Page 1

POLE MOUNT MINI INSTALLATION

Updated 22 May 2014

The Pole Mount Mini is an easy to install and flexible system designed to allow

ONE SYSTEMS loudspeaker systems to be mounted to pole structures. The only

products approved for use with the Pole Mount Mini are the 103IM and 106IM or

transformer variants of the 103IM or 106IM.

NO OTHER LOUDSPEAKERS SHOULD BE SUBSTITUTED!

The following actions MUST be performed PRIOR to beginning the installation of

the Pole Mount System:

1. T his installation guide must be completely read and understood

2. The instruction manual “Rigging and Suspension of ONE SYSTEMS

Products” must be read and understood. This instruction manual is available

at www.onesystems.com

3. The manufacturer of the pole MUST be consulted to verify the applicability

of the Pole Mount Mini and ONE SYSTEMS loudspeaker to the specific

pole.

4. The Pole Mount Mini and loudspeaker should be installed only by one

experienced in the overhead suspension of items and familiar with the

applicable local and national codes governing installation of these products

and also governing the attachment of these products to the specific pole

structure.

5. The Pole Mount Mini is not suitable for use in Marine environments. DO NOT

use the Pole Mount Mini with One Systems Marine grade Loudspeaker

enclosures!

CAUTION: All structures outdoors are subjected to wind forces. These forces

must be considered when suspending any product outdoors. It is necessary to

know the “Effective Projected Area” (EPA) of the loudspeaker prior to installation

of the loudspeaker and Pole Mount Mini. This data must be supplied to the pole

manufacturer in order to determine safe operation conditions for the loudspeaker

and Pole Mount Mini when mounted to a specific pole. See Appendix 1 of this

installation manual for “ Equivalent Projected Area (EPA) values for the 103IM

in the “Education” section of the web site.

Page 2

and 106IM. These values may also be found on the ONE SYSTEMS web site at

www.onesystems.com.

IMPORTAN T NOT E: All pr od uc ts in di re ct we at her ins tal la ti o ns can be

subjected to high wind speeds. For w ind speed e xposure over 74 miles per

hour (119.1 kilometers per hour, 64.3 knots) the loudspeaker enclosure,

bracket, banding, and link assembly or safety must be inspected for signs of

damage or fatigue!

INSTALLATION

The Pole Mount Mini consists of two parts: the pole bracket assembly, and the

forged shoulder eye bolts and supplied cable assembly. The pol e brac ket is

shown in Figure 1. The bracket shown in figure 1 is designed for use on circular

poles with diameters of 4 inches (101.6mm) or larger. The Pole Mount Mini may

also be used on square or rectangular pole faces of 3.75 inches (92mm). Round

pole diameters that are smaller than 4 inches or square/rectangular face widths

of less than 3.75 inches must not be used.

