Page 1

1

Pan and Tilt Brackets Installation Guide

(Standard and Marine grade)

PT-76a, PT-38a, PT-30 and PT-10 INSTALLATION

(Revised May 2014)

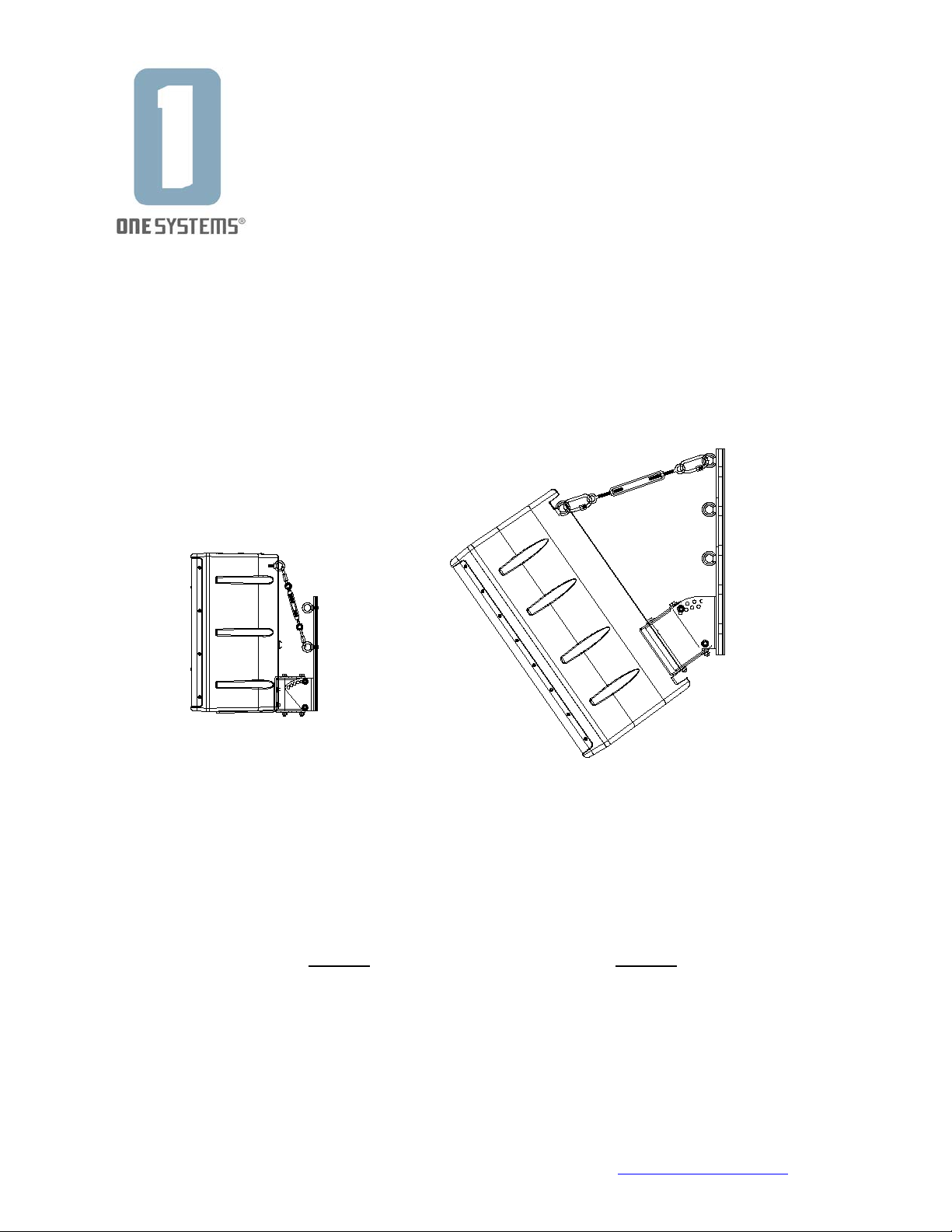

PT-38a with 108IM PT-76a with 112IM

The PT-76a, PT-38a, PT-30 and PT-10 are easy to install and flexible systems

designed to allow ONE SYSTEMS loudspeaker products to be mounted to wall and

certain pole structures. The PT-10 and P T-30 i nst ruc ti ons ar e f oun d at the end of this

document. The only products approved for use with the PT-76a PT-38a, PT-30 and PT10 are as follows:

PT-76a PT-38a

112IM 108IM

112IM-70/100 108IM-70/100

112IM-100 208CIM

212CIM 208CIM-70/100

108CIM

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 2

2

PT-76a

212CIM-70/100

212IM

212IM-70/100

312CIM

312CIM-70/100

Cross Field Array (CFA)

Cross Field Array – 2 (CFA-2)

118IM Sub

PT-10 PT-30

103IM 108IM

103IM-70 108IM-70/100

103IM-100 208CIM

106IM 208CIM-70/100

106IM-70 108CIM

106IM-100

NOTE: The PT-76a and PT-38a were desig n ed for instal l ation on flat surfaces ONLY!

The PT-76 and PT-38 may NOT be pole mounted. Only the PT-30 is designed and

approved for pole mounting. One Systems offers the Pole Mount System-3 and the Pole

Mount System Ex-3 as well as the PT-30 for pole mo unti ng appl i cations. (See more

information in the PT-30 section below regarding pole mounting)

NO OTHER LOUDSPEAKERS SHOULD BE S UBSTITUTED!

The following actions MUST be performed PRIOR to beginning the installation of the

PT-76a, PT-38a, PT-30 or PT-10:

1. This installation guide must be completely read and understood

2. The instruction manual “Rigging and Suspension of ONE SYSTEMS

Products” must be read and understood. (This instruction manual is

available along with other technical papers at www.onesystems.com under

the “Documentation” tab

3. The structure of the mating surface MUST be capable of supporting the

combined weight of the pan and tilt bracket, the loudspeaker and all

associated rigging; and must satisfy the required safety factors specified by

local and national codes, as well as safe rigging practices.

The PT-76a weighs 10.5kg (23.1 lbs). The Pt-38a weights 4.16kg (9.2 lbs).

The PT-30 weighs 4.16kg (9.2 lbs). The PT-10 weighs 0.274kg (0.6 lbs)

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 3

3

4. The PT-76a, PT-38a, PT-30 and PT-10 pan and tilt brackets should be

installed only by someone experienced in the overhead suspension o f

items. They should be familiar with applicable local/national codes

governing the installation of these types of products and those governing

the attachment of these types of products to specific pole structures.

5. The PT-76a and PT-38a are available in both 304 grade and 316 (Marine)

grade stainless steel. If the Marine grade version (316 stainless steel) is

being used then all associated rigging must also be 316 grade stainless

steel. If the PT-30 Marine grade product is being used please note that 316

grade Band-It straps are required.

NOTE: Caution should be exercised when connecting One Systems Marine grade products

and Marine grade rigging to other metallic, non 316 grade stainless steel surfaces (dissimilar

metals). The potential for galvanic corrosion is high in marine environments where the One

Systems Marine grade enclosures and rigging are specified or required. Compatible metals and

appropriate anode to cathode area ratios must be maintained. A structural engineer with

galvanic corrosion experience should be consulted prior to installation of marine grade products,

or ANY One Systems products in marine environments.

CAUTION: All structures outdoors are subjected to wind forces. These forces must be

considered when suspending any product outdoors. It is necessary to know the

“Effective Projected Area” (EPA) of the loudspeaker prior to installation of the

loudspeaker and the PT-76a, PT-38a, PT-30 or PT-10. See Appendix 1 of this

installation manual for effective projected areas for each enclosure rated for use with

the PT-76a, PT-38a, PT-30 and PT-10.

