Page 1

F-5400 Insertion and Inline

Thermal Mass Flow Sensor

Installation and Operation Guide

ONICON

Flow and Energy Measurement

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699

2031-1 / 107032 Rev B

www.onicon.com • sales@onicon.com

07-18

Page 2

Model F-5400

Notice

This publication must be read in its entirety before performing any operation. Failure

and/or damage to the equipment. Should this equipment require repair or adjustment

to understand and follow these instructions could result in serious personal injury

beyond the procedures given herein, contact the factory at:

ONICON

11451 BELCHER ROAD SOUTH

LARGO, FL 33773

TELEPHONE: 727-447-6140

FAX: 727-442-5699

EMAIL: SERVICE@ONICON.COM

DISCLAIMER

Download Technical Data Sheets from our website:

www.onicon.com

ONICON believes that the information provided herein is accurate; however, be

advised that the information contained herein is NOT a guarantee for satisfactory

results. Specifically, this information is neither a warranty nor guarantee,

expressed or implied, regarding performance, merchantability, fitness, or any other

matter with respect to the products; nor recommendation for the use of the product/

process information in conflict with any patent. Please note that ONICON reserves

the right to change and/or improve the product design and specification without

notice.

ONICON F-5400 Manuals:

• ONICON F-5000 View™ Manual

All ONICON Manuals and software available in English only.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 2

Page 3

Table Of Contents

1. Introduction Page 5

a. Quick Start Guide Page 5

2. Installation (Mechanical) Page 9

a. Installation Depth Page 14

b. Orientation of Flowmeter Page 13

c. Rotating the Probe/Enclosure Page 14

d. Sensor Elements Page 14

e. Compression Fittings Page 16

3. Wiring (Electrical) Page 20

a. General Wiring Page 20

b. Signal Wiring Page 22

c. Pulse/Alarm Wiring (optional feature) Page 24

4. Operation (Standard Operation) Page 26

a. Start Up Page 8

5. Maintenance Page 27

a. Precautions Page 27

b. Troubleshooting Page 28

6. Appendices Page 32

a. Specifications Page 32

b. Agency Approvals Page 34

c. Dimensions Page 35

d. Warranty Page 35

e. Returning your meter Page 39

7. Glossary of Terms and Abbreviations Page 40

8. Index Page 41

Model F-5400

TABLE OF CONTENTS

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 3

Page 4

Model F-5400

Introduction: Safety Information

This sensor was calibrated at the factory before shipment. To ensure correct use of the sensor, please read

this manual thoroughly.

Regarding this Manual:

• This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without ONICON's written

permission.

• All reasonable effort has been made to ensure the accuracy of the contents of this manual. However, if any

errors are found, please inform ONICON.

• ONICON assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, ONICON assumes no responsibility

for any such harm owing to any defects in the product which were not predictable, or for any indirect

damages.

Safety Precautions:

DISCLAIMERINTRODUCTION

The following general safety precautions must be observed during all phases of installation, operation,

service, and repair of this product. Failure to comply with these precautions or with specific WARNINGS

given elsewhere in this manual violates safety standards of design, manufacture, and intended use of

the product . ONICON Incorporated assumes no liability for the customer's failure to comply with these

requirements. If this product is used in a manner not specified in this manual, the protection provided by

this product may be impaired.

The following symbols are used in this manual:

Messages identified as "Note" or "Important Note" contain information critical to the

i

proper operation of the product.

Messages identified as "Caution" (refer to accompanying documents) contain

information regarding potential damage to the product or other ancillary products.

Messages identified as "Warning" contain information regarding the personal safety of

individuals involved in the installation, operation or service of this product.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 4

Page 5

Model F-5400

Introduction: Quick Start Guide

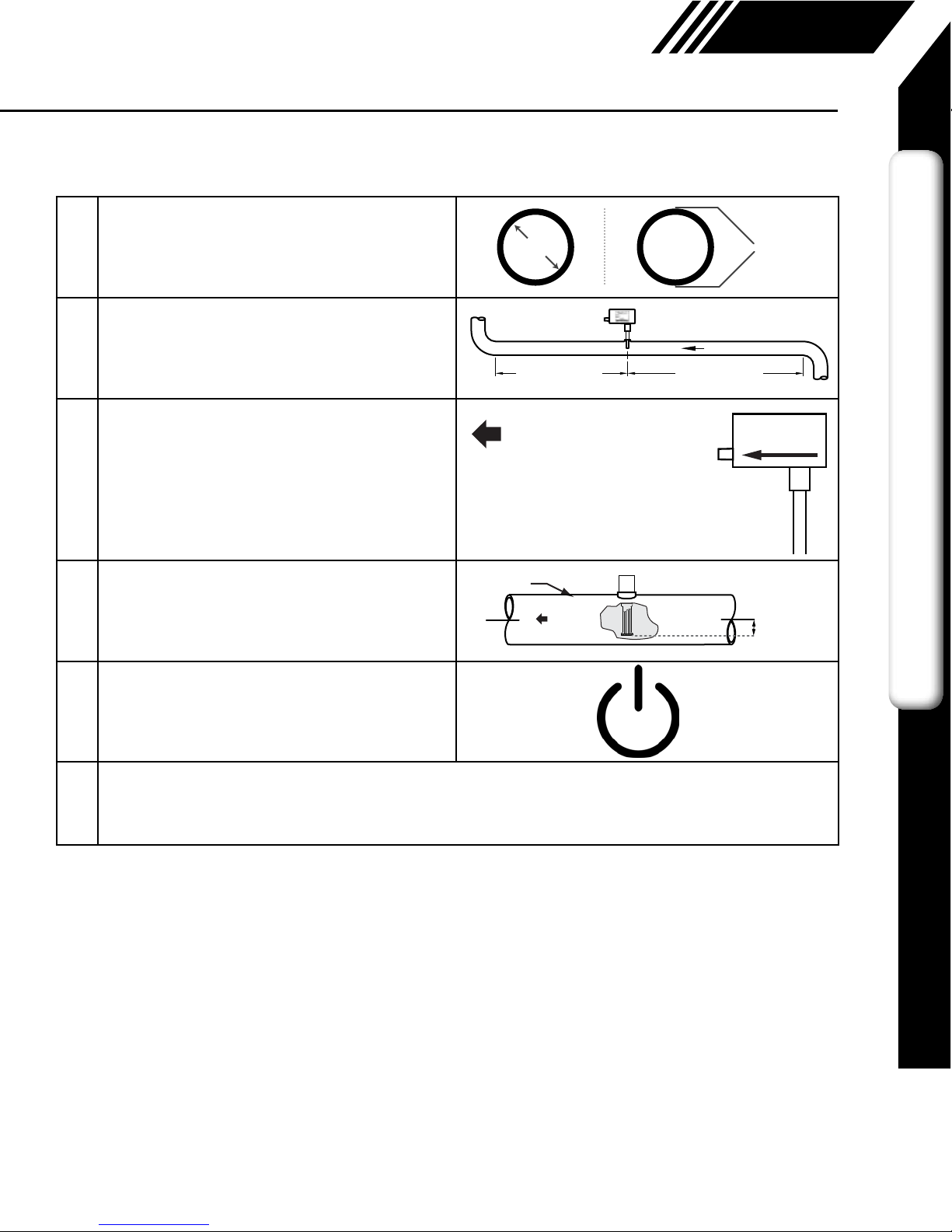

Use the table and images below as a guide while using the worksheet on the next page to record your notes.

Note: Please read the entire Quick-start procedure before beginning installation.

1. Record inside diameter (ID). Ensure the actual

pipe ID matches the pipe ID shown on the

factory calibration certificate.

2. Record upstream and downstream straight-pipe

requirements based on information in the tables

for either insertion (p. 13) or inline (p. 19).

3. The arrow on the enclosure indicates the

direction of flow.

INSIDE

DIAMETER (ID)

FLOW

Downstream Upstream

FLOW

OUTER

DIAMETER (OD)

INTRODUCTION

ARROW ON ENCLOSURE MUST

POINT IN DIRECTION OF FLOW

4. Ensure correct probe depth setting. If using 1 ½"

PIPE

size pipe, please see note on p. 14.

C

L

FLOW

0.73"

(18.5 mm)

5. Power on the flow meter

6. Check the remaining flow meter settings by accessing the meter settings by using the F-5000 View™

software tool. Record the settings in the spaces given for items A - D on the following page.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 5

Page 6

Model F-5400

Introduction: Quick Start Guide

Before powering on your meter, use this worksheet to record your notes.

Serial Number: Serial Number: Serial Number: Serial Number:

Item to verify

1. What is the Pipe ID? ID = ID = ID = ID =

2. Calculate the Upstream/

Downstream straight-pipe

requirements

3. Is the arrow on enclosure

pointed in direction of flow?

4. Is the probe depth setting

correct?

After powering on your meter, check items A - D below by accessing the meter settings through the F-5000

View software tool.

DISCLAIMERINTRODUCTION

A. Which flow units have been

set in meter? (SCFH, KG/H,

etc..)

B. Correct values for reference

temperature and pressure?

C. Confirm the pipe ID listed

above same as "Pipe_id="

D. Verify the 4mA and 20mA

meter settings

UP =

DN =

Y / N Y / N Y / N Y / N

Y / N Y / N Y / N Y / N

Y / N Y / N Y / N Y / N

4mA =

20mA =

UP =

DN =

4mA =

20mA =

UP =

DN =

4mA =

20mA =

UP =

DN =

4mA =

20mA =

Your Notes:

If you are experiencing any problems after completing this procedure, please call the ONICON Service

Department at 727-447-6140 to review this information.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 6

Page 7

Introduction

Model F-5400

Welcome

Product

Description

Thank you for purchasing the Model F-5400 Thermal Gas Mass Flow Meter from

ONICON. The Model F-5400 is one of the most technically advanced flow meters

in the world. An extensive engineering effort has been invested to deliver advanced

features, accurate measurement performance and outstanding reliability.

