Page 1

FB-3500 BI-DIRECTIONAL ELECTROMAGNETIC FLOW METER

Installation and Operation Guide

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699

www.onicon.com • sales@onicon.com

05-140718-3 / 18611

Page 2

SAFETY INFORMATION

i

!

!

This meter was calibrated at the factory before shipment. To ensure correct use of the meter, please read

this manual thoroughly.

Regarding this Manual:

• This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without

ONICON’s written permission.

• ONICON makes no warranty of any kind with regard to this material, including, but not

limited to, implied warranties of merchantability and suitability for a particular purpose.

• All reasonable effort has been made to ensure the accuracy of the contents of this manual.

However, if any errors are found, please inform ONICON.

• ONICON assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, ONICON assumes

no responsibility for any such harm owing to any defects in the product which were not

predictable, or for any indirect damages.

Safety Precautions:

The following general safety precautions must be observed during all phases of installation,

operation, service, and repair of this product. Failure to comply with these precautions or with

specic WARNINGS given elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the product. ONICON Incorporated assumes no liability for the

customer’s failure to comply with these requirements. If this product is used in a manner not

specied in this manual, the protection provided by this product may be impaired.

The following symbols are used in this manual:

WARNING

Messages identied as “Warning” contain information regarding the personal safety of

individuals involved in the installation, operation or service of this product.

CAUTION

Messages identied as “Caution” contain information regarding potential damage to the

product or other ancillary products.

IMPORTANT NOTE

Messages identied as “Important Note” contain information critical to the proper operation of

the product.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION .................................................................................................5

1.1 PURPOSE OF THIS GUIDE .......................................................................5

1.2 TYPICAL INSERTION ELECTROMAGNETIC FLOW METER ................5

1.3 STANDARD FEATURES AND SPECIFICATIONS ....................................6

1.4 ADDITIONAL REQUIRED HARDWARE ...................................................7

1.5 ADDITIONAL HARDWARE THAT MAY BE REQUIRED .........................8

1.5.1 Grounding Rings .......................................................................... 8

2.0 UNPACKING ...................................................................................................... 9

2.1 CHECKING THAT YOU HAVE RECEIVED EVERYTHING ......................9

3.0 INSTALLATION, REMOVAL & ADJUSTMENT ................................................10

3.1 INSTALLATION SITE SELECTION ........................................................10

3.1.1 General Site Selection Guidelines ............................................10

3.1.2 Insufcient Straight Run Site Selection Guidelines .................11

3.2 MECHANICAL INSTALLATION ............................................................. 12

3.2.1 Installation Kit ...........................................................................13

3.2.2 ONICON Standard Installation Hardware Kit ..........................13

3.2.3 ONICON Hot Tap Installation Hardware Kit ............................ 13

3.2.4 Customer Supplied Installation Hardware ............................... 14

3.2.5 Conrming the Stack Height .....................................................15

3.2.6 Installing the Flow Meter ..........................................................16

3.3 INSERTION OF THE METER ..................................................................17

3.3.1 Inserting the Flow Meter ...........................................................17

3.4 REMOVAL OF THE METER .................................................................... 18

3.5 WIRING CONNECTIONS ........................................................................20

3.5.1 Signal & Power Wiring Connections ......................................... 21

3.5.2 Earth Connections ......................................................................22

4.0 START-UP & COMMISSIONIING FOR ONICON INSERTION

ELECTROMAGNETIC FLOW METERS ............................................................. 23

4.1 HELPFUL HINTS FOR START-UP AND COMMISSIONING .................23

4.2 START-UP AND COMMISSIONING ....................................................... 24

4.3 START-UP AND COMMISSIONING WORKSHEET ............................... 25

4.4 TROUBLESHOOTING GUIDE ................................................................. 26

4.4.1 Earth Connections & Electrical Noise Reduction .....................26

APPENDIX

Conditions of Sale

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 3

Page 4

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 4

Page 5

!

SECTION 1.0: INTRODUCTION

We, at ONICON Incorporated, would like to thank you for purchasing our quality American made

FB-3500 Bi-Directional Electromagnetic Flow Meter. As our valued customer, our commitment to you

is to provide fast reliable service, while continuing to offer you quality products to meet your growing

ow measurement needs.

1.1 PURPOSE OF THIS GUIDE

We have written this guide to provide the persons responsible for the installation, operation and

maintenance of your ow meter with the most specic equipment information they will need.

This is NOT an electrical or plumbing trade manual.

WARNING

Please do not permit persons to install, operate or maintain this equipment unless they have a

complete knowledge of their trade skills and are competent to work on high pressure hot and cold

water and steam systems, according to their individual trades. Death or permanent injury may

result from accidents with these systems.

This guide is the basic reference tool for all ONICON FB-3500 Bi-Directional Electromagnetic

Flow Meters. If you have not purchased all of the options, there will be references in this manual

which are not applicable to your meter(s).