IMPORTANT NOTE: All products in direct weather installations can be subjected to high wind

speeds. For wind speed exposure over 74 miles per hour (119.1 kilometers per hour, 64.3

knots) the loudspeaker enclosure, bracket, banding, and link assembly or safety must be

inspected for signs of damage or fatigue!

INSTALLATION

NOTE: See separate instructions below for the PT-10 and PT-30

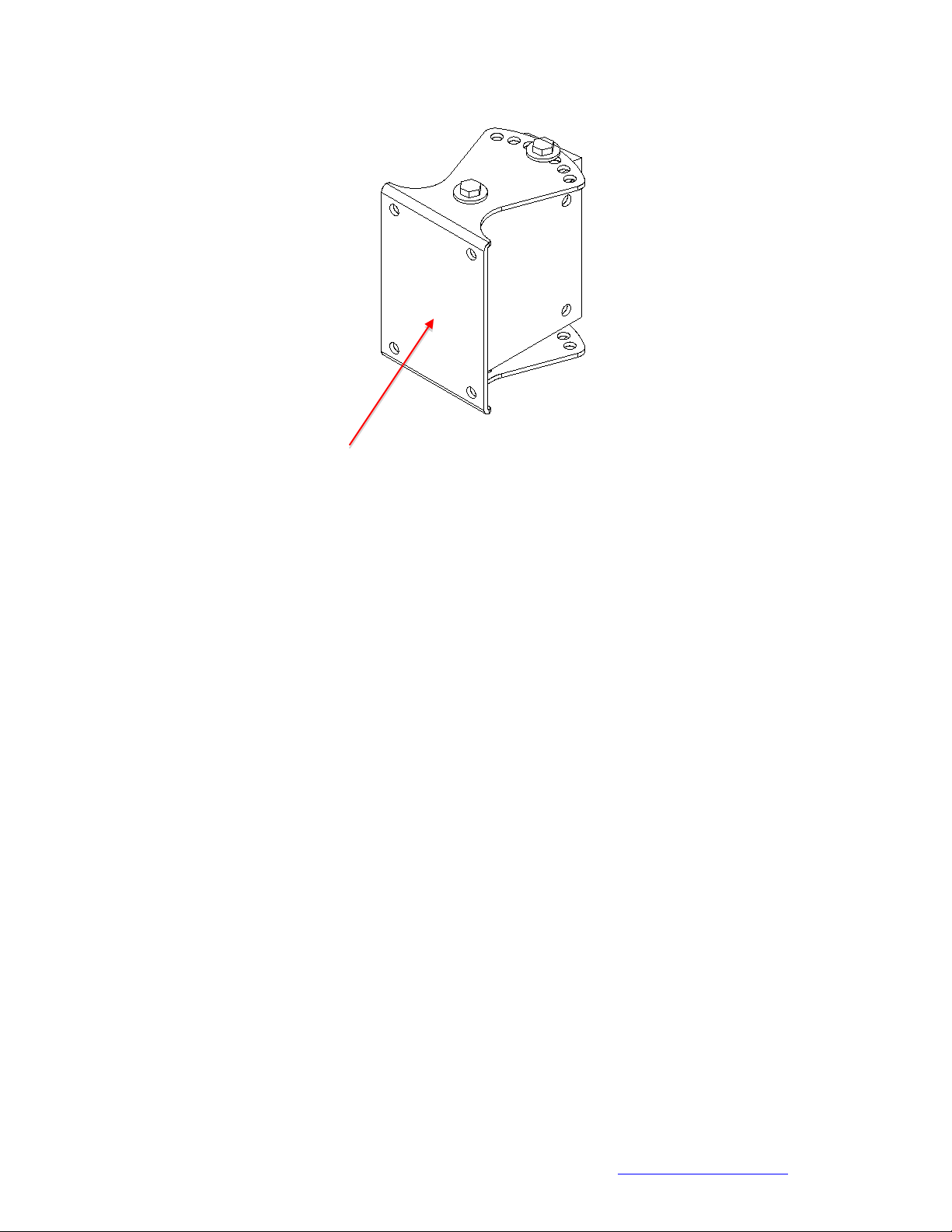

The PT-76a and PT-38a consist of three parts: the wall bracket, the loudspeaker

bracket, and the Link. Th e PT-76a wall bracket and loudspeaker bracket are shown in

Figure 1. Figure 1a shows the wall bracket portion of the PT-76a. The PT-76a bracket

allows the loudspeaker to be oriented from a 0 degree down tilt to a maximum down tilt

of 35 degrees in 5 degrees increments. The PT-38a allows a down tilt of 40 degrees in

8 degree increments.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 4

4

Figure 1

Figure 1a

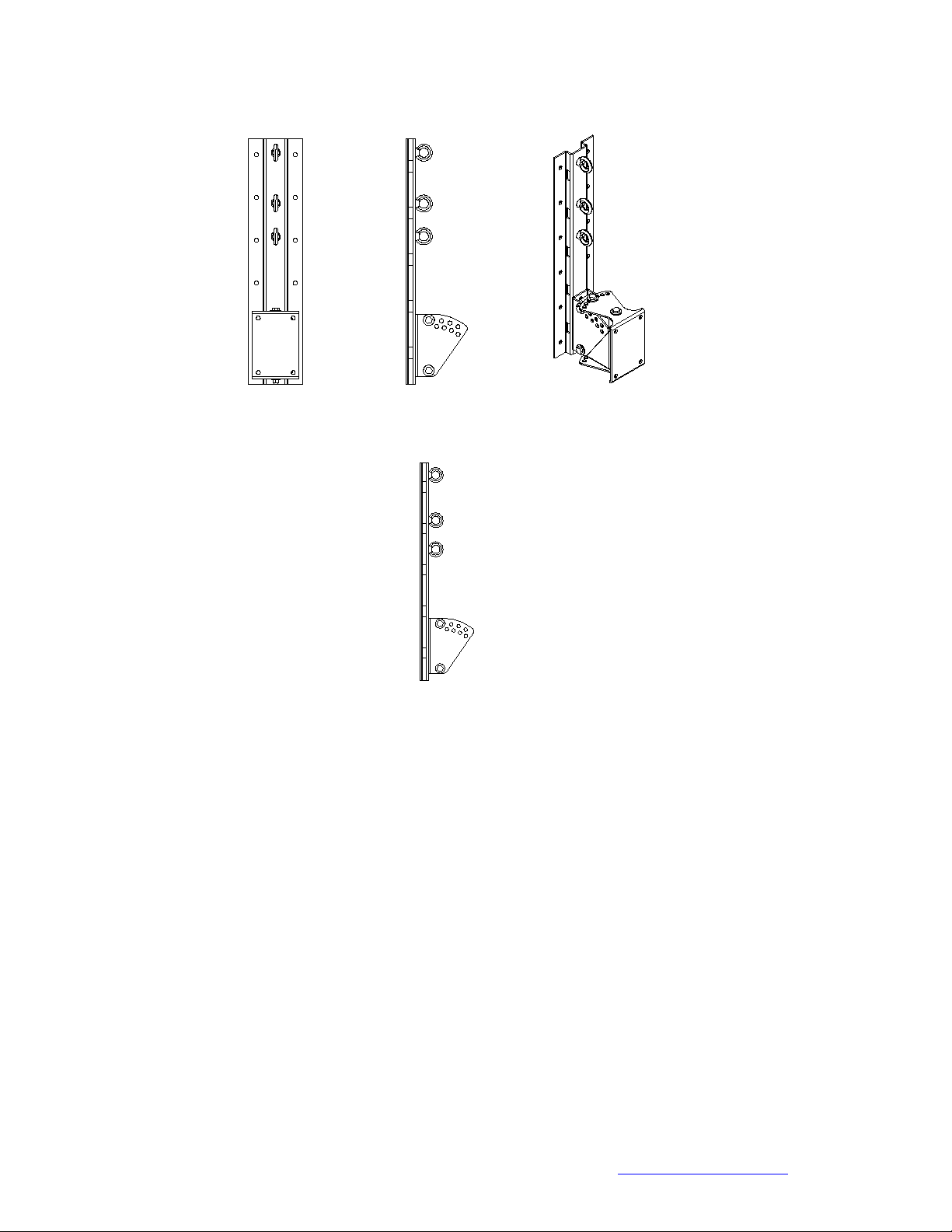

The PT-38a wall bracket and loudspeaker bracket are shown in Figure 2.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 5

