Page 1

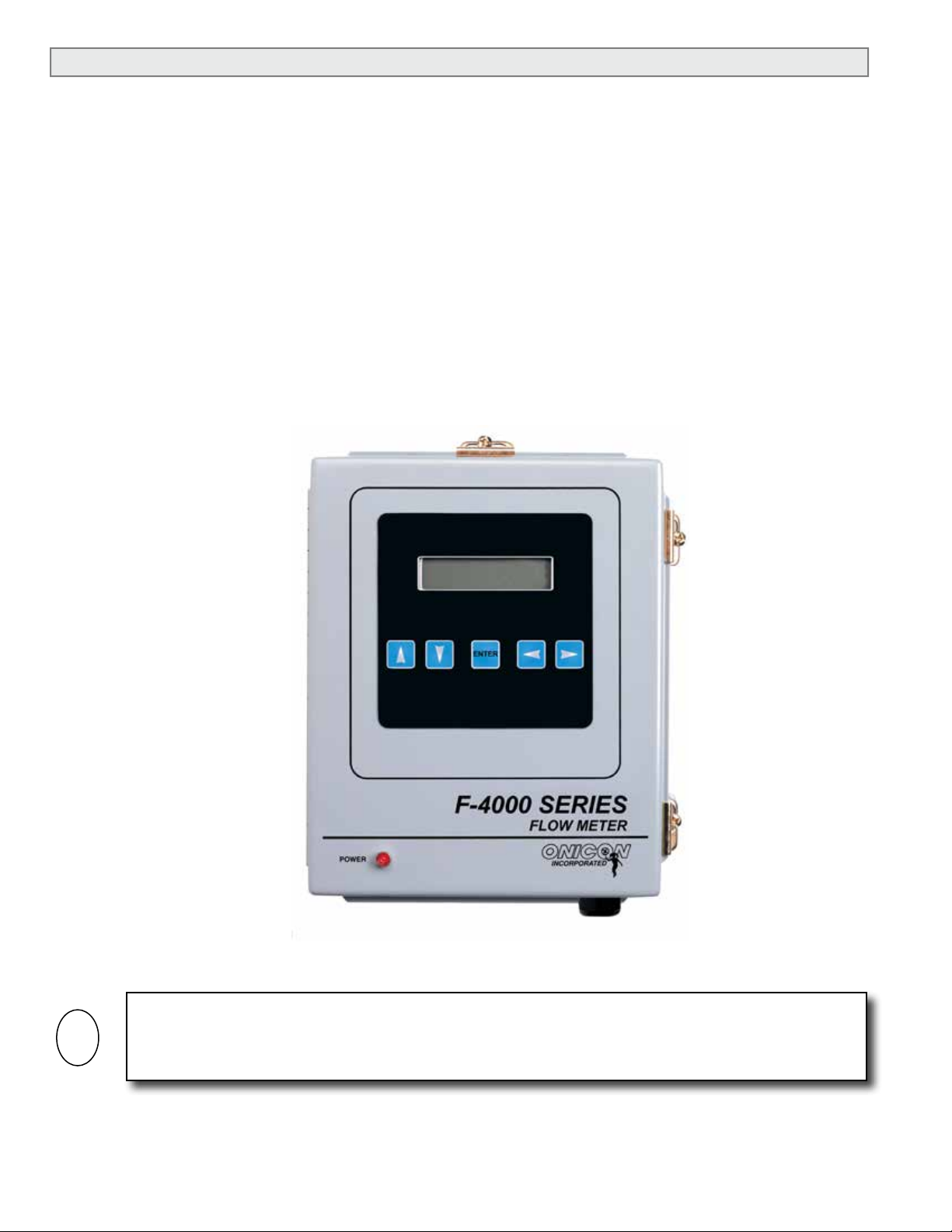

F-4000 Series

Clamp-on Ultrasonic Flow Meter

Installation & Basic Operation Guide

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699

www.onicon.com • sales@onicon.com

05-150707-13 / 18838

Page 2

SAFETY INFORMATION

!

!

i

This meter was calibrated at the factory before shipment. To ensure correct use of the meter, please

read this manual thoroughly.

Regarding this Manual:

• This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without

ONICON’s written permission.

• ONICON makes no warranty of any kind with regard to this material, including, but not

limited to, implied warranties of merchantability and suitability for a particular purpose.

• All reasonable effort has been made to ensure the accuracy of the contents of this manual.

However, if any errors are found, please inform ONICON.

• ONICON assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, ONICON assumes

no responsibility for any such harm owing to any defects in the product which were not

predictable, or for any indirect damages.

Safety Precautions:

The following general safety precautions must be observed during all phases of installation,

operation, service, and repair of this product. Failure to comply with these precautions or with

specic WARNINGS given elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the product. ONICON Incorporated assumes no liability for the

customer’s failure to comply with these requirements. If this product is used in a manner not

specied in this manual, the protection provided by this product may be impaired.

The following symbols are used in this manual:

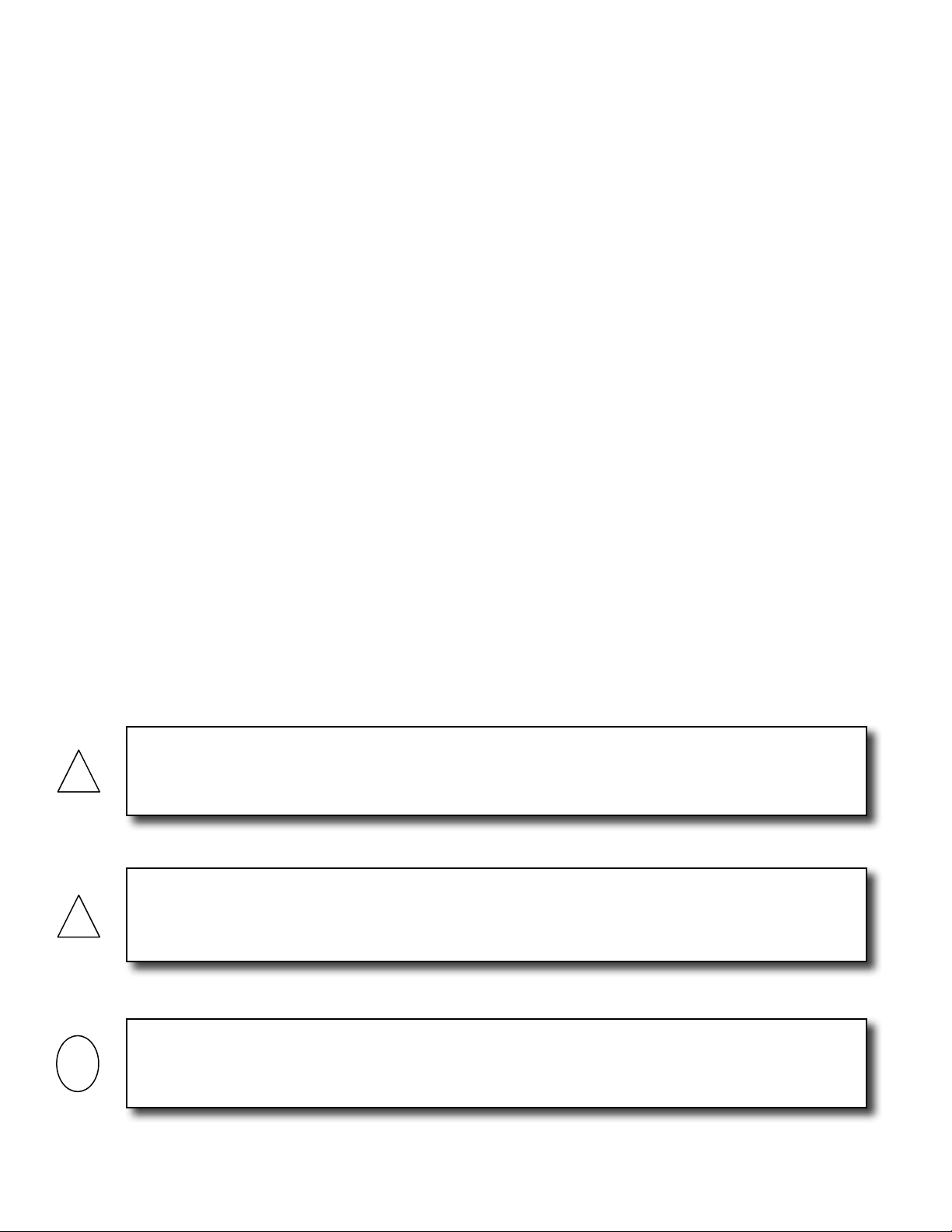

WARNING

Messages identied as “Warning” contain information regarding the personal safety of individuals

involved in the installation, operation or service of this product.

CAUTION

Messages identied as “Caution” contain information regarding potential damage to the product or

other ancillary products.

IMPORTANT NOTE

Messages identied as “Important Note” contain information critical to the proper operation of the

product.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION .................................................................................................5

1.1 PURPOSE OF THIS GUIDE ...................................................................... 5

1.2 PRINCIPLE OF OPERATION .................................................................... 5

1.3 TYPICAL FLOW METER INSTALLATION ..............................................5

1.4 STANDARD FEATURES AND SPECIFICATIONS ................................... 6

1.5 MAINTENANCE ........................................................................................7

1.6 ADDITIONAL REQUIRED HARDWARE ................................................... 7

1.7 ADDITIONAL HARDWARE THAT MAY BE REQUIRED .........................7

1.8 WORKING ENVIRONMENT ....................................................................7

1.9 WARRANTY AND SERIAL NUMBER ....................................................7

2.0 UNPACKING ...................................................................................................... 8

2.1 CHECKING THAT YOU HAVE RECEIVED EVERYTHING ..................... 8

3.0 INSTALLATION ................................................................................................... 9

3.1 OVERVIEW ...............................................................................................9

3.2 SITE SELECTION .....................................................................................10

3.3 MECHANICAL INSTALLATION ............................................................. 12

3.3.1 Mounting the Enclosure ............................................................ 12

3.3.2 Preparing the Pipe .....................................................................13

3.3.3 Reect Mode Mounting Using Frames and Spacer Bar ............13

3.3.4 Reect Mode Mounting Using Track Mount Hardware ...........14

3.3.5 Direct Mode Mounting Using Brackets and Spacer Bar ........... 16

3.3.6 Direct Mode Mounting Using Track Mount Hardware.............20

3.3.7 Installing Transducers In Bracket and Spacer

Bar Hardware .............................................................................22

3.3.8 Installing Transducers In Track Mount Hardware .................... 23

3.4 CONNECTING THE TRANSDUCER SIGNAL CABLES ........................24

3.5 INSTALLING THE F-CONNECTORS ...................................................... 25

3.5.1 Cable Preparation .......................................................................25

3.5.2 Cable & Connector Assembly .................................................... 25

3.5.3 Final Assembly ..........................................................................25

3.6 ELECTRICAL INSTALLATION ...............................................................26

3.6.1 Input Power Options .................................................................26

3.6.2 Electrical Connections ............................................................... 27

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 3

Page 4

4.0 START-UP .................................................................................................... 29

4.1 PROGRAM MODE KEYPAD FUNCTIONS ............................................. 29

4.2 RECALLING A SAVED SITE ...................................................................30

4.3 INSTALLING RECALLED SITES ............................................................. 31

4.3.1 Reect Mount Installations .......................................................31

4.3.2 Direct Mount Installations .........................................................32

4.4 NAVIGATING THE RUN MODE MENU PAGES ..................................... 33

4.5 SECURITY SWITCH ................................................................................35

5.0 BACNET / MODBUS COMMUNICATIONS ......................................................36

5.1 BACnet Modbus Communications ..........................................................36

5.2 Change Network Settings ........................................................................38

5.3 BACnet .................................................................................................... 39

5.4 Modbus ....................................................................................................42

6.0 COMMISSIONING FOR ONICON CLAMP-ON

ULTRASONIC FLOW METERS..........................................................................45

6.1 HELPFUL HINTS FOR START-UP AND COMMISSIONING .................45

6.2 COMMISSIONING PROCEDURE ............................................................ 45

6.3 COMMISSIONING WORKSHEET ........................................................... 46

7.0 TROUBLESHOOTING ........................................................................................ 47

APPENDIX

A-1 SONIC VELOCITY RELATIVE TO TEMPERATURE OF PURE WATER

A-2 F-4000 SERIES MOTHER BOARD AC

A-3 F-4000 SERIES MOTHER BOARD DC

A-4 CONDITIONS OF SALE

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 4

Page 5

SECTION 1.0: INTRODUCTION

1.1 PURPOSE OF THIS GUIDE

The purpose of this guide is to provide installation and commissioning procedures and basic

operating and servicing instructions for the ONICON F-4000 Series Ultrasonic Flow Meter.

