Onfloor 496898 User Manual

SAFETY

, OPERATION MANUAL & PARTS LIST

OF16H

M

ULTI-PURPOSE

FLOOR MACHINE

This unit is intended for commercial use.

READ & FOLLOW ALL

INSTRUCTIONS,WARNINGS & CAUTION

®

BEFORE USING THIS FLOOR MACHINE

LEASE READ CAREFULLY BEFORE OPERATING

P

This floor machine will afford you many years of

trouble free operating satisfaction if it is given

proper care. All parts have passed rigid quality

control standards before being assembled to

produce the finished product. Prior to packaging, units are again inspected for assurance of

flawless operation.

This floor machine was protectively packed to

prevent damage in shipment. We recommend

that upon delivery, remove the unit from its

carton and carefully inspect it for any possible

damage in transit. A warranty card is affixed to

the handle. It is your responsibility to fill it out

and send it to our office to register your

purchase and start your warranty. Failure to

send us this card in one week upon receipt of

the machine may void the warranty.

If damage is discovered, immediately notify

the transportation company that delivered

your floor machine. As a shipper, we are unable

to act upon any claim for concealed damage.

You must originate any claim within 5 days of

delivery.

These instructions are for your protection and

information. PLEASE READ CAREFULLY!

Failure to follow these precautions could result

in injury or discomfort.

Treat this floor machine as you would any other

high grade precision made product. Throwing,

dropping, unreasonable bumping across thresholds and other misuse may result in a damaged

unit and invalidate the warranty.

AVE THESE INSTRUCTIONS

S

Address: 777 South Street,P.O. Box 2310, Newburgh, New York 12550-0606

TEL: 877.356.6703 / 845.565.6623 / FAX: 845.565.8894

Internet Address: www.onfloor.com / info@onfloor.com

PAGE 1

PN 496928 Rev A - OF16H Floor Machine - Printed in USA 04/08/08

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

To reduce the risk of fire, electric shock or injury;

Read all instructions before using this floor machine.

1) DO NOT leave the floor machine plugged

in when not in use. Unplug from the outlet

when not in use and/or before servicing.

2) Electric shock could occur if exposed to

rain. Store indoors.

3) This is NOT a toy. Close attention is nec-

essary when used around or near children.

4) Use only as described in this manual. Use

only manufacturer's recommended attachments.

5) DO NOT use with damaged cord plug. If

the floor machine is not working as it should

because it has been dropped, damaged, left

outdoors, or dropped into water, contact the

manufacturer or authorized service center.

6) DO NOT handle the plug or operate with

wet hands.

7) DO NOT pull or carry by cord, use power

cord as a handle, close a door on cord, or

pull cord around sharp edges or corners. DO

NOT run floor machine over the cord. Keep

cord away from heated surfaces.

8) DO NOT unplug by pulling on cord. To

unplug, grasp plug, not the power cord.

9) DO NOT put any object into motor open-

ings.

10) Keep hair, loose clothing, fingers and all

parts of body away from moving parts.

11) DO NOT use an optional vacuum with-

out the manufacturer’s filters in place.

12) DO NOT operate where anesthetics and

oxygen are used.

13) DO NOT use an extension cord.

GROUNDING INSTRUCTIONS & METHODS

DANGER:

14) DO NOT use around flammable or com-

bustible liquids such as gasoline or use in

areas where they may be present.

15) Replace damaged or worn parts immedi-

ately with genuine Grind ’N Go equipment

parts to maintain safety and protect your limited warranty.

16) Floor sanding can result in an explosive mixture of fine dust and air. Use a

floor sanding machine only in a well ventilated area.

17) DO NOT leave sawdust in the filter

bag when sander is not in use, this is a

fire hazard.