5

Figure 2

Prior to mounting the wall bracket to the wall the speaker mount section should be

removed. See Figures 2a and 2b.

NOTE: The M10 bolts associated with the “pan” axis should be left in place, as shown in

both Figures 2a and 2b.

The wall bracket section should now be mounted to the wall surface. The PT-76a has

12 mounting holes and the PT-38a has 8 mounti ng holes for allowing fasteners to join

the bracket and loudspeaker assembly to the mating surface.

IT IS NECESSARY TO USE ALL MOUNTING HOLES TO INSURE A SAFE AND

SECURE MATE TO THE ASSOCIATED SURFACE! (12 for the PT-76a and 8 for the

PT-38a)

All fasteners associated with the mounting of the Pan and Tilt bracket and loudspeaker

assembly to the mating surface are the responsibility of others. The design and

structural capacity of mating surfaces (such as walls) vary greatly and specific fasteners

are designed for use with specific mating surfaces. One Systems does not recommend

any mating fasteners and strongly urges the installer to consult with one experienced in

suspension of products from the specific mating surfaces and the appropriate choice of

fasteners for those spe ci fic surfaces.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 6

6

The wall bracket section should be secured firmly to the mating surface using the

appropriate fastening system. The fastening system should be determined by the

structure of the mating sur face.

IT IS CRITICAL THAT THE MATING SURFACE BE CAPABLE OF SUPPORTING THE

LOAD OF THE PT BRACKET, THE LOUDSPEAKER AND ALL SUSPEN SION

HARDWARE, AS WELL AS PROVIDING THE PROPER SAFETY FACTORS. DO NOT

ATTEMPT TO SUSPEND THE BRACKET AND LOUDSPEAKER UNTIL THE

STRUCTURAL CHARACTERISTICS O F THE MATING SURFACE ARE

UNDERSTOOD. DO NOT INSTALL THE PT BRACKET AND LOUDSPEAKER IF THE

MATING SURFACE IS NOT CAPABLE OF SUPPORTING THE ENTIRE ASSEMBLY

WEIGHT, AS WELL AS PROVIDING THE REQUIRED SAFETY FACTORS!

After the PT wall section of the bracket is securely mounted to the m at ing surface, the

loudspeaker section should be mounted to the loudspeaker using the fasteners supplied.

(DO NOT SUBSTITUTE FASTENE RS) The loudspeaker mount section of each bracket

is shown in figures 2a and 2b. IMPOR TAN T, see the note below regarding the supplied

gasket. This note applies to the PT-76a bracket ONLY!

NOTE: There is a silicone rubber gasket supplied with the PT-76a. This gasket is used

when the 112IM, 212CIM, 212IM, 312CIM or 115TW is mounted using the PT-76a.

(This gasket is NOT REQUIRED when mounting the CFA or CFA-2 enclosures.)

Remove the pressure sensitive adhesive covering and attach the gasket to the

mounting surface of the PT-76a bracket where it joins the loudspeaker as shown below.

Figure 2a PT-38a speaker mount bracket

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 7

7

NOTE: The supplied gasket must be mounted to this surface of the PT-76a PRIOR to

attaching this part to the rear of the 112IM, 212CIM, 212IM or 312CIM enclosure!

Figure 2b PT-76 speaker mount bracket

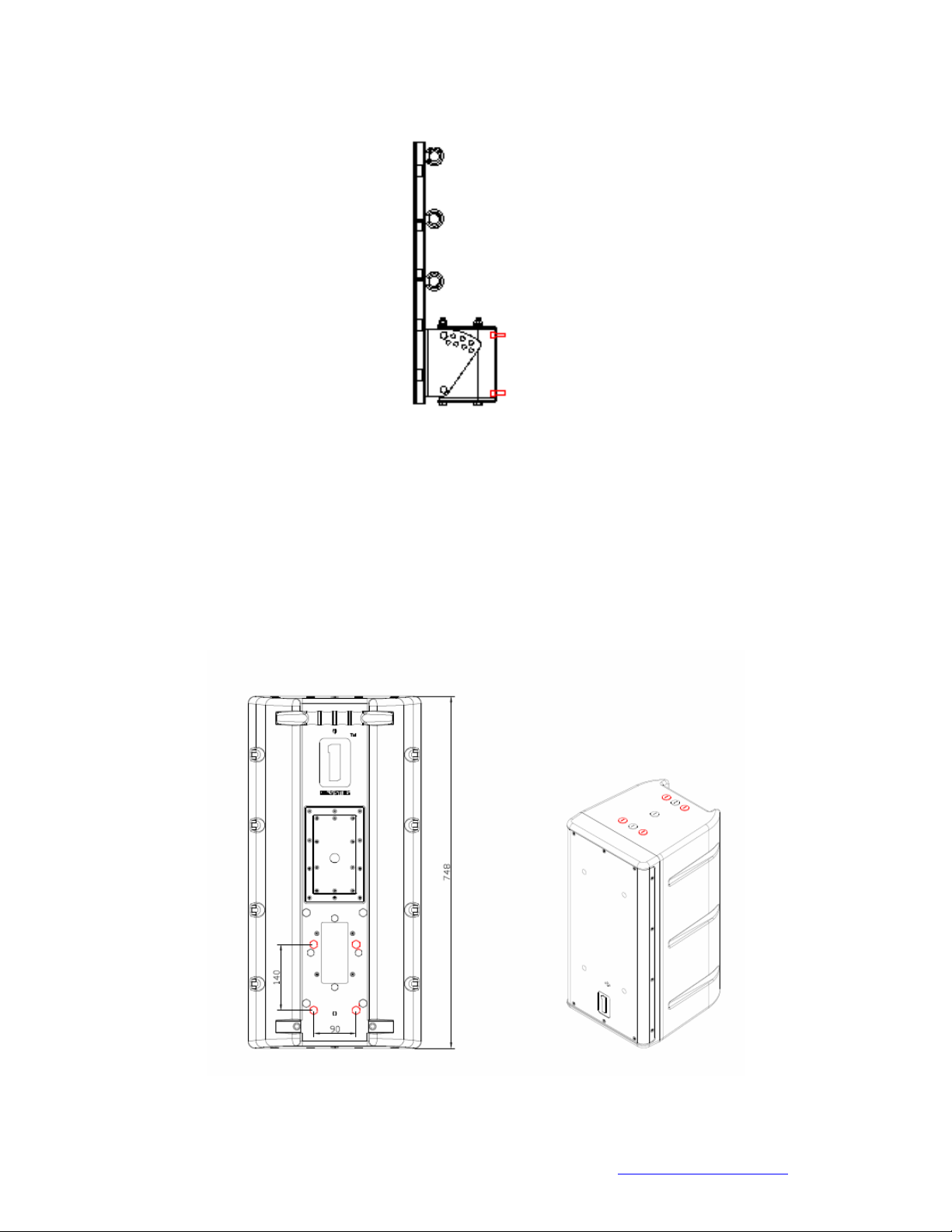

The PT-76a mounts to the rear of ALL IM series enclosures, except for the 108IM and

208CIM, using the 140mm x 90mm M10 locations as shown in figure 2c. The PT-38a

mounts to the top or bottom or top of the 108IM or 208CIM as shown in figure 2c using

the M8 locations. The mounting locations are highlighted in red. (SEE IMPORTANT

NOTE REGARDING THE M10 FLAT WASHERS AND T HE PT-76a BELOW)

DO NOT SUBSTITUTE MOUNTING LOCATIO NS!

