Page 1

D-1400 and D-1402 Portable Metering System

Installation and Operation Guide

0722-2

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax (727) 442-5699

www.onicon.com • sales@onicon.com

05-14

Page 2

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 2

Page 3

TABLE OF CONTENTS

1.0 INTRODUCTION ..................................................................................................5

1.1 Purpose of this guide ................................................................................. 5

1.2 System Description .................................................................................... 5

1.3 System Components ..................................................................................5

2.0 SYSTEM OPERATION AND SET-UP ................................................................... 7

2.1 System Operation ......................................................................................7

2.2 Initial System Set-up .................................................................................6

2.3 Basic Flow Measurement ..........................................................................7

2.4 Flow Proling Measurment ....................................................................... 7

2.5 System Storage and Maintenance Recommendations .............................. 8

2.6 Flow Meter Information ............................................................................9

3.0 INSTALLATION, REMOVAL AND ADJUSTMENT ............................................8

3.1 Site Selection .............................................................................................8

3.2 Mechanical Installation ............................................................................. 9

3.3 Insertion of the Meter ..............................................................................10

3.4 Removal of the Meter ...............................................................................14

CONDITIONS OF SALE ................................................................................................ 16

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 3

Page 4

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 4

Page 5

SECTION 1: INTRODUCTION

1.1 PURPOSE OF THIS GUIDE

The purpose of this guide is to provide installation procedures and basic operating and servicing

instructions for the ONICON Model D-1401 and

D-1402 Portable Metering System.

1.2 SYSTEM DESCRIPTION

The D-1401 and D-1402 Portable Metering Systems are designed to measure the ow rate of conductive liquids in multiple pipe sizes. They can also be used to perform ow proling for analysis of ow

measurement problems.

The D-1401 Portable Metering System includes a F-1100 single turbine ow meter and can be used to

measure 1.25 inch and larger pipe sizes.

The D-1402 Portable Metering System includes a F-1200 dual turbine ow meter and can be used to

measure 2.5 inch and larger pipe sizes.

The ow meter portion of the system is typically inserted into

a lled and pressurized pipe via an existing one inch minimum

diameter full port ball valve. For pipes that can be easily drained

before and after measurement, the ow meter can be inserted

into a one inch minimum diameter outlet that can accept a one

inch NPT male threaded adaptor. For lled and pressurized

pipes without installed full port valves, wet tapping installation

hardware kits are available from ONICON.

The display module includes an LCD display, control switches

and cable. A single 9 volt alkaline battery, located in the display

module battery compartment, powers the complete system,

including the ow meter.

1.3 System Components

The D-1401 Portable Metering System contains the following components:

• Model F-1100 Insertion Turbine Flow Meter

• Model D-1401 battery powered hand-held display

• Carrying case

• Owner’s manual

• Laminated conversion chart. (*Serialized for the specic F-1100 ow meter *)

The D-1402 Portable Metering System contains the following components:

• Model F-1200 Insertion Turbine Flow Meter

• Model D-1402 battery powered hand-held display

• Carrying case

• Owner’s manual

• Laminated conversion chart. (*Serialized for the specic F-1200 ow meter *)

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 5

Page 6

GENERAL SPECIFICATIONS

ACCURACY

• ± 0.4% of reading from 3.3 to 33 ft/sec

• ± 0.8% of reading from 1 to 3.3 ft/sec

• ± 2.0% of reading from 0.4 to 1 ft/sec

SENSING METHOD

Electromagnetic sensing (no moving parts)

AVAILABLE METER SIZES

(nominal pipe diameters in inches)

1, 1½, 2, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24, 26, 30,

34, 36, 40, 42 & 48 (Inquire for other sizes)

LIQUID TEMPERATURE RANGES

32° to 130° F

BODY MATERIAL

Heavy duty plastic enclosure with

sliding door for battery

RATE IDICATOR

• Type: Six digit LCD with 0.46” numbers

• Calibration: Set at the factory to read turbine

frequency in Hertz. A conversion chart allows the

user to convert frequency to volumentric ow rate

(GPM) in any pipe size. Factory will set to read

GPM or any other units for particular pipe size upon

request.

• Field programming possible

• Memory: Non-volatile E2PROM memory retains

all programming parameters and count value in the

event of power interruption

POWER SUPPLY

9 Volt battery (NEDA Type 1604) in rear compartment powers the ow meter and LCD display

OUTPUT SIGNALS PROVIDED

• Isolated 4 – 20mA analog output for ow rate

• (2) Programmable pulse outputs (open collector)

AMBIENT TEMPERATURE RANGE

32° to 130° F

ELECTRICAL CONNECTIONS

Pre-wired inline cable connector for ow meter connection

Note: Specications are subject to change without

notice

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 6

Page 7

1.4 ADDITIONAL REQUIRED HARDWARE

Flow Meter

ONICON offers a wide variety of ow meters to satisfy most liquid, gas and steam

metering applications. Please refer to ONICON’s ow meter literature, or consult

ONICON or your local representative for help in selecting the ow meter that will best

t your requirements.

1.5 WORKING ENVIRONMENT

The D-100 was designed for installation and use in typical industrial environments that are

free of corrosive liquids and fumes, direct liquid exposure, heavy condensation, temperature

extremes, direct sunlight, and vibrations. The operating ambient air temperature range is -20° F

to 140° F. Electrical power should be relatively clean, free of high frequency noise, large voltage

transients, and protected from power surges and brown-outs.

1.6 WARRANTY & SERIAL NUMBER

Warranty

ONICON’s 2-year “No-fault” warranty reduces start-up costs by extending coverage for

incidental damage during installation. Certain exclusions apply. Please refer to ONICON’s

Conditions of Sale for details.