1.2 PRINCIPLE OF OPERATION

ONICON F-4000 Series Ultrasonic Flow Meters utilize the differential transit time method to

measure the velocity of relatively clean liquids in full pipes. By measuring the difference between

transit times of ultrasonic sound waves travelling between two transducers, the ow velocity and

direction are accurately determined.

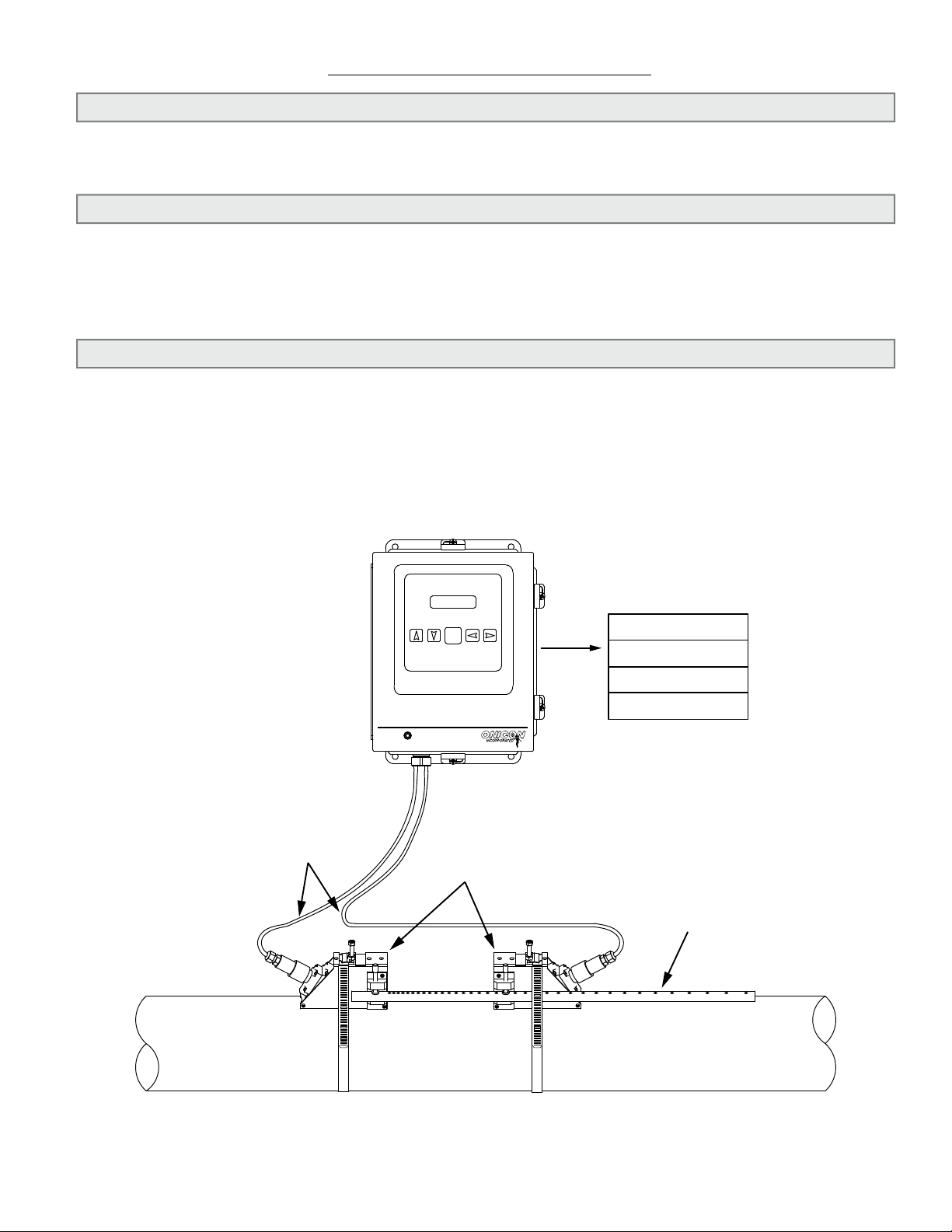

1.3 TYPICAL F-4000 FLOW METER

The F-4000 Series Ultrasonic Flow Meter utilizes clamp-on signal transducers that mount on

the outside wall of the pipe. It is suitable for measuring the volumetric ow of liquids in a wide

variety of applications including bi-directional ow applications. The meter is housed in a steel

wall-mounted enclosure with a built-in user interface/display.

TYPICAL INSTALLATION

Coaxial

Transducer

Cables

POWER

ENTER

F-4000 SERIES

FLOW METER

Precision

Matched

Transducers

OUTPUT SIGNALS

4-20mA

Scaled Pulse

Relay Output

Mounting

Hardware

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 5

Page 6

1.4 STANDARD FEATURES AND SPECIFICATIONS

• Wall-mounted NEMA 4 steel enclosure with 2-line alphanumeric user interface/display

• One externally powered electrically isolated 4-20 mA analog output for ow rate

• One scalable electrically isolated open collector pulse output for totalizing ow

• One programmable form C relay to indicate ow direction or alarm.

GENERAL SPECIFICATIONS

ACCURACY

± 1.0% of reading from 1 to 40 ft/sec

± 0.01 ft/s for velocities below 1 ft/sec

OVERALL FLOW RANGE

0.1 to 40 ft/sec

SENSING METHOD

Clamp-on ultrasonic, differential transit time

method in direct or reect mode

PIPE SIZE RANGE

½” through 48” nominal diameter

PROGRAMMING

Factory programmed for specic application

MEMORY

Non-volatile memory retains all program

parameters and totalized values in the event of

power loss.

DISPLAY

Alphanumeric 2-line, 16-characters per line

multifunction LCD display

(Character height, 0.2”)

Displays total ow, ow rate, speed of sound,

% gain, % aeration, signal strength, ow

direction & alarm conditions

Rate display range: 0 - 9,999,999

Totalizer display range: 0 – 99,999,999

Totalizers will roll over to zero when maximum

count is exceeded.

OUTPUT SIGNALS PROVIDED

Analog output: Electrically isolated 4-20 mA

(Externally powered 10 – 30 VDC)

Scalable pulse output: Optically isolated open

collector (Contact rating: 30 VDC, 10 mA

maximum, pulse duration: 50 ms)

Relay output for ow direction or alarm:

Programmable form C relay (Contact rating: 30

VDC, 250 mA maximum)

FLUID TEMPERATURE RANGE

Standard: -40° F to 250° F

Optional: High Temperature -40° F to 446° F

AMBIENT OPERATING TEMPERATURE RANGE

14° F to 122° F

STORAGE TEMPERATURE RANGE

-4˚ F to 140˚ F

MECHANICAL

MATERIALS OF CONSTRUCTION

Electronics enclosure: Wall-mount, powder coat

painted steel enclosure with stainless steel

hardware

Transducer mounting hardware: Anodized

aluminum and stainless steel

Transducers: Anodized aluminum and plastic

ENCLOSURE RATINGS

NEMA 4, weathertight

ELECTRICAL

This equipment is intended for INSTALLATION

CATEGORY (OVERVOLTAGE CATEGORY) II

applications. Installations must comply with all local,

state and federal building codes.

INPUT POWER – Factory selectable

11.5 to 28.5 VDC, 10 Watts maximum

(Internal: 5x20mm, 250V/2.0A fuse)

90-240 VAC 50/60 Hz, 15 VA maximum

(Internal: 5x20mm, 250V/0.5A fuse)

OVERCURRENT PROTECTIVE DEVICE RATINGS:

Supply mains overcurrent protective devices with

the following ratings:

120 VAC 50/60 Hz – 15 A

230 VAC 50 Hz – 6 A

ELECTRICAL CONNECTIONS

Enclosed terminal connections, cable access through

four standard ¾” conduit openings

Transducer signals: (2) F-connectors supplied with

quick-disconnect adapters

Input power: 3 terminal removable connectors

(12 – 22 AWG)

Signal inputs/outputs: PCB mount terminal blocks

(14 – 26 AWG)

WIRING

Transducer signals: Use Belden 9269 coaxial cable or

equivalent (93Ω nominal impedance)

24 VDC input power: Use PVC jacketed copper cable

with a wire gauge suitable for the length of run and

required maximum current carrying capacity.

Provide a separate protective earth wire.

120/230 VAC input power: Use a 3-wire service

with one wire a protective earth ground.

Signal inputs/outputs: Use PVC jacketed copper

shielded cable with a wire gauge suitable for the

length of run and required maximum current

carrying capacity.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 6

Page 7

1.5 MAINTENANCE

Periodically inspect the power cables, transducer cables, cable glands and the enclosure for signs

of damage. Inspect transducer installation and mounting hardware for loose connections.

1.6 ADDITIONAL REQUIRED HARDWARE

Installation hardware: ONICON clamp-on ultrasonic ow meters typically require installation

hardware. Hardware requirements vary by pipe size and material.

1.7 ADDITIONAL HARDWARE THAT MAY BE REQUIRED

Flex conduit may be required to connect transducer to rigid conduit. Do not connect transducers

to rigid conduit.

1.8 WORKING ENVIRONMENT

The F-4000 was designed for installation and use in typical commercial/industrial environments.

The following considerations must be observed in selecting a location for the meter:

• The ambient operating temperature range is 14° F (-10° C) to 122° F (50° C).

• Do not expose the meter to corrosive liquids or fumes.

• Avoid installation locations that are close to strong sources of electrical interference.

• Avoid installing the electronics enclosure in direct sunlight.

• Avoid installation locations where the transducers will be exposed to vibrations in the

piping system.

• Always run transducer cables in dedicated conduit separate from signal and power cables.

• Do not run signal cables for the meter in conduit with mains (AC) power cables.

1.9 WARRANTY & SERIAL NUMBER

Warranty

ONICON provides a 2-year warranty for this product. Certain exclusions apply. Please refer to

ONICON’s Conditions of Sale for details.

Serial Number

The serial number of your F-4000 is located outside and inside the enclosure. All components

of your F-4000 (electronics enclosure & transducers) will bear identical serial numbers. Serial

numbers are unique identiers that you should have available when contacting ONICON for

assistance regarding your meter.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 7

Page 8

SECTION 2.0: UNPACKING

i

The F-4000 is generally shipped in one package unless optional hardware or equipment is ordered.

Notify the freight carrier (all products are shipped insured) and ONICON if any items are damaged in transit.

2.1 CHECKING THAT YOU HAVE RECEIVED EVERYTHING

• Standard Documentation

Enclosed with each F-4000 is a comprehensive documentation package that includes the

following items:

This F-4000 Ultrasonic Flow Meter Installation and Operation Guide

The Flow Meter Certicate of Calibration

Site Installation Details Document

Please notify ONICON if any of these items are missing.

IMPORTANT NOTE

The ONICON F-4000 Ultrasonic Flow Meter is a custom calibrated system. Unless specically noted

in writing by ONICON, ALL COMPONENTS (electronics enclosure and ultrasonic transducers)

share the same serial number and must be installed together as a system. Mixing components from

different systems will result in signicant errors in calibration.

