Page 1

1

Pan and Tilt Bracket Installation Guide

OPA-PTB

August 2013

OPA-PTB with OPALine enclosure

The On Point Audio OPA-PTB is an easy to install and flexible system designed to allow

the OPALine loudspeaker enclosure to be mounted to wall or other structural flat

surfaces. The only products approved for use with the OPA-PTB are the OPALine

enclosure and the OPA-12. NO other products may be substituted!

Page 2

2

NOTE: The OPA-PTB was designed to be mounted on walls or other structural flat

surfaces ONLY! The OPALine enclosure and OPA-P T B are for INDOOR use only! DO

NOT USE IN OUTDOOR ENVIRONMENTS!

NO OTHER LOUDSPEAKERS SHOULD BE S UBSTITUTED!

The following actions MUST be performed PRIOR to beginning the install ati on of the

OPA-PTB and OPALine or OPA-12 enclosure:

1. This installation guide must be completely read and understood.

2. The instruc ti on man ual “Ri g g i ng and Suspension of On Point Audio

Products” must be read and understood. (This instruction manual is

available along with other technical papers at www.onpointaudio.com)

3. The structure of the mating surface MUST be capable of supporting the

combined weight of the OPA-PTB bracket, the OPALine or OPA-12

loudspeaker and all associated rigging. It must satisfy the required safety

factors specified by local and national codes, as well as safe rigging

practices. The OPA-PTB weighs 9.7k g (21.4 lbs). The OPALine enclosure

weighs 39kg (86 lbs). The OPA-12 enclosure weighs 33kg (66lbs)

4. The OPA-PTB pan and tilt bracket should be installed only by someone

experienced in the overhead suspension of items. They should be familiar

with applicable local/national codes governing the installation of these types

of products and those governing the attachment of these types of products

to specific structures.

CAUTION: The OPA-PTB bracket and OPALine and OPA-12 enclosures are designed

for INDOOR use and installation ONLY! DO NOT INSTALL IN OUTDOOR

ENVIRONMENTS!

Page 3

3

INSTALLATION

The OPA-PTB consists of three parts: the wall bracket; the loudspeaker bracket; and

the Link. The OPA-PTB wall bracket and loudspeaker bracket are shown in Figure 1.