Serial Number

The serial number of your D-100 is located outside and inside the enclosure. Also located

inside the enclosure is a label with the serial number of the associated ONICON ow

meter or sensor your D-100 was intended to be used with. The serial numbers are unique

identiers that you should have available when contacting ONICON for assistance

regarding the installation or use of this product.

SECTION: 2.0 SYSTEM OPERATION AND SET-UP

2.1 SYSTEM OPERATION

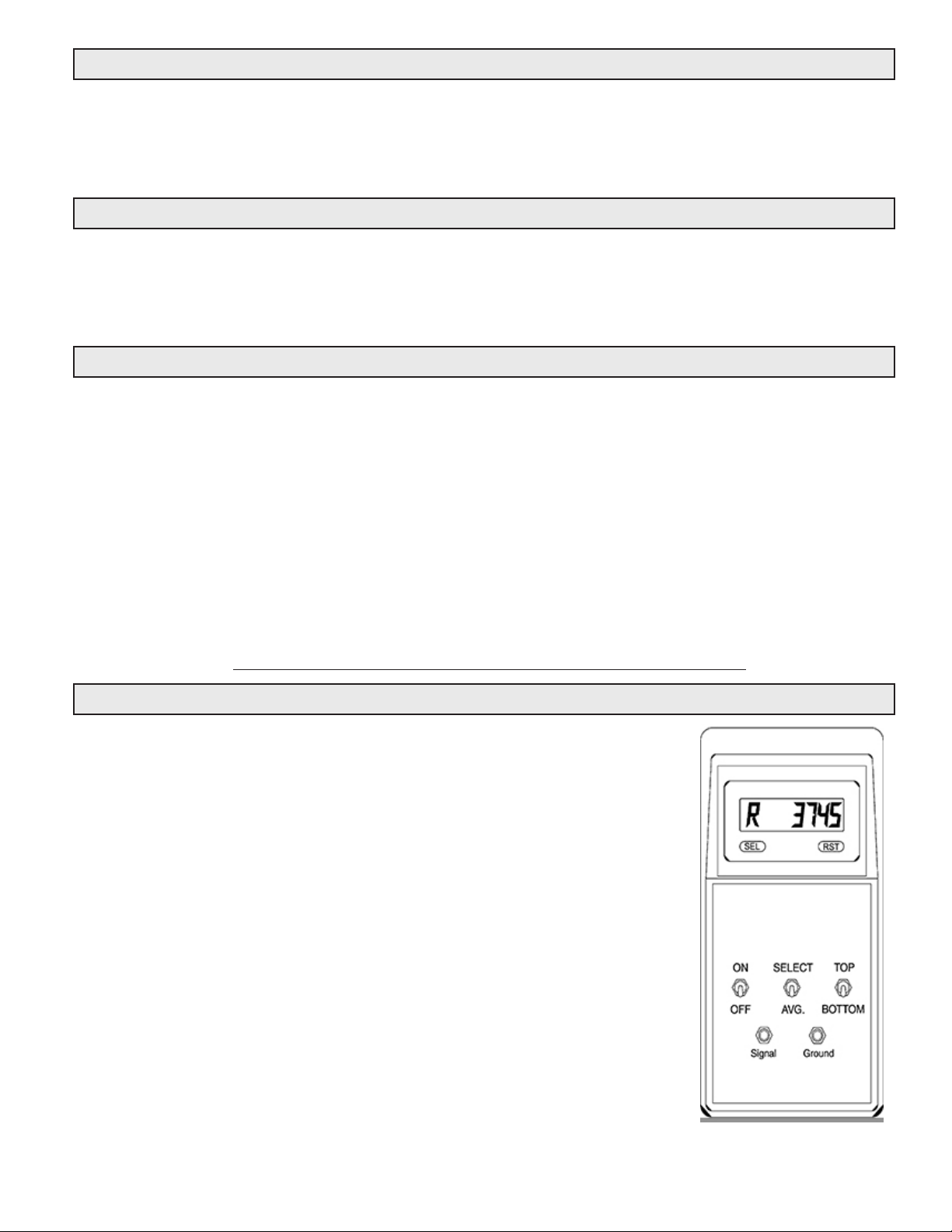

The D-1401 and D-1402 Display Module LCD display shows the ow

rate as a number representing the frequency output signal, in Hertz,

from the ow meter.

The D-1401 Display Module shows the frequency output signal of the

single turbine from the F-1100.

The D-1402 Display Module shows the averaged output from both

turbines. This system also has the capability of displaying the

individual output from the top or bottom turbine by using the

selection switches on the Display Module.

This frequency output is then converted to gallons per minute for the

pipe size being measured via the laminated conversion chart included

with the system.

Please contact ONICON to obtain conversion factors for any pipe

sizes not listed on the chart, or if you require a ow rate unit of

measure other than gallons or liters.

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 7

Page 8

2.2 INITIAL SYSTEM SET-UP

1. Insert the ow meter into the pipe to be measured. (See manual section entitled “Flow

Meter Information” for specic information on installation procedures and recommended

insertion depths.)

2. Plug the Display module cable connector into the connector on the ow meter output cable.

3. Turn the Display module power switch to the “ON” position and verify that a number

appears on the LCD display.

2.3 BASIC FLOW MEASUREMENT

1. Turn the power switch (left) to “ON” position.

2. Set the middle switch to “AVG” and allow 45 seconds for the ow meter circuitry to

stabilize.

3. Record the average reading in Hz on the display and refer to the laminated conversion

chart to calculate the ow rate. Please note that the frequency number displayed may vary

rapidly (by as much as 10-15%) as a result of the actual ow conditions in the pipe.

4. Locate the pipe size being measured on the laminated conversion chart and determine the

“Z Factor” for gallons per minute (or liters per minute) for that pipe size.

