Page 1

1

Marc h 28, 2014

One Systems Natatorium (Indoor Swimming Pool)

Speaker Products Installation Manual

One System s has devel op ed a nar r ow focus, appl icatio n s pecific set of pro du c ts designed

for use in Natatorium (indoor swimming pool) environments. The 108IM/NAT and 112/NAT

are constructed using very high molybdenum content stainless steel for all internal and

external structural rigging members.

Indoor swimming pool environments can present very high relative humidity and harsh

chemical atmospheres. The combination of humidity and airborne chemical composition

restricts the mounting of the 112/NAT or 108/NAT to wall mounting in solid concrete or grout

filled block (CMU) concrete walls ONLY! One Systems does not allow wire rope suspension

of its products in Natatorium environments. Call One Systems regarding direct mounting to

the structural steel of the indoor swimming pool building (Galvanic isolation is required!).

One Systems offers recommendations for installation on solid concrete and grout filled block

walls. Contact One Systems for additional information.

Commonly us e d st ainless steels such as 304-grade and 316 -grade, known as austenitic

steels, offer good corrosion resistance and strength in harsh environments. Marine-grade

(speci fical l y kn ow n as 31 6-gr a de s tainless steel) offers additional protection in salt spray,

ocean front, and cruise ship applications. Unfortunately, these austenitic materials are

susceptible to chloride stress corrosion cracking (SCC). Both 304-grade and 316-grade are

susceptible to SCC. SCC is a particular problem in indoor swimming pool environments and

can result in structural failure of the rigging components. The chlorine based chemicals in

the water react with “human” by-products, suc h as sweat, and produce chloramines. These

chloramines an d hy dr oly zed bypr o duc t s pass into the atmosphere and are deposited on all

surfaces in the Natatorium. They are transported throughout the space via the air handling

system of the venue. This is particularly problematic in areas above the pool surface that are

not routinely washed down or cleaned. Loudspeakers and their associated rigging are

typically mounted far above the “splash zone” and these chloramines are left to settle on

structural surfaces, so that SCC can progress to critical levels. Unfortunately, there are no

establi sh ed t hr e sholds for c hl or am i n e exposur e and ass o ci ated stress levels in th e structur al

members, so SCC can be a significant concern in Natatorium environments. Additionally

there are no visual inspection methods that will detect SCC, so careful monitoring will not

insure th at s tr uctural members are fr ee from this effect. One Systems cannot recommend

the use of stainless steel wire ropes for suspension because of the issues discussed above.

Alternate structural materials, such as aluminum or plated steels, can al so suffer fr om

chloramine attack and other corrosion mechanisms. Fortunately, there are several grades of

stainless steels that are extremely resistance to Chloride SCC. Super austenitic stainless

Page 2

steels consisting of 6% molybdenum are excellent choices. There are several super

austenitic grades that are very strong and well suited for structural members due to their

excellent SCC resistance. These grades are recognized by several European countries as

being the only acceptable stainless steels for use in Natatorium environments where they

are load bearing and above the “splash” zone and not routinely washed or cleaned. One

Systems uses AL6XN (N08367) material. Oth er m ater i als ar e 1. 4547 and 1. 45 29 6%Mo

stainless steels.

NOTE: ONE SYSTEMS DOES NOT RECOMMEND MOUNTING

IT’S PRODUCTS DIRECTLY TO THE NATATORIUM

STRUCTURAL STEEL DUE TO THE

COMPLEXITY OF THE GALVANIC

ISOLATION DESIGN AND THE CORROSIVE NATURE

2

OF THE ENVIRONMENT! (Contact One Systems for

additional information.)

NOTE: THIS MANUAL DOES NOT COVER THE USE OF WIRE

ROPES OR OTHER SUSPENSION METHODS

CONNECTED TO THE STRUCTURAL STEEL OF THE

BUILDING!

NOTE: STAINLESS STEEL WIRE ROPES ARE NOT

RECOMMENDED FOR USE IN

NATATORIUM (INDOOR SWIMMING POOL)

ENVIRONMENTS FOR LOUDSPEAKER SUSPENSION !

NOTE: DO NOT ATTEMPT ANY OF THE OPERATIONS IN THIS

MANUAL IF YOU DO NOT FULLY UNDERSTAND THEN! ALWAYS

CONSULT AN EXPERT WITH EXPERIENCE IN THE OPERATIONS

NOTED IN THIS MANUAL!

Page 3

NOTE: THIS MANUAL CONSISTS OF FOUR (4) SECTIONS:

1. GENERAL ASSEMBLY OF THE LOUDSPEAKER Page 4

2. MOUNTING TO SOLID CONCRETE WALLS Page 6

3. MOUNTING TO CONCRETE BLOCK

A. GROUT FILLED CMU BLOCKS Page 13

3

MOUNTING TO HOLLOW CORE BLOCK IS NOT PERMITTED!

4. General NAT product specif ications Page 25

NOTE: DO NOT ATTEMPT ANY OF THE OPERATIONS IN THIS

MANUAL IF YOU DO NOT FULLY UNDERSTAND! ALWAYS

CONSULT AN EXPERT WITH EXPERIENCE IN THE OPERATIONS

NOTED IN THIS MANUAL!

NOTE: All drilling operations in the manual require masonry bits. Consult

and expert regarding the appropriate bit!

Page 4

U-Bracket Assembly of the 108IM/NAT and 112IM/NAT

The One Systems 108IM/NAT and 112IM/NAT use high molybdenum content stainless steel

for all structural and load bearing points. Both products are supplied with an external “Ubracket” mounti ng c o n figurati on. Thi s is the only ap pr oved mounting method for the NAT

loudspeaker series.

4

NOTE: There are ONLY three (3) mounting points on the NAT enclosures. Two points ar e

used for the ex t er nal U-bracket and the third point may be used as a secondary safety point.

Both the 108IM/NAT and 112IM/NAT are supplied with external U-brackets, bolts and

washers that are required to mount the U-bracket to the enclosure. DO NOT SUBSTITUTE

ANY PARTS USE D TO ATTACH THE U-BRACKET TO THE EN C LOSURE!

The U-bracket (AL6XN material) and associated washers and bolts are supplied and

attach ed to eac h en cl os ure. The bracket must be disassemble d f or ins tal l ation.

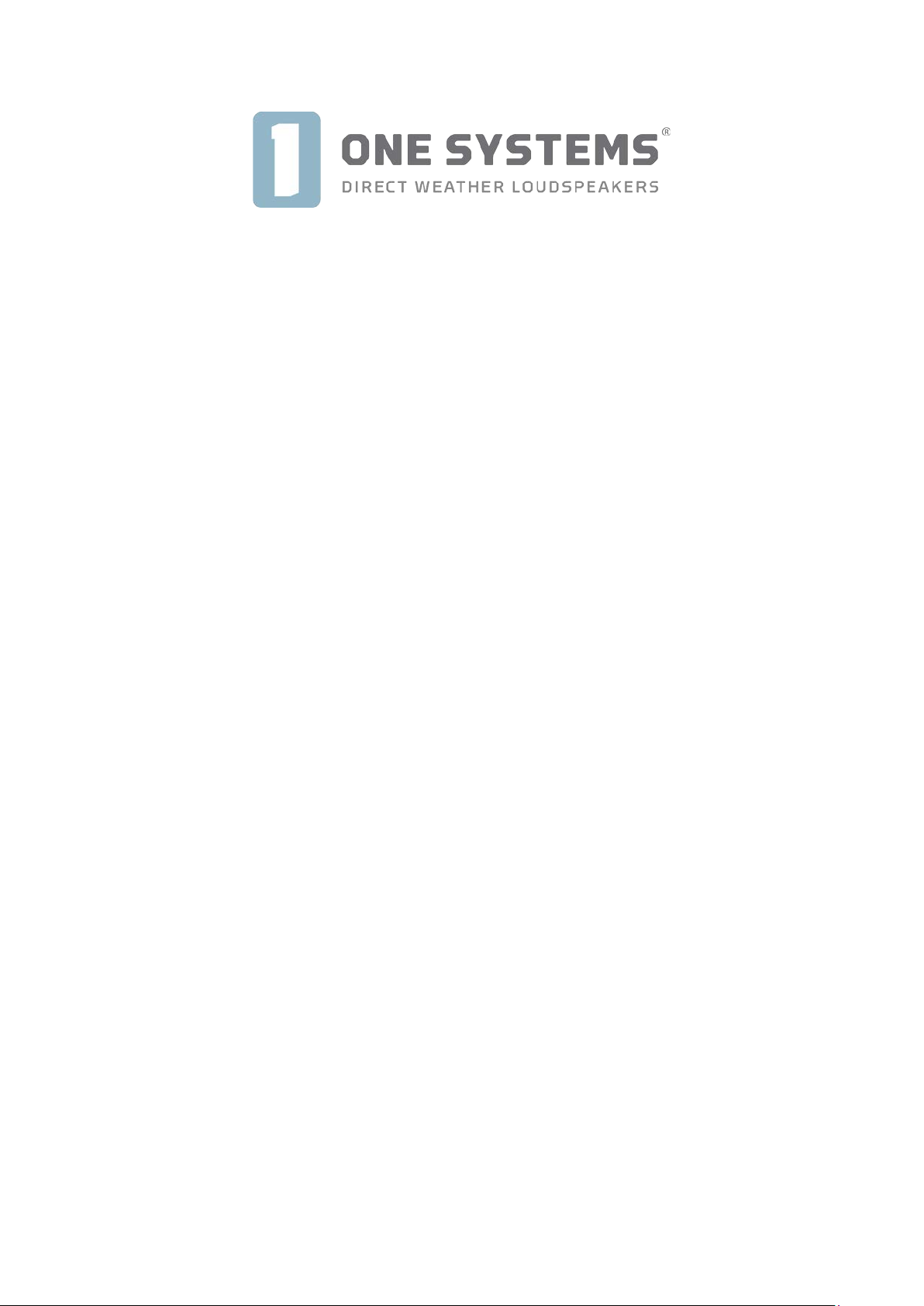

The enclosure and attached U-bracket are shown in the image below. The enclosure is

attach ed to the U Br acket using the supplied AL6XN bolts and Nord-Lock washers. The

108/NAT uses 5/16” bolts and 5/16” (M8) Nord Lock washers. The 112/NAT uses 3/8” bolts

and 3/8” Nord Lock washers. DO NOT SUB STITUTE TH ESE PARTS. The enclosure

should be mou nt ed t o the U br acket AFTER the U bracket has been mounted to either a

solid concrete wall or grout filled block (CMU) wall!