Side view wall Front view wall Loudspeaker Full assembly

bracket assembly bracket assembly bracket

Figure 1

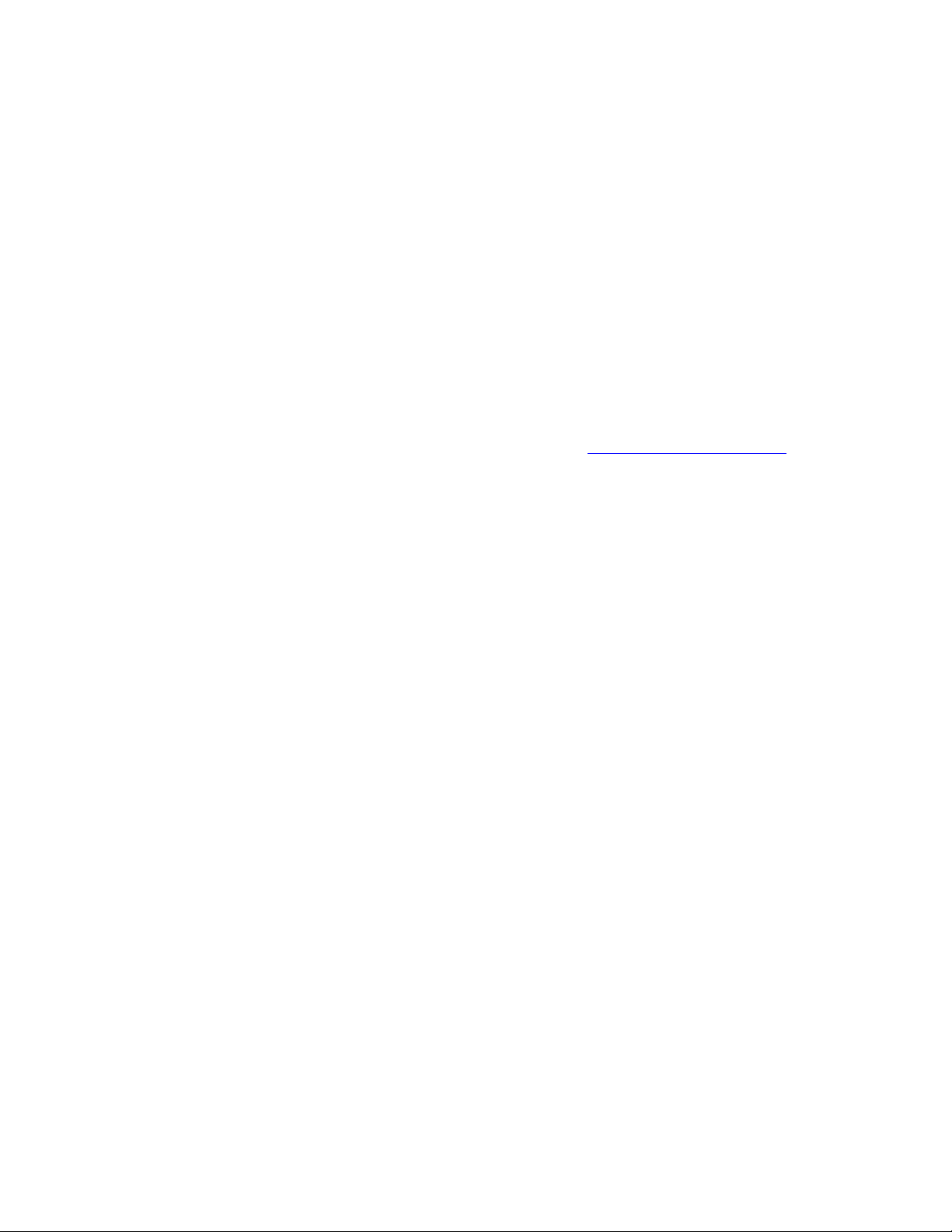

Prior to mounting the wall bracket to the wall or appropriate flat surface, the loudspeaker

bracket section shoul d be removed. The loudspeaker bracket is removed by taking out

the two M10 bolts that hold the loudspeaker bracket to the wall bracket assembly. The

M10 bolts are shown in figure 1a below.

Page 4

4

Remove the M10 bolts shown above

Figure 1a

NOTE: The M10 bolts associated with the “pan” axis should be left in place, as shown in

Figure 2 below.

Leave the “pan axis” M10 bolts in place

Figure 2

Page 5

5

The wall bracket section should now be mounted to the wall surface. The OPA-PTB has

10 mounting holes for allowing fasteners to join the bracket and loudspeaker assembly

to the mating surface.

IT IS NECESSARY TO USE ALL MOUNTING HOLES TO ENSURE A SAFE AND

SECURE MATE TO THE ASSOCIATED SURFACE!

All fasteners associated with the mounting of the OPA-PTB bracket and loudspeaker

assembly to the mating surface are the responsibility of others. The design and

structural capacity of mating surfaces (suc h as walls) vary greatly and specific fasteners

are designed for use with specific mating surfaces. On Point Audio does not

recommend any mating fasteners and strongly urges the installer to consult with one

experienced in suspension of products from the specific mating surfaces and the

appropriate choice of fasteners for those specific surfaces.

The wall bracket section should be secured firmly to the mating surface using the

appropriate fastening system. The fastening system should be determined by the

structure of the mating sur face.

IT IS CRITICAL THAT THE MATING SURFACE BE CAPABLE OF SUPPORTING THE

LOAD OF THE OPA-PTB BRACKET, THE OPALINE OR OPA-12 LOUDSPEAKER

AND ALL SUSPENSION HARDWARE, AS WELL AS PROVIDING THE PROPER

SAFETY FACTORS. DO NOT ATTEMPT TO SUSPEND THE BRACKET AND

LOUDSPEAKER UNTIL THE STRUCTURAL CHARACTERISTICS OF THE MATING

SURFACE ARE UNDERSTOOD. DO NOT INSTALL THE OPA-PTB BRACKET AND

OPALINE OR OPA-12 LOUDSPEAKER IF THE MATING SURFACE IS NOT CAPABLE

OF SUPPORTING THE ENTIRE ASSEMBLY WEIGHT, AS WELL AS PROVIDING

THE REQUIRED SAFETY FACTORS!

