Page 1

F-1500 Series Insertion Turbine Flow Meter

Installation and Operation Guide

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699

1018-6 / 35726

www.onicon.com • sales@onicon.com

02-18

Page 2

SAFETY INFORMATION

i

!

!

This meter was calibrated at the factory before shipment. To ensure correct use of the meter, please read

this manual thoroughly.

Regarding this manual:

• This manual should be passed on to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed without prior notice.

• All rights reserved. No part of this manual may be reproduced in any form without

ONICON’s written permission.

• ONICON makes no warranty of any kind with regard to this material, including, but not

limited to, implied warranties of merchantability and suitability for a particular purpose.

• All reasonable effort has been made to ensure the accuracy of the contents of this manual.

However, if any errors are found, please inform ONICON.

• ONICON assumes no responsibilities for this product except as stated in the warranty.

• If the customer or any third party is harmed by the use of this product, ONICON assumes

no responsibility for any such harm owing to any defects in the product which were not

predictable, or for any indirect damages.

Safety Precautions:

The following general safety precautions must be observed during all phases of installation,

operation, service, and repair of this product. Failure to comply with these precautions or with

specic WARNINGS given elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the product. ONICON Incorporated assumes no liability for the

customer’s failure to comply with these requirements. If this product is used in a manner not

specied in this manual, the protection provided by this product may be impaired.

The following symbols are used in this manual:

WARNING

Messages identied as “WARNING” contain information regarding the personal safety of

individuals involved in the installation, operation or service of this product.

CAUTION

Messages identied as “CAUTION” contain information regarding potential damage to the

product or other ancillary products.

Messages identied as “IMPORTANT NOTE” contain information critical to the proper

operation of the product.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 2

IMPORTANT NOTE

Page 3

WARNINGS AND CAUTIONS

!

!

WARNING

Consult the ow meter nameplate for specic ow meter approvals before any hazardous

location installation.

Hot tapping must be performed by a trained professional. U.S. regulations often require a hot

tap permit. The manufacturer of the hot tap equipment and/or the contractor performing the hot

tap is responsible for providing proof of such a permit.

All ow meter connections, isolation valves and ttings for cold/hot tapping must have the

same or higher pressure rating as the main pipeline.

For F-1500 series insertion ow meter installations, an insertion tool must be used for any

installation where a ow meter is inserted under pressure greater than 50 psig.

To avoid serious injury, DO NOT loosen a compression tting under pressure.

To avoid potential electric shock, follow National Electric Code or your local code when wiring

this unit to a power source. Failure to do so could result in injury or death. All AC power

connections must be in accordance with published CE directives. All wiring procedures must

be performed with the power Off.

Before attempting any ow meter repair, verify that the line is not pressurized. Always remove

main power before disassembling any part of the mass ow meter.

CAUTION

Calibration must be performed by qualied personnel. ONICON Incorporated, strongly

recommends that you return your ow meter to the factory for calibration.

In order to achieve accurate and repeatable performance, the ow meter must be installed with

at least the specied minimum length of straight pipe upstream and downstream of the ow

meter’s location.

When using toxic or corrosive gases, purge the line with inert gas for a minimum of four hours

at full gas ow before installing the ow meter.

For F-1500 series insertion ow meter installations, the sensor alignment pointer must point

downstream in the direction of ow.

The AC wire insulation temperature rating must meet or exceed 85° C (185° F)

No part of this publication may be copied or distributed, transmitted, transcribed, stored in a

retrieval system, or translated into any human or computer language, in any form or by any means,

electronic, mechanical, manual, or otherwise, or disclosed to third parties without the express

written permission of ONICON Incorporated. The information contained in this manual is subject

to change without notice.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 3

Page 4

TABLE OF CONTENTS

1.0 INTRODUCTION .................................................................................................7

1.1 Purpose of This Guide ............................................................................... 7

1.2 ONICON F-1500 Series Insertion Turbine Flow Meters ...........................7

1.2.1 Using This Manual .....................................................................8

1.2.2 Receipt of System Components .................................................. 8

1.2.3 Technical Assistance ...................................................................8

1.2.4 Warranty .......................................................................................8

1.3 How the ONICON Insertion Turbine Mass Flow Meter Operates ............9

1.3.1 Velocity Measurement .................................................................9

Table 1. Measurable Range .....................................................9

1.3.2 Temperature Measurement .......................................................... 9

1.3.3 Pressure Measurement .................................................................9

1.4 Flow Meter Conguration .......................................................................10

1.4.1 Multivariable Options ...............................................................10

1.4.2 Line Size / Process Connections / Materials ............................10

1.4.3 Flow Meter Electronics ..............................................................10

2.0 INSTALLATION .................................................................................................11

2.1 Installation Overview ..............................................................................11

2.1.1 Flow Meter Installation Requirements .....................................11

2.1.2 Unobstructed Flow Requirements ............................................11

2.2 Flow Meter Installation ...........................................................................12

Figure 1. Isolation Valve Requirements ...............................12

2.2.1 Standard Installation Guidelines ..............................................13

2.2.2 Hot Tap Guidelines ....................................................................14

Figure 2. Hot Tap Sequence .................................................14

2.3 FLOW METER INSERTION .....................................................................15

2.3.1 Installing Flow Meters ...............................................................15

Figure 3. Insertion Calculation (Meter w Insertion Tool .....15

2.3.2 Flow Meters with Permanent Insertion Tool ............................16

Figure 4. Flow Meters with Permanent Insertion Tool .......16

2.3.3 Flow Meters with Removable Insertion Tool............................17

Figure 5. Flow Meters with Removable Insertion Tool .......17

2.3.4 Packing Gland Connection (No Insertion Tool) ........................19

Figure 6. Insertion Calculation (without Insertion Tool) ....19

2.3.5 Flow Meters with No Insertion Tool .........................................20

2.4 ADJUSTING THE DISPLAY ORIENTATION ..........................................20

Figure 7. Display/Keypad Viewing Adjustment ..................20

2.5 LOOP-POWERED FLOW METER WIRING CONNECTIONS ................21

Figure 8. Wiring Terminals for Loop-Powered Version ....... 21

2.5.1 Input Power Connections .......................................................... 21

Figure 9. DC Power Connections .........................................21

2.5.2 4-20 mA OUTPUT CONNECTIONS ..........................................22

Figure 10. Load Resistance Versus Input Voltage ................22

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 4

Page 5

2.5.3 Frequency Output Connections ................................................ 22

Figure 11. Isolated Frequency Output External Power ....... 22

Figure 12. Non-Isolated Frequency Output External Pwr ...22

2.5.4 Optional Backlight Connection .................................................23

Figure 13. Backlight Using External Power Supply ............ 23

2.5.5 Remote Electronics Wiring ........................................................ 23

Figure 14. Loop-Powered Junction Box Connections .........23

Figure 15. Loop-Power Mass Box Sensor Connections ....... 23

2.6 HIGH POWER METER WIRING CONNECTIONS ..................................24

Figure 16. AC Wiring Terminals ..........................................24

2.6.1 Input Power Connections .......................................................... 24

Figure 17. AC Power Connections .......................................24

Figure 18. DC Wiring Terminals ...........................................25

Figure 19. DC Power Connections .......................................25

2.6.2 4-20 mA OUTPUT CONNECTIONS ..........................................25

Figure 20. Load Resistance Versus Input Voltage ................26

Figure 21. Isolated 4–20 mA Output External Power .........26

Figure 22. Non-Isolated 4–20 mA Output Input Power ...... 26

Figure 23. Isolated 4–20 mA Output Using Meter Power ... 26

2.6.3 Frequency Output Connections ................................................ 27

Figure 24. Isolated Frequency External Power .................... 27

Figure 25. Non-Isolated Frequency Output Input Power ....27

Figure 26. Isolated Frequency Provided Power Supply ......27

2.6.4 Pulse Output Connections ........................................................28

Figure 27. Isolated Pulse Output External Power ...............28

Figure 28. Non-Isolated Pulse Output Input Power ............ 28

Figure 29. Isolated Pulse Output Provided Power ..............28

2.6.5 Alarm Output Connections ....................................................... 29

Figure 30. Isolated Alarm Output External Power .............. 29

Figure 31. Non-Isolated Alarm Output Internal Power .......29

Figure 32. Isolated Alarm Output Provided Power ............. 29

2.6.6 Remote Electronics Wiring ........................................................ 30

Figure 33. High Power Junction Box Sensor Connections .. 30

2.6.7 Optional Input Electronics Wiring ............................................ 30

2.6.8 OPTIONAL ENERGY EMS RTD INPUT WIRING .....................31

Figure 34. Optional Energy EMS RTD Input Wiring ...........31

2.6.9 OPTIONAL EXTERNAL 4-20 mA INPUT WIRING ..................31

Figure 35. External 4-20 mA Input Wiring External Pwr ....31

Figure 36. External 4-20 mA Input Wiring - DC Powered...31

Figure 37. External 4-20 mA Input Wiring - AC Powered ..32

2.6.10 OPTIONAL CONTACT CLOSURE INPUT WIRING ................. 32

Figure 38. Optional Contact Closure Input Wiring .............32

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 5

Page 6

3.0 OPERATING INSTRUCTIONS ......................................................................... 33

3.1 FLOW METER DISPLAY/KEYPAD .........................................................33

Figure 39. Flow Meter Display/Keypad ............................... 33

3.2 START-UP ................................................................................................34

3.3 USING THE SET-UP MENUS .................................................................. 35

3.3.1 Programming the Flow Meter ....................................................36

3.3.2 Output Menu ..............................................................................37

3.3.3 Display Menu .............................................................................39

3.3.4 Alarms Menu .............................................................................40

3.3.5 Totalizer #1 Menu ......................................................................41

3.3.6 Totalizer #2 Menu ......................................................................42

3.3.7 Energy Menu – For Energy Meters Only ...................................43

3.3.8 Fluid Menu ................................................................................44

3.3.9 UNITS MENU ............................................................................45

3.3.10 TIME & DATE MENU ................................................................46

3.3.11 Diagnostics Menu ......................................................................47

3.3.12 Calibration Menu ....................................................................... 48

3.3.13 Password Menu ..........................................................................48

4.0. SERIAL COMMUNICATIONS .......................................................................... 49

4.1 HART COMMUNICATIONS....................................................................49

4.1.1 WIRING .....................................................................................49

Figure 40. Loop Powered Meter Wiring (HART) .................49

Figure 41. DC Powered Meter Wiring (HART) ....................50

Figure 42. AC Powered Meter Wiring (HART) ....................50

4.1.2 HART Commands with the DD Menu .....................................51

4.1.3 HART Commands with Generic DD Menu ............................... 55

4.2 MODBUS COMMUNICATIONS .............................................................58

4.2.1 Wiring ........................................................................................ 58

Figure 43. RS-485 Wiring (MODBUS) ..................................58

4.2.2 Menu Items ................................................................................58

Table 2. Byte Order ............................................................... 59

4.2.3 Register Denitions ....................................................................60

Table 3. Register Denitions .................................................60

4.3 BACnet MS/TP Communications ...........................................................65

4.3.1. BACnet MS/TP Description ......................................................65

4.3.2. Baud Rates on the MS/TP Bus ..................................................65

4.3.2.1. Baud Rate and MAC address conguration ................. 65

4.3.3. Supported BACnet Objects ........................................................65

4.3.3.1. Device Object: ...............................................................67

4.3.3.2. Analog Input Object ......................................................68

4.3.3.3. Binary Input Object ......................................................69

4.3.3.4. Binary Value Object ......................................................69

4.3.4. ANNEX BACnet Conformance Statement ................................69

APPENDIX

A-1 Ordering Information

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 6

Page 7

SECTION 1.0: INTRODUCTION

!

We at ONICON Incorporated, would like to thank you for purchasing our quality, U.S. made, Turbine

Flow Meter. As our valued customer, our commitment to you is to provide fast reliable service and

assistance, while continuing to offer you new products to meet your growing ow measurement needs.

1.1 PURPOSE OF THIS GUIDE

We have written this guide to provide the persons responsible for the installation, operation and

maintenance of your turbine ow meter with the most specic equipment information they will

need. This is NOT an electrical or plumbing trade manual.

WARNING

Please do not permit any persons to install, operate or maintain this equipment unless they have a

complete knowledge of their trade skills and are competent to work on high pressure hot and cold

water, steam or pressurized gas systems, according to their individual trades. Death or permanent

injury may result from accidents with these systems.