5. Then multiply the Z factor by the average reading in Hz from step 3 to obtain the ow rate

in gallons per minute.

2.4 FLOW PROFILING MEASUREMENT

D-1401 / D-1402 Systems:

Signicant information about the nature of ow across the entire pipe diameter can be obtained by

taking ow measurements at incremental insertion depths.

Depending on the pipe size to be measured, determine an appropriate measurement increment that

will provide the required information. (For example: when measuring the ow prole of an 8 inch

pipe, measurements may be made at 1 inch increments to provide the desired prole.)

With the ow meter properly inserted in the pipe, loosen the hot tap adaptor lock nut and push

the meter into the pipe until the end of the meter touches the far pipe wall. Using this as a starting

point, pull the meter back out by the desired increment of measurement and measure the ow rate.

Repeat this process until readings have been made across the entire interior diameter of the pipe.

In large pipes where the ow meter is not long enough to touch the far pipe wall, measurements

can be made using the near pipe wall as a starting point. Push the ow meter into the pipe just

until a ow reading is obtained on the display. (For the D-1402 systems, the top turbine output can

be observed to see when it clears the pipe wall and begins to spin.) Beginning at that point, start

making measurements at the desired incremental insertion depths.

D-1402 System Only:

When using a D-1402 system, the individual top and bottom turbine frequencies can be observed

as a reference to the amount of rotational swirl that is present at each insertion depth measurement

point.

To utilize this function, set the middle switch to “SELECT”. The right switch can then be toggled

between “TOP” and “BOTTOM” to display the individual turbine frequencies.

A stable, uniform ow velocity at the measurement depth will be indicated by having the same or

very close (+/- 10%) to the same frequency reading on both the top and bottom turbine.

A signicant difference between the top and bottom turbine frequency numbers will indicate the

presence of ow turbulence and swirl at the measurement depth. The top and bottom turbines

rotate in opposite directions. Turbulence and swirl will either increase or decrease the speed of

rotation of one of the turbines and will have the opposite effect on the other turbine.

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 8

Page 9

2.6 SYSTEM STORAGE AND MAINTENANCE RECOMMENDATION

1. Always store the system in its carrying case when not in use.

2. Before long-term storage of the system, blow all excess water from the ow meter turbine

assembly and wipe the ow meter stem assembly dry with a clean cloth. Do not put any

lubricants on the turbine assembly. Oil based lubricants will damage the ow meter’s o-ring

seals.

3. If storing the system for long periods of time, remove the 9 volt battery from the Display

Module and store it separately.

4. The ow meter’s hot tap adapter should be pushed completely down over the turbine

assembly and locked so that the turbines are protected when moving the system to a new

location or when storing the system.

5. The ow meter turbines, bearings and shafts can be cleaned using a 30 percent white

vinegar to 70 percent tap water solution. An old toothbrush can be used to lightly brush

around the bearings. Rinse with clean water and blow off excess water before storing.

