Onfloor Propel Operating Manual

Operating Manual

PROPEL

Striker 2840 Parts List - PN 220868 - Printed in USA 03/18/08

TM

This manual is furnished with each new ONFLOOR. It provides necessary operating and preventive

maintenance instructions. Read this manual completely and understand the machine before operating

or servicing the machine.

This machine will provide excellent service. However, the best results will be obtained at minimum

costs if:

The machine is operated with reasonable care.

The machine is maintained regularly by following maintenance instructions provided.

The machine is maintained with ONFLOOR supplied parts.

Copyright © 2007 ONFLOOR

RADIAL AT OPERATOR MANUAL

TABLE OF CONTENTS

Page

SAFETY PRECAUTIONS

OPERATION

OPERATOR RESPONSIBILITY

COMPONENT LOCATION

ATTACHING THE SWEEPER TO THE FORKLIFT

GENERAL SWEEPING AND BRUSH INFORMATION

SWEEPING

MAIN BROOM ADJUSTMENT

SIDE BROOM ADJUSTMENT

EMPTYING THE HOPPER

REMOVING THE SWEEPER FROM THE FORKLIFT

SWEEPER TROUBLESHOOTING

MAINTENANCE

REPLACING THE MAIN BROOM

2-6

7

7

8

9-11

12

13-14

15

16

17-19

20-21

22

23

23-24

ADJUSTING THE MAIN BROOM TAPER

REPLACING THE SIDE BROOMS

HOPPER DUST FILTER

REPLACING THE HOPPER DUST FILTER

SKIRTS AND SEALS

BEARINGS

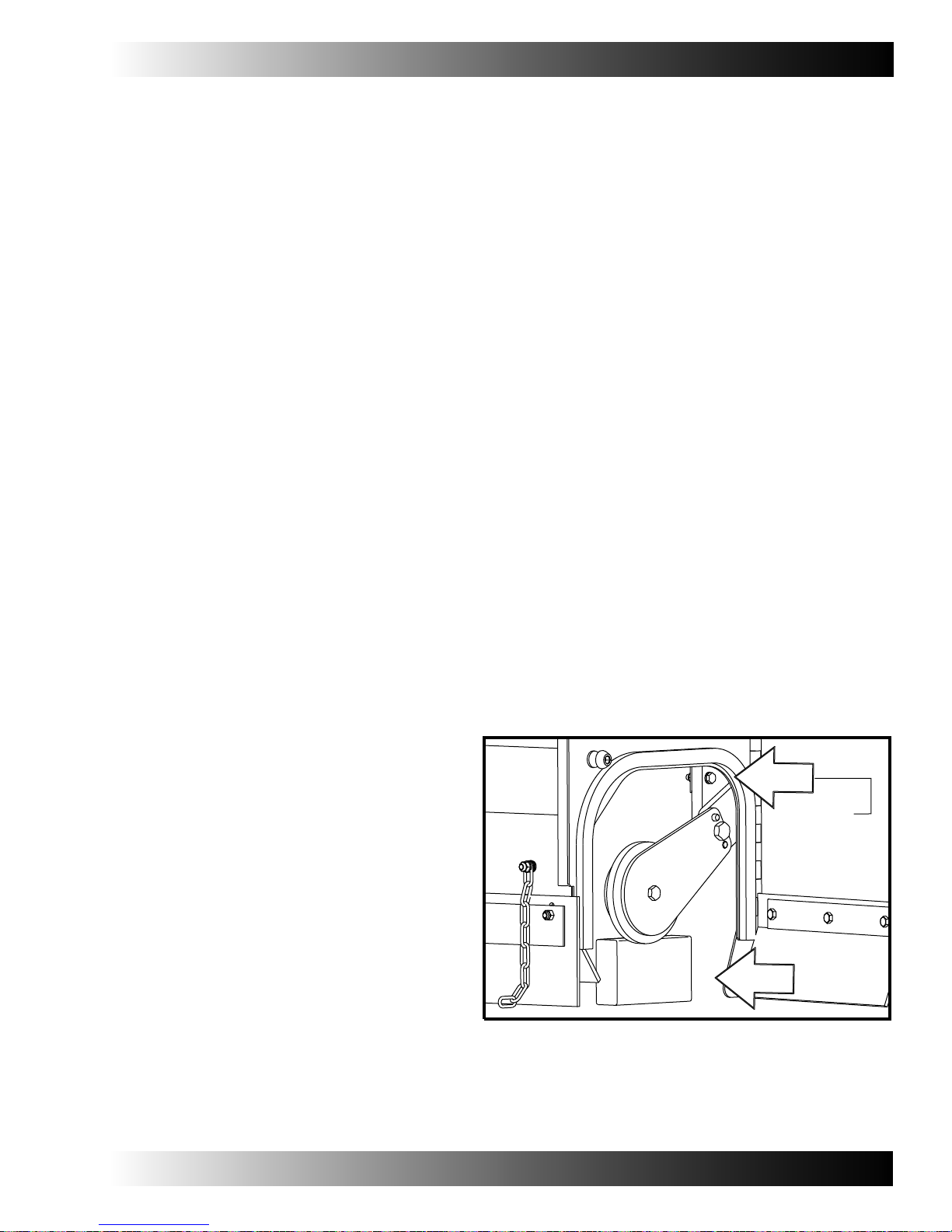

V-BELT TENSION

STATIC DRAG CHAIN

HOPPER SKID BLOCK

TIRES

FORKTUBE PIVOT BOLT

TRANSPORTIN THE MACHINE

MACHINE JACKING

SPECIFICATIONS

25

26

27

28

29-32

32

32

32

32

33

33

33

34

35

1

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The following precautions illustrated herein are

imperative for safe machine operation:

WARNING: To warn of hazards or

unsafe practices which could result

in severe personal injury or death.

FOR SAFETY: Identify actions

that must be followed for safe

operation of sweeper and forklift

equipment.

The machine is suited to sweep and collect

disposable debris. Do not use the machine in

ways other than described in this Operator

Manual. The machine is not designed for use

on public roads.

The following information signals potentially

dangerous conditions to the operator or

equipment.

WARNING: Forklift emits noxious gases.

Operating in unventilated environments may

result in respiratory damage or asphyxiation.

For exposure limits, contact your regulatory

authorities. Keep engine tuned properly.

WARNING: Raised hopper may fall.

Stay clear of hopper.

WARNING: Moving belt and pulleys.

Keep away from belt drive.

FOR SAFETY:

1. Do not operate sweeper or forklift:

- Unless properly trained and authorized.

- Unless operator manual is read and

understood.

- If it is not in proper operating

condition.

- In flammable or explosive areas.

- In areas with possible falling objects

unless equipped with overhead guard.

3. When using machine:

- Go slow on inclines and slippery

surfaces.

- Do not carry passengers on

machine.

- Use care when reversing machine.

- Use brakes to stop machine.

- Move machine with care when

hopper is raised.

- Make sure adequate clearance is

available before raising hopper.

- Always follow safety and traffic

rules.

- Report machine damage or faulty

operation immediately.

4. Before leaving or servicing machine:

- Stop on level surface.

- Set parking brake.

- Turn off machine and remove key.

5. When servicing machine:

- Avoid moving parts. Do not wear

loose clothing.

- Block machine tires before jacking

machine up.

- Jack machine up at designated

locations only.

- Use hoist or jack that will support

the weight of the machine.

- Wear eye and ear protection when

using pressurized air or water.

6. When loading/unloading machine

onto/off truck or trailer:

- Use truck or trailer that will

support the weight of the machine.

- Block machine tires.

- Tie machine down to truck or

trailer.

2

FOR SAFETY

1. Do Not Operate Machine:

-Unless Trained And Authorized.

-Unless Operation Manual Is Read.

And Understood.

-In Flammable Or Explosive Areas.

-In Poorly Ventilated Areas.

2. Do Not Raise Hopper:

-Unless Machine Is On A Level

Surface.

-Unless Sweeper Is Positioned Directly In

Front of Forklift And Inline With Forklift.

3. Do Not Use Flammable Cleaning

Agents.

4. Go Slow On Grades And Slippery

Surfaces.

5. Before Leaving Machine:

-Stop On Level Surface.

-Turn Off Key And Set Parking

Brake.

-When Parking Remove Key.