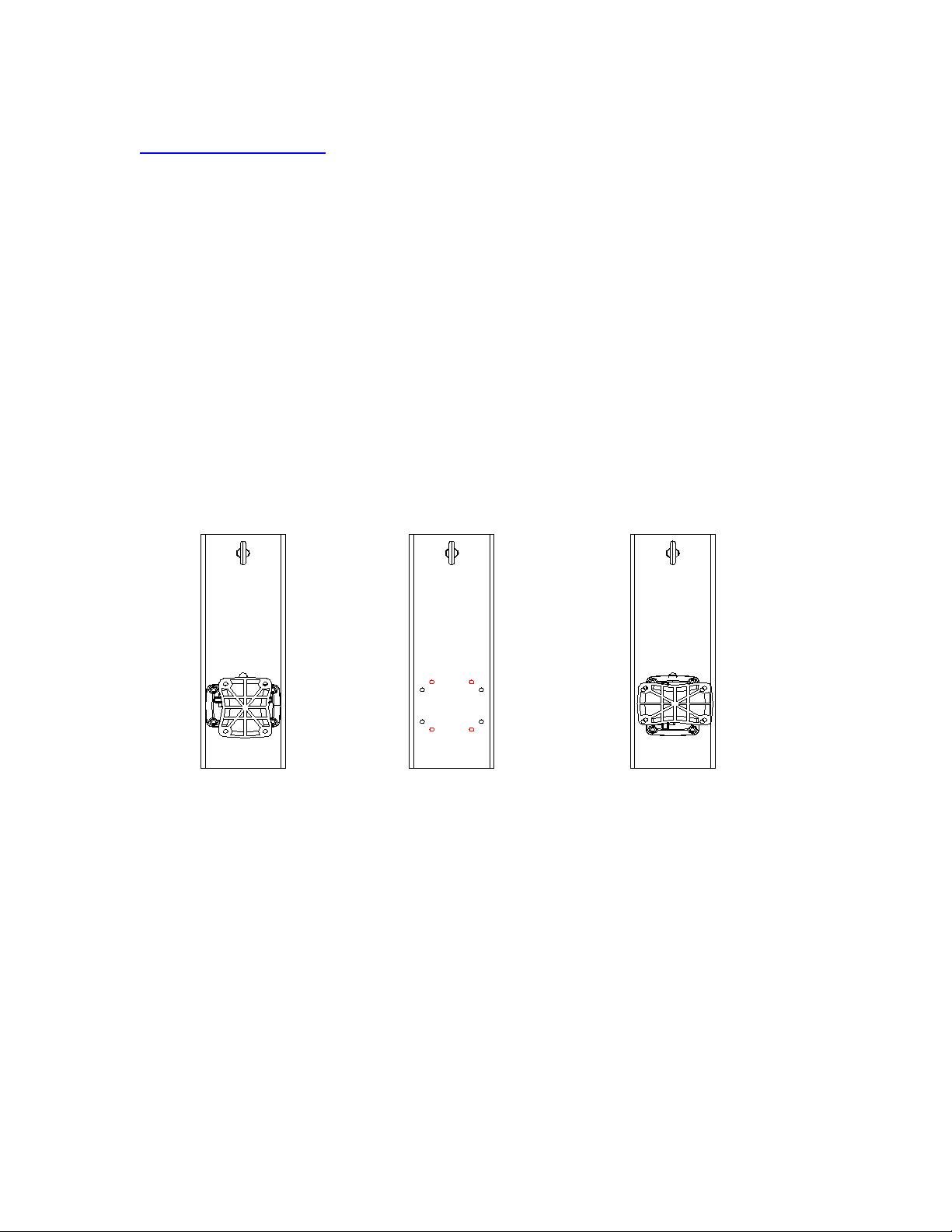

Figure 1

NOTE!

The PT-10 pan and tilt bracket may be oriented in two ways on the Pole Mount

Mini back plate. The orientation on the left is used when the 106IM is to be

mounted. Using this configuration will result in the 106IM being oriented in a

vertical orientation. The PT-10 is mount ed using the 4 black holes shown in the

center image above. The red holes, also shown in the center image, should be

used when a 103IM is mounted and the desired orientation of the enclosure is

vertical. The PT-10 should be mounted to the stainless steel back pl ate be f or e

the back plated is mounted to a pole.

Page 3

1. NOTE: It is best to preset the desired pan and tilt angles PRIOR to mounting

the Pole Mount Mini on a pole. (Step 2 below offers details).

Use ONLY the supplied nuts and bolts to mount the PT-10 to the Pole Mount

Mini back plate. DO NOT substitute any parts!

Mount the pole mount section ( se e fig ur e 1 above) of the bracket to the pole at

the desired height on the pole. The br ack et is mounted to the pole using BANDIT stainless steel bands. DO NOT SUSTITUTE bands of other material or other

widths! There are three locations on the pole bracket for bands.

IMPORTANT: ALL THREE BAND LOCATIONS MUST BE USED.

Figure 2 below illustrates the locations for the stainless steel band clamps.

IMPORTANT: It is REQUIRED that each of the three bands be double wrapped.

Double wrapping will insure a strong and secure mounting of the bracket to the

pole. The stainless steel banding materials should be as follows:

BAND-IT # C206R9 stainless steel bands

BAND-IT # C25699 buckles

BAND-IT # C00169 tensioning tool

The stainless steel band is Type 201SS 0.030 inches (0.762mm) thick and 0.750

inches (19mm) wide.

WARNING: Do NOT substitute banding materials or banding dimensions.

Page 4

Figure 2

Installation instructions from BAND-IT should be followed ex actl y. Operating

instructions are supplied with the tensioning tool. (All BAND-IT parts and tools

purchased separately. These parts and tools are not supplied by ONE

SYSTEMS).

The stainless steel banding material, buckles and tensioning tools are available

from the following locations (or though distributors recommended by these

locations):

BAND-IT IDEX, Inc.

4799 Dahlia St.

Denver Colorado 8021 6

USA

1-800-525-0758

FELIX PONCE

Calle Ignacio Zaragonza No. 8

Colonia Ahuehuetes Atizapan 52953

Edo. de Mexico

(52) 555825 8502

Page 5

BAND-IT Company Limited

Speedwell Industrial Estate

Stavely, Nr. Chesterfield

Derbyshire, S43 3PF England

Home Sales (44) 1246-479479

Export Sales (44) 1246 479480

BAND-IT Clamps (ASIA) Pte. Ltd.

11 Second Chin Bee Road

Singapore 618777

65-62658853

BAND-IT Shanghai Sales Office

207 room

Wanbao International Business Centre

660# Xinhua Road

Shanghai, China 200052

021-62826348-308

2. Attach the appropriate eye bolt to the enclosure. The eye bolt is attac hed to

the rear (top rear) of the 106IM. The eye bolt is attached to the top of the

103IM. There are two eye bolts supplied. One is an M8 eyebolt for use on the

106IM. The second eye bolt is an M5 and is for use on a 103IM. Use the

eyebolt that mates with the specific loudspeaker being mounted to the Pole

Mount Mini.

Next, the pan and tilt angles of the PT-10 bracket should be set.

