Onfloor SWOOP Installation Manual

SAFETY

, OPERATION MANUAL & PARTS LIST

SWOOP

OLISHING

P

FLOOR MACHINE

This unit is intended for commercial use.

®

READ

& FOLLOW ALL

INSTRUCTIONS, WARNINGS & CAUTIONS

BEFORE USING THIS POLISHING MACHINE

PLEASE READ CAREFULLY BEFORE OPERATING

This machine will afford you many years of trouble

free operating satisfaction if it is given proper care. All

parts have passed rigid quality control standards

before being assembled to produce the finished product. Prior to packaging, the units are again inspected

for assurance of flawless operation.

This polishing machine was protectively packed to prevent damage in shipment. We recommend that upon

delivery, remove the unit from its pallet and carefully

inspect it for any possible damage in transit.

If damage is discovered, immediately notify the transportation company that delivered your floor machine.

As a shipper, we are unable to act upon any claim for

concealed damage. You must originate any claim within 5 days of delivery.

These instructions are for your protection and information. PLEASE READ CAREFULLY! Failure to follow these

precautions could result in injury or discomfort.

Treat this machine as you would any other high grade

precision made product. Throwing, dropping, unreasonable bumping across thresholds and other misuse

may result in a damaged unit and invalidate the warranty.

SWOOP Manual & Parts List - PN 234656 - Rev C (applicable to previous versions of this model) - Printed in USA 12/10/07

SAVE THESE INSTRUCTIONS

PAGE 1

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

To reduce the risk of fire, electric shock or injury;

Read all instructions before using this grinding machine.

1) DO NOT leave the machine plugged in when not in

use. Unplug from the outlet when not in use and/or

before servicing.

2) Electric shock could occur if exposed to rain. Store

indoors.

3) This is NOT a toy. Close attention is necessary when

used around or near children.

4) Use only as described in this manual. Use only

manufacturer's recommended attachments.

5) Inspect all power cords for damage before operating the machine and DO NOT use with damaged

cord plug.

6) If the machine is not working as it should because it

has been dropped, damaged, left outdoors in the

weather, contact the manufacturer or authorized service center.

7) DO NOT operate this machine in a wet environment.

8) DO NOT

9) DO NOT plug any equipment into the machine

unless it is recommended by the manufacturer.

handle the plug or operate with wet hands.

12) Before flipping the polishing deck assembly

back, unplug all power cord from the motor.

Keep hair, loose clothing, fingers and all parts of

14)

body away from moving parts.

15) DO NOT operate the machine without a vacuum

and the manufacturer’s filters in place.

16) DO NOT operate where anesthetics and oxygen

are used.

17) DO NOT use around flammable or combustible liq-

uids such as gasoline or use in areas where they may

be present.

18) Replace damaged or worn parts immediately with

genuine manufacturer equipment parts to maintain safety and protect your limited warranty.

19) The power source MUST be properly grounded.

If using a generator check the manufacturers

grounding instructions.

20) The electrical box panel MUST only be opened

by a licensed electrician or authorized service technician and the power cord MUST be unplugged.

21) When transporting the machine from one location to another keep the machine on level ground.

10) DO NOT

close a door on cord, or pull cord around sharp edges

or corners. DO NOT run machine over the cord. Keep

cord away from heated surfaces.

11) DO NOT unplug by pulling on cord. To unplug,

grasp plug, not the power cord.

13) DO NOT put any object into motor openings.

pull by cord, use power cord as a handle,

ANGER:

D

Improper use of the grounding plug can result in a risk of electrical shock.

PAGE 2

22) Prior to operating this machine, ensure that the

proper voltage is established (480) 3 phase power,

minimum 30 AMPS.

23) Ensure proper machine rotation is established

with vacuum and motor assembly.

ABOUT THE SWOOP POLISHER

Trigger and Trigger Lock

Electrical Panel Box

Motor Assembly

Vacuum Hose Port

Steel Handle Pin

Main Power Cord

w/Twist Lock Plug

Polishing

Decks

Assembly

Dust Skirt

PAGE 3

AA

TTTTAACCHHMMEENNTT

DD

EESSCCRRIIPPTTIIOONN

POLISHING VELCRO PAD HOLDER:

Used to hold the diamond polishing disks in place. The velcro pad holder can

remain through the polishing steps (grits: 100/200/400/800/1500/3000).

This will cut down on storage space and maximizes the use of a single set of

drivers.