SAFETY PRECAUTIONS

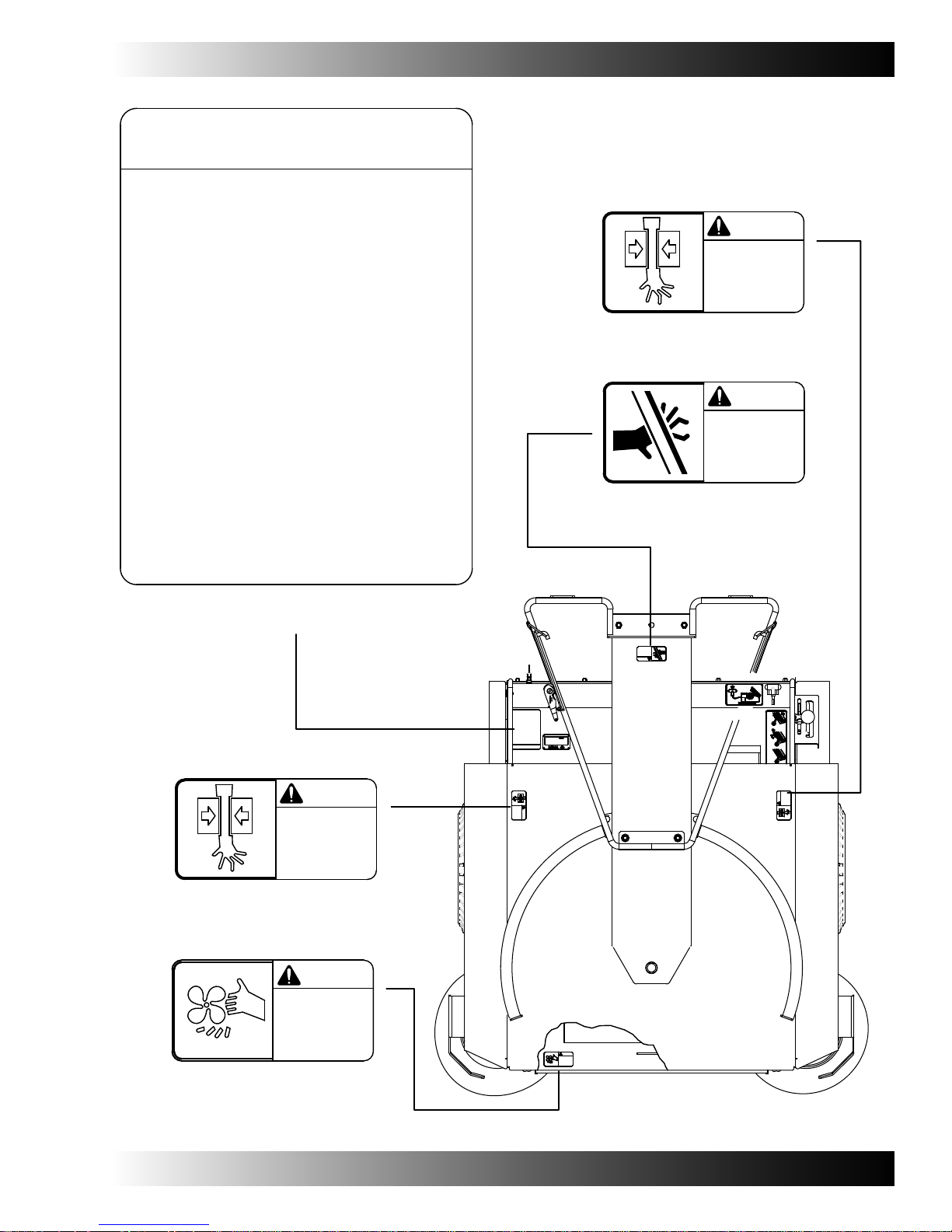

The following safety labels are mounted on the

machine in the locations indicated. If these or

any label becomes damaged or illegible, install

a new label in its place.

WARNING

Keep Limbs

Clear Of

Pinch Point

DECAL, PINCH POINT WARNING

WARNING

Stay Clear

Of Swinging

Tube

DECAL, SWINGING TUBE WARNING

6. Contact Your Dealer For Manufactures Original

Or Equivalent Replacement Parts.

DECAL, FOR SAFETY

WARNING

Keep Limbs

Clear Of

Pinch Point

DECAL, PINCH POINT WARNING

WARNING

90-88004

Tube

Of Swinging

Stay Clear

WARNING

90-88024

Equivalent Replacement Parts.

6. Use Trex Company Supplied Or

-When Parking Remove Key.

Brake.

-Turn Off Key And Set Parking

-Stop On Level Surface.

5. Before Leaving Machine:

Surfaces.

4. Go Slow On Grades And Slippery

Agents.

3. Do Not Use Flammable Cleaning

Front of Forklift And Inline With Forklift.

-Unless Sweeper Is Positioned Directly In

Surface.

-Unless Machine Is On A Level

2. Do Not Raise Hopper:

-In Poorly Ventilated Areas.

OLATHE, KS 66062

-In Flammable Or Explosive Areas.

19925-A W.161ST STREET

And Understood.

GROSS WT.__________LBS.__________KG.

-Unless Operation Manual Is Read.

-Unless Trained And Authorized.

SERIAL NO.

1. Do Not Operate Machine:

MODEL NO.