2.6 FLOW METER INFORMATION

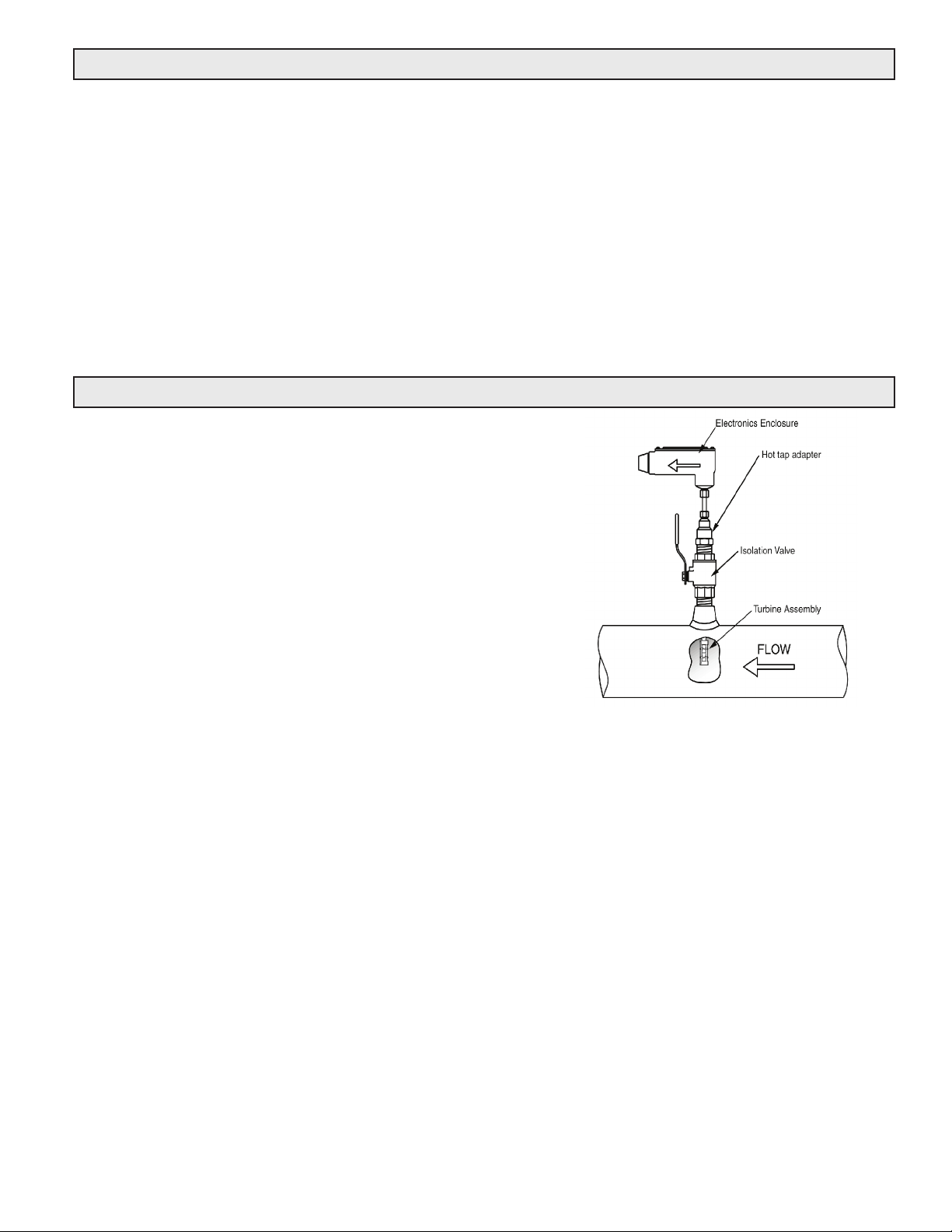

ONICON’s D-1401 / D-1402 Insertion Turbine Flow Meter measures the velocity of owing liquids by counting

the frequency at which the blades of a rotating turbine

pass a xed electrode. Circuitry within the ow meter

electronics enclosure then converts the rotational rate to

a frequency output.

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 9

Page 10

SECTION 3.0: INSTALLATION

The D-100 should be installed by qualied individuals with knowledge and experience in the heating,

cooling, and uid metering elds. ONICON will be happy to assist with technical recommendations

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 10

Page 11

and to provide guidance by telephone and/or email. On-site eld engineering, installation and service

are also available at an additional cost. The installer should use good trade practices and must adhere

to all state, federal and local building codes.

3.1 SITE SELECTION

Careful attention to the site selection for the system components will help the installers with the

initial installation, reduce start-up problems and make future maintenance easier. For example,

do not install the ow meter where it will be difcult for personnel to perform periodic

maintenance and calibration. When selecting a site for mounting the system components,

consider the criteria under Section 1.5 WORKING ENVIRONMENT, as well as the following:

The D-100

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 11

Page 12

Find an easily accessible location where wire connections can be made and meter readings

can be taken from oor level. Mount the D-100 on a vibration free surface. Avoid locations

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 12

Page 13

such as the plenum of a fan coil, heat exchanger or any housing that may contain electric

motors or other strong sources of electrical interference.

The Flow Meter

Choose the location with the longest straight run of unobstructed pipe. Please refer to the

ow meter installation manual for specic information regarding the straight run

requirements for the ow meter used with this display.

3.2 MECHANICAL INSTALLATION

Find an easily accessible location where electrical connections can be made and meter readings

can be taken from the oor level. Mount the display on a vibration free surface. Avoid sites such

as the plenum of a fan coil, heat exchanger, or other housings containing motors.

3.3 ELECTRICAL INSTALLATION

The electrical installation of this product must comply with all federal, state and local building

codes. Connect and re-verify all input, output, network interface and safety earth wiring

connections prior to connecting power.

The drawing below shows where signal, power and earth connections are made on the mother

board located inside the D-100 enclosure. Network and digital pulse input connections are

made on the network interface board (not shown). Refer to section 3.3.1 for detailed information

on connecting ow meters, sensors, output signal and power connections.

3.3.1 Input Signal Connections from Flow Meter

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 13

Page 14

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 14

Page 15

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 15

Page 16

H1

1

Earth Connection

1/4 AMP

F1

G

G

D3

J2-12

D4

20075-50 REV. A

G

+24

+15

60HZ

J2-1

10

1

5

H3

R7

LED1

J1

R1

D1

D2

T1

VAR1

TB1

NEUTRALF124V

AMP

TB1

24V NEUTRAL

OHM 5%

3W

Input Power Connection

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 16

Page 17

GAL X 100

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 17

Page 18

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 18

Page 19

4.6 COMMISSIONING

pp

p

;

g

y

d

gy (

Upon initial installation, it is strongly recommended that both the D-100 and its associated ow

meter be commissioned to ensure that they are properly installed and functioning correctly.

This process involves verifying the mechanical installation, measuring ow signals and then

comparing these measurements to the specied installation and operating parameters listed on

the certicate of calibration provided with the display. The data collected during this initial

commissioning process will then serve as baseline data for periodic revalidation of the meter

operation.

INTEGRATED D-100 DISPLAY

COMMISSIONING PROCEDURE

Please read all installation instructions carefully before

proceeding. Wiring diagrams are located in this manual.

Use the display Certicate of Calibration to verify that

the specied installation & operating parameters match

the actual conditions at the location where the display

is installed. A worksheet for checking these steps and

recording measured values is located on the following

page.

METER INFORMATION

Meter Tag:

BTU Meter Model: SYSTEM-30

Serial No: 134036

SPECIFIED INSTALLATION & OPERATING PARAMETERS

Pipe Information: 1 Inch Copper Tube

Design Maximum Flow Rate: 40.0 GPM

Design Supply Temperature: MODE 1: 45°F

Design Return Temperature: MODE 1: 55°F

Fluid: 25% Ethylene Glycol

Fluid Specific Heat: 0.885 BTU/lb°F

Fluid Density: 65.06 lb/ft³

CONFIGURATION DATA

Enclosure Type:

Input Supply Voltage: 24 AC/DC

Thermowell Type:

Calibrated By: Date: 09/01/2004

ONICON Incorporated certifies that the flow and temperature sensors provided with this Btu meter have been individually calibrated based on the

a

CERTIFICATE OF CALIBRATION

Shane Hamilton

rovided above

standards directl

lication specific data

1500 North Belcher Road, Clearwater, Florida 33765 Tel (727) 447-6140 Fax (727) 442-5699

usin

traceable to the U.S. National Institute of Standards an

CALIBRATION AND PROGRAMMING DATA

Firmware Version: CFM4.6S30

Communications Protocol:

Device Network Address:

Flow Sensor MF Code: 547.500

Programmed Units & Multipliers:

Energy Total: BTU x 1K Energy Rate: BTU/HR x 1K

Flow Total: GAL x 10 Flow Rate: GPM x 1

Temperature: °F

Damping: 5

Pulse Duration: 500 ms

Supply Temperature Slope: 9.969 Offset: -0.870

Return Temperature Slope: 10.004 Offset: -0.130

OUTPUT SIGNAL SCALING

Energy Total(s): 1 Pulse = BTU x 1K

Flow Rate: NA

Energy Rate: NA

Supply T: NA

Return T: NA

Delta T: NA

Technolo

N.I.S.T.).

1. Conrm that the D-100 is being

installed with the correct ow meter

and any optional sensors.

2. Conrm that the D-100 is being

installed in accordance with

Sections 1.5 and 3.1 of this manual.

Check the label inside the front cover of the D-100 and conrm that the

serial numbers match the serial numbers of the ow meter and any optional

sensors being used.

Conrm that the installation location is not in direct sunlight and is

removed from sources of strong electrical interference. The display should

be mounted on a vibration-free surface where it will be protected against

spraying, splashing and the seepage of water.

3. Conrm the pipe diameter and pipe

material.

Conrm that the ow meter is tagged for the pipe diameter and material in

which it is to be installed and that this information matches the information

provided on the display certicate of calibration. When in doubt, measure

the circumference of the pipe.

Pipe O.D. = (circumference / 3.14) – (insulation thickness x 2)

4. Conrm that the ow meter installation

conforms to the requirements specied

in the ow meter installation manual.

Verify that the ow meter is installed in a location with enough straight

unobstructed run upstream and downstream of the pipe. Also verify that

the ow meter is properly oriented with respect to ow direction, and for

insertion meters ensure that the meter is installed to the correct insertion

depth.

5. Conrm that any optional sensors are

properly installed.

Verify that any optional sensors connected to the D-100 are installed in

accordance with the manufacturer’s installation instructions. Also conrm

that the sensor output matches the information shown on the D-100 C of C.

6. Conrm that the correct supply voltage

has been provided.

Verify and measure the AC input voltage to the display.

Input voltages should be within the following ranges.

24VAC: 20 – 28VAC

24VAC when connected to an F-3500 and the D-100 is equipped with a

multi-analog board: 21.6 – 28VAC

120VAC: 108 - 132 VAC

230VAC: 207 - 253 VAC

In order to proceed with the following steps, the display, ow meter and optional sensors must be operating and there must

be ow in the pipes. Flow signal readings should be taken while holding the ow rate constant, if possible.

7. Select the ow rate page on the D-100

front panel display.

Scroll through the D-100 display pages and select the ow rate page. Verify

that the engineering units and multiplier shown match those on the C of C.

8. Note and record the ow reading. Note the displayed ow rate and conrm that it is within the expected

range. For D-100 displays connected to ow meters with integral displays,

conrm that the ow readings shown on the two displays agree. Record the

ow rates.

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 19

Page 20

9. For ow meters that provide a

frequency output, measure and

record output(s). Compare calculated

vs. displayed ow rates.

(F-1200 or FB-1200 only).Conrm both

turbines produce pulses

10. Compare and record the displayed values with those shown on the building

control system.

End of standard commissioning. Please contact ONICON if any questions arise.

The average frequency output signal is a 0-15 VDC pulsed output

ranging up to 200 Hz and must be measured with a frequency counter or

oscilloscope. Measure DC Frequency (Hz) at T4 from terminal 6(+) to 7(-).

GPM = Frequency in Hz X 60 X Meter Factor in ppg (refer to calibration tag

for meter factor)

For the F-1200 or FB-1200 Dual Turbine model, also measure and record

the top and bottom turbine signals.

Top Turbine: T4-12(+) to T4-2(-) Bottom Turbine: T4-13(+) to T4-2(-)

Also measure DC volts on same terminals. 5 to 7 VDC is normal for a

spinning turbine, 0 or 14+ VDC indicates a stopped turbine. (1 to 4 VDC

could indicate a problem.)

Scroll through the D-100 menu pages and conrm that the rate and total

current values and engineering units shown agree with the information

shown on the building control system display. Record the results.

COMMISSIONING WORKSHEET

Please read all installation instructions carefully prior to proceeding with these steps. Wiring

diagrams are located in this manual. Use the following worksheet for checking off the

commissioning steps and recording measured values.

Step Test/Measurement D-100 S/N: D-100 S/N: D-100 S/N:

1. Conrm and record

serial number(s)

Flow meter:

Sensor(s):

Flow meter:

Sensor(s):

Flow meter:

Sensor(s):

2. Proper installation site

selection (Y / N)

3. Record pipe diameter

4. Record number of

unobstructed upstream/

downstream pipe

diameters

5. Sensor(s)properly

installed (Y / N)

6. Record supply voltages

7. Verify that engineering

units & multipliers match

(Y/N)

8. Record ow rate and

total(s)

9. Record actual and

calculated values

10. Record displayed values D-100:

Flow rate:

Mode 1 total:

Mode 2 total:

Actual:

Calculated:

Flow rate:

Mode 1 total:

Mode 2 total:

Actual:

Calculated:

D-100:

Flow rate:

Mode 1 total:

Mode 2 total:

Actual:

Calculated:

D-100:

System:

System:

System:

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 20

Page 21

SECTION 5.0: DIAGNOSTICS

i

i

5.1 DIAGNOSTICS

The ONICON D-100 display is programmable. Factory programmed settings provide rate and

total values in accordance with the customer’s application data. Refer to the D-100 calibration

sheet for a complete listing of factory settings. These settings may be reviewed and changed with

assistance from ONICON factory service personnel. The display is also equipped with diagnostic

indicator lights and self diagnostic test signals that conrm the operation of the microprocessor

and its input circuitry. Please contact the ONICON factory service personnel if any of the

diagnostic lights or test signals listed below indicates a potential problem with the operation of

the Btu meter.