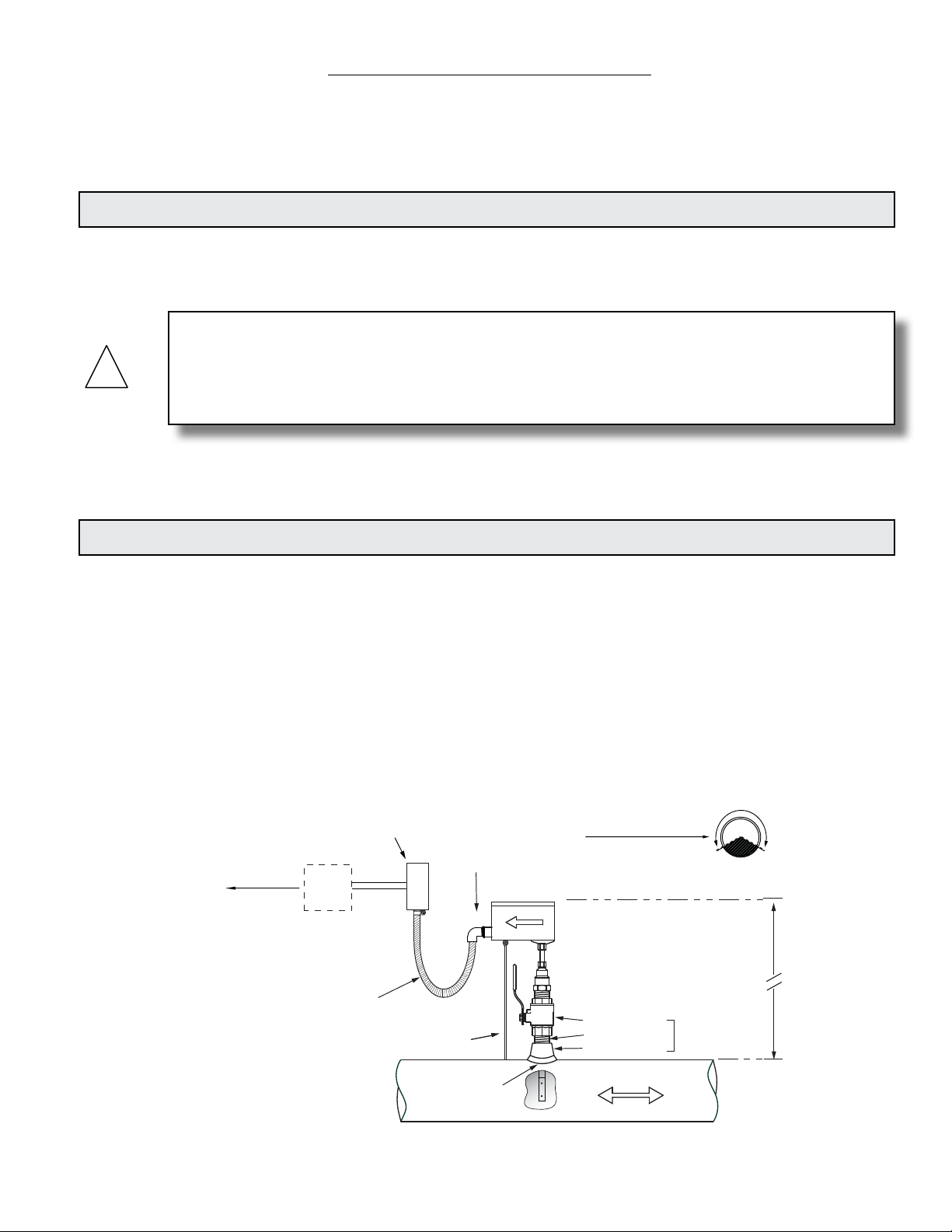

1.2 TYPICAL INSERTION ELECTROMAGNETIC FLOW METER

Faraday’s Law of electromagnetic induction states that a voltage will be induced in a conductor

when it passes through a magnetic eld, and the induced voltage will be directly proportional to

the velocity of the conductor.

ONICON FB-3500 Bi-Directional Electromagnetic Flow Meters generate pulsating magnetic elds

that are used to induce a voltage into the conductive uid owing through the pipe. Electrodes

located on the ow meter sensor head measure the induced voltage. Circuitry within the ow

meter electronics enclosure then converts the voltage to digital and analog signals that convey

ow rate and total data via connecting the cable to any of ONICON’s display devices, Btu meters

and/or to a data acquisition system.

Typical Meter Installation

(New construction or scheduled shutdown)

Output signal(s)

to control

system

ONICON

Display or

BTU Meter

(Optional)

Allow enough slack

in the flexible conduit

to permit the meter

to be removed

from the valve.

Customer provided

conduit and adapters

Insertion depth

gage provided

with each meter

½" FNPT

conduit connection

• Install in vertical or horizontal pipe

• For horizontal pipe position meter

anywhere in upper 240˚

Standard Installation

Kit for Steel Pipe

1" Full port ball valve

1" Close nipple

1" Branch outlet

CLEARANCE

REQUIRED

FOR INSTALLATION

Typically

30" - 40"

depending on

pipe size and

height of valve

assembly.

1¼" for

hot tap

Minimum Hole Size = 1"

Must be centered

Note: Installation kits vary based on pipe material and application. For installations in pressurized (live)

systems, use "Hot tap" 1¼ inch installation kit and drill hole using a 1 inch wet tap drill.

FLOW

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 5

Page 6

1.3 STANDARD FEATURES AND SPECIFICATIONS

Accuracy

± 1.0% of reading from 2 to 20 ft/sec

± 0.02 ft/sec below 2 ft/sec

Sensing Method

Electromagnetic, no moving parts

Pipe Size Range

3” through 72” nominal

Input Power

20 - 28 VAC 50/60 Hz, 250 mA maximum

20 - 28 VDC, 250 mA maximum

Liquid Temperature Range

15° to 250° F

Ambient Temperature Range

-5° to 150° F

Operating Pressure

400 PSI maximum

Pressure Drop

Less than 0.1 psi at 12 ft/s velocity in 3” and larger pipes

Materials of Construction

Wetted metal components - 316L stainless steel

Sensor head - Polypropylene

Electronics enclosure - Powder coat painted cast aluminum

Enclosure Rating

Weathertight, NEMA 4

Electrical Connections

10’ of PVC jacketed cable with ½” NPT conduit connection

OUTPUT SIGNALS PROVIDED

Analog Output (Isolated)

Selectable: 4-20 mA, 0-10 V or 0-5 V

Frequency Output

0 – 15 VDC, 0 – 500 Hz

Pulse/Contact Closure Outputs (four)

Isolated solid state dry contact

Contact maximum ratings: 100 mA, 50 VDC

Scalable Pulse Outputs (two)

Forward & Reverse Flow Totalization

Pulse Duration: 0.5, 1, 2 or 6 seconds

Directional Contact Output:

Switch closed when ow is in direction of ow arrow on enclosure

Latches at 0.2 ft/s

Switches within 20 seconds of direction change

Master Alarm Output:

Switch closed indicates alarm condition

This product is covered by one or more of the following patents: 6,431,011 and 6,463,807.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 6

Page 7

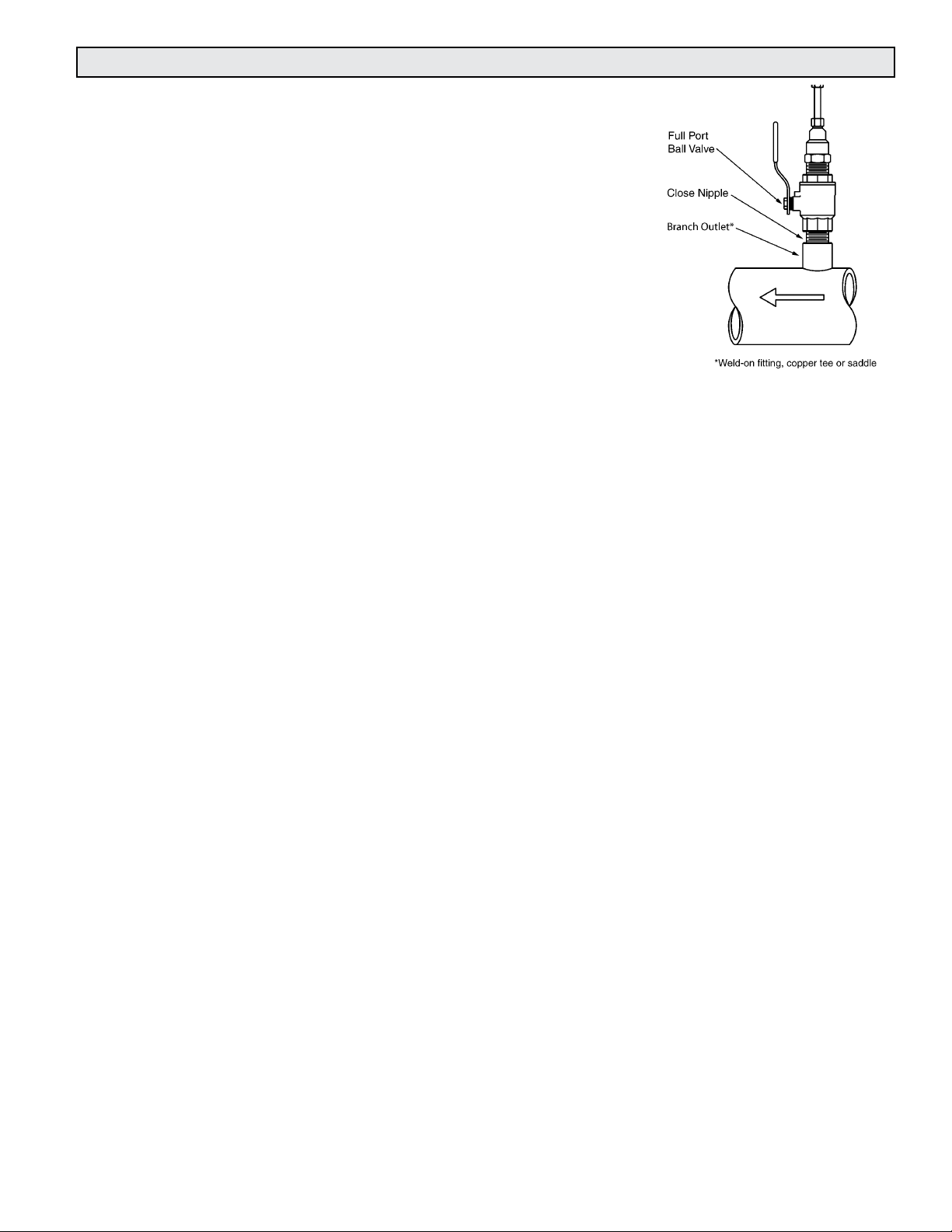

1.4 ADDITIONAL REQUIRED HARDWARE

All ONICON insertion type meters can be installed and removed via

a 1” or larger full port ball valve without system shutdown. The

terms “Standard” and “Hot Tap” refer to the installation method of

the isolation valve kit only.