Each Nord Lock washer set consists of TWO parts and BOTH must be used on each bolt

assembly. See the image below. The Nord Lock washer is shown in light blue col or .

Page 5

Also note the supplied silicone washer. This large washer must be located between the NAT

enclosure and the U-bracket. This silicone washer will help prevent rotation of the NAT

enclosur e onc e th e des i r e d ai m i ng an gl e is ac hieved.

5

Silicone washer AL6XN bracket Nord Lock washer AL6XN bolt

NOTE: It is critical that the correct torque values be observed when assembling the Ubracket assembly.

The 5/16” bol ts used on the 10 8IM/ NA T U-bracket should be tig ht ened to a torque value of

14ft lb. (19.0Nm)

The 3/8” used on the 112IM/NAT U-bracket should be tightened to a torque value of 24ft lb.

(32.5Nm).

Full installation instructions for the Nord Lock washers may be found on the One Systems

web site (www.onesystems.com

Natatorium section.

) in the Technical Papers/Install Guides under the

NOTE: In d oor swim m ing po ols (N a tatori um s) ca n be very harsh

environments. It is necessary to perform a yearly inspection of all

rigging elements. It is also necessary to perform a yearly visual

inspection on the U-bracket silicone washers (see the image

above). Any signs of degradation or corrosion will require

replacement of any structural elements, including the silicone

washers.

Page 6

Mounting to Solid Concret e Wa l ls:

(Concrete anchors are NOT ALLOWED for use with cinder block

construction)

IMPORTANT: IT IS THE RESPONSIB ILITY OF THE INSTALLER TO

VERIFY THAT THE WALL SURFACE IS STRUCTURALLY CAPABLE

OF SUPPORTING THE PRODUCT AND ALL ASSOCIATED SAFETY

FACTORS AS REQURED BY ALL APPLICABLE CODES AND SAFE

SUSPENSION PRACTICES. THE INSTALLER SHOULD CONSULT

WITH A STRUCTURAL ENGINEER PRIOR TO INSTALLATION TO

INSURE THAT THE WALL SURFACE CAN SUPPORT THE WEIGHT

OF THE 112/NAT OR 108/NAT AND ALL ASSOCIATED RIGGING

AND ALL REQUIRED SAFETY FACTORS. THE COMPOSITION OF

6

THE WALL STRUCTURE

STRUCTURAL ENGINEER PRIOR TO INSTALLATION!

MUST BE REVIEWED BY A

STOP: The approved anchors (Fischer FAZ II 10/10 C) require

a minimum solid concrete wall thickness of 3.937 inches

(100mm). DO NOT mount the NAT loudspeaker to a solid

concrete wall if the wall thickness is not at least 3.937 inches

(100mm) thick!

The NAT products are approved for use with the FAZ II 10/10C

for WALL mounting only! DO NOT MOUNT FROM A CEILING!

STOP: USING FAZ II 10/10 C ANCHORS REQUIRES A

TORQUE WRENCH CAPABLE OF 33 FT-LBS (45MN) OF

TORQUE. THESE ANCHORS MUST BE TORQUED TO THIS

VALUE. DO NOT INSTALL IF YOU DO NOT HAVE A

TORQUE WRENCH!

NOTE: The anchors referenced below are for use in solid concrete ONLY!

DO NOT use with cinder block (CMU) wall construction!

NOTE: ALL installation instructions below are guidelines. It is necessary to read the

additional installation instructions provided by Fischer. Additional instructions may

be found on the One Systems web site in the Documentation section. The Natatorium

section is found in the Tech Papers/Install guides section under the onesystems.com

Documentation Tab. This document is ESR 2948.

Page 7

IT IS NECESSARY TO READ ESR 2948 AND UNDERSTAND THIS

DOCUMENT PRIOR TO INSTALLATION.

INSURE THAT THE SOLID CONCRETE CONFORMS TO SECTION

5.0 OF ESR 2948 AND OBSERVE ALL REQUIREM ENTS IN THIS

“CONDITIONS OF USE” SECTION!

BRACKET LOCATION ON SOLID CONCRE TE WALLS

IMPORTANT NOTE: The mounting holes in the concrete

MUST be drilled at least 8 inches (203.2mm) away from any

edges or openings in the solid concrete wall! DO NOT drill

the bracket mounting holes in the solid concrete where

wall edges or openings in the wall are closer then 8 inches

(203.2mm)!

7

Solid Concrete Anchors:

If the 108IM/NAT or 112IM/NAT are to be mounted on a solid concrete surface, then

approved concrete anchors must be used. The ONLY approved source for concrete anchors

is Fischer Fixings LLC. Do not substitute any other anchors!

The approved concr ete anchor s ar e as fol low s :

108IM/NAT Fischer FAZ II 10/10 C (the “C” is a designator for 1.4529 6% Mo stainless

steel)

112IM/NAT Fischer FAZ II 10/10 C (the “C” is a designator for 1.4529 6% Mo stainless

steel)

Page 8

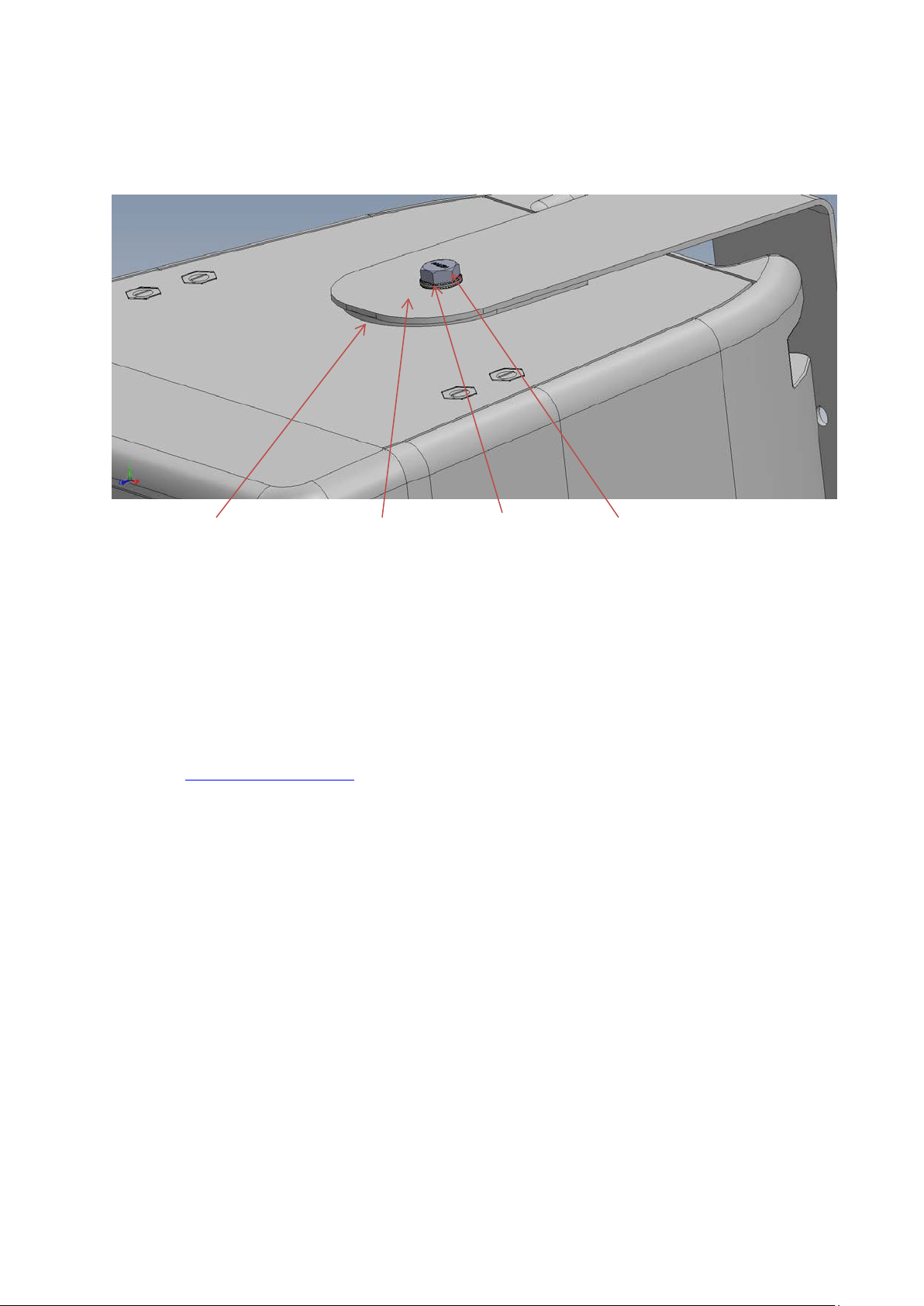

NOTE: ONLY HORIZONTAL MOUNTING IS PE RMITTED WHEN MOUNT ING ON SOLID

CONCRETE WAL LS! DO NOT MOUNT THE U-B RACKET IN A VERTICAL

ORIENTATION!