This guide is the basic reference tool for ONICON F-1500 Series Turbine Flow Meters. If you have

not purchased all of the options, there will be references in this manual which are not applicable

to your meter(s).

1.2 ONICON F-1500 SERIES INSERTION TURBINE FLOW METERS

The ONICON F-1500 Insertion Turbine Flow Meters provide a reliable solution for process

ow measurement. From a single entry point in the pipeline, F-1500 meters offer precise

measurements of mass or volumetric ow rates.

Multi-Parameter Mass Flow Meters

Mass ow meters utilize three primary sensing elements: a rotating turbine velocity sensor, an

RTD temperature sensor, and an optional solid state pressure sensor to measure the mass ow rate

of gases, liquids, and steam.

Meters are available as loop powered devices or with up to three 4-20 mA analog output signals

for monitoring your choice of the ve process variables (mass ow, volumetric ow, temperature,

pressure and uid density). The Energy Monitoring option permits real-time calculation of energy

consumption for a facility or process. BACnet MS/TP and MODBUS RTU RS485 interface options

are also available.

Volumetric Flow Meters

The primary sensing element of a volumetric ow meter is a rotating turbine velocity sensor.

Meters are loop powered. The analog 4-20 mA output signal offers your choice of volumetric

or mass ow rate. Mass ow rate is based on a constant value for uid density stored in the

instrument’s memory.

Both the mass and volumetric ow meters are provide with a local keypad / display which

provides instantaneous ow rate, total, and process parameters in engineering units. A pulse

output signal for remote totalization and BACnet MS/TP, MODBUS RTU RS485 or HART

communications are also available.

Digital electronics allow for easy reconguration for most gases, liquids and steam. ONICON

meters’ simple installation combines with an easy-to-use interface that provides quick set up,

long term reliability and accurate mass ow measurement over a wide range of ows, pressures

and temperatures.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 7

Page 8

1.2.1 Using This Manual

This manual provides information needed to install and operate the F-1500 insertion style

ow meter.

Section 1 includes the introduction and product description.

Section 2 provides information needed for installation.

Section 3 describes system operation and programming.

Section 4 provides information on HART, MODBUS and BACnet protocols.

Section 5 covers troubleshooting and repair.

Appendix A - Product Specications

Appendix B– Flow Meter Calculations

Appendix C – Glossary of Terms

Appendix D – Terms & Conditions

1.2.2 Receipt of System Components

When receiving an ONICON ow meter, carefully check the outside packing carton for

damage incurred in shipment. If the carton is damaged, notify the local carrier and submit

a report to the factory or distributor. Remove the packing slip and check that all ordered

components are present. Make sure any spare parts or accessories are not discarded with the

packing material. Do not return any equipment to the factory without rst contacting ONICON

Customer Service.

1.2.3 Technical Assistance

If you encounter a problem with your ow meter, review the conguration information

for each step of the installation, operation and set up procedures. Verify that your settings

and adjustments are consistent with factory recommendations. Refer to Section 5,

Troubleshooting, for specic information and recommendations.

If the problem persists after following the troubleshooting procedures outlined in Section 5,

contact ONICON Incorporated Technical Support at

(727) 447-6140 between 8:00AM and 5:00PM EST.

When calling Technical Support, have the following information on hand:

The serial number and model number (shown on the meter nameplate)

The problem you are encountering and any corrective action taken

Application information (uid, pressure, temperature and piping conguration)

1.2.4 Warranty

Warranty ONICON’s complete warranty is included in Appendix D of this manual as part of

the “Conditions of Sale”. ONICON provides a two-year warranty.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 8

Page 9

1.3 HOW THE ONICON INSERTION TURBINE MASS FLOW METER OPERATES

ONICON F-1500 Series Insertion Turbine Mass Flow Meters are designed to monitor mass ow

rate by directly measuring uid velocity, temperature and when required, pressure. The builtin ow computer calculates the mass ow rate and volumetric ow rate based on these direct

measurements. The sensing head is built into the insertion turbine meter’s ow body. To measure

uid velocity, the ow meter incorporates a rotating turbine in the ow stream. The rotation

is converted into an electrical output that is proportional to the uid velocity. Temperature is

measured using a platinum resistance temperature detector (PRTD). When require, pressure

measurement is achieved using an integral solid state pressure transducer.

1.3.1 Velocity Measurement

Fluid passing through the turbine causes its rotor to spin. The rotor is fabricated from 17-4PH

stainless steel which is slightly magnetic, and is positioned in close proximity to a passive

magnetic pickup coil. As each blade rotates by the pickup coil, a small sinusoidal voltage is

generated. This sinusoidal voltage is then amplied, ltered, and shaped by the measurement

electronics. The frequency of the signal is proportional to the owing velocity.

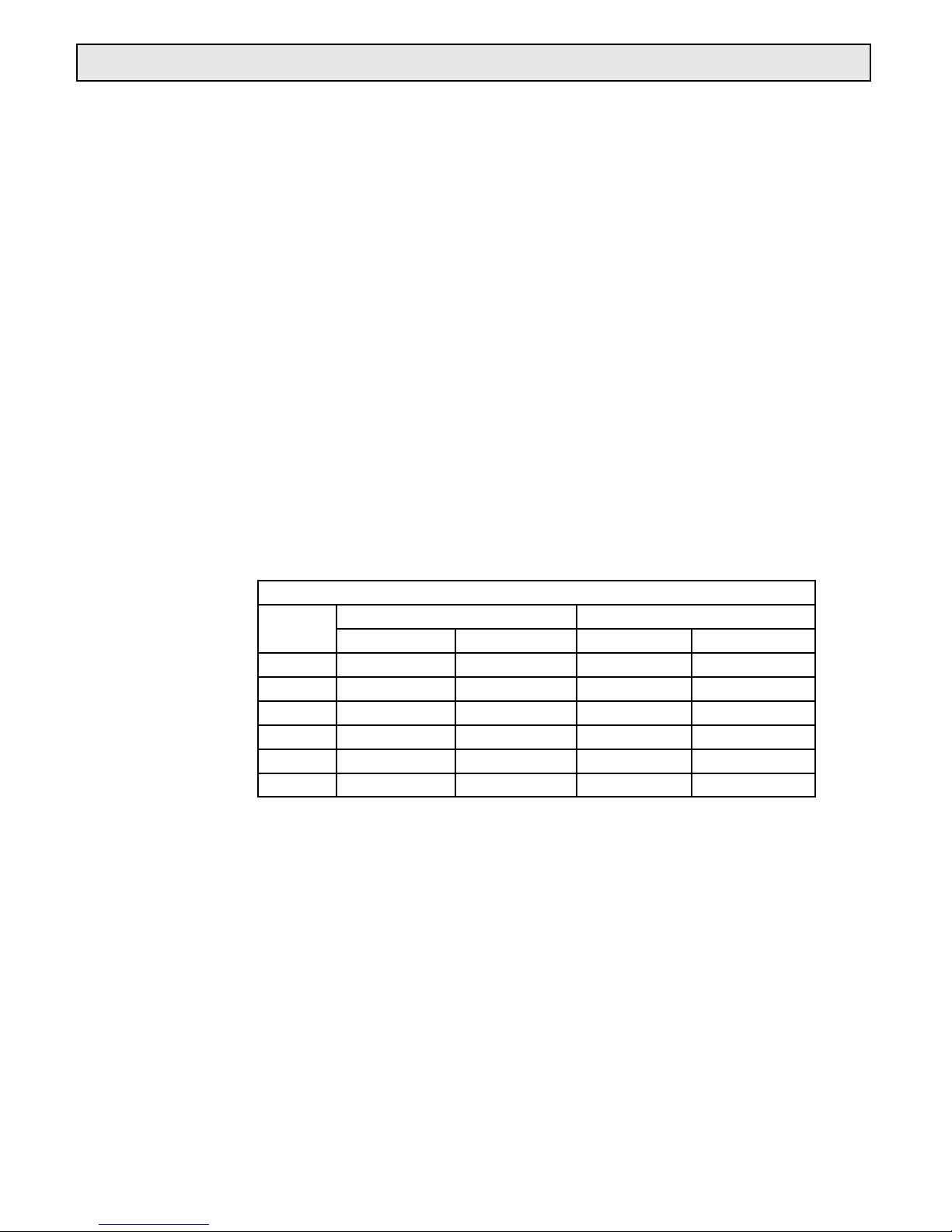

Flow Velocity Range

To ensure trouble-free operation, turbine ow meters must be correctly sized so that the ow

velocity range through the meter lies within the measurable velocity range.

The measurable range is dened by the minimum and maximum velocity using the following table.

Gas or Steam

Minimum Velocity Maximum Velocity

ft/sec m/sec ft/sec m/sec

R40 3.5 1.07 43.0 13.11

R30 4.0 1.22 62.5 19.05

R25 5.0 1.52 80.0 24.38

R20 7.0 2.13 100.0 30.48

R15 8.5 2.59 134.6 41.03

R10 12.0 3.66 205.0 62.48

Table 1. Measurable Range

The pressure drop for F-1500 Series insertion meters is negligible.

1.3.2 Temperature Measurement

This ow meter uses a 1000 ohm platinum resistance temperature detector (PRTD) to measure

uid temperature.

1.3.3 Pressure Measurement

The F-1500 incorporates a solid-state pressure transducer isolated by a 316 SS diaphragm.

The transducer itself is micro-machined silicon, fabricated using integrated circuit processing

technology. A nine-point pressure/temperature calibration is performed on every sensor.

Digital compensation allows these transducers to operate within a 0.3% of full scale accuracy

band within the entire ambient temperature range of -40° F to 140° F (-40° C to 60° C).

Thermal isolation of the pressure transducer ensures the same accuracy across the allowable

process uid temperature range of -200° F to 750° F (-128° C to 400° C).

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 9

Page 10

1.4 Flow Meter Conguration

The F-1500 Insertion Turbine Mass Flow Meter has a sensing head which contains the turbine

rotor, temperature sensor, and pressure tap. The pressure sensor, if provided, is located in the

pressure transducer housing between the stem and electronics housing.

The meter is installed through a full block valve and mounting adapter having a clear,

cylindrical port diameter of 1.875” diameter. It can be installed during system downtime or

using standard “Hot Tap” procedures.

The meter directly monitors the velocity at a point in the cross-sectional area of a pipe, duct, or

stack. The velocity at a point in the pipe varies as a function of the Reynolds number. When a

uid ows through a pipe, the velocity generated is not constant across the diameter. The uid

velocity varies across the diameter of the pipe creating a “Velocity Prole”. That is, velocities

near the center of the pipe are faster than those nearer to the wall. In addition, the velocity prole

varies in concert with ow rate from the lowest to the highest ows. Mathematical descriptions

of this prole have been developed for over 100 years. By knowing the velocity prole and the

ow rate at a single point, the average ow rate can be determined. The accuracy of the ow rate

computation depends on adherence to the piping installation requirements given in Chapter 2. If

adherence to those guidelines cannot be met, contact the factory for specic installation advice.

1.4.1 Multivariable Options

Different versions of the meter are capable of providing the following ow measurement options:

Volumetric ow; Mass ow with temperature compensation; Mass ow with temperature and

pressure compensation; Steam energy ow with temperature compensation; Steam energy

ow with temperature and pressure compensation, Mass or Energy ow with temperature and

external pressure compensation and Net Energy using a second temperature sensor.

1.4.2 Line Size / Process Connections / Materials

The F-1500 can be used in line sizes 2” and greater and is built with a packing gland design

using 2 inch NPT, or 2 inch anged connections (ANSI 150, 300, 600, PN16, 40, or 64 class

anges). The packing gland design is available with a permanent or removable retractor.

1.4.3 Flow Meter Electronics

The ow meter electronics are available mounted directly to the ow body, or mounted remotely.

The electronics housing may be used indoors or outdoors, including wet environments. Available

input power options are: DC loop powered (2-wire), DC powered, or AC powered. Three analog

output signals are available for your choice of three of the ve process variables: mass ow rate,

volumetric ow rate, temperature, pressure or uid density. A pulse output signal for remote

totalization and BACnet, MODBUS or HART communications is also available.

Each meter includes a local 2 x 16 character LCD display housed within the enclosure.

Local operation and reconguration is accomplished using six push-button operated via

nger touch. For hazardous locations, the six buttons can be operated with the electronics

enclosure sealed using a hand-held magnet, thereby maintaining the integrity of the

hazardous location certication.