• The Wall Mount Enclosure

Remove the F-4000 enclosure from the shipping carton and inspect it inside and out for

physical damage. Please notify ONICON immediately if you discover any damage.

Transducers are shipped in the same carton with the enclosure. Inspect the transducers for

signs of damage. Each transducer will have a label attached with a serial number identical to

that found on the F-4000 enclosure. Included with the transducers are two dry coupling pads

and one tube of coupling compound.

• Transducers Cables

Transducer cables are coiled and packed separately in the outer carton. Taped to the cables

is a termination kit that includes the ttings necessary to terminate the transducer end of the

cables. The other end of each cable is already terminated.

• Installation Hardware

Installation hardware may include mounting brackets and a spacer bar or a track mount

assembly. Taped to this hardware will be a mounting strap kit. This kit includes the mounting

straps used to secure the hardware onto the pipe, a sanding block for preparing the pipe

surface, and a mylar mounting guide used when mounting transducers in direct operating

mode. The kit will also include a copy of the F-4000 Site Installation Details for this meter.

This document provides specic details such as transducer spacing. This information is

unique to the specic installation site and is identied by the meter location tag name and the

serial number of the meter.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 8

Page 9

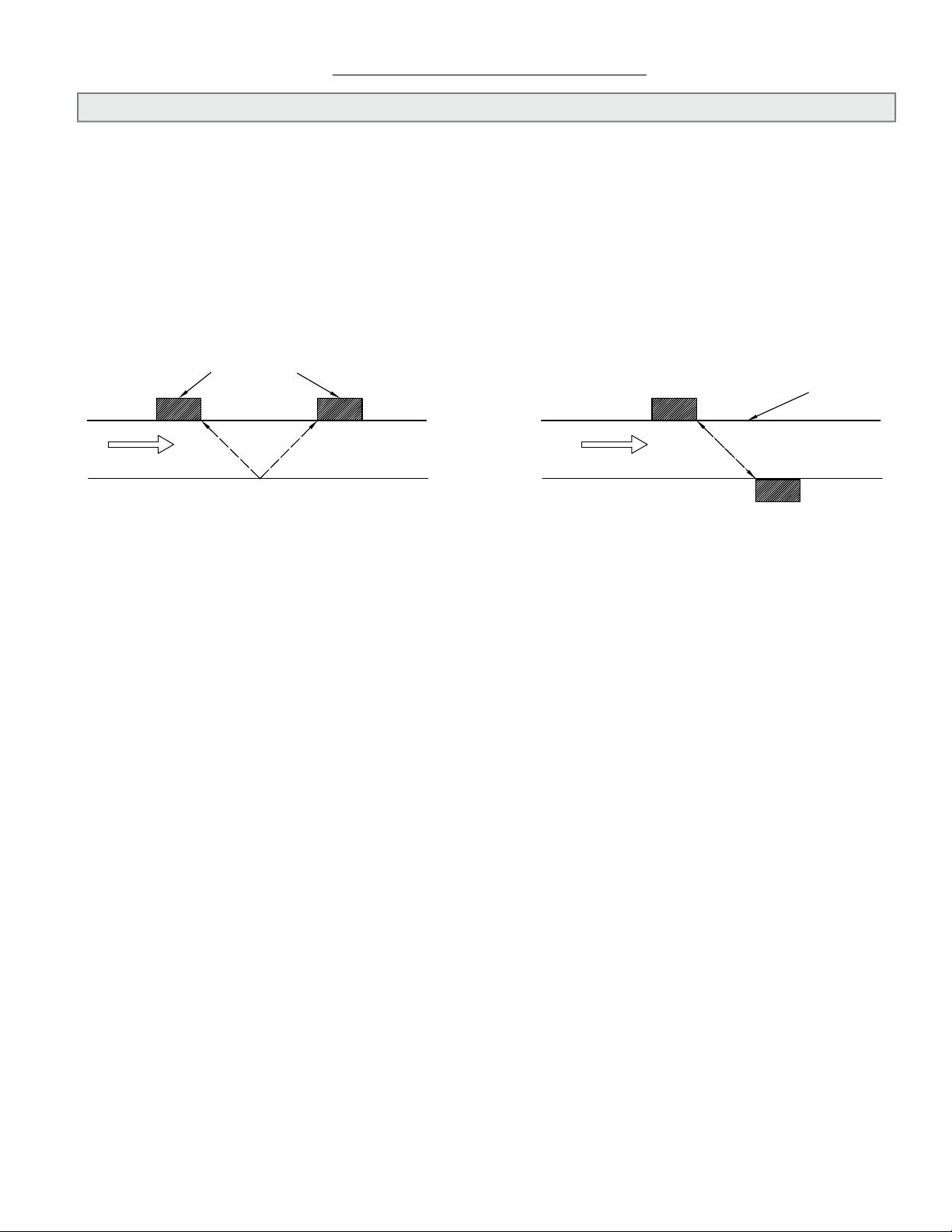

SECTION 3.0: INSTALLATION

3.1 OVERVIEW

Each F-4000 Series Ultrasonic Flow Meter is provided with a pair of precision matched ultrasonic

transducers. The transducers are mounted (clamped) on to the outside wall of the pipe. Coaxial

cables convey the transducer signals to the wall mount enclosure containing the signal processing

circuitry and the user interface display. Ultrasonic transducers can be congured to operate

in either reect or direct operating modes. The choice of operating mode is dictated by the

conguration settings programmed into the meter. For new installations, conguration data is

programmed into the meter prior to shipment. This data is saved as a “Site”. Site data determines

the transducer operating mode and the spacing between the transducers. This information is

provided with the installation hardware in a document titled, “F-4000 Site Installation Details”.

Transducers

Flow Flow

Reflect Mode

Direct Mode

Pipe Wall

Reect Mode

Reect mount is the recommended operating mode whenever possible. It is the simplest way

to mount the transducers. Operating in the reect mode also minimizes the effects of some ow

distortions and enables the use of the auto zero function.

Direct Mode

Direct mount provides a shorter sonic beam path. This usually improves performance with

sonically attenuative liquids or pipe materials. Direct mount is required for plastic pipes. Direct

mounting only requires half the distance between electrodes when compared to the reect mode

and may be the only option if the availability of mounting space is limited.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 9

Page 10

3.2 SITE SELECTION

i

Careful attention to the site selection for the system components will help the installers with the

initial installation, reduce start-up problems and make future maintenance easier. For example,

do not install the meter where it will be difcult for personnel to perform periodic maintenance.

When selecting a site for mounting the system components, consider the criteria under Section

1.8 WORKING ENVIRONMENT, as well as the following:

The Wall-Mount Enclosure

Find an easily accessible location where wire connections can be made and meter readings can

be taken from oor level. Mount the enclosure on a vibration-free surface. Avoid sites such as

the plenum of a fan coil, heat exchanger, or other housings containing motors. Avoid mounting

the enclosure in close proximity to VFD’s, electric motors or other strong sources of electrical

interference.

IMPORTANT NOTE

The maximum allowable distance between the wall-mount enclosure and the transducers installed

on the pipe is 300 feet.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 10

Page 11

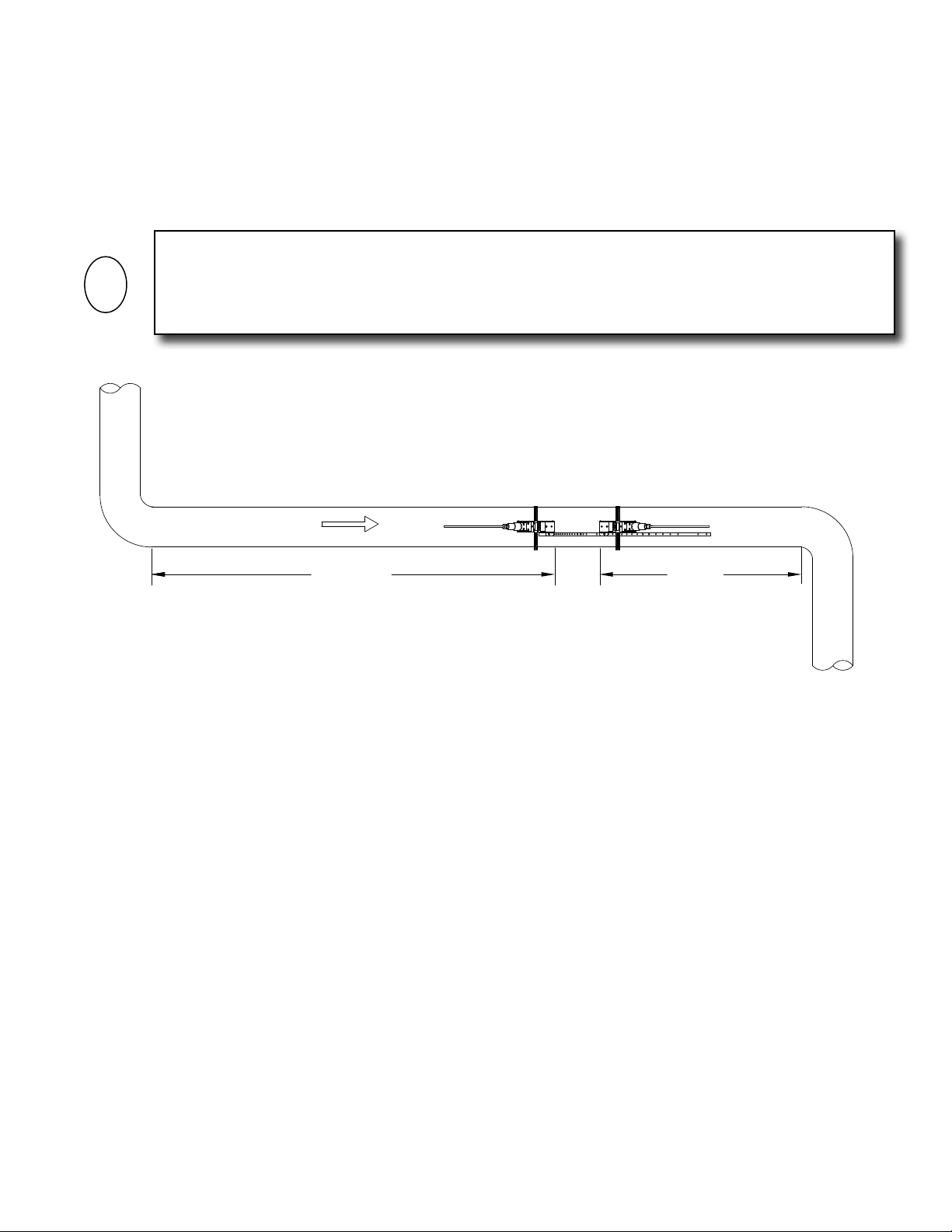

i

The Transducers

For best results, the transducers must be installed on a straight run of pipe, free of bends, tees,

valves, transitions, insertion probes and obstructions of any kind. For most installations, ten

straight unobstructed pipe diameters upstream and ve diameters downstream of the transducers

is the minimum recommended distance for proper operation. Additional considerations are

outlined below.

IMPORTANT NOTE

In some cases, longer straight runs may be necessary where the transducers are placed downstream

from devices which cause unusual ow prole disruptions or swirl; for example, modulating valves

or two elbows in close proximity and out of plane, etc.

Flow

10 Dia. 5 Dia.

• Do not, if possible, install the transducers downstream from a throttling valve, a mixing tank,

the discharge of a positive displacement pump or any other equipment that could possibly

aerate the liquid. The best location will be as free as possible from ow disturbances,

vibration, sources of heat, noise, or radiated energy.

• Avoid mounting the transducers on a section of pipe with any external scale. Remove all

scale, rust, loose paint, etc., from the location prior to mounting the transducers.

• Do not mount the transducers on a surface aberration (pipe seam, etc.).

• Do not mount transducers from different ultrasonic ow meters on the same pipe.