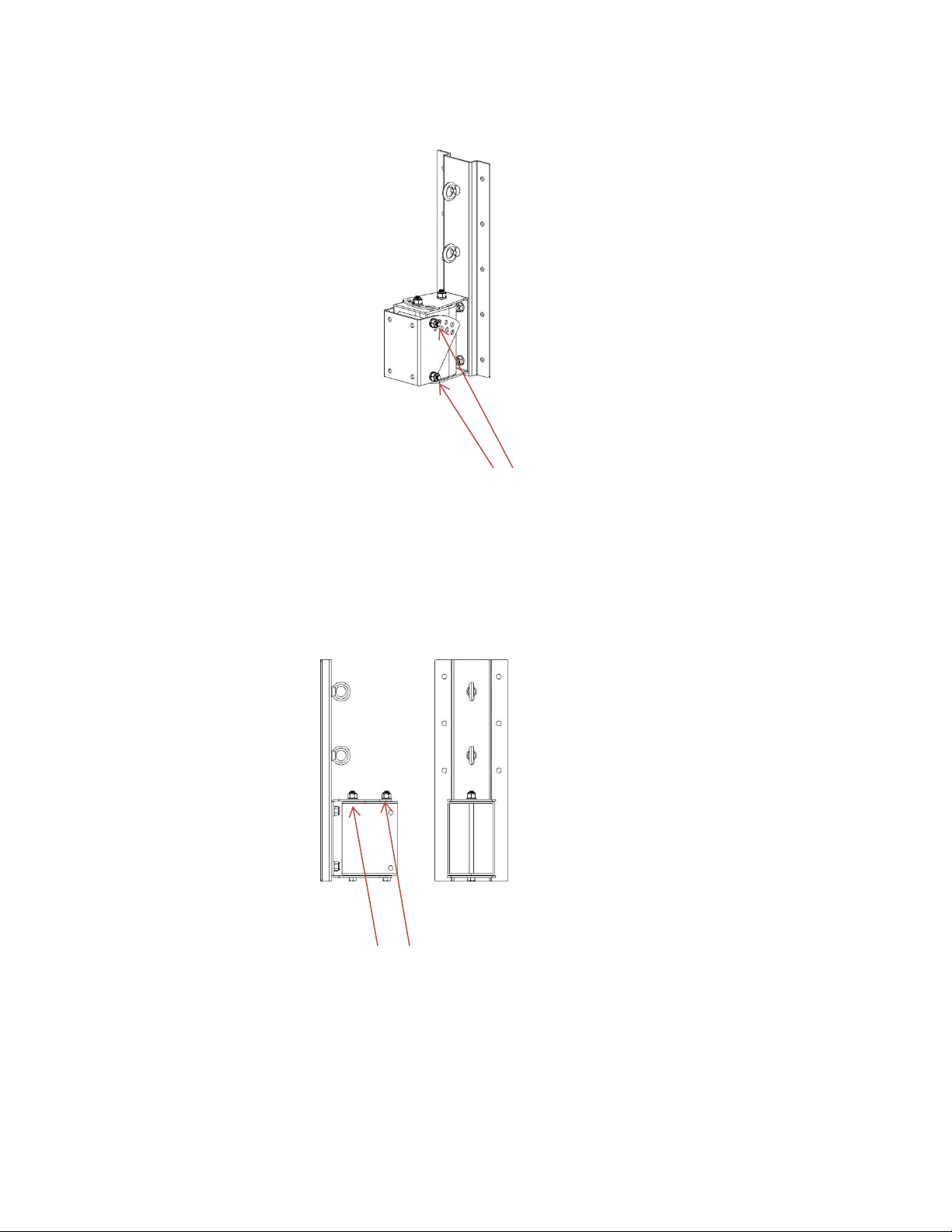

After the OPA-PTB wall section of the bracket is securely mounted to the mating

surface, the loudspeaker section should be mounted to the OPALine or OPA-12

loudspeaker using the fas te ner s suppl i ed . (DO NOT SUBSTITUTE FASTENERS) The

loudspeaker mount section of the bracket is shown in figures 3a and 3b.

Figure 3a Loudspeaker bracket

Page 6

6

Figure 3b showing Loudspeaker bracket

mounted to the OPALine enclosure

DO NOT SUBSTITUTE MOUNTING LOCATIO NS!

NOTE: There are 4 each hex head M10 bolts supplied in the mounting kit of the OPAPTB. When mounting the OPALine or OPA-12 enclosure to the OPA-PTB use 4 each of

the 45 mm M10 bolts. Additionally, there is a forged shoulder eyebolt supplied in the

OPA-PTB kit. This eyebolt must be installed in the top, rear center portion of the

OPALine or OPA-12 enclosure. Make sure that the eyebolt is seated on the surface of

the enclosure. The eyebolt is shown below in figure 4.

Figure 4 showing forged shoulder eyebolt installed

Page 7

7

The loudspeaker and loudspeaker section of the bracket may now be joined to the wall

section and the required pan and tilt angles selected. This is a two person job and

extreme care should be exercised to avoid serious injury.

USE EXTREME CAUTION! The loudspeaker is heavy and it is likely that the desired

mounting location is high in the air. This process should never be attempted by a single

person.

TWO OR MORE PEOPLE ARE REQUIRED TO MOUNT THE LOUDSPEAKER

ENCLOSURE TO THE OPA-PTB bracket. Safety harnesses should always be worn

when working from an elevated platform.