NOTE: There are 8 each hex head M10 bolts supplied in the mounting kit of the PT-76a.

When mounting the 115TW (wood) enclosures to the PT-76 use 4 each of the 45mm

(longer) M10 bolts. The 4 shorter M10 bolts are used for the IM series injection molded

enclosures and the CFA enclosures.

NOTE: There are M10 flat washers in the PT-76a kit. DO NOT USE THESE WASHERS

FOR MOUNTING THE 112IM, 212CIM, 212IM ,or 312CIM! The M10 flat washers are

for use with the CFA and CFA-2 ONLY! (See the image below, DO NOT use flat

washers under the M10 bolts used to mount the 112IM, 212CIM, 212IM, or 312CIM.)

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 8

8

The image above shows the M10 bolts WITHOUT WASHERS used to mount either a

112IM, 212CIM, 212IM, or 312CIM. The M10 flat washers are used ONLY with the CFA

or CFA-2 enclosure!

Additionally, there are forged shoulder eyebolts supplied in the PT kits, 4 each M10

eyebolts for the PT-76a and 3 each M8 eyebolt for the PT-38a. One of these eyebolts

must be installed in the top, rear portion of the enclosure. When installing the PT-76a,

use the longer of the two M10 eyebolts for wood enclosures and the shorter of the two

M10 eyebolts for the IM series enclosures. Make sure that the eyebolt is seated on the

surface of the enclosure.

Figure 2c

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 9

9

The loudspeaker and loudspeaker section of the br ac ket m ay now be joined to the wall

section and the required pan and tilt angles selected. This is a two person job and

extreme care should be exercised to avoid serious injury.

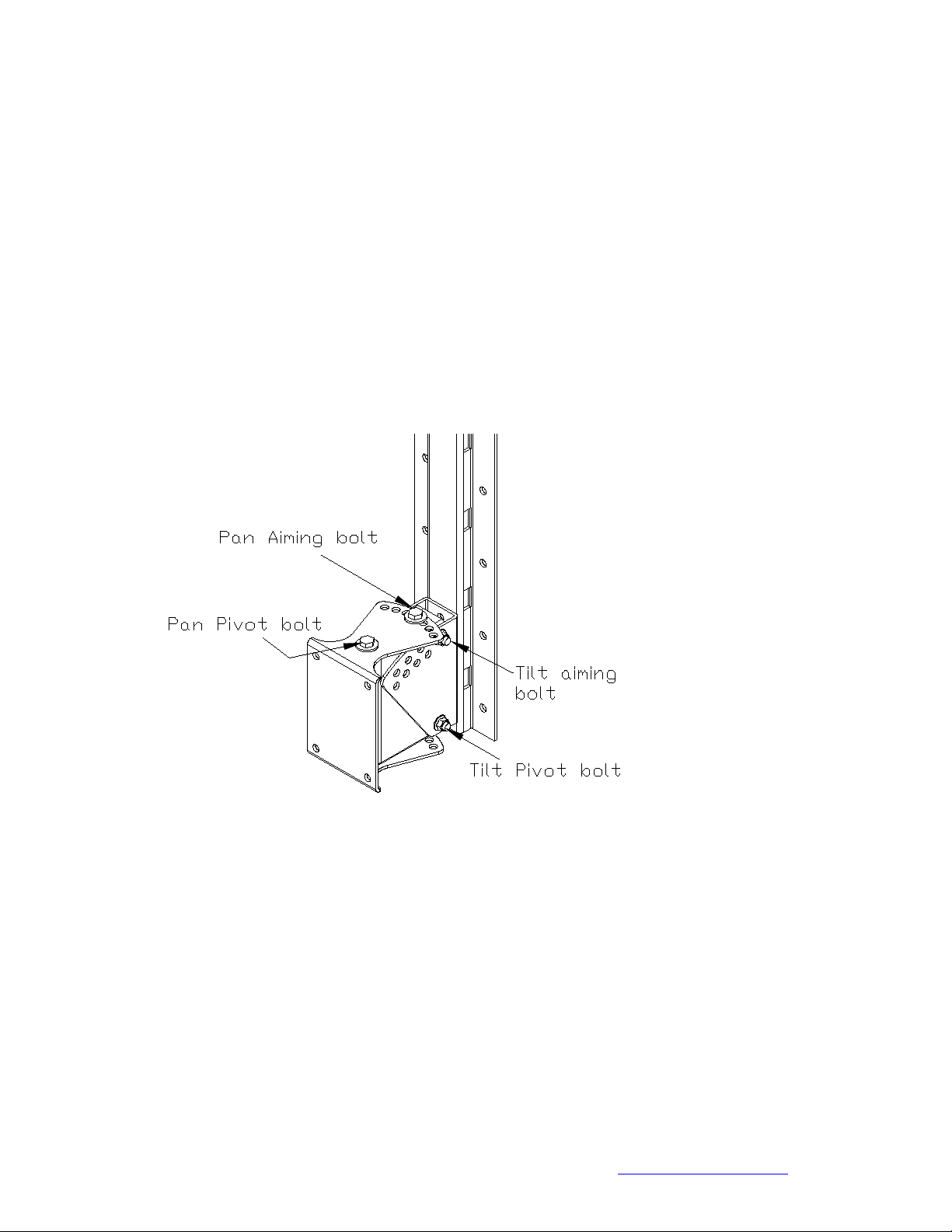

The M10 tilt pivot bolt should be inserted first and secured but not completely tightened

using the nylon insert M10 nuts supplied. The tilt pivot bolt is shown below in Figure 2d.

Then the M10 tilt aiming bolt should be inserted and nylon insert nuts applied. Then the

tilt axis bolts should be tightened.

CAUTION: DO NOT REMOVE THE PAN PIVOT BOLT

Next the pan angle may be adjusted by removing the M10 pan aiming bolt, but NOT the

pan pivot bolt, and setting the desired pan angle and then re inserting the M10 bolt.

Once both the tilt and pan angles are set, make sure that all bolts are tight and secure.

Figure 2d

INSTALLING THE LINK

Figure 3 is a representation of the Link assembly. This assembly MUST be used

whenever the PT-76a, PT-38a or the PT-30 is being used. Each pan and tilt bracket is

supplied with a link assembly.

SEE SECTION 5 OF THIS MANUAL FOR DETAILS ON THE PROPER MOUNTING

OF THE LINK ASSEMBLY!

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 10

10

Figure 3

1. Next, the loudspeaker bracket should be mounted to the loudspeaker using the

supplied M10 (M8 for the 108IM and 208CIM ) stainless steel bol ts a nd washers.