The pan and tilt function allows pan and tilt angles in 10 degree increments.

Note: Two different center pieces are supplied for the PT-10 bracket that will

accommodate 20 degree increments, with each center piece incremented by 10

degrees to allow for the 10 degree total pan and tilt adjustment. Select the proper

center piece that provides the correct aiming angles. See the illustration below

for details on the center piece of the PT-10.

NOTE: DO NOT use both center pieces!

Page 6

Now the loudspeaker (103IM or 106IM) should be mounted to the loudspeaker

bracket (PT-10) using the supplied stainless steel bolts and w asher s ( M5) . It is

recommended that the desired pan and tilt angles of the loudspeaker be set on

the PT-10 portion of the assembly prior to mounting the loudspeaker.

The instructions for the PT-10 portion of the Pole Mount Mini are also included

and should be referred to when setting the pan and tilt angles.

3. The Pole Mount Mini is supplied with a forged shoulder eye bolt. This bolt is

designed to be used with a secondary cable assembly. This cable assembly

must be configured AFTER the enclosure is mounted on the PT-10 portion of

the Pole Mount Mini.

An M8 eye bolt is supplied to allow the 106IM enclos ur e to be fitt e d with the

supplied cable assembly. An M5 eye bolt is supplied to allow the 103IM to be

fitted with the supplied cable assembly.

INSTALLING THE POLE MOUNT SYSTEM WITHOUT THE CABLE ASSEMBLY

IS NOT ALLOWED!

NOTE: Review all remaining sections before configuring the cable assembly!

4. Configuration of the supplied cable parts (cable, thimbles and compression

sleeves).

DO NOT PRE ASSEMBLE THE CABLE.

Page 7

The cable assembly MUST be assembled AFTER the enclosure is mounted to

the bracket and the bracket is suspended. See Figure 5 for detail of the finished

assembly.

The cable assembly consists of a length of 1/16 inch stainless steel wire rope,

two ¼ inch stainless steel thimbles, and two oval sleeves. The ¼ inch thimbles

must be spread to fit over each of the eyebolts. The wire rope should be

configured and the sleeves crimped AFTER the thimbles have been installed

around the eyebolts. The cable parts are shown in figure 3. The length of the

wire rope is determined by the pan and tilt angles of the enclosure.

Figure 3

Figure 3 is a photograph of the wire rope section and one of the thimbles as well

as one of the oval sleeves. Make sure that the oval sleeve is crimped using the

proper crimping tool. A close view of the assembly is shown in Figure 5.

NOTE: A special crimping tool is required for stainless steel compression

sleeves. The use of a tool that is not approved for use with stainless steel

compression sleeves will result in reduced ratings for the wire rope assembly.

The proper tool to use is produced by:

Loos and Company, Cableware Division

901 Industrial Blvd.

Naples, Fl 34104-3715

1-800-321-5667

The correct tool is:

No. 0-3/64SC

This tool is designed for use with stainless steel compression sl eeves. This

tool or the equivalent must be used when swaging the compression

sleeves. When crimping stainless steel com pr essio n sl e eves you MUST

Page 8

use one size smaller diameter on the crimping tool. For 1/16” sleeves and

cable you MUST use a 3/64” crimp set.

The cable assembly requires the use of a compression tool to securely fit the

oval sleeves. One Systems does not supply this compression tool. The assembly

of the cable must be done by one who is experienced and competent in wire rope

assembly and is familiar with the operation of the required tools.

See Figures 4 and 5 for details of the proper cable assembly to the enclosure

and bracket.

Figure 4 shows both the 103IM and 106IM loudspeakers mounted to the Pole

Mount Mini bracket with the cable assemblies included. The length of the wire

rope should be adjusted so that there is very mild tension on the cable assembly.

The cable assembly should not be loose or have any slack but the cable

assembly should not be so tight as to begin pulling the top of the enclosure back

toward vertical. The length of the wire rope is determined by the tilt and pan

angles of the enclosure.

Figure 4

Page 9

Figure 5

Figure 5 is a close up view of the wire rope assembly. One end is connected to

the M8 eyebolt on the Pole Mount Mini and the other end to the eyebolt mounted

to the enclosure (103IM shown in Figure 5, for the 108IM the eyebolt in located

on the rear of the enclosure near the top).

Note: The ¼ inch thimbles must be spread slightly to fit over the eyebolts and

then recompressed.

APPENDIX 1

(Projected Area Values)

The values below should be supplied to the specific pole manufacturer for safety

calculations. These values were determined by adding the projected areas of th e

high frequency horns, the woofer cones and ports to the cross sectional area of

the front of each enclosure lis ted bel ow.

103IM …………………………….

67 in^2 (43,000 mm^2)

106IM…………………………….

The products referenced in this manual are in conformity with the following

standards or other normative documents: Machinery Directive 2006/42/EC

© One Systems, Inc. 2014 (revision of 2011 edition) www.onesystems.com

136 in^2 (88,000mm^2)

Loading...

Loading...