Standard Installation Hardware: For new construction or

scheduled shutdown, once kit is installed, the ow meter can

be installed or removed without system shutdown.

Hot Tap Installation Hardware: For applications which require the

access hole in the pipe to be drilled through the valve using a

wet tap drilling machine while the hydronic system is

pressurized and operating.

NOTE: Installation hardware materials vary greatly based on pipe material, pipe size and

standard vs. hot tap versions.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 7

Page 8

1.5 ADDITIONAL HARDWARE THAT MAY BE REQUIRED

5/8

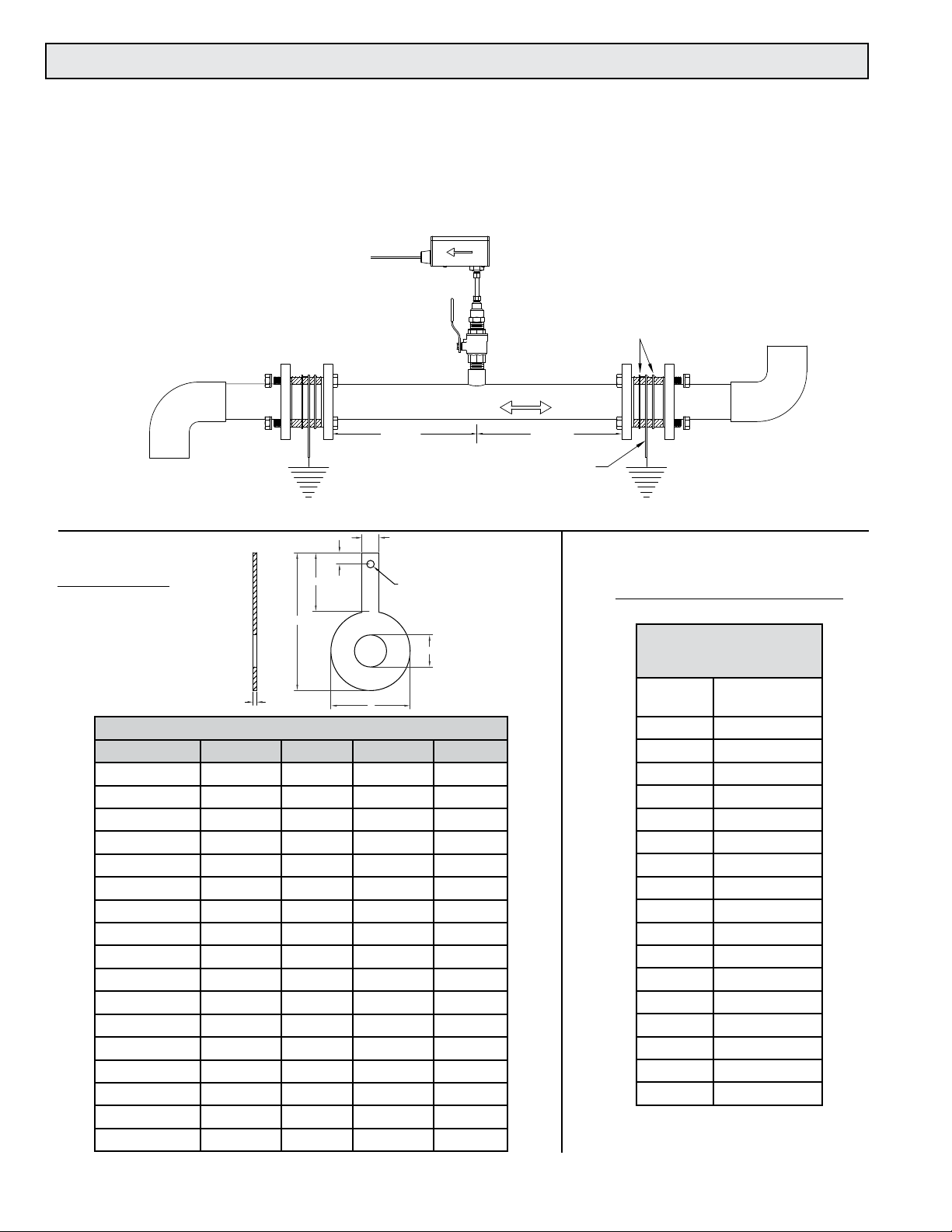

1.5.1 Grounding Rings

Grounding rings may be required whenever meters are installed in non-metallic or lined pipes.

Grounding rings placed before and after the meter eliminate electrical noise that will interfere

with the proper operation of the meter. ONICON provides grounding rings as an optional

accessory. Grounding ring dimensional information and part numbers are listed below. For proper

operation, grounding rings are required before and after the meter.

Typical Installation

Non-conductive Pipe

Gasket (4PL)

Flow Direction

DIMENSIONS

Nominal Size Bore A C D

1” 1 - 1/16 2 - 5/8 4 - 9/16 1 - 15/16

1.5” 1 – 9/16 3 – 3/8 5 - 5/16 1 - 15/16

2” 2 – 1/16 4 – 1/8 6 - 1/16 1 - 15/16

3” 3 – 1/16 5 – 3/8 7 - 5/16 1 - 15/16

4” 4 – 1/16 6 – 7/8 8 - 13/16 1 - 15/16

6” 6 8 – 3/4 10 - 11/16 1 - 15/16

8” 8 11 12 - 15/16 1 - 15/16

10” 9 – 1/2 13 – 3/8 15 - 5/8 2 - 1/4

12” 11 – 9/16 16 – 1/8 18 - 9/16 2 - 7/16

14” 13 – 1/2 17 – 3/4 20 - 3/8 2 - 5/8

16” 15 – 1/4 20 – 1/4 22 - 7/8 2 - 5/8

18” 17 – 3/8 21 – 5/8 24 - 1/4 2 - 5/8

20” 19 23 - 7/8 26 - 11/16 2 - 13/16

24” 23 28 – 1/4 31 - 1/8 2 - 7/8

30” 29 34 – 3/4 38 3 - 1/2

36” 35 41 – 1/4 45 - 1/4 4

42” 41 48 52 - 1/2 4 - 1/2

3/8

D

C

1/8”

A

Grounding Ring Dimensions

10 DIA

1/4

Bore

10 DIA

Grounding Ring (2PL)

ORDERING INFORMATION

ANSI Class 150

316 Stainless Steel

Grounding Rings (pair)

Nominal

Size

1” 19265

1½” 19266

2” 19267

3” 19268

4” 19269

6” 19270

8” 19271

10” 19272

12” 19273

14” 19274

16” 19275

18” 19276

20” 19277

24” 19278

30” 19279

36” 19280

42” 19281

ONICON Part

Number

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 8

Page 9

SECTION 2.0: UNPACKING

ONICON insertion magnetic ow meters are packed and shipped in individual cartons. An optional

installation hardware kit INSTL 1 or INSTL 2, if ordered, will be packaged with each meter. All other

installation hardware and peripheral devices, including Btu meters and display modules, will be packaged

and shipped separately.