DO NOT SUBSTITUE ANY PARTS

NOTE: There is a silicone rubber gasket supplied with the PT-76. This gasket is

used when the 112IM, 212CIM, 212IM or 312CIM is mounted using the PT-76. (This

gasket is NOT REQUIRED when mounting the CFA or CFA-2 enclosures.) Remove

the pressure sensitive adhesive covering and attach the gasket to the mounting

surface of the bracket where it joins to either the 112IM or 212CIM as shown below.

(This does NOT APPLY to Pt-38 or PT-30 bracket asse mbli es .

NOTE: The supplied gasket must be mounted to this surface of the PT-76a PRIOR to

attaching this part to the rear of the 112IM, 212CIM, 212IM, or 312CIM enclosure! This

applies to the PT-76a only!

2. Now the M10 (M8 for 108I M and 208C IM ) forged shoulder “eye” bolt should be

installed in the top rear of the loudspeaker enclosure. Make sure that that eyebolt

is seated on the enclosure surface.

3. NOTE: There two (2) forged shoulder eye bolts included. O ne has a 17mm

threaded section and the second has a 40mm threaded section. Use the 17mm

threaded section eye bolt for the 112IM, 212CIM, 212IM, 312CIM and CFA

enclosures. Use the 40mm threaded section for the 115TW wood enclosure.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 11

11

4. The loudspeaker may now be placed on t he pole br ac ket .

USE EXTREME CAUTION! The loudspeaker is heavy and it is likely that the desired

mounting location is high in the air. This process should never be attempted by a single

person.

TWO OR MORE PEOPLE ARE REQUIRED TO MOUNT THE LOUDSPEAKER

ENCLOSURE TO THE WALL OR POLE AND PT bracket. Safety harnesses should

always be worn when working from an elevated platform.

The PT-76a mounts to the rear of ALL IM series enclosures, except for the 108IM ,

108CIM and 208CIM, usi ng the 140 mm x 90mm M10 locations as shown in figure 2c.

The PT-38 mounts to the top or bottom or top of the 108IM, 108CIM or 208CIM as

shown in figure 2c using the M8 locations. The mounting locations are highlighted in red.

(SEE IMPORTANT NOTE REGARDING THE M10 FLAT WASHERS AND THE PT-76a

BELOW)

DO NOT SUBSTITUTE MOUNTING LOCATIO NS!

NOTE: There are 8 each hex head M10 bolts supplied in the mounting kit of the PT-76.

When mounting the 115TW (wood) enclosures to the PT-76 use 4 each of the 45mm

(longer) M10 bolts. The 4 shorter M10 bolts are used for the IM series injection molded

enclosures and the CFA enclosures.

NOTE: There are M10 flat washers in the PT-76a kit. DO NOT USE THESE WASHERS

FOR MOUNTING THE 112IM, 212CIM, 212IM, 312CIM or 115TW! The M10 flat

washers are for use with the CFA and CFA-2 ONLY! (See the image below, DO NOT

use flat washers under the M10 bolts used to mount t he 11 2IM 21 2C I M , 312CI M, or

115TW.)

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 12

12

The image above shows the M10 bolts WITHOUT WASHERS used to mount either a

112IM, 212CIM, 212IM, 312CIM or 115TW. The M10 flat washers are used ONLY with

the CFA enclosure!

CAUTION: DO NOT REMOVE THE PAN PIVOT BOLT (See Figure 2d)

The M10 tilt pivot bolt should be inserted first and secured but not completely tightened

using the nylon insert M10 nut supplied. The tilt pivot bolt is shown below in Figure 2d.

Then the M10 tilt aiming bolt should be inserted and nylon insert nuts applied. Then the

tilt axis bolts should be tightened.

Next the pan angle may be adjusted by removing the M10 pan aiming bolt, but NOT the

pan pivot bolt, and setting the desired pan angle and then re inserting the M10 bolt.

Once both the tilt and pan angles are set, make sure that all bolts are tight and secure.

UNDER NO CIRCUMSTANCES SHOULD THE LOUDSPEAKER DOWNWARD TILT

EXCEED 35 DEGREES FROM VERTICAL FOR THE PT-76a. (MAXIMUM 40

DEGREES FOR THE PT-38a)

SECTION 5 LINK ASSEMBLY

Now the Link must be installed.

INSTALLING the Pan and Tilt Brackets WITHOUT THE LINK IS NOT ALLOWED!

The Link (see figure 3) consists of stainless steel quick links, a stainless steel

turnbuckle, and several links of stainless steel chain. The use of the chain pi eces and

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 13

13

quick links with the turnbuckle is based on the tilt angle of the enclosure. The turnbuckle

should always be used.

DO NOT SUBSTITUTE ANY PART OF THIS LINK ASSEMBLY!

The Link should be tightened by rotating the turnbuckle until there is

tension on the Link assembly. Do not over tighten. The purpose of the Link

is to provide support for the main Pole Mount System tilting bracket at the

bottom of the assembly.

The back plate sections of the PT-76a and PT-38a have eyebolts attached to them.

There are 3 eyebolts on the back plate section of the PT-76a and 2 eyebol ts on the

back plate section of the PT-38a. Figure 7 illustrates which eyebolt should be used for

each down tilt angle.

PT-76a PT-38a

Figure 7

Make sure to use the appropriate combination of Link parts to insure proper connection

between the PT bracket assembly and the specific One Systems enclosure. The

required combination of Link parts is determined by the down tilt angle of the enclosure.

The assembly may be configured with any combination of turnbuckle, chain link

sections and quick link in order to achieve the proper tension on the system, but the

turnbuckle must always be used. Figures 8a, 8b, and 8c show a 108IM and PT-38a at

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 14

14

vertical, 24 degrees and 40 degrees using the eyebolt positions shown in Figure 7. Note

that Figure 8a and 8b use the same link and turnbuckle combination but different

eyebolt locations and the Figure 8c uses chain sections as well as the quick links and

the turnbucklel

Figure 8a

Figure 8a represents the Link assembly with the enclosure in a vertical orientation and

the Link using the lower eyebolt position

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 15

15

Figure 8b

Figure 8b represents the Link with the enclosure in a 24 degree tilt. The Link is using

the top eyebolt and the turnbuckle has been adjusted to provide mild tension.

Figure 8c

Figure 8c represents the Link assembly with the enclosure in a 40 degree tilt. The Link

assembly uses the top eyebolt and the stainless steel chain has been added to achieve

the proper tension on the assembly. Notice the “dropped” chain links in Figure 8c.

Warning: If the turnbuckle assembly is turned and the loudspeaker enclosure angle

begins to change (if the down tilt angle begins to move toward 0 degrees vertical then

the turnbuckle has been OVER TIGHTENED. Turn the turnbuckle until the down tilt

angle is set by the M10 thru bolt on the pole bracket but there is still slight tension on

the turnbuckle.

Figure 9 below shows a 312CIM mounted to a PT-76a. The down tilt is 35 degrees so

the top eyebolt is utilized as per Figure 7.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 16

16

Figure 9

Figure 9 represents the maximum down tilt angle of 35 degrees from vertical. Note that

because the down tilt angle is 35 degrees the top eyebolt has been used, again per

Figure 7.

Figure 10 is a close up view of the Link assembly. Certain down tilt angles may require

a link to be “dropped” from the chain as shown below. The lower quick link is positioned

in various chain segments based on the desired degree of down tilt. The turnbuckle

should be adjusted, as described in this section

In any position, the turnbuckle must be adjusted to allow the proper amount of tension

on the Link. The Link should never pull the loudspeaker up towards vertical. The Link

may be configured with or without the chain section and quick link depending on the

down tilt angle of the enclosure.

