Oneida Air Systems PRO SERIES 2000 User Manual

Dust Collector

- Baldor

Shown with optional

bolt together Angle Iron

stand and optional 55

gal. steel drum.

*Models may

vary sligthly in

appearance.

Oneida Air Systems, Inc. 1001 West Fayette St., Syracuse, N.Y. 13204

Phone 1-800-732-4065 315-476-5151 Fax 315-476-5044 www.oneida-air.com

Thank You for Choosing an Oneida Air Systems Product!

OAS manufactures and sells dust collection equipment only. Our qualified technicians and

sales staff are available 7:30am - 6:00pm EST Mon. - Thur. and 7:30am - 5:00pm EST Fri. to

answer any questions concerning OAS products and dust collection. Call for ductwork design

and ductwork quotes, including system pricing and shipping cost.

Read the entire Owners Manual before installing or operating system!

Table of Contents

Page

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

X.

XI.

System Start-Up Information

Commercial Configurations

General Specifications & Fan Performance Curves

Dimensions

General Assembly

General Assembly Instructions

Bracket Assembly

Filter Assembly

Filter Maintenance

Filter Efficiency Gauge Mounting Instructions

Directions for Cleaning External Filter

2

3

4

5

6

7

8

9

10

11

12

XII.

XIII.

XIV.

XV.

XVI.

XVII.

XVIII.

XVIV.

Pro 2000 Owners Manual

Fan / Blower Wiring Diagram

Troubleshooting

Fire Hazards -

Terms and Conditions

Stand Assembly

Accessories

Fan Motor Maintenance

Remote Wiring Diagram

Read Before Installing System

c

O.A.S. 2007

13

14

15

16

17

18

19

20

1

I. System Start-Up Information

1. Read the installation and maintenance instructions as well as the recommended

safety practices in this manual.

2. Install Ductwork completely before operating collector:

A.) Seal ductwork with silicone sealant or duct tape.

B.) Have Dust Bin in place and sealed.

3. Have licensed electrician wire Fan / Blower according to wire diagram on pg. 13

in this owners manual.

4. Have licensed electrician check current draw on motor with all gates open. Current

draw should not exceed maximum motor amperage. (OAS is not responsible for

damage to motors caused by improper installation, wiring or failure to follow these

directions.)

Caution

The Direct Drive Fan / Blower makes the system top heavy!

Use extreme care when setting the unit up!

Warning

Do not operate Fan / Blower unless Cyclone and Dust Bin

are in place. Motor will over heat!

Warning

Check amperage draw during operation with all blast gates

open. Make certain amperage is not outside operating limit

indicated on motor plate!

Warning

If amperage is too high - shut down immediately!

Pro 2000 Owners Manual

(See troubleshooting section.)