• Do not run the transducer coaxial cables in common bundles with cables from other

instrumentation. You can run these cables through a common conduit ONLY if they originate

at the same ow meter.

• Never mount transducers under water, unless you have specically purchased submersible

transducers and you install them in accordance with factory instructions.

• Avoid mounting transducers on the top of a horizontal pipe. The best placement on a

horizontal pipe is either the 10:00 or 2:00 position for reect mode, or one sensor at 9:00 and

one sensor at 3:00 for direct mode.

• Do not mount transducers on the bottom of a horizontal pipe.

• Mounting on a vertical pipe is recommended only if ow is in the upward direction. When

mounting on a vertical pipe owing in a downward direction, make sure there is sufcient

back pressure in the system to maintain a full pipe.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 11

Page 12

!

i

3.3 MECHANICAL INSTALLATION

This ONICON F-4000 Ultrasonic Flow Meter is a custom calibrated system. Unless specically

noted in writing by ONICON, ALL COMPONENTS (electronics enclosure and precision matched

transducers) share the same serial number and must be installed together as a system. Mixing

components from different systems will result in signicant errors in calibration.

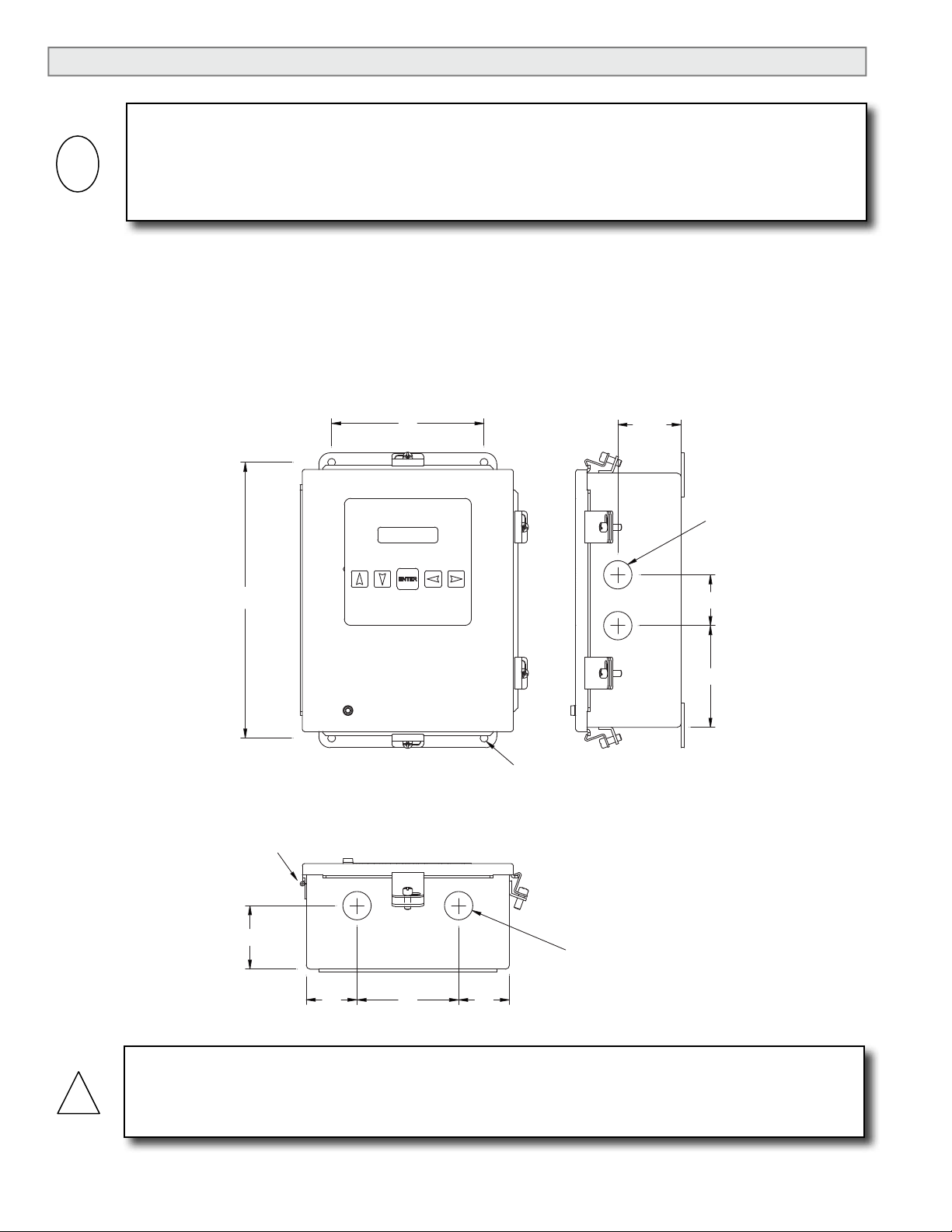

3.3.1 Mounting the Enclosure

Find an easily accessible location where electrical connections can be made and meter

readings can be taken from the oor level. Mount the enclosure on a vibration-free

surface. Avoid sites such as the plenum of a fan coil, heat exchanger, or other housings

containing motors. Avoid mounting the enclosure in close proximity to VFD’s, electric

motors or other strong sources of electrical interference.

IMPORTANT NOTE

6” 2.5”

10.75”

Hinge side shown

for refernce.

2.5”

2xØ1.115

2”

4”

4xØ0.312

2xØ1.115

2”

4”

2”

CAUTION

Do not drill additional holes in this enclosure. Doing so may damage the electronic circuitry

contained within and will void all warranties.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 12

Page 13

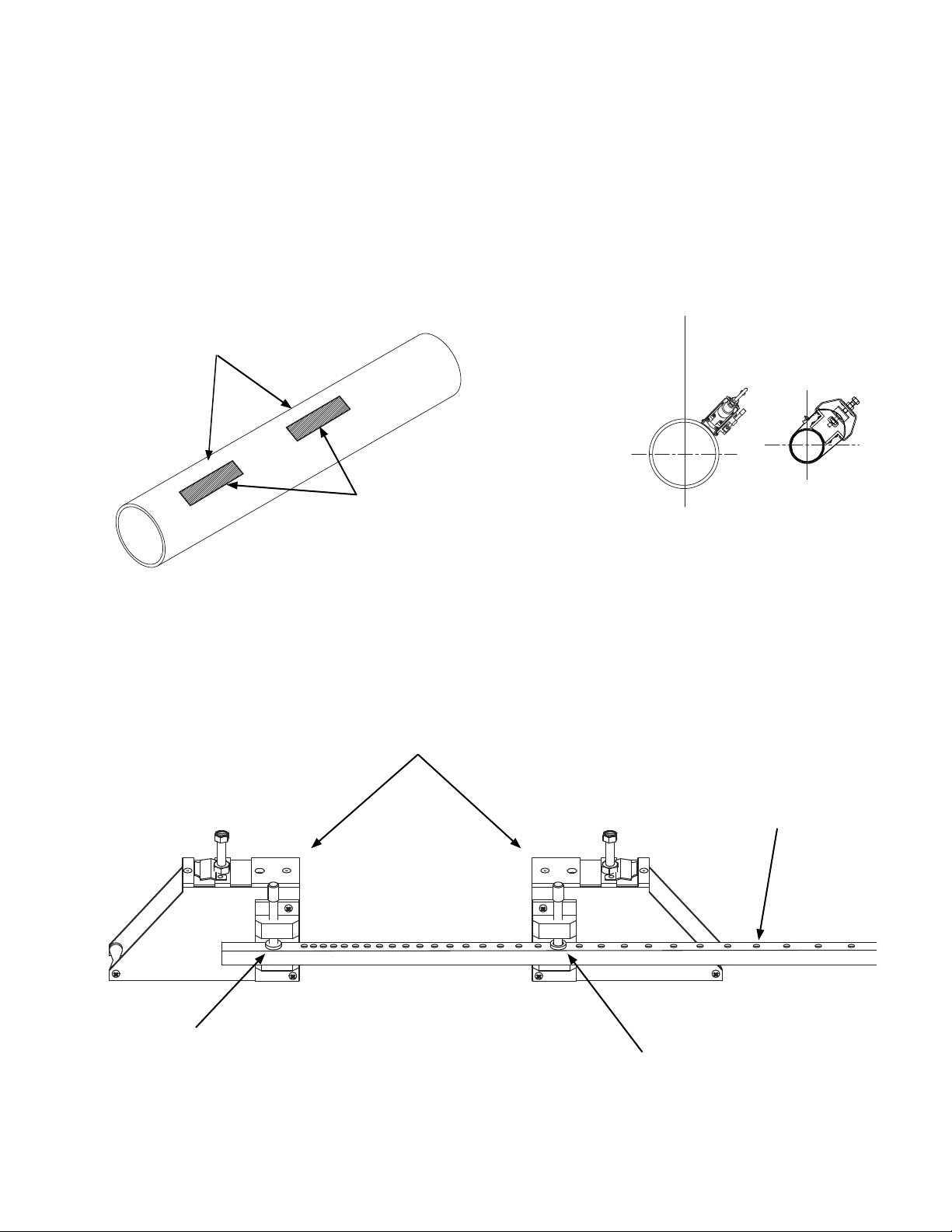

3.3.2 Preparing the Pipe

Once a suitable section of straight pipe has been located, the pipe surface must be

prepared. Refer to the Site Installation Details document provided with the installation

hardware to determine the transducer spacing dimensions. Prepare the pipe surface as

shown below. Clean and de-grease two rectangles where the transducers will be located.

Use the small sanding block provided with the installation hardware as necessary to

remove any grit, corrosion, rust, loose paint or other contaminants. The cleaned surface

should extend at least ½” beyond the length and width of the transducers.

Always install hardware at the 10:00 or 2:00 position on horizontal pipes. This prevents

the ow meter from being affect by air trapped at the top of the pipe.

Refer to site installation details

document for transducer spacing.

Prepare mounting

locations for transducers.

