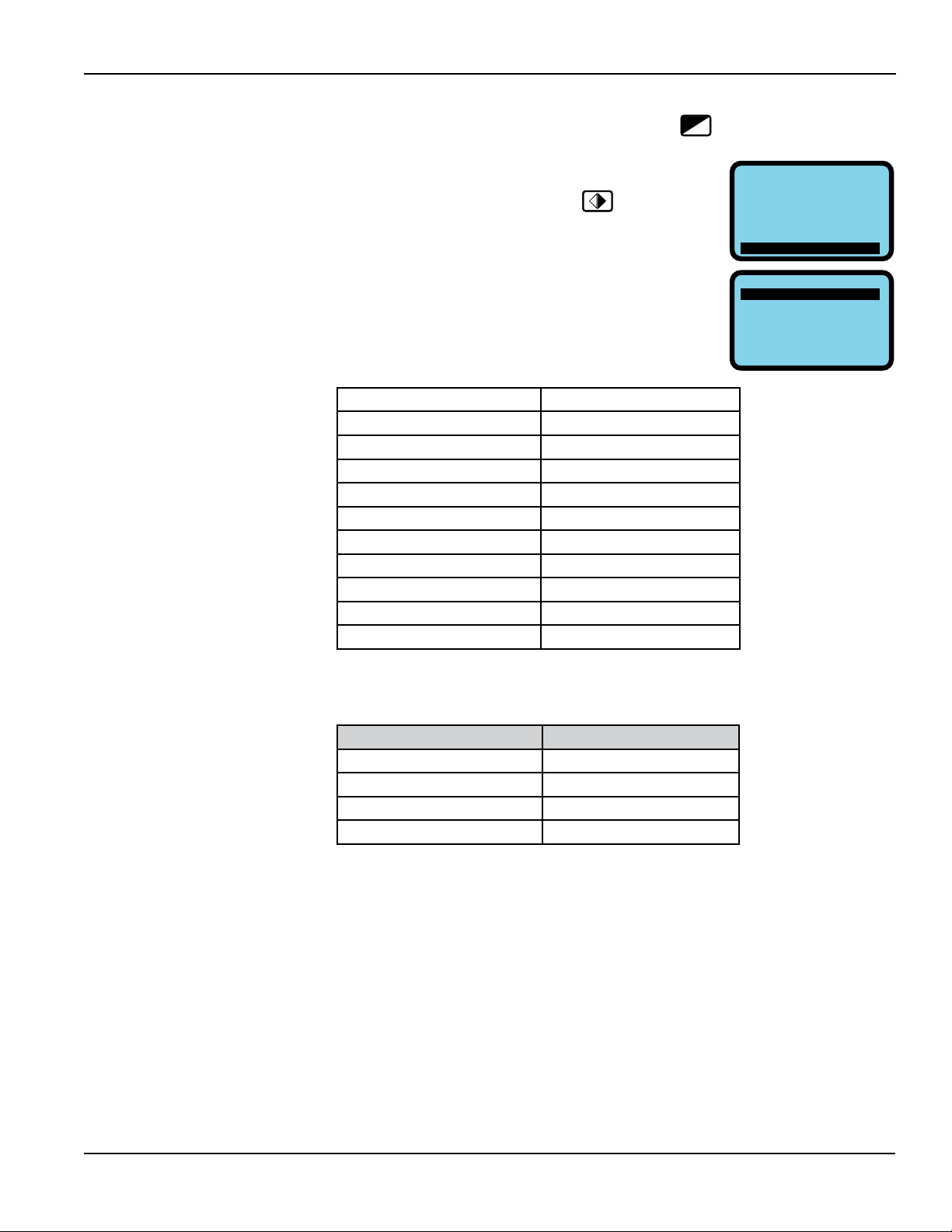

The FT-3100 transmitter is equipped with a lighted graphic display and 3-button

user interface as shown below.

0

Briefly press the middle button to advance

to the next menu page.

ENTER

ESC

The ENTER button is used in programming.

STATUS ICONS

Icon Description Icon Description

Empty Pipe Signal Error

Low Flow Alarm Excitation Error

High Flow Alarm General Alarm (Flashing)

Flow Rate Overow Flow Rate Simulation (Flashing)

Pulse 1 Overow Pulse 2 Overow

Generic Alarm (Flashing) Calibration (Flashing)

A multicolored LED inside the eld wiring compartment provides

addition information on the operating status.