Please open all packages with care to prevent damage to their contents. Carefully inspect each item for

signs of damage in transit. The ow meter stem should be straight and free of blemishes or abrasions. The

sensor head should have a smooth continuous surface that is free of abrasions.

All ONICON products are shipped insured unless the customer specically requests otherwise. Please

notify the shipping company and ONICON immediately if any items are damaged in transit. Save all

packing material for inspection by the shipper.

2.1 CHECKING THAT YOU HAVE RECEIVED EVERYTHING

• Standard Documentation

Enclosed with each meter is a comprehensive documentation package that includes the

following items:

Installation and Operation Guide

Flow Meter Certicate of Calibration

Please notify the ONICON if any of these documents are missing.

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter

Optional INSTL1 or INSTL2 Installation Hardware Kit, if ordered

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 9

Page 10

SECTION 3.0: INSTALLATION, REMOVAL AND ADJUSTMENT

!

WARNING

Insertion ow meters may be installed in pipes which are under high pressure. Accidents with

these systems can cause serious injury or death. Only persons experienced with high pressure

systems and related knowledge in the heating, cooling and uid metering elds should attempt

to install, adjust, or remove the ow meter. Please read all instructions before attempting to

insert or remove a ow meter.

ONICON will be happy to assist with technical recommendations and to provide guidance by

telephone or e-mail. On-site eld engineering, installation and service is also available at additional cost.

3.1 INSTALLATION SITE SELECTION

Install the ow meter where it will be accessible for personnel to perform necessary periodic

maintenance. The clearance required for installation is typically 30”- 40” from the pipe wall to

the nearest obstruction above the valve assembly. This clearance dimension will increase with

large diameter pipes. The environment should be free of corrosive liquids/fumes, temperature

extremes and heavy vibration. The following diagrams should be used as a guide to the proper

location for installing the meter.

3.1.1 General Site Selection Guidelines

GENERAL PRACTICES:

1. For best results, install the ow meter in a straight run of pipe, free of bends, tees,

valves, transitions and obstructions.

2. Straight run recommendations vary based on the nature of the upstream obstruction.

See the table below for guidelines in determining upstream straight run

recommendations based on the nature of the obstruction. Please note that depending

upon specic location details, more or less straight run may be required to produce a

satisfactory ow prole.

For 3” and larger pipe diameters

Obstruction on either side of meter

Single bend preceded by ≥ 9 diameters of

straight pipe

Pipe size reduction / expansion in straight

pipe run

Single bend preceded by ≤ 9 diameters of

straight pipe

Outowing tee / pump outow 20 Diameters

Multiple bends out of plane 30 Diameters

Inowing tee 30 Diameters

Control / modulating valve 30 Diameters

Straight run distance recommended

between meter and obstruction

10 Diameters

10 Diameters

15 Diameters

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 10

Page 11

! i !

How To Determine The Available Straight Pipe Diameters:

For each application, locate the longest straight, unobstructed section of pipe (no bends, tees, valves,

other insertion probes, size transitions).

The longest straight pipe run in inches divided by nominal pipe size in inches equals

“diameters of straight pipe.”

For closed loop applications, consider both the supply and return lines as possible locations.

IMPORTANT NOTE

Always use the maximum available straight run. When more than the minimum required straight

run is available, place the meter such that the excess straight run is maximized on both sides of

the meter location.

• Acceptable to install in vertical pipe

• Position meter anywhere in upper 240°

for horizontal pipe

CLEARANCE

REQUIRED FOR

INSTALLATION

50%

Upstream

Downstream

3.1.2 Insufcient Straight Run Site Selection Guidelines

If there is insufcient available straight run, allow 50% of the run upstream and 50%

of the run downstream. If the total length of straight run is less than 20 diameters,

performance may degrade and consideration should be given to changing to the F-3100 or

F-3200 In-Line Electromagnetic Flow Meters.

Typically 30” - 40”

depending on pipe size

and height of valve

assembly.

50%

Some installations may work better with straight run optimized for ow in one direction.

For example, with ow meters installed in the bypass line between de-coupled constant

volume primary and variable secondary loops, it may be more important to accurately

measure positive ow (from supply to return.) Negative ow measurements (from return

to supply) are generally less critical, and it may be enough just to know that any negative

ow is present. In this scenario, maximizing straight run for positive ow might be a

preferred strategy.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 11

Page 12

3.2 MECHANICAL INSTALLATION

!

! i !

ONICON Insertion Electromagnetic Flow Meters employ a hot tap adapter design that allows for

insertion and removal, when necessary, without interrupting ow and draining the pipe. To take

advantage of this feature, the ow meter must be installed through an isolation valve. The

installation must allow for sufcient overhead clearance to fully extract the meter, and a full 1”

opening in the pipe wall is required to clear the sensor head and allow for insertion. Make sure

that your valves and ttings are full port and at least 1” in actual internal diameter.

CLEARANCE

REQUIRED

FOR INSTALLATION

Typically

30" - 40"

depending on

pipe size and

height of valve

assembly.

Standard Installation

Kit for Steel Pipe

Minimum Hole Size = 1"

Must be centered

1" Full port ball valve

1" Close nipple

1" Branch outlet

NOTE: Use stainless steel or brass

close nipple only.

1¼" for

hot tap

CAUTION

ONICON insertion style ow meters must be installed through a valve assembly. Failure to do so

negates the ability to remove the meter without shutting down and draining the system. It will

also result in an excessive amount of stem protruding from the pipe. Excessive stem lengths

unneccessarily expose the meter to incidental damage.

IMPORTANT NOTE

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 12

Flow meters installed through oversized access holes will be subjected to undesirable turbulence

that may affect the accuracy of the meter.

Page 13

3.2.1 Installation Kit

ONICON offers a wide range of installation hardware kits for commonly used pipe

materials. The kits are specically designed for ONICON ow meters, and their use is

recommended.

The use of ONICON installation hardware kits accomplishes two important objectives.

First, it ensures that the proper hardware is used. Second, it simplies order processing

by standardizing the dimensions of the installation hardware. ONICON must have an

accurate measurement of the overall height of the installation hardware as measured from

the outside wall of the pipe to the top of the valve in order to determine the correct stem

length when assembling the meter in our factory. ONICON documents refer to this

dimension as the stack height.

ONICON installation hardware kits consist of three separate component parts:

Some type of

threaded branch

outlet,

interconnecting

An

close nipple,

Different pipe materials require different branch outlets and may include additional

bushings to properly size the opening.

3.2.2 ONICON Standard Installation Hardware Kit

And a full port

isolation valve.

Standard installation hardware kits are designed to be installed on piping systems that

are drained and at atmospheric pressure. The access hole is drilled (1” minimum) prior

to installation of the branch outlet with 1” NPT threads, close nipple and full port ball

valve. Once the isolation valve is installed, the piping system can be ushed, lled and

pressurized. The ow meter may now be inserted or removed by hand without having to

drain the system. Please read all instructions before proceeding with meter insertion.