The electronics include nonvolatile memory that stores all conguration information. The

nonvolatile memory allows the ow meter to function immediately upon power up or after

an interruption in power. All ow meters are calibrated and congured for the customer’s

ow application.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 10

Page 11

SECTION 2.0 INSTALLATION

!

2.1 INSTALLATION OVERVIEW

ONICON F-1500 Insertion Turbine Flow Meter installations are simple and straightforward. After

reviewing the installation requirements given below, see page 24 for installation instructions.

Wiring instructions begin on page 38.

2.1.1 Flow Meter Installation Requirements

WARNING

Consult the ow meter nameplate for specic ow meter approvals before any

hazardous location installation.

Before installing the ow meter, verify the installation site allows for these considerations:

1. Line pressure and temperature will not exceed the ow meter rating.

2. The location meets the required minimum number of pipe diameters upstream and

downstream of the sensor head as illustrated in Figure 4.

3. Safe and convenient access with adequate overhead clearance for maintenance purposes.

4. Verify that the cable entry into the instrument meets the specic standard required for

hazardous area installations.

5. For remote installations, verify the supplied cable length is sufcient to connect the ow

meter sensor to the remote electronics.

Also, before installation, check your ow system for anomalies such as:

• Leaks

• Valves or restrictions in the ow path that could create disturbances in the ow

prole that might cause unexpected ow rate indications

• Avoid areas where high RF, EMI, or other electrical interference may be present.

Devices such as VFD’s (variable frequency drives), large AC motors, etc

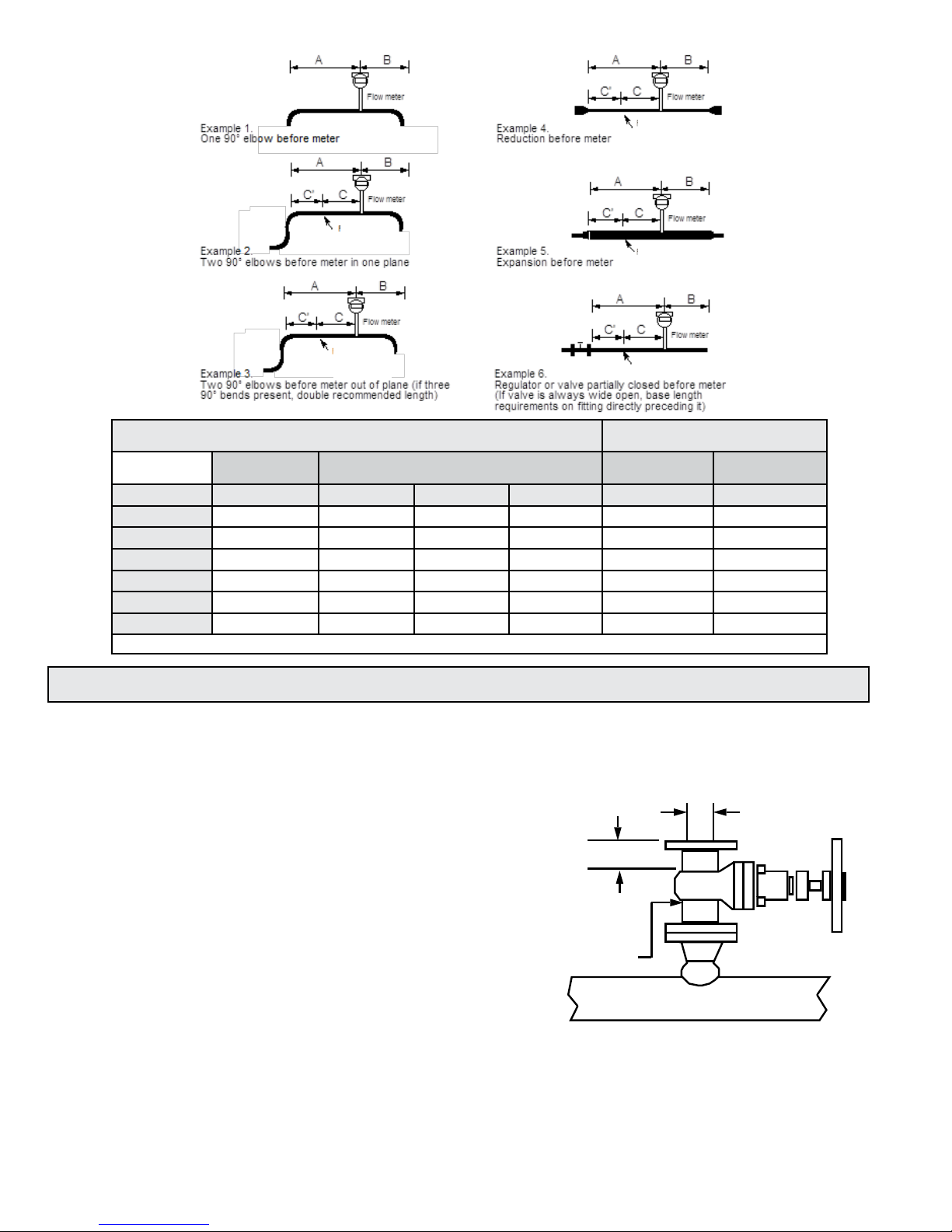

2.1.2 Unobstructed Flow Requirements

Select an installation site that will minimize possible distortion in the ow prole. Valves,

elbows, control valves and other piping components may cause ow disturbances. Check

your specic piping condition against the examples shown below. In order to achieve

accurate and repeatable performance, install the ow meter using the recommended number

of straight run pipe diameters upstream and downstream of the sensor.

Note: For liquid applications in vertical pipes, avoid installing with ow in the downward

direction because the pipe may not be full at all points. Choose to install the meter with ow

in the upward direction, if possible.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 11

Page 12

1.875-inch min.

valve bore

2- inch min.

2- inch

valve size

Flow

straightener

(if used)

Flow

straightener

(if used)

Flow straightener

(if used)

Flow straightener

(if used)

Flow straightener (if used)

Minimum Required

Upstream Diameters

No Flow

Straightener

Example A A C C’ B B

1 10 D N/A N/A N/A 5 D 5 D

2 15 D 10 D 8 D 2 D 5 D 5 D

3 30 D 15 D 13 D 2 D 5 D 5 D

4 10 D N/A N/A N/A 5 D 5 D

5 20 D 10 D 8 D 2 D 5 D 5 D

6 50 D 25 D 23 D 2 D 5 D 5 D

2.2 FLOW METER INSTALLATION

Prepare the pipeline for installation using either a standard or hot tap method described on the

following pages. Refer to a standard code for all pipe tapping operations. The following tapping

instructions are general in nature and intended for guideline purposes only. Before installing

the meter, review the mounting position and isolation value requirements given below.

Mounting Position

Allow clearance between the electronics enclosure

top and any other obstruction when the meter is

fully retracted.

Minimum Required

Downstream Diameters

With Flow Straightener No Flow

D = Internal diameter of channel.

Straightener

With Flow

Straightener

Isolation Valve Selection

Always install an isolation valve. If you supply

the isolation valve, it must meet the following

requirements:

1. A minimum valve bore diameter of 1.875”

is required, and the valve’s body size should

be 2”. Normally, gate valves are used.

2. Verify that the valve’s body and ange rating are within the ow meter’s maximum

operating pressure and temperature.

3. Choose an isolation valve with at least two inches existing between the ange face

and the gate portion of the valve. This ensures that the ow meter’s sensor head will

not interfere with the operation of the isolation valve.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 12

Figure 1. Isolation Valve Requirements

Page 13

2.2.1 Standard Installation Guidelines

!

!

CAUTION

When using toxic or corrosive gases, purge the line with inert gas for a minimum of

four hours at full gas ow before installing the ow meter.

Refer to a standard code for all pipe tapping operations. The following tapping instructions

are general in nature and intended as a guideline only.

1. Conrm that the installation site meets the minimum upstream and downstream pipe

diameter requirements. See Figure 4.

2. Turn off the ow of process gas, liquid or steam. Verify that the line is not

pressurized.

3. Use a cutting torch or sharp cutting tool to tap into the pipe. The pipe opening must

be at least 1.875” in diameter. (Do not attempt to insert the sensor probe through a

smaller hole.)

4. Remove all burrs from the hole. Rough edges may cause ow prole distortions

that could affect ow meter accuracy. Also, obstructions could damage the sensor

assembly when inserting into the pipe.

All ow meter connections, isolation valves and ttings for cold tapping must have the

same or higher pressure rating as the main pipeline.

After cutting, measure the thickness of the cut-out and record this number for

calculating the insertion depth.

5. Weld the ow meter pipe connection onto the pipe. Make sure this connection is

within ± 5° perpendicular to the pipe center line.

Install the isolation valve.

6. When welding is complete and all ttings are installed, close the isolation valve or

cap the line. Run a static pressure check on the welds. If pressure loss or leaks are

detected, repair the joint and re-test.

7. The rst time the sensor is inserted, install the check-disc tool on the ow meter

rather than the rotor.

8. Open the isolation valve and insert the check-disc tool. After successful insertion,

retract the sensor and remove the ow meter.

9. Install the rotor and connect the meter to the pipe process connection.

10. Calculate the sensor probe insertion depth and insert the sensor probe into the pipe

as described on the following pages.

WARNING

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 13

Page 14

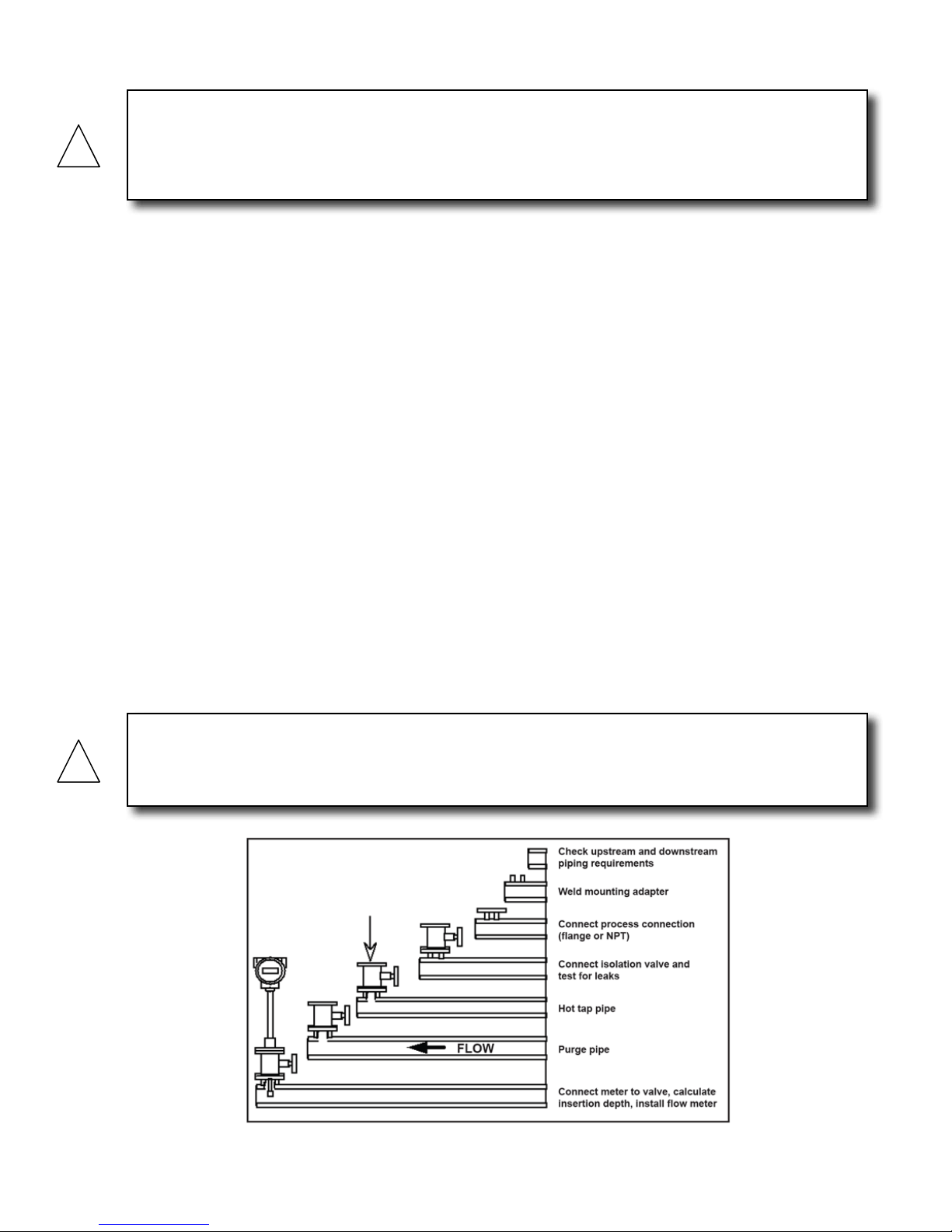

2.2.2 Hot Tap Guidelines

!