This Instruction Manual contains the electrical and mechanical installation instructions

as well as details for programming, maintaining and troubleshooting the meter.

This manual is divided into the following sections: Introduction, Installation, Wiring,

Operation, Maintenance, Troubleshooting, Appendices, Glossary and Index.

Theory of Operation

The Model F-5400 is an innovative Thermal Mass Gas Flow Meter and Temperature

Transmitter. It is microprocessor-based and field programmable. The F-5400 thermal

sensor operates on the law that gases absorb heat. A heated sensor placed in an air

or gas stream transfers heat in proportion to the stream’s mass velocity. There are

two sensor elements. One sensor element detects the gas temperature and a second

element is maintained at a constant temperature above the gas temperature. The

energy applied to the heated sensor to maintain a constant temperature differential

(constant ∆ T) is directly proportional to the mass flow velocity. The F-5400 flow

meter maintains accurate flow measurement over a large temperature and pressure

range.

INTRODUCTION

Mass Flow

DDC-Sensor™

Technology

Mass Flow

The Model F-5400 measures mass flow; an advantage over other flow meters which

measure volumetric flow. Volumetric flow is incomplete because temperature and

pressure are unknown and must be measured separately. For example, the mass

flow of a gas depends on its temperature and pressure. As temperature and pressure

changes, the gas volume changes but not its mass. Therefore a device measuring

mass flow is independent of temperature and pressure changes. The Model F-5400

provides a direct measurement of gas flow in Mass units (kg/hr, lb/hr), standard units

(SCFM, SLPM) or normal units (NM3/hr, NLPM) with no additional temperature or

pressure measurements required.

DDC-Sensor™ Technology Description

The ONICON DDC-Sensor™ is a new state of the art sensor technology used in the

ONICON Model F-5400 Thermal Gas Flow Meter. The DDC-Sensor™, a Direct Digitally

Controlled sensor, is unlike other thermal flow sensors available on the market.

Instead of using traditional analog circuitry, the DDC-Sensor™ is interfaced directly to

the F-5400 microprocessor for more speed and programmability. The DDC-Sensor™

quickly and accurately responds to changes in process variables by utilizing the

microprocessor to determine mass flow rate, totalized flow, and temperature.

ONICON’s DDC-Sensor™ provides a technology platform for calculating accurate gas

correlations.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 7

Page 8

Model F-5400

Introduction

Flow

Calibration

I/O Description

DISCLAIMERINTRODUCTION

Flow Calibration

The ONICON Calibration Lab maintains instrument calibration data on every flow meter.

Calibration files include details on process conditions, customer gas, line size and

other information. All NIST-traceable equipment utilized for the calibration procedure is

identified on the Calibration Certificate, which is sent with every flow meter.

Calibration records include details on process conditions, calibration fluid, line size and

other information. All NIST-traceable equipment utilized for the calibration procedure is

identified, as is the calibration history of all reference equipment.

In addition to the Calibration Certificate, a certified flow table that correlates current

outputs with scaled units of flow is produced for each calibrated device.

I/O Description

The F-5400 features a galvanically isolated 4-20mA analog output and a second output

for pulse. There is also a mini USB port for interfacing with a laptop or computer. The

4-20mA output can be configured for flow rate or process gas temperature and can be

scaled by the user. The pulse output can be used for pulse or alarm, is programmable

to represent flow rate and can be scaled for units per pulse at a maximum pulse output

frequency of 1Hz.

i

USB Interface

F-5000 View™ interfaces to the USB port and is a free PC-based software program

that displays flow meter readings and permits flow meter configuration. The optional

D-100 flow display provides a local indication of rate and total and a network interface

for BACnet, MODBUS, LonWorks, JCI - N2 or Siemens - P1 FLN networks.

Note: The latest version of the F-5000 View software is available for download at http://

www.onicon.com/F5500.html.

USB Interface

The mini USB interface is a standard feature which allows communication with a

PC to monitor readings and configure settings. F-5000 View, is a free application

program from ONICON that connects to the USB interface and allows data monitoring,

configuration setting, data logging to Excel, and an option to save and recall F-5400

configuration data.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 8

Page 9

Installation: General

Model F-5400

Installation Model F-5400

Flow Meter

Scope

This section describes how to install the ONICON Model F-5400 Flow Meter and how to

get started:

1. Determine lateral position on the pipe

2. Ensure correct orientation of the meter and check alignment of the sensor elements

3. Determine the installation depth of the probe

4. Tighten compression fitting to complete installation

Installation procedures must be performed using a combination of the end user’s

best engineering practices, in compliance with local codes, and manufacturer’s

recommendations.

General Precautions

The following general precautions should be observed:

1. Exercise care when handling the flow meter to avoid damaging the probe, sensor or

enclosure.

2. The enclosure cover must be closed except during installation or configuration.

3. Mounting F-5400 in direct sunlight can cause the temperature inside the enclosure

to increase beyond design limits, resulting in reduced component life. It is

recommended that a sunshade be installed to avoid direct sunlight (see maximum

enclosure operating temperature specification on p. 33).

4. Ensure the arrow on the meter enclosure is in line with the direction of flow in the

pipe.

5. Do not install the F-5400 enclosure near an igniter, igniter-controller or switching

equipment.

6. Do not install an external power supply in a cabinet containing an igniter controller or

switching equipment.

7. For accurate flow measurement: review flow meter placement instructions before

installation to ensure a proper flow profile in the pipe.

INSTALLATION

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 9

Page 10

Model F-5400

Installation: Insertion Type

Insertion Flow

Meter Lateral

Placement

INSTALLATION

i

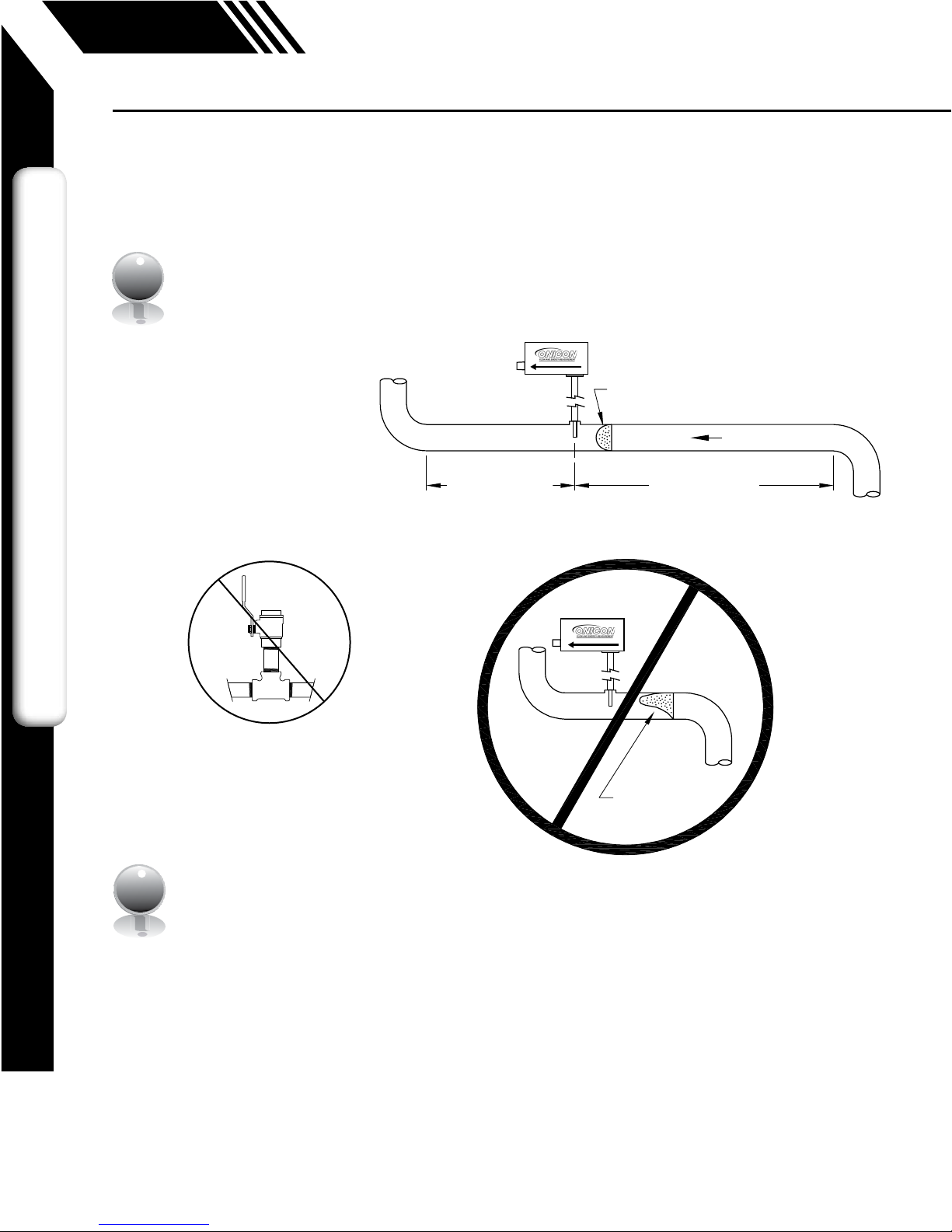

Instructions for Insertion Flow Meter Lateral Placement

Install the Model F-5400 Insertion style flow meter so that it is far enough away from

bends in the pipe, obstructions, or changes in line sizes to ensure a consistent flow

profile. Review the straight run requirements table on p. 13.