Figure 10

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 17

17

Secondary safety cables are STRONGLY recommended and should be

secured to a structural point NOT associated with the PT bracket or

loudspeaker. The Link assembly is NOT a secondary safety cable.

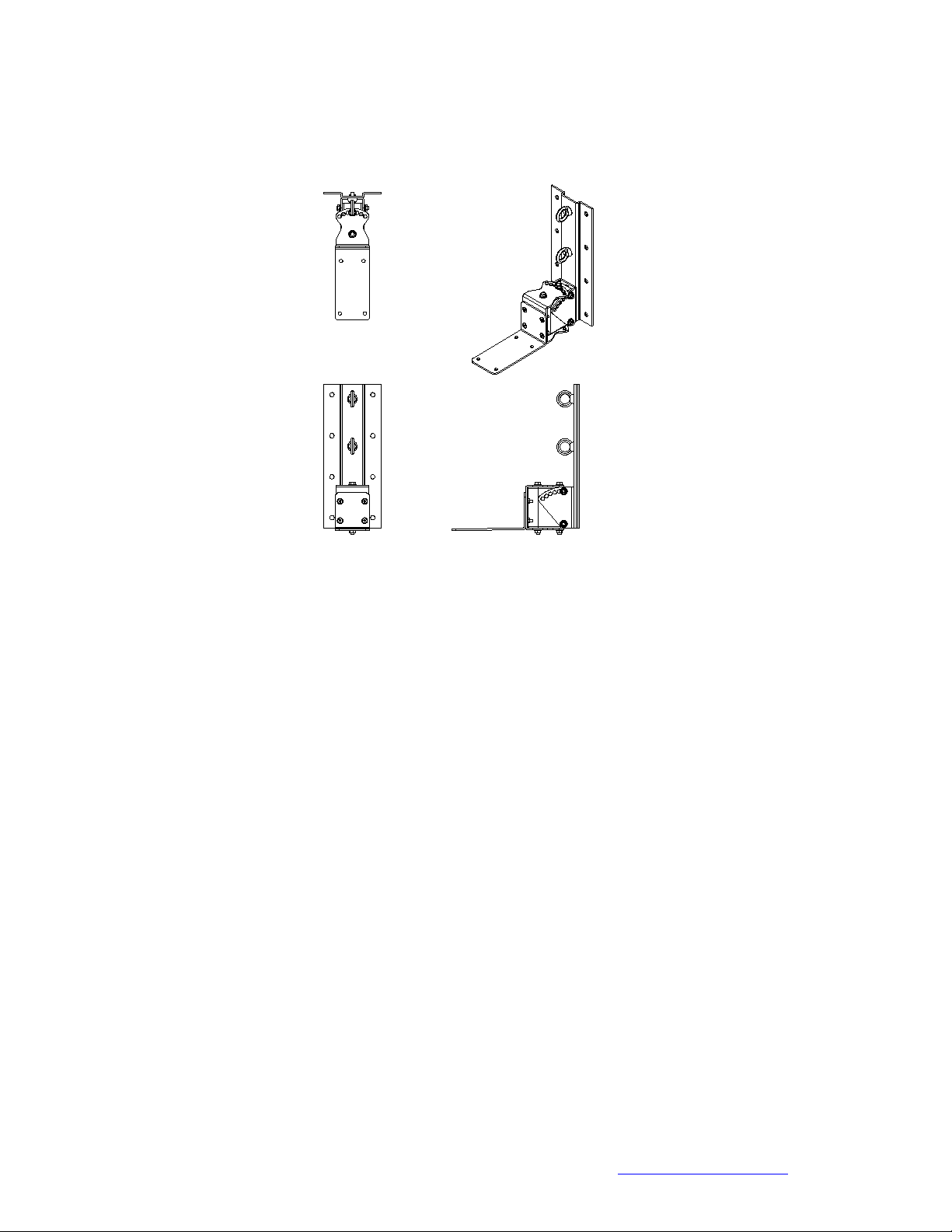

PT-10 Installation

The One Systems PT-10 is designed for use with the 103IM and 106IM family of One

Systems products only .

DO NOT SUBSTITUTE OTHER LOUDSP EAKER ENCLOSURES!

The PT-10 has been designed as a low cost yet flexible pan and tilt system and is

intended for use with small format, low Q loudspeaker systems. The PT-10 offers 10

degree aiming increments and will provide up to 5 steps within the nominal 100 degree

pattern of either the 103IM or the 106IM. Figure 11 represents the PT-10 pan and tilt

bracket.

Figure 11

There are two center pieces that may be used for aiming with the PT-10 bracket. Each

“center piece” offers aiming resolution of 20 degrees but substitution of the center

pieces will yield aiming resolution of 10 degrees.

Figure 12a shows the two center pieces. The 10 degree aiming resolution is achieved

by substituting the appropriate center piece to achieve a TOTAL resolution of 10

degrees between the two center pieces. These two center pieces are interchangeable

and may be used to set the desired angles.

Note the “rotated clock” section in “Part 2” of Figure 11a below. This section is rotated

10 degrees from the part labeled “Part 1” and is what allows the aiming increments to

be adjusted in 10 degrees steps.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 18

18

FIGURE 11a

Figure 12 shows a One Systems 103IM mounted to a PT10. There are 4 M5 stainless

steel bolts that are supplied with the PT-10 for mounting to either the 103IM or the

106IM. Once the PT-10 is mounted to the specific loudspeaker enclosure the two

stainless steel bolts on the center piece of the PT-10 may be loosened to allow the

bracket to be rotated in both the “pan” and “tilt” axis. Once proper loudspeaker aiming is

achieved both of these bolts must be securely fastened to insure the assembly will not

move.

NOTE: It is strongly recommended that a “temporary” thread locker be used to secure

the two M6 bolts that set both the pan and the tilt angles of the PT-10.

NOTE: It is necessary to fit an additional/secondary safety assembly

between the loudspeaker enclosure and the mounting surface. This safety

assembly is not supplied by One Systems. The safety assembly must

conform to local and national codes!

Figure 12

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 19

19

Secondary safety cables MUST be used with the PT-10 and should be

secured to a structural point NOT associated with the PT bracket or

loudspeaker. This secondary safety should be connected between the

loudspeaker and the mounting surface!