Red LED: Alarm

Blue LED: USB comm enabled

Green LED: Normal Operation

ONICON Incorporated 727.447.6140 Page 5 onicon.com

Page 6

FT-3100 TRANSMITTER PROGRAMMING GUIDE

ACCESS CODE

Code : 4

999999990

*******

QUICK START

E. P. Detect=

R max=kohm

Pls2=Gal

Tpls2=ms

A1S=Gal/m

Main Menu

ON

0220

1000.0

0500.0

004500

2 ALARM(S)

0

+0.00

Gal/m

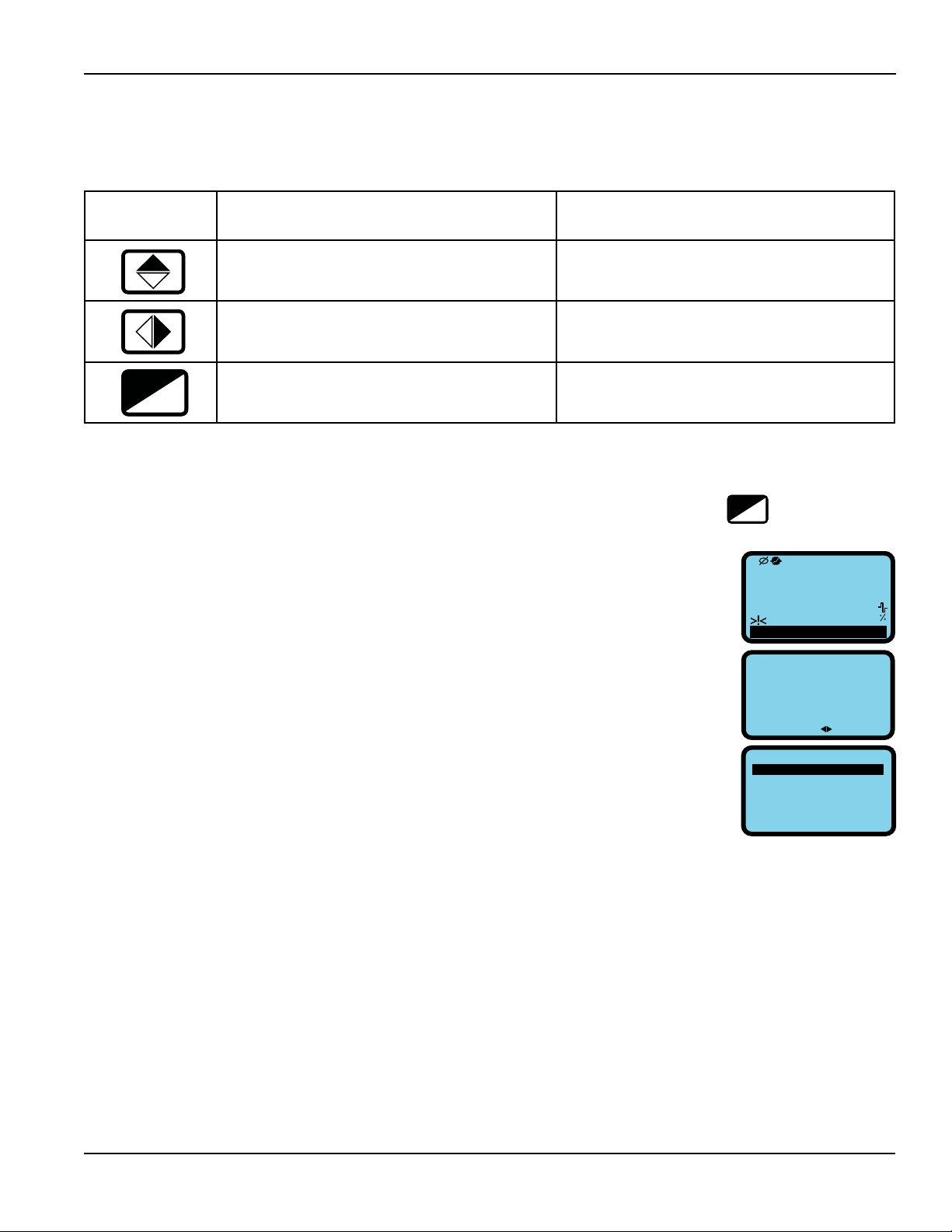

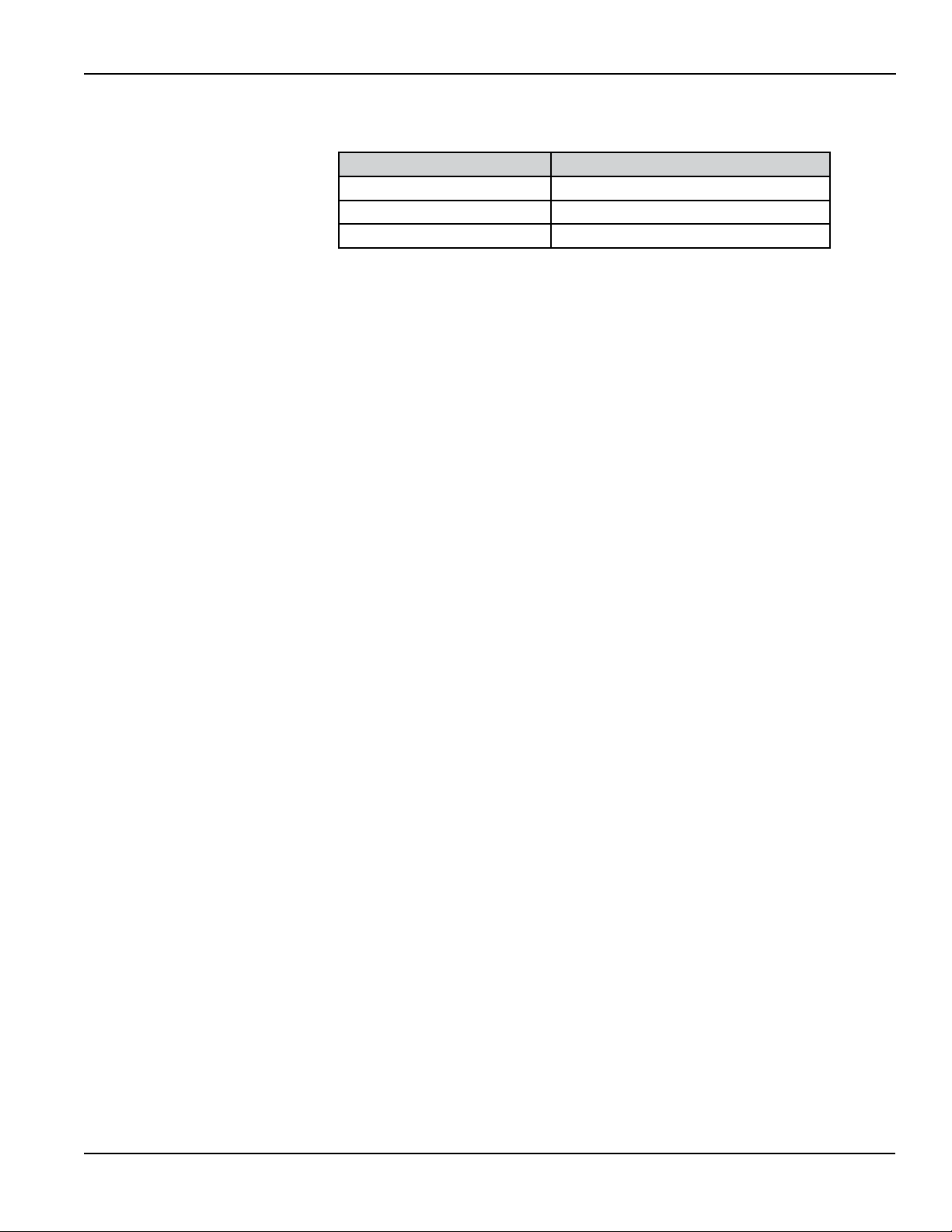

1.3 ACCESSING THE

PROGRAMMING MENUS

Access to the programming menus is password protected. The factory default

access code is 4********. The three user interface push-button functions described

below change when operating in the program mode.

Push Button Short Press

(<1 second)

• Increments the numeric value or selected

parameter

• Returns to the previous menu item

• Moves the cursor to the right on input elds

• Advances to the next menu item

• Changes the process data display

• Enters or leaves the selected function

ENTER

ESC

SECTION 2.0:

QUICK START MENU

• Enters the program mode

• Cancels the selected function in progress

The most commonly used programming functions are available in the Quick Start

menu. The menu can be accessed by briey pressing the

the access code 4*******. Additional programming options are accessed via the

Main Menu.

Long Press

(>1 second)

• Decrements the numeric value

• Advances to the next menu item

• Moves the cursor to the left on input elds

• Returns to the previous menu item

• Exits the current menu

• Conrms the selected function to enable the

totalizer reset request, when enabled.

key and entering

ENTER

ESC

1. From the main screen, quickly press the

Enter key.

2. Enter the access code.

3. Enter into the Quick Start menu.

ONICON Incorporated 727.447.6140 Page 6 onicon.com

Page 7

FT-3100 TRANSMITTER PROGRAMMING GUIDE

2.1 MENU - QUICK START

Empty Pipe Detector

[E.P.Detect = ON]

Empty Pipe Threshold

[R max = kohm XXXX]

Empty Pipe Detector [E.P.Detect = ON]

Empty Pipe Threshold [R max = kohm XXXX]

Scaled Pulse Out 2 Volume [Pls2 = Gal XXX.XXX]

Output 2 Pulse Duration [Tpls2 = XXXX.X]

Analog Output 1 Full Scale Value [A1S = Gal/m XXXXXX]

MAIN MENU

This setting enables or disables the empty pipe detector.

The Empty Pipe Detector senses when uid is drained from the pipe and the ow

sensing electrodes are exposed to air. When this occurs, the displayed ow rate

will drop to zero and the empty pipe icon will be displayed in the upper lefthand side of the display window. If the current (mA) output alarm is active, the

milliamp output will also indicate an alarm condition.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or o. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

The empty pipe threshold function is used to set the maximum allowable

resistance value between the ow sensing electrodes in the transmitter. The

transmitter will go into empty pipe alarm when the value is exceeded. The default

value is 500. The maximum allowable value is 9,999.

Scaled Pulse Output 2

[Pls2 = Gal X.XXXX]

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the resistance. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

This function is only available when output pulse 2 in OUTPUTS menu (menu 7)

[Out2 = XXXXX] is set to Pulses+, Pulses- or Pulses±. When active, Scaled Output

Pulse 2 sets the unit of measure and the volume or mass that equates to one

pulse. This pulse weight setting is limited by the diameter of the ow sensor.

The list of units of measure available for selection can be in US/IMPERIAL or SI

units depending on the pulse 2 unit type [Pl2 unit = IMPERIAL] setting in UNITS

menu (menu 2). In the same way, the list will show mass units, if mass units are

enabled [Mass units = OFF] in menu 2. The tables below show the available units

of measure.