DO NOT MOUNT VERTICALLY ON SOLID CONCRETE WALLS

MOUNT BRACKET AND ENCLOSURE HORIZONTALLY ONLY!

NOTE: When mounting to a solid concrete wall ONLY one anchor per side on the U bracket

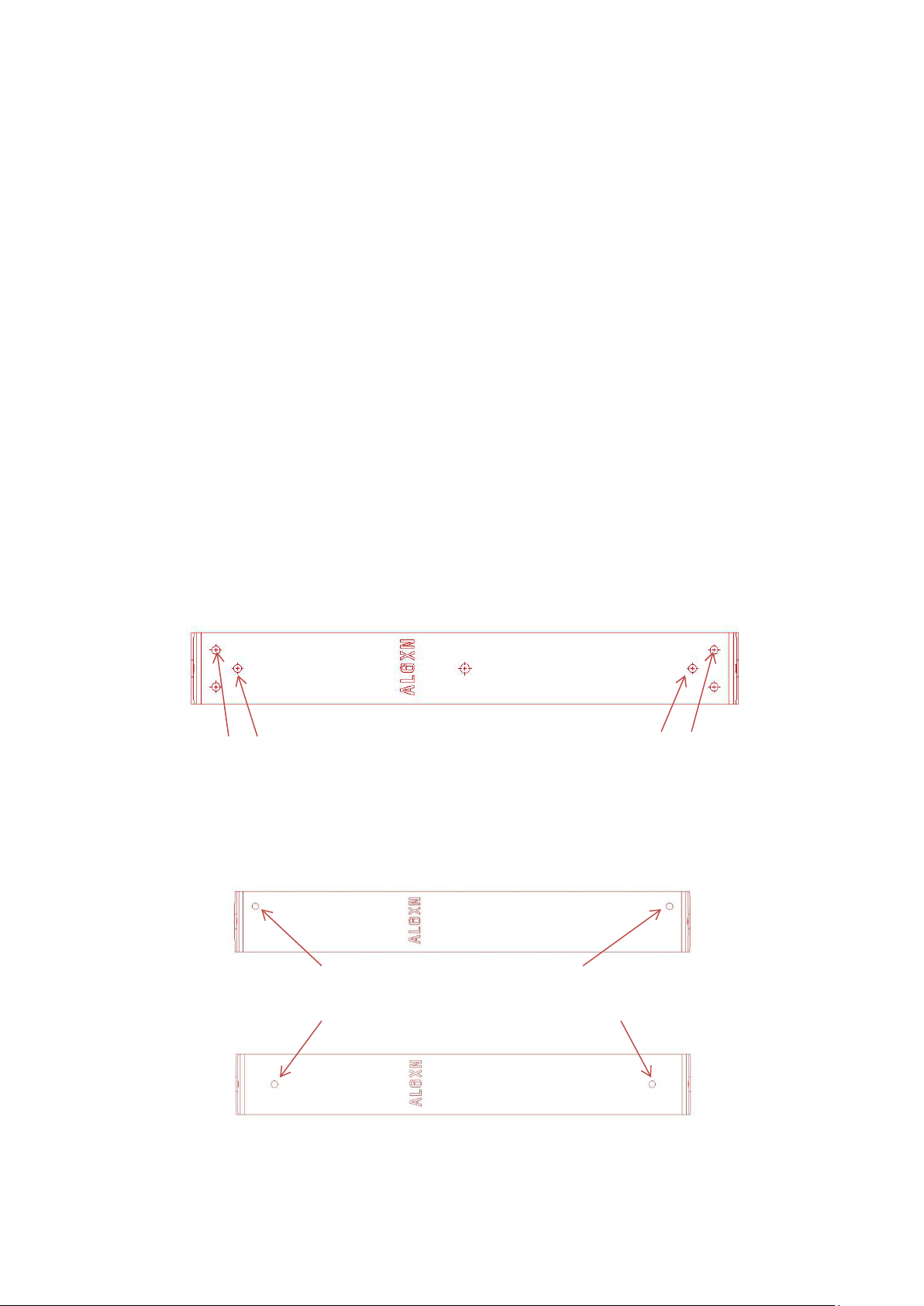

is permitted. DO NOT USE MORE THEN ONE ANCHOR PER SIDE (see im ag e below)

NOTE: Only certain holes on the U-bracket may be used and

8

ONLY horizontal mounting is permitted. Dril l only ONE

mounting hole per side.

The 112/NAT U-bracket is shown below

Use ONLY one hole per side. Use either of the holes shown BUT not both holes.

NOTE: DO NOT DRILL MORE THEN ONE HOLE PER SIDE!

The images below show the mounting holes allowed.

Use these two holes ONLY!

OR

Alternately these two holes ONLY!

Page 9

9

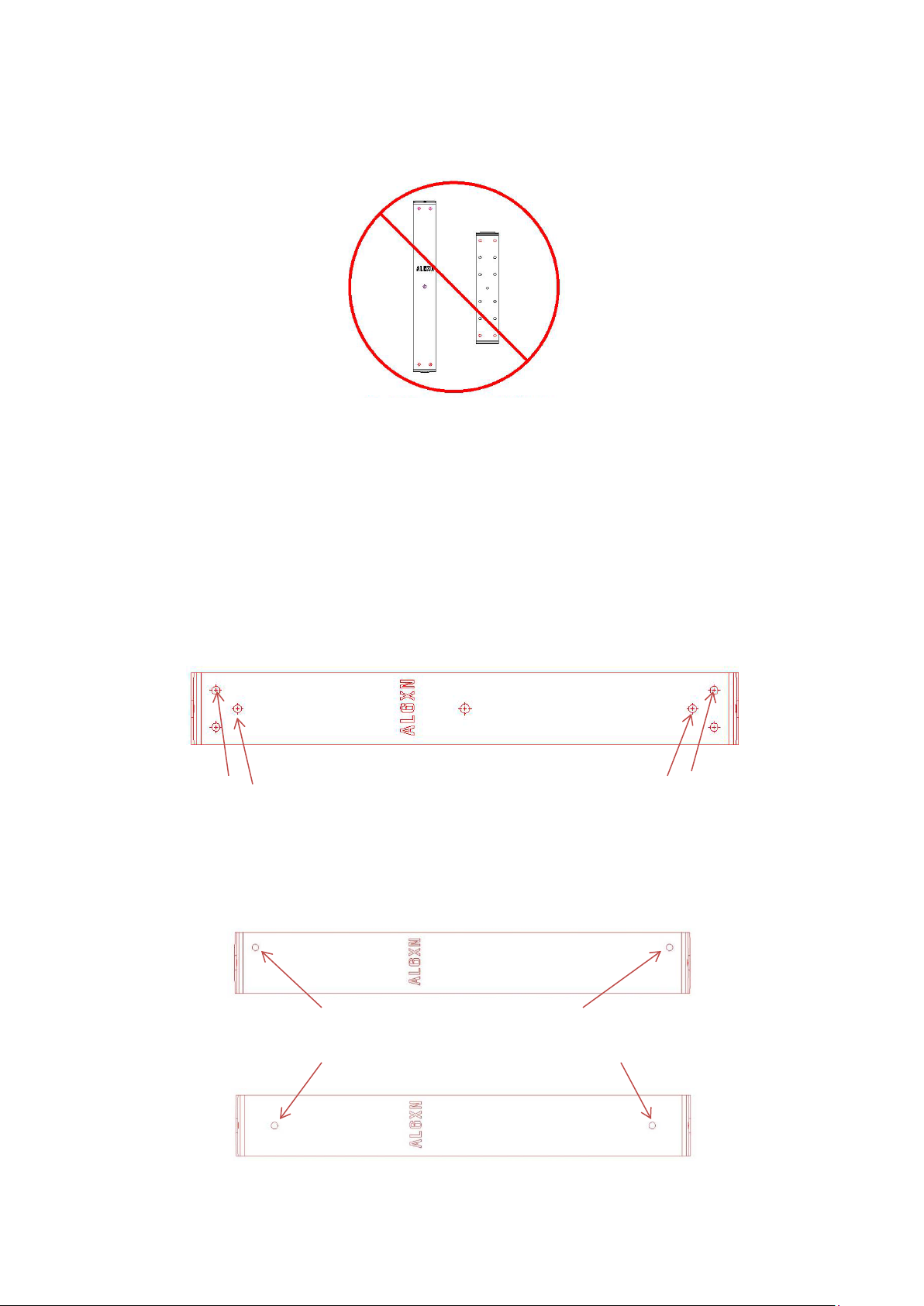

The 108/NAT U-bracket is shown below

Use ONLY one hole per side. Use either of the holes shown BUT not both holes.

NOTE: DO NOT DRILL MORE THEN ONE HOLE PER SIDE!

The images below show the mounting holes allowed.

Use these two holes ONLY !

OR

Alternately these two holes ONLY

The required hole depth is 3 11/32 inches (85mm) and should be verified

prior to installation of the FAZ II 10/10C anchor! INSURE THAT THE

HOLE IS THE CORRECT DEPTH! This hole should be perpendicular

to the surface of the wall. DO NOT drill at an angle!

NOTE: Avoid drilling into rebar. Rebar locators may be rented from

many sources to determine the location of rebar in the solid concrete.

Page 10

10

To install the FAZ II 10/10C anchor follow the steps listed below:

1. Create the drill hole. 3 11/32 (3.343 inches) deep (85mm) and 10mm diameter.

INSURE THAT THE HOLE IS THE CORRECT DEPTH!