AA

TTTTAACCHHMMEENNTT

II

NNSSTTAALLLLAATTIIOONN

&& CC

HHAANNGGIINNGG

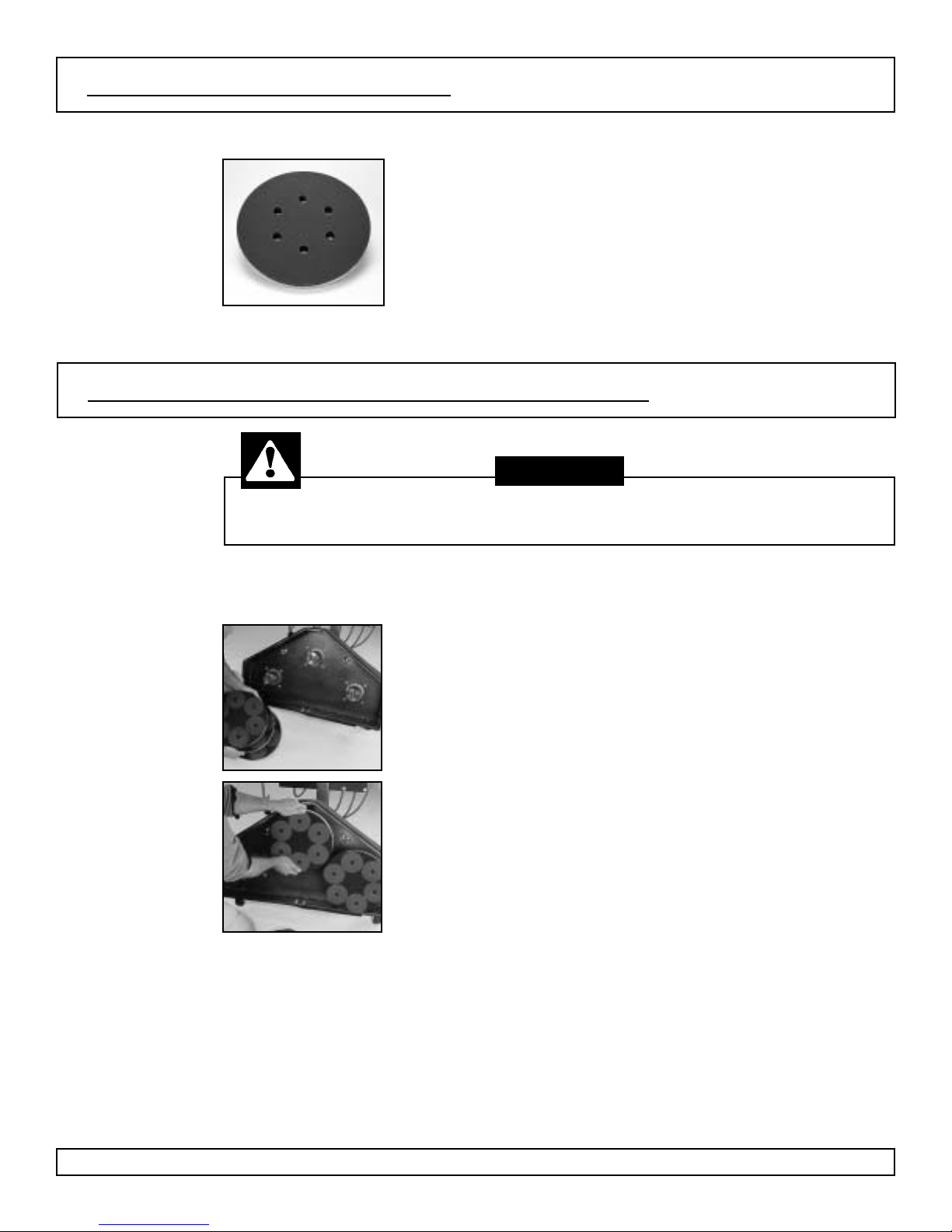

CAUTION:

When installing or changing the velcor drivers and diamonds, turn OFF the machine

and disconnect the power cord from the electrical outlet.

Remove the plugs from the power box.

Pad Holder Installation

1) Lift up the deck assem-

bly and tilt back as shown.

2) Position the diamond

disks to be used on the

bottom of the pad holder

as shown.

3) Line up the holes on

the pad holder with the

four metal pins protruding

from each of the three

heads on the bowls.

9) Move the SWOOP to where the polishing is to begin

and return deck assembly to the operation position.

11) To adjust skirt, align the skirt with the center of

the machine and wrap it around with the bottom edge

touching the floor.

12) Follow Operating Instruction and begin again.

Pad Holder Removal

1) Using both hands, reach beneath the bottom side of

the velcor pad holder and pull up towards yourself to

free it from the machine.

4) Push the pad holder on

by hand and if necessary,

carefully tap it into place

with a rubber mallet.

PAGE 4

Loading...

Loading...