Note: The probe diameter is ¾".

Fig. 2.1: Upstream and Downstream Pipe IDs for Insertion Meters

Proper

Flow

Prole

FLOW

Downstream

Upstream

Do not substitute threaded tees for

the welded branch outlet. Contact

ONICON if you need installation

hardware for threaded pipe.

Irregular Flow

Prole

Note: An irregular flow profile may affect sensor accuracy.

i

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 10

Page 11

Installation: Insertion Type

Model F-5400

Installation

Hardware

Installation Hardware

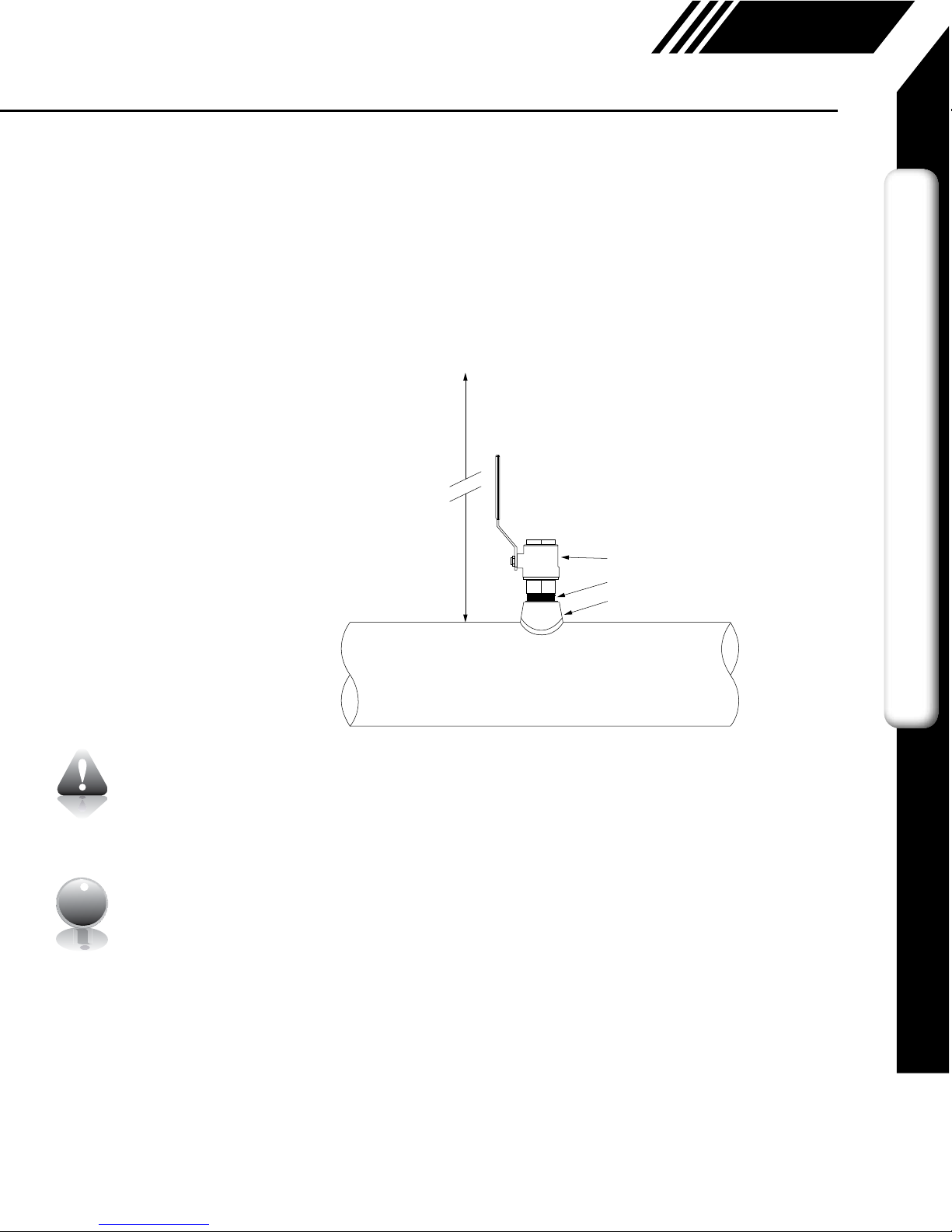

ONICON F-5400 Insertion Thermal Mass Flow Meters employ a process adapter

fitting design that allows for insertion and removal without interrupting flow. To take

advantage of this feature, the flow meter must be installed through an isolation valve.

The installation must allow for sufficient overhead clearance to fully extract the meter,

and a full 7/8" hole in the pipe wall is required to clear the sensor head and allow for

insertion. Make sure that your valves and fittings are full port and at least 1" in actual

internal diameter.

Fig. 2.2: Installation Requirements

Standard Installation

Kit for Steel Pipe

CLEARANCE

REQUIRED

FOR INSTALLATION

Typically 30” - 40”

depending on pipe size and

height of valve

assembly.

1” Full Port Ball Valve

1” Close Nipple

1” Branch Outlet

INSTALLATION

i

Flow

Conditioners

Minimum Hole Size = 7/8”

Must be centered

Caution: ONICON insertion style flow meters must be installed through a valve

assembly. Failure to do so negates the ability to remove the meter without shutting

down and purging the system. It will also result in an excessive amount of stem

protruding from the pipe. Excessive stem lengths unnecessarily expose the meter to

incidental damage.

Important Note: Flow meters installed through oversized access holes will be subjected

to undesirable turbulence that may affect the accuracy of the meter.

Flow Conditioners

Flow conditioners may be required when an insufficient straight run of pipe is available

upstream of the proposed sensor location. ONICON provides flow conditioners as an