This hole should be strai ght an d perpendicular to the surface of the wall.

DO NOT drill at an angle!

solid concrete walls!

Consult with someone with experience drilling into

THE ACTUAL BRACKET LOCATION MUST BE AS NOTED ON PAGE

7 IN THE SECTION “BRACKET LOCATION ON SOLID CONCRETE

WALLS”!

NOTE: The hole diameter MUST be drilled with a 10mm diameter bit. Do not

substitute an imperial diameter. A metric 10mm diameter drill bit must be used!

ELECTRIC D RILLS MUST BE USED AND IN ROTATION MODE ONLY!

Note: One Systems offers the NASH 1009008A 10mm drill bit. This drill may be

sourced from One Systems Nashville.

2. Clean the hole completely using the tool shown below. It is important to

completely clean the hole. The cleaning operation should be performed several

times!

NOTE: It is critical to completely clean the drilled hole. It is necessary to follow the

anchor manufacturers cleaning instructions. See the recommended Fischer tool

(89300) below and may be sourced directly thru Fischer.

Page 11

11

NOTE: The bracket images shown below are for illustration purposes only. In actual

assembly the NAT external U-bracket for the 108/NAT or 112/NAT must be used!

IMP ORTANT: BEF ORE DRIVING THE FAZ II 1 0/ 10 C ANCHOR INTO THE HOLE , INSURE

THAT THE HEX NUT IS IN THE PROPER POSITION. THE CORRECT POSITION OF THE

HEX NUT IS W HEN 5/64 inches to 1/8

BOLT IS PROJECT ING BEYOND THE END O F T HE NUT.

th

inches (2mm TO 3 mm) OF THE THREADED

2mm to 3mm this end of thread exposed

3. Mount the 108/NAT or 112/NAT U-bracket over the holes and drive the FAZ II 10/10C

anchor in place as shown.

The FAZ II 10/10C is driven in place as shown below. The NAT U-bracket must be

in place before the anchor is driven into the hole!

4. Apply the required torque as shown below in the center image. The required

torque is 33ft lbs (45 NM).

NOTE: The FAZ II 10/10 C is supplied with the correct washer and nut. DO NOT

SUBSTITUTE ANY PARTS!

Additional instructions for inst all i n g these concrete anchors are found on the One Systems

web site (www.onesystems.com

Guides”. The document is ESR 2948. THIS DOCUMENT MUST BE READ AND

UNDERSTOOD PRIOR TO INSTALLATION!

) in the Documentation section under “Tech Papers/Install

Page 12

12

NOTE: The required torque on the FAX II 10/10C M10 nut is 33 ft-lbf

(45 Nm). DO NOT EXCEED THI S TO RQUE BUT INSURE THAT THIS

TORQUE IS APPLIED.

Once the FAZ II 10/10C nut is tightened to the specified torque, DO NOT re-torque

or tighten further. DO NOT re-torque later !

NOTE: DO NOT USE ANY THREAD LOCKER WITH THIS PRODUCT! Use ONLY

the parts supplied!

The contact information for Fischer is:

Fischer Fi xi n gs LLC

62 Orange Ave

Suffern, New York 10901

www.fischerfixingsusa.com

Phone: + 1-845-504-5098

NOTE: These anchors are NOT PERMITTED for use with “cinder block”

(CMU) construction! See information below for grout filled masonry

block.

Below is what is nee ded to hang a single 112/NAT or 108/NAT cabinet in a solid concrete

wall:

2 ea. NASH 1009007A FAZ II 10/10C Fischer anchors. One Systems Nashville supplied.

1 ea. Fischer air tool (Fischer part 89300…this part is re-useable). Fischer supplied

1ea. NASH 1009008A 10mm Masonry Drill Bit. One Systems supplied

Page 13

13

MOUNTING TO GROUT FILLED CONCRE TE BL O CK

IMPORTANT: IT IS THE RESPONSIBILITY OF THE INSTALLER TO

VERIFY THAT THE WALL SURFACE IS STRUCTURALLY CAPABLE

OF SUPPORTING THE PRODUCT AND ALL ASSOCIATED SAFETY

FACTORS AS REQURED BY ALL APPLICABLE CODES AND SAFE

SUSPENSION PRACTICES. THE INSTALLER SHOULD CONSULT

WITH A STRUCTURAL ENGINEER PRIOR TO INSTALLATION TO

INSURE THAT THE WALL SURFACE CAN SUPPORT THE WEIGHT

OF THE 112/NAT OR 108/N AT AND ALL ASSOCIATED RIGGING

AND ALL REQUIRED SAFETY FACTORS. THE COMPOSITION OF

THE WALL STRUCTURE

STRUCTURAL ENGINEER PRIOR TO INSTALLATION!

MUST BE REVIEWED BY A

NOTE: MOUNTING ON HOLL OW CORE BLOCK(CMU) IS

NOT PERMTTED! DO NOT MOUNT ON HOLLOW CORE

BLOCK!

MOUNT ON GROUT FILLED BLOCK ONLY!

STOP! THE BLOCK SIZE MUST BE 16 INCHES X 8 INCHES

X 8 INCHES! (OR METRI C EQUIVALENT ) DO NOT USE

SMALLER BLOCK SIZE. DO NOT ATTEMPT TO MOUNT THE

112NAT OR 108NAT TO SMALLER BLOCK SIZES!

THE BLOCK (CMU) MUST BE ASTM C-90 OR EQUIVALENT!

A TORQUE WRENCH IS REQUIRED F OR THIS

INSTALLATION!

BRACKET LOCATION ON GROUT FILLED BL O CK WALLS!

The mounting holes in the grout filled concrete block

MUST be drilled at least 12 inches (305mm) away from any

edges or openings in the grout filled block wall! DO NOT

drill the bracket mounting holes in the grout filled CMU

(concrete masonry unit) block where wall edges or

openings in the wall are closer then 12 inches (305mm)!

Page 14

14

One Systems requires ONLY horizontal mounting to grout filled concrete block

(CMU). Both the 112/NAT and 108/NAT must be mounted horizontally as shown

below.

NOTE: ONLY HORIZONTAL MOUNTING IS PE RMITTED WHEN MOUNT ING ON GROUT

FILLED BLOCK WALLS! DO NO T MOUNT THE U BRACK ET IN A VER TICAL

ORIENTATION!

DO NOT MOUNT VERTICALLY ON GROUT FILLED BLOCK WALLS

MOUNT BRACKET AND ENCLOSURE HORIZONTALLY ONLY!

DO NOT MOUNT THE 112/NAT OR 108/NAT VERTICALLY. MOU NT ONLY AS

SHOW N BELOW! Note the horizontal orientation of the U-Bracket!

THE ACTUAL BRACKET LOCATION MUST BE AS NOTED ON PAGE

13 IN THE SECTION “BRACKET LOCATION ON GROUT FILLED

BLOCK WALLS”!

Page 15

The 112/NAT and 108/NAT must be mounted by drilling thru the entire grout filled

block as shown below. It is necessary to drill completely thru the grouted block and

run the 3/8”-16 AL6XN all thread thru the block. Large AL6XN backing plates for

structural support are required. The front and back sides of the block are shown in

the images below. The drilled hole should be thoroughly cleaned prior to inserting

the 3/8”-16 AL6XN all threaded rod.

IMPORTANT NOTE: THE HOLE MUST BE DRILLED STRAIGHT. INSURE THAT

THE HOLE IS NOT DRILLED AT AN ANGLE. THE NORD-LOCK WASHERS AND

NUTS MUST BE F LAT AND PARALLEL W ITH BOTH TH E U BRACKET AND

BACKING PLATES FOR THE NORD LOCK WASHERS TO FUNCTION

PROPERLY. INSURE THAT THE HOLE IS NOT DRILLED AT AN ANGLE!

Consult with someone with experience drilling into grout filled block walls!

The front side is shown in the image below. This image shows the block wall and

NAT U-bracket.

15

SEE PAGE 13 FOR PROPER LOCATION OF THE BRACKET ON THE WALL IN

THE SECTION LABELED “BRACKET LOCATION ON GROUT FIL LED BLOCK

WALLS”!

The rear side of the mounting configuration is shown in the image below. Note the

required use of the large AL6XN “backing plates”. These plates MUST be used.

BACKING PLATE LOCATION NOTE: Insure that the backing plates touch a single

block only! Do not allow the backing plates to bridge across to a second CMU block!

AL6XN backing plates on “rear” section

Page 16

16

A side view of the assembly is shown below. NOTE: The silicone sealing caulk is not

shown on this image but is required for this assembly.

MOUNT ON GROUT FILLED BLOCKS ONLY!

An image of the Nord-Lock washer set is shown below. Note the two parts of each

washer set and the orientation of the washer parts. Add it iona l inform ation for the

Nord-Lock washers may be found on the One Systems web site in the Natatorium

section of the Documents section under “Tech papers/Install guides”.

The image below shows the location of the silicone caulk.

NOTE: USE ONLY BOSS 801 SILICONE. DO NOT SUBSTITUT E ANY OTHER

MATERIAL OR ANY OTHER BRAND. USE BOSS 801 SILICONE ONLY!

The application of the Boss 801 silicone is the final step of the mounting process.

Apply the Silicone to the proper location AFTER the U-bracket and backing plates

have been installed and tightened to the specified torque. Pages 19 thru 21 describe

the installation of the 112/NAT and pages 22 thru 24 describe the installat ion of the

108/NAT. DO NOT proceed to these pages yet. It is necessary to continue reading

the information below prior to beginning the actual bracke t instal lation.