5.1.1 Diagnostic Lights

Low Voltage Power Supply

Located on the power supply board inside the System-10 BTU Meter (refer to page A-3),

these two LEDs will be illuminated when the positive and negative ve volt supplies

are present.

Liquid Flow

Located just above the power supply on the motherboard (refer to page A-1) is the ow

indicator LED. The LED will ash at a rate that is proportional to the liquid ow rate.

An unlit LED indicates no ow signal.

5.1.2 Flow Test Signals

Located on the right side of the motherboard (refer to A-1) immediately above the power

supply board is a three position slide switch used to test the ow input. When the switch

is in the top position, the input is connected to the ow meter. When the switch is in the

middle position, the input is connected to two test terminals used to apply a variable

frequency to simulate ow. When the switch is in the bottom position, the input is

connected to a 50/60 Hz signal that simulates a xed ow rate. Refer to the calibration

certicate to determine the correct display reading when operating in the 50/60 Hz test

mode.

IMPORTANT NOTE

The second line of the display will alternate between TEST MODE and the normal display of

engineering units and multipliers whenever the ow test switch is in the TEST or 60 Hz positions.

IMPORTANT NOTE

After operating for ve minutes in either the TEST or 60 Hz mode, the displayed ow and energy

rate will be disabled, and the meter will report a zero ow rate and a zero energy rate to the

network. The meter will remain in this state until the switch is set to RUN.

5.1.3 Ai3 & Ai4 Test Signals

As you are facing the component side of the processor board, the Ai3/Ai4 Test push button

is along the top edge of the board just to the left of the at ribbon cable. It is labeled TEMP

TEST. When pressed, a xed current will be applied to each sensor input. Both Ai3 and

Ai4 will produce an output equal to 37.5% of their programmed full scale output. This test

conrms the operation of the D-100 processor board input circuitry for Ai3 and Ai4.

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 21

Page 22

5.2 TROUBLESHOOTING GUIDE FOR D-100 DISPLAY

NOTE: Also refer to the COMMISSIONING GUIDE located on the preceding pages.

Reported Problem Possible Solutions

Flow rate is indication zero ow.

(When uid is owing in the pipe.)

• Verify that the correct supply voltage is

present at the ow meter power input.

• Verify that the ow meter signal outputs

are properly wired to the display.

• For insertion meters, verify that the

meter is correctly inserted and parallel

with the pipe.

• For turbine meters, verify that the turbines

are not clogged with debris.

• Re-conrm that there is really ow in the

pipe.

Displayed ow rate is too high or too low. • Verify that the serial number of the ow

meter matches the serial number shown

on the label inside the D-100 front cover.

• Verify that the correct supply voltage is

present at the ow meter power input.

• Verify that the pipe diameter matches the

diameter shown on the calibration

certicate and on the ow meter tag.

• For insertion meters, verify that the

meter is correctly inserted and parallel

with the pipe.

• For turbine meters, verify that the turbines

are not clogged with debris.

Ai3 and/or Ai4 sensor values are too high or

too low.

• Verify that the sensor scaling matches

that programmed values shown on the

label inside the D-100 front cover and on

the calibration certicate.

• Conrm that the control system is

correctly scaled.

Data is not available at the control system. • Verify network addresses are properly

programmed into the D-100.

• If applicable, verify the Baud rate.

• Check the polarity of the network

connections.

For technical assistance, contact ONICON Incorporated at (727) 447-6140.

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 22

Page 23

APPENDIX

A-1 D-100 DISPLAY MOTHER BOARD

A-2 D-100 PROCESSOR BOARD

A-3 D-100 POWER SUPPLY BOARD

A-4 D-100 ANALOG OUTPUT BOARD

A-5 D-100 ANALOG OUTPUT BOARD With 4 Analog Outputs

A-6 CONDITIONS OF SALE

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page 23

Page 24

D-100 DISPLAY MOTHER BOARD

Pulse and analog output connections

OUTPUTS

TOTALIZER OUTPUT

TOTALIZER OUTPUT

H1

1

H2

1

5

10

15

20

25

30

H3

1

5

10

15

20

25

30

MODE 1

(+)

MODE 2

(-)

MODE STATUS

CHANNEL A

ANNALOG OUTPUT

CHANNEL B

ANALOG OUTPUT

CHANNEL C

ANALOG OUTPUT

CHANNEL D

ANALOG OUTPUT

ALARM

OUTPUT

S1

RUN

+

-

+

-

+

-

+

-

LED1

T1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

FLOW

INDICATOR

T3

T4

10

11

12

13

T5

TEST

D1

D2

+ -

15 V PULSE

D3

D4

35

40

45

35

40

45

60 HZ

T1

ANALOG INPUTS

1

2

3

4

5

SIGNAL

REFERENCE

SIGNAL

REFERENCE

SHIELDS

FLOW METER INPUTS

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

J2-12

24 VDC SUPPLY +

SUPPLY COMMON SHIELD

4-20mA +

4-20mA FREQUENCY +

FREQUENCY DIRECTION +

DIRECTION ALARM +

ALARM TOP TURBINE

BOTTOM TURBINE

AUXILIARY FLOW METER SIGNALS

4-20mA 0-10 VDC +

ANALOG COMMON -

ISOLATED ANALOG COMMON -

SCALED +

SCALED -

G

G

+24

+15

10

Ai3Ai4

Ai2

Di2

G

60HZ

J2-1

1

5

H3

Ai3 & Ai4 analog

input connections

Ai2 / Di2

Flow meter

connections

R7

C5

D5

C4

R1

R5

U2

R3

LED1

J1

ONICON INC.