FOR SAFETY

Keep Limbs

Pinch Point

Clear Of

WARNING

3

2

1

WARNING

Clear Of

Pinch Point

Keep Limbs

Keep Away

From Fan

Inlet

DECAL, FAN WARNING

WARNING

Keep Away

From Fan

Inlet

3

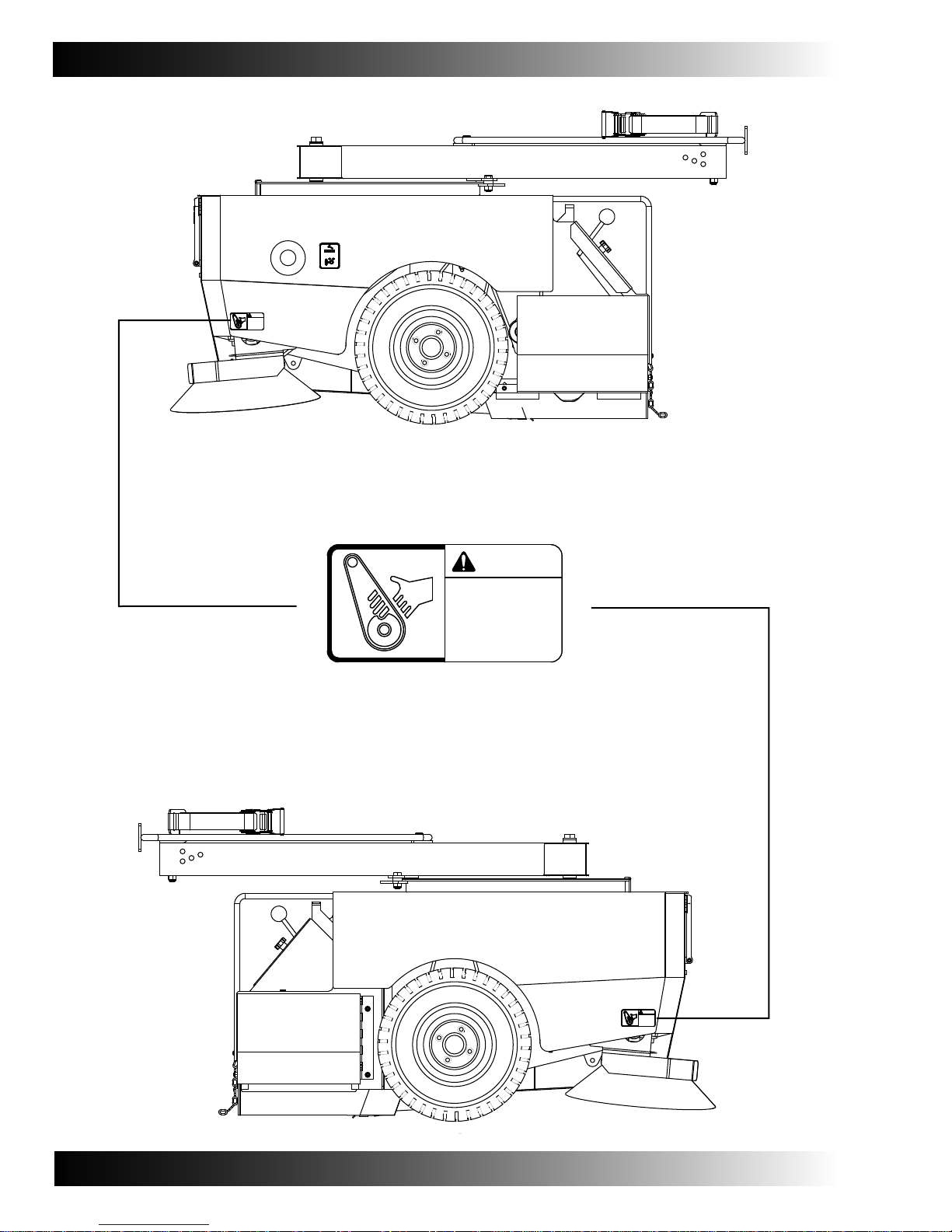

SAFETY PRECAUTIONS

WARNING

Keep Away

From

Belt Drive

90-88008

WARNING

Keep Away

From

Belt Drive

DECAL, BELT WARNING

WARNING

Keep Away

From

Belt Drive

4

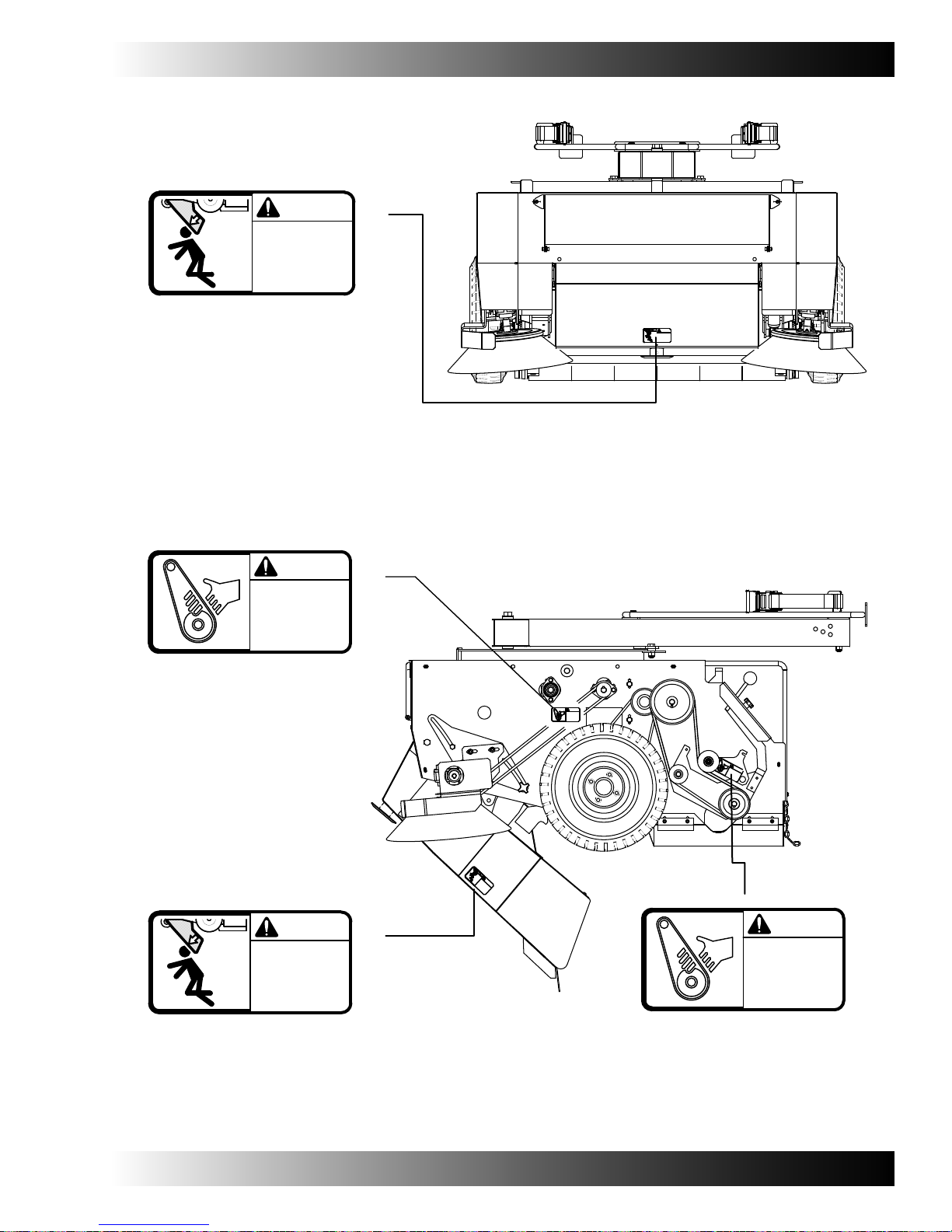

WARNING

Stay Clear

Of Hopper

SAFETY PRECAUTIONS

DECAL, HOPPER WARNING

WARNING

Keep Away

From

Belt Drive

DECAL, BELT WARNING

WARNING

Stay Clear

Of Hopper

90-88006

WARNING

Keep Away

From

Belt Drive

WARNING

Keep Away

From

Belt Drive

WARNING

Stay Clear

Of Hopper

DECAL, HOPPER WARNING

90-88006

WARNING

Stay Clear

Of Hopper

WARNING

Keep Away

From

Belt Drive

DECAL, BELT WARNING

5

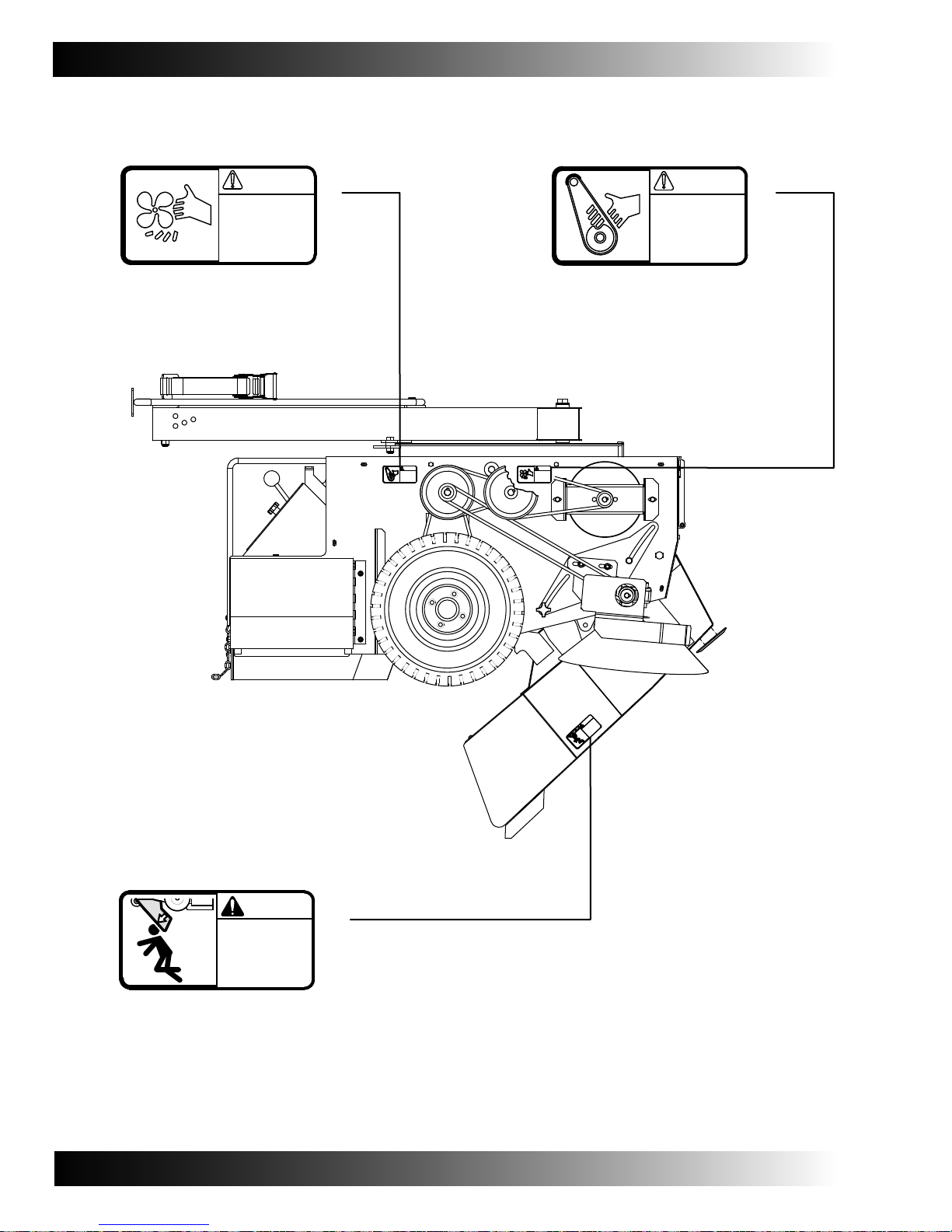

SAFETY PRECAUTIONS

WARNING

Keep Away

From Fan

Inlet

DECAL, FAN WARNING

WARNING

Keep Away

From

Belt Drive

DECAL, BELT WARNING

WARNING

Keep Away

From

Belt Drive

WARNING

Keep Away

From Fan

Inlet

WARNING

Stay Clear

Of Hopper

DECAL, HOPPER WARNING

WARNING

Stay Clear

Of Hopper

90-88006

6

OPERATOR RESPONSIBILITY

The operator’s responsibility is to oversee

daily maintenance and checkups of the

machine to ensure safe and effective

mechanical operation. The operator

is expected to inform service personnel

when required maintenance schedules

occur as stated in the MAINTENANCE

section of this operators manual.

Read manual carefully before operating

this equipment.

FOR SAFETY: Do not operate machine,

unless operation manual is read and

understood.

OPERATION

Check the machine for shipping damage.

Check to make sure machine is complete

per shipping instructions.

Keep you machine regularly maintained by

following the maintenance information in this

manual. We recommend taking advantage of

a regularly scheduled service contact from

your authorized dealer.

Order parts and supplies directly from your

authorized representative. Use the parts

manual provided when ordering parts.