ONICON Incorporated 727.447.6140 Page 7 onicon.com

Page 8

FT-3100 TRANSMITTER PROGRAMMING GUIDE

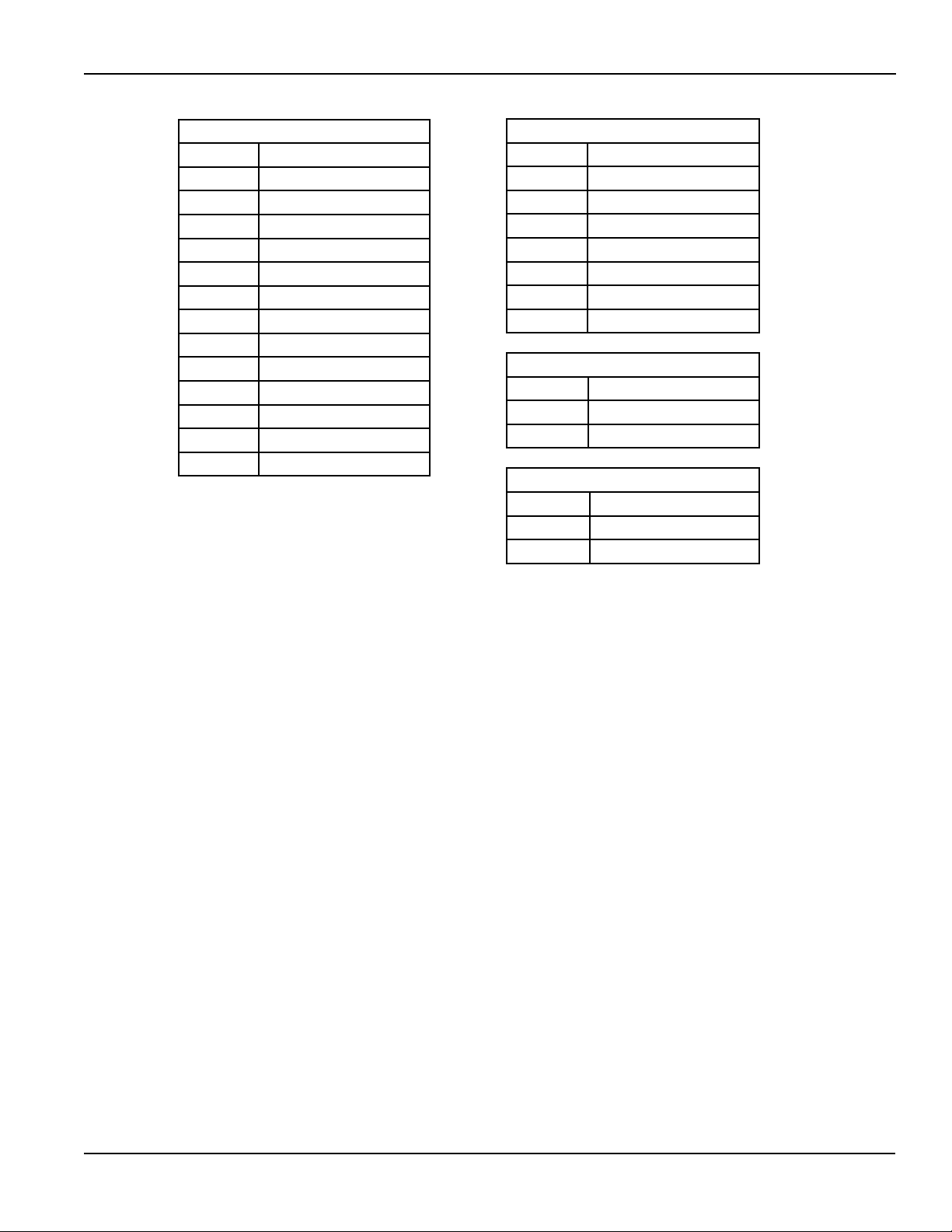

US/IMPERIAL Volume Units

3

in

Cubic Inch

Gal US Gallon

ttG US Gallon x 10,000

3

ft

Cubic Foot

bbl Standard Barrel

BBL Barrel of Oil

3

hf

Kf

3

Cubic Foot x 100

Cubic Foot x 1,000

KGL US Gallon x 1,000

IGL Imperial Gallon

IKG Imperial Gallon x 1,000

Aft Acre Foot

MGL Mega Gallon (US)

IMG Imperial Mega Gallon

SI/METRIC Volume Units

3

cm

Cubic Centimeter

ml Mililiter

l Liter

3

dm

Cubic Decimeter

dal Decaliter

hl Hectoliter

3

m

Cubic Meter

ML Megaliter

US/IMPERIAL Mass Units

Oz Ounce

Lb Pound

Ton Short Ton (2,000 lbs)

SI/METRIC Mass Units

g Gram

kg Kilogram

t Metric Ton (1,000 kg)

Output 2 Pulse Duration

[Tpls2 = ms X.XXXX]

Analog Output 1 Full

Scale Value

[A1S = Gal/m XXXXXX]

To enter a new value, press enter to access the function and use the right arrow

key to move the cursor and the up arrow key to change the entry. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

Output 2 pulse duration is only active when scaled pulse output 2 [Pls2= Gal

X.XXXX] is active. It is used to set the duration of each pulse. The duration is set

in milliseconds with a range of 0.4 to 9999.99.

Note: Pulse durations must match the requirements of the input they are

connected to. Very short pulse times may not be counted by the input and long

duration pulsed may damage electromechanical registers.

To enter a new value, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the pulse duration.

Press enter to accept the change and exit the function. Press escape to exit the

program mode. Table of Contents

This function sets the full scale ow value for the analog output.

The maximum allowable ow rate is a function of the diameter of the ow sensor.

Regardless of the diameter, the maximum ow rate setting cannot exceed a

velocity of 10 m/s.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 8 onicon.com