optional accessory.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 11

Page 12

Flow

Minumum upstream

straight run distance

with conditioner

Minumum

downstream

straight run

distance

Minumum upstream

straight run distance

without conditioner

A

Optional

Flow Conditioner

Model F-5400

Installation: Insertion Type

Optional Flow

Conditioners

INSTALLATION

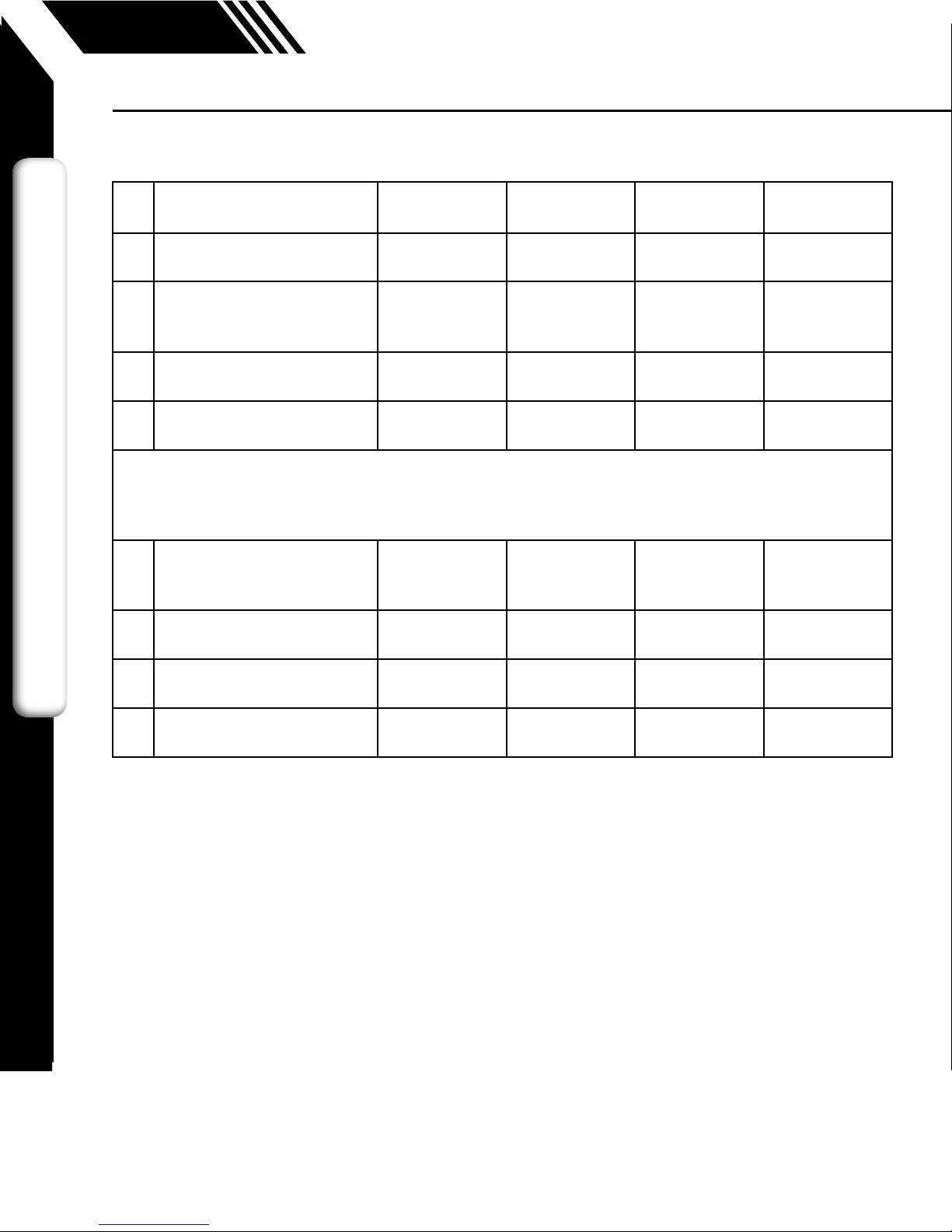

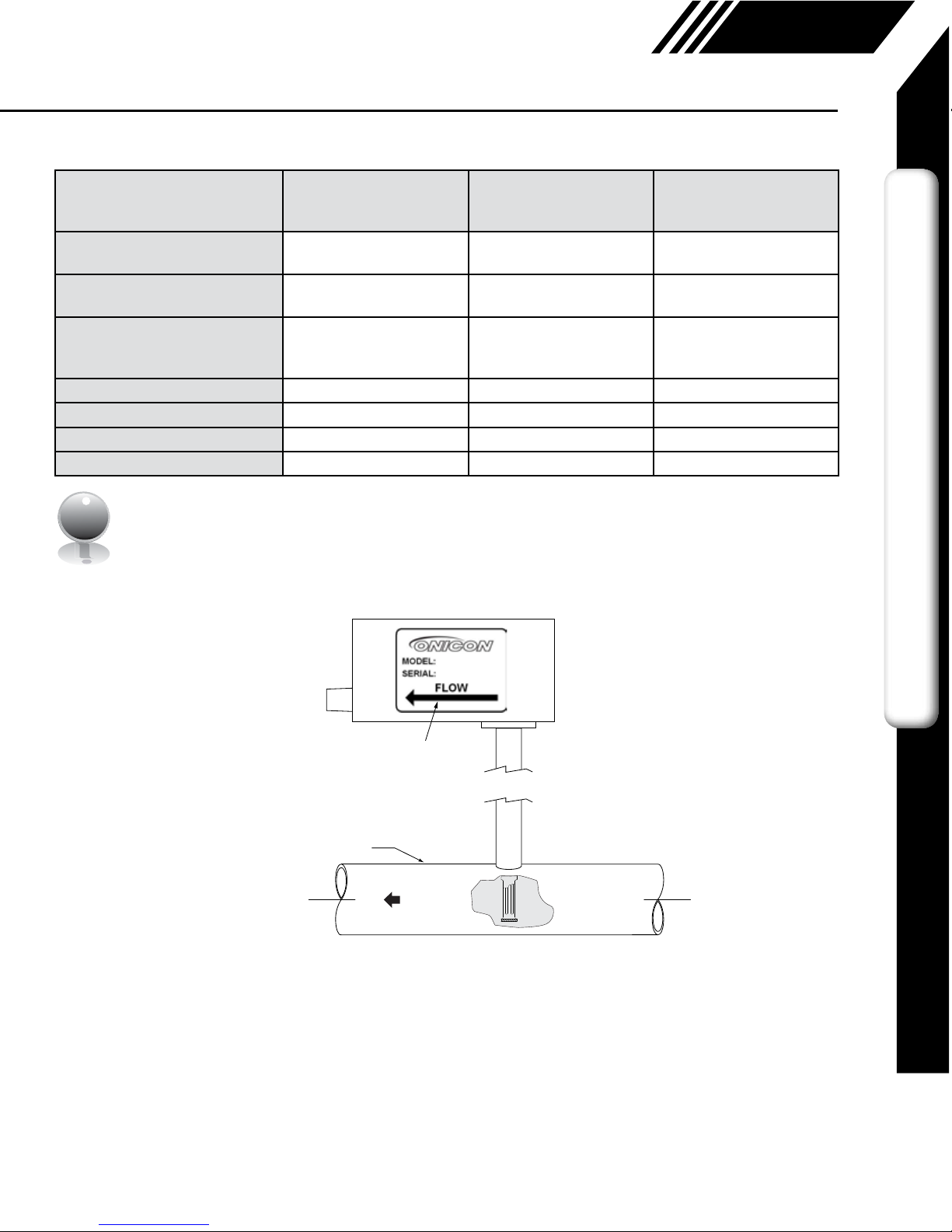

Fig. 2.3: Placement of Optional Flow Conditioners in Pipe

A

Schedule 40 Flow Conditioners

Nom. Dia. Dimension A

Flow

Flow conditioning

assembly inserted

here

ANSI class flanges

(user supplied)

1½" 6.00"

2" 6.00"

2½" 9.00"

3" 9.00"

4" 9.00"

6" 12.00"

ONICON flow conditioners are designed to be installed between two flanges (provided

by installer) that are located a specific distance upstream of the flow sensor. The use

of flow conditioners significantly reduces the upstream straight pipe length requirement

for flow sensor. The size of the flow conditioner must match the pipe size.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 12

Page 13

Installation: Insertion Type

Fig. 2.4: Straight Run Requirements for Upstream Obstructions - Insertion

Model F-5400

Straight run required

Upstream obstruction

Single bend preceded by ≥ 9

diameters of straight pipe

Pipe size reduction in straight pipe

run

Multiple bends in plane with < 9

diameters of straight pipe between

them

Pipe size expansion in straight run 30 Diameters 10 Diameters 5 Diameters

Tees 30 Diameters 10 Diameters 5 Diameters

Multiple bends out of pipe 40 Diameters 10 Diameters 5 Diameters

Modulating or regulating valve 40 Diameters 10 Diameters 5 Diameters

upstream of meter location

without flow conditioner

15 Diameters 3 Diameters 5 Diameters

15 Diameters 3 Diameters 5 Diameters

20 Diameters 9 Diameters 5 Diameters

Straight run required

upstream of flow

conditioner mounting flange

Straight run required

downstream of meter

location

Important Note: Always use the maximum available straight run. When more than

i

the minimum required straight run is available place the meter such that the excess

straight run is upstream of the meter location.

Sensor

Fig. 2.5: Orientation of Flow Meter

Orientation

Direction of

Flow

INSTALLATION

ARROW ON ENCLOSURE

INDICATES DIRECTION OF

FLOW

PIPE

FLOW

Install the meter with the flow direction arrow on the enclosure pointing in the direction

of flow in the pipe.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 13

Page 14

Model F-5400

Installation: Insertion Type

Sensor

Element

Alignment

INSTALLATION

Installing the

Sensor

Sensor Elements

Every F-5400 flowmeter is equipped with equal length sensor elements. To be sure that

the flowmeter elements are lined up correctly in the process stream, please refer to

"Fig. 2.5: Orientation of Flow Meter" on page 13 and be sure that the Flow Direction

Indicator is pointing in the direction of flow in the pipe.

Fig. 2.6: Sensor Elements

+5°

FLOW

FLOW

-5°

Note: Rotational misalignment should not exceed ±5°.

Installing the Sensor

There are two different versions of the insertion style F-5400. The standard version

and the high pressure version are shown below.

Fig. 2.7a: Standard F-5400

The standard version of the F-5400

is hand insertable into pipes with

operating pressures up to 60 psig.

Fig. 2.7b: High Pressure F-5400

"X"

The high pressure version of the F-5400 is hand insertable

up to 100 psig. For applications above 100 psig, it is

necessary to isolate flow and relieve pressure before

attempting to install or remove the meter. The maximum

operating pressure for this version of the meter is 150 psig.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 14

Page 15

Installation: Insertion Type

Model F-5400

Installation

Procedure

Installation Procedure

The installation depth of the sensor in the pipe is dependent on the pipe size. To get the most

accurate reading, proper placement of the sensor window within the pipe is necessary. Use

the following procedure to determine the proper depth setting for your meter. The procedure is

valid for nominal pipe sizes 1.5" through 8". The maximum allowable height of the installation

hardware (branch outlet, close nipple & ball valve) is 6" as measured from the outside wall of

the pipe to the top of the valve. Procedure:

1. Locate the pipe inside diameter (ID) listed on the calibration information label on the side of

the flow meter enclosure. This information is also available on the calibration certificate.

2. Confirm that this ID corresponds to the nominal diameter of the pipe where the meter is

installed.

a. To determine the nominal pipe size, measure the circumference of the pipe without the

insulation and divide this value by pi (3.14). This will give you the outside diameter (OD).

b. Use the table below to locate the nominal pipe size and ID based on the OD

c. The table provides dimensions for common schedule 40 and schedule 80 pipes.

d. Contact ONICON for assistance if your pipe dimensions are not shown.

3. Once the ID is confirmed, prepare to insert the flow sensor by ensuring the compression

fitting is loose.

4. Thread the process adapter fitting on to the ball valve and tighten. Use the appropriate

thread sealant, as required, to ensure a leak free connection.

5. Open the ball valve and carefully insert the flow sensor until the end of the stem just

contacts the opposite wall of the pipe.

6. Mark the position of the stem where it exits the top of the compression fitting.

7. Withdraw the stem "X" distance as measured from the top of the compression fitting. At the

same time, position the electronics enclosure parallel to the pipe in the correct orientation

relative to the flow direction as shown in "Fig. 2.5: Orientation of Flow Meter" on page 13.

This will position the sensor with its axis in line with the flow and in the correct direction.

8. Read the instructions on the next page before tightening the compression fitting.

- - FOR METERS WITH THE HIGH PRESSURE SAFETY CABLE - -

9. Once the compression fitting is tight, attach the safety cable using the capture nut provided.

10. If necessary, rotate the top clamp to re-align the cable with the bottom clamp. When

rotating the clamp, make sure that it remains at the top of the stem pressed firmly against

the spacer. (see appendices for details)

* refer to model number coding to determine the stem length of your meter.