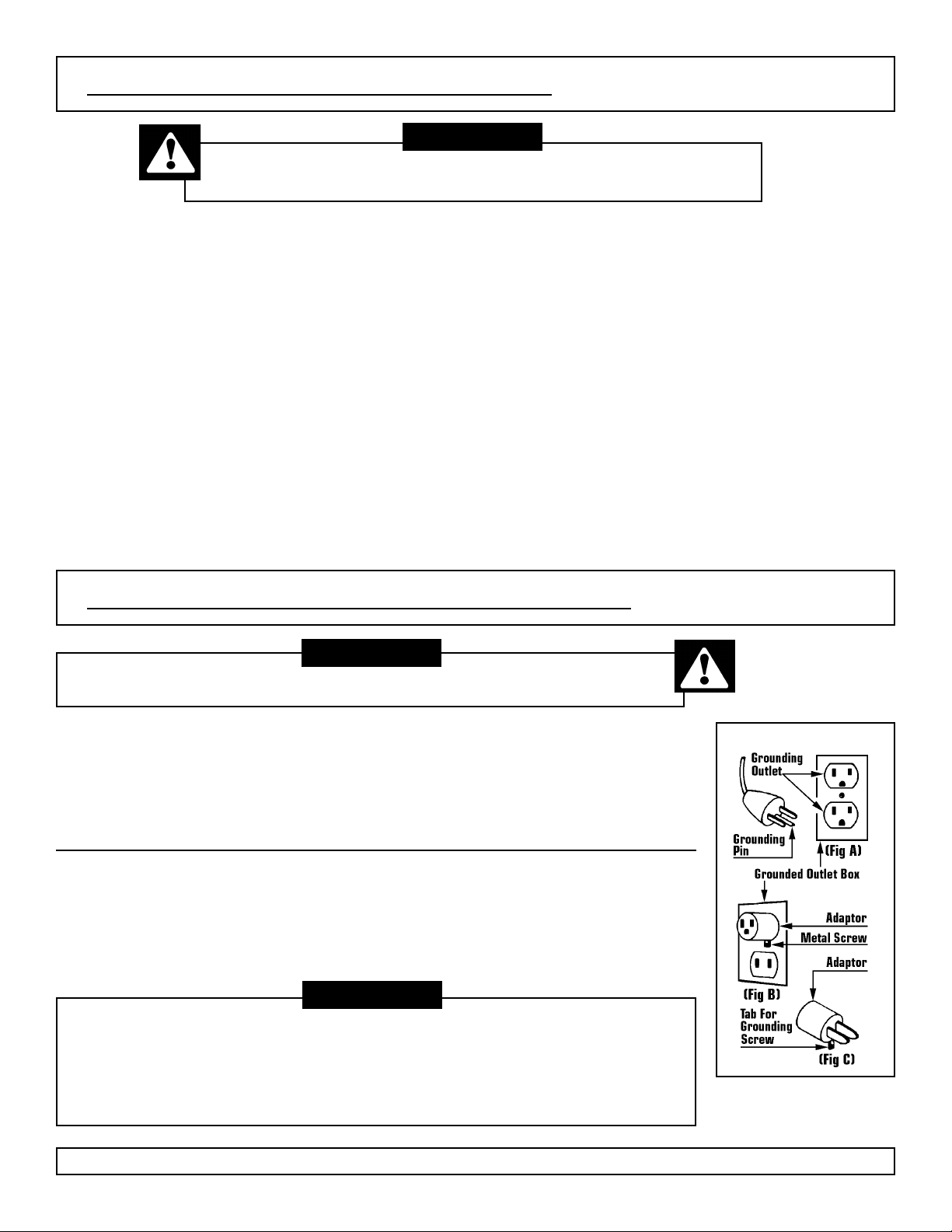

This floor machine must be connected to

a properly grounded outlet only. (See

grounding method below.)

Improper use of the grounding plug can result in a risk of electrical shock.

This floor machine must be

grounded. If it should malfunction

or breakdown, grounding provides

a path of least resistance for electrical current to reduce the risk of

electric shock.

This floor sander is for use on a nominal 120 volt

circuit, and has a grounding plug that looks like the

plug illustrated in (Fig A). A temporary adaptor that

looks like the adaptor illustrated in (Fig B & C) may

be used to connect the plug to a 2-pole receptacle

as shown in (Fig A) if a properly grounded outlet is

not available.