Page 9

FT-3100 TRANSMITTER PROGRAMMING GUIDE

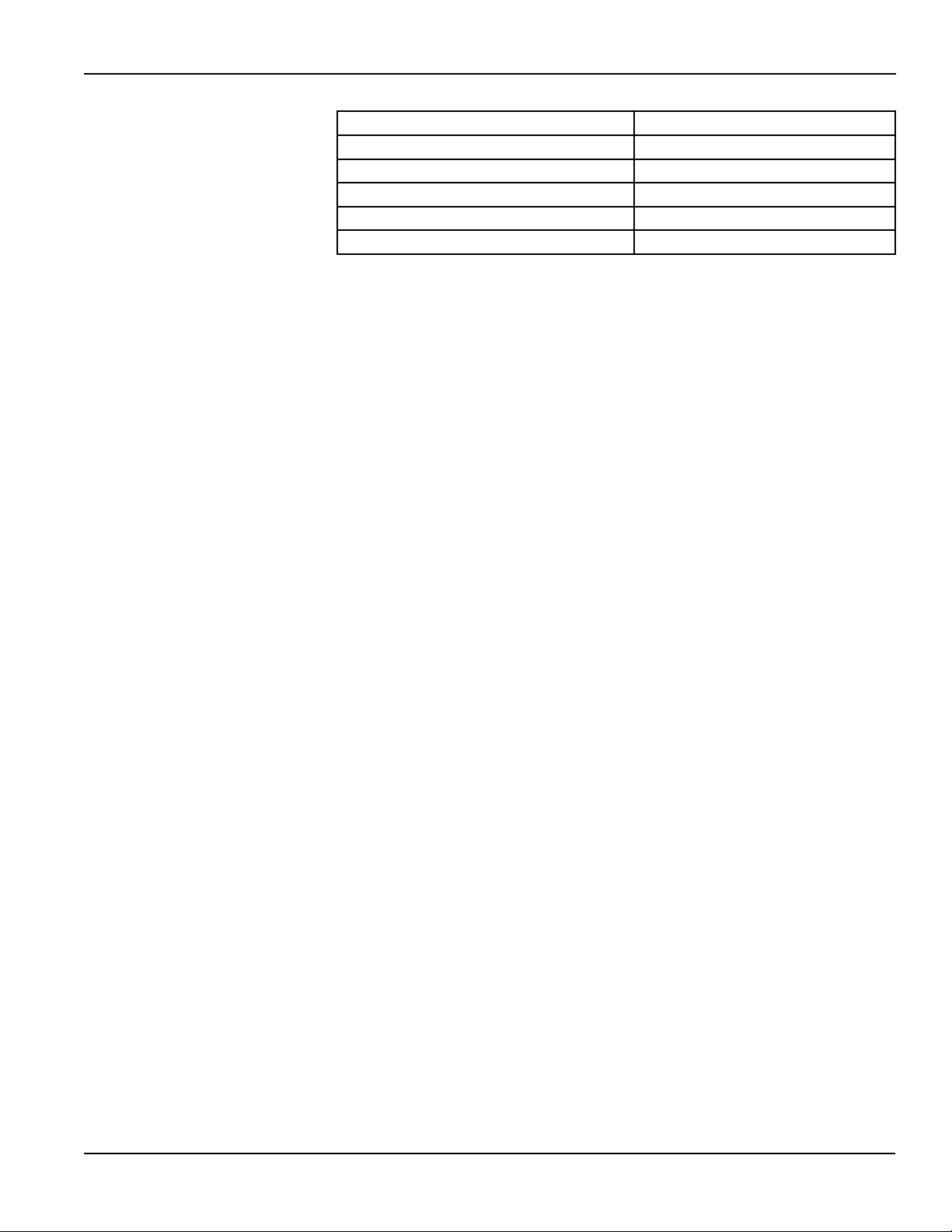

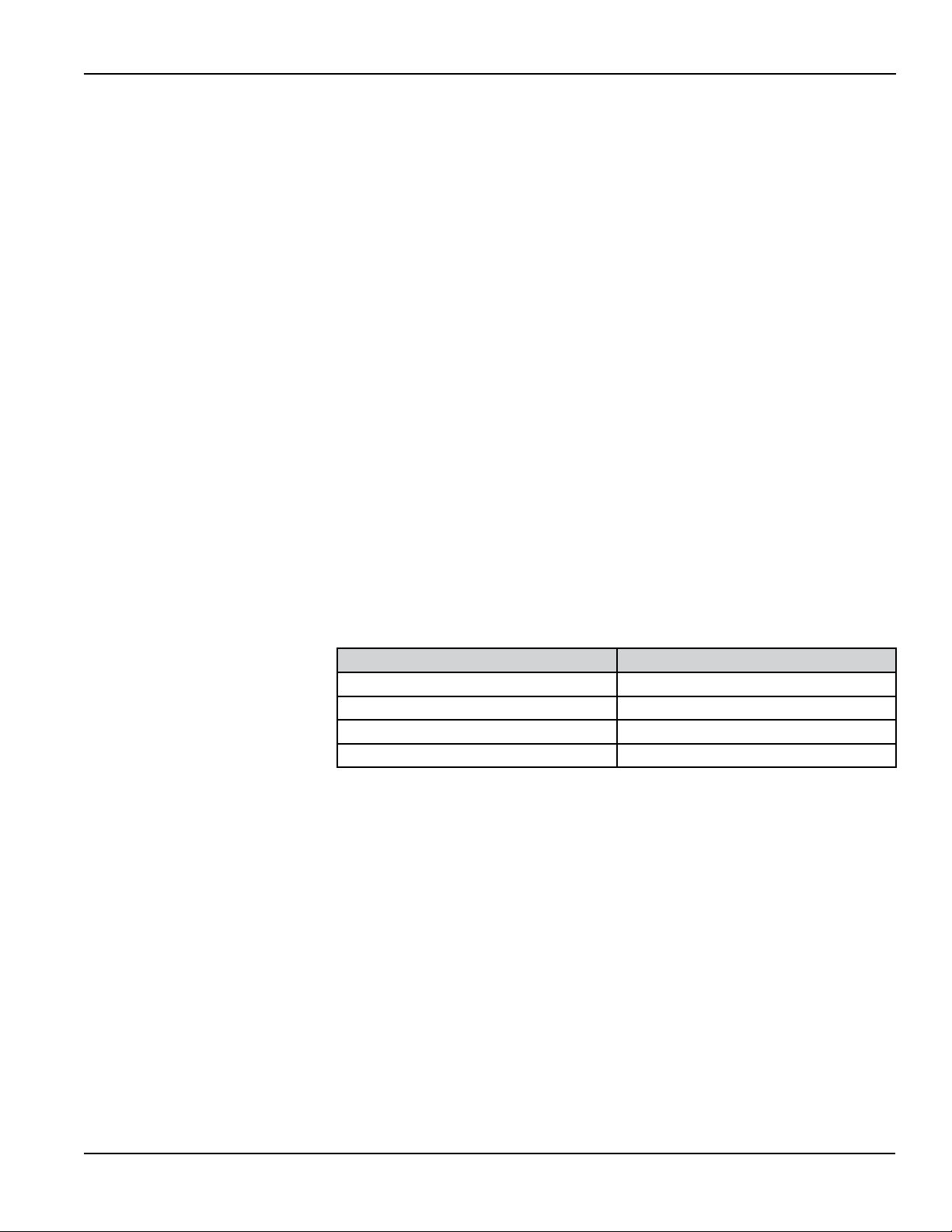

SECTION 3.0: MAIN MENU

3.1 MENU 1 - SENSOR

The menu can be accessed by briey pressing the

access code 4*******.

1. From Quick Start menu, push

repeatedly

until Main Menu is highlighted.

2. Enter into the main menu.

Sensor Body Model [S Model = XXX]

Liner Material [Lining = XXXXXX]

Unit Type [U type = XXXXXX]

Diameter [Diam. = in XXX]

KA [KA = ± XX.XXX]

KZ [KZ = ± XXXX]

Empty Pipe Detector [E.P.Detect = ON]

Empty Pipe Threshold [R max = kohm XXXX]

Elecrode Cleaning [El. Cleaning = MIN]

Sensor Cable Length [S.Cable = ft XXX]

Alarm Delay Interval [S.err.delay = XXX]

key and entering the

ENTER

ESC

QUICK START

E. P. Detect=

R max=kohm

Pls2=Gal

Tpls2=ms

A1S=Gal/m

Main Menu

MAIN MENU

1-Sensor

2-Units

3-Scales

4-Measure

5-Alarms

6-Inputs

ON

0220

1000.0

0500.0

004500

Sensor Body Model

[S.Model = XXX]

Enter the numeric code for the type of sensor body connected to the transmitter.

Body Type Sensor Code

Threaded Steel 011

Threaded Polypropylene 013

Wafer 002

Flanged 004

To change the setting, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the code as per the table

above. Press enter to accept the change and exit the function. Press escape to

exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 9 onicon.com

Page 10

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Liner Material

[Lining = XXXXXX]

Unit Type

[U.type = XXXXXX]

Diameter

[Diam. = in XXX]

Select the sensor body liner material from the following list.

Liner Material* Code

PTFE PTFE

Polypropylene PP

Ebonite HR

*Disregard all liner material options that are not shown in this list.

To change the setting, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the code as per the table

above. Press enter to accept the change and exit the function. Press escape to

exit the program mode. Table of Contents

This parameter congures the transmitter for U.S. (imperial) or SI (metric) units.

To change the existing setting, press enter to access the function and use the up

arrow key to change the setting. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This must be set to match the nominal diameter of the sensor body connected

to the transmitter. If the Unit Type is set to U.S. units, the nominal sizes will be in

inches. For SI units, the nominal sizes will be in millimeters.

KA

[KA = ± XX.XXX]

KZ

[KZ = ± XXXX]

To enter a new diameter, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

KA is one of two coecients of calibration that are derived during the sensor

body factory calibration. Both variables must be programmed in to the

transmitter to ensure accurate ow measurement. The KA value is provided on

the certicate of calibration and on a label on the sensor body.

To enter a new coecient, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

KZ is the second of two coecients of calibration that are derived during the

sensor body factory calibration. Both variables must be programmed in to the

transmitter to ensure accurate ow measurement. The KZ value is provided on

the certicate of calibration and on a label on the sensor body.

To enter a new coecient, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 10 onicon.com

Page 11

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Empty Pipe Detector

[E.P.Detect = ON]

Empty Pipe Threshold

[R max = kohm XXXX]

Electrode Cleaning

[El. Cleaning = MIN]

This setting enables or disables the empty pipe detector.

The Empty Pipe Detector senses when uid is drained from the pipe and the ow

sensing electrodes are exposed to air. When this occurs, the displayed ow rate

will drop to zero and the empty pipe icon will be displayed in the upper left-hand

side of the display window. If the current (mA) output alarm is active the milliamp

output will also indicate an alarm condition.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

The empty pipe threshold function is used to set the maximum allowable

resistance value between the ow sensing electrodes in the transmitter. The

transmitter will go into empty pipe alarm when the value is exceeded. The default

value is 500. The maximum allowable value is 9,999.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the resistance. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

When enabled, the electrode cleaning function transmits a depolarizing signal to

the electrodes in between ow measurement cycles. This function is enabled by

default whenever the empty pipe alarm is active. The default setting, when active,

is AVG. It should only be used with uid conductivities >100µS/cm.

Electrode Cleaning Settings Code

O OFF

Minimum MIN

Average AVG

Maximum MAX

To change the existing setting, press enter to access the function and use the up

arrow key to change the setting. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 11 onicon.com

Page 12

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Sensor Cable Length

[S.cable = ft XXX]

Enter the remote transmitter cable length. The allowable cable length is a

function of the uid conductivity with a maximum allowable cable length of 164ft

(50m). Use of the remote mount transmitter option with conductivity levels of

less the 15µS/cm is not recommended. Use the table below to determine the

maximum cable length for your installation.