INSTALLATION

Nominal Dia. OD

1 ½" 1.900" 1.610" 1.500" Always Use 0.1" 15"

2" 2.375" 2.067" 1.939" 0.304" 0.240" 15"

2 ½" 2.875" 2.469" 2.323" 0.505" 0.432" 15"

3" 3.500" 3.068" 2.900" 0.804" 0.720" 15"

4" 4.500" 4.026" 3.826" 1.283" 1.183" 15"

6" 6.625" 6.065" 5.761" 2.303" 2.151" 18"

8" 8.625" 7.981" 7.625" 3.261" 3.083" 18"

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 15

ID X

Sch. 40 Sch. 80 Sch. 40 Sch. 80

Min. Stem

Length*

Page 16

Model F-5400

Installation: Insertion Type

Compression

Fittings

INSTALLATION

Compression Fittings

While holding the fitting body steady, finger tighten the nut. Then, tighten the nut with

wrenches an additional one and one-quarter (1 ¼) turn. If beginning at 6 o'clock, the

wrench would make one full turn back to 6 o'clock and rest at the 9 o'clock position for

proper compression. See Figure 2.8 below.

Caution: Tightening the compression fitting will crimp the fitting to the stem of the flow

meter and lock the depth setting into place. Don’t tighten the compression fitting until

you’ve completed all steps in the installation section of this manual.

Fig. 2.8: Proper Tightening of the Compression Fitting Nut

Removing the

Meter

Removal of the Meter

Follow these instructions for safe removal of the meter from the pipe.

WARNING: SYSTEM MAY BE UNDER HIGH PRESSURE.

Do not attempt to remove meters with the standard process adapter fitting from any

piping system operating at pressures above 60psig without first relieving pressure in the

pipe.

Do not attempt to remove any meter with the high pressure process adapter fitting and

cable assembly operating at pressures above 100 psig without first relieving pressure in

the pipe.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 16

Page 17

Installation: Insertion Type

Model F-5400

Removing the

Meter

When removing the flow meter, be sure to hold the electronics enclosure firmly by

hand before unscrewing the compression fitting nut. Failure to do this will allow the

pressure in the pipe to suddenly and rapidly force the meter from the pipe potentially

causing serious injury. The meter could

also be damaged or break apart causing

a break in the seal with the resultant loss

of fluid from the piping system. The hand

effort required to hold the meter will be

0.44 times the pipe pressure.

Procedure:

1. Slowly unscrew the compression

fitting nut while maintaining a firm

grip on the enclosure to counteract

the effect of pressure in the pipe.

2. Once the nut is fully disengaged

from the threads, the meter will be

free to move. Carefully withdraw the

flow meter stem from the pipe until

the sensor head is fully inside the

process adapter fitting.

3. After the meter is completely

withdrawn, slowly close the valve to isolate flow.

Compression tting

Compression tting

nut

Process adapter

tting

Ball valve

INSTALLATION

i

i

NOTE: At this point, the piping system is isolated, but the process adapter fitting

will contain a small volume of process fluid under pressure.

4. After the valve is completely closed, slowly unscrew the compression fitting from

the top of the process adapter fitting leaving the adapter fitting on the ball valve.

NOTE: As the compression fitting is removed, pressure will be vented from the ball

valve.

5. For meters provided with the high pressure adapter fitting, disconnect the safety

cable at the bottom by removing the capture nut. Be sure to fully re-attach the nut

to the cable once the meter is removed from the pipe.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 17

Page 18

Model F-5400

Installation: Inline Type

Flow Meter

Placement

Inline Type

INSTALLATION

Instructions for Inline Flow Meter Placement

Install the Model F-5400 Inline style flow meter so that it is far enough away from

bends in the pipe, obstructions, or changes in line sizes to ensure a consistent flow

profile. Review the straight run requirements table on p. 19.

The Model F-5400 is threaded or flanged to the customer’s pipe. Care should be

taken to ensure that the diameter of the mating pipe is the same diameter as the Model

F-5400 flow body or errors in flow readings can occur. The installation procedure

should be a combination of the end user’s best engineering practices, in compliance

with local codes, and the manufacturer’s recommendations.

See "Fig. 2.10: Straight Run Requirements for Upstream Obstructions - Inline" on page

19 for a detailed look at upstream and downstream pipe diameters for inline meters.

Fig. 2.9: Upstream and Downstream Pipe IDs for Inline Meters

Proper

Flow

Prole

FLOW

Downstream

Upstream

Irregular Flow

Prole

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 18

Page 19

Installation: Inline Type

Model F-5400

Upstream

Fig. 2.10: Straight Run Requirements for Upstream Obstructions - Inline

Obstructions

Minimum straight run required upstream of flow meter process connection based

Upstream obstruction

Single bend preceded by ≥ 9 diameters

of straight pipe OR Pipe size reduction in

straight pipe run

Multiple bends in plane with < 9

diameters of straight pipe between them

OR Pipe size expansion in straight run

Tees 7.5" 10" 12.5" 15" 20" 25" 30" 40" 60"

Multiple bends out of plane 7.5" 10" 12.5" 15" 20" 25" 30" 40" 60"

Modulating or regulating valves OR

Diaphragm or roots type utility meters

Flow Body

Orientation

Inline Type

Inline Orientation

Install the flow body so that the arrow on the enclosure is pointing in the direction of

flow.

on the nature of the upstream obstruction

¾" 1" 1 ¼" 1 ½" 2" 2 ½" 3" 4" 6"

2.25" 3" 3.75" 4.5" 6" 7.5" 9" 12" 18"

6.75" 9" 11.25" 13.5" 18" 22.5" 27" 36" 54"

9" 12" 15" 18" 24" 30" 36" 48 72"

Minimum downstream straight run required after flow meter process connection

2.25" 3" 3.75" 4.5" 6" 7.5" 9" 12" 18"

INSTALLATION

i

Fig. 2.11: Orientation of an Inline Meter - Flow Direction Indicator

ARROW ON ENCLOSURE

INDICATES DIRECTION OF

FLOW

Flow Body

FLOW

Note: ONICON does not supply gaskets for this product.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 19

Page 20

Model F-5400

Wiring: General

Precautions

INSTALLATION

Wiring Instructions

The F-5400 is provided with a 10ft unterminated cable for field wiring connections.

This cable is not designed to be removed in the field.

Make all connections to the attached 10ft. cable.

The most common causes of electronic failures are miswired connections during

installation. When adding additional cable, record and carefully document any

substitution of wire colors. Additional cable may be purchased from ONICON that will

allow you to maintain the existing color coding.

The cable provided contains 22 AWG color-coded wires for signal and power.

CAUTION: Do not attempt to remove the existing cable or to remove the factoryinstalled connection fitting. Doing so will compromise the weather tight integrity of the

enclosure and may void the warranty.

Wiring Precautions - WARNING:

• Do not open the enclosure when energized or an explosive atmosphere is present.

• Connect earth ground to the green earth wire provided in the cable to reduce the

potential of an electrostatic charging hazard.

• All plumbing and electrical installations of flow meters must be in compliance

with local codes, the end user’s best engineering practices, and manufacturer’s

recommendations.

• Do not install the F-5400 enclosure near an igniter, igniter-controller or switching

equipment to eliminate the possibility of noise interference.

• Do not install an external power supply in a cabinet containing an igniter controller or

switching equipment.

• This flow meter contains components that can be damaged by static electricity. You

must discharge yourself by touching a grounded steel pipe or other grounded metal

prior to working inside this flow meter.

CAUTION: Only qualified personnel should attempt to make electrical connections to

the F-5400. Failure to properly connect the F-5400 power or signal connections may

result in damage to the F-5400 and/or to associated peripheral equipment.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 20

Page 21

Wiring: Power and Signal Wiring

Model F-5400

Signal and Power

Wiring

Output

signal(s) to

control

system

Allow enough slack in the

flexible conduit to permit

the meter to be removed

from the valve.

Fig. 3.1: Signal and Power Wiring Connections

Customer provided

conduit and adapters

ONICON

Display

(Optional)

½” FNPT

conduit connection

INSTALLATION

FLOW

Wire Color Description

Red (+) Power supply 12 to 28VDC, 6 Watts

Black ( - ) Power supply common

Green Chassis Ground

4-20mA Analog Output (Loop Powered)

Blue (+) VDC (12-28 VDC) External supply voltage

Brown (+) Isolated 4-20mA analog output

Pulse Output

White (+) Pulse output, isolated open collector output, 12-28VDC @ 10mA maximum

Orange ( - ) Pulse output

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 21

Page 22

Model F-5400

Wiring: Signal Wiring

4-20mA Loop

Power Provided

by Customer

(Recommended)

WIRING

4-20mA Output Wiring: Customer-Supplied Power Source

Connect 4-20mA wiring as shown in the diagram below.

Fig. 3.2: 4-20mA Output Wiring for Customer-Supplied Power Source

Customer PLC or DCS

+12 to 28VDC

4-20mA Flow Rate or Temperature

250 ohms typical with 28VDC Power

125 ohms or less for 12VDC Power

*(see notes below)

12 to 28VDC Return

F-5400 Factory Installed Cable

Blue

+

-

Brown

Important Notes:

i

• When using a 12 volt power supply, the load resistor on the 4-20mA

output must be 125 ohms or less to operate properly.

• When using 24 volt power, the load resistor is typically 250 ohms. A 250

ohm resistor in the 4-20mA circuit will result in a 1 to 5 volt signal to the

PLC or DCS.

• When using a 24 volt power supply, the load resistor on the 4-20mA

output must be 600 ohms or less.

• Some PLC and DCS equipment have built in load resistors, please refer to

the technical manuals of such equipment.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 22

Page 23

Wiring: Signal Wiring

Model F-5400

4-20mA Loop

Power Provided

by F-5400

Customer PLC or DCS

+12 to 28VDC

12 to 28VDC Return

4-20mA Flow Rate or Temperature

250 ohms typical with 28VDC Power

125 ohms or less for 12VDC Power

*(see notes below)

4-20mA Output Wiring: Loop Power Provided by F-5400

Connect 4-20mA wiring as shown in the diagram below.