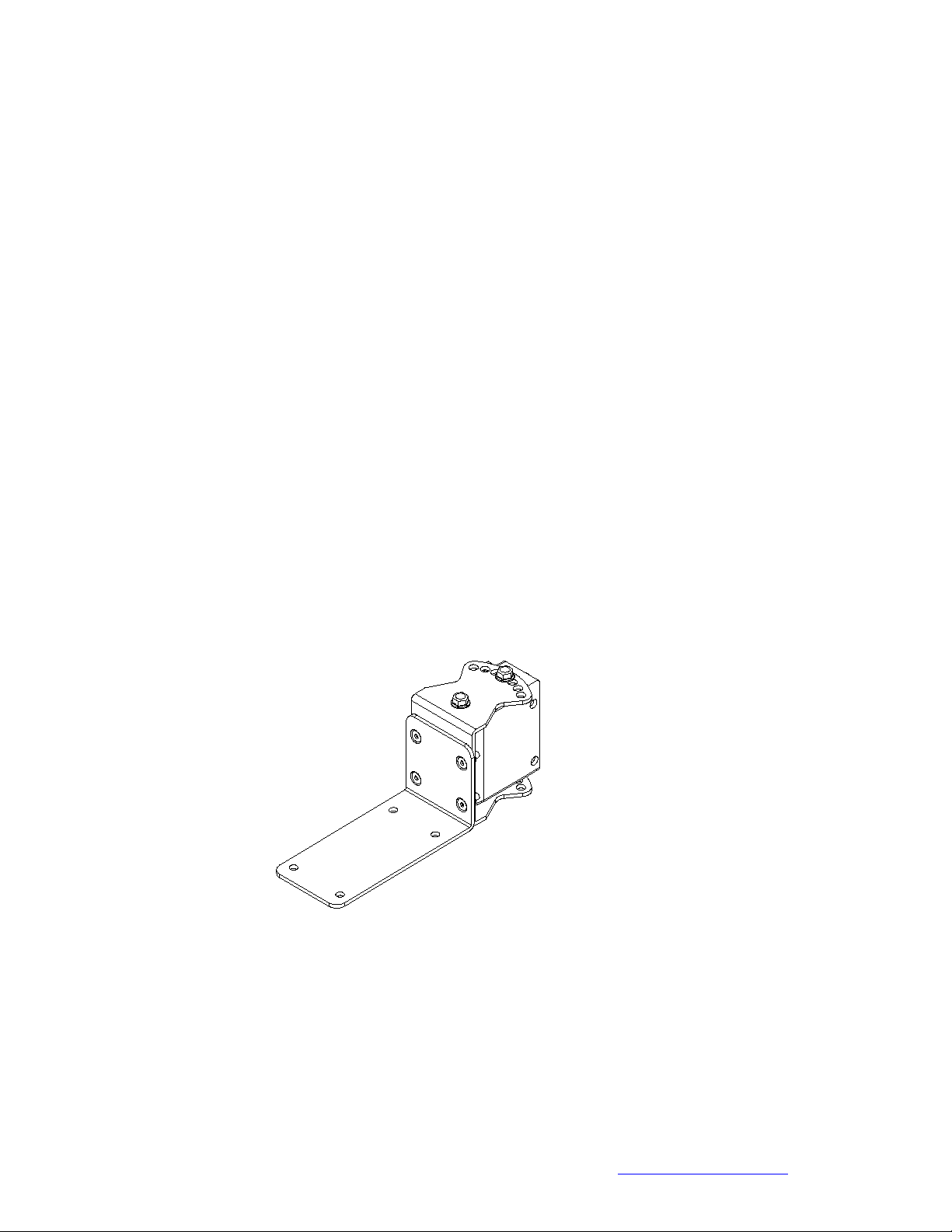

PT-30 Installation

The PT-30 is available in two versions. The “standard” version is made with 304 grade

stainless steel. The PT-30 is also available in a “Marine grade” version that uses 316

grade stainless steel. The PT-30 was designed for use on small diameter round and

square/rectangular poles.

See important note on page 3 regarding mounting in “Marine” environments!

For square/rectangular poles the minimum flat dimension must be 3.75 inches

(95.25mm) and for round poles the minimum required diameter is 4 inches (101.6mm).

The PT-30 was designed for use with the 108IM and its transformer variants and for the

208CIM and its transformer variants only. NO SUBSTITUTIONS ARE ALLOWED!

NOTE: One Systems does not imply suitability of specific pole diameters. Each pole

must be verified by the pole manu fact ur er or ot hers as to the struc tural suitability of the

pole for use with the total load of the PT-30, the loudspeaker, and all required safety

factors.

THE PT-30 is designed for pole mounting ON LY ! DO NOT wall mount the PT-30!

The PT-30 is shown below. The PT-30 allows a down tilt of 40 degrees i n 8 deg r ee

increments.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 20

20

PT-30

The PT-30 consists of three parts: the pole bracket, the lou dspeaker bracket, and the

Link. The PT-30 pole bracket is shown below.

Views of the PT-30

NOTE: There are three M8 forged shoulder eyebolts supplied with the PT-30. Make

sure that two of them are mounted to the PT-30 back plate as shown above BEFORE

attempting to mount the PT-30 assembly to a pole structure!

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 21

21

NOTE: Instructions for mounting the Band-It bands are supplied by Band-It

The PT-30 has three slots for mounting the back bracket assembly on a pole. ALL

THREE slots MUST be used. Each slot MUST be DOUBLE WRAPPED (two

INDEPENDENT bands per slot!) using the specified Band-It straps ONLY! DO NOT

substitute any other straps. IT IS NECESSARY TO USE ALL MOUNTING SLOTS TO

INSURE A SAFE AND SECURE MATE TO THE ASSOCIATED SURFACE!

IT IS CRITICAL THAT THE MATING SURFACE (Pole) BE CAPABLE OF

SUPPORTING THE LOAD OF THE PT-30 BRACKET, THE LOUDSPEAKER AND ALL

SUSPENSION HARDWARE, AS WELL AS PROVIDING THE PROPER SAFETY

FACTORS. DO NOT ATTEMPT TO SUSPEND T HE BRACKET AND LOUDSPEAKER

UNTIL THE STRUCTURAL CHARACTERISTICS OF THE MATING SURFACE (Pole)

ARE UNDERSTOOD. DO NOT INSTALL THE PT BRACKET AND LOUDSPEAKER IF

THE MATING SURFACE (Pole) IS NOT CAPABLE OF SUPPORTING THE ENTIRE

ASSEMBLY WEIGHT, AS WELL AS PROVIDIN G THE REQUIR ED SAF E TY

FACTORS!

IMPORTANT: There are 3 slots indicated by the red arrows in the image below. Each of

the 3 slots must be utilized to insure a secure mount to a pole. ALL 3 slots must use

double wrapped bands (Two independent bands wrapped in each slot)! The image

below shows the PT-30 mount to a round pole. As shown, ALL three band slots must be

used and all locations MUST be double wrapped (two independent band assemblies per

slot!)

The red arrows indicate the 3 slots used to band the PT-30 to a pole structure

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 22

22

The PT-30 showing ALL three band locations used

Mount the PT-30 bracket assem bl y to the pole at the desired height on the pole. The

bracket is mounted to the pole using BAND-IT stainless steel bands. DO NOT

SUSTITUTE bands of other mat erial or other widths! There are 3 locations for the PT-30

and ALL 3 slots MUST BE USED.

It is REQUIRED that ALL bands be DOUBLE wrapped (Two independent bands per

slot!). Double wrapping will insure a strong and secure mounting of the bracket to the

pole. The selection of stainless steel banding materials i s bas ed on the in ten ded

application. The 304 grade bands and buckles should be used when the 304 grade PT30 is used. The bands should be sourced from BAND-IT ONLY and should be as

follows:

BAND-IT # C206R9 stainless steel bands

BAND-IT # C25699 buckles

BAND-IT # C00169 tensioning tool

The stainless steel band is Type 201SS 0.030 inches (0.762mm) thick and 0.750 inches

(19mm) wide.

IF the “Marine grade” 316 stainless steel version of the PT-30 is used then the bands

are as follows.

BAND-IT # C406R9 stainless steel bands (316 stainless steel)

BAND-IT # C45699 buckles (316 stainless steel)

BAND-IT # C00169 tensioning tool

The stainless steel band is 316 grade 0.030 inches thick by 0.750 inches wide

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 23

23

WARNING: Do NOT substitute banding materials or banding dimensions.