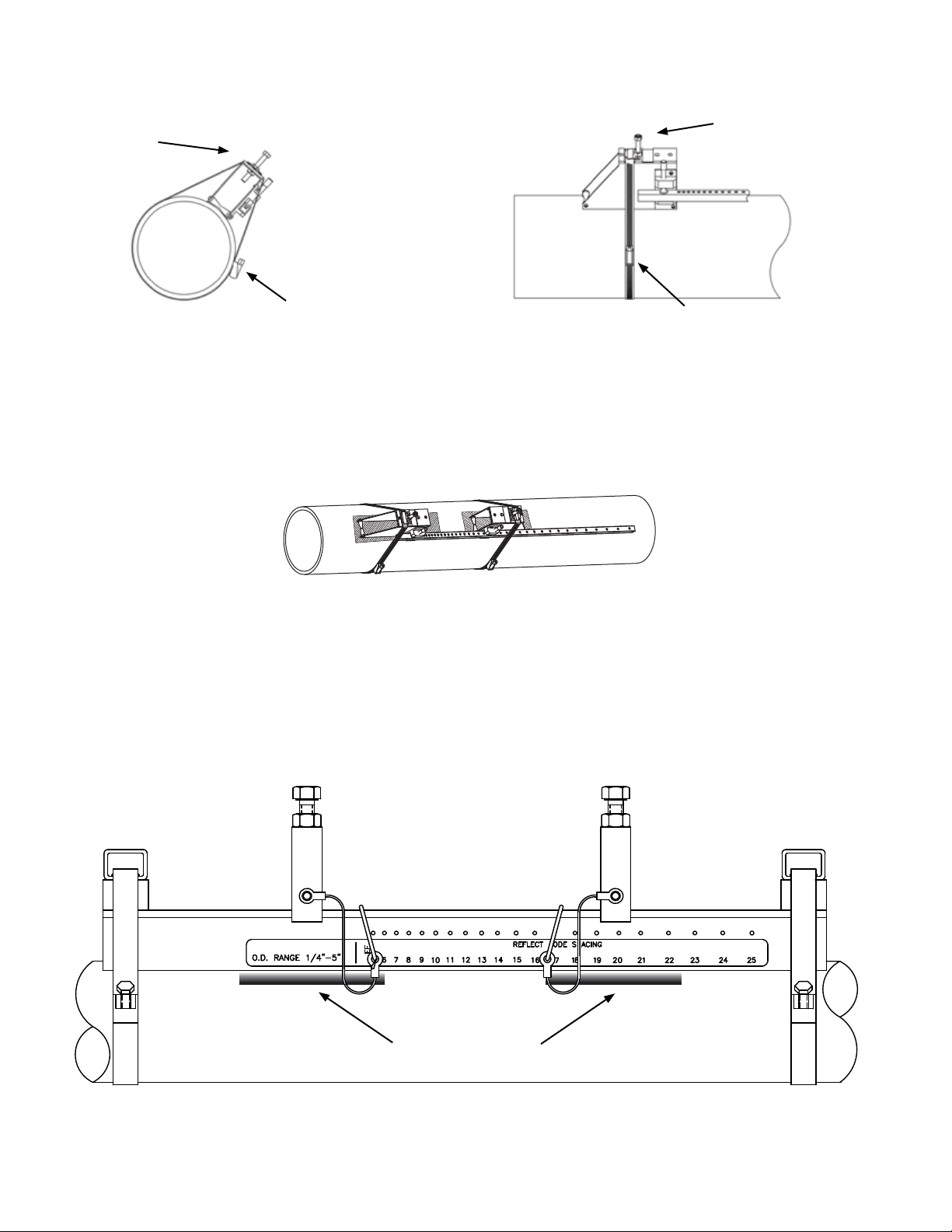

3.3.3 Reect Mode Mounting Using Frames and Spacer Bar

1. Prepare the pipe surface as described in section 3.3.2.

2. On a at surface, assemble the hardware as shown in the drawing below.

Orient mounting brackets as shown.

For horizontal pipes, locate transducers at

the 10:00 or 2:00 position.

Numbered index holes

Reference hole

Refer to the Site Installation Details document

provided with the installation hardware to

determine the correct hole location.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 13

Page 14

Spring clip

3. Install the mounting straps as shown below. For larger pipes, use multiple straps

connected end-to-end to increase the length of each strap. Leave enough slack in the

straps to allow the assembly to be correctly positioned on the pipe.

Wrap the rst mounting strap

around the pipe and under the

spring clip on top of the mounting

bracket. Make sure to position

it so there is easy access to the

adjustment screw. Repeat this

procedure for the second mounting

bracket.

Adjustment screw Adjustment screw

Spring clip

4. Move the hardware assembly to its nal position on the pipe. Align the brackets

with the prepared surface for each transducer as shown below, ensuring that the

entire assembly is properly oriented along the axis of the pipe. Tighten the assembly

rmly on the pipe. Do not over tighten the straps.

3.3.4 Reect Mode Mounting Using Track Mount Hardware

1. Prepare the pipe surface as described in section 3.3.2.

2. Place the track mount hardware assembly at the 10:00 or 2:00 position on the pipe at

the desired mounting location. Ensure that it is a clean, smooth area without any raised

spots or seams.

TRACK 4 00

Prepared Surfaces

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 14

Page 15

3. Holding the track mount assembly in place, wrap one of the mounting straps around

the pipe as shown in the drawing below. Tighten the tension screw enough to hold the

assembly on the pipe, but still allow rotation. Repeat for the other mounting strap.

Mounting Strap Mounting Strap

TRACK 4 00

Prepared Surfaces

4. Rotate the track mount assembly as necessary to its nal itended mounting position

on the pipe, then tighten both tension screws just enough to prevent rotation. Do not

over tighten.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 15

Page 16

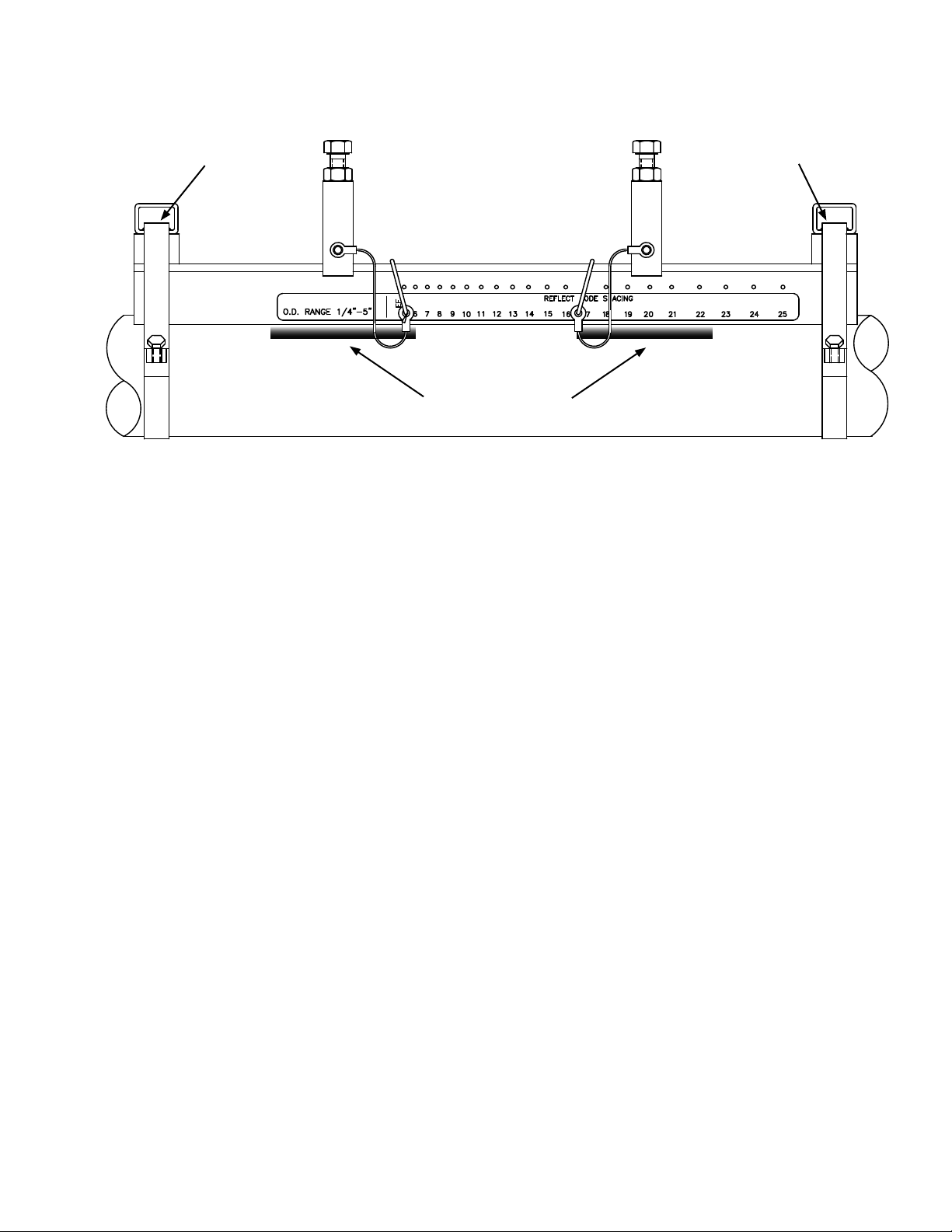

3.3.5 Direct Mode Mounting Using Brackets and Spacer Bar

i

1. Once the installation site selection process described in section 3.2 is complete,

prepare the pipe where the rst sensor will be mounted.

IMPORTANT NOTE

Direct mode mounting requires that transducers be installed on opposite sides of the pipe. For

horizontal pipes, the transducers should be located at the 3 o’clock and 9 o’clock positions.

2. To prepare the pipe, temporarily position a mounting bracket on the pipe where you

will be mounting it. Ensure that the pipe surface is smooth without any raised areas

(seams, etc.) With a pencil, marker or chalk, draw a generous rectangle around the

bracket. Clean and de-grease the area within the rectangle. Use the small sanding block

provided with the installation hardware as necessary to remove any grit, corrosion,

rust, loose paint or other contaminants. Be sure to wipe the surface clean after sanding.

The cleaned surface should extend at least ½” beyond the length and width of the

mounting bracket.

3. Attach the spacer bar to one of the mounting brackets at the reference hole.

Clamping Screw

Spacer Bar

Reference Hole

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 16

Page 17

4. Position the mounting bracket and spacer bar in the center of the cleaned area and

secure it in place with a mounting strap as shown below. Make sure the mounting

strap tightening screw is facing up. Note that the angled end of the bracket must be

facing away from where the other bracket will be mounted. While tightening the strap,

check to ensure that the bracket remains centered on the pipe. (The bracket is centered

on the pipe when the bottom edges of both aluminum side plates on the bracket are in

full contact with the pipe surface.)

5. Attach the second bracket to the spacer bar at the numbered index hole specied on

the site installation details document provided with the installation hardware. Note

that the angled end of the bracket must be facing away from the other mounting

bracket.

Orient mounting brackets as shown.

Numbered index holes

Reference hole

Refer to the Site Installation Details document

provided with the installation hardware to

determine the correct hole location.

6. Check to ensure that this bracket is lined up on the center of the pipe. While holding

the bracket centered on the pipe, place a mark (with pencil or chalk) at the center of

the tapered roller at the bottom of the bracket as shown below. Next, mark along the

edge of the bracket as indicated in the drawing below.

Place mark at center

of tapered roller.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 17

Draw line along edge

of bracket.

Page 18

7. Remove the bracket from the spacer bar and then remove the spacer bar from the

1.5869

bracket that is strapped to the pipe. Using the spacer bar as a straight edge, draw a line

down the center of the pipe intersecting the mark made at the center of the tapered

roller and the line drawn against the edge of the bracket as shown below.

1.5869

Spacer bar

Draw line using spacer

bar as edge.

8. Wrap the Mylar spacing guide around the pipe so that the left edge is against the

transducer edge mark. Arrange so that one end overlaps the other. Ensure that it is

snug around the pipe and mark along the overlapping edge.

Draw the guide tightly

Mylar spacing guide

around the pipe and mark

at the overlapping edge.

9. Remove Mylar spacing guide and lay it out on a at surface. Either measure the exact

distance half-way between the overlap edge and the mark at the overlap, or fold the

guide from the overlap edge to overlap mark and draw a line at the fold or halfway

point.

50%

50%

Overlap edge mark

10. Reinstall the spacing guide; its edge abutting the bracket edge mark on the pipe and the

overlapping edge in line with the line drawn down the center of the pipe. Tape it in

this position on the pipe. Take the second bracket and place it against the edge of the

guide with its tapered roller centered on the half way mark drawn on the guide.

Mylar spacing guide aligned

with marks on pipe.

Bracket aligned with edge of

guide and centered on marks

on the guide.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 18

Page 19

11. Ensure that the bracket is sitting on a smooth area without any raised spots (seams,

etc.). Mark a generous rectangle around the bracket with a pencil, marker or chalk.

Remove the bracket and the Mylar guide.

12. Clean and de-grease the area within the rectangle. Use the small sanding block

provided with the installation hardware as necessary to remove any grit, corrosion,

rust, loose paint or other contaminants. The cleaned surface should extend at least ½”

beyond the length and width of the mounting bracket.

13. Replace the Mylar guide back in the same position it was in and re-tape it to the pipe.

14. Position the bracket as before against the edge of the guide with its tapered roller

centered on the half way mark drawn on the guide. Secure it in place with a mounting

strap as shown below. Make sure the mounting strap tightening screw is facing toward

the bracket so you can hold it in place while tightening the screw. Note that the angled

end of the bracket must be facing away from where the other bracket will be mounted.

While tightening the strap, check to ensure that the bracket remains centered on the

pipe. (The bracket is centered on the pipe when the bottom edges of both aluminum

side plates on the bracket are in full contact with the pipe surface.)