c

O.A.S. 2007

2

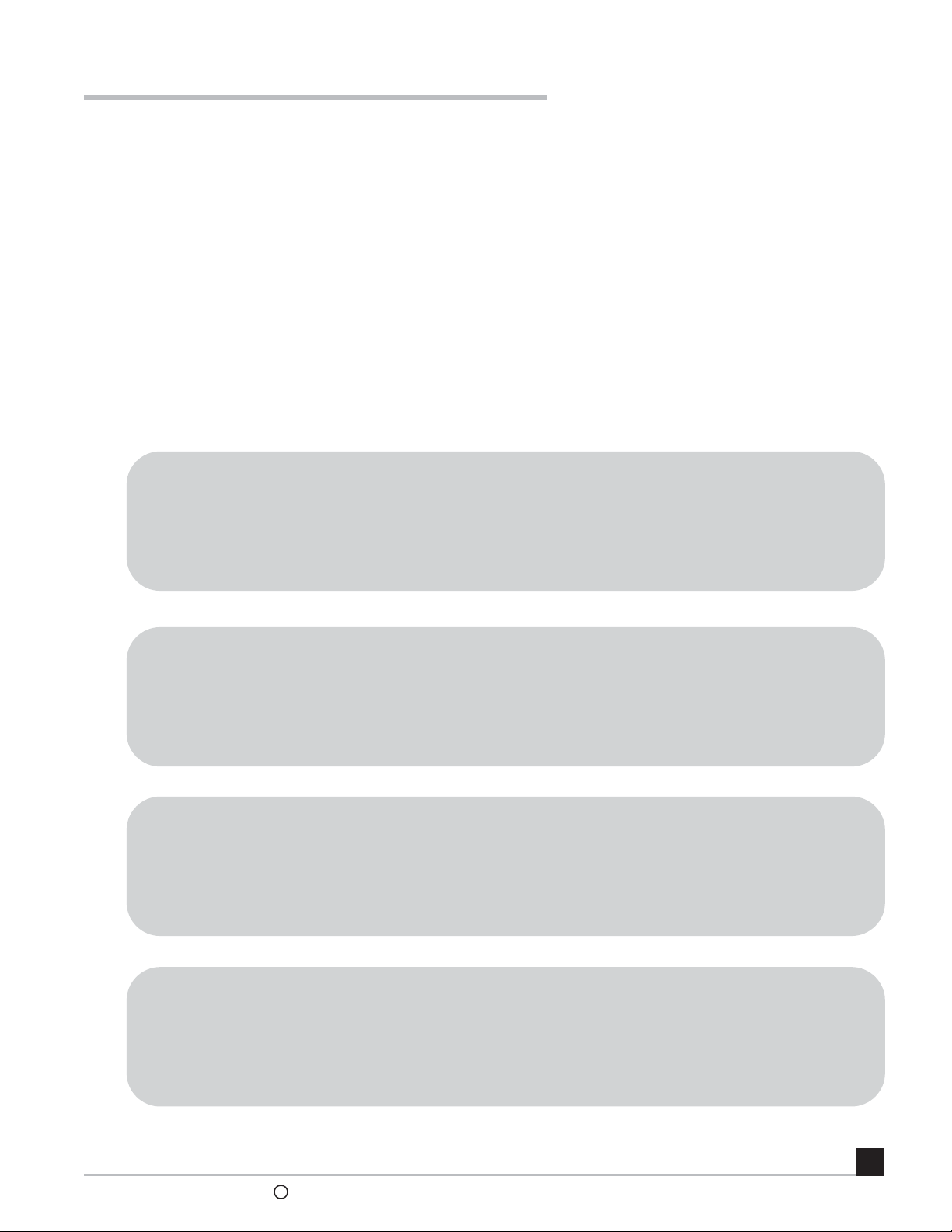

II. Pro Series 2000 Configurations

Caution:

If exhaust air is vented outside you must provide make up / return air.

Flue gases (carbon monoxide) can be drawn into the shop from furnaces,

water heaters or other appliances.

1. External Cartridge Filter -

Cartridge Filter Media

1 Pleated Spun-Bonded Cartridge Filter 62 / 130 Sq. Ft.

Accredited, independent lab tested.

Bathed in teflon-like coating for easy dust release.

Captures 99.9% of Test Material from 0.2 - 2 microns.

Included

Wall Bracket

Silencer Included with Filter

Included Square-to-Round Inlet

Silencer

included

w/ Filter

Included Silencer

Do Not Remove

Pro 2000 Owners Manual

Shown with optional

Angle Iron Stand

and optional 55 gal.

steel drum.

c

O.A.S. 2007

Kit Contents:

2

3

1

4

0

5

INCHES W.C.