Apply a generous bead of the Boss 801 silicone caulk around the OUTSIDE

perimeter of the NAT U bracket and the block wall. Also apply a generous bead of

Boss 801 silicone caulk around the OUTSIDE perimeter the AL6XN backing plates

and the wall as shown below.

Page 17

NOTE: DO NOT APPLY TH E BOSS 801 SILICONE BETWEEN THE U BRACKET

AND THE WALL OR BETWEEN THE BACKIN G PLATE AND THE WALL. THE

SILICONE BEAD SHOULD BE APPLIED AROUND THE PERIMETER ONLY!

17

MOUNT ON GROUT FILLED BLOCKS ONLY!

Page 18

18

The image below illustrates the location of the Boss 801 silicone (shown

in blue color). The entire perimeter should be caulked. Do not apply the

silicone between the U-bracket and the wall or the backing plate and the

wall.

Note the location of the silicone beads shown in blue above. The correct location

forms a fillet as shown above. Do not apply between the wall and the U-bracket or

wall and backing plate.

The U-Bracket side includes one U-bracket, two AL6XN nuts, two Nord-Lock

washers, and a bead of Boss 801 silicone caulk.

The rear side consists of two AL6XN backing plates, two AL6XN nuts, two Nord-Lock

washers, and two beads of Boss 801 silicone caulk (one bead aroun d each backing

plate).

There are ONLY two AL6XN all thread rods used in the assembly, ONE per side

only!

NOTE: All of the i n for m a ti o n fr om pa ge 13 t hru page 18 applies to

BOTH the 112/NAT and 108/NAT. The additiona l informatio n fo u nd

below in pages 19 thru 21 is specific to the 112/NAT. The

information found below in pages 22 thru 24 is specific to th e

108/NAT.

THE INFORMATION ON PAGES 13 THRU 18 MUST BE READ

BEFORE PROCEEDING TO THE SPECIFIC BRACKET

INSTALLATION SECTIONS!

Page 19

19

MOUNTING THE 112/NAT

NOTE: It is important to properly locate the NAT U-bracket on

the block wall. The 112/NAT and 108/NAT each require a

different mounting location relative to the concrete block cells.

The drilled thru hole must NOT be located near the edges of

the block or in the grout between the blocks. See the section on

page 13,

WALLS

“BRACKET LOCATION ON GROUT FILLED BLOCK

” for additional details.

NOTE: MOUNTING ON HOLLOW CORE BLOCK IS NO T

PERMTTED! DO NOT MOUNT ON HOLLOW CORE BLOCK!

MOUNT ON GROUT FILLED BLOCK ONLY!

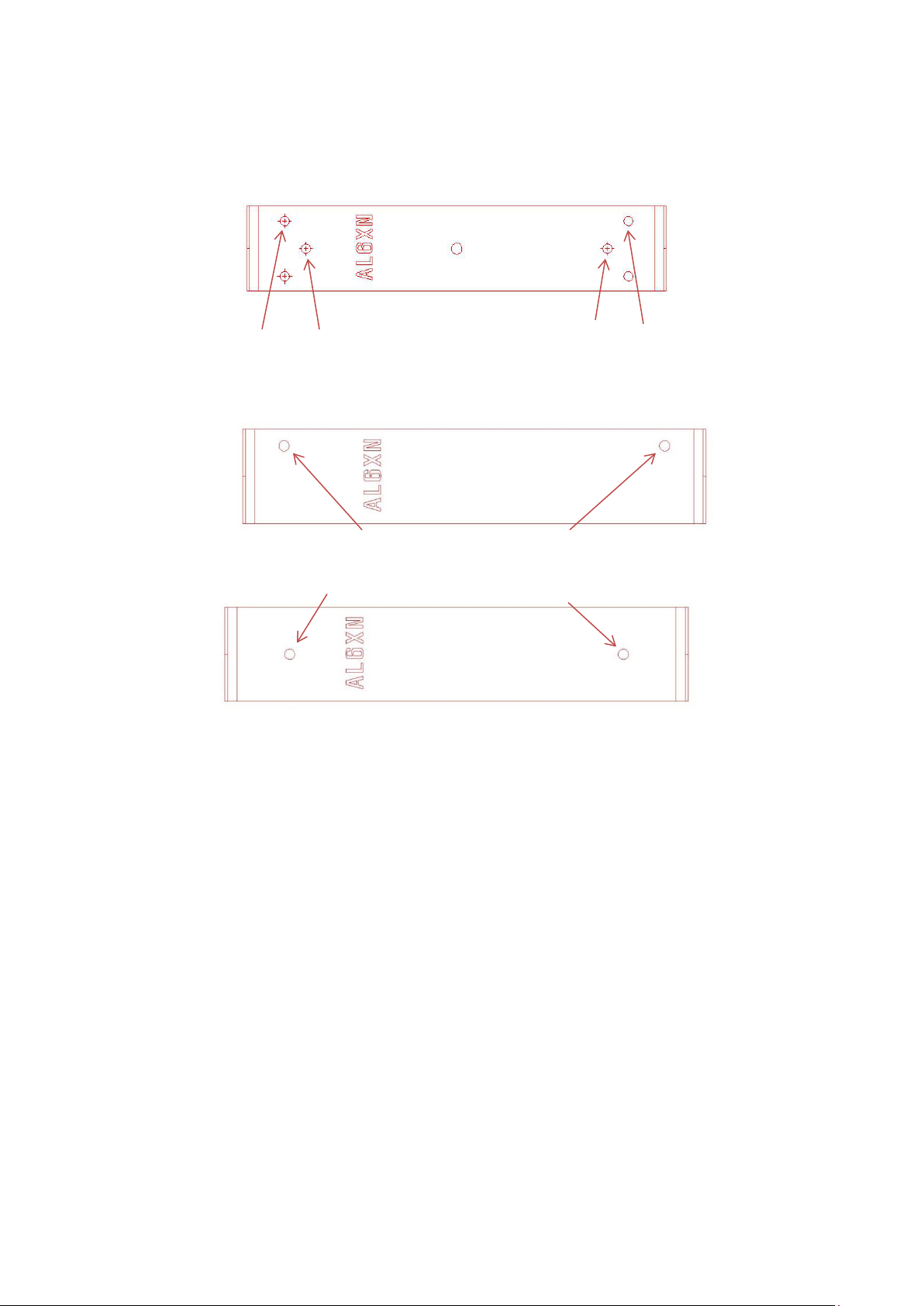

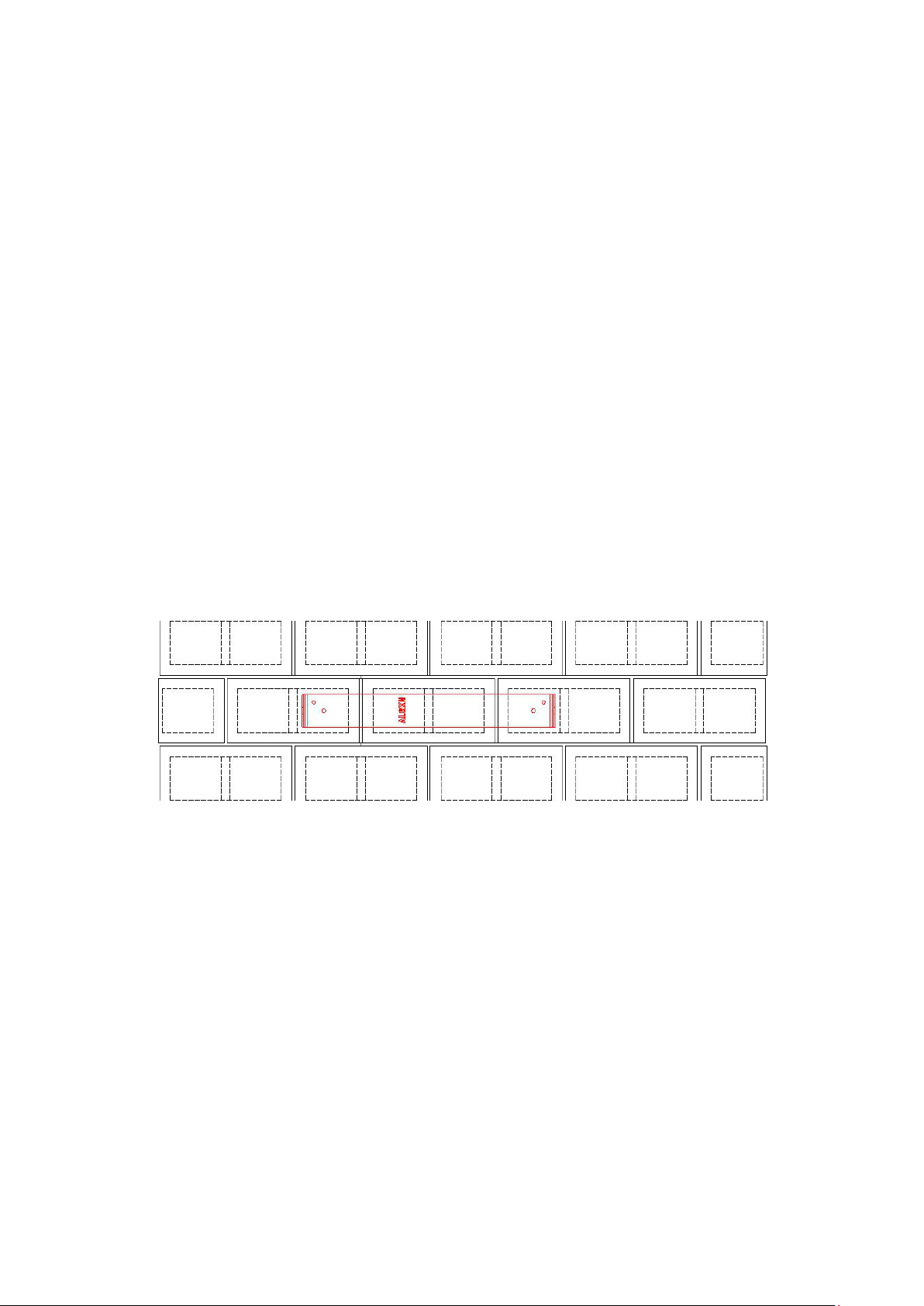

NOTE: Only certain holes on the U-bracket may be used and

only horizontal mounting is permitted. Drill only one mounting

hole per side.