7

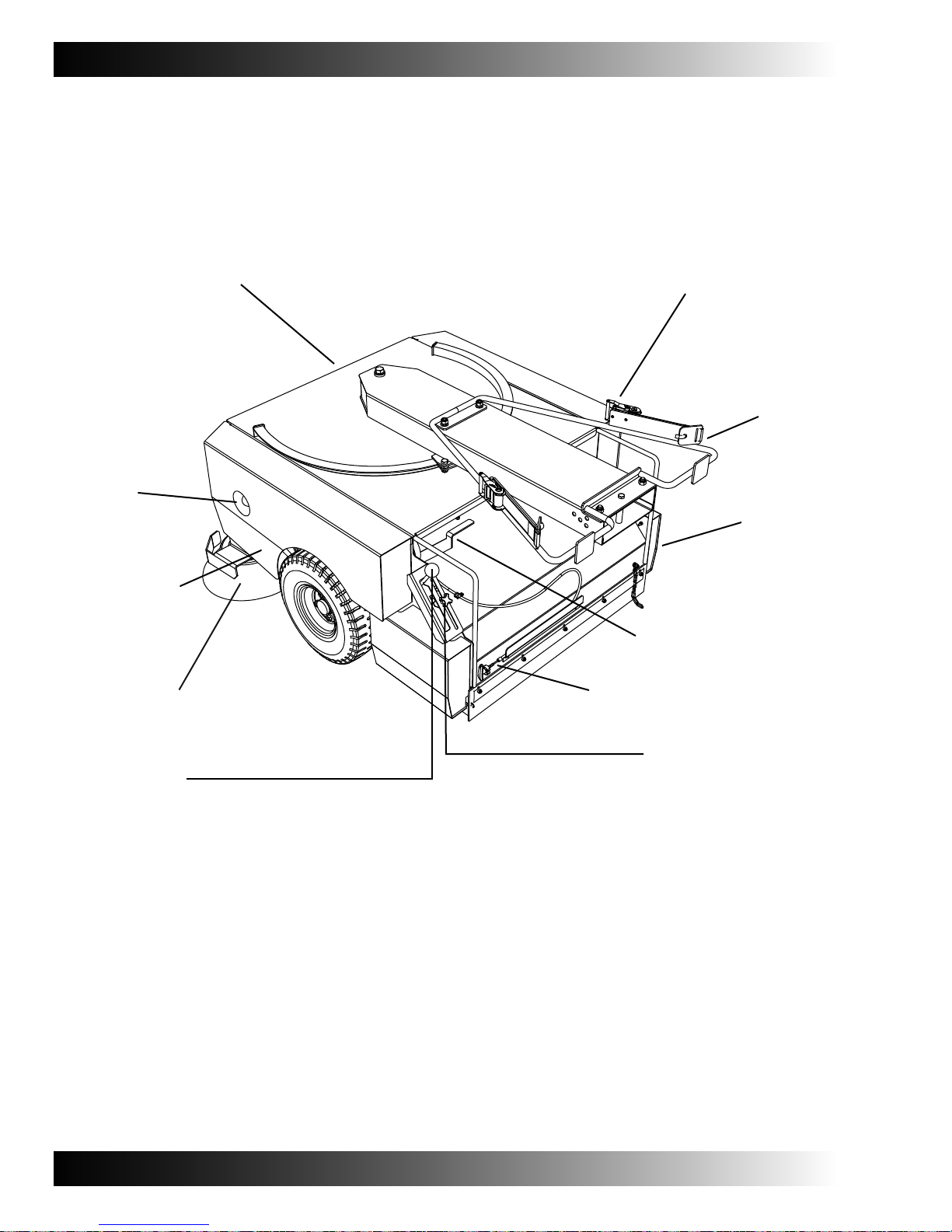

OPERATION

&),4%2!##%33$//2

&),4%2

3(!+%2

3)$%

"2//-

!$*534-%.4

+./"

3)$%"2//-

2%4!).).'

342!02!4#(%4

2%4!).).'

342!0

MAIN

BROOM

DOOR

(/00%2,!4#(,%6%2

(/00%22%,%!3%4(!.$,%

-!)."2//,)&4,%6%2

8

-!)."2//-,%6%2

34/0!33%-",9

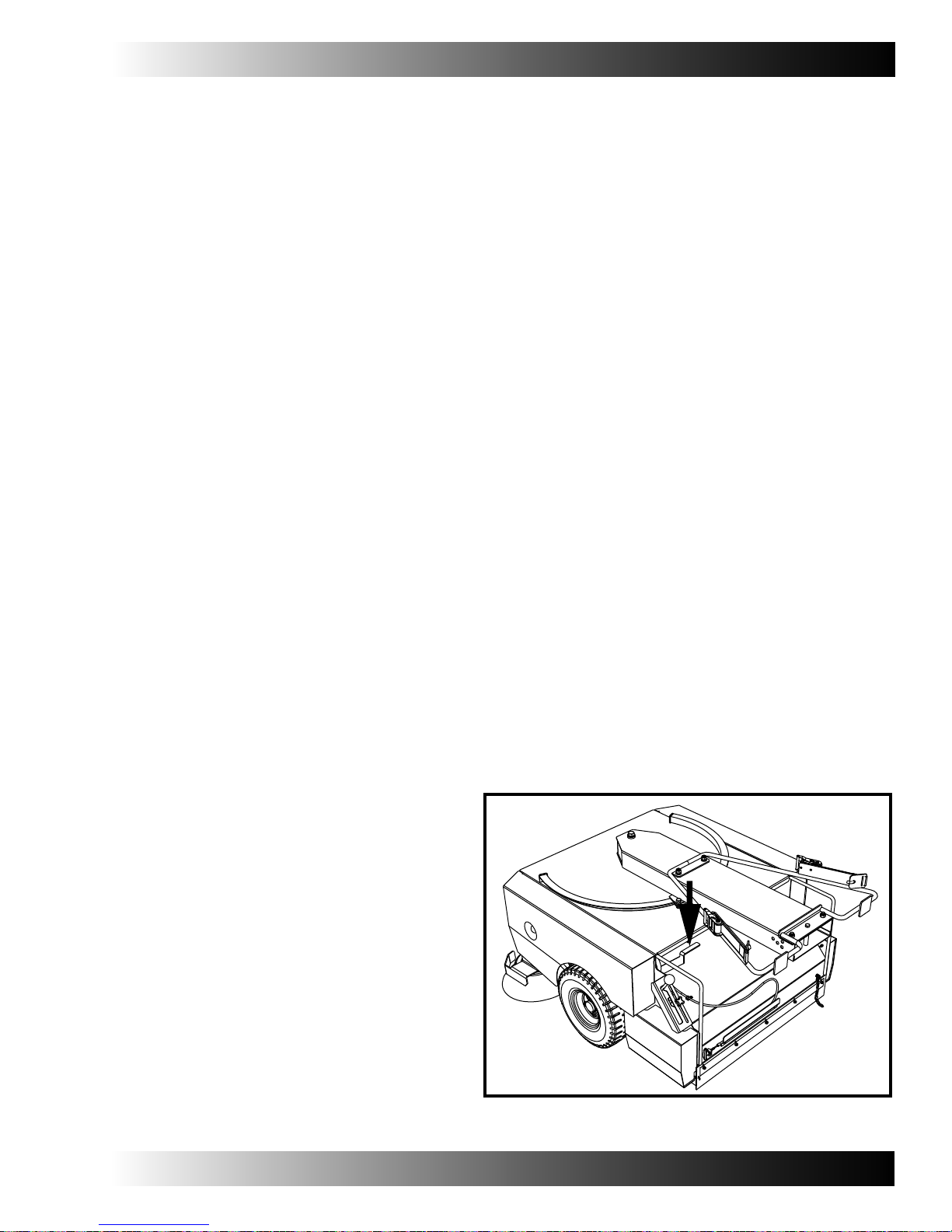

ATTACHING THE SWEEPER TO THE FORKLIFT

NOTE: Do not use this sweeper on forklifts

with forks that are more than 1219mm

(48 in.) long.

FOR SAFETY: When not in use, the

sweeper must be stored on a flat, level

surface. The wheels must be chocked to

prevent movement of the sweeper.

NOTE: If the sweeper is being installed on

a different forklift than the forklift previously

used, reposition the horizontal pin into the

highest hole in the mounting tube as shown.

1. The forklift forks must be centered

and positioned with approximately a

25mm (1 in.) space between the forks.

2. Position and level the forks so that they

are in line with the inlet of the sweeper

mounting tube.

OPERATION

3. Drive the forklift slowly forward so that

the forks slide easily into the sweeper

mounting tube. If there is any resistance

when sliding the forks into the tube, or

there is a tendency to push the sweeper

out of position, stop the forklift and

reposition the forks so that they slide

easily into the mounting tube.

4. Stop the forward movement of the

forklift when the two vertical plates on

the sweeper mounting tube contact the

fork mounting rack of the forklift.

5. Lower forks until they lay flat on the

bottom of the sweeper mounting tube.

FOR SAFETY: Before leaving the forklift,

stop on a level surface, set the forklift

parking brake, turn off the forklift and

remove the key.

6. Position the horizontal pin into the lowest

hole possible, above the forklift forks as

shown. If the pin does not slide easily

over the forks, use the next higher hole

position. Lock pin in position by inserting

hair spring pins.

9

OPERATION

7. Be sure that the two vertical plates on the

sweeper mounting tube are in contact

with the fork mounting rack of the forklift.

8. Perform the following steps using both

mounting straps.