Gauge

Bracket

8 Ft. Hose and Connection

Included Filter Efficiency Gauge

Included Magnetic Starter

3

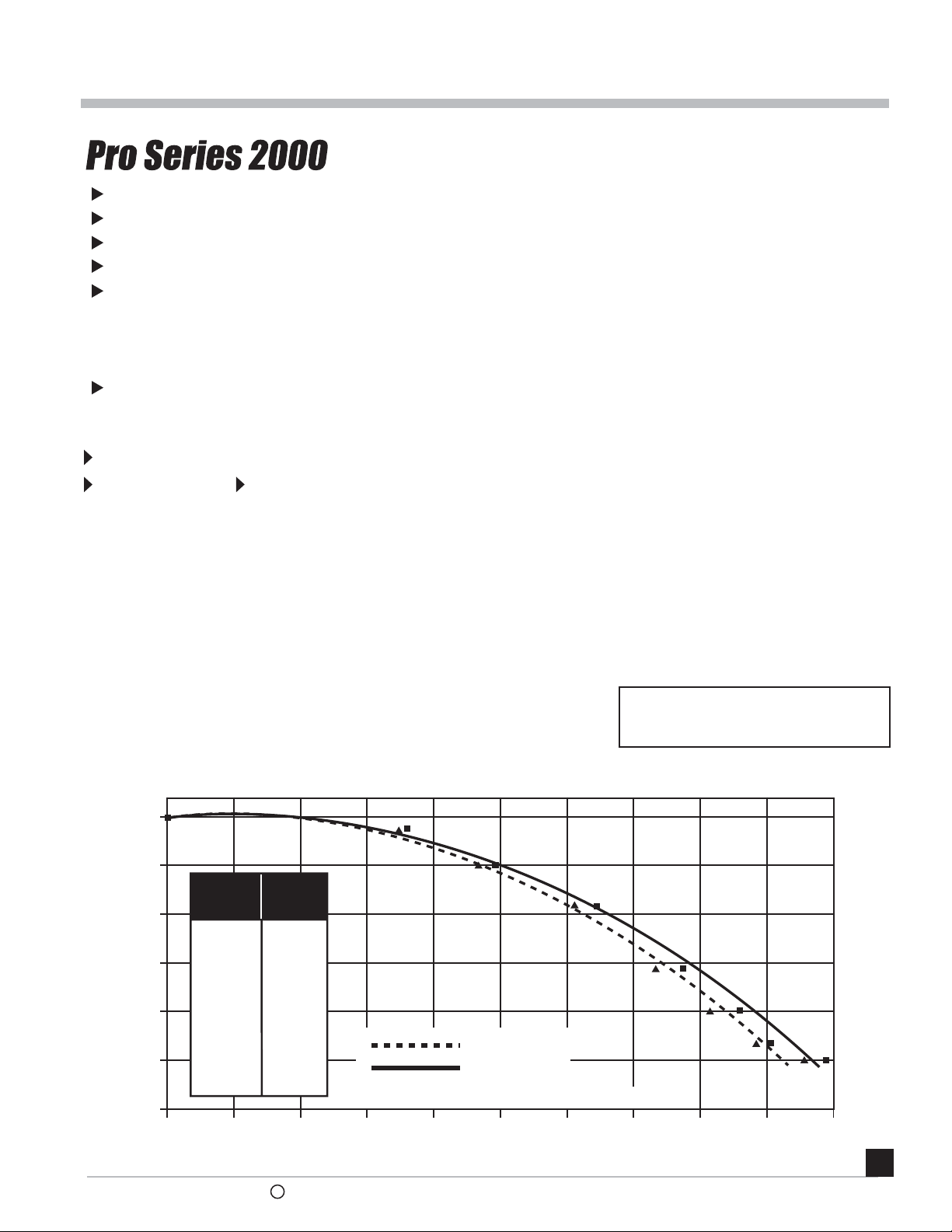

III. General Specifications & Fan Performance Curves

1973 CFM @ 2 SP w/c w/o filter

Full 16 gauge galvanized cyclone & 14 ga. barrel

Rectangular inlet with included Square to Round to 8

Rectangular outlet

Cast aluminum fan wheel

back inclined non-sparking, non-ferrous dynamic, two-planed balanced to ISO 6.3

specifications.

Sound 80 - 82dB @ 10 with Built-in Silencer and Filter

130 Sq. Ft. Filter Media / Spun-Bonded

U.S. Made Baldor / TEFC / Class F / 1.15 SF

Single Phase

5hp Motor

208 - 230V

19.8A

Three Phase

5hp Motor

208 - 230 / 460V

13.6 - 12.4 / 6.2A

System Fan Curve

12

12

10

CFM

8

6

4

2

Static Pressure at Cyclone Inlet

0

Pro 2000 Owners Manual

w/o Filter

1973

1802

1709

1543

1273

987

736

0

0 200 400 600 1000800

SP @

Inlet

2.00

2.75

4.00

5.80

8.10

10.00

11.10

12.00

c

O.A.S. 2007

Static pressure and volume together determine

a fans performance. Several factors, such as

layout of ductwork and diameter of openings,

can affect a fans performance.