Installation instructions from BAND-IT should be followed exactly. Operating instructions

are supplied with the tensioning tool. (All BAND-IT parts and tools purchas ed

separately. These parts and tools are not supplied by ONE SYSTEMS)

The stainless steel banding material, buckles and tensioning tools are available from the

following locations (or though distributors recommended by these locations):

BAND-IT IDEX, Inc.

4799 Dahlia St.

Denver Colorado 8021 6

USA

1-800-525-0758

FELIX PONCE

Calle Ignacio Zaragonza No. 8

Colonia Ahuehuetes Atizapan 52953

Edo. de Mexico

(52) 555825 8502

BAND-IT Company Limited

Speedwell Industrial Estate

Stavely, Nr. Chesterfield

Derbyshire, S43 3PF England

Home Sales (44) 1246-479479

Export Sales (44) 1246 479480

BAND-IT Clamps (ASIA) Pte. Ltd.

11 Second Chin Bee Road

Singapore 618777

65-62658853

BAND-IT Shanghai Sales Office

207 room

Wanbao International Business Centre

660# Xinhua Road

Shanghai, China 200052

021-62826348-308

Now the M8 forged shoulder “eye” bolt should be installed in the top rear of the

loudspeaker enclosur e. Make sure that that eyebolt is seated on the enclosure surface.

Note that the desired pan and tilt angles may be set either before or after the

loudspeaker is mounted to the PT-30 assembly. However, the pan and tilt angle

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 24

24

adjustments must be double checked and tightened after the loudspeaker has been

mounted.

Next, the loudspeaker should be mount ed to the PT-30 using the supplied M8 stainless

steel bolts and internal tooth lock washers. DO NOT SUBSTITUE ANY PARTS.

PT-30 speaker mount bracket section

The PT-30 mounts to the top or bottom of the 108IM or 208CIM as shown in the figure

below using the M8 locations. The mounting locations are highlighted in red.

Note: Remove all 7 M8 cover plugs before installing the loudspeaker on the PT-30

bracket plate!

DO NOT SUBSTITUTE MOUNTING LOCATIO NS!

PT-30 Mounting locations (top or bottom) for 108IM/208CIM

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 25

25

There are mounting locations on both the top and bottom of the 108IM/208CIM and

either the top or bottom may be used. Then enclosure may be oriented with the high

frequency section either at the top or bottom of the configuration.

USE EXTREME CAUTION! The loudspeaker is heavy and it is likely that the desired

mounting location is high in the air. This process should never be attempted by a single

person.

TWO PEOPLE ARE REQUIRED TO MOUNT THE LOUDSPEAKER ENCLOSURE TO

THE POLE AND PT brackets. Safety harnesses should always be worn when working

from an elevated platfo r m.

Once both the tilt and pan angles are set, make sure that all bolts are tight and secure.

UNDER NO CIRCUMSTANCES SHOULD THE LOUDSPEAKER DO WN TILT

EXCEED 40 DEGREES FROM VERTICAL FOR THE PT-30!

LINK ASSEMBLY

Now the Link must be installed.

INSTALLING the Pan and Tilt Bracket WITHOUT THE LINK IS NOT ALLOWED!

The Link consists of stainless steel quick links, a stainless steel turnbuckle, and several

links of stainless steel chain. T he use of the chain pieces and quick links with the

turnbuckle is based on the tilt angle of the enclosure. The turnbuckle should always be

used.

DO NOT SUBSTITUTE ANY PART OF THIS LINK ASSEMBLY!

The Link should be tightened by rotating the turnbuckle until there is tension on the Link

assembly. Do not over tighten. The purpose of the Link is to provide support for the

main Pole Mount System tilting bracket at the bottom of the assembly.

The back plate section of the PT-30 has two eyebolts attached to it. The figure below

illustrates the proper eye bolt to use for each down tilt angle of the bracket.

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 26

26

PT-30 EYE BOLT AIMING LOCATIONS

Make sure to use the appropriate combination of Link parts to insure proper connection

between the Pole Mount System and the specific One Systems enclosure. The required

combination of Link parts is determined by the down tilt angle of the enclosure.

The assembly may be configured with any combination of turnbuckle, chain link

sections and quick link in order to achieve the proper tension on the system, but the

turnbuckle must always be used. The figures below show a 108IM or 208CIM and PT30 at vertical, 24 degrees and 40 degrees using the eyebolt positions shown in the “PT30 EYE BOLT AIMING LOCATIONS” image. Note that Figure 8a and 8b use the same

link and turnbuckle combination but different eyebolt locations and the Figure 8c uses

chain sections as well as the quick links and the turnbuckle.

Figure 8a

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 27

27

This image represents the Link assembly with the enclosure in a vertical orientation and

the Link using the lower eyebolt position

Figure 8b

Figure 8b represents the Link with the enclosure in a 24 degree tilt. The Link is using

the top eyebolt and the turnbuckle has been adjusted to provide mild tension.

Figure 8c

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 28

28

Figure 8c represents the Link assembly with the enclosure in a 40 degree tilt. The Link

assembly uses the top eyebolt and the stainless steel chain has been added to achieve

the proper tension on the assembly. Notice the “dropped” chain links in Figure 8c.

Warning: If the turnbuckle assembly is turned and the loudspeaker enclosure angle

begins to change (if the down tilt angle begins to move toward 0 degrees vertical then

the turnbuckle has been OVER TIGHTENED. Turn the turnbuckle until the down tilt

angle is set by the M10 thru bolt on the pole bracket and there is slight tension on the

Link assembly.

Figure 10 is a close up view of the Link assembly. Certain down tilt angles may require

a link to be “dropped” from the chain as shown below. The lower quick link is positioned

in various chain segments based on the desired degree of down tilt. The turnbuckle

should be adjusted, as described in this section

In any position, the turnbuckle must be adjusted to allow the proper amount of tension

on the Link. The Link should never pull the loudspeaker up towards vertical. The Link

may be configured with or without the chain section and quick link depending on the

down tilt angle of the enclosure.

Figure 10

Secondary safety cables are STRONGLY recommended and should be

secured to a structural point NOT associated with the PT bracket or

loudspeaker. The Link assembly is NOT a secondary safety!

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Page 29

29

APPENDIX 1

(Projected Area Values)

The values below should be supplied to the specific pole manufacturer for safety

calculations. These values were determined by adding the projected areas of the high

frequency horns, the woofer cones and ports to the cross sectional area of the front of

each enclosure listed below. Each enclosure will present a different EPA based on wind

direction. The values listed below are for wind loads directly into the front of the

enclosure and represent maximum values.

103IM …………………………… 67 in^2 (43,000mm^2)

106IM…………………………… 136 in^2 (88,000mm^2)

108IM………………………….... 250 in^2 (161,290mm^2)

(60x40 HF horn)

208CIM………………………..… 207 in^2 (133,550mm^2)

108CIM………………………….. 169.4in^2 (109,278mm^2)

112IM …………………………… 600 in^2 (387,096 mm^2)

(60x40 HF horn)

212CIM…………………………… 600 in^2 (387,096mm^2)

212IM …………………………….. 804 in^2 (550,000 mm^2)

312CIM…………………………… 804 in^2 (550,000mm^2)

Cross Field Array……………….. 2,708in^2 (1,750,000mm^2)

CFA-2……………………………. 855 in^2 (552,100mm^2)

118IM Sub……………………….. 531 in^2 (342,516mm^2)

The products referenced in this manual are in conformity with the following

standards or other normative documents: Machinery Directive 2006/42/EC

One Systems, Inc. 6204 Gardendale Dr., Nashville, TN 37215 www.onesystems.com

Loading...

Loading...