!

WARNING

Hot tapping must be performed by a trained professional. US regulations often require

a hot tap permit. The manufacturer of the hot tap equipment and/or the contractor

performing the hot tap is responsible for providing proof of such a permit.

Refer to a standard code for all pipe tapping operations. The following tapping instructions

are general in nature and intended as a guideline only.

1. Conrm that the installation site meets the minimum upstream and downstream pipe

diameter requirements.

2. Weld a 2” mounting adapter on the pipe. Make sure the mounting adapter is within ± 5°

perpendicular to the pipe center line (see previous page). The pipe opening must be at

least 1.875” in diameter.

3. Connect a 2” process connection on the mounting adapter.

4. Connect an isolation valve on the process connection. The valve’s full open bore must be

at least 1.875” in diameter.

5. Run a static pressure check on the welds. If pressure loss or leaks are detected, repair the

joint and re-test.

6. Connect the hot tapping equipment to the isolation valve, open the isolation valve and

drill at least a 1.875” diameter hole.

7. Retract the drill, close the isolation valve, and remove the hot tapping equipment.

8. The rst time the sensor is installed, install the check-disc tool on the ow meter rather

than the rotor.

9. Open the isolation valve and insert the check-disc tool. After successful insertion, retract

the sensor, close the isolation valve and remove the ow meter.

10. Install the rotor, connect the ow meter to the isolation valve and open the isolation valve.

11. Calculate the sensor probe insertion depth and insert the sensor probe into the pipe as

described on the following pages.

WARNING

All ow meter connections, isolation valves, and ttings for hot tapping must have the

same or higher pressure rating as the main pipeline.

Figure 2. Hot Tap Sequence

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 14

Page 15

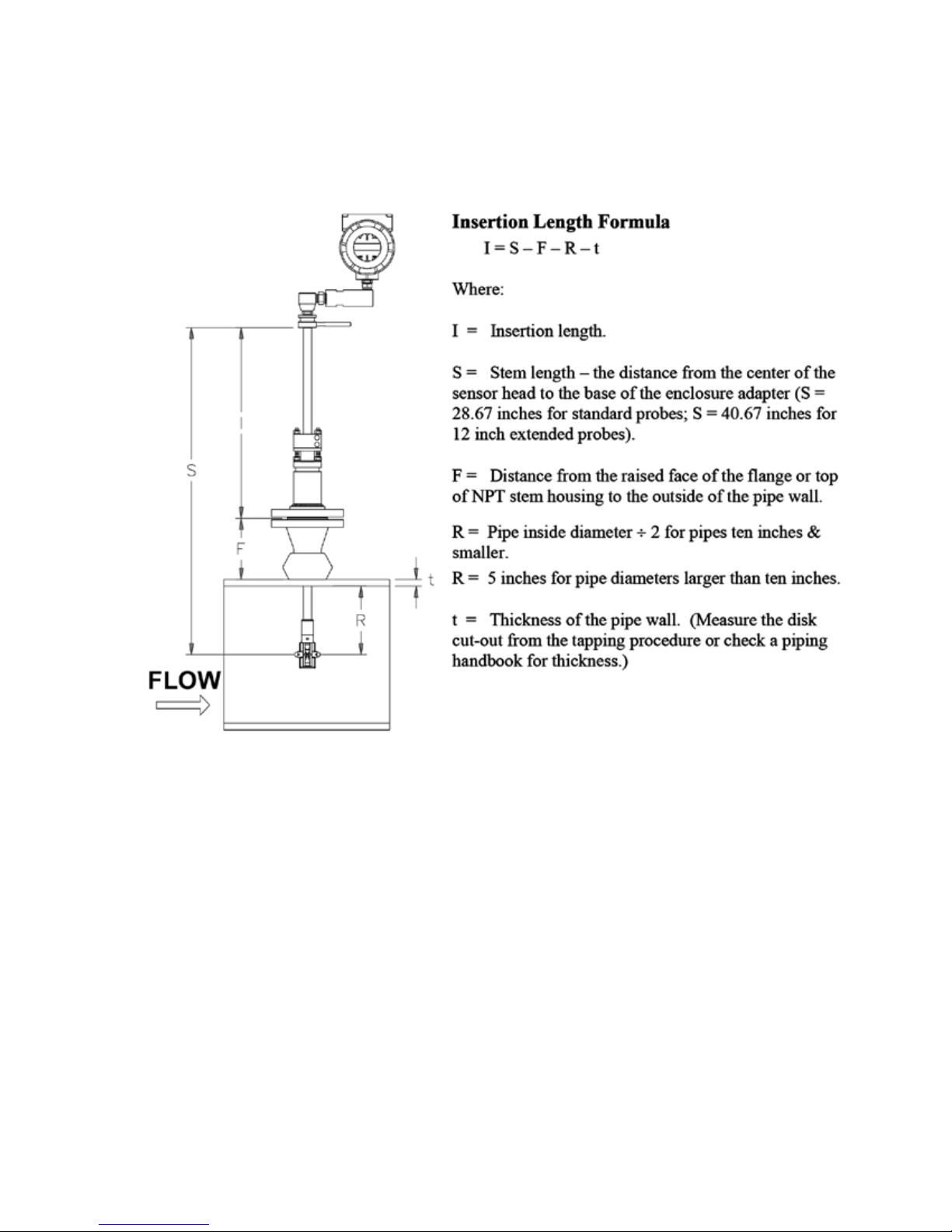

2.3 FLOW METER INSERTION

!

The sensor head must be properly positioned in the pipe. For this reason, it is important that

insertion length calculations are carefully followed. A sensor probe inserted at the wrong depth in

the pipe will result in inaccurate readings.

Insertion ow meters are applicable to pipes 2” and larger. For pipe sizes 10” and smaller, the

center line of the meter’s sensing head is located at the pipe’s center line. For pipe sizes larger

than 10”, the center line of the sensing head is located in the pipe’s cross section 5” from the inner

wall of the pipe; i.e., its “wetted” depth from the wall to the center line of the sensing head is 5”.

Insertion ow meters are available in two probe lengths:

• Standard Probe conguration is used with most ow meter process connections. The length,

S, of the stem is 28.67”.

• 12-Inch Extended Probe conguration is used with exceptionally lengthy ow meter process

connections. The length, S, of the stem is 40.67”.

Use the Correct Insertion Formula

Depending on your ow meter’s process connection, use the applicable insertion length formula

and installation procedure as follows:

• Flow meters with a packing gland type connection (NPT or anged) congured with an

insertion tool, follow the instructions beginning on page 29.

• Flow meters with a packing gland type connection (NPT or anged) without an insertion tool,

follow the instructions beginning on page 32.

WARNING

An insertion tool must be used for any installation where a ow meter is inserted under

pressure greater than 50 psig.

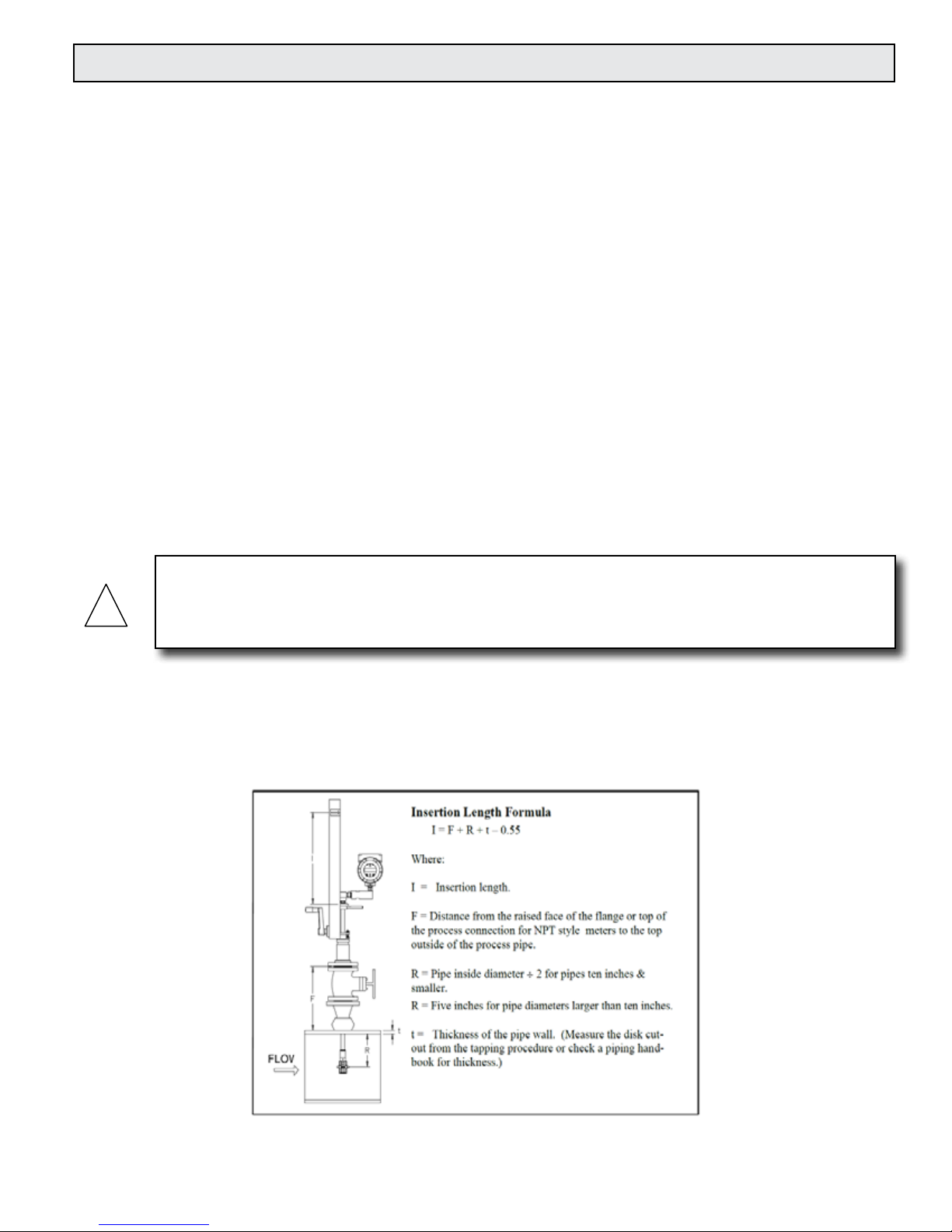

2.3.1 Installing Flow Meters *

Use the formula below to determine the insertion depth for ow meters (NPT and anged)

equipped with an insertion tool. To install, see the next page for instructions for meters with a

permanent insertion tool. For meters with a removable insertion tool, see page 17.

Figure 3. Insertion Calculation (Meters with Insertion Tool)

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 15

Page 16

Example 1: Flange Style Meters:

To install an F-1500 ow meter into a 14 inch schedule 40 pipe, the following measurements

are taken:

F = 12 inches

R = 5 inches

t = 0.438 inches

The example insertion length is 16.89 inches.

Example 2: NPT Style Meters:

The length of thread engagement on the NPT style meters is also subtracted in the equation. The

length of the threaded portion of the NPT meter is 1.18 inches. Measure the thread portion still

showing after the installation and subtract that amount from 1.18 inches. This gives you the

thread engagement length. If this cannot be measured use .55 inch for this amount.

F = 12 inches

R = 5 inches

t = 0.438 inches

The example insertion length is 16.34 inches.

*All dimensions are in inches.