Mylar spacing guide aligned

with marks on pipe.

Bracket aligned with edge of

guide and centered on marks

on the guide.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 19

Page 20

3.3.6 Direct Mode Mounting Using Track Mount Hardware

i

1. Once the installation site selection process described in section 3.2 is complete,

prepare the pipe where the rst sensor will be mounted.

IMPORTANT NOTE

Direct mode mounting requires that transducers be installed on opposite sides of the pipe. For

horizontal pipes, the transducers should be located at the 3 o’clock and 9 o’clock positions.

2. To prepare the pipe, temporarily position one track mount hardware assembly on each

side of the pipe where you intend to permanently mount them as shown below.

Ensure that pipe surface is smooth without any raised areas (seams, etc.) With a

pencil, marker or chalk, draw a rectangle around each track mount assembly. Remove

the hardware from the pipe and clean and de-grease the area within the rectangles. Use

the small sanding block provided with the installation hardware as necessary to

remove any grit, corrosion, rust, loose paint or other contaminants. Be sure to wipe

the surface clean after sanding. The cleaned surface should extend at least ½” beyond

the length and width of each assembly.

Mark pipe around each

track and clean within

the marked area.

TRACK 400

O.D. RANGE 1/4"-5"

TRACK 400

O.D. RANGE 1/4"-5"

0 1 4 53 86

2

REF

9

5 86

7

10

9

7

10

13

DIRECT MODE SPACING

12

13

REFLECT MODE SPACING

15

141211

15

1411

16

16

2019 21

18

17

2019 21

18

17

24 25

23

22

24 25

23

22

3. Re-install the two track mount hardware assemblies on the pipe and loosely secure

them in place with the mounting straps provided. Align the assemblies such that they

are positioned on top of the cleaned surfaces.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 20

Page 21

4. Wrap the Mylar spacing guide around the pipe placing it against the end of the track

mount assemblies. Ensure that it is snug around the pipe and mark along the

overlapping edge.

Wrap Mylar spacing guide

around pipe and mark

along overlapping edge.

TRACK 400

O.D. RANGE 1/4"-5"

TRACK 400

O.D. RANGE 1/4"-5"

0 1 4 53 86

2

REF

9

5 86

7

9

7

REFLECT MODE SPACING

15

141211

13

16

10

DIRECT MODE SPACING

15

1411

12

13

10

2019 21

18

17

16

2019 21

18

17

24 25

23

22

24 25

23

22

Draw the guide tightly

around the pipe and mark

at the overlapping edge.

5. Remove Mylar spacing guide and lay it out on a at surface. Either measure the exact

distance half-way between the overlap edge and the mark at the overlap, or fold the

guide from the overlap edge to overlap mark and draw a line at the fold or halfway

point.

Overlap edge mark

50%

50%

6. Reinstall the spacing guide and tape it in place. Use the edge of the guide to align each

assembly bracket as shown.

7. Rotate the track assemblies until the center of one track aligns with the center line

on the spacer guide, and the center of the other track aligns at the point where the

spacer guide ends meet. The tracks should now be 180° apart. Tighten both mounting

straps to secure the assembly to the pipe. Do not over tighten.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 21

Page 22

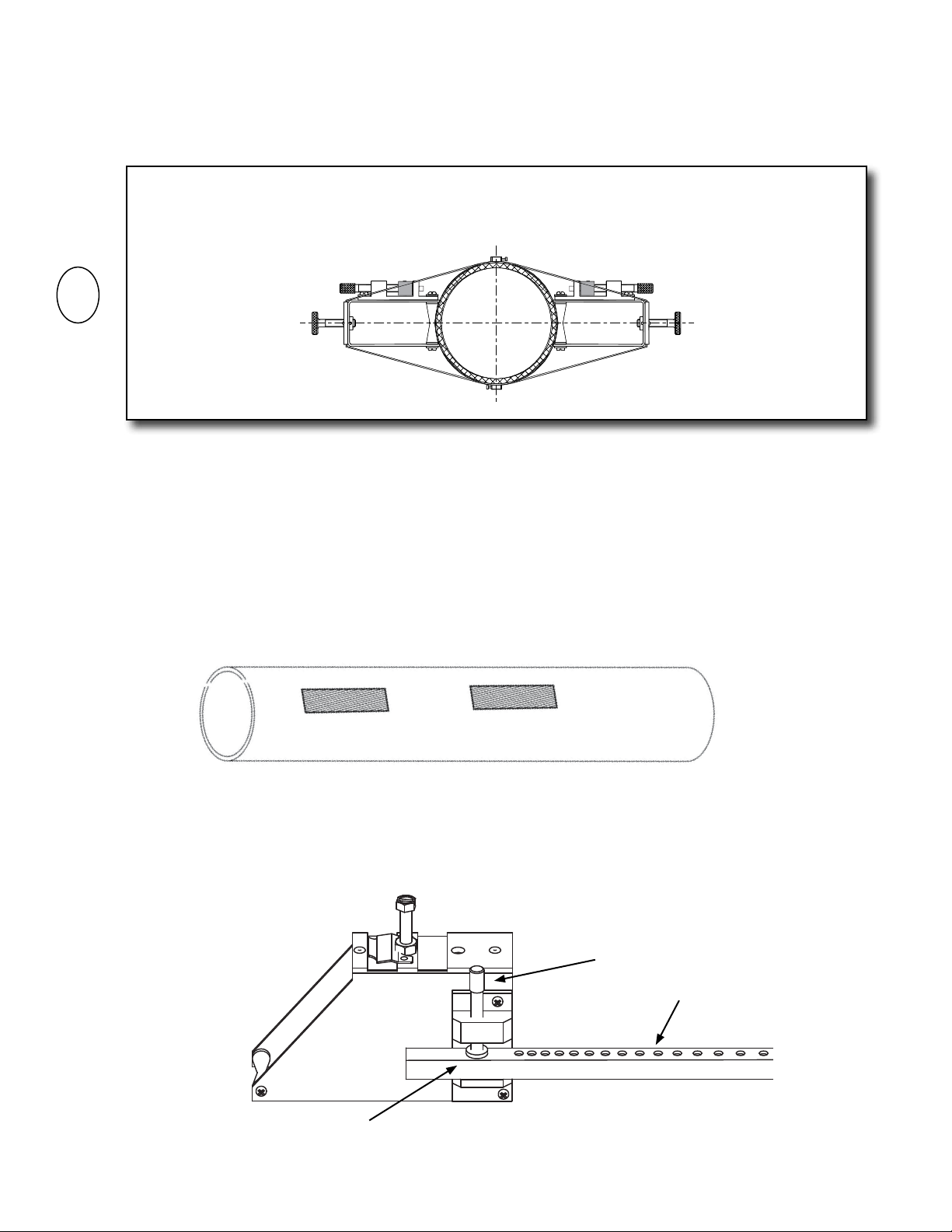

3.3.7 Installing Transducers In Bracket and Spacer Bar Hardware

1. Apply the dry coupling pad to the transducer as show below.

Apply a continuous

lengthwise 1/2” wide bead

of coupling compound

down the center of the

transducer.

2. This step only applies to reect mount transducers installed on copper and steel pipes.

For all other applications, skip to step 3.

Apply the dry coupling pad to the transducer as show below.

Place the dry coupling

pad on the transducer.

Gently press down just

enough to seat and center

the pad.

3. Slide the transducer into the mounting bracket back end rst, aligning the angled edge

of the transducer with the angled edge of the bracket. Do not allow the bottom of the

transducer to make contact with the pipe until it butts against the mounting bracket

stop. Push down rmly on the transducer to mate with pipe.

When installing the transducer,

do not allow the bottom face to

touch the pipe surface until it is

fully inserted to the stop.

Apply a second bead

of coupling compound

down the center of the dry

coupling pad.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 22

Page 23

REF

O.D. RANGE 1/4"-5"

6

7

5

Track 400

17

REFLECT MODE SPACING

13

9

10

8 12111514

16 1918202221232524

15.94

(405)

(71.1)

3.0

(76.2)

2.8

REF

O.D. RANGE 1/4"-5"

6

7

5

Track 400

17

REFLECT MODE SPACING

13

9

10

8 12111514

16 1918202221

23

CUSTOMER'S PIPE

2524

REF

O.D. RANGE 1/4"-5"

6

7

5

Track 400

9

10

8 11

15.94

(405)

4. Tighten the transducer clamping screw to hold the transducer rmly in place.

Do not over tighten the screw.

Transducer Clamping Screw

5. Repeat procedure for the second transducer.

3.3.8 Installing Transducers In Track Mount Hardware

1. Insert the index pin into the reference hole.

Reference hole

Track 400

O.D. RANGE 1/4"-5"

REF

9

675

8 11

10

2. Repeat step 1 and 2 in Section 3.3.7 as necessary to apply couplant and pad to

tranducer.

3. Place the transducer between the track rails, slightly behind the pin and under the

clamping screw assembly. Slide it forward until it butts rmly against the reference

pin. Once the transducer is in place, secure it with the sensor clamping screw. Do not

over tighten.

Clamping screw

Track 400

O.D. RANGE 1/4"-5"

REF

9

675

8

10

4. Repeat procedure for the second transducer.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 23

Page 24

3.4 CONNECTING THE TRANSDUCER SIGNAL CABLES

!

ONICON F-4000 transducer cables are special purpose coaxial cables. Care must be taken when

installing the cables to ensure that electrical noise will not affect the performance of the meter.

The cables must NOT be bundled or run in conduit with any other signal or power cables. The

maximum allowable cable length is 300 ft.

To install the cables, rst locate and install the wall-mount electronics enclosure and the

transducers.

Strain relief provided

Strain relief provided

FLOW

TYPICAL INSTALLATION WITH CONDUIT

TYPICAL INSTALLATION WITHOUT CONDUIT

FLOW

The transducer cables are provided with connectors already

installed at one end of the cable. Install this end of each

cable at the electronics enclosure as shown below using the

right angle adapters provided. When installing the cable,

avoid routing it close to strong sources of electrical noise,

and do not install cables in raceways with power or other

signal cables.

Once the correct cable length has been determined, install

the F-connectors provided to terminate the end of each cable.

WARNING

For proper operation, cables must not be bundled or run in conduit with any other signal or power

cables.

ENCLOSURE END (REF.)

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 24

Page 25

3.5 INSTALLING THE F-CONNECTORS

INSTRUCTIONS

9/16”

DIELECTRIC

CENTER

CONDUCTOR

5/16”

1/4”

CABLE

1/16” - 3/32” DIELECTRIC

EXTENDS BEYOND BRAID

COPPER BRAID

"F" CONNECTOR

CABLE

DIELECTRIC

CENTER

CONDUCTOR

1/16"

9/16”

DIELECTRIC

CENTER

CONDUCTOR

5/16”

1/4”

CABLE

1/16” - 3/32” DIELECTRIC

EXTENDS BEYOND BRAID

1/32” MAX. PROJECTION

OF DIELECTRIC

COPPER BRAID

Prior to installing the F-connectors, slide the upstream and downstream cable markers over the

ends of the cables followed by the strain relief and NPT adapters.

3.5.1 Cable Preparation

Strip and trim to length as shown. Do not push copper braid back over jacket.

3.5.2 Cable & Connector Assembly

3.5.3 Final Assembly

9/16”

CABLE

Thread cable into connector until the dielectric slightly protrudes from the end of the

barrel. The center conductor should protrude approximately 1/16” beyond the connector

1/4”

1/16” - 3/32” DIELECTRIC

EXTENDS BEYOND BRAID

COPPER BRAID

DIELECTRIC

CENTER

CONDUCTOR

5/16”

body as shown.

1/32” MAX. PROJECTION

OF DIELECTRIC

CABLE

"F" CONNECTOR

CENTER

CONDUCTOR

DIELECTRIC

1/16"

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 25

Place shrink tubing over the connector and shrink in place with hot air gun.