Fig. 3.3: 4-20mA Output Wiring for Loop Power Provided by F-5400

F-5400 Factory Installed Cable

Red

Black

Blue

Brown

+

-

WIRING

Important Notes:

i

• When using a 12 volt power supply, the load resistor on the 4-20mA

output must be 125 ohms or less to operate properly.

• When using 24 volt power, the load resistor is typically 250 ohms. A 250

ohm resistor in the 4-20mA circuit will result in a 1 to 5 volt signal to the

PLC or DCS.

• When using a 24 volt power supply, the load resistor on the 4-20mA

output must be 600 ohms or less.

• Some PLC and DCS equipment have built in load resistors, please refer to

the technical manuals of such equipment.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 23

Page 24

Model F-5400

Model F-5400

Wiring: Pulse/Alarm Wiring

Pulse/Alarm

Output Wiring:

WIRING

WIRING

Pulse/Alarm Output Wiring: Customer Supplied Power Source (Recommended)

Connect pulse/alarm wiring as shown in the diagram below. The pulse/alarm output

is an open collector circuit capable of sinking a maximum of 10mA of current. Pulse

or alarm selection is programmed using the F-5000 View software. Only one option,

pulse or alarm, can be active at a time. The pulse output is normally low (open

collector output closed) and pulses high +12 to 24VDC (open collector output open)

for 500 milliseconds when the total flow is measured. The maximum frequency setting

of the pulse output is 1 Hz.

When the output is configured for Alarm, the output will be low (open collector closed)

when there is no alarm and high +12 to 24VDC (open collector output open) when an

alarm is present.

Fig. 3.4: Pulse/Alarm Output Isolated (Recommended)

Customer PLC or DCS

+12 to 28VDC

2.4K Ohm typical with 24VDC Power

1.2K Ohm typical with 12VDC Power

F-5400 Factory Installed Cable

i

Pulse or Alarm

Output

12 to 28VDC Return

Important Notes:

• The F-5400 Pulse/Alarm output is typically used to drive digital circuitry or

solid-state relays. The output of a solid state relay may, in turn, operate loads

such as electromechanical relays or alarm indicators.

• The maximum load current of the Pulse/Alarm output is 10mA. Choose a load

resistance that provides approximately 10mA with the power supply operating

voltage.

+

-

White

Orange

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 24

Page 25

Wiring: Pulse/Alarm Wiring

Model F-5400

Pulse/Alarm

Output Wiring

2.4K Ohm typical with 24VDC Power

1.2K Ohm typical with 12VDC Power

Pulse/Alarm Output Wiring: Power Provided by F-5400

Connect pulse/alarm wiring as shown in the diagram below. The pulse/alarm output

is an open collector circuit capable of sinking a maximum of 10mA of current. Pulse

or alarm selection is programmed using the F-5000 View software. Only one option,

pulse or alarm, can be active at a time.

When the output is configured for Alarm, the output will be low (open collector closed)

when there is no alarm and high +12 to 24VDC (open collector output open) when an

alarm is present.

Fig. 3.5: Pulse/Alarm Output Power Provided by F-5400

Customer PLC or DCS

+12 to 28VDC

12 to 28VDC Return

F-5400 Factory Installed Cable

Red

Black

WIRING

i

Pulse or Alarm

Output

+

-

White

Orange

Important Notes:

• The F-5400 Pulse/Alarm output is typically used to drive digital circuitry or

solid-state relays. The output of a solid state relay may, in turn, operate

loads such as electromechanical relays or alarm indicators.

• The maximum load current of the Pulse/Alarm output is 10mA. Choose a

load resistance that provides approximately 10mA with the power supply

operating voltage.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 25

Page 26

Model F-5400

Operation: Start Up

Start Up

Sequence

Programming

F-5400 Settings

OPERATION

i

Start Up Sequence

The F-5400 automatically enters the Run/Measure mode, measures gas flow and

transmits measurement data after power up.

Programming and Configuring Flow Meter and Flow Meter Settings

The F-5400 is a field configurable flow meter. To access the flow meter settings, open

the cover of the enclosure and use the mini USB port to connect the flow meter to

a PC or laptop. Download and run the F-5000 View software while connected to the

F-5400 USB port.

Please refer to the F-5000 View Manual for specific instructions on the function and

usage of the software to configure your meter.

Note: The latest version of the F-5000 View software is available for download at www.

onicon.com/5400 or www.onicon.com/5500.

Fig. 4.1: Locating the Mini USB Port

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 09/16 - 2031 / 107032 Page 26

Page 27

Maintenance: Precautions/General

PRECAUTIONS

WARNING! BEFORE ATTEMPTING ANY MAINTENANCE, TAKE THE NECESSARY SAFETY

PRECAUTIONS BEFORE REMOVING THE PROBE FROM THE DUCT (EXAMPLE: PURGE

LINES OF TOXIC AND/OR EXPLOSIVE GAS, DEPRESSURIZE, ETC...).

WARNING! EXPLOSION HAZARD. DO NOT REMOVE OR REPLACE COMPONENTS

OR FUSES UNLESS POWER HAS BEEN DISCONNECTED WHEN A FLAMMABLE OR

COMBUSTIBLE ATMOSPHERE IS PRESENT.

WARNING! EXPLOSION HAZARD. DO NOT DISCONNECT EQUIPMENT WHEN A

FLAMMABLE OR COMBUSTIBLE ATMOSPHERE IS PRESENT.

Access to Electronics

Accessing electronics is not normally required for maintenance purposes. If a loose

connection is suspected, open the cover of the meter to access the wiring terminations.

CAUTION: BE SURE POWER TO METER IS SWITCHED OFF BEFORE ATTEMPTING TO

ACCESS ELECTRONICS. If there is a problem and a loose connection is not found, please

contact ONICON Customer Service for technical assistance at 727-447-6140.

Model F-5400

MAINTENANCE

Broken or Damaged Probe

If the sensor is broken or damaged, the probe and electronics must be returned to the

factory. A new sensor will be installed and calibrated. Refer to "Returning Your Meter" on

p. 39.

Flow Calibration

To ensure continued high accuracy of your Model F-5400 Flow Meter, ONICON Inc.

provides a full NIST traceable calibration.

Fuse Replacement

Warning! Turn input power OFF before removing or installing a fuse. Use only

recommended fuse replacements.

Verify the fuse is defective by measuring it with an Ohm Meter (Two replacement fuses are

provided with each unit). Replacement fuse is Littelfuse part number 0454.750MR

To replace the fuse:

The fuse F1 is located near the power terminal block and can be removed by using

tweezers or needle-nose pliers.

Sensor Cleaning

The sensor is insensitive to small amounts of residue, but continued use in dirty

environments will necessitate periodic cleaning. To inspect the sensor, remove power

from electronics and remove the unit from the pipe or duct, exposing the sensor elements.

If they are visibly dirty, clean them with water or alcohol (ethanol) using an appropriate

brush until they appear clean again. Even though the sensor elements are rugged, avoid

touching them with any solid object and use a light touch while cleaning them.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 09/16 - 2031 / 107032 Page 27

Page 28

Model F-5400

Model F-5400

Troubleshooting: General

Troubleshooting

Problem Possible Cause(s) Action(s)

Flow measurement

seems low

Unit will not power-up 1. No power input

Troubleshooting

Caution! The electronics and sensor supplied by ONICON are calibrated as a single

precision mass flow meter. Interchanging sensors will decrease the accuracy of the

flow meter. If you experience any problem with your Model F-5400 Flow meter, call

ONICON Customer Service Department, Technical Assistance at 727-447-6140.

LED Indicators

The LED indicator near the terminal blocks of the F-5400 electronics board show the

status of the F-5400. The Heartbeat LED blinks fast when the F-5400 is powered up,

and blinks about once a second when the F-5400 operates normally.

1. Probe not oriented properly

2. Sensor dirty

2. Bad fuse

MAINTENANCE

3. Bad Power supply

TROUBLESHOOTING

1. Orient probe per Insertion installation section

(p. 10)

2. Clean sensor (p. 27)

1. Check fuse (F1) located next to TS1 on main

board.

2. Check for correct power supply voltage at

TS1 on main board.

If fuse is OK and unit still won’t power up, call

ONICON for additional assistance

Meter resets 1. Intermittent power

2. Electromagnetic

interference (EMI)

Flow measurement is

erratic or fluctuating

1. Very turbulent flow

2. Sensor dirty

3. Sensor broken

4. Probe not mounted

securely

5. Malfunction in flow meter

6. Meter installed incorrectly

1. Measure the power input voltage

2. Check Power input and output cables

grounding and routing.

1. Increase dampening (see filter settings in the

F-5000 View Manual)

2. Clean sensor (Refer to Maintenance section,

p. 27)

3. Return flow meter to ONICON for repair

(Refer to p. 39 for shipping instructions)

4. Remount probe (see Installation section, p.

10); must be mounted securely without

vibration. If vibration persists, choose a new

mounting location without vibration.

5. Return flow meter to ONICON for repair

(Refer to p. 39 for shipping instructions)

6. Re-install meter according to instructions

(Refer to installation section, p. 10)

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107023 Page 28

Page 29

Troubleshooting: Installation Problems

Model F-5400

Model F-5400

Installation

Problems

Installation Problems

The following is a summary listing of problems that may be encountered with the

installation of the F-5400 Thermal Mass Flow Meter.

Improper wiring connections for power and/or 4-20mA output signal.

1.

A separate power source is recommended for the F-5400 main board and the

4-20mA output signals. Two wires supply 24VDC power to the main board. Two

wires are used for the 4-20mA output signals. Refer to wiring section (p. 20) for

further guidance.

Inadequate power source.

2.

The F-5400 requires 12 to 28VDC at up to 6 Watts to operate. A 20 Watt power

supply is recommended for powering the F-5400 to ensure it operates properly

under all conditions. If the voltage supplied at the input terminals of the F-5400 is

not within the range, a variety of problems will occur.