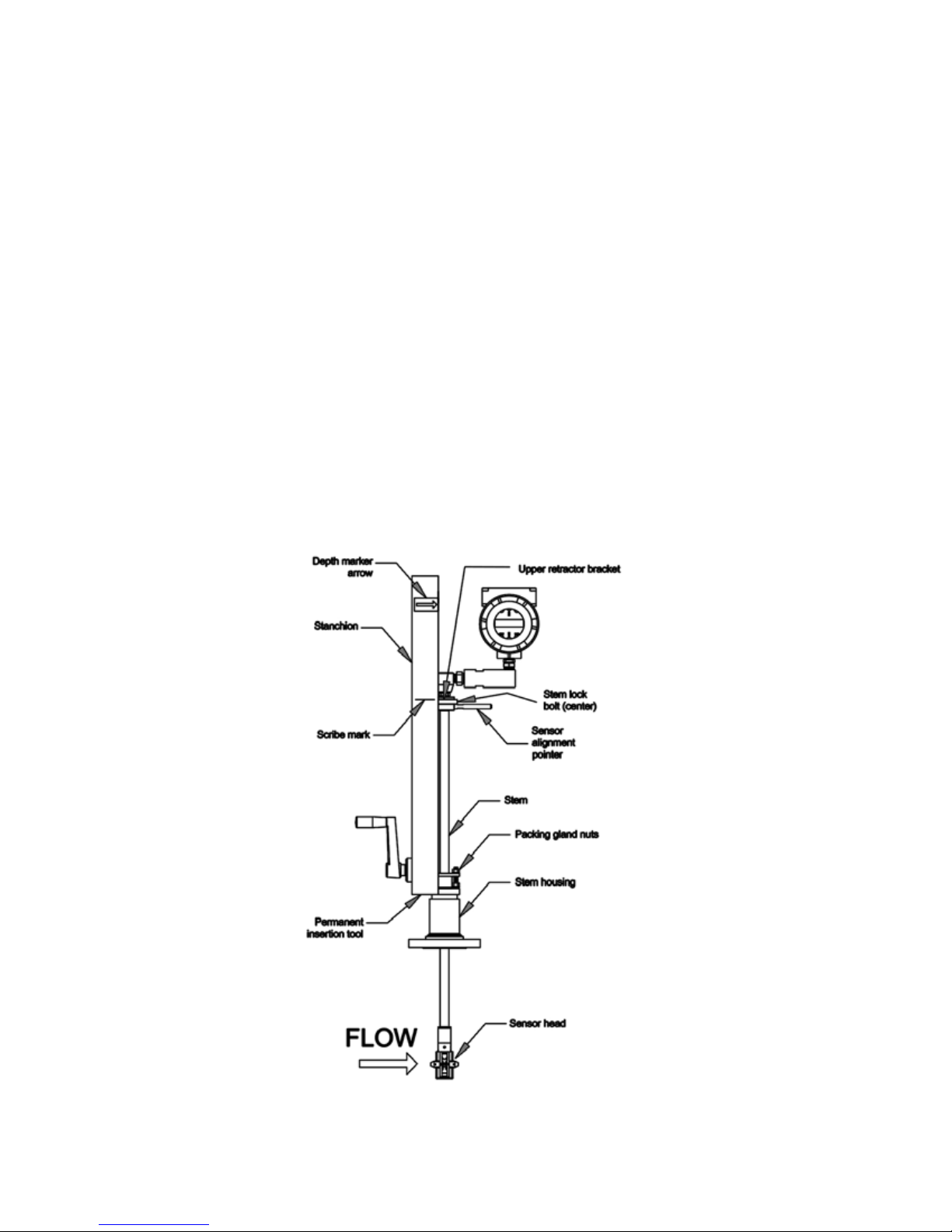

2.3.2 Insertion Procedure for Flow Meters with Permanent Insertion Tool

Figure 4. Flow Meter with Permanent Insertion Tool

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 16

Page 17

1. Calculate the required sensor probe insertion length (see previous page). Measure from the

!

i

depth marker arrow down the stanchion and scribe a mark at the calculated insertion depth.

2. Fully retract the ow meter until the sensor head is touching the bottom of the stem housing.

Attach the meter assembly to the full-port isolation valve. Use Teon tape or pipe sealant to

improve seal and prevent seizing on NPT style.

3. Loosen the two packing gland nuts on the stem housing of the meter. Loosen the stem lock

bolt adjacent to the sensor alignment pointer. Align the sensor head using the sensor alignment pointer. Adjust the alignment pointer parallel to the pipe and pointing downstream.

Tighten the stem lock bolt to secure the sensor position.

4. Slowly open the isolation valve to the full open position. If necessary, slightly tighten the

two packing gland nuts to reduce the leakage around the stem.

5. Turn the insertion tool handle clockwise to insert the sensor head into the pipe. Continue

until the top of the upper retractor bracket aligns with the insertion length position scribed

on the stanchion. Do not force the stem into the pipe.

6. Tighten the packing gland nuts to stop leakage around the stem. Do not torque over 20 ft-lb.

CAUTION

The sensor alignment pointer must point downstream, in the direction of ow.

IMPORTANT NOTE

If line pressure is above 500 psig, it could require up to 25 ft lb of torque to insert the

ow meter. Do not confuse this with possible interference in the pipe.

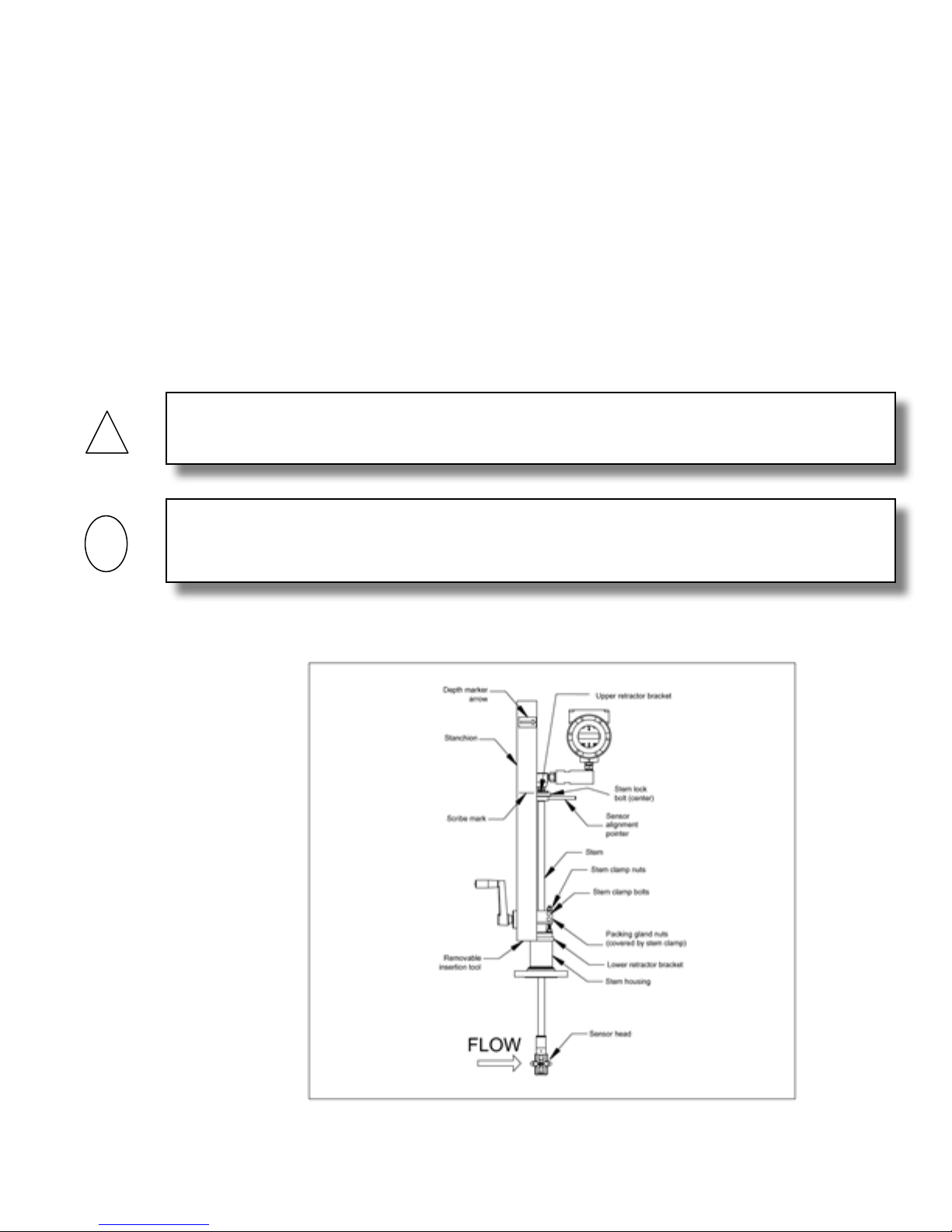

2.3.3 Insertion Procedure for Flow Meters with Removable Insertion Tool

Figure 5. Flow Meter with Removable Insertion Tool

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 17

Page 18

1. Calculate the required sensor probe insertion length. Measure from the depth marker

!

i

arrow down the stanchion and scribe a mark at the calculated insertion depth.

2. Fully retract the ow meter until the sensor head is touching the bottom of the stem

housing. Attach the meter assembly to the full-port isolation valve. Use Teon tape or

pipe sealant to improve seal and prevent seizing on NPT style.

3. Remove the two top stem clamp nuts and loosen two stem clamp bolts. Slide the stem

clamp away to expose the packing gland nuts.

4. Loosen the two packing gland nuts. Loosen the stem lock bolt adjacent to the sensor

alignment pointer. Align the sensor head using the sensor alignment pointer. Adjust the

alignment pointer parallel to the pipe and pointing downstream. Tighten the stem lock

bolt to secure the sensor position.

5. Slowly open the isolation valve to the full open position. If necessary, slightly tighten

the two packing gland nuts to reduce the leakage around the stem.

6. Turn the insertion tool handle clockwise to insert the stem into the pipe. Continue until

the top of the upper retractor bracket lines up with the insertion length mark scribed on

the stanchion. Do not force the stem into the pipe.

CAUTION

The sensor alignment pointer must point downstream, in the direction of ow.

IMPORTANT NOTE

If line pressure is above 500 psig, it could require up to 25 ft lb of torque to insert the

ow meter. Do not confuse this with possible interference in the pipe.

7. Tighten the packing gland nuts to stop leakage around the stem. Do not torque over 20 ft-lbs.

8. Slide the stem clamp back into position. Torque stem clamp bolts to 15 ft-lbs. Replace the

stem clamp nuts and torque to 10-15 ft-lbs.

9. To separate the insertion tool from the ow meter, remove four socket head cap bolts

securing the upper and lower retractor brackets. Remove the insertion tool.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 18

Page 19

2.3.4 Installation of Meters with Packing Gland Connection (No Insertion Tool)*

Use the following formula to determine insertion depth for meters with a packing gland

connection (NPT and anged) without an insertion tool.

Figure 6. Flow Meter with Removable Insertion Tool

Example:

To install the F-1500 ow meter with a standard probe (S = 28.67) into a

14 inch schedule 40 pipe, the following measurements are taken:

F = 3 inches

R = 5 inches

t = 0.438 inches

The example insertion length is 20.23 inches.

*All dimensions are in inches.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 19

Page 20

2.3.5 Insertion Procedure for Flow Meters with No Insertion Tool

!

!

1. Calculate the required sensor probe insertion length.

2. Fully retract the stem until the sensor head is touching the bottom of the stem housing.

Remove the two top stem clamp nuts and loosen two stem clamp bolts. Slide the stem

clamp away to expose the packing gland nuts. Loosen the two packing gland nuts.

3. Align the sensor head using the sensor alignment pointer. Adjust the alignment pointer

parallel to the pipe and pointing downstream.

4. Insert the sensor head into the pipe until insertion length, I, is achieved. Do not force the

stem into the pipe.

5. Tighten the packing gland nuts to stop leakage around the stem. Do not torque over 20 ft-lbs.

6. Slide the stem clamp back into position. Torque stem clamp bolts to 15 ft-lbs. Replace

the stem clamp nuts and torque to 10-15 ft-lbs.

WARNING

The line pressure must be less than 50 psig for installation.

CAUTION

The sensor alignment pointer must point downstream, in the direction of ow.