3.2.3 ONICON Hot Tap Installation Hardware Kit

ONICON offers an alternative installation hardware kit when it is not practical to relieve

pressure and drain the system. In this case, a 1¼” branch outlet, close nipple and 1¼” full

port ball valve are installed rst. Then, a hot tap drilling apparatus is used to drill a 1”

diameter hole through the valve. This eliminates the need to shut down and drain the

pipe. Please read all instructions before proceeding with meter insertion.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 13

Page 14

!

3.2.4 Customer Supplied Installation Hardware

!

!

There are occasions where circumstances require that the customer provide the

installation hardware or that the ow meter be installed through existing hardware. In

these cases, it is important to conrm that the installation hardware is suitable for use

with the ow meter provided by ONICON before it is installed. The installation must

allow for sufcient overhead clearance to fully extract the meter and a full 1” opening in

the pipe wall is required to clear the sensor head and allow for insertion. Make sure that

your valves and ttings are full port and at least 1” in actual internal diameter.

Installation hardware generally consists of three separate component parts:

Some type of

threaded branch

outlet,

An

interconnecting

close nipple,

And a full port

isolation valve.

CAUTION

Do not use threaded steel or slip PVC tees to provide the 1” opening in the pipe. Tees of this

type will cause signicant errors in the ow measurement.

CAUTION

In order to provide the ow meter with the correct stem length, ONICON must know the

overall height of the installation hardware as measured from the outside wall of the pipe to

the top of the valve where the meter is installed.

CAUTION

Use stainless steel or brass nipple only.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 14

Page 15

3.2.5 Conrming the Stack Height

ONICON insertion ow meter stem lengths vary according to the pipe diameter and the

height of the installation hardware stack. ONICON records the stack height dimension

provided by the customer at the time of order entry, and the information is used to size the

stem. The dimension is shown on the laminated insertion depth gage tag attached to the

meter.

Prior to installing the meter, conrm that the stack height recorded on the tag is close

to the actual stack height. Flow meter stems are intentionally over sized to allow for

variations of at least 2” in the stack height. Contact ONICON prior to installation if there is

any question regarding stack height or stem length. This way ONICON can offer you credit

for your meter if you decide to exchange the meter for one with a different stem length.

Returns may be subject to a restocking fee.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 15

Page 16

!

3.2.6 Installing the Flow Meter

!

When you are ready to rell the system, make sure that all lines are lled with water before

inserting the meter into the ow stream. If the lines are not lled and this is a hot water

system, some water may ash to steam and exceed the high temperature limit for the sensor

head assembly. This ash over could also exceed the pressure ratings of the meter and the

assembly could fail allowing steam and hot water to escape causing serious injury.

Tools needed for standard installation:

• 1 5/16” wrench or adjustable wrench

• 5/8” wrench or small adjustable wrench

• pipe wrench (to hold valve in place)

• pipe thread sealant

Flush, ll and pressure test the piping system prior to installing the meter. Loosen

clamping nut to facilitate installation.

WARNING

Clamping nut

Apply paste or

Teon tape as

necessary.

Keep sensor

head fully

withdrawn

during

installation.

Thread hot

tap adaper on

to ball valve

and tighten as

necessary.

Maintain a rm

grip on the

enclosure when

opening valve.

Crack

valve to

test for

leaks.

CAUTION

If there are any leaks around the clamping nut or stem, DO NOT ATTEMPT TO STOP THE

LEAKAGE BY OVERTIGHTENING THE CLAMPING NUT. Damage to this nut or the clamping

ring under the nut may prevent the assembly from properly holding the meter in the pipe. The

clamping nut is not part of the sealing mechanism. Any leaks in this area indicate that the “O”

ring is not sealing properly and you must contact ONICON for assistance.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 16

Page 17

!

3.3 INSERTION OF THE METER

WARNING

SYSTEM MAY BE UNDER HIGH PRESSURE. When adjusting the meter position or removing

it, be sure to hold the electronics enclosure rmly by hand before SLOWLY loosening the

positioning clamping nut. Failure to do this will allow the pressure to suddenly and rapidly

force the meter from the pipe causing serious injury. The meter could also be damaged or break

apart causing a break in the water seal with the resultant loss of large amounts of water. The

hand effort required to hold the meter will be 0.11 times the pipe pressure.

Begin by calculating the effort that will be required to hold the meter. Establish adequate footing

for this task, taking extra caution when working from a ladder or platform. Use the following

formula:

E=0.11 x P Where: E = effort in pounds

P = system pressure in pounds per square inch

Example: In a 300 PSI system, 33 pounds of effort is required to insert the meter into the pipe.

3.3.1 Inserting the Flow Meter

Step 1:

Maintain a rm grip

on the enclosure

to counteract

the effects of the

pressure in the pipe.

Step 2:

Slowly open the

valve to the full

open position.

Step 4:

Orient the enclosure to parallel with the pipe and

in alignment with the ow direction arrow.

Step 6:

Carefully tighten

the clamping

nut. DO NOT

OVERTIGHTEN.

Step 5:

Slowly push down on

the ow meter until

the bottom of the

enclosure rests on the

top of the depth gage.

Step 3:

Use the end of the depth gage to pierce any

insulation that may be present and rest the

gage on the outside wall of the pipe.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 17

Page 18

!

3.4 REMOVAL OF THE METER

SYSTEM MAY BE UNDER HIGH PRESSURE. When removing the ow meter, be sure to hold

the electronics enclosure rmly by hand before slowly loosening the positioning clamping

nut. Failure to do this will allow the pressure in the pipe to suddenly and rapidly force the

meter from the pipe causing serious injury. The meter could also be damaged or break apart

causing a break in the water seal with the resultant loss of large amounts of water. The hand

effort required to hold the meter will be 0.11 times the pipe pressure.

WARNING

Step 1:

Slowly loosen the position

clamping nut while

maintaining a rm grip on the

enclosure to counteract the

effect of pressure in the pipe.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 18

Step 2:

Carefully withdraw the

ow meter stem from

the pipe until the sensor

head is fully inside the

hot tap adapter.

Page 19

!

!

NOTE:

The hot tap adapter will contain

a small amount of water.

Step 3:

After the meter is completely

withdrawn, slowly close the

valve to isolate ow.

Step 4:

After the valve is completely closed,

unscrew the hot tap adapter from the

valve. For hot water meters, partially

unscrew the adapter to vent pressure

before fully removing the meter.

CAUTION

The main cause of damage to meters comes from accidentally closing the valve on the sensor

head. To avoid this, gently rotate the meter by twisting the electronics enclosure back and forth

(twist the stem, do not bend it) while you slowly close the valve. If the valve touches any part of

the meter, you will feel it as you are twisting the meter. If the valve touches anything, it means

the meter is not fully withdrawn. Usually a gentle twisting motion while withdrawing the meter

will clear any obstruction and permit the meter to withdraw completely. (Excessive build-up on

the stem may require the hot tap “O” ring to be lubricated with silicone.)

WARNING

In hot water systems, even a small amount of water can cause serious personal injury. Use extra

caution when working with hot water meters.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 19

Page 20

3.5 WIRING CONNECTIONS

!

!

Make all connections to the attached 10ft cable.

The most common causes of electronic failures are miswired connections during installation.

When adding additional cable, record and carefully document any substitution of wire colors.

Additional cable may be purchased from ONICON that will allow you to maintain the existing

color coding.

All electrical connections to the FB-3500 must be made through the 10ft cable provided with the

meter. This cable is not designed to be removed in the eld, and any attempt to do so will

compromise the weather tight integrity of the enclosure.