20036 Rev. D

PROCESSOR BOARD

VAR1

F1

1/4 AMP

TB1

120VAC

NEUTRAL

20075-50 REV. A

EXPANSION SLOTS FOR:

1. COMMUNICATIONS BOARD

2. ANALOG OUTPUT BOARD

C6

D6

C1

C2

U1

C3

R1

POWER SUPPLY

*Standard: 24 VAC

Optional: 120 or 230 VAC

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page A-1

Page 25

D-100 PROCESSOR BOARD

RESET

TEMP TEST

PROG MODE

ENABLE

DEVICE ADDRESS

PROGRAM ENABLE

SERIAL

COMM

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page A-2

Page 26

D-100 POWER SUPPLY BOARD

D1

D2

T1

D3

D4

J2-12

+24

+15

10

G

G

G

60HZ

J2-1

5

1

H3

Fuse

Holder

VAR1

1/4 AMP

TB1

F1

24V

NEUTRAL

VAC CONNECTION

R1

20075-50 REV. A

C3

C1

U1

C6

D6D5

C2

R5

R1

C5

C4

J1

R7

U2

R3

LED1

FUSES

24 VAC 120 VAC 230 VAC

3AG 3AG 3AG

1 AMP 1/4 AMP 1/8 AMP

250 VOLT 250 VOLT 250 VOLT

SLO-BLO SLO-BLO SLO-BLO

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page A-3

Page 27

D-100 ANALOG OUTPUT BOARD

ISO ANALOG OUT

20039_5_REV B

C10

C20

C21

45 40 35 30 25 20 15 10 5 1

U20

C23

U10

U11

U12

R3

C22

U6

R1

R2

R8

U14

C8

D1

C15

C9

T2

C12

U17

C24

C13

Q1

C7

C3

C11

R6

R7

R5

U8

C1

C14

C18

H1

C2

H2

U16

U15

FLOW

DELTA T

BTU RATE

LO TEMP

HI TEMP

C16

C17

D7

D5

D6

R14

R9

R15

R10

D4

U9

Q2

H3

R11

R13

SPAN

ZERO

0-10 VDC

4-20 mA

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page A-4

Page 28

D-100 ANALOG OUTPUT BOARD

with 4 analog outputs

4 CH. Analog

ONICON INC. 20049 Rev. A

U1

151015202530354045

H1

R52

R1

C1

R3

D3

C6

U2

R4

D5

R6

C18

U3

Q2 Q1

C8

C10

C7

C2

C5R5

C9

C13

C15

D1

U4

C16

C4

U5

D2

C12

D7D6

C11

C14

U20

R50

C37

R51

C36

U19

J5

R2 R7

Hi Temp

R8C3

Flow Rate

C17

U6

D8

C19

R12

R10

R11

R14

C20

R11

Lo Temp

Flow Rate

C22

R17

R18 R19

U9

J6

D14

C23

R23

R21

R22

R25 R24

C24

J7

J8

R28

BTU Rate

R29

R30

Flow Rate

U12

C26

R39

Delta T

R40

R41

Flow Rate

U15

C30

C28

D18

C27

R34

R32

R33

R34 R35

D22

C31

R45

R43

R44

C32

R47

R46

U18

D21D20

D10

D4

D12

D13

D16

D17

C34

C35

U7

U10

U13

U16

C25

C29

C33

C21

D9

R27

D11

D15

D19

D26

R16

D23

R38

D24

R49

Q3

Q4

D25

Q5

Q6

T1

R9

R15

0-10V

R20 R26

R31

R37

R42 R48

0-10V

0-10V

0-10V

0-5V

0-5V

0-5V

0-5V

CH A.

SPAN

ZERO

J1

4-20mA

CH B

SPAN

ZERO

J2

4-20mA

CH C

SPAN

ZERO

J3

4-20mA

CH D

SPAN

ZERO

J4

4-20mA

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page A-5

Page 29

CONDITIONS OF SALE

1. ACCEPTANCE: The following Conditions of Sale apply to all sales of ONICON’s products. These provisions shall apply even if ONICON fails to

object to provisions appearing on, incorporated by, referenced in, or attached to Buyer’s purchase order form. Buyer’s acceptance of delivery of

ONICON’s products constitutes its acceptance of these Conditions of Sale.

2. DELIVERY AND TITLE: All product shipments are Ex Works and title passes to the Buyer at the time ONICON delivers the

merchandise to the carrier. Risk of loss or damage to the product passes to the Buyer at the time ONICON delivers the product to the carrier.

The Buyer immediately upon receipt should inspect all shipments, and should there be any evidence of damage or loss in transit, Buyer must le

claims or tracers upon carrier. ONICON will assist in tracing shipments upon request.

3. LIMITED WARRANTY: ONICON warrants that for a period of two (2) years following the date of original shipment of an ONICON product: (i) the

product will conform to ONICON’s standard written specications applicable to such product in effect on the date of Buyer’s order, or as modied

by ONICON’s quotation or Buyer’s purchase order accepted by ONICON, (ii) the product will be free from defects in workmanship, and (iii) that

ONICON has title to the product prior to shipment to the Buyer; provided, however, that the warranties provided herein shall be void and may not

apply in the event Buyer misuses or damages a product, including, but not limited to, any use by the Buyer of a product for an application other

than one of a type approved by ONICON. ONICON’s sole liability and Buyer’s sole remedy for any breach of the foregoing warranty is for

ONICON to repair or replace, at ONICON’s option, any defective product that is returned to ONICON during the warranty period. EXCEPT AS

MAY BE SPECIFICALLY AGREED BY ONICON IN WRITING IN RELATION TO EACH SALE, NO OTHER WARRANTIES SHALL APPLY,

WHETHER EXPRESSED, IMPLIED OR STATUTORY, AND THERE SHALL BE NO IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE.