Use ONLY one hole per side. Use either of the holes shown BUT not both holes.

NOTE: DO NOT DRILL MORE THEN ONE HOLE PER SIDE!

The images below show the mounting holes allowed.

Use these two holes ONLY!

OR

Alternately these two holes ONLY!

Page 20

20

The required hole size is 1/2 inches (12.7mm). Drill completely thru the concrete

block. Use a rotary drill only! (One Systems does not supply this 1/2” masonry drill)

NOTE: Avoid drilling into rebar. Rebar locators may be rented from

many sources to determine the location of rebar in the concrete block.

IMPORTANT NOTE: THE HOLE MUST BE DRILLED STRAIGHT. INSURE THAT

THE HOLE IS NOT DRILLED AT AN ANGLE. THE NORD-LOCK WASHERS AND

NUTS MUST BE FLAT AND PARALLEL WITH BOTH THE U BRACKET AND

BACKING PLATES FOR THE NORD LOCK WASHERS TO FUNCTION

PROPERLY. INSURE THAT THE HOL E IS NOT DRILLED AT AN ANGLE!

Consult with someone with experience drilling into grout filled block walls!

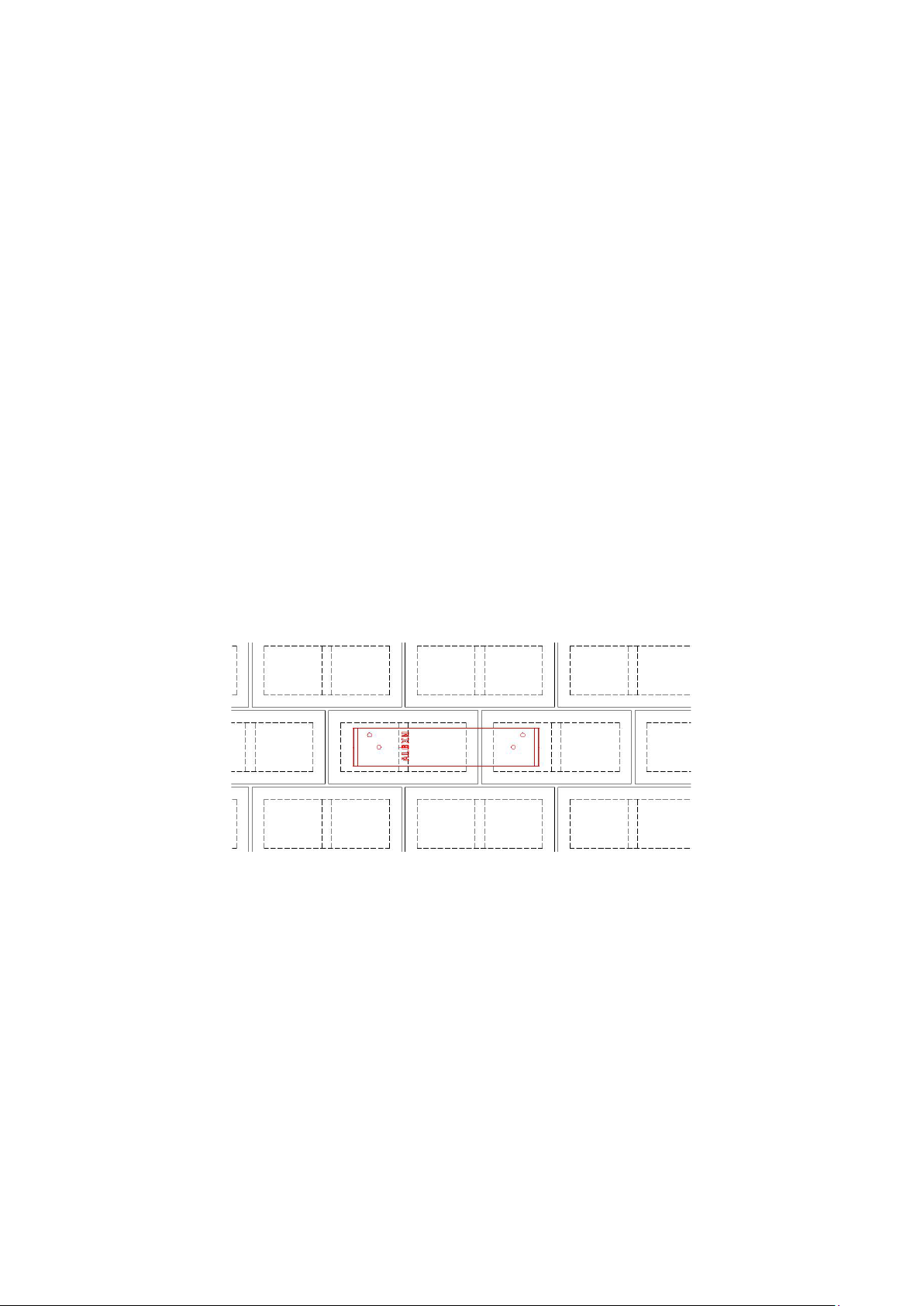

The location of the holes in the blocks (one per side) is shown below. The two holes

shown per side only represent the allowed mounting locations. ONLY one hole

per side shou ld be dr ill ed!

NOTE: Please note the location of the bracket relative to the structure of the blocks.

The 1/2” mounting holes (only one per side) must NOT be drilled between the

blocks. Insure that the holes are drilled in the block “cores” only and away from the

block vertical members!

Please note in the image above how the 112/NAT U-bracket spans across 3

individual concrete blocks. The dashed lines represent the internal structure of the

individual blocks. Only drill the holes in the “core” areas as shown above!

NOTE: It is critical to note the lo catio n of the U-bracket relative to the

individual blocks when mounting the 112/NAT.

When tightening the nuts a torque of 21 ft. lbs (28.5Nm) should be

used.

washer pairs before tightening to minimize settlements. KEEP BOTH NUTS

SECURED WHILE TIGHTENING!

NOTE THE APPR OXIMATE LOCATION OF THE BACKING PLATES ON PAG E 21.

When turning the nuts turn both nuts in order to close the cams on both

Page 21

21

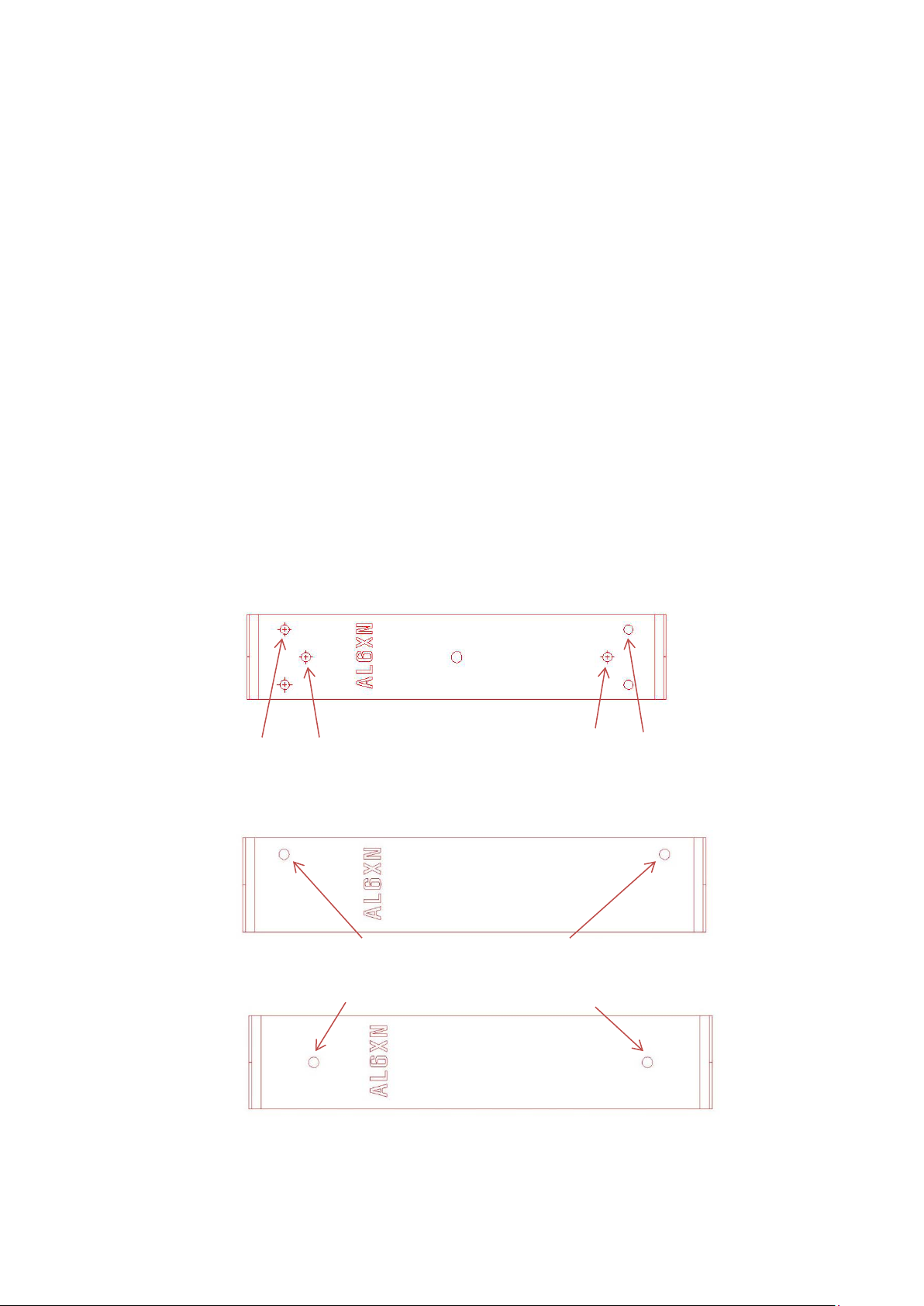

The image below shows the rear of the block wall with the approximate location of

the rear AL6XN backing plates. The backing plates are shown in red.