The cable provided contains 22 AWG color-coded wires for signal and power and a separate

18 AWG green/yellow earth wire.

Special care is required to ensure that the FB-3500 is connected to earth through the green/yellow

earth wire. This connection is required to prevent random electrical noise from interfering with

the operation of the meter. (See section 3.5.2 for details.)

CAUTION

Do not attempt to remove the existing cable or to remove the factory installed connection tting.

Doing so will compromise the weather tight integrity of the enclosure and may void the warranty.

CAUTION

Only qualied personnel should attempt to make electrical connections to the FB-3500. Failure

to properly connect the FB-3500 power, signal or earth connections may result in damage to the

FB-3500 and/or to associated peripheral equipment.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 20

Page 21

!

3.5.1 Signal and Power Wiring Connections

Customer provided

conduit and adapters

Output signal(s)

to control

system

ONICON

Display or

BTU Meter

(Optional)

Allow enough slack

in the flexible conduit

to permit the meter

to be removed

from the valve.

Insertion depth

gage provided

with each meter

½" FNPT

conduit connection

FLOW

Wire Color Description Notes

Red (+) Supply voltage: 24±4 VDC @ 250 mA or 24±4 VAC,

60 Hz, 6 VAC

Black (-) Isolated supply voltage common Connect to power supply (-): DC (-) or

Green / Y ellow Earth ground connection Required to operate the meter

Green (+) Isolated frequency output Required when connecting to ONICON

Yellow (-) Frequency output common

Blue (+) Isolated analog output Congurable as a 4-20 mA, 0-10 V or

Brown (-) Isolated analog output common

Gray Forward ow, scaled output, isolated dry contact Scalable dry contact pulse output for

Violet

Gray / Black Reverse ow, scaled output, isolated dry contact Scalable dry contact pulse output for

Violet / Black

Orange / Black Flow direction indicator, isolated dry contact Contact closed when ow is in direction

White / Black

Diagnostic Signals

Orange Master alarm, isolated dry contact Dry contact closure signal indicating

White

Connect to power supply (+): DC (+) or

AC (line)

AC (neutral)

display or BTU meter

0-5 V output

forward ow totalization

reverse ow totalization

of arrow on meter

fault condition

CAUTION

Failure to provide a proper earth connection to the meter may result in excessive electrical

noise that will interfere with the operation of the meter.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 21

Page 22

! i ! ! i !

3.5.2 Earth Connection

FB-3500 Bi-Directional Electromagnetic Flow Meters are designed to detect microvolt

signal levels at the electrodes located on the sensor head. These signals are generated

as conductive uids ow through the magnetic eld generated by the meter. If enough

random electrical noise is present at the electrodes, it can interfere with the ow

measurement. Care must be taken during installation to minimize the effects of electrical

noise on the ow meter.

The most effective way to minimize the effects of electrical noise is to make sure that

the pipe, the uid and the ow meter body are all connected to earth ground. This

accomplishes two important goals. First, it ensures that the pipe, uid and ow meter are

all at the same electrical potential, and second, it ensures that this electrical potential is

the same as earth ground.

In order to be certain that the meter is properly connected to earth, the ow meter earth

cable should be run directly to a known earth connection. The length of this earth cable

should be as short as practically possible, preferably ≤25 feet in length. The table below

lists earth connections from best to worst. If necessary, a separate earth cable should be

connected to the metal pipe near the meter.

IMPORTANT NOTE

Non-metallic pipes are more susceptible to electrical noise. Grounding rings installed upstream

and downstream of the meter location to reduce the electrical noise present in the pipe may be

required for proper operation. Refer to section 1.5.1 of this manual for additional information on

the use of grounding rings.

Earth Connections (stranded wire 14 – 18 AWG)

Best Earth grounding rod driven into the ground

Earth wire connected directly to the building electrical service panel.

Worst Earth wire connection inside an electrical outlet near the meter.

IMPORTANT NOTE

Under certain circumstances, connecting the meter to earth through the green/yellow earth wire

may increase the amount of electrical noise present at the meter. Contact ONICON for technical

assistance if you experience increased noise levels with the earth wire connected to earth.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 22

Page 23

SECTION 4.0: START-UP & COMMISSIONING FOR ONICON

INSERTION ELECTROMAGNETIC FLOW METERS

4.1 HELPFUL HINTS FOR START-UP AND COMMISSIONING

A step-by-step procedure and companion worksheet are located on the next two pages. Please

read all installation instructions carefully before proceeding with installation, start-up and

commissioning.

1. ONICON ow meters are individually calibrated for a particular application. Be

sure to verify the pipe size and location.

2. The electronic ow sensing systems will not work in air.

3. When measuring analog output signals, remember that current (mA) must be

measured in series, while voltage is measured in parallel. If the 4-20 mA signal

is already connected to a control system, you must break the connection and

measure the signal in series.

4. When measuring frequency outputs in Hz, take your multimeter out of “autorange

mode” and manually set the range for a voltage level above 15 VDC. This will

prevent false readings when signal is not present.

5. All wiring connections should be made at the end of the factory cable. Do not

attempt to remove the factory installed cable or change the orientation of the

electronics enclosure.

6. Never connect power to analog or frequency output signal wires. ONICON FB-3500

ow meters are not “loop powered” devices.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 23

Page 24

4.2 START-UP AND COMMISSIONING

Please read the entire procedure before proceeding. A worksheet for checking off the following

steps and recording measured values is located on the next page.

1. Conrm ow meter

location. Conrm adequate

straight pipe run to achieve

desired results.

2. Conrm pipe size. Conrm that the meter is tagged for the pipe size in which it is installed. When in doubt,

3. Conrm insertion depth and

orientation.

4. Conrm control system

programming.

5. Conrm connection to

correct ONICON display or

Btu meter (if ordered).

6. Verify wiring before

connecting power.

7. Conrm correct supply voltage. Verify that 24 (±4) V is available.

8. Connect power. Wait approximately 45 seconds after power-on before proceeding further.

The following steps require ow in the pipe. Flow signal readings should be taken while holding the ow rate constant, if possible.

Otherwise, take the various output readings as quickly as possible.

9. Test ow direction indicator.

Conrm that ow direction

contact closure output

changes state when the ow

direction reverses.

10. Measure and record

frequency output.

Is the meter located in the correct location as required by the plans?

Compare actual straight pipe upstream and downstream of the meter location to

recommended distances identied in this manual. Contact ONICON’s technical support

department to discuss specics of your application. If straight pipe run is very short,

consult factory PRIOR to installing the meter to discuss possibility of upgrade to an

F-3000 series in-line meter.

measure the circumference of the pipe. Pipe O.D. = (circumference / 3.14) – (insulation

thickness x 2).

Each ow meter comes with an attached insertion gage and instruction tag. Ensure that

the meter is inserted to the correct depth and that the electronics enclosure is parallel to

the pipe with the arrow in the direction of ow.

Conrm that the control system input point is properly congured for the analog range

(or scale factor) identied on the calibration tag & certicate.

Conrm that the ow meter serial number matches the ONICON display or Btu meter

serial number (when ordered together).

Prior to connecting the power, verify that the wiring is correct as shown in this manual and/

or the additional wiring diagram provided with ONICON display or Btu meter. If in doubt,

contact ONICON for assistance before proceeding further.

Following the steps outlined in sections 3.3.1 of this manual, loosen the clamping nut, rotate

the enclosure 180° and conrm that the ow direction contact closure changes state.

Return the meter to its correct orientation in the pipe, reset the insertion depth and tighten

the clamping nut.