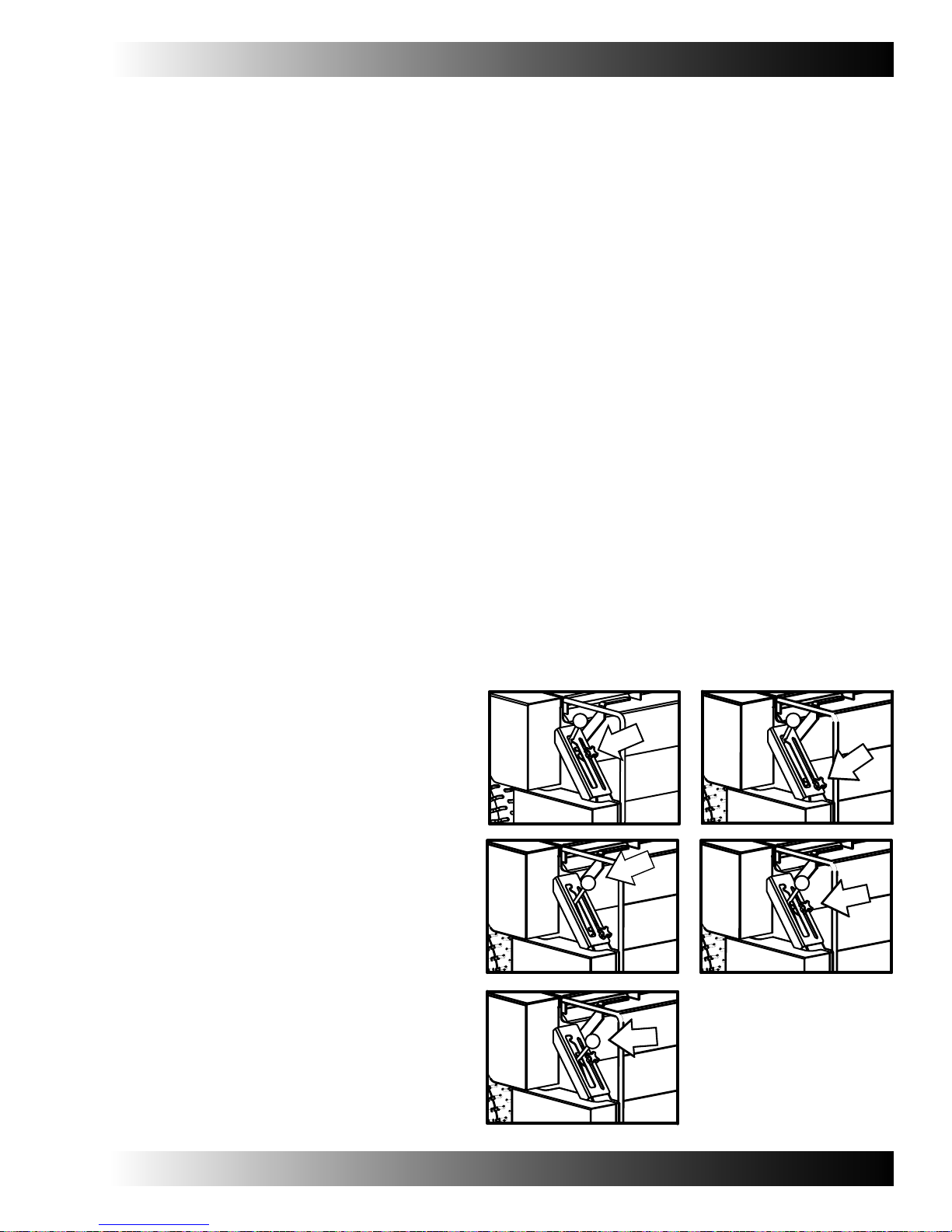

9. Fully open the ratchet handle, as shown,

to unlock the restraining strap.

10. Pull out a short length of the strap.

Note: Pulling out an excessive amount of

strap may result in the strap coming off

of the ratchet drum. To reattach the strap

onto the ratchet drum, thread the free end

of the strap through, then one inch past

the slot in the ratchet drum. Be sure that

the free end of the strap remains one inch

past the drum as you operate the ratchet

handle. Continue until the strap makes at

least one full wrap around the drum.

11. Wrap the strap around the forklift fork

mounting rack as shown and hook the

metal strap end onto the retaining pin.

12. Operate the ratchet handles to tighten

the restraining strap. Tighten the strap

until the slack is removed, then continue

tightening one more ratchet tooth (click).

Do not over tighten the straps.

13. Raise the sweeper only high enough to

clear the ground.

FOR SAFETY: Do not raise the sweeper

off of the ground unless the body of the

sweeper is in line and centered with the

fork tube.

Note: Raise the sweeper off of the ground

before driving the forklift in reverse.

Attempting to drive the forklift in reverse

with the sweeper on the ground may

result in damage to the sweeper.

10

14. Remove the retaining pin from the

front support leg, raise the support

leg, and reinstall the retaining pin.

15. Drive slowly to the sweeping area.

OPERATION

11

OPERATION

GENERAL SWEEPING AND BRUSH INFORMATION

Pick up oversized debris before sweeping. Flatten or remove large boxes from aisles before

sweeping. Pick up long pieces of wire, string, twine, etc., which can become entangled in the

brooms or broom hubs.

For the most efficient operation, plan your sweeping in advance. Arrange long runs with a

minimum of stopping and starting. Move debris from areas where the sweeper cannot go, into

larger aisles ahead of time. Sweep an entire floor or section at one time. Overlap the sweeping

paths. Avoid hitting posts or scraping walls.

Avoid turning the steering wheel too sharply when the machine is in motion. The sweeper is

very responsive to the movement of the steering wheel. Avoid sudden turns, except in

emergencies.

It is not necessary to push the sweeper at high speed. The sweeper is designed to sweep with

maximum efficiency when driven at 2-3 mph, the speed of a brisk walk.

For the best sweeping results, use the correct broom type for your sweeping application. Chose

your sweeping brooms from the following list of brooms and applications:

Poly & wire 6-double row main broom

This broom is ideal for most applications. The wire bristles loosen lightly compacted debris.

The polypropylene bristles sweep general debris with excellent hopper loading.

Nylon 6-double row main broom

This broom is good for general sweeping. The nylon bristles have the longest life of the various

bristle types. This broom provides good hopper loading.

High density nylon 18-row main broom

This broom is good for heavy dust conditions on rough surfaces. This broom provides good

pick and excellent life.

Stiff poly & wire 6-row main broom

This broom is good for heavier compacted debris. The wire bristles loosen compacted debris.

The polypropylene bristles sweep general debris with excellent hopper loading.

Poly side broom

This side broom is ideal for most applications, including light to medium debris in both indoor

and outdoor applications.

Nylon side broom

A longer life, general purpose broom, recommended for rough surfaces.

12

SWEEPING

1. Raise the sweeper only high enough to

clear the ground and drive slowly to the

sweeping area.

FOR SAFETY: Do not raise the sweeper

off of the ground unless the body of the

sweeper is in line and centered with the

fork tube.

OPERATION

Note: Raise the sweeper off of the

ground before driving the forklift

in reverse. Attempting to drive the

forklift in reverse with the sweeper

on the ground may result in damage

to the sweeper.

2. Slowly lower the sweeper to the ground.

3. Tilt the forklift forks until the body of the

sweeper is level (parallel to the ground).

“QUICK LEVEL”

“Quick level” is a simple method for

leveling the sweeper. To “quick level”

the sweeper, check the positions of the

sides brooms and the rear skirt.

The side brooms should have correct

contact the ground (not lifted off the

ground or pushed into the ground).

“Quick level” allows the operator to

adjust the tilt of the sweeper, even while

sweeping, from the operator position.

#ORRECT

)NCORRECT

#ORRECT

After the initial adjustment, simply check

the rear skirt and adjust the fork height as

necessary.

4. Adjust main broom and sidebroom.

NOTE: In order for “quick level “to be effective,

the side brooms and rear skirt

must be properly adjusted.

)NCORRECT

13

OPERATION

FOR SAFETY: Before leaving the

forklift, stop on a level surface, set

the forklift parking brake, turn off

the forklift and remove the key.

5. Lower the main broom lever into the

locking slot.

6. Begin sweeping.

OPERATION ON INCLINES

Drive the sweeper slowly on inclines.

Warning: Forklift may tip over.

Do not turn the machine on

inclines. Do not drive the machine

across inclines. Drive only

straight up or straight down

inclines.

14

MAIN BROOM

The main broom sweeps debris into the

debris hopper.

Check the main broom daily for damage

or wear. Remove any debris found

tangled on the main broom or main

broom hubs.

Check the main broom daily for proper

adjustment.

For maximum life, the main broom

should be turned end-for-end after

every 50 hours of use.

The main broom should be replaced

when the bristles are worn to 50mm

(1.50 in.) in length, or when the main

broom no longer sweeps effectively

in your application.

OPERATION

ADJUSTING THE MAIN BROOM

The sweeper must be mounted to the

forklift, on the ground, and leveled.

FOR SAFETY: Before leaving the

forklift, stop on a level surface, set the

forklift parking brake, turn off the

forklift and remove the key.

1. Loosen the knob on the main broom

locking assembly. Note that the locking

assembly has two fingers that extend into

the main broom lever slot.

2. Slide the locking assembly to the bottom

of the slot.

3. Move the main broom lever from the

“broom up” top position and lower it

until the main broom contacts the floor.

4. Raise the locking assembly until the top

finger touches the main broom lever.

Tighten the knob on the locking assembly.

5. Position the main broom lever between

the two fingers of the locking assembly.