Flow measurement seems inaccurate.

3.

• Check to ensure that the flow meter is installed so that the arrow on the

enclosure is pointed in the direction of flow. Refer to Figure 2.5 (p. 13). If

not, change orientation of meter.

• Check that the insertion depth of the sensor/probe is correct. The end of the

probe should be adjusted as per Figure 2.7 (p. 14).

TROUBLESHOOTING

TROUBLESHOOTING

• Ensure that the proper upstream and downstream pipe requirements have

been met. Use "Fig. 2.1: Upstream and Downstream Pipe IDs for Insertion

Meters" on page 10 and "Fig. 2.4: Straight Run Requirements for Upstream

Obstructions - Insertion" on page 13 to determine the required lengths.

If complex flow disturbances are upstream of the sensor, extension of the

straight pipe may be required to ensure accurate flow measurement. Contact

ONICON for assistance.

• Ensure that pipe inside diameter in the meter matches data on the ONICON

Calibration Certificate. The pipe inside diameter is programmed into the flow

meter using the F-5000 View software.

Erratic flow reading (especially a flow reading spiking high).

4.

This may be a symptom of moisture in the flow stream. ONICON flow meters

are designed to work in relatively dry gas applications only. Contact ONICON to

discuss resolutions to this problem.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 29

Page 30

Model F-5100

Model F-5400

Troubleshooting: Installation Problems

5.

Installation

Problems

Flow meter is not responding to flow.

• Check to ensure adequate power is supplied to the flow meter. If

things appear to be correct, perform this functional test before calling

ONICON. Carefully remove the probe and sensor from the pipe. Blow

on the sensor to see if a response occurs. If nothing happens, take

a damp rag or sponge and place it in contact with the sensor. A

reading should occur. Contact ONICON Customer Service with this

information.

Display and/or 4-20mA signal reading above zero flow when no flow is

6.

occurring in the pipe.

If the reading is less than 5% of full scale, it is likely this is a normal

condition caused by convection flow created by the heated sensor. It does

not mean that the zero of the instrument is improperly set. The ONICON

sensor is extremely sensitive to gas flow and can even read the small flow

caused by convection. If this is an unacceptable condition, please contact

ONICON Customer Service for alternatives.

TROUBLESHOOTING

TROUBLESHOOTING

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 30

Page 31

Troubleshooting: Alarm Codes

Model F-5100

Model F-5400

Alarm Codes

Precautions

Alarm

Code

13 Flow rate above high

limits

14 Flow rate below low

limits

15 Temperature above high

limits

16 Temperature below low

limits

25 Simulation mode Meter is in Simulation Mode. Refer to the F-5000 View Manual. Use the SIM

26 Pulse/alarm output over

range

32 4-20mA is out of range Refer to the F-5000 View Manual. Use the Set I/O section to verify range

Alarm Codes

To view alarms, use the F-5000 View software and use the following table to adjust

settings accordingly.

Reason Action

Refer to the F-5000 View Manual and check Alarm settings to verify limit is

within range. Check ALM = HiFloAlm under PRM.

Refer to the F-5000 View Manual and check Alarm settings to verify limit is

within range. Check ALM = LoFloAlm under PRM.

Refer to the F-5000 View Manual and check Alarm settings to verify limit is

within range. Check ALM=HiTempAlm under PRM.

Refer to the F-5000 View Manual and check Alarm settings to verify limit is

within range. Check ALM = LoTempAlm

Section under Diagnostics to return to normal operation.

Refer to the F-5000 View Manual. Verify the Pulse/alarm Output settings are

within limits.

limits.

TROUBLESHOOTING

TROUBLESHOOTING

36 Database CRC Error Refer to the F-5000 View Manual. Verify the programmed values are verified

and corrected before clearing the error. Contact ONICON Service Department

for possible causes.

37 Total Alarm Error Refer to the F-5000 View Manual to Reset Total.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 31

Page 32

Model F-5400

Appendices: Specifications

Performance &

Operating Specs

Performance Specs

Flow Accuracy:

Natural Gas and Propane: 1% R 500 - 7000 SFPM

Natural Gas and Propane: 2% R 100 - 500 SFPM

Air: ±1% of reading ±0.5% of full scale

Accuracy specification applies to customer's selected flow range

Maximum range: 15 to 35,000 SFPM (0.07 to 71 NMPS)

Minimum range: 15 to 1,000 SFPM (0.07 to 4.7 NMPS)

Flow Response Time: 1 second (one time constant)

Temperature Accuracy: ±1° F (±0.6° C)

Calibration:

Factory Calibration to NIST traceable standards

Operating Specs

Units of Measurement (field selectable):

SCFM, SCFH, NM3/H, NM3/M, KG/H, KG/M, KG/S, LB/H, LB/M, LB/S, NLPH,

NLPM, MMSCFD, LB/D, SLPM, NLPS, MSCFD, SM3/H, MT/H, NM3/D, MMSCFM,

SCFD, MCFD, SM3/M, SM3/D

TROUBLESHOOTING

i

Flow Velocity Range:

15 to 35,000 SFPM (0.07 to 178 NMPS)

Turndown: up to 1000:1; 100:1 typical

Pipe Diameter SCFM NM3/hr

1.5" (40mm) 0-210 0-330

2" (50mm) 0-350 0-550

3" (80mm) 0-770 0-1,210

4" (100mm) 0-1,330 0-2,100

6" (150mm) 0-3,000 0-4,730

8" (200mm) 0-5,210 0-8,220

12" (300mm) 0-11,700 0-18,450

Note: To determine if the F-5400 will operate accurately in other pipe sizes, divide the maximum flow

rate by the pipe area. The application is acceptable if the resulting velocity is within the velocity range

above.

Flow Ranges

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 32

Page 33

Appendices: Specifications

Model F-5400

Operating Specs

i

Relative Humidity: Non-condensing

Note: Condensing liquids contacting the sensor can cause erratic flow indication.

Gas Pressure (maximum):

Insertion: 300 psig (20.7 barg)*

Process adapter fitting: 60 psig (4.1 barg)

Inline:

Flanged - ANSI 150 (230 PSIG at 100°F (16 barg))

NPT - 300 PSIG (20.7 barg)

Temperature:

DDC-Sensor™: -40 to 250°F (-40 to 121°C)

Enclosure: -40 to 158°F (-40 to 70°C)*

Input Power: 12 to 28VDC, 6 watts minimum (CE requirement)

Full Input Power Range: 10 to 30VDC.

A 20 Watt or greater power supply is recommended to power the F-5400.

Outputs:

Channel 1:

Standard isolated 4-20mA output configured to indicate either flow or temperature;

fault indication per NAMUR NE43.

TROUBLESHOOTING

The 4-20mA load resistance must be 125 ohms or less when operating on 12 volt

power and 600 ohms or less on 24 volt power.

Channel 2:

Pulse Output: Isolated open collector output rated for 5 to 24VDC, 10mA

maximum load. The output can be configured as a 500ms scaled pulse for

totalization or as an alarm indication.

USB Communication:

Isolated mini USB 2.0 for interfacing with a laptop or computer is standard.

F-5000 View: A free PC-based software tool that provides complete configuration,

remote process monitoring, and data logging functions through USB

communication.

4-20mA and Pulse Verification:

Simulation mode used to align 4-20mA output and pulse output with the input to

customer’s PLC/DCS.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 33

Page 34

Model F-5400

Appendices: Specifications

Physical Specs

Agency

Approvals

APPENDICES

Physical Specs

Sensor material:

316 stainless steel

Enclosure:

Aluminum.

Process Adapter Fitting:

60 psig (4.1 barg) max.

Flow Meter Installation:

ONICON-supplied compression fitting connects to customer-supplied ¾” female

coupling welded to pipe.

Agency Approvals

CE Mark: Approved

EMC Directive; 2014/30/EU

Emissions and Immunity Testing: EN61326-1:2013

FM (USA) and FMc (Canada): Pending

Class I, Division 2

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 34

Page 35

BALL VALVE, 1 IN. FEMALE NPT,

Appendices: Dimensions

Model F-5400

Local with

Process

Adapter

Fitting

3.05 [77.5]

COMPRESSION FITTING,

3/4" TUBE, 316 SST

PROCESS ADAPTER FITTING

FULL PORT, BRONZE

Fig. 7.1 Insertion Meter with Process Adapter Fitting Dimensions

Measurements shown in inches (millimeters).