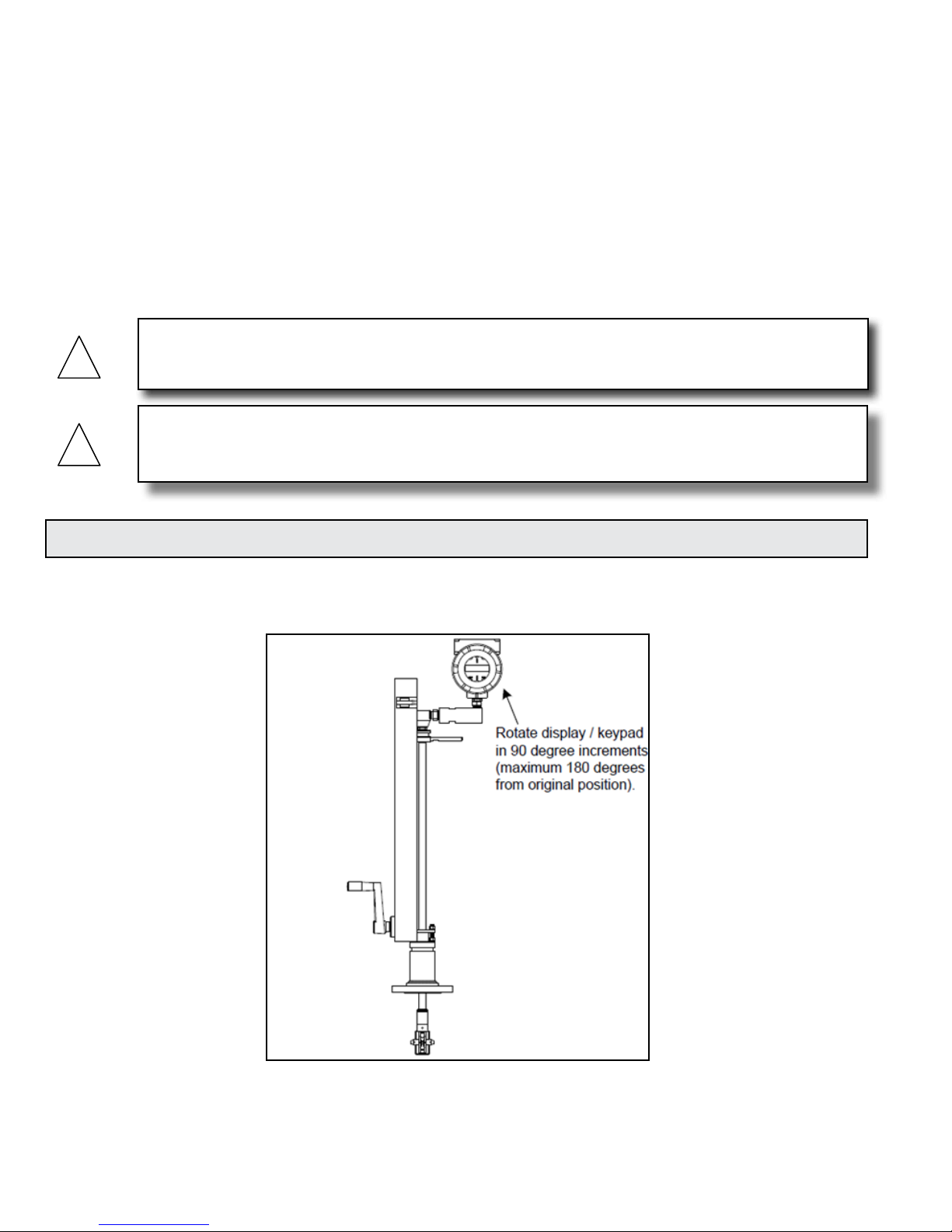

2.4 ADJUSTING THE DISPLAY ORIENTATION

Depending on installation requirements, you may need to rotate the position of the LCD

display / keypad. The orientation of the display / keypad may be changed in 90 degree

increments for easier viewing.

Figure 7. Display/Keypad Viewing Adjustment

The electronics boards are electrostatically sensitive. Wear a grounding wrist strap and make

sure to observe proper handling precautions required for static-sensitive components. To

adjust the display:

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 20

Page 21

1. Disconnect power to the ow meter.

!

LOOP

POWER

+ -

FREQ

OUT

PULSE

OUT

--

+

+

OPTIONAL

BACKLIGHT

POWER

+ -

2. Loosen the small set screw which secures the electronics enclosure cover. Unscrew and

remove the cover.

3. Loosen the four captive screws.

4. Carefully pull the display/microprocessor board away from the meter standoffs. Make

sure not to damage the connected ribbon cable.

5. Rotate the display/microprocessor board to the desired position. Maximum turn, two

positions left or two positions right (180°).

6. Align the board with the captive screws. Check that the ribbon cable is folded neatly

behind the board with no twists or crimps.

7. Tighten the screws. Replace the cover and set screw. Restore power to the meter.

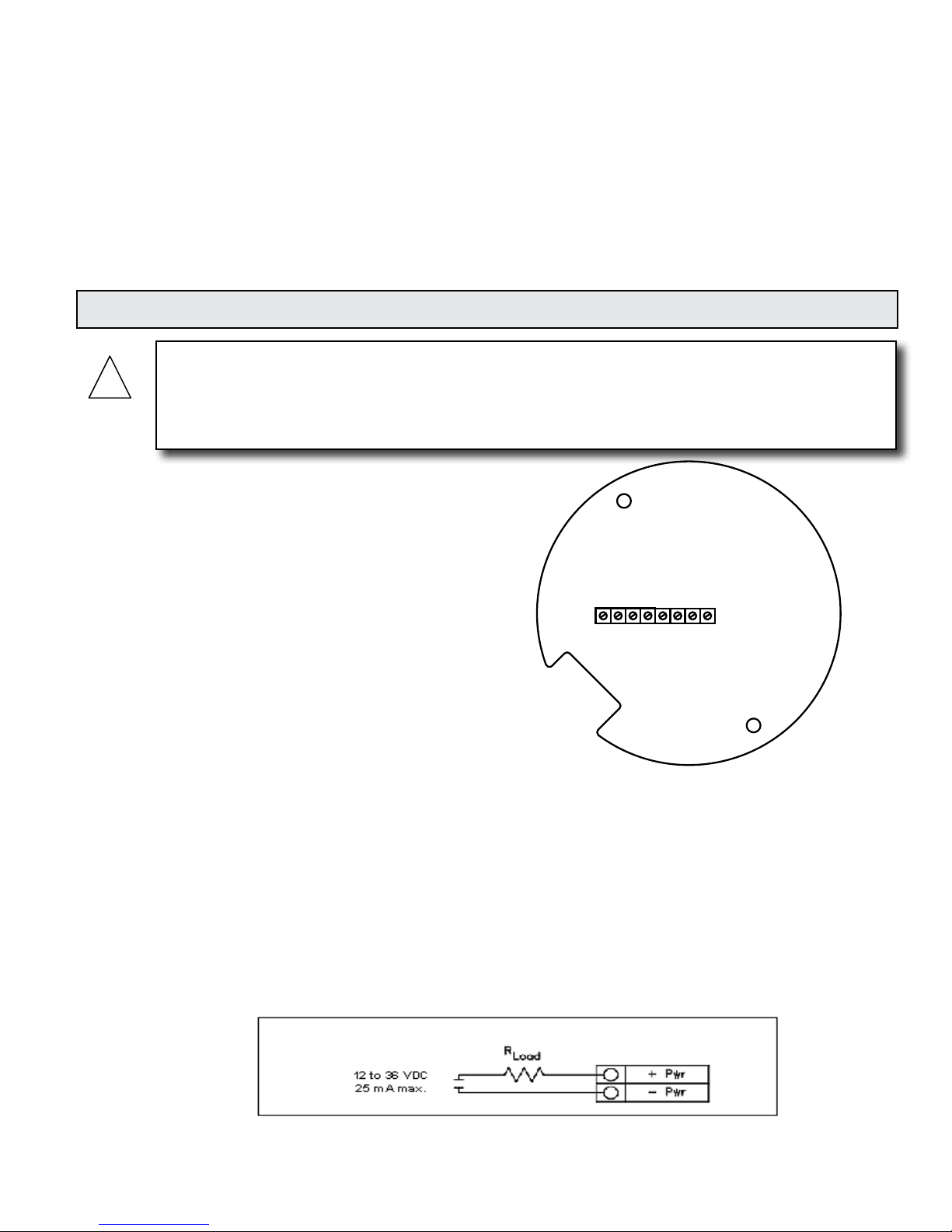

2.5 LOOP-POWERED FLOW METER WIRING CONNECTIONS

WARNING

To avoid potential electric shock, follow National Electric Code safety practices or your local code

when wiring this unit to a power source and to peripheral devices. Failure to do so could result in

injury or death. All wiring procedures must be performed with the power off.

The NEMA 4X enclosure contains an

integral wiring compartment with one dual

strip terminal block (located in the smaller

end of the enclosure). Two ¾" female NPT

conduit entries are available for separate

power and signal wiring. For all hazardous

area installations, make sure to use an

agency-approved tting at each conduit

entry. If conduit seals are used, they must

be installed within 18" (457 mm) of the

enclosure.

2.5.1 Input Power Connections

To access the wiring terminal blocks, locate and loosen the small set screw which locks

the small enclosure cover in place. Unscrew the cover to expose the terminal block.

DC Power Wiring

Connect 4-20 mA loop power (12 to 36 VDC at 25 mA, 1W max.) to the +Loop Power and –

Loop Power terminals on the terminal block. Torque all connections to 4.43 to 5.31 in-lbs (0.5

to 0.6 Nm). The DC power wire size must be 20 to 10 AWG with the wire stripped ¼" (7 mm).

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 21

Figure 8. Wiring Terminals for Loop-Powered Version

Figure 9. DC Power Connections

Page 22

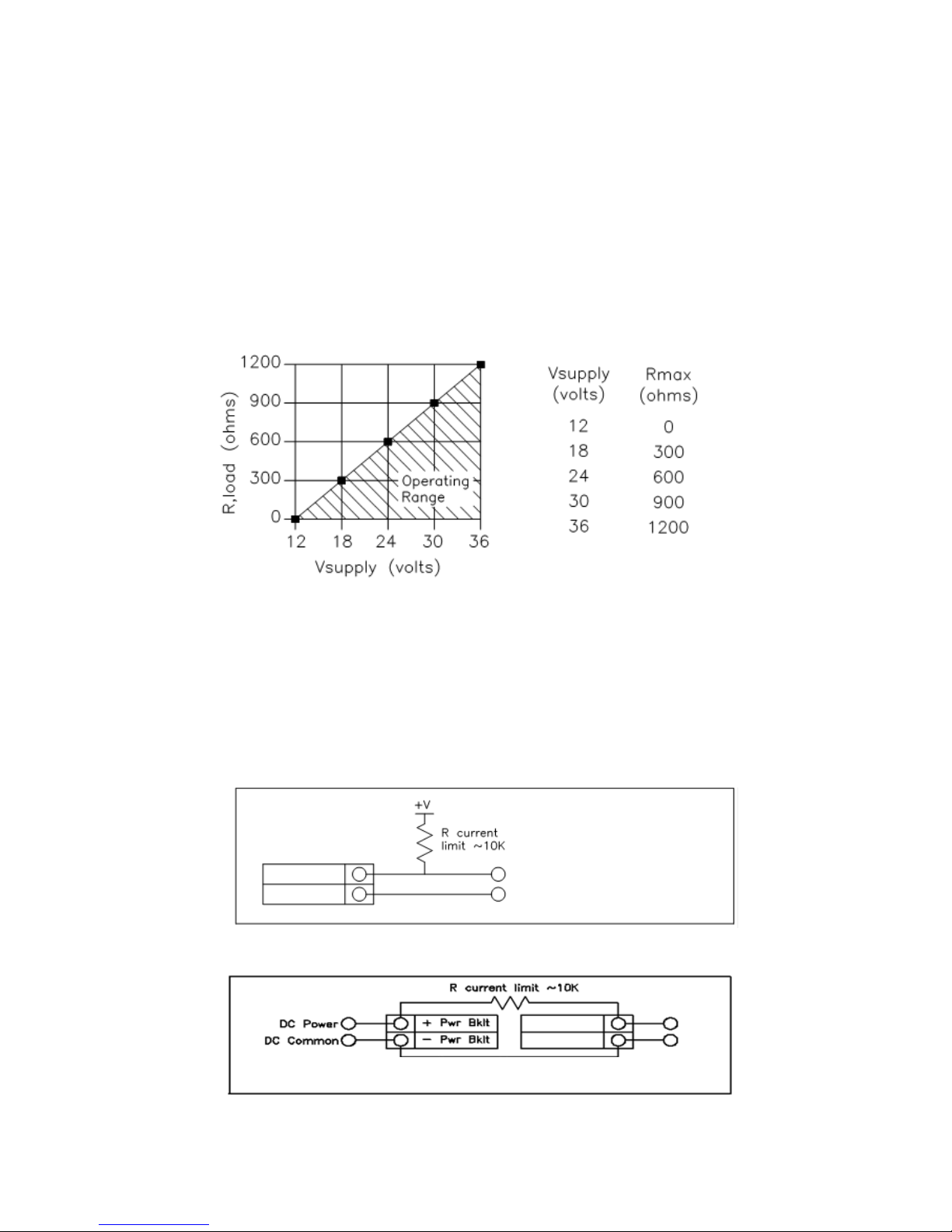

2.5.2 4-20 mA OUTPUT CONNECTIONS

Freq. Out -

Freq. Out +

Freq. Out voltage = +V

Select resistor so that current

through Freq. Out <= 40 mA

Freq. Out voltage = +V

Select resistor so that current through Freq. Out <= 40 mA

Freq. Out +

Freq. Out -

The loop powered meter has a single 4-20 mA loop. The 4-20 mA loop current is

controlled by the meter electronics. The electronics must be wired in series with the sense

resistor or current meter. The current control electronics requires at least 12 volts at the

input terminals to operate correctly.