The main broom is now in the optimum

position for sweeping.

15

OPERATION

SIDE BROOMS

The side brooms move debris from the

edges of the sweeping area into the path

of the main broom.

Check the side brooms daily for damage

or wear. Remove any debris found tangled

on the side brooms or side broom drive hubs.

Check the side brooms daily for proper

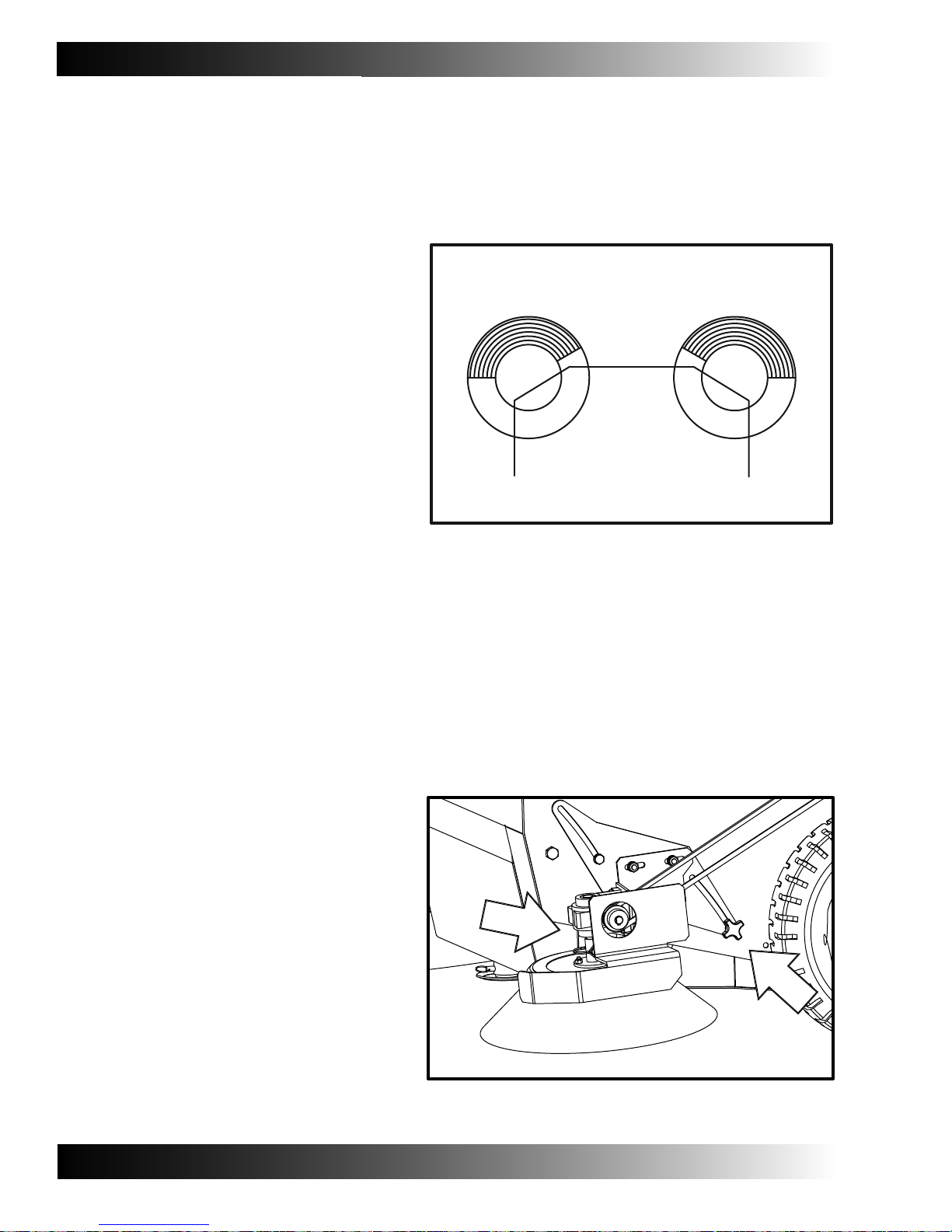

adjustment. The right side broom should

contact the floor from a 10 o’clock to

3 o’clock pattern. The left side broom

should contact the floor from a

9 o’clock to 2 o’clock pattern.

For maximum life, the side brooms should

be swapped (from one side to the other)

after every 50 hours of use.

The side brooms should be replaced when

the bristles are too short to sweep effectively

in your application.

ADJUSTING THE SIDE BROOM

The sweeper must be mounted to the

forklift, on the ground, and leveled.

FOR SAFETY: Before leaving the

forklift, stop on a level surface, set

the forklift parking brake, turn off

the forklift and remove the key.

,%&43)$%"2//-

6)%7%$&2/-!"/6%

3)$%"2//-#/.4!#47)4(4(%&,//2

2)'(43)$%"2//-

6)%7%$&2/-!"/6%

WARNING: Moving belts and pulleys.

Do not attempt to adjust the side broom

when the sweeper is in motion.

1. Loosen the side broom adjustment knob.

2. Raise or lower the side broom to the

correct position. The side broom

assembly can be easily adjusted by

grasping the front of the side broom

gearbox housing with one hand, and

the horizontal plate behind the gearbox

with the other hand. Pull up and

toward the front, or push down

and toward the rear.

3. Tighten the side broom adjustment knob.

It is not necessary to adjust the side broom

drive belt when adjusting the side broom

height.

16

EMPTYING THE HOPPER

1. Slowly move the sweeper forward until the sweeper

is positioned over the debris container or debris

dumping site.

FOR SAFETY: Do not raise the sweeper off

of the ground unless the body of the sweeper

is in line and centered with the fork tube.

OPERATION

FOR SAFETY: When using machine,

Make sure adequate clearance is available

before raising sweeper.

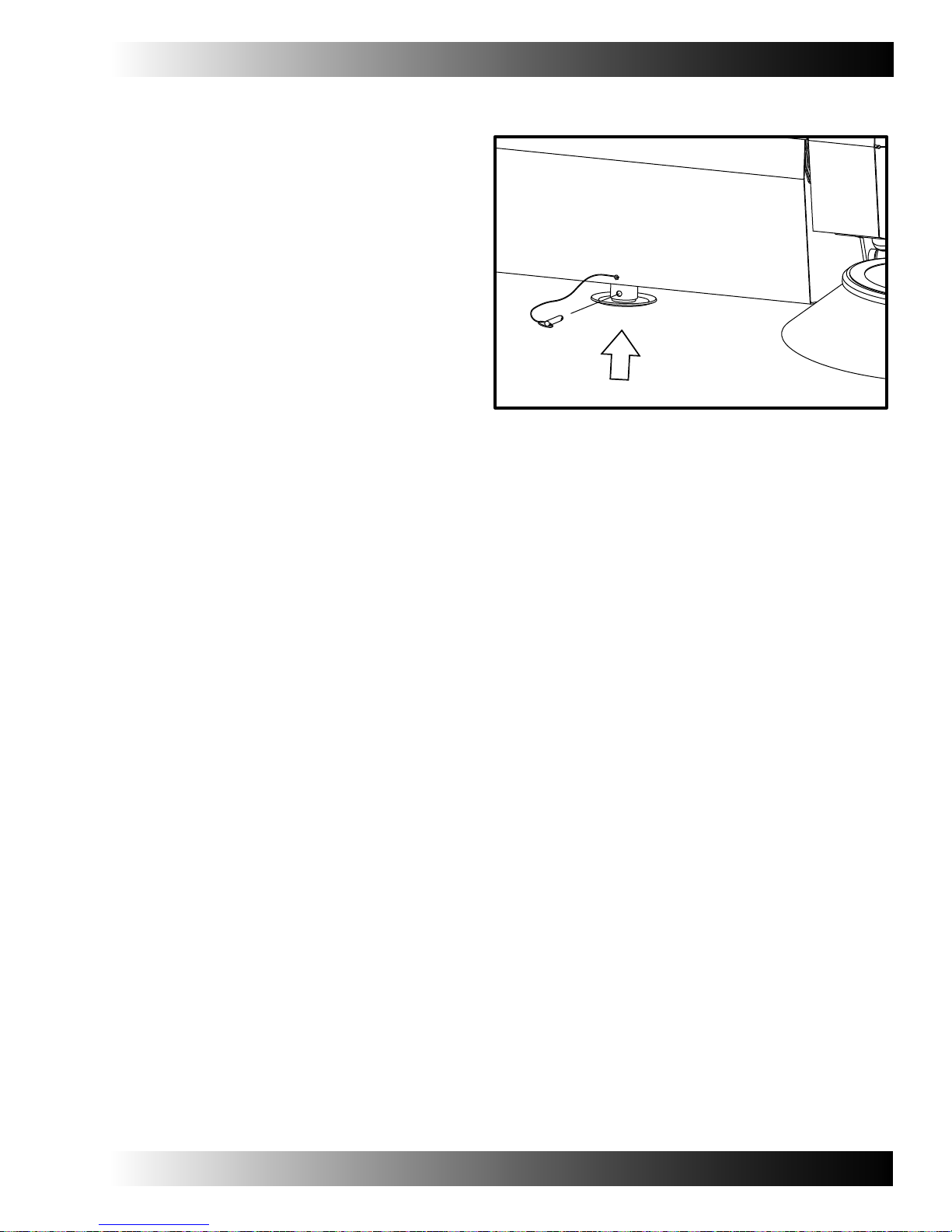

2. Pull and Push the filter shaker knob

to clean the hopper dust filter. Return

the knob to the full-in storage position.