Alarm Delay Interval

[S.err.delay = m XXX]

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the length. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

This function delays the activation of empty pipe, excitation error and signal error

alarms. The range of the delay interval is from 0 to 500 measurement cycles. For

meters up to 10” (250mm) in diameter this equates to 0 to 10 seconds. For 12” to

20” (300 to 500mm) meters, the interval range is from 0 to 25 seconds.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the interval. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 12 onicon.com

Page 13

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.2 MENU 2 - UNITS

Diameter Unit Type [Diam = in]

Remote Mount Cable Unit Type [S.cable = ft]

Flow Rate Unit Type [FR unit = IMPERIAL]

Pulse 1 Unit Type [Pl1 unit = IMPERIAL]

Pulse 2 Unit Type [Pl2 unit = IMPERIAL]

Total Forward Flow Totalizer Unit Type [T+unit = IMPERIAL]

Total Forward Flow Totalizer Units [T+unit = Gal]

Total Forward Flow Totalizer Decimal Point Position [T+D.P. = X]

Partial Forward Flow Totaliazer Unit Type [P+unit = IMPERIAL]

Partial Forward Flow Totalizer Units [P+unit = Gal]

Partial Forward Flow Totalizer Decimal Point Position [P+D.P. = X]

Total Reverse Flow Totalizer Unit Type [T-unit = IMPERIAL]

Total Reverse Flow Totalizer Units [T-unit = Gal]

Total Reverse Flow Totalizer Decimal Point Position [T-D.P. = X]

Partial Reverse Flow Totalizer Unit Type [P-unit = IMPERIAL]

Partial Reverse Flow Totalizer Units [P-unit = Gal]

Partial Reverse Flow Totalizer Decimal Point Position [P-D.P. = X]

Temperature Unit Type [Temp.unit = °F]

Mass Units Enable [Mass units = OFF]

Specic Gravity Coecient [Sg = kg/dm

3

X.XXXX]

Diameter Unit Type

[Diam. = in]

Remote Mount Cable Unit Type

[S.cable = ft]

Flow Rate Unit Type

[FR unit = IMPERIAL]

This function sets the nominal diameter of the sensor body for U.S. (imperial) or

SI (metric) units. This setting changes the list of nominal diameters in SENSOR

menu (menu 1) [Diam. = ft XXX] from U.S to SI units.

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets the cable length measurement units for U.S. (imperial) or SI

(metric). This setting changes the way cable lengths are entered in SENSOR menu

(menu 1) [S.cable = ft XXX].

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets the list of ow measurement units for U.S (imperial) or SI

(metric).

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 13 onicon.com

Page 14

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Pulse 1 Unit Type

[Pl1 unit = IMPERIAL]

Pulse 2 Unit Type

[Pl2 unit = IMPERIAL]

Total Forward Flow

Totalizer Unit Type

[T+ unit = IMPERIAL]

This function sets the list of totalizer measurement units for U.S. (imperial) or

SI (metric) for output 1. The function is only active when the output 1 function

selection [Out1 = XXXXXX] is set for scaled pulse

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets the list of totalizer measurement units for U.S. (imperial) or

SI (metric) for output 2. The function is only active when the output 2 function

selection [Out2 = XXXXXX] is set for scaled pulse

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets the list of forward ow totalizer measurement units for U.S

(imperial) or SI (metric).

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

Total Forward Flow

Totalizer Units

[T+ unit = Gal]

Total Forward Flow Totalizer

Decimal Point Position

[T+ D.P. = X]

Partial Forward Flow

Totalizer Unit Type

[P+ unit = IMPERIAL]

This function sets measurement unit for the forward ow totalizer.

To change the existing setting, press enter to access the function. Use the up

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets the position of the decimal point when displaying the forward

ow total.

To move the decimal point, press enter to access the function. Use the up and/

or right arrow keys to change the selection. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

This function sets the list of partial forward ow totalizer measurement units for

U.S (imperial) or SI (metric).

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 14 onicon.com

Page 15

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Partial Forward Flow

Totalizer Units

[P+ unit = Gal]

Partial Forward Flow Totalizer

Decimal Point Position

[P+ D.P. = X]

Total Reverse Flow

Totalizer Unit Type

[T- unit = IMPERIAL]

Total Reverse Flow

Totalizer Units

[T- unit = Gal]

This function sets measurement unit for the partial forward ow totalizer.

To change the existing setting, press enter to access the function. Use the up

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets the position of the decimal point when displaying the forward

ow total.

To move the decimal point, press enter to access the function. Use the up and/

or right arrow keys to change the selection. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

This function sets the list of reverse ow totalizer measurement units for U.S

(imperial) or SI (metric).

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets measurement unit for the reverse ow totalizer.

To change the existing setting, press enter to access the function. Use the up

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

Total Reverse Flow Totalizer

Decimal Point Position

[T- D.P. = X]

Partial Reverse Flow

Totalizer Unit Type

[P- unit = IMPERIAL]

Partial Reverse Flow

Totalizer Units

[P- unit = Gal]

This function sets the position of the decimal point when displaying the reverse

ow total.

To move the decimal point, press enter to access the function. Use the up and/

or right arrow keys to change the selection. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

This function sets the list of partial reverse ow totalizer measurement units for

U.S (imperial) or SI (metric).

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

This function sets measurement unit for the partial reverse ow totalizer.

To change the existing setting, press enter to access the function. Use the up

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 15 onicon.com

Page 16

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Partial Reverse Flow Totalizer

Decimal Point Position

[P- D.P. = X]

Temperature Unit Type

[Temp. unit = °F]

Mass Units Enable

[Mass units = OFF]

Specic Gravity Coecient

[Sg = kg/dm3 X.XXXX]

This function sets the position of the decimal point when displaying the reverse

ow total.

To move the decimal point, press enter to access the function. Use the up and/

or right arrow keys to change the selection. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

This function sets the measurement units for the on-board temperature sensor.

To change the existing setting, press enter to access the function. Use the right

arrow key to change the selection. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

Enables or disables the mass measurement function. When enabled,

measurement unit lists for ow rates and totals will be in mass units.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

This function is only enabled when mass units are enabled. The static value

entered here will be used to convert volumetric ow into mass ow.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the coecient. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 16 onicon.com

Page 17

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.3 MENU 3 - SCALES

Full Scale Flow Rate 1

[FS1= Gal/m XXX.X]

Full Scale Flow Rate 1 [FS1 = Gal/m XXX.X]

Full Scale Flow Rate 2 [FS2 = Gal X.XX.X]

Pulse Output 1 Unit and Multiplier [Pls1 = X.XXXXX]

Pulse Output 1 Duration [Tpls1 = ms X.XXXXX]

Pulse Output 2 Unit and Multiplier [Pls2 = Gal X.XXXXX]

Pulse Output 2 Duration [Tpls2 = ms X.XXXXX

Frequency Output 1 Full Scale Frequency [Frq1 = Hz X.XXXXX]

Frequency Output 2 Full Scale Frequency [Frq2 = Hz X.XXXXX]

The full scale ow rate 1 function sets the unit of measure and time base for the

meter and the maximum ow rate for range 1. This eects the ow rate display

and the alarm function. It also sets the unit of measure and time base for the

analog output.

The maximum allowable ow rate is a function of the diameter of the ow sensor.

Regardless of the diameter, the maximum ow rate setting cannot exceed a

velocity of 10 m/s. The following rules apply to the maximum ow rate setting.

These may also aect the selection of the unit of measure and the time base.

• The largest numeric value representing ow is 9999. Larger values use units

with multipliers.

• The full scale ow rate setting cannot exceed 10 m/s

• The full scale ow rate must be greater than 0.4 m/s

US/IMPERIAL Volume Units

3

in

Cubic Inch

Gal US Gallon

ttG US Gallon x 10,000

3

ft

Cubic Foot

bbl Standard Barrel

BBL Barrel of Oil

3

hf

Kf

3

Cubic Foot x 100

Cubic Foot x 1,000

KGL US Gallon x 1,000

IGL Imperial Gallon

IKG Imperial Gallon x 1,000

Aft Acre Foot

MGL Mega Gallon (US)

IMG Imperial Mega Gallon

The list of units of measure available for selection can be in US/IMPERIAL or

SI units depending on the ow rate unit type [FR unit = IMPERIAL] selected in

UNITS menu (menu 2). In the same way, the list will show mass units, if mass units

are enabled [Mass units= OFF] in menu 2.

The tables below show the available units of measure.

Time Base

s Seconds

m Minutes

h Hours

US/IMPERIAL Mass Units

Oz Ounce

Lb Pound

Ton Short Ton (2,000 lbs)

d Days

SI/METRIC Volume Units

3

cm

Cubic Centimeter

ml Mililiter

l Liter

3

dm

Cubic Decimeter

dal Decaliter

hl Hectoliter

3

m

Cubic Meter

ML Megaliter

SI/METRIC Mass Units

g Gram

kg Kilogram

t Metric Ton (1,000 kg)

To enter a new value, press enter to

access the function. Use the right

arrow key to move the cursor and

the up arrow key to change the

entry. Press enter to accept the

change and exit the function. Press

escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 17 onicon.com

Page 18

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Full Scale Flow Rate 2

[FS2 = Gal/m XXX.X]

Scaled Pulse Output 1

[Pls1 = Gal X.XXXX]

The full scale ow rate 2 function sets the maximum ow rate for range 2, when

the autorange function [Autorange = ON/OFF] in MEASURE menu (menu 4) is

turned on. Range 2 uses the unit of measure and time base setting from full scale

ow rate 1.