The maximum loop resistance (load) for the current loop output is dependent upon the

supply voltage and is given in Figure 18. The 4-20 mA loop is optically isolated from the

ow meter electronics.

R

is the total resistance in the loop, including the wiring resistance (R

load

To calculate R

, the maximum Rl

max

from the supply voltage and divide by the maximum loop current, 20 mA. Thus:

= R

for the loop, subtract the minimum terminal voltage

oad

load

wire

+ R

sense

).

The maximum resistance R

load

Figure 10. Load Resistance Versus Input Voltage

2.5.3 Frequency Output Connections

The frequency output is used for a remote counter. It can be scaled to output a 1 to 10 kHz

signal proportional to mass or volume ow, temperature, pressure or density.

The frequency output requires a separate 5 to 36 VDC power supply and there are current

and power specications that must be observed when using this output. The output can

conduct a current up to 40 mA and can dissipate up to 200 mW. The output is isolated

from the meter electronics and power supply.

= R

max

= (V

– 12V) / 0.020 A

supply

Figure 11. Isolated Frequency Output Using External Power Supply

Figure 12. Non-Isolated Frequency Output Using External Power Supply

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 22

Page 23

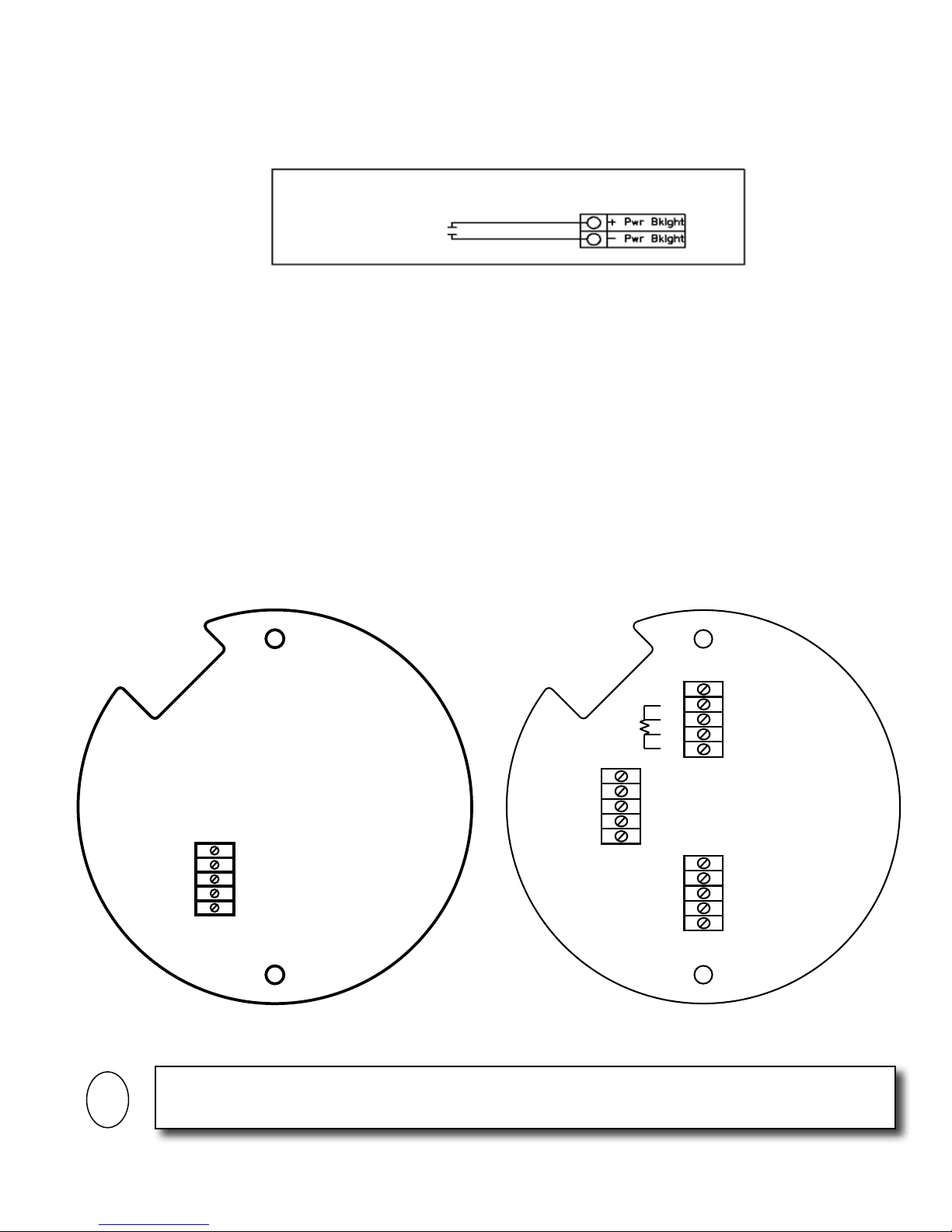

2.5.4 Optional Backlight Connection

12 to 36 VDC

35 mA max.

RED 1

BLK 1

BLK 2

RED 2

SHLD 1&2

SENSOR V1

VORTEX

GND

PWR

SENSOR V2

SHIELD

!

i

!

PRESSURE

TEMPERATURE

RED 2

SHLD 1&2

BLK 2

SHIELD

SHIELD

SENSOR V

2

SHIELD

SENSOR V

1

VORTEX

BLK 1

PWR

S

1

E

1

S

2

T

2

T

1

T

3

E

2

T

4

GND

RED 1

P

3

P

1

P

2

P

4

SHLD 3&4

SHLD 5&6

RED 6

BLK 6

BLK 5

RED 5

BLK 3

BLK 4

RED 4

RED 3

The loop power meter has an optional backlight connection provided. It is intended to be

powered by a separate 12 to 36 VDC at 35 mA max. power supply or by the pulse power

input. Both options are shown below.

Figure 13. Backlight Using External Power Supply

2.5.5 Remote Electronics Wiring

The remote electronics enclosure should be mounted in a convenient, easy to reach

location. For hazardous location installations, make sure to observe agency requirements

for installation. Allow some slack in the interface cable between the junction box and the

remote electronics enclosure. To prevent damage to the wiring connections, do not put

stress on the terminations at any time.

The meter is shipped with temporary strain relief glands at each end of the cable.

Disconnect the cable from the meter’s terminal block inside the junction box - not at the

remote electronics enclosure. Remove both glands and install appropriate conduit entry

glands and conduit. When installation is complete, re-connect each labeled wire to the

corresponding terminal position on the junction box terminal block. Make sure to connect

each wire pair’s shield. Note: Incorrect connection will cause the meter to malfunction.

Figure 14. Loop-Powered Volumetric Flowmeter

Junction Box Sensor Connections

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 23

Figure 15. Loop-Power Mass Flowmeter

Junction Box Sensor Connections

IMPORTANT NOTE

Numeric code in junction box label matches wire labels.

Page 24

2.6 HIGH POWER METER WIRING CONNECTIONS

!

4-20

mA 3

AC

PWR

IN

4-20

mA 1

24

VDC

OUT

+ - +

4-20

mA 2

- + - +

RS485

RS485

RS485 GND

-

OPTION 2

+

ALARM

2

HOT

PULSE

OUT

NEUT

FREQ

OUT

+ - +

ALARM

1

-+ -

4

OPTION 1

1 2 3 15 2 3

ALARM

3

- + -

4 5

+

-

!

100 to 240 VAC @ 5 Watts Max.

Chassis screw safety

ground must be used

for proper operation.

WARNING

To avoid potential electric shock, follow National Electric Code safety practices or your local code

when wiring this unit to a power source and to peripheral devices. Failure to do so could result in

injury or death. All AC power connections must be in accordance with published CE directives.

All wiring procedures must be performed with the power off.

The NEMA 4X enclosure contains an integral

wiring compartment with multiple dual

strip terminal blocks (located in the smaller

end of the enclosure). Two 3/4" female NPT

conduit entries are available for separate

power and signal wiring. For all hazardous

area installations, make sure to use an agencyapproved tting at each conduit entry. If

conduit seals are used, they must be installed

within 18" (457 mm) of the enclosure.

2.6.1 Input Power Connections

To access the wiring terminal blocks, locate and loosen the small set screw which locks

the small enclosure cover in place. Unscrew the cover to expose the terminal blocks.

The AC wire insulation temperature rating must meet or exceed 85°C (185°F).

AC Power Wiring

The AC power wire size must be 20 to 10 AWG with the wire stripped 1/4 inch (7 mm).

The wire insulation temperature must meet or exceed 185°F (85°C). Connect 100 to 240

VAC (5 W maximum) to the Hot and Neutral terminals on the terminal block. Connect the

ground wire to the safety ground lug ( ). Torque all connections to 4.43 to 5.31 in-lbs

(0.5 to 0.6 Nm). Use a separate conduit entry for signal lines to reduce the possibility of

AC noise interference.

Figure 16. AC Wiring Terminals

CAUTION

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 24

Figure 17. AC Power Connections

Page 25

4-20

mA 3

4-20

mA 1

DC

PWR

+ - +

4-20

mA 2

- + - +

RS485

RS485

RS485 GND

-

OPTION 2

+

ALARM

2

PULSE

OUT

FREQ

OUT

+ - +

ALARM

1

-+ -

4

OPTION 1

1 2 3 15 2 3

ALARM

3

- + -

4 5

+

-

Figure 18. DC Wiring Terminals

!

18 to 36 VDC @ 300 mA Max.

DC Power Wiring

The DC power wire size must be 20 to 10 AWG with the wire stripped 1/4" (7 mm).

Connect 18 to 36 VDC (300 mA, 9 W maximum) to the +DC Pwr and –DC Pwr terminals

on the terminal block. Torque all connections to 4.43 to 5.31 in-lbs (0.5 to 0.6 Nm).

Figure 19. DC Power Connections

The DC wire insulation temperature rating must meet or exceed 185° F (85° C).

2.6.2 4-20 mA OUTPUT CONNECTIONS

CAUTION

The externally powered versions of the meters have a single 4-20 mA loop powered

output. Two additional loops are available on the optional communication board. The 4-20

mA loop current is controlled by the meter electronics. The electronics must be wired in

series with the sense resistor or current meter. The current control electronics require a

minimum of 12 volts at the input terminals to operate correctly.

The maximum loop resistance (load) for the current loop output is dependent upon the

supply voltage and is given in Figure 30. The 4-20 mA loop is optically isolated from the

ow meter electronics.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 25

Page 26

R

DC powered meters only

RL > 250 Ohm

DC Power

DC Common

mA Meter

For HART

communications

the signal loop

must have a

minimum of 250

ohms load

resistance.

AC units only

Meter Provided DC

Power

R

L

> 250 Ohm

24 VDC

24 VDC

For HART

communications

the signal loop

must have a

minimum of 250

ohms load

resistance.

mA Meter

is the total resistance in the loop, including the wiring resistance (R

load

To calculate R

, the maximum R

max

for the loop, subtract the minimum terminal voltage

load

load

= R

wire

from the supply voltage and divide by the maximum loop current, 20 mA. Thus:

+ R

sense

).

The maximum resistance R

load

= R

max

= (V

– 12V) / 0.020 A

supply

Figure 20. Load Resistance Versus Input Voltage

4-20 mA voltage = +V

mA

For Hart communications,

signal loop must have a

minimum of 250 ohms load

resistance RL.