Pro Series 2000

11.1

*Fan curves vary slightly with different filter packages.

10

- With Filter

- Without Filter

CFM

1200

8.1

1400 2000

5.8

4

2.75

2

18001600

4

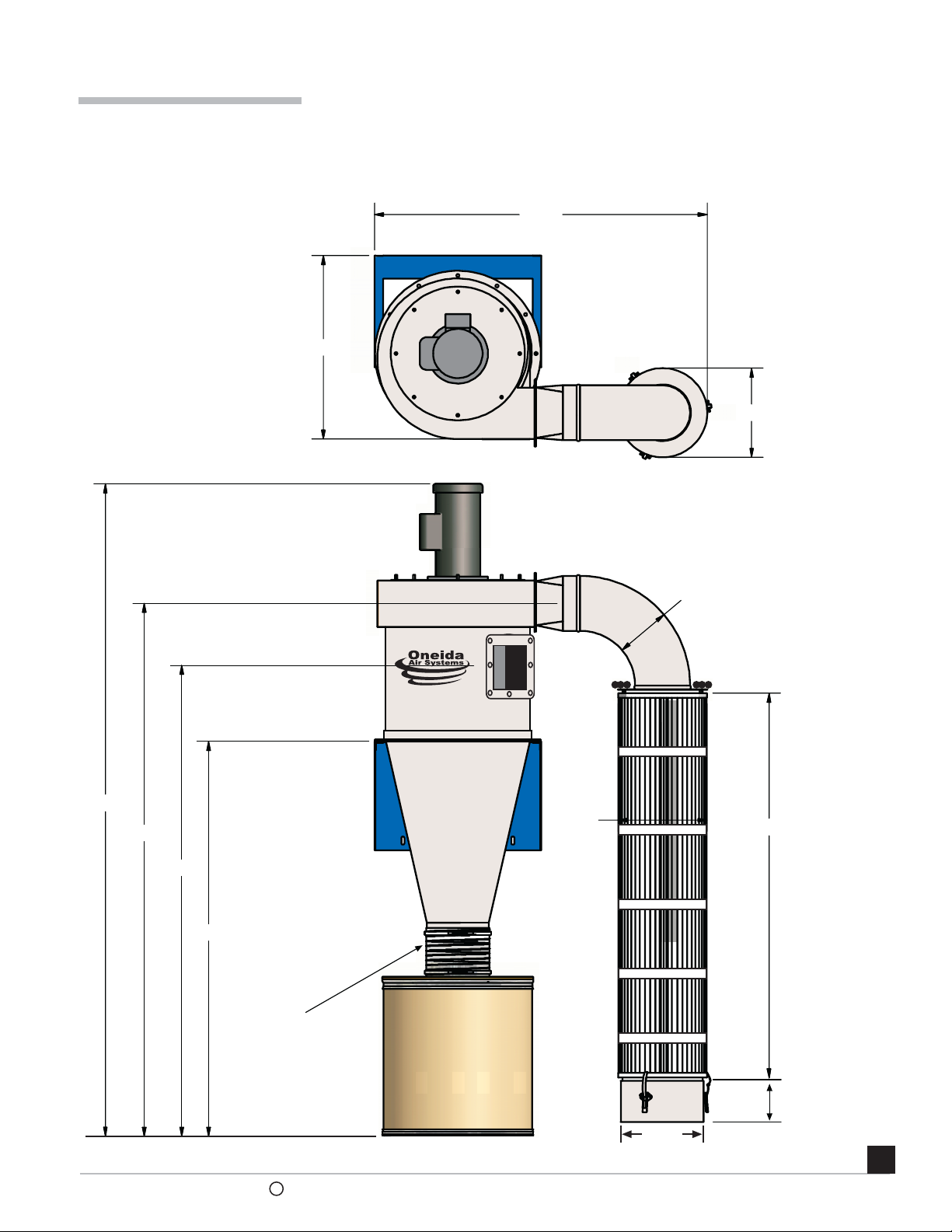

IV. Dimensions

For Minimum Mounting Heights w/ 62 Filter.