2.15 [54.6]

.81 [20.6]

1/2"-14 NPT,

FEMALE

4.30 [109.2]

ELECTRONICS ENCLOSURE

PROCESS ADAPTER FITTING

SUPPLIED WITH METER

INSTALL KIT, INSTALLED

AT INSTALLATION

5.88 [149.4].98 [24.8]

1.28 [32.4]

4.31 [109.5]

4.36 [110.7]

"LL"

NOMINAL LENGTH

APPENDICES

INSTALL KIT

PROCESS ADAPTER FITTING

Collar

Spacer

HIGH PRESSURE

PROCESS ADAPTER

FITTING

THREADOLET, 1" OUTLET,

CARBON STEEL

STANDARD

NOTE: PROCESS ADAPTER FITTING &

INSTALL KIT SHOWN ASSEMBLED

Crimped stop

Cable

Screwed stop

Table 7.1 Insertion Meter with 316 stainless steel

probe

PROBE

RETAINING RING

SENSING AREA

Process Adapter Fitting

[inches / millimeters]

C

L

Dimension “LL”

15.0" (381 mm)

18.0" (457 mm)

.73 [18.5]

Ø.75 [19.1]

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 35

Page 36

Model F-5400

Appendices: Dimensions

Local Inline NPT Meter

2.15 [54.6]

3.05 [77.5]

.81 [20.6]

APPENDICES

1/2"-14 NPT,

FEMALE

4.30 [109.2]

Fig. 7.2: Inline Meter with 316 Stainless Steel Flow Body and

NPT End Connections Dimensions

5.88 [149.4].98 [24.8]

1.28 [32.4]

ELECTRONICS ENCLOSURE

2X MALE NPT

"L"

"H"

Table 7.2 Inline Meter with 316 stainless steel flow body and NPT End Connections

Body Size Dimension “L” Dimension “H”

[inches] [inches] [inches / millimeters]

0.75" 12" 8.37" (213mm)

1.00" 12" 8.37" (213mm)

1.25" 12" 8.37" (213mm)

1.50" 12" 10.37" (263mm)

2.00" 12" 10.37" (263mm)

2.50" 18" 10.37" (263mm)

3.00" 18" 10.37" (263mm)

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 36

Page 37

Appendices: Dimensions

Model F-5400

Local Inline

Flange Meter

2.15 [54.6]

3.05 [77.5]

.81 [20.6]

1/2"-14 NPT,

FEMALE

4.30 [109.2]

Fig. 7.3: Inline Meter with 316 Stainless Steel Flow Body and 150# RF Flange

End Connections Dimensions

5.88 [149.4].98 [24.8]

1.28 [32.4]

ELECTRONICS ENCLOSURE

2X FLANGE, RAISED

FACE, ANSI B16.5

"L"

APPENDICES

"H"

Table 7.3 Inline Meter with 316 stainless steel flow body and 150# RF Flange End Connections

Body Size Dimension “L” Dimension “H”

[inches] [inches] [inches / milliimeters]

0.75" 12" 8.37" (213mm)

1.00" 12" 8.37" (213mm)

1.25" 12" 8.37" (213mm)

1.50" 12" 10.37" (263mm)

2.00" 12" 10.37" (263mm)

2.50" 18" 10.37" (263mm)

3.00" 18" 10.37" (263mm)

4.00" 18" 10.37" (263mm)

6.00" 24" 10.37" (263mm)

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 37

Page 38

Model F-5400

Appendices: Warranty

Warranty

APPENDICES

Warranty

(a) ONICON warrants that the products furnished under this Agreement will be free

from defects in material and workmanship for a period of two years from the date

of shipment. The customer shall provide notice of any defect to ONICON, within one

week after the Customer’s discovery of such defect. The sole obligation and liability of

ONICON, under this warranty shall be repair or replace, at its option, without cost to the

Customer, the defective product or part.

(b) Upon request by ONICON, the product or part claimed to be defective shall

immediately be returned at the Customer’s expense to ONICON. Replaced or repaired

products or parts will be shipped to the Customer at the expense of ONICON. ONICON

shall have the right of final determination as to the existence and cause of defect.

(c) There shall be no warranty or liability for any products or parts that have been

subject to misuse, accident, negligence, failure of electric power or modifications by

the Customer without the written approval of ONICON. Final determination of warranty

eligibility shall be made by ONICON. If a warranty claim is considered invalid for any

reason, the Customer will be charged for services performed and expenses incurred

by ONICON, in handling and shipping the returned unit.

(d) The liability of ONICON shall be limited to replacing or repairing, at its option, any

defective parts which are returned. Labor and related expenses incurred to install

replacement parts are not covered by this warranty.

(e) As to replacement parts supplied or repairs made during the original warranty

period, the warranty period for the replacement or repaired part shall terminate with the

termination of the warranty period of the original product or part.

(f) The use of these products is under exclusive control of the purchaser and ONICON

specifically denies any responsibility for the calibration of units and/or accuracy

of work performed or the safety of the system in which ONICON products is used.

EXTERNAL SAFETY DEVICES MUST BE USED WITH THIS EQUIPMENT.

(g) No warranty is made with respect to custom equipment or products produced

to Buyer’s specifications except as specifically stated in writing by ONICON and

contained in the agreement.

(h) THE FOREGOING WARRANTY CONSTITUTES THE SOLE LIABILITY OF ONICON,

AND THE CUSTOMER’S SOLE REMEDY WITH RESPECT TO THE PRODUCTS

AND IS IN LIEU OF ALL OTHER WARRANTIES, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, LIABILITIES, AND

REMEDIES. EXCEPT AS THUS PROVIDED, ONICON, DISCLAIMS ALL WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 38

Page 39

Appendices: Returning Your Meter

Model F-5400

Returning Your

Meter

Returning Your Meter

The ONICON Customer Service Department

(PH: 727-447-6140 or FAX: 727-442-5699) can help you through the process of

returning a meter for service.

If it becomes necessary to return a ONICON flow meter for service or recalibration,

please follow these steps:

1. A Return Material Authorization (RMA) Number must be obtained from the ONICON

Customer Service Department prior to returning any ONICON meter(s).

2. Please have your meter’s serial number(s) available.

3. Read and complete the ONICON RMA Customer Information Form. Be sure to

initial the decontamination statement as well as provide complete return shipping

instructions (we cannot deliver to post office boxes).

4. The entire flow meter must be returned, including all electronics (unless

specifically instructed to do otherwise). ALL serial numbers must match their

corresponding meters. This is especially necessary when returning flow body

models.

5. Clean and decontaminate all wetted parts before returning to ONICON.

6. Ship the meter to the following address:

APPENDICES

i

What to Expect

During Servicing

ONICON

399 Reservation Road

Marina, CA 93933

Attn: Service Dept.

[RMA Number]

Note: Be sure to review all of the information on the Customer Information Form before

sending your meter to the ONICON Customer Service Department. The ONICON

Shipping/Receiving Department cannot accept meters that have not been prepared

appropriately.

What to expect while your meter is being serviced

Depending on the type of service required when returning your ONICON meter, there

are varying turnover times for servicing a meter. The average time needed to service

the meter is 7-10 days (not including shipping or peak production times).

If you have already shipped your meter to ONICON for servicing and would like to

check the status of your meter, please call ONICON at (727) 447-6140 and ask for

Service.

Rush recalibration service is available for a fee. Restrictions apply.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 39

Page 40

Model F-5400

Aa

Definitions

Glossary of Terms and Definitions

AWG American Wire Gauge

Bara Bar absolute

CTC Contact

CAL Calibration

CHG Change

COM Communication

CSV Current Sense Voltage

DC Direct Current

DN Down

ELP Elapsed time

Feq Frequency

Ft^2 Square Feet

I/O Input/Output

INP Input

LB Pound

LB/D Pound per Day

LB/H Pound per Hour

DEFINITIONS

LB/M Pound per Minute

LB/S Pound per Second

LCD Liquid Crystal

KG Kilogram

KG/H Kilogram per Hour

KG/M Kilogram per Minute

KG/S Kilogram per Second

M^2 Square Meter

mmHG Pressure in millimeters of mercury

MMSCFD Million Standard Cubic Feet per Day

MXFLO Maximum Flow

NEMA National Electrical Manufactures

Association

NIST National Institute of Standards and

Technology

NL Normal Liter

NLPH Normal Liter per Hour

NLPM Normal Liter per Minute

NM3 Normal cubic Meter

NM3/H Normal cubic Meter per Hour

NM3/M Normal cubic Meter per Minute

NPT National Pipe Thread

PDA Personal hand held computer

PC Personal Computer

P/U Pulse per Unit

PIP A^2 Pipe Area

PLC Programmable Logic Controller

PRM Parameters

PRS Pressure

PSIA Pounds per Square Inch Absolute

Pt Point

PSW Password

SIM Simulation

SCF Standard Cubic Feet

SCFM Standard Cubic Feet per Minute

SCFH Standard Cubic Feet per Hour

SCFD Standard Cubic Feet per Day

SPC Special Control

STP Standard Temperature and

Pressure

TMP Temperature

TSI Internal Variable

TSV Internal Variable

UNT Unit

U/P Unit per Pulse

420 4-20mA output

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 40

Page 41

Model F-5400

Index

Index

Access to Electronics, p. 20

Alarm Codes, p. 31

Alarm wiring, p. 24

Breakage or Damage of Probe, p. 27

Dimension Details, p. 35

Equal length sensors, p. 14

Flow Meter Placement, p. 10

Fuse Replacement, p. 27

Glossary, p. 40

Installation,

Compression Fitting - Insertion, p. 16

General Precautions, p. 9

Lateral Placement, p. 10

Mounting, p. 10

Orientation of Meter, p. 13

Introduction, p. 7

Mounting meter, p. 10

Orientation of meter, p. 13

Preventative Maintenance, p. 27

Product Description, p. 7

Replacements Fuses, p. 27

Return Procedure, p. 39

Sensor Cleaning, p. 27

Sensor Orientation, p. 14

Theory of Operation, p. 7

Troubleshooting, p. 28

Alarm Codes, p. 31

General, p. 28

Installation Problems, p. 30

USB Interface, p. 8

Warranty, p. 35

Wiring

Alarms, p. 24

Pulse/Alarm Outputs, p. 24

Instructions, p. 16

Precautions, p. 20

Aa

DEFINITIONS

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 41

Page 42

Aa

i

Wiring

Definition of Terms

Troubleshooting Tips

Information

Caution - (refer to accompanying documents):

Please follow the specified instructions and

general safety practices.

Indicates compliance with the WEEE Directive.

Please dispose of the product in accordance

with local regulations and conventions.

Indicates compliance with the applicable

European Union Directives for Safety and

EMC (Electromagnetic Compatibility Directive

2014/30/EU).

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-5400 Thermal Mass Flow Meter Manual 12/16 - 2031 / 107032 Page 42

Loading...

Loading...