R

L

> 250

Meter

Figure 21. Isolated 4–20 mA Output Using External Power Supply

Figure 22. Non-Isolated 4–20 mA Output Using Meter Input Power Supply

Figure 23. Isolated 4–20 mA Output Using Meter Provided Power Supply

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 26

Page 27

2.6.3 Frequency Output Connections

+

24 VDC Out

- 24 VDC Out

AC units only

Meter provided DC Power

Freq. Out +

Freq. Out -

Freq. Out voltage = + Power voltage for meter

R current limit ~10K

The frequency output is used for a remote counter. It can be scaled to output a 1 to 10 kHz

signal proportional to mass or volume ow, temperature, pressure or density.

The frequency output requires a separate 5 to 36 VDC power supply; however, there are

current and power specications that must be observed. The output can conduct a current

up to 40 mA and can dissipate up to 200 mW. The output is isolated from the meter

electronics and power supply.

There are three connection options for the frequency output. The rst has a separate power

supply (Figure 36). The second uses the ow meter power supply (Figure 37) (DC powered

units only), and the third uses the internal 24 VDC power supply (Figure 38)(AC powered

units only). Use the rst option with a separate power supply (5 to 36 VDC) if a specic

voltage is needed for the frequency output. Use the second conguration if the voltage at the

ow meter power supply is an acceptable driver voltage for the load connected. (Take into

account that the current used by the frequency load comes from the meter’s power supply).

Use the third conguration if you have an AC powered unit only. In any case, the voltage of

the frequency output is the same as the voltage supplied to the circuit.

AC or DC powered meters

Freq Out +

Freq Out -

Freq. Out voltage = +V

Select resistor so that current

through Freq. Out ≤ 40 mA.

Figure 24. Isolated Frequency Output Using External Power Supply

DC powered meters only

DC Powered meters only

R current limit ~10K

PWR

PWR

Freq. Out voltage = + Power voltage for meter

. Out +

Freq

Freq. Out -

Figure 25. Non-Isolated Frequency Output Using Input Power Supply

AC units only

Meter provided DC power

Figure 26. Isolated Frequency Output Using Meter Provided Power Supply

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 27

Page 28

2.6.4 Pulse Output Connections

AC or DC powered meters

PWR

PWR

DC Powered meters only

+

24 VDC Out

- 24 VDC Out

AC units only

Meter provided DC Power

The pulse output is used for a remote counter. When the preset volume or mass (dened

in the totalizer settings, on page 62) has passed the meter, the output provides a 50

millisecond square pulse.

The pulse output optical relay is a normally-open single-pole relay. The relay has a

nominal 200 V / 160 ohm rating. This means that it has a nominal on-resistance of 160

ohms, and the largest voltage that it can withstand across the output terminals is 200 V.

However, there are current and power specications that must be observed. The relay

can conduct a current up to 40 mA and can dissipate up to 320 mW. The relay output is

isolated from the meter electronics and power supply.

There are three connection options for the pulse output. The rst has a separate power

supply (Figure 37). The second uses the ow meter power supply (Figure 38) (DC powered

units only), and the third uses the internal 24 VDC power supply (Figure 39)(AC powered

units only). Use the rst option with a separate power supply (5 to 36 VDC) if a specic

voltage is needed for the pulse output. Use the second conguration if the voltage at the

ow meter power supply is an acceptable driver voltage for the load connected. (Take into

account that the current used by the pulse load comes from the meter’s power supply).

Use the third conguration if you have an AC powered unit only. In any case, the voltage

of the pulse output is the same as the voltage supplied to the circuit.

Pulse voltage = +V

Select resistor so that current

through pulse ≤ 40 mA.

Figure 27. Isolated Pulse Output Using External Power Supply

DC powered meters only

igure 28. Non-Isolated Pulse Output Using Input Power Supply

F

AC units only

Meter provided DC power

Figure 29. Isolated Pulse Output Using Meter Provided Power Supply

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 28

Page 29

2.6.5 Alarm Output Connections

AC or DC powered meters

ALARM

ALARM

DC units only

+ 24VDC Out

- 24VDC Out

AC units only

Meter provided

DC Power

One alarm output (Alarm 1) is included on the standard meter. Two or more alarms (Alarm

2 and Alarm 3) are included on the optional communication board. The alarm output

optical relays are normally open single-pole relays. The relays have a nominal 200 V /

160 ohm rating. This means that each relay has a nominal on-resistance of 160 ohms and

the largest voltage that it can withstand across the output terminals is 200 V. However,

there are current and power specications that must be observed. The relay can conduct a

current up to 40 mA and can dissipate up to 320 mW. The relay output is isolated from the

meter electronics and power supply. When the alarm relay is closed, the current draw will

be constant. Make sure to size Rload appropriately.

There are three connection options for the alarm output. The rst has a separate power

supply (Figure 40). The second uses the ow meter power supply (Figure 41) (DC powered

units only) and the third uses the meter provided power supply (Figure 42)(AC powered

units only). Use the rst option with a separate power supply (5 to 36 VDC) if a specic

voltage is needed for the alarm output. Use the second conguration if the voltage at the

ow meter power supply is an acceptable driver voltage for the load connected. (Take into

account that the current used by the alarm load comes from the meter’s power supply).

Use the third if you have an AC powered unit only. In any case, the voltage of the alarm

output is the same as the voltage supplied to the circuit.

The alarm output is used for transmitting high or low process conditions as dened in the

alarm settings (see page 45).

Pulse voltage = +V

Select resistor so that current

through pulse ≤ 40 mA.

Figure 30. Isolated Alarm Output Using External Power Supply

Figure 31. Non-Isolated Alarm Output Using Internal Power Supply

AC units only

Meter provided

DC power

Figure 32. Isolated Alarm Output Using Meter Provided Power Supply

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 29

Page 30

2.6.6 Remote Electronics Wiring

PRESSURE

TEMPERATURE

RED 2

SHLD 1&2

BLK 2

SHIELD

SHIELD

SENSOR V

2

SHIELD

SENSOR V

1

VORTEX

BLK 1

PWR

S

1

E

1

S

2

T

2

T

1

T

3

E

2

T

4

GND

RED 1

P

3

P

1

P

2

P

4

SHLD 3&4

SHLD 5&6

RED 6

BLK 6

BLK 5

RED 5

BLK 3

BLK 4

RED 4

RED 3

!

i

!

Option 2Option 1

1 2 3 4 5 1 2 3 4 5

The remote electronics enclosure should be mounted in a convenient, easy to

reach location. For hazardous location installations, make sure to observe agency

requirements for installation. Allow some slack in the interface cable between the

junction box and the remote electronics enclosure. To prevent damage to the wiring

connections, do not put stress on the terminations at any time.

The meter is shipped with temporary

strain relief glands at each end of

the cable. Disconnect the cable from

the meter’s terminal block inside

the junction box, not at the remote

electronics (where the LCD display

is located) after enclosure. Remove

both glands and install appropriate

conduit entry glands and conduit.

When installation is complete,

reconnect each labeled wire to the

corresponding terminal position

on the junction box terminal block.

Make sure to connect each wire pair’s

shield. Note: Incorrect connection

will cause the meter to malfunction.

Numeric code in junction box label matches wire labels.

2.6.7 Optional Input Electronics Wiring

The meter has two optional input wiring terminals. These can be used to input a remote

or second RTD input in the case of an energy monitoring meter, for the input of a remote

pressure transducer, to pass a contact closure or for a remote density measurement to

name a few. In any case, the wiring diagram will be included with the meter if any of the

options are specied. Otherwise, the optional terminal blocks will be left blank and

non-functional.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 30

Figure 33. High Power Flow Meter Junction Box

Sensor Connections

IMPORTANT NOTE

Page 31

2.6.8 OPTIONAL ENERGY EMS RTD INPUT WIRING

Option 2Option 1

1 2 3 4 5 1 2 3 4 5

R = 1000 ohm

Red

Red

Black Black

Option 2Option 1

1 2 3 4 5 1 2 3 4 5

Power

Ext. 4-20 mA

Input Device

External

+

-

Option 2Option 1

1 2 3 4 5 1 2 3 4 5

Ext. 4-20 mA

Input Device

+ DC PWR

- DC PWR

DC PWR

DC COMMON

DC powered meter only.

Figure 34. Optional Energy EMS RTD Input Wiring

The recommended customer supplied second RTD is a Class A 1000 ohm 4-wire platinum

RTD. If a second RTD is not being used, then the factory supplied 1000 ohm resistor needs

to be installed in its place.

2.6.9 OPTIONAL EXTERNAL 4-20 mA INPUT WIRING

The meter is set to have Option 1 used for the external input. Programming menus that

pertain to the optional 4-20 mA input are located in the Hidden Diagnostics Menu in

section 5.

Figure 35. External 4-20 mA Input Wiring - External Power Supply

Follow the above diagram to wire the external 4-20 mA input into the ow meter using an

external power supply.

Figure 36. External 4-20 mA Input Wiring - DC Powered Meter

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 31

Follow the above diagram to wire the external 4-20 mA input into the ow meter using

power supplied to the input of a DC powered meter.

Page 32

Figure 37. External 4-20 mA Input Wiring - AC Powered Meter

Option 2Option 1

1 2 3 4 5 1 2 3 4 5

Ext. 4-20 mA

Input Device

+ 24 VDC OUT

- 24 VDC OUT

AC units only. Meter

provided DC power.

Option 2Option

1

1 2 3 4 5 1 2 3 4 5

Follow the above diagram to wire the external 4-20 mA input into the ow meter using

power from the 24 VDC output of an AC powered meter.

2.6.10 OPTIONAL CONTACT CLOSURE INPUT WIRING

Figure 38. Optional Contact Closure Input Wiring

Follow the above diagram to wire an external switch input into the ow meter. The meter

is congured to have Option 1 used for the external input. If the above switch is used to

remotely reset the totalizer, a push-button switch with a momentary contact closure is

recommended.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 32

Page 33

SECTION 3: OPERATING INSTRUCTIONS

After installing the ow meter, you are ready to begin operation. The sections in this chapter explain

the display / keypad commands, meter start-up and programming. The meter is ready to operate at

start-up without any special programming. To enter parameters and system settings unique to your

operation, see the following pages for instructions on using the set-up menus.

3.1 FLOW METER DISPLAY/KEYPAD

The ow meter’s digital electronics allow you to set, adjust

and monitor system parameters and performance. A full range

of commands are available through the display/keypad. The

LCD display gives 2 x 16 characters for ow monitoring and

programming. The six push-buttons can be operated with the

enclosure cover removed. Or, the explosion proof cover can

remain in place and the keypad operated with a hand-held

magnet positioned at the side of the enclosure as shown in the

illustration at the left.

F-1500 SERIES

From the Run Mode, the ENTER key allows access

to the Set-up Menus (through a password screen).

Within the Set-up Menus (through a password

screen). Within the Set-up Menus, pressing ENTER

activates the current eld. To set new parameters,

press the ENTER key until an underline cursor

appears. Use the ⇑ ⇓ ⇐ ⇒ keys to select new

parameters. Press ENTER to continue. (If change

is not allowed, ENTER has no eect.) All outputs

are disabled when using the Set-up Menus.

The EXIT key is active within the Set-up Menus.

When using a Set-up Menu, EXIT returns you to

the Run Mode. If you are changing a parameter

and make a mistake, EXIT allows you to start over.

The ⇑ ⇓ ⇐ ⇒ keys advance through each screen

of the current menu. When changing a system

parameter, all ⇑ ⇓ ⇐ ⇒ keys are available to enter

new parameters.

11451 Belcher Road South, Largo FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699 • sales@onicon.com

F-1500 Turbine Flow Meter Manual 02/18 - 1018-6 / 35726 Page 33

Figure 39. Flow Meter Display / Keypad

Page 34

3.2 START-UP

i

Setup

Menus

Password

Mass Flow

Rate

Volume

Flow Rate

Temperature

Pressure

Density

Total

Alarm 1

Status

Fluid

ENTER

Date & Time

Alarm 2

Status

Alarm 3

Status

Run Mode

Screens

Energy

*

ENTER

Press Exit to return

to Run Mode.

Use

keys to access

each item.

*

Energy

Meters Only

To begin ow meter operation:

1. Verify the ow meter is installed and wired as described in Section 2.

2. Apply power to the meter. At start-up, the unit runs a series of self-tests that check the RAM,

ROM, EPROM and all ow sensing components. After completing the self-test sequence, the

Run Mode screens appear.

3. The Run Mode displays ow information as determined by system settings. Some screens