*Dimensions subject to slight variation in manufacturing.

53.00

27.00

18.00

00.00

1

81.00

72.00

60.00

Dimensions shown with

5" flex hose between

drum and cone collars

35 Gal Shown

Add 8"for 55 Gal

8.00

18.00

8.00

62.00

Pro 2000 Owners Manual

c

O.A.S. 2007

4.00

16.00

5

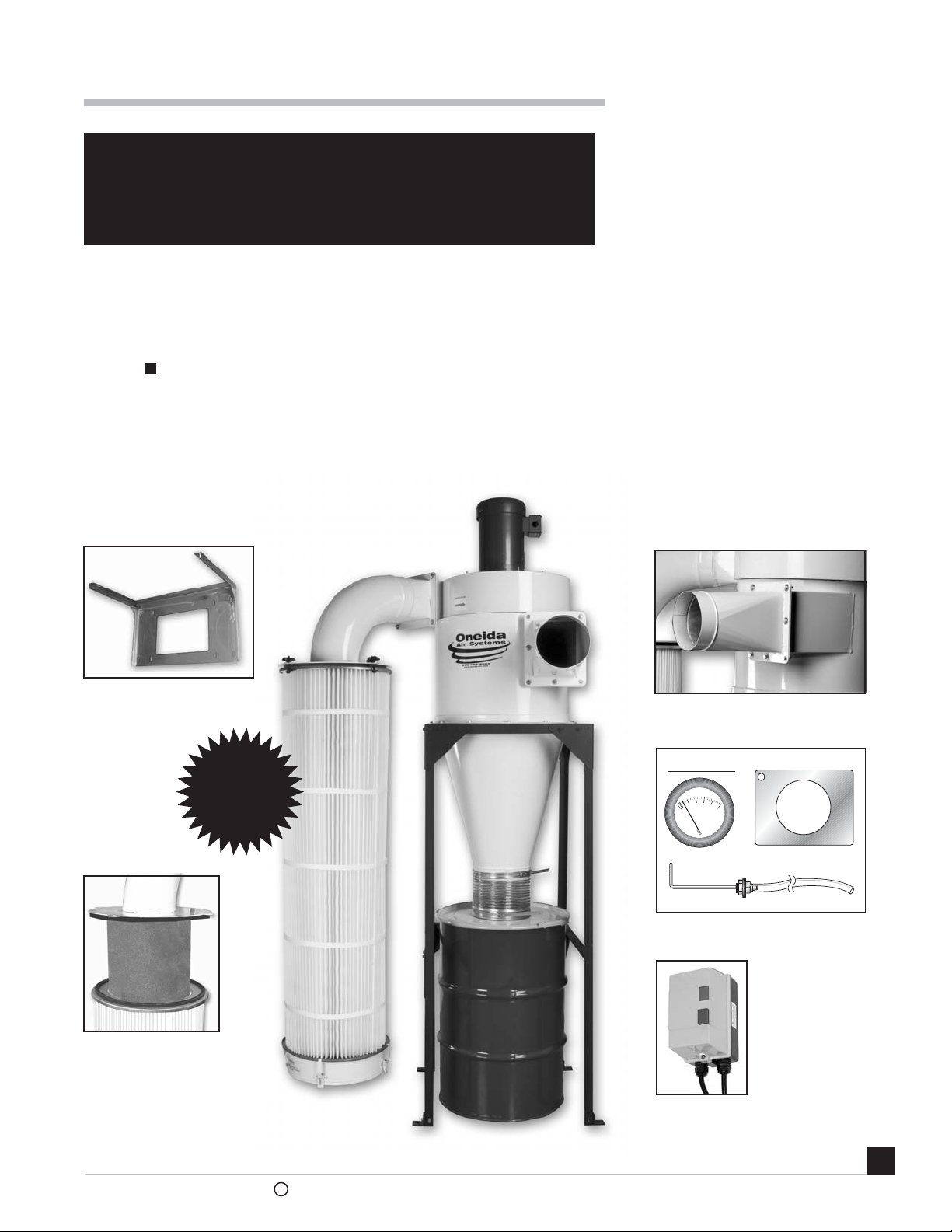