The frequency output signal is a 0-15 VDC pulsed output ranging up to 200 Hz and must

be measured with a multimeter. Measue DC frequency (Hz) from GREEN (+) to YELLOW

(-). Also measure DC volts on same wires. Five to seven is normal for a pulsating output.

Zero VDC indicates no output.

GPM = frequency in Hz X 60

meter factor in ppg (Refer to calibration tag for meter factor.)

11. Measure and record

analog or pulse outputs.

Current Output:

Voltage Output:

Scaled Output:

12. Compare various output

signals to each other and to

the ow rate displayed by the

control system.

End of standard start-up and commissioning. Please contact ONICON at (727) 447-6140 with any questions.

Refer to ow meter wiring diagram for wire colors for the various outputs available, based

on your

particular ow meter model. Use the following formulas to calculate ow rate from

measured analog signals:

GPM = (measured current in mA - 4) X Full Scale Analog Flow Rate

16

GPM = measured VDC X Full Scale Analog Flow Rate

10

Each contact closure = unit volume identied as “Scale Factor” (measure and record time

interval between contact closures)

Compare the ow rates calculated in steps 10 and 11 to each other and to the ow

rate indicated by the control system. Refer to troubleshooting guide when readings are

inconsistent.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 24

Page 25

4.3 START-UP AND COMMISSIONING WORKSHEET

Please read all installation instructions carefully prior to proceeding with these steps. Use the

following worksheet for checking off the commissioning steps and recording measured values.

Steps 9 - 12 require ow in the pipe. Flow signal readings should be taken while holding

the ow rate constant, if possible. Otherwise, take the various output readings as quickly as

possible.

STEP TEST/MEASUREMENT S/N: _________ S/N: ________ S/N: ________ S/N: _________

1. Meter location:

2.

3. Insertion depth

4. Control system

5. Match display or Btu

6. Signal connections

7. Supply voltage veried:

8. Connect power:

The following steps require ow in the pipe. Flow signal readings should be taken while holding the ow rate

constant if possible. Otherwise, take the various output readings as quickly as possible.

9. Flow direction indicator

10. Frequency output(s):

Conrm pipe size:

and orientation:

programming:

meter serial number

(S/N) if ordered:

veried:

changes state (Y/N)

Avg = green

Average frequency (Hz):

Average frequency

(VDC):

Calculated ow rate:

11. Analog or pulse

output(s)

4-20 mA signal:

0-5 / 0-10 V signal:

Scaled output interval:

Calculated ow rate:

12. Flow rate displayed

by control system:

___________Hz

_________VDC

_________GPM

___________mA

_________VDC

_____________

_________GPM

_________GPM _________GPM _________GPM _________GPM

___________Hz

_________VDC

_________GPM

___________mA

_________VDC

_____________

_________GPM

___________Hz

_________VDC

_________GPM

___________mA

_________VDC

_____________

_________GPM

___________Hz

_________VDC

_________GPM

__________mA

_________VDC

_____________

_________GPM

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 25

Page 26

4.4 TROUBLESHOOTING GUIDE

NOTE: Also refer to the START-UP AND COMMISSIONING GUIDE located on page 22.

REPORTED PROBLEM POSSIBLE SOLUTIONS

No signal • Verify that the meter is properly inserted into the pipe.

• Verify that the electronics enclosure is parallel with the pipe.

• Verify 24 V supply voltage.

• Verify correct wiring to control system (see wiring diagram).

• Verify that there is ow in the pipe.

• Verify that the meter earth cable is connected to earth.

• Check to see if the alarm contact closure output is closed (orange &

white wires). A closed contact could indicate either an empty pipe or

excessive electrical noise, possibly due to a poor earth ground.

• Low conductivity water (≤ 20 µsiemens) may activate the empty pipe

detector and/or increase the potential for electrical noise problems.

Reading is too high or

low

• Verify pipe size. Contact ONICON if pipe size is different from

calibration tag.

• Verify that the meter is properly inserted into the pipe.

• Verify that the electronics enclosure is parallel with the pipe.

• Verify correct wiring to control system (see wiring diagram).

• Conrm that the output signals are consistent with each other

(frequency vs. analog, etc).

• Conrm that the control system is programmed for correct ow range or

scale factor.

• Verify that the meter earth cable is connected to earth. A poor earth

connection can lead to excessive noise that can affect the ow reading.

Flow direction

indicator does not

change state when ow

direction changes.

Analog signal seems

high or low and does

not correspond to

frequency output

• Meter will not switch at very low ow velocities. Conrm that ow

velocity exceeds 0.2 ft/sec.

• Check for open connections between each contact closure wire (orange /

black & white / black) and the control system input.

• Check for ground loop or offset voltage:

• Disconnect analog signal input from control system and measure analog

output directly from the ow meter. Reconnect signal input to control

system and measure the analog signals again. Any difference between

these readings indicates a potential ground loop or offset voltage. Please

contact ONICON for further assistance.

Control system displays

ow rate, but no ow

rate is indicated on the

local display module or

• Verify that all wires from the ow meter are connected to the display

module or Btu meter.

• The frequency output wires (green and yellow) must be connected for

any ONICON display or Btu meter.

Btu meter

4.4.1 Earth Connections & Electrical Noise Reduction

Introduction

FB-3500 Electromagnetic Flow Meters are designed to detect microvolt signal levels at the

electrodes located on the sensor head. These signals are generated as conductive uids

ow through the magnetic eld generated by the meter. If enough random electrical noise

is present at the electrodes, it can interfere with the ow signal measurement. Care must

be taken during installation to minimize the effects of electrical noise on the ow meter.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 26

Page 27

! i !

Minimizing Electrical Noise

The most effective way to minimize the effects of electrical noise is to make sure that

the pipe, the uid and the ow meter body are all connected to earth ground. This

accomplishes two important goals. First, it ensures that the pipe, uid and ow meter are

all at the same electrical potential. Second, it ensures that this electrical potential is

the same as earth ground.

IMPORTANT NOTE

Non-metallic pipes are more susceptible to electrical noise. Grounding rings installed upstream

and downstream of the meter location to reduce the electrical noise present in the pipe may be

required for proper operation. Refer to section 1.5.1 of this manual for additional information

on the use of grounding rings.

In order to be certain that the meter is properly connected to earth, the ow meter earth

cable should be run directly to a known earth connection. The length of this earth cable

should be as short as practically possible, preferably ≤25 feet in length. The table below

lists earth connections from best to worst. If necessary, a separate earth cable should be

connected to the metal pipe near the meter.

Earth Connections (stranded wire 14 - 18 AWG)

Best Earth grounding rod driven into the ground to the depth of the water table.

Earth wire connected directly to the building electrical service panel.

Worst Earth wire connection inside an electrical outlet near the meter.

Diagnosing Electrical Noise Problems

When diagnosing electrical noise problems, it is important to understand that one of four

possible conditions are likely to exist. They are as listed in the table below. In order to

minimize the effects of noise, it is helpful to understand which of the following conditions

are present.

Earth Connection at

Flow Meter

Good earth connection

≤ 25 feet from ow meter

Good earth connection

≤ 25 feet from ow

meter

Poor earth connection Pipe & uid are

Pipe / Fluid Earth

Connection

Pipe & uid are

connected to earth

Pipe & uid are not

connected to earth

connected to earth

Poor earth connection Pipe & uid are not

connected to earth

Expected

Noise

Level

Low None required

Moderate A separate earth connection can be

made directly to the metal pipe or to the

uid. Non-metalic pipes may require

grounding rings installed upstream and

downstream of the meter location.