FOR SAFETY: Before leaving the

forklift, stop on a level surface, set

the forklift parking brake, turn off

the forklift and remove the key.

3. Slowly raise the sweeper until the tires

of the sweeper just clear the debris

container, or, if there is no container,

raise the sweeper until the bottom of

the sweeper is approximately 1meter

(three ft.) above the debris dumping site.

#/22%#4

).#/22%#4

17

OPERATION

4. Dismount the forklift.

FOR SAFETY: Before leaving the forklift,

stop on a level surface, set the forklift parking

brake, turn off the forklift and remove the key.

WARNING: Moving hopper may cause

injury or death. Be sure that the area

under and around the hopper is clear

before emptying the hopper.

WARNING: Hopper may fall. Do not

go under raised sweeper.

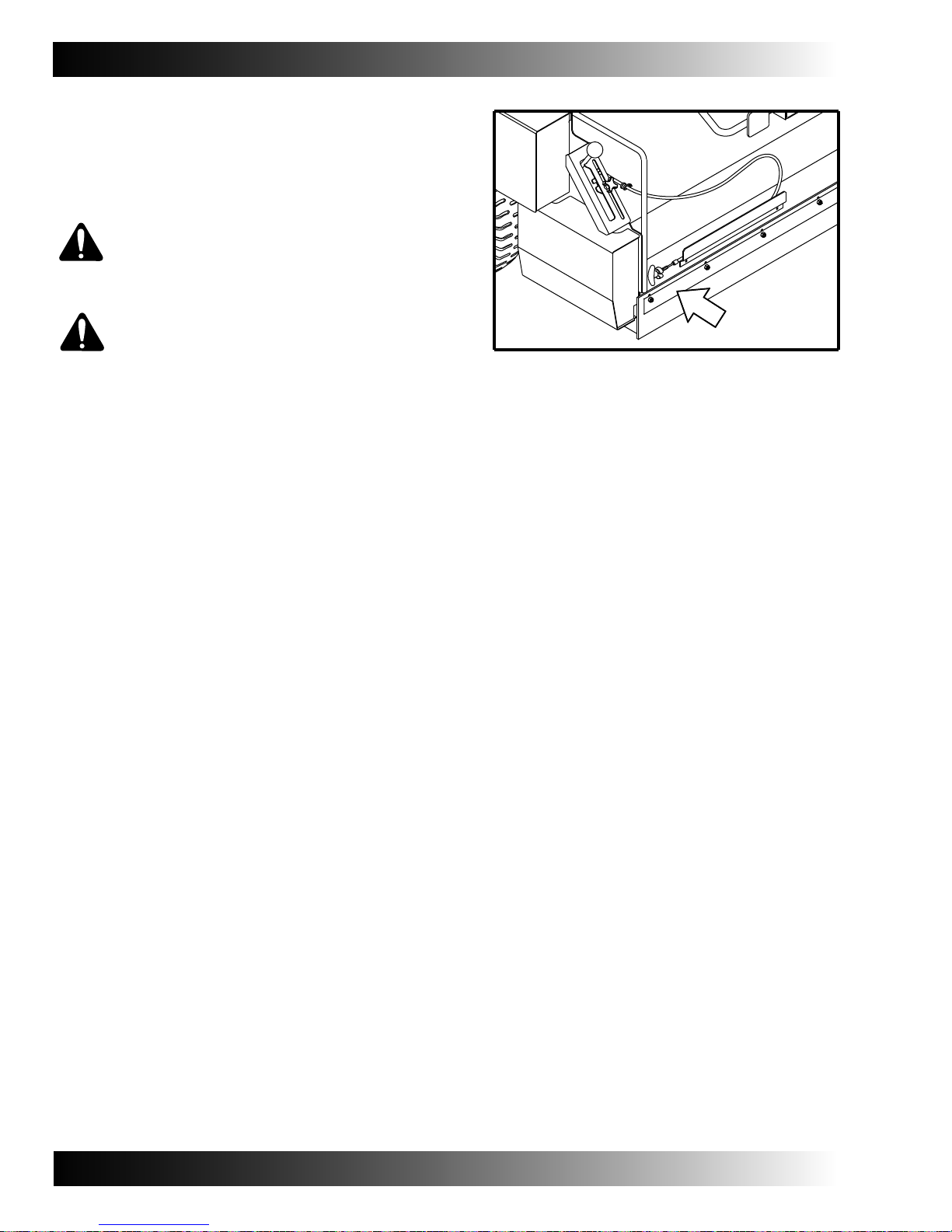

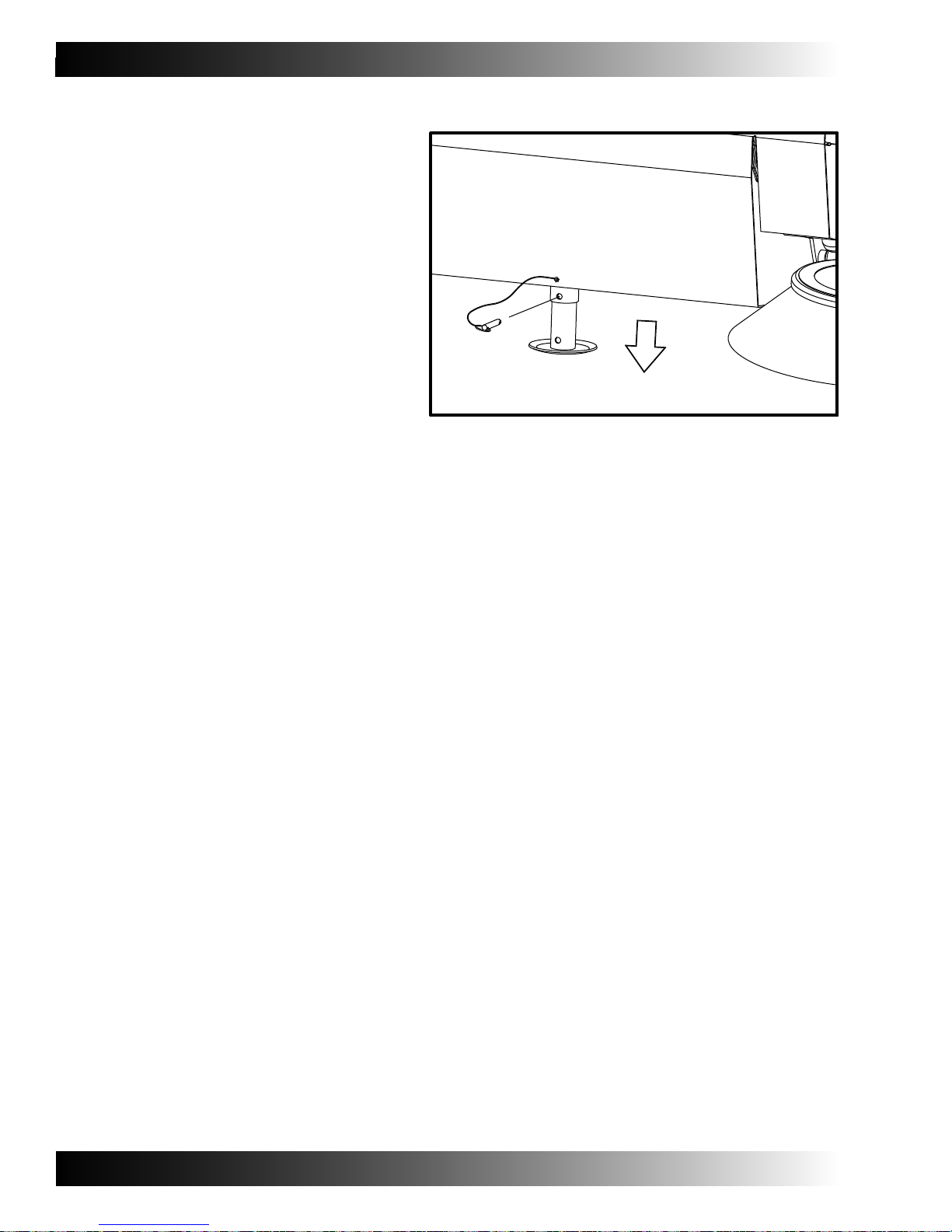

5. Remove the hopper release T-Handle from the

retaining clip, and lift the release cable from

the channel.

6. Stand clear of the sweeper.

7. Release the hopper by pulling the T-handle of the

hopper release cable.

18

8. Place the release cable into the channel,

and replace the hopper release T-handle

into its retaining clip.

9. Raise the sweeper enough so that the

lowered hopper will clear the top of

the debris container.

10. Slowly back the sweeper away from

the debris dumping site.

FOR SAFETY: When using machine,

use care when driving in reverse.

11. Slowly lower the sweeper until the

low end of the hopper is approximately

30.5cm (12 in) above the ground.

12. While slowly moving the sweeper

forward, lower the sweeper the

remaining distance to the ground.