The OPALine or OPA-12 enclosure, with loudspeaker bracket attached, should be

mounted to the wall section of the OPA-PTB.

The M10 tilt pivot bolt should be inserted first and secured, but not completely tightened

using the nylon insert M10 nuts that are supplied. The tilt pivot bolt is shown below in

Figure 5. At this point the M10 tilt aiming bolt (Figure 5a) should be inserted into the

desired angle and the nylon insert nuts applied. Then the tilt axis bolts should be

partially tightened. (see below for FULL tightening recommendations after the aiming

bolt has been set to the proper angle).

Figure 5 showing the tilt pivot bolt. This must be inserted first.

Figure 5a below shows the tilt aiming bolt. This can only be inserted AFTER the tile

pivot bolt is installed and partially tightened!

Page 8

8

Figure 5a showing tilt aiming bolt

Now the pan aiming bolt can be adjusted if needed. NOTE: The pa n pivot bolt should

NOT be removed.

The pan angle can be adjusted by removing the pan angle aiming bolt as shown below

in Figure 5b.

Pan angle aiming bolt Pan angle pivot bolt (DO NOT REMOVE)

Figure 5b

!Once both the tilt and pan angles are set, make sure that all aiming and piv ot bolts for

both the pan and tilt axis are tight and secure!

Page 9

9

INSTALLING THE LINK

Figure 6 is a representation of the Link assembly. This assembly MUST be used

whenever the OPA-PTB and the OPALine or OPA-12 enclosure are being used

together. Each pan and tilt bracket is supplied with a link assembly.

Figure 6

UNDER NO CIRCUMSTANCES SHOULD THE DOWNWARD TILT OF THE

LOUDSPEAKER EXCEED 35 DEGREES FROM VERTICAL FOR THE OPA-PTB and

OPALine enclosure.

SECTION 5 LINK ASSEMBLY

Now the Link must be installed.

INSTALLING the OPA-PTB Bracket WITHOUT THE LINK IS NOT ALLOWED!

The Link (see figure 6) consists of quick links, a turnbuckle, and several links of steel

chain. The use of the chain pieces and quick links with the turnbuckle is based on the tilt

angle of the enclosure. The turnbuckle should always be used.

DO NOT SUBSTITUTE ANY PART OF THIS LINK ASSEMBLY!

The Link should be tightened by rotating the turnbuckle until there is

tension on the Link assembly. Do not over tighten. The purpose of the Link

is to provide support for the main OPA-PTB tilting bracket at the bottom of

the assembly. ONLY ROTATE THE TURNBUCKLE UNTIL THERE IS

VERY SLIGHT TENSION. DO NOT TIGHTEN B E YOND THIS P OI NT!

The back plate section of the OPA-P TB has eyebolts attached to it. There are two (2)

eyebolts on the back plate section of the OPA-PTB.

Make certain to use the appropriate combination of Link parts to ensure proper

connection between the OPA-PTB bracket assembly and the OPALine or OPA-12

enclosure. The required combination of link parts is determined by the down tilt angle of

the enclosure.

Page 10

10

The assembly may be configured with any combination of turnbuckle, chain link

sections and quick link in order to achieve the proper tension on the system, but the

turnbuckle must always be used. The selection of the correct eyebolt will be determined

by the down tilt angle of the enclosure.

Warning: If the turnbuckle assembly is turned and the loudspeaker enclosure angle

begins to change, (if the down tilt angle begins to move toward 0 degrees vertical) then

the turnbuckle has been OVER TIGHTENED. Turn the turnbuckle until the down tilt

angle is set by the M10 thru bolt on the pole bracket, but there still should be slight

tension on the turnbuckle.

Figure 7 is a close up view of the Link assembly. Certain down tilt angles may require a

link to be “dropped” from the chain as shown below. The lower quick link is positioned in

various chain segments based on the desired degree of down tilt. The turnbuckle should

be adjusted, as described in this section.

In any position, the turnbuckle must be adjusted to allow the proper amount of tension

on the Link. The Link should never pull the loudspeaker up towards vertical. The Link

may be configured with or without the chain section and quick link, depending on the

down tilt angle of the enclosure.

Figure 7

Secondary safety cables are STRONGLY recommended and should be

secured to a structural point NOT associated with the OPA-PTB brac ket or

loudspeaker enclosure. The Link assembly is NOT a secondary safety

cable.

The products referenced in this manual are in conformity with the following

standards or other normative documents: Machinery Directive 2006/42/EC

©On Point Audio, Inc. 2013 Nashville, TN U.S.A. www.onpointaudio.com

Loading...

Loading...