Moderate Removing the earth connection at the

ow meter may reduce the noise level.

If this is a long wire run, break the

connection where the wire connects to

the cable coming out of the ow meter. If

noise level is still too high, locate a better

earth connection for the ow meter.

High Locate a better earth connection for

the ow meter. If noise level is still too

high, locate a better earth connection

for the pipe or uid.

Possible Remedies

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 27

Page 28

1. ACCEPTANCE: The following Conditions of Sale apply to all sales of ONICON’s products. These provisions shall apply even

CONDITIONS OF SALE

if ONICON fails to object to provisions appearing on, incorporated by, referenced in, or attached to Buyer’s purchase order

form. Buyer’s acceptance of delivery of ONICON’s products constitutes its acceptance of these Conditions of Sale.

2. DELIVERY AND TITLE: All product shipments are Ex Works shipping point and title passes to the Buyer at the time ONICON

delivers the merchandise to the carrier. Risk of loss or damage to the product passes to the Buyer at the time ONICON delivers

the product to the carrier. The Buyer immediately upon receipt should inspect all shipments, and should there be any evidence of

damage or loss in transit, Buyer must le claims or tracers upon carrier. ONICON will assist in tracing shipments upon request.

3. LIMITED WARRANTY: ONICON warrants that for a period of two (2) years following the date of original shipment of an

ONICON product: (i) the product will conform to ONICON’s standard written specications applicable to such product in effect

on the date of Buyer’s order, or as modied by ONICON’s quotation or Buyer’s purchase order accepted by ONICON, (ii) the

product will be free from defects in workmanship, and (iii) that ONICON has title to the product prior to shipment to the Buyer;

provided, however, that the warranties provided herein shall be void and may not apply in the event Buyer misuses or

damages a product, including, but not limited to, any use by the Buyer of a product for an application other than one of a type

approved by ONICON. ONICON’s sole liability and Buyer’s sole remedy for any breach of the foregoing warranty is for

ONICON to repair or replace, at ONICON’s option, any defective product that is returned to ONICON during the warranty

period. EXCEPT AS MAY BE SPECIFICALLY AGREED BY ONICON IN WRITING IN RELATION TO EACH SALE, NO

OTHER WARRANTIES SHALL APPLY, WHETHER EXPRESSED, IMPLIED OR STATUTORY, AND THERE SHALL BE NO

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

4. REMEDIES: ONICON’s OBLIGATION UNDER THE FOREGOING WARRANTIES IS LIMITED SOLELY TO REPAIR OR

REPLACEMENT, AT ONICON’s OPTION, OF DEFECTIVE OR NONCONFORMING PRODUCTS. ONICON SHALL NOT BE

LIABLE FOR CONSEQUENTIAL, INDIRECT, PUNITIVE, INCIDENTAL, OR SPECIAL DAMAGES WHETHER FOUND ON

CONTRACT, TORT OR ANY OTHER THEORY OF LAW. No products shall be returned to ONICON without its prior consent

and transportation and insurance costs shall be prepaid. Any repair or replacement of ONICON’s products under the foregoing

warranty will be at no charge to the Buyer provided such repair is done at the ONICON factory or authorized service center.

ONICON products that are repaired or replaced under this warranty will be returned to Buyer via the same method of shipment

use to return the product to ONICON. Repair or replacement of ONICON products is conditioned upon ONICON’s

acknowledgement of any alleged defect or nonconformance during the warranty period and issuance of a Return

Authorization number. All product returns must reference the Return Authorization number on the outside of the shipping

carton and on any paperwork referencing the return.

5. PRICES AND PAYMENT TERMS: The prices set forth in the most recent quote or acknowledgement as applicable, supersede

all previous prices or quotations. All quotations are subject to change or withdrawal without notice except as may be specically

noted on the face of the quotation. The prices shown do not include sales, excise or government charges payable by ONICON to

Federal, State, or local authority. Any such tax or charge now or hereafter imposed upon the sale or shipment of the products

under this contract will be added to the purchase price. Buyer agrees to reimburse ONICON for such tax or charge or provide

ONICON with an acceptable exemption certicate. Payment of invoices will be due 30 days from the date of shipment of the

products contained therein. In the event that payment of an invoice is not received by the invoice due date, ONICON will assess

a late fee not to exceed 1.5% per month or 18% per year, or the maximum allowableby law whichever is lower.

6. CANCELLATION: Buyer may cancel its order, or any part of it, by sending written notice of cancellation to ONICON and

paying a reasonable cancellation fee as determined by ONICON. The reasonable cancellation fee will reect, among other

factors, the expenses already incurred and commitments made by ONICON, sales and administrative costs and prot as

determined by ONICON. If Buyer received a reduced price based on the quantity of products ordered, but has not purchased

the applicable quantity at the time of cancellation, Buyer will pay the price it would have paid had ONICON’s sale price been

based on the quantity actually purchased.

7. CHANGES: If Buyer makes any changes in its drawings, designs, or specications applicable in any contract with ONICON

that cause an increase or decrease in the cost of performance of the contract, or if such changes result in rework or obsolescence, an

equitable adjustment shall be made to the contract. Such changes are subject to ONICON’s prior written consent.

8. EXCUSABLE DELAY: ONICON shall under no circumstance be responsible for failure to ll any order or orders when due to: res,

oods, riots, strikes, freight embargoes or transportation delays, shortage of labor, inability to secure fuel, material supplies, or power

at current price or on account of shortages thereof, acts of God or of the public enemy, any existing or future laws or acts of the

Federal or State Government (including specically, but not exclusively, and orders, rules or regulations issued by any ofcial or

agency of any such government) affecting the conduct of ONICON’s business with which ONICON in its judgment and discretion

deems it advisable to comply as a legal or patriotic duty, or due to any cause beyond ONICON’s reasonable control.

9. PATENTS: ONICON shall defend all suits or proceedings brought against Buyer or its customers arising from claimed

infringements of any patent, trademark, service mark or copyright for any product furnished by ONICON and shall indemnify it

against all costs, fees, and damages on the condition Buyer promptly noties ONICON in writing and provides information and

assistance to enable ONICON to conduct the defense, provided that ONICON shall have no such obligation in case of

infringement resulting from ONICON’s conformance to special requirements of Buyer. If ONICON is not able to settle any such

suit or proceeding on acceptable terms, ONICON may, at its option, require return of the infringing product and refund the

purchase price to Buyer less a reasonable allowance for depreciation or use.

10. FAIR LABOR STANDARDS ACT: ONICON represents that all products delivered under this contract are furnished in

accordance with the applicable provisions of the Fair Labor Standards Act as amended.

11. APPLICABLE LAW: This document and any resulting contract shall be governed by and construed in accordance with the

laws of the State of Florida. The courts of the State of Florida and the federal courts located in Florida shall have jurisdiction

and venue with respect to litigation to this contract. In the event of litigation, the prevailing party shall be entitled to recover

attorney’s fees and costs from the non-prevailing party, including appellate attorney’s fees.

12. MODIFICATIONS: These Conditions of Sale along with the prices, quantities, delivery schedules and other provisions and

instructions in applicable quotations by ONICON or Buyer’s purchase orders accepted by ONICON shall constitute the entire

agreement between ONICON and Buyer pertaining to any resulting contract. They can be modied only in writing.

1 1451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

FB-3500 Bi-Directional Insertion Electromagnetic Flow Meter Manual 05/14 - 0718-3 Page 28

Loading...

Loading...