4. REMEDIES: ONICON’s OBLIGATION UNDER THE FOREGOING WARRANTIES IS LIMITED SOLELY TO REPAIR OR REPLACEMENT, AT

ONICON’s OPTION, OF DEFECTIVE OR NONCONFORMING PRODUCTS. ONICON SHALL NOT BE LIABLE FOR CONSEQUENTIAL,

INDIRECT, PUNITIVE, INCIDENTAL, OR SPECIAL DAMAGES WHETHER FOUND ON CONTRACT, TORT OR ANY OTHER THEORY OF LAW.

No products shall be returned to ONICON without its prior consent and transportation and insurance costs shall be prepaid. Any repair or

replacement of ONICON’s products under the foregoing warranty will be at no charge to the Buyer provided such repair is done at the ONICON

factory or authorized service center. ONICON products that are repaired or replaced under this warranty will be returned to Buyer via the same

method of shipment use to return the product to ONICON. Repair or replacement of ONICON products is conditioned upon ONICON’s

acknowledgement of any alleged defect or nonconformance during the warranty period and issuance of a Return Authorization number. All

product returns must reference the Return Authorization number on the outside of the shipping carton and on any paperwork referencing the

return.

5. PRICES AND PAYMENT TERMS: The prices set forth in the most recent quote or acknowledgement as applicable, supersede all previous prices

or quotations. All quotations are subject to change or withdrawal without notice except as may be specically noted on the face of the quotation.

The prices shown do not include sales, excise or government charges payable by ONICON to Federal, State, or local authority. Any such tax or

charge now or hereafter imposed upon the sale or shipment of the products under this contract will be added to the purchase price. Buyer agrees

to reimburse ONICON for such tax or charge or provide ONICON with an acceptable exemption certicate. Payment of invoices will be due 30

days from the date of shipment of the products contained therein. In the event that payment of an invoice is not received by the invoice due date,

ONICON will assess a late fee not to exceed 1.5% per month or 18% per year, or the maximum allowable by law whichever is lower.

6. CANCELLATION: Buyer may cancel its order, or any part of it, by sending written notice of cancellation to ONICON and paying a reasonable

cancellation fee as determined by ONICON. The reasonable cancellation fee will reect, among other factors, the expenses already incurred and

commitments made by ONICON, sales and administrative costs and prot as determined by ONICON. If Buyer received a reduced price based on

the quantity of products ordered, but has not purchased the applicable quantity at the time of cancellation, Buyer will pay the price it would have

paid had ONICON’s sale price been based on the quantity actually purchased.

7. CHANGES: If Buyer makes any changes in its drawings, designs, or specications applicable in any contract with ONICON that cause an increase

or decrease in the cost of performance of the contract, or if such changes result in rework or obsolescence, an equitable adjustment shall be made

to the contract. Such changes are subject to ONICON’s prior written consent.

8. EXCUSABLE DELAY: ONICON shall under no circumstance be responsible for failure to ll any order or orders when due to: res, oods, riots,

strikes, freight embargoes or transportation delays, shortage of labor, inability to secure fuel, material supplies, or power at current price or on

account of shortages thereof, acts of God or of the public enemy, any existing or future laws or acts of the Federal or State Government (including

specically, but not exclusively, and orders, rules or regulations issued by any ofcial or agency of any such government) affecting the conduct of

ONICON’s business with which ONICON in its judgment and discretion deems it advisable to comply as a legal or patriotic duty, or due to any

cause beyond ONICON’s reasonable control.

9. PATENTS: ONICON shall defend all suits or proceedings brought against Buyer or its customers arising from claimed infringements of any

patent, trademark, service mark or copyright for any product furnished by ONICON and shall indemnify it against all costs, fees, and damages on

the condition Buyer promptly noties ONICON in writing and provides information and assistance to enable ONICON to conduct the defense,

provided that ONICON shall have no such obligation in case of infringement resulting from ONICON’s conformance to special requirements of

Buyer. If ONICON is not able to settle any such suit or proceeding on acceptable terms, ONICON may, at its option, require return of the

infringing product and refund the purchase price to Buyer less a reasonable allowance for depreciation or use.

10. FAIR LABOR STANDARDS ACT: ONICON represents that all products delivered under this contract are furnished in accordance with the

applicable provisions of the Fair Labor Standards Act as amended.

11. APPLICABLE LAW: This document and any resulting contract shall be governed by and construed in accordance with the laws of the State of

Florida. The courts of the State of Florida and the federal courts located in Florida shall have jurisdiction and venue with respect to litigation to

this contract. In the event of litigation, the prevailing party shall be entitled to recover attorney’s fees and costs from the non-prevailing party,

including appellate attorney’s fees.

12. MODIFICATIONS: These Conditions of Sale along with the prices, quantities, delivery schedules and other provisions and instructions in

applicable quotations by ONICON or Buyer’s purchase orders accepted by ONICON shall constitute the entire agreement between ONICON and

1 1451 Belcher Road South, Largo, FL 33773 • USA • T el +1 (727) 447-6140 • Fax (727) 442-5699 • sales@onicon.com

Buyer pertaining to any resulting contract. They can be modied only in writing.

D-1400 Portable Metereing System Manual 05/14 - 0722-2 Page A-6

Loading...

Loading...