The maximum allowable ow rate is a function of the diameter of the ow sensor.

Regardless of the diameter, the maximum ow rate setting cannot exceed a

velocity of 10 m/s. The following rules apply to the maximum ow rate setting.

These may also aect the selection of the unit of measure and the time base.

• The largest numeric value representing ow is 9999. Larger values use units

with multipliers.

• The full scale ow rate setting cannot exceed 10 m/s

• The full scale ow rate must be greater than 0.4 m/s

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the entry. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

This function is only available when output pulse 1 in OUTPUTS menu (menu 7)

[Out1 = XXXXX] is set to Pulses+, Pulses- or Pulses±. When active, scaled output

pulse 1 sets the unit of measure and the volume or mass that equates to one

pulse. This pulse weight setting is limited by the diameter of the ow sensor.

The list of units of measure available for selection can be in US/IMPERIAL or SI

units depending on the pulse 1 unit type [Pl1 unit = IMPERIAL] setting in UNITS

menu (menu 2). In the same way, the list will show mass units, if mass units are

enabled [Mass units= OFF] in menu 2. The tables below show the available units

of measure.

US/IMPERIAL Volume Units

3

in

Cubic Inch

Gal US Gallon

ttG US Gallon x 10,000

3

ft

Cubic Foot

bbl Standard Barrel

BBL Barrel of Oil

3

hf

Kf

3

Cubic Foot x 100

Cubic Foot x 1,000

KGL US Gallon x 1,000

IGL Imperial Gallon

IKG Imperial Gallon x 1,000

Aft Acre Foot

MGL Mega Gallon (US)

IMG Imperial Mega Gallon

SI/METRIC Volume Units

3

cm

Cubic Centimeter

ml Mililiter

l Liter

3

dm

Cubic Decimeter

dal Decaliter

hl Hectoliter

3

m

Cubic Meter

ML Megaliter

US/IMPERIAL Mass Units

Oz Ounce

Lb Pound

Ton Short Ton (2,000 lbs)

SI/METRIC Mass Units

g Gram

kg Kilogram

t Metric Ton (1,000 kg)

To enter a new value, press enter to access the function. Use the right

arrow key to move the cursor and the up arrow key to change the entry.

Press enter to accept the change and exit the function. Press escape to exit

the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 18 onicon.com

Page 19

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Output 1 Pulse Duration

[Tpls1 = ms X.XXXX]

Output 1 Full Scale Frequency

[Frq1 = Hz X.XXXXX]

Output 1 pulse duration is only active when scaled pulse output 1 [Pls1 = Gal

X.XXXX] is active. It is used to set the duration of each pulse. The duration is set

in milliseconds with a range of 0.4 to 9999.99.

Note: Pulse durations must match the requirements of the input they are connected

to. Very short pulse times may not be counted by the input and long duration

pulsed may damage electromechanical registers.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the pulse length. Press enter

to accept the change and exit the function. Press escape to exit the program

mode. Table of Contents

This function is only available when output pulse 1 in OUTPUTS menu (menu 7)

[Out1 = XXXXX] is set to Freq+, Freq- or Freq±. When active, output 1 full scale

frequency sets maximum frequency for the output. This maximum frequency

equals the maximum ow rate set by full scale ow rate 1 [FS1 = Gal/m XXX.X] in

SCALES menu (menu 3).

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the pulse length. Press enter

to accept the change and exit the function. Press escape to exit the program

mode. Table of Contents

Scaled Pulse Output 2

[Pls2 = Gal X.XXXX]

This function is only available when output pulse 2 in OUTPUTS menu (menu 7)

[Out2 = XXXXX] is set to Pulses+, Pulses- or Pulses±. When active, scaled output

pulse 2 sets the unit of measure and the volume or mass that equates to one

pulse. This pulse weight setting is limited by the diameter of the ow sensor.

The list of units of measure available for selection can be in US/IMPERIAL or SI

units depending on the pulse 2 unit type [Pl2 unit= IMPERIAL] setting in UNITS

menu (menu 2). In the same way, the list will show mass units, if mass units are

enabled [Mass units = OFF] in menu 2. The tables below show the available units

of measure.

The tables shown for scaled pulse output 1 units of measure also apply to this

output.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the entry. Press enter to

accept the change and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 19 onicon.com

Page 20

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Output 2 Pulse Duration

[Tpls2 = ms X.XXXX]

Output 2 Full Scale

Frequency

[Frq2 = Hz X.XXXXX]

Output 2 Pulse Duration is only active when scaled pulse output 2 [Pls2 = Gal

X.XXXX] is active. It is used to set the duration of each pulse. The duration is set

in milliseconds with a range of 0.4 to 9999.99.

Note: Pulse durations must match the requirements of the input they are connected

to. Very short pulse times may not be counted by the input and long duration

pulsed may damage electromechanical registers.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the pulse length. Press enter

to accept the change and exit the function. Press escape to exit the program

mode. Table of Contents

This function is only available when output pulse 2 in OUTPUTS menu (menu 7)

[Out2 = XXXXX] is set to Freq+, Freq- or Freq±. When active, output 2 full scale

frequency sets maximum frequency for the output. This maximum frequency

equals the maximum ow rate set by full scale ow rate 2 [FS2 = Gal/m XXX.X] in

SCALES menu (menu 3).

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the pulse length. Press enter

to accept the change and exit the function. Press escape to exit the program

mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 20 onicon.com

Page 21

FT-3100 TRANSMITTER PROGRAMMING GUIDE

FLOWRATE(%)

Example wtih damping to OFF

FILTERS

Damping = OFF

60

50

40

30

20

10

0

0 2 4 6 8 10 12 14 16 18 20 22

IN

>>>>>

.FLOWRATE

OUT

>>>>>

TIME (Sec)

.MEASURE

3.4 MENU 4 - MEASURE

Flow Signal Damping

[Damping = SMART]

Flow Signal Damping [Damping=SMART]

Low Flow Cut-o [Cut-o=%XXX]

Autorange [Autorange= OFF]

High Immunity Input Filter [H.im.inp = OFF]

The ow signal damping function allows the user to smooth out the eects of

sudden changes in the ow readings on the display and the output. Damping

may be applied using the “Smart” lter or by setting xed time interval ltering. It

is recommended to start with no damping.

Smart ltering automatically adapts to changing ow conditions. This lter will

provide signicant ltering when large, rapid changes are detected and minimal

ltering when ow is more stable. This type of ltering is useful when large

changes in ow occur at random intervals.

Time based ltering applies a xed time constant to the ltering algorithm.

Longer time constants increase the damping eect, but they also reduce

response time. See examples below. This type of ltering is useful when the

variations in ow are relatively constant and repeatable. Damping time interval

are 0.2, 0.5, 1, 2, 5, 10, 20, 50, 100, 200, 500 & 1000 seconds.

60

Example wtih damping to OFF

50

40

30

FLOWRATE(%)

20

10

0

0 2 4 6 8 10 12 14 16 18 20 22

.FLOWRATE

>>>>>

Damping = OFF

FILTERS

IN

TIME (Sec)

OUT

>>>>>

60

Example wtih damping to 5,0sec.

50

40

30

FLOWRATE(%)

20

.MEASURE

IN

10

0

0 2 4 6 8 10 12 14 16 18 20 22

.FLOWRATE

>>>>>

FILTERS

Damping = from 0.2s to 1000s

TIME (Sec)

OUT

>>>>>

.MEASURE

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the lter setting. Press enter

to accept the change and exit the function. Press escape to exit the program

mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 21 onicon.com

Page 22

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Low Flow Cut-o

[Cut-o = % XXX]

Autorange

[Autorange = OFF]

This function sets the low ow cut-o for ow measurement. The meter will

report all ow measurements below the threshold as zero ow. This cuto function is necessary to prevent small random noise signals from being

reported as ow. It is based on a percentage of the full scale ow rate 1 [FS1=

Gal/m XXX.X] in SCALES menu (menu 3). The allowable settings are between

0 and 25% of full scale. For most applications a value between 0.1 and 1.0% is

recommended.

To enter a new value, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the cut-o percentage.

Press enter to accept the change and exit the function. Press escape to exit the

program mode. Table of Contents

When autorange is enabled the meter will operate with two dierent ow ranges.

In order to get the best results, range 1 [FS1= Gal/m XXX.X] in SCALES menu

(menu 3) must be larger than range 2 [FS2= Gal/m XXX.X].