CABLE

SHRINK SLEEVE

(DWP125 - 1/2 X 3/4”)

F-CONNECTOR

P/N SPCF 59 I

1/8” (MIN)

Page 26

!

3.6 ELECTRICAL INSTALLATION

!

!

!

All user supplied conduit ttings, junction boxes, etc. must be installed in compliance with

federal, state and local building codes.

3.6.1 Input Power Options

The F-4000 can be ordered with two different input voltage options. This is not user

selectable in the eld. The input power options are:

11.5 - 28.5 VDC, 10 Watts maximum

90 - 240 VAC 50/60 Hz, 15 VA maximum

WARNING

Conduit openings in the F-4000 enclosure must be closed with UL listed ttings applicable to NEMA

4 enclosures.

WARNING

The protective earth connection must be made as shown in Section 3.6.2. Failure to do so will result

in an increased risk of injury.

WARNING

All mains voltage connections must be made through the pre-drilled conduit/strain relief opening

located at the bottom of the enclosure. Failure to do so will result in an increased risk of injury.

CAUTION

This product must be connected to earth ground for proper operation. Failure to do so may result in

erratic operation.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 26

Page 27

3.6.2 Electrical Connections

!

WARNING

Turn off mains power at the source prior to making power connections to the F-4000. Contact with

exposed live wiring may result in electric shock, burns and/or serious injury.

Protective Earth

ACDCHOT

POS +

NEU

NEG -

GND

GND

AC 90 - 240 VAC 50/60 Hz

DC 11.5 - 28.5 VDC

TB1

TB-1

I OUT 1

TB-2

TB-3

TB-4

RELAY 1 DIGITAL IN1 DIGITAL IN2

TB-5

TB-6

TB-7

TB-8

TB-9

TB-10

TB-11

TB-12

TB-13

TB-14

PGEN

TB-15

TB-16

See the table on the next page for text block 1 wiring connections.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 27

Page 28

Analog Output (IO1)

Term # Function Description

1 (+) 4 - 20 loop supply

2 (-) 4 - 20 loop return

Loop (externally) powered

4 - 20 mA output

3 Shield

RL=250 W typical, 750 W maximum

Vc=24 VDC typical / 30 VDC maximum

USER CONNECTIONS F-4000 INPUTS AND OUTPUTS

30Vd c

V

c

max

R

= 0 to 750

L

Relay Output (RELAY OUTPUT)

Term # Function Description

4 Common Relay Common

5 Normally Open Relay Output

6 Normally Closed Relay Output

7 Shield

RL=300 W minimum

Digital Inputs (NO TOT, CLR TOT)

Term # Function Description

8 (+) No Totalizer

9 (-) No Totalizer

Digital input used to inhibit

totalizer

10 Shield

11 (+) Reset Totalizer Digital input used to reset

totalizer to zero

12 (-) Reset Totalizer

13 Shield

Vc=2-10VDC; Then R

Vc=>10≤30VDC; Then R

=OW

L

=(Vc-10)/.02

L

30Vd c

V

c

max

ION= 100

ION= 4

V

c

= 4

I

ON

V

c

(min)

30Vd c

max

(min)

30Vd c

max

- 20

- 20

(max)

(max)

(max)

R

mA

mA

mA

C

L

NO

NC

R

L

R

L

500Ω

500Ω

Pulse Output (PULSE OUTPUT)

Term# Function Description

14 (+) Pulse Output Programmable pulse

ION= 10

30Vd c

V

c

max

(max)

mA

R

L

output. Optically isolated

(externally powered) open

V

o

collector.

15 (-) Pulse Output

16 Shield

Vc= +30 VDC maximum

RL = 3K W minimum

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 28

Page 29

SECTION 4.0: START-UP

i

Each time an F-4000 ow meter is installed on a pipe, a new installation “site” must be created or

an existing site must be recalled from memory. An installation “site” contains all of the operating

parameters required to congure the meter for one specic installation. If it does not exist, it must be

created before the meter can measure ow.

ONICON F-4000 ow meters are normally shipped with the intended installation site pre-programmed

into the memory of the meter. This pre-programmed site was created and stored in the memory at the

ONICON factory and is based on installation data provided to ONICON when the meter was ordered.

The information programmed into the site is also provided in a document that accompanies the

installation hardware. It is titled, “Site Installation Details”.

If the information contained in the Site Installation Details document matches that specic installation

location, then the stored site can be recalled as per section 4.2 below. If there is any discrepancy, the

site must be edited and resaved before it is used. Contact ONICON for assistance in editing or creating

a new site.

Once a site has been recalled and loaded into active memory, the transducers can be activated by using

the “Install” function. During this process the meter will automatically select the optimum operating

frequency and establish a speed of sound reading for the uid in the pipe. Depending on the pipe

material and the operating mode (reect or direct) the meter may also adjust for any zero offsets and set

the level for the empty pipe detector.

4.1 PROGRAM MODE KEYPAD FUNCTIONS

Keypad Pushbuttons Description of functions in program mode

Enter program mode or save selected option or numeric entry.

Right enters menu function or moves down to lower level menu.

Left exits menu function or moves up to higher menu level.

Used to scroll up and down through menu or option lists.

IMPORTANT NOTE

When powering the meter for the rst time, a splash screen message may scroll across the display.

This will only happen when no site is installed.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 29

Page 30

4.2 RECALLING A SAVED SITE

i

If this is the rst time the meter is installed, conrm that the site to be recalled matches the actual installation as

described above. This can be done by reviewing the Site Installations Detail document provided with the meter.

The procedure below is used to recall a saved site and load it into active memory. Recalling a site will

automatically over write any previously loaded site.

IMPORTANT NOTE

Choose the appropriate site from those listed. The site created at the ONICON factory is the serial

number of the meter. “Z” sites are factory defaults, and should not be used without rst consulting

ONICON technical service.

If at any time you wish to return to the beginning of this procedure, press repeatedly

until you arrive at Step#1.

Step

1.

2.

3.

4.

5.

6.

Press the Following

Keypad Pushbutton

(Press as necessary)

Displayed Information

(After Keypress)

Comment

Choose the appropriate site from those listed. The

correct site is the serial number of the meter. “Z”

sites are factory defaults, and should not be used.

7.

8.

9.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 30

Page 31

4.3 INSTALLING RECALLED SITES

When you “Install” a site, you activate the transducers so the meter can read ow. During this process,

the meter will select the best operating frequency and establish baseline operating parameters such as

the speed of sound reading in meters/second.

There are two different procedures for installing a site. One procedure is for transducers mounted in the

reect mode on steel or copper pipe. The other is for transducers mounted in the direct mode. The two

procedures are detailed below.

4.3.1 Reect Mount Installations

Follow the specic instructions below to complete the installation of the meter in reect mount

mode. If your meter is installed in direct mount mode, advance to section 4.2.2.

Step

1.

2.

3.

4.

5.

If at any time you wish to return to the beginning of this procedure, press

you arrive at Step#1.

Press the Following

Keypad Pushbutton

(Press 3 times)

Displayed Information

(After Keypress)

Comment

Your transducer model and size may be different.

Consult the Site Installation Details form for the

exact series and size.

repeatedly until

6.

(Press 3 times)

7.

8.

9.

It is possible that the meter will display a message other than the speed of sound. Section 6 in this manual

describes these messages and how to resolve them. Please contact ONICON with questions or concerns.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 31

Display will cycle through drives as the initial

installation is completed. Wait for this to complete.

Page 32

10. None

Displays the measured speed of sound. This number

should closely approximate the speed of sound

listed on the Site Installation Details document.

11.

If a “Use Actual Zero” message appears when installing a meter on a copper tube, follow the instructions

provided at the end of this table to complete the installation.

12. None

13.

AutoZero is checking and correcting for any zero

offset. Wait for this to complete.

MTYmatic is the default empty pipe detection

setting.

You are no longer in the program mode. The meter is

now measuring ow. Run mode menus are described

in section 4.4.

Alternate Procedure for Zeroing Flow When Installing Meter on Copper Tube

1. None

2.

Complete the following steps only if ow can be stopped in the pipe. If not, skip to the last step in this table.

Follow the procedure outlined below if the AutoZero

failed to activate on copper tubing.

MTYmatic is the default empty pipe detection

setting.

3.

4

5.

6.

7. None

8.

Enter Zero Flow Adjust. Use Up/Down keys as

necessary to select Actual Zero.

Display will integrate zero ow for 60 seconds, do

not hit enter until complete.

Zero ow integration complete.

You are no longer in the program mode.

The meter is now measuring ow.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 32

Page 33

4.3.2 Direct Mount installations

Follow the specic instructions below to complete the installation of the meter in direct

mount mode.

Step

1.

2.

3.

4.

5.

If at any time you wish to return to the beginning of this procedure, press

until you arrive at Step#1.

Press the Following

Keypad Pushbutton

(Press 3 times)

Displayed Information

(After Keypress)

Comment

Your transducer model and size may be different.

Consult the Site Installation Details form for the exact

series and size.

repeatedly

6.

(Press 3 times)

7.

8.

9.

It is possible that the meter will display a message other than the speed of sound. Section 6 in this manual

describes these messages and how to resolve them. Please contact ONICON with questions or concerns.

10. None

Complete the following steps only if ow can be stopped in the pipe. If not, skip to the last step in this table.

11.

Display will cycle through drives as the initial

installation is completed. Wait for this to complete.

Displays the measured speed of sound. This number

should closely approximate the speed of sound

listed on the Site Installation Details document.

MTYmatic is the default empty pipe detection

setting.

12.

13.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 33

Enter Zero Flow Adjust. Use Up/Down keys as

necessary to select Actual Zero.

Page 34

14.

15.

16. None

17.

Display will integrate zero ow for 60 seconds, do

not hit enter until complete.

Zero ow integration complete.

You are no longer in the program mode.

The meter is now measuring ow.

4.4 NAVIGATING THE RUN MODE MENU PAGES

The display contains two lines of alphanumeric characters. Each line can be independently set to

display any of the seven operating parameters listed below.

Keypad Pushbuttons Description of functions in run mode

Not used in run mode.

Right arrow activates cursor below left most character on the

display. The cursor must be active and visible before you can

change the displayed data. Left arrow not used.

Used to scroll up and down through the display menu options.

Flow Rate – displays the current instantaneous ow value (e.g. 20.3 GAL/M). Note that reverse

ow is indicated by a minus sign preceding the displayed value (e.g. – 20.3 GAL/M).

Flow Total – displays the current ow total (e.g. 15030.5 GAL) Note: ow multipliers can be kilo

(K) or mega (M). The resolution of the displayed total can be set to show 1 – 3 digits to the right of

the decimal point. Totalizer will roll over to zero when the maximum count is exceeded.

Gain Level Percentage (Valc) – displays the signal amplier gain level as a percentage value. The

higher the Valc value, the better. Valc values greater than 30 are generally considered good.

Aeration Percentage (Vaer) - displays the noise level generally associated with entrained air as a

percentage value. Lower values indicate less entrained air.

Signal Strength (mV) - displays the actual signal level in millivolts. Higher signal levels indicate a

good sonic coupling.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 34

Page 35

Speed of Sound (M/S)- displays the current speed of sound of the uid in meters/second.

i

Operating Status (----------) displays the current status of alram messages. The table below briey

describes the one letter code for each message.

Letter Alarm Message

S Spacing - indicates a problem with the spacing of the transducers.

Z Zero - indicates a fault with the zeroing function.

E Empty - indicates that the empty pipe alarm is active.

R Rate - indicates a ow rate above or below the maximum or minimum alarm levels.

F Fault - indicates three continuous seconds without a new data update.

A Aeration - indicates excessive amounts of entrained air in the ow stream.

M Memory - last valid reading for a selected interval during a fault condition.

K Make-up - indicates an in-process make-up occurred.

I Interface - indicates the maximum speed of sound alarm set-point was exceeded.