OPERATION

NOTE: Failure to move the forklift

forward while lowering the hopper

may cause damage to the hopper lip

skirts.

13. Dismount the forklift.

FOR SAFETY: Before leaving the

forklift, stop on a level surface, set

the forklift parking brake, turn off

the forklift and remove the key.

14. Push down the hopper latch lever until

the hopper locks into the “sweeping”

position.

19

OPERATION

REMOVING THE SWEEPER FROM THE FORKLIFT

1. Remove the retaining pin from the front

support leg, lower the support leg, and

reinstall the retaining pin.

2. Position the raised sweeper over the sweeper

storage location.

FOR SAFETY: When not in use, the

sweeper must be stored on a flat, level

surface. The wheels must be chocked

to prevent movement of the sweeper.

3. Slowly lower the sweeper to the ground.

FOR SAFETY: Before leaving the

forklift, stop on a level surface, set the

forklift parking brake, turn off the

forklift and remove the key.

Perform the following steps with both

mounting straps.

4. Fully open the ratchet handle, as shown,

to unlock the restraining strap.

5. Loosen the strap and remove the metal

strap end from the retaining pin.

6. Disconnect the strap from the forklift fork

mounting rack.

7. Store the retaining strap by hooking the

metal strap end onto the retaining pin.

8. Operate the ratchet handles to tighten the

restraining strap. Tighten the strap until the

slack is removed.

Do not over tighten the straps.

9. Drive the forklift slowly backwards so that

the forks slide easily out of the sweeper

mounting tube. If there is any resistance

when sliding the forks out of the tube, or

there is a tendency to pull the sweeper out of

position, stop the forklift and reposition the

forks so that they slide easily out of the

mounting tube.

FOR SAFETY: Before leaving the

forklift, stop on a level surface, set the

forklift parking brake, turn off the forklift

and remove the key.

20

10. Chock the sweeper tires to prevent

movement of the sweeper.

11. Raise the main broom lever into the

“broom up” (top) position. This will

raise the main broom off of the floor,

and prevent flat spots from forming

on the main broom.

OPERATION

21

OPERATION

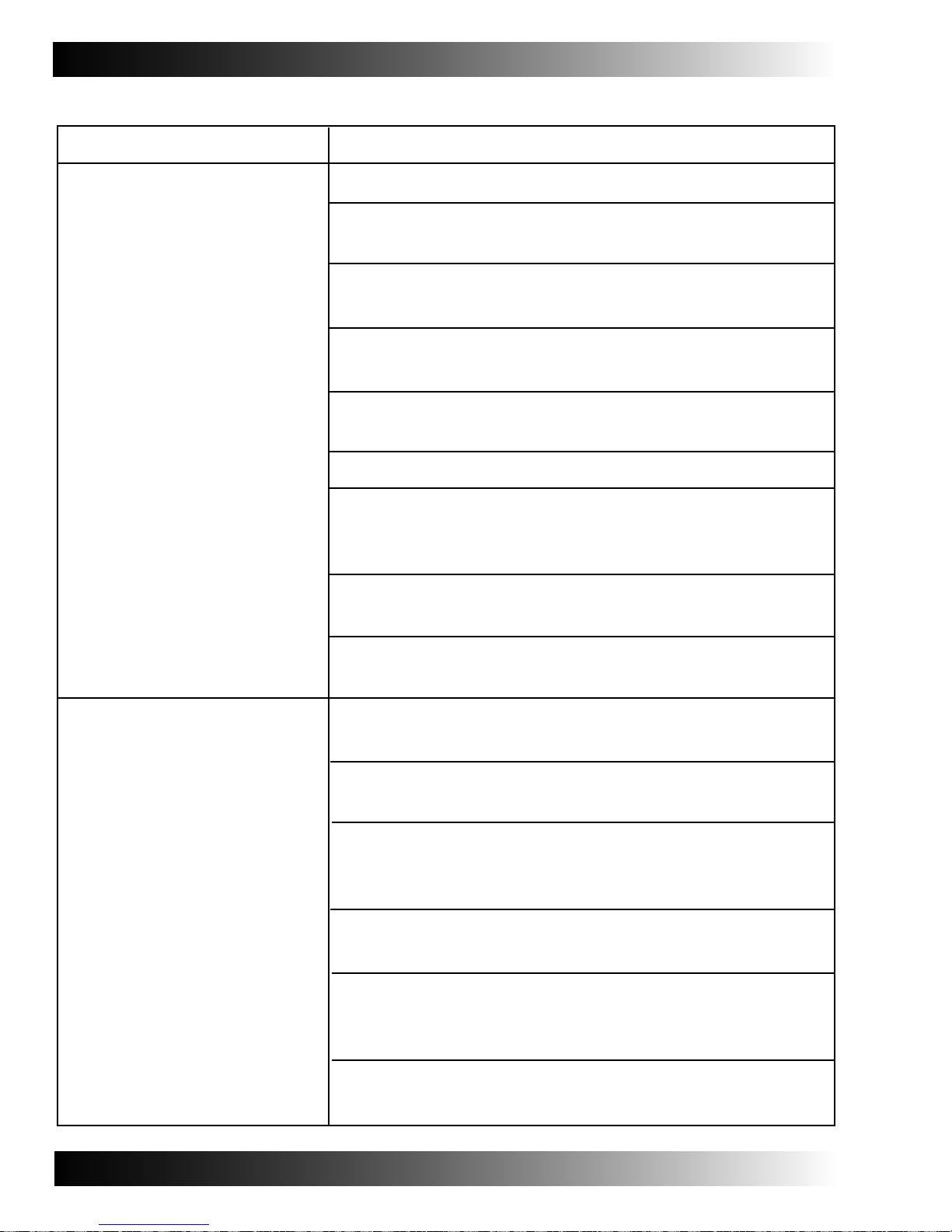

SWEEPER TROUBLESHOOTING

Problem

Poor Sweeping Performance

Cause

Worn Broom(s)

Main and side brooms

adjusted properly

Main broom drive failure

Side broom drive failure

Debris wound around

main broom hub(s)

Hopper full

Skirts or seals out of

adjustment, worn or

damaged

Wrong sweeping broom

Remedy

Replace Broom(s)

Adjust main and side

brooms

Check and replace faulty

belt(s) or gearbox

Check and replace faulty

belt(s) or gearbox

Free main broom hub(s)

of debris

Empty hopper

Replace or adjust

skirts or seals

Contact dealer

Representative

Excessive Dusting

Side brooms stirring up

dust

Hopper dust filter

clogged

Hopper dust filter

incorrectly installed

Hopper dust filter not

shaking clean

Vacuum impeller failure

Skirts or seals out of

adjustment, worn or

damaged

Filter access door partialy

or completely open

Raise or remove side

brooms

Shake and/or clean or

replace dust filter

Install dust filter inside

all three filter locators

Remove dust filter and

clean by hand - replace

filter shaker wipers if worn

Check and replace faulty

belt(s)

Replace or adjust skirts

or seals

Close and latch filter access

door

22

REPLACING THE MAIN BROOM

1. When replacing the main broom, raise

the main broom lever into the “broom up”

(top) position. When rotating the broom

end-for-end, leave the locking assembly

in place, and lower the main broom lever

until it contacts the top edge of the

locking assembly.

2. Open the main broom door by grasping

the end of the broom door and pulling

sharply.

MAINTENANCE

3. Remove the broom mounting plate bolt.

-!)."2//-$//2

-/5.4).'0,!4%

-/5.4).'0,!4%"/,4

23

MAINTENANCE

4. Remove the broom mounting plate.

5. Grasp the broom core and pull the

broom out of the broom chamber.

6. Slide the new brush, or the existing

brush, turned end-for-end, into the

broom chamber.

7. Push the main broom onto the drive hub.

Push and rotate the broom, until it fully

engages the drive hub.

8. Replace the broom mounting plate by

lining up the two outer holes in the

mounting plate with the two pins on the

sweeper frame.

-!)."2//-

-/5.4).'0,!4%

9. Replace and tighten the broom mounting

plate bolt

10. Close the main broom door.

11. Adjust the main broom before sweeping.

24

30!#%2

",/#+

"%!2).'

",/#+

"/,43

ADJUSTING THE MAIN BROOM TAPER

Main broom taper (one end of the main

broom wears more, and so is smaller in

diameter than the other end). This can be

eliminated by adjusting the main broom

bearing blocks.

The sweeper must be on a smooth surface,

and leveled.

1. Remove the main broom.

2. Obtain two equal-size spacer blocks

and place one below the main broom

drive hub.

3. Lower the main broom lever until the

drive hub rests on the spacer block.

4. Replace the main broom mounting plate

and tighten the retaining bolt.

MAINTENANCE

5. Position the second spacer block under

the main broom idler hub.

6. If both broom hubs are in contact with

the spacer blocks then no adjustment

is required. If one of the broom hubs is

in contact with the spacer block, but

the other hub is not, an adjustment is

required.

7. Loosen the two bolts that hold the main

broom bearing block to the adjustment

bracket.

8. Move the bearing blocks up or down

until both broom hubs are in contact

with the spacer blocks.

9. Tighten the two bearing block bolts.

10. Remove the spacer blocks.

11. Reinstall the main broom.

12. Close the main broom.

13. Adjust the main broom.

25

Loading...

Loading...