When the ow rate increases and reaches the 100% of the full scale 1, then the

meter automatically switches to full scale 2. When the ow rate decreases to a

value on full scale 2 equal to the 90% of full scale.1, then the meter reverts to full

scale 1.

When autorange is enabled, the manual range change function [Range change=

OFF] in INPUTS menu (menu 6) cannot be used.

High Immunity Input Filter

[H. im. inp. = OFF]

Note: This function does NOT increase the accuracy of the measurement; it only

increases the resolution of the 4-20 mA output when the meter is operating at very

low ow rates (e.g. The ow rate of a domestic water distribution with much higher

daytime ow versus nighttime ow).

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and exit

the function. Press escape to exit the program mode. T

able of Contents

When enabled, the high immunity input lter will increase ltering at the input

circuitry. This ltering is only eective when conductivity levels are greater than

500 µS/cm. It should only be used after all other methods of minimizing noise

have been employed as this will aect the ow measurement. The default setting

is o.

Note: The use of this lter will reduce ow measurement accuracy.

To change the existing setting, press enter to access the function. Use the up

arrow key to turn the function on or off. Press enter to accept the change and exit

the function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 22 onicon.com

Page 23

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.5 MENU 5 - ALARMS

Maximum Forward Flow

Alarm Threshold

[Max+ = Gal/m OFF]

Maximum Forward Flow Alarm Threshold [Max + = Gal/m OFF]

Maximum Reverse Flow Alarm Threshold [Max - = Gal/m OFF]

Minimum Forward Flow Alarm Threshold [Min + = Gal/m OFF]

Minimum Reverse Flow Alarm Threshold [Min - = Gal/m OFF]

Hysteresis Threshold [Hysteresis = % XX]

Current Output Alarm State Value [mA v.alarm = % XXX]

Frequency Output Alarm State Value [Hz v.alarm = % XXX]

This function sets the alarm threshold for maximum forward ow. Flow rates

above this threshold will trigger the alarm. The threshold value is entered as a

ow rate in the engineering units shown. The minimum value must be ≥1% of

the full scale maximum ow rate of the meter (10m/s or 32.8ft/s velocity). Alarm

threshold values are entered in 1% increments of the full scale limit up to 100%.

Example: In a 6” pipe 32.8 ft/s is equal to 2853 GPM. 1% of this value would be

approximately 28.5GPM. Alarm threshold values would be entered in increments

of 28.5 GPM.

To enter a value, press enter to access the function. Use the up arrow and right

arrow keys change the threshold value. Press enter to accept the change and exit

the function. Press escape to exit the program mode. T

able of Contents

Maximum Reverse Flow

Alarm Threshold

[Max - = Gal/m OFF]

Minimum Forward Flow

Alarm Threshold

[Min + = Gal/m OFF]

This function sets the alarm threshold for maximum reverse ow. Flow rates

above this threshold will trigger the alarm. The threshold value is entered as a

ow rate in the engineering units shown. The minimum value must be ≥1% of

the full scale maximum ow rate of the meter (10m/s or 32.8ft/s velocity). Alarm

threshold values are entered in 1% increments of the full scale limit up to 100%.

Example: In a 6” pipe 32.8 ft/s is equal to 2853 GPM. 1% of this value would be

approximately 28.5GPM. Alarm threshold values would be entered in increments

of 28.5 GPM.

To enter a value, press enter to access the function. Use the up arrow and right

arrow keys change the threshold value. Press enter to accept the change and exit

the function. Press escape to exit the program mode. Table of Contents

This function sets the alarm threshold for minimum forward ow. Flow rates

below this threshold will trigger the alarm. The threshold value is entered as a

ow rate in the engineering units shown. The minimum value must be ≥1% of

the full scale maximum ow rate of the meter (10m/s or 32.8ft/s velocity). Alarm

threshold values are entered in 1% increments of the full scale limit up to 100%.

Example: In a 6” pipe 32.8 ft/s is equal to 2853 GPM. 1% of this value would be

approximately 28.5GPM. Alarm threshold values would be entered in increments

of 28.5 GPM.

To enter a value, press enter to access the function. Use the up arrow and right

arrow keys change the threshold value. Press enter to accept the change and exit

the function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 23 onicon.com

Page 24

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Minimum Reverse Flow

Alarm Threshold

[Min - = Gal/m OFF]

Alarm Hysteresis Threshold

[Hysteresis = % XXX]

This function sets the alarm threshold for minimum reverse ow. Flow rates

below this threshold will trigger the alarm. The threshold value is entered as a

ow rate in the engineering units shown. The minimum value must be ≥1% of

the full scale maximum ow rate of the meter (10m/s or 32.8ft/s velocity). Alarm

threshold values are entered in 1% increments of the full scale limit up to 100%.

Example: In a 6” pipe 32.8 ft/s is equal to 2853 GPM. 1% of this value would be

approximately 28.5GPM. Alarm threshold values would be entered in increments

of 28.5 GPM.

To enter a value, press enter to access the function. Use the up arrow and right

arrow keys change the threshold value. Press enter to accept the change and exit

the function. Press escape to exit the program mode. T

able of Contents

This function is used to dene the ow value where the meter exits the minimum

or maximum ow alarm state. When ows drop below the threshold for the

maximum ow alarm or rises above the minimum ow alarm by more than

the hysteresis percentage value, the meter exits the alarm state. It is set as a

percentage of the full scale ow rate 1 [FS1 = Gal/m XXX.X] in SCALES menu

(menu 3. The range of settings is 0-25% of full scale.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the threshold percentage.

Press enter to accept the change and exit the function. Press escape to exit the

program mode. Table of Contents

mA Output Value When in

Alarm State

[mA v.alarm = % XXX]

This function establishes the 0/4-20mA output level when the meter is in an

alarm condition caused by an empty pipe, ADC error or an open coil indication.

The alarm value is set as a percentage of the 0/4 – 20mA output. The valid range

is 0-125% of 20mA. For example, a setting of 10% would cause the output to go

to 2mA when the meter is in the alarm state. One or more alarm icons will also be

displayed in the upper left hand side of the display when this alarm is active.

The default setting is 20% (4mA.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 24 onicon.com

Page 25

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Frequency Output Value When

in Alarm State

[Hz v.alarm = % XXX]

This function establishes the frequency output level for output 1 or output 2

when the meter is in an alarm condition caused by an empty pipe, ADC error or

an open coil indication.

This function is only available when either output pulse 1or output pulse 2 in

OUTPUTS menu (menu 7) [Out1 = XXXXX] [Out2 = XXXXX] is set to Freq+, Freqor Freq±.

The alarm value is set as a percentage of the full scale frequency. The valid range

is 0 – 125%. The default setting is 0%. One or more alarm icons will also be

displayed in the upper left hand side of the display when this alarm is active.

The default setting will cause the frequency output to indicate 0 Hz when in the

alarm state.

To enter a new value, press enter to access the function. Use the right arrow key

to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 25 onicon.com

Page 26

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.6 MENU 6 - INPUTS

Total Forward Flow

Totalizer Reset Enable

[T+ reset = ON]

Partial Forward Flow

Totalizer Reset Enable

[P+ reset = OFF]

Total Forward Flow Totalizer Reset Enable [T+ reset = ON]

Partial Forward Flow Totalizer Reset Enable [P+ reset = OFF]

Total Reverse Flow Totalizer Reset Enable [T- reset = OFF]

Partial Reverse Flow Totalizer Reset Enable [P- reset = OFF]

Disable Flow Measurement via Pulse Input [Meas. lock = OFF]

Activate Autozero Calibration via Pulse Input [Calibration = OFF]

Change Flow Range via Pulse Input [Range change = OFF]

When enabled, this function allows the forward ow totalizer to be remotely

reset via the transmitter’s pulse input.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

When enabled, this function allows the partial forward ow totalizer to be

remotely reset via the transmitter’s pulse input.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

Total Reverse Flow Totalizer

Reset Enable

[T- reset = OFF]

Partial Reverse Flow Totalizer

Reset Enable

[P- reset = OFF]

Disable Totalizers via

Pulse Input

[Meas. Lock = OFF]

When enabled, this function allows the total reverse ow totalizer to be remotely

reset via the transmitter’s pulse input.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

When enabled, this function allows the partial reverse ow totalizer to be

remotely reset via the transmitter’s pulse input.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

When enabled, this function allows the all ow totalizers to be remotely disabled

via the transmitter’s pulse input.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 26 onicon.com

Page 27

FT-3100 TRANSMITTER PROGRAMMING GUIDE

Activate Autozero Calibration

via Pulse Input

[Calibration = OFF]

Change Flow Range via

Pulse Input

[Range change = OFF]

When enabled, this function allows the autozero calibration function to be

remotely activated via the transmitter’s pulse input.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

When enabled, this function allows the pulse input to be used to remotely

change the ow range to full scale ow rate 2 [FS2 = Gal/m XXX.X] in SCALES

menu (menu 3).