4.5 SECURITY SWITCH

The ONICON F-4200 features a security switch that prevents changes to program settings when

enabled. The meter is shipped with this security switch disabled so that the user can recall and

install the saved “site.” It is strongly recommended that this switch be moved to the enabled

position once the meter is fully operational.

Left: Security Disabled Right: Security Enabled

IMPORTANT NOTE

With the security switch enabled, you can still navigate through the programming menus, but

you cannot change any of the settings. A “SECURITY” message will appear on the LCD display to

indicate that the security switch is enabled.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 35

Page 36

SECTION 5.0: BACnet / Modbus Communications

5.1 BACnet / Modbus Communications

The ONICON F-4000 Ultrasonic Flow meter is provided with an RS485 interface for connection to

either a BACnet MS/TP or Modbus RTU network. Each meter is individually programmed at the

factory with application specic data provided by the customer during the process of ordering the

meter. This would normally include programming of all the settings necessary to allow the meter to

communicate over the desired network.

All of the network communications parameters can also be manually changed in the eld. The

information provided below describes each parameter setting in detail and the table in section 5.2

shows how to change the settings.

Modbus RTU Communications

The Modbus RTU protocol is a data link protocol that uses the services of the RS-485

physical layer. Modbus is a master/slave protocol. Only one master device originates

messages on the network. Slave devices on the network only communicate when responding

to a data request from the master device. The ONICON F-4000 implementation of Modbus

RTU is as a slave device.

BACnet MS/TP Communications

The The BACnet Master-Slave/Token-Passing (MS/TP) protocol is a data link protocol that

uses the services of the RS-485 physical layer. BACnet MS/TP is a peer-to-peer, multiplemaster protocol based on token passing. Only master devices can receive the token, and only

the device holding the token is allowed to originate a message on the bus. Slave devices

on the bus only communicate on the bus when responding to a data request from a master

device. The ONICON F-4000 implementation of BACnet MS/TP is as a slave only device. It

does not support Who-is / I-am services. To add these services, it will be necessary to either

install the device as a virtual device on a network master or use a proxy server to provide

these services on larger networks.

Baud Rates on the RS485 Network

An RS485 network can be congured to communicate at different baud rates. It is very

important that all of the devices on the network bus communicate at the same baud rate.

The baud rate setting determines the rate at which devices communicate data over the

network. The available Baud rate settings available on F-4000 are: 300, 1200, 2400, 4800,

9600 and 38400. The default Baud rate setting is 9600 bps.

Parity Settings for Modbus

The Modbus protocol includes error detection in the form of a parity check. Every device on

the network must use the same parity setting. The ONICON F-4000 parity selections can be

“Even”, “None” or “Odd”. The default setting is “None”.

Word Order Settings for Modbus

Modbus master devices can be congured with differing data structures within Modbus

messages. The word order format of the slave device must match the requirements of the

master. The ONICON F-4000 word order can be “Normal” or “Reversed”. The default setting

is “Normal”.

RS485 Network Addressing

Before the F-4000 can communicate on the RS485 network, the appropriate device address

must be programmed into the meter. The valid address range is 1 – 254. The default address

is 001. This address is used by both BACnet and Modbus networks.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 36

Page 37

BACnet Instance and Network Numbers

Before the F-4000 can communicate on the BACnet network, the appropriate instance and

network numbers must be programmed into the meter. The valid instance number range is

1- 4,194,303. The instance number cannot be duplicated by any other device on the entire

extended BACnet network. The default instance number is 4194303.

The valid network number range is 1- 65,530. Each network number denes a specic RS485

sub-network and is unique on the entire extended BACnet network. The default network number is 1.

Both must be assigned to the meter.

Device Name for BACnet

The BACnet Device Object object_name property is writable. This name will be shown on the

network as the name of the meter. It can be up to 15 characters long. The default name is “ONICON”.

Biasing and Termination on the RS485 Network

The ONICON F-4000 does not provide biasing voltage to the RS485 network. A 120Ω

termination resistor should be installed across the RS485 terminals as show below when the

meter is installed at the end of the line.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 37

Page 38

5.2 Changing Network Communications Settings

Step

1.

2. Meter Facilites

3.

4.

5.

6.

7.

8.

9.

Press the Following

Keypad Pushbutton

(Press 7 times)

Displayed Information

(After Keypress)

Perferred Units

> English

RS-485 Setup

Protocol

>Modbus

Protocol

:Modbus

Baud Rate

>9600

Baud Rate

:9600

Parity

>None

to change protocol

to change Baud rate

Comment

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

Parity

:None

Word Format

>Normal

Word Format

:Normal

Address

>1

Address

=_1

Device Number (Instance)

>4194303

Device Number

=_4194303

Network Number

>0

Network Number

=_0

Device Name

>ONICON

Device Name

?ONICON

Device Name

>ONICON

to change parity setting

This step not shown with BACnet protocol

to change Modbus word format

Use

This step not shown with Modbus protocol

Use

Use

Use

to change address

to change number

to change number

to change number

22.

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 38

Exit program mode

Page 39

5.3 BACnet

DEVICE OBJECT

Property Description and/or Example

Object _ Identier Instance number (1- 4,194,303)

Set via front panel user interface

Object _ Name Writeable (15 characters max) Default: ONICON

Object _ Type Device (8)

System _ Status OPERATIONAL (0)

Vendor _ Name ONICON Inc.

Vendor _ Identier 206

Model _ Name F-4000

Firmware _ Revision 2.04.06 (or later)

Application _ Software _ Version 012813-1338

Protocol _ Version 1

Protocol _ Revision 10

Protocol _ Services _ Supported Read property, read property multiple, write property

Protocol _ Object _ Types _ Supported Device, Analog Value, Binary Value

Object _ List Dx, AV0…AV28, BV0…BV10

Max _ APDU _ Length _ Supported 480

Segmentation _ Supported No _ Segmentation (3)

Local _ Time HH:MM:SS

Local _ Date MM:DD:YY

APDU _ Timeout 0

Number _ Of _ APDU _ Retries 0

Device _ Address _ Binding 0

Database _ Revision 2

ANALOG VALUE OBJECT List

BACnet Object Object _ Name BACnet Object Object _ Name

AV0 Flow AV15 Highest expected ow

AV1 Average ow AV16 Lowest expected ow

AV2 Raw ow AV17 Aeration alarm level

AV3 Volume total AV18 Slew mode selection

AV4 Sonic velocity AV19 Time averaging period

AV5 Delta time AV20 Smart slew seed

AV6 Valc AV21 Device status

AV7 Aeration AV22 Site name

AV8 Deadband control AV23 Version information

AV9 Batch/sample total AV24 Date/time last reset

AV10 High ow alarm level AV25 Op sys P/N

AV11 Low ow alarm level AV26 Firmware checksum

AV12 Vs alarm level AV27 Compile time info

AV13 Flow velocity AV28 System date/time

AV14 Signal

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 39

Page 40

ANALOG VALUE OBJECT Properties

Property Identier Description and/or Example R/W

Object_Identier Unique identier number R

Object_Type 2 – Analog Value R

Present_Value Real (Floating point) Number R

Description Character string representing engineering units (e.g. GAL/MIN) R

Units No-units (95) R

Status_Flags IN_ALARM,FAULT,OVERRIDDEN,OUT_OF_SERVICE (e.g. 0,0,0,0) R

Event_State 0 - NORMAL R

Out_Of_Service 0 - FALSE R

BINARY VALUE OBJECTS

BACnet Object Description

BV0 Totalizer reset (Read/Write)

BV1 Spacing alarm (Read only)

BV2 Empty alarm (Read only)

BV3 Rate alarm(Read only)

BV4 Fault alarm (Read only)

BV5 Aeration alarm (Read only)

BV6 Memory alarm (Read only)

BV7 Makeup alarm (Read only)

BV8 Interface alarm (Read only)

BV9 Pig alarm (Read only)

BV10 Zeromatic alarm (Read only)

BINARY VALUE OBJECT Properties

Property Identier Description and/or Example R/W

Object_Identier Unique identier number R

Object_Type 5 – Binary Value R

Present_Value Binary (e.g. 0 or 1) R/W*

Description Character string representing object function (e.g. Aeration Alarm) R

Priority_Array Manual Operator (8) R

Status_Flags IN_ALARM,FAULT,OVERRIDDEN,OUT_OF_SERVICE (e.g. 0,0,0,0) R

Event_State NORMAL R

Out_Of_Service FALSE R

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 40

Page 41

BACnet Protocol Implementation Conformance Statement

Date: April 13, 2012

Vendor Name: ONICON, Inc.

Product Name: F-4000 Series Ultrasonic Flow Meter

Product Model Number: F-4000

Application Software Version: 012813-1338

Firmware Revision: 2.04.06

BACnet Protocol Revision: 1

Product Description: Clamp-on ultrasonic ow meter for liquids

BACnet Standardized Device Prole (Annex L):

o BACnet Operator Workstation (B-OWS)

o BACnet Advanced Operator Workstation (BAWS)

o BACnet Operator Display (B-OD)

o BACnet Building Controller (B-BC)

o BACnet Advanced Application Controller (BAAC)

o BACnet Application Specic Controller (BASC)

þ BACnet Smart Sensor (B-SS)

o BACnet Smart Actuator (B-SA)

List all BACnet Interoperability Building blocks Supported (Annex K):

þ K.1.2 BIBB – Data Sharing – ReadProperty-B (DS-RP-B)

þ K.1.4 BIBB – Data Sharing – ReadPropertyMultiple-B (DS-RPM-B)

þ K.1.8 BIBB – Data Sharing – WriteProperty-B (DS-WP-B)

Segmentation Capability:

Segmentation is not supported

Standard Object Types Supported:

þ Device Object

þ Binary Value Object

þ Analog Value Object

Dynamically Creatable Object: None

Dynamically Deletable Object: None

Optional Properties Supported:

Device Object:

PROP_LOCAL_TIME

PROP_LOCAL_DATE

PROP_DESCRIPTION

Binary Value Object:

PROP_DESCRIPTION

Analog Value Object:

PROP_DESCRIPTION

Operational Writable Properties: None

Operational Conditional Writable Properties: None

Proprietary Properties: None

Range Restrictions: None

Data Link Layer Options:

o BACnet IP, (Annex J)

o BACnet IP, (Annex J), Foreign Device

o ISO 8802-3, Ethernet (Clause 7)

o ATA 878.1, 2.5 Mb. ARCNET (Clause 8)

o ATA 878.1, EIA-485 ARCNET (Clause 8), baud rate(s)

o MS/TP master (Clause 9), baud rate(s):

þ MS/TP slave (Clause 9), baud rate(s): 300, 1200, 2400, 4800, 9600, 38400

o Point-To-Point, EIA 232 (Clause 10), baud rate(s):

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-4000 Series Ultrasonic Flow Meter Manual 05/15 - 0707-13 / 18838 Page 41

Page 42

o Point-To-Point, modem, (Clause 10), baud rate(s):

o LonTalk, (Clause 11), medium:

o BACnet/ZigBee (ANNEX O)

o Other:

Device Address Binding:

Is static device binding supported? o Yes þ No

Networking Options:

o Router, Clause 6 - List all routing congurations, e.g., ARCNET-Ethernet, Ethernet- MS/TP, etc.

o Annex H, BACnet Tunneling Router over IP

5.4 Modbus

Modbus is a commonly used protocol for communication in supervisory and data acquisition

(SCADA) applications. It uses registers to address data which can be formatted in various types

including, REAL, INTEGER, & BOOLEAN (coils).

The following Modbus Function Codes are supported:

Function Code Name Description

1 Read Coil(s) Read one or more coil present values (0 or 1)

2 Read Discreet Input(s) Read one or more discreet input present values (0 or 1)

3 Read Holding Register(s) Read one or more holding register present values

4 Read Input Register(s) Read one or more input register present values

5 Write Single Coil Write (0 or 1) to a single coil

6 Write Single Register Write to a single holding register

15 Write Multiple Coils Write (0 or 1) to multiple coils