Approximate location of 112/NAT rear backing plates on grout filled block wall.

BACKING PLATE LOCATION NOTE: Insure that the backing plates touch a single

block only! Do not allow the backing plates to bridge across to a second CMU block!

All parts except the Boss 801 silicone are available from One Systems.

To mount either a 112/NAT the following parts are required:

2 ea. NASH1009010A 3/8”-16 AL6XN all thread

2 ea. NASH 1009011A Backing plate

4 ea. NASH1009006A Nord-Lock 3-8inSPSS-254 washer sets (each set

consists of two parts bonded together!)

4 ea. NASH1009002A 3/8”-16 AL6XN nuts

1 ea. Boss 801 silicone caulk (contact Boss at 1 800 928 2677 for local distributors

or sources. Call this number for International sources as well.)

Page 22

22

MOUNTING THE 108/NAT

NOTE: MOUNTING ON HOLLOW CORE BLOCK IS NO T

PERMTTED! DO NOT MOUNT ON HOLLOW CORE BLOCK!

MOUNT ON GROUT FILLED BLOCK ONLY!

NOTE: It is important to properly locat e the NAT U-bracket on

the block wall. The 112/NAT and 108/NAT each require a

different mounting location relative to the concrete block cells.

The drilled thru hole must NOT be located near the edges of

the block or in the grout between the blocks. See the section on

page 13,

WALLS

“BRACKET LOCATION ON GROUT FILLED BLOCK

” for additional details.

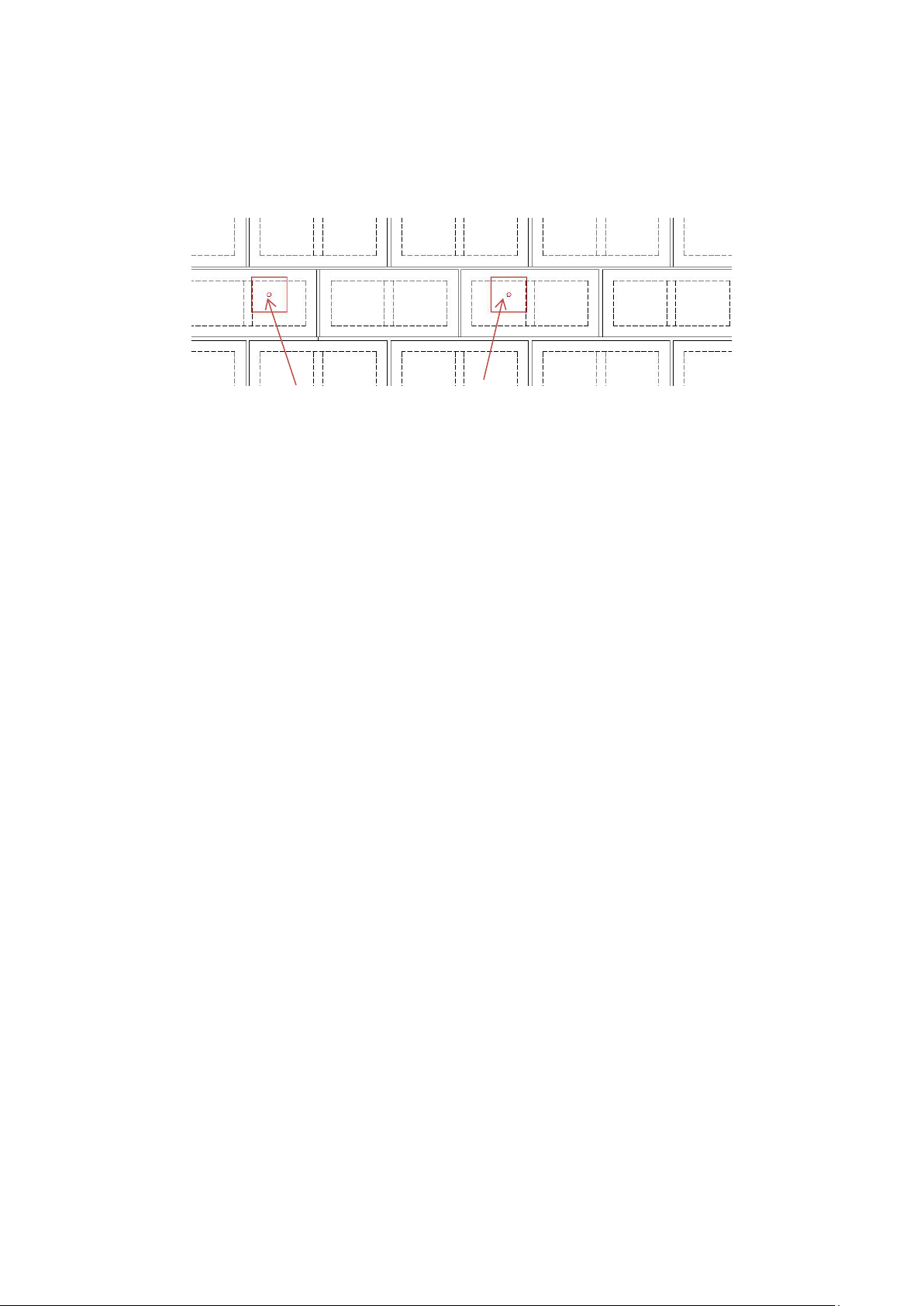

NOTE: Only certain holes on the U-bracket may be used and

ONLY horizontal mounting is permitted. Dril l only ONE

mounting hole per side.

Use ONLY one hole per side. Use either of the holes shown BUT not both holes.

NOTE: DO NOT DRILL MORE THEN ONE HOLE PER SIDE!

The images below show the mounting holes allowed.

Use these two holes ONLY!

OR

Alternately these two holes ONLY!

Page 23

23

The required hole s ize is 1/2 inches (12.7mm). Drill completely thru the concrete

block. Use a rotary drill only! (One Systems does not supply he 1/2” masonry drill).

NOTE: Avoid drilling into rebar. Rebar locators may be rented from

many sources to determine the location of rebar in the concrete block.

IMPORTANT NOTE: THE HOLE MUST BE DRILLED STRAIGHT. INSURE THAT

THE HOLE IS NOT DRILLED AT AN ANGLE. THE NORD-LOCK WASHERS AND

NUTS MUST BE FLAT AND PARALLEL WITH BOTH THE U BRACKET AND

BACKING PLATES FOR THE NORD LOCK WASHERS TO FUNCTION

PROPERLY. INSURE THAT THE HOLE IS NOT DRILLED AT AN ANGLE!

Consult with someone with experience drilling into grout filled block walls!