Note: this function cannot be used when the autorange [Autorange = OFF] function

in MEASURE menu (menu 4) is enabled.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 27 onicon.com

Page 28

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.7 MENU 7 - OUTPUTS

Digital Output 1

Function Select

[Out1 = XXXXXX]

Digital Output 2

Function Select

[Out2 = XXXXXX]

OFF: Disables output

MAX AL+: Maximum forward ow rate alarm (Energized = no alarm)

MIN AL+: Minimum forward ow rate alarm (Energized = no alarm)

MAX/MIN+: Maximum or minimum forward ow rate alarms (Energized = no alarm)

MAX AL-: Maximum reverse ow rate alarm (Energized = no alarm)

MIN AL-: Minimum reverse ow rate alarm (Energized = no alarm)

MAX/MIN-: Maximum or minimum reverse ow rate alarms (Energized = no alarm)

MAX/MIN +/-: Maximum and minimum ow rate alarm, either direction (Energized = no alarm)

P. EMPTY: Empty pipe alarm output (Energized = no alarm)

HARDW.AL.: Master alarm for open coil, empty pipe or measurement error (Energized = no alarm)

OVERFLOW: Flow out of range alarm (Energized = no alarm)

ALL ALARMS: Activates when any alarm is active (Energized = no alarm)

EXT. COMM.: Allows the pulse output state (high or low) to be set via MODBUS

F.R. SIGN: Flow direction indication (Energized = reverse (-) ow)

*SCALE: Indicates which scale is active (Energized = Scale2)

FREQ+: Frequency output proportional to forward (+) direction ow rate

FREQ-: Frequency output proportional to reverse (-) direction ow rate

FREQ+/-: Frequency output to forward (+) / reverse (-) direction ow rate

PULSES.+: Scaled pulse output for forward (+) direction ow rate

PULSES-: Scaled pulse output for reverse (-) direction ow rate

PULSES+/-: Scaled pulse output for forward (+) / reverse (-) direction ow rate

Digital Output 1 Function Select [Out1 = XXXXXX]

Digital Output 2 Function Select [Out2 = XXXXXX]

mA Output 1 Function & Scaling [Out mA1 = 4_20 +/-]

Analog Output 1 Full Scale Value [A1S = Gal/m XXXXXX]

The available functions for digital output 1 are listed in the table below.

The available functions for digital output 2 are listed in the table below.

Digital Output Functions

*This function is only available when either the autorange [Autorange= OFF] function in menu 4 or the

change ow range via pulse input [Range change= OFF] function INPUTS (MENU 6 are active.

To change the setting, press enter to access the function. Use the up and right arrow keys to change

the setting. Press enter to accept the change and exit the function. Press escape to exit the program

mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 28 onicon.com

Page 29

FT-3100 TRANSMITTER PROGRAMMING GUIDE

mA Output 1 Function &

Scaling

[Out mA1 = 4_20 +/-]

OUTPUT CURRENT IN mA FOR THE ASSOCIATED % OF FULL SCALE FLOW

mA Output Conguration Options Reverse Flow Value Zero Direct Flow Value

The available functions for current (mA) output 1 are listed in the table below.

There are three elds to modify when setting up an output:

• Zero scale value: 0 or 4mA

• Full scale value: 20 or 22mA

• Output function: + = forward (+) ow, - = reverse (-) ow, blank = absolute

ow, -0+ = zero ow center scale

The values corresponding to the scale points are shown in the following chart:

≥ -110% -100% 0% +100% ≥ +110%

0 - 20 + 0 0 0 20 20

0 - 22 + 0 0 0 20 22

4 - 20 + 4 4 4 20 20

4 - 22 + 4 4 4 20 22

0 - 20 - 20 20 0 0 0

0 - 22 - 22 20 0 0 0

4 - 20 - 20 20 4 4 4

4 - 22 - 22 20 4 4 4

0 - 20 20 20 0 20 20

0 - 22 22 20 0 20 22

4 - 20 20 20 4 20 20

4 - 22 22 20 4 20 22

0 - 20 - 0+ 0 0 10 20 20

0 - 22 - 0+ 0 1 11 21 22

4 - 20 - 0+ 4 4 12 20 20

4 - 22 - 0+ 4 4 12 20 22

To change the setting, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

Analog Output 1 Full

This function sets the full scale ow value for the analog output.

Scale Value

[A1S = Gal/m XXXXXX]

The maximum allowable

ow rate is a function of the diameter of the ow sensor.

Regardless of the diameter, the maximum ow rate setting cannot exceed a

velocity of 10 m/s.

To change the setting, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

ONICON Incorporated 727.447.6140 Page 29 onicon.com

Page 30

FT-3100 TRANSMITTER PROGRAMMING GUIDE

3.8 MENU 9 - DISPLAY

Display Language

[Language = GB]

Contrast Adjustment

[Contrast = X]

Display Language [Language = GB]

Contrast Adjustment [Contrast = X]

Display/User Interface Inactivity Time Interval [Disp. times = s XXX]

Display Refresh Frequency [D. rate = Hz X]

Enable Partial Totalizers [Part. tot. = OFF]

Enable Negative Totalizers [Neg. tot. = OFF]

Enable Net Totalizers [Net tot. = OFF]

Enable Quick Start Menu [Quick start = ON]

Default Display Page [Disp. fn. = X]

Default Lock [Disp. lock = OFF]

Select English (GB) or Italian (IT) for display text.

To change the existing setting, press enter to access the function. Use the up

arrow key to change the setting. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

Set the desired contrast level to optimize viewing. The allowable range is 0 to 9.

To change the existing setting, press enter to access the function. Use the up

arrow key to change the setting. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

Display/User Interface

Inactivity Time Interval

[Disp. times = s XXX]

Display Refresh Frequency

[D. rate = Hz X]

This function sets the time interval for returning to normal operation following

a period of inactivity when using the display/user interface. Allowable settings

range from 20 to 255 seconds.

To change the setting, press enter to access the function. Use the right arrow

key to move the cursor and the up arrow key to change the value. Press enter to

accept changes and exit the function. Press escape to exit the program mode.

Table of Contents

This function sets the display refresh rate. It is used to optimize viewing. It does

not aect the data refresh rate. The settings are 1, 2, 5 or 10 Hz.

To change the existing setting, press enter to access the function. Use the up

arrow key to change the setting. Press enter to accept the change and exit the

function. Press escape to exit the program mode. Table of Contents

ONICON Incorporated 727.447.6140 Page 30 onicon.com

Page 31

FT-3100 TRANSMITTER PROGRAMMING GUIDE

2 ALARM(S)

0.000GalP+

0

2 ALARM(S)

0

0.000

Gal/m

GalT+

0.000GalP+

0.204GalT-

0.000GalP-

2 ALARM(S)

0

0.000

Gal/m

GalT+

0.000GalP+

0.204GalT-

0.000GalP-

0

Enable Partial Totalizers

[Part. tot. = OFF]

This function enables or disables the display of partial totalizer data. When

enabled, the following pages are visible on the display.

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and

exit the function. Press escape to exit the program mode. Table of Contents

9

5

2

Gal/m

Gal

T+

Gal

P+

2 ALARM(S)

6

P-

Gal

2 ALARM(S)

0.000

0.000

0.000GalT+

0.000GalP+

0.204GalT-

0.000

Enable Negative Totalizers

[Neg. tot. = OFF]

This function enables or disables the display of negative totalizer data. When

enabled, the following pages are visible on the display.

10

0.204GalT-

2 ALARM(S)

3

Gal/m

Gal

T-

Gal

P-

2 ALARM(S)

To change the existing setting, press enter to access the function and use the up

arrow key to turn the function on or off. Press enter to accept the change and exit

the function. Press escape to exit the program mode. T

0.204

0.000

5

11

2 ALARM(S)

0.000GalP-

6

P-

Gal

2 ALARM(S)

able of Contents

0.000GalT+

0.000GalP+

0.204GalT-

0.000

ONICON Incorporated 727.447.6140 Page 31 onicon.com

Page 32

FT-3100 TRANSMITTER PROGRAMMING GUIDE

2 ALARM(S)

0

+0.000

-0.204

Gal/m

Gal

Gal

TN

PN

Enable Net Totalizers

[Net tot. = OFF]