This machine is equipped with an

equipment-grounded plug.

The plug must be inserted into an

appropriate outlet that is properly installed and grounded in

accordance with all local codes

and ordinances

The temporary adaptor should be used only until a

properly grounded outlet (Fig A) can be installed by

a qualified electrician. The green color rigid ear, lug,

or like extending from the adaptor must be connected to a permanent ground such as a properly grounded outlet box cover. Whenever the adaptor is used,

it must be held in place by the metal screw (Fig C).

If repair or replacement of the

cord or plug is necessary, DO NOT

connect the grounding wire to

either flat blade terminal. The

insulated wire with an outer

surface that is green with or without yellow stripes is the grounding

wire.

WARNING:

Improper connection of the equipment-grounding conductor can result in a risk of electrical shock.

Check with a qualified electrician or service person if you are in doubt as to whether the outlet is

properly grounded. DO NOT modify the plug provided with the machine. If it will not fit the

outlet, have a proper outlet installed by a qualified electrician.

In Canada, use of a temporary adaptor is not permitted by the Canadian Electrical Code.

NOTE:

Page 2

AA

TTTTAACCHHMMEENNTTSS

II

NNSSTTAALLLLAATTIIOONN

When installing or changing the accessories, turn OFF the machine

and disconnect the power cord from the electrical outlet.

&& CC

CAUTION:

HHAANNGGIINNGG

Before Installation Or Changing

Attachments:

1) Unplug the machine from the wall outlet.

2) Ensure handle is in the storage position (straight up)

and locked in place with the quick release pin.

3) Tilt machine back by bracing it with your foot until

the handle is laying on the floor and the three heads

are fully exposed.

Note: It is recommended that a towel or pad is placed

under the machine to protect the floor.

Changing and Installation of Attachments

When installing or removing attachments, always wear

protective gloves.

1) Position the first attachment head at 12 o’clock.

2) Using both hands, reach beneath the bottom side of

the attachment and pull up towards yourself to free it

from the machine.

OPERATING INSTRUCTIONS

3) Select the attachment required for the job, and line

up the holes on the attachment with the four metal

pins protruding from each of the three heads.

4) Push attachments on by hand and if necessary, care-

fully tap it into place with a rubber mallet.

5) Repeat steps 1 thru 4 with the remaining 2 attach-

ments.

6) Carefully raise the handle, supporting the axle with

your foot to control the head of the machine as it is

placed on the floor.

7) Since the attachments are different heights, you

may need to adjust the dust skirt to make sure it is

level with the attachments. This will ensure clean and

virtually dust-free operation.

9) To adjust skirt, align the skirt with the center of the

machine and wrap it around.

10) Move the handle back to the operating position

and lock in place with the quick release pin.

1) Clear the floor of any materials or objects.

2) Select and install the accessory set required for the

job. (See above for installation instructions.)

3) Move handle from the upright “storage” position to

the angled “operating” position and lock in place with

the quick release pin.

4) Place your hands on the handle grips tilt sander

back on the transport wheels.

5) Engage the safety trigger and trigger lock beneath

the right handle grip.

6) When the machine is running, carefully lower it

onto the working surface and release the trigger lock.

7) To stop the machine release the safety trigger and

it will automatically turn OFF.

8) Move the machine side-to-side while maintaining a

steady, consistent pace with the machine.

9) When not in use, a set of attachments MUST be left

on the sander to protect the heads.

Note: If the machine unexpectedly shuts down due to

a circuit overload, before restarting wait 30 seconds,

then press the reset button .

CAUTION:

DO NOT attempt to operate this unit if the machine is not fully assembled.

When servicing or replacing accessories turn OFF the machine and

disconnect from the power source.

Prior to operating the machine, tilt machine back on transport wheels,

turn ON the machine and carefully lower the machine onto the working surface.

Page 3

Loading...

Loading...