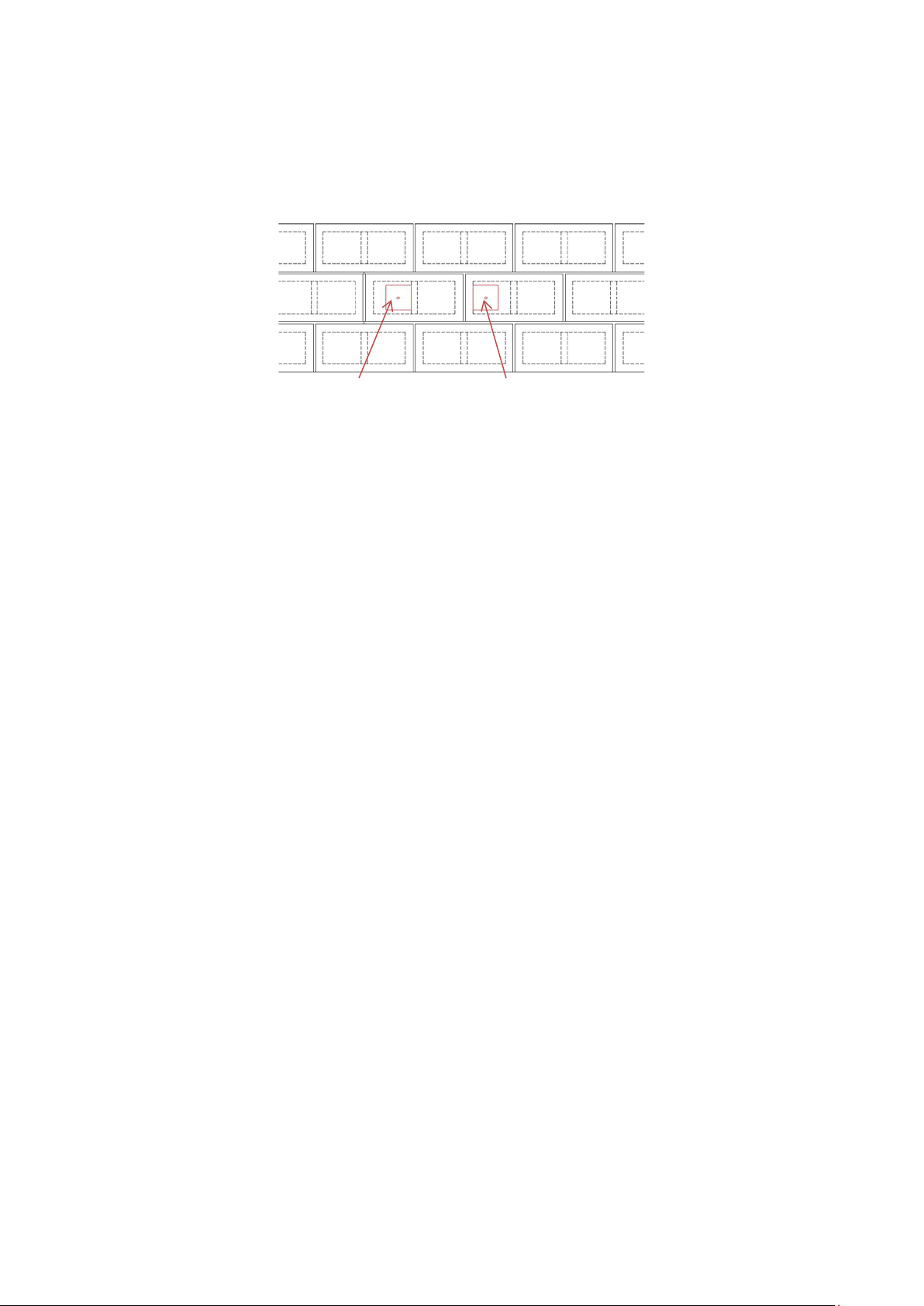

The location of the holes in the blocks (one per side) is shown below.

The two holes shown per side in the image below only rep resent the allow ed

mounting locations. ONLY one hole per side should be drilled!

NOTE: Please note the location of the bracket relative to the structure of the blocks.

The 1/2” mounting holes (only one per side) must NOT be drilled into the grout

between the blocks. Insure that the holes are drilled in the block “cores” only and

away from the block vertical members!

Please note in the image above how the 108/NAT U-Bracket spans across 2

individual concrete blocks. The dashed lines represent the internal structure of the

individual blocks. Only drill the holes in the “core” areas as shown above!

NOTE: It is critical to note the location of the U-Bracket relative to the

individual blocks when mounting the 108/NAT.

When tightening the nuts a torque of 21 ft. lb. (28.5Nm) should be

used.

washer pairs before tightening to minimize settlements. KEEP BOTH NUTS

SECURED WHILE TIGHTENING!

NOTE THE APPR OXIMATE LOCATION OF THE BACKING PLATES ON PAG E 24.

When turning the nuts turn both nuts in order to close the cams on both

Page 24

24

The image below shows the rear of the block wall with the approximate location of

the rear AL6XN backing plates. The backing plates are shown in red.

Approximate location of 108/NAT rear backing plates on grout filled block wall.

BACKING PLATE LOCATION NOTE: Insure that the backing plates touch a single

block only! Do not allow the backing plates to bridge across to a second CMU block!

All parts except the Boss 801 silicone are available from One Systems.

To mount either a 108/NAT the following parts are required:

2 ea. NASH1009010A 3/8”-16 AL6XN all thread

2 ea. NASH 1009011A Backing plate

4 ea. NASH1009006A Nord-Lock 3-8inSPSS-254 washer sets (each set

consists of two parts bonded together!)

4 ea. NASH1009002A 3/8”-16 AL6XN nuts

1 ea. Boss 801 silicone caulk (contact Boss at 1 800 928 2677 for local distributors

or sources). Call this number for International distributors as well.)

Page 25

25

108IM/NAT

The 108IM/NAT features an 8” ( 20 3m m ) low fre qu enc y dr i v er and an ETS bas e d hi gh

frequency compression driver. The 108IM/NAT HF driver is a very high performance and

medium for m at des i g n. T he 1 08IM/NAT is supplie d with two high fr eq uency horn s , bot h of

which are ful l y rotatabl e and interchangeable. The ETS-64 is a 60 degree by 40 degree

wave guide and is mounted in the enclosure as supplied by the factory. The 108IM/NAT also

includes an ET S-105/60 hor n that feat ur es a 10 5 de gr ee by 60 degr ee aco us ti cal radi ation

pattern . Th e pr ocedure for ch a ngi n g the high frequency horns is found on the One Systems

web site in the documentation section under the “tech papers and install guides” tab. (One

Systems Interchangeable High Frequency Horns (For 108IM loudspeaker).

The 108IM/NAT is a high performance system specifically designed for use in indoor

swimm i ng pool envi r o nm e nt s. The desig n features a peak power ha ndl ing ratin g o f 80 0

watts and is av ailable in an 8 ohm (lo Z) confi gur a tion only. There ar e only tw o m ou nti ng

points (AL-6XN) and the 108/NAT may be suspended using the supplied “U” bracket only.

(Note: there is a third point on the rear of the enclosure for use as a secondary safety.)

The 108IM/NAT is supplied with an external weather cover and IP68 gland nut for simple

wiring. The input is via a barrier strip. The enclosure is available in white color.

The 108IM/NAT is a closed box design. This acoustic configuration allows for simple low

frequency equalization using mixer strip EQ or other shelving style filters.

112IM/NAT

The 112IM/NAT features a 12” (305mm) low frequency driver and an ET based large format

high frequency compressi o n dr i ver . T he 11 2IM/NAT HF driver is a very high performance

large format design. The 112IM/NAT is supplied with a high frequency horn that is fully

rotatable and interchangeable. The ET64 is a 60 degree by 40 degree wave guide and is

mounted in the enclosure as supplied by the factory. The 112IM/NAT can als o be fitted with

the ET-105/60 horn that features a 105 degree by 60 degree acoustical radiation pattern (the

ET-105/60 is not incl ud ed in the fac tor y su ppl i e d 112IM/NAT, but may be ordered from One

Systems at no additional charge). T he pr ocedure for changing the high frequency horns is

found on the One Systems web site in the documentation sectio n un der t h e “tech papers

and install guides” tab (One Systems Interchangeable High Frequency Horns for 112IM,

115TW and 11 5RW horns lou dsp eakers) . This same procedure should be followed for the

112IM/NAT.

The 112IM/NAT is a high performance system specifically designed for use in indoor

swimm i ng pool envi r o nm e nt s. The desig n features a peak power ha ndl ing ratin g o f 32 00

watts and is av ailable in an 8-ohm (lo Z) configuration only. There are only two mounting

points (AL-6XN stainless steel) and the 112IM/NAT may be suspended using the supplied Ubracket onl y .( Note: there is a third point on the rear of the enclosure for use as a secondary

safety.) The enclosure is only available in white color.

The 112IM/NAT is supplied with an external weather cover and IP68 gland nut for simple

wiring. The input is via a barrier strip.

Page 26

The 112IM/NAT is a closed box design. This acoustic configuration allows for simple low

frequency equalization using mixer strip EQ or other shelving style filters.

108IM/NAT Features and Benefits

Designed for use in Natatorium (Indoor Swimming Pool) Environments

8-Inch Two-Way High-Performance Sealed Enclosure Design

Two Fully Rotatable and Interchangeable High Frequency Horns

Available in White Finish

Low Impedance (8-Ohm) High Pow er Design

U-bracket Suspension Suppli ed

108IM/NAT Specifications

26

Frequency Response 65Hz – 16kHz

Coverage Pattern 60 X 40 (ETS60/40)

105 X 60 (ETS105/60)

Passive Crossover 2000Hz (ET S 60x 40)

1600Hz (ETS 10 5x60)

Inputs Barrier Strip (Full Range Only)

System Sensitivity 92dB (1 watt - 1 meter)

Power Handling 200 watts continuous

400 watts program

800 watts peak

Nominal Impedance 8-ohms

Low Frequency One Systems ONE8-134 Woofer

High Frequency One Systems ETS Compression Driver

Suspension/Mounting Points 2 Each U-bracket mount only (Supplied) 5/16”

1 Safety Point on enclosure rear

Enclosure Dimensions 483.8mm x 243mm x 271mm

19” x 9.6” x 10.7”

Weight 16.5kg (36.3 lb.) including U Bracket

Optional Accessories No Optional Acces s or i es All owed

Page 27

112IM/N AT Features and Benefits

Designed for use in Natatorium (Indoor Swimming Pool) Environments

12 Inch Two Way High Performance Sealed Enclosure Design

Fully Rotatable and Interchangeable High Frequency Horns

Available in White Finish

Low Impedance (8-Ohm) High Power Design

U-bracket Suspension Suppli ed

112IM/NAT Specifications

Frequency Response 60Hz – 16kHz

Coverage Pattern 60 X 40 (ETS6 0/ 40)

Available 105 X 60 (E TS105/60 )

Passive Crossover 1800Hz (ET 60x40)

1300Hz (ET 105x60)

Inputs Barrier Strip (Full Range Only)

System Sensitivity 96dB (1 watt – 1 meter)

Power Handling 800 watts continuous

1600 watts program

3200 watts peak

Nominal Impedance 8-ohms

Low Frequency ONE SYSTEMS 12I/O-1 Woofer

High Frequency ONE SYSTEMS ET-1F Compression Driver

Suspension/Mounting Points 2 Each U-bracket mount only (Supplied) 3/8”

1 Safety Point on Enclosure rear

Enclosure Dimensions 749mm x 368mm x 414mm

29.5” x 14.5” x 16 .3”

Weight 36.6kg (80.7 lb.) including U-bracket

Optional Accessories No Optional Accessories Allowed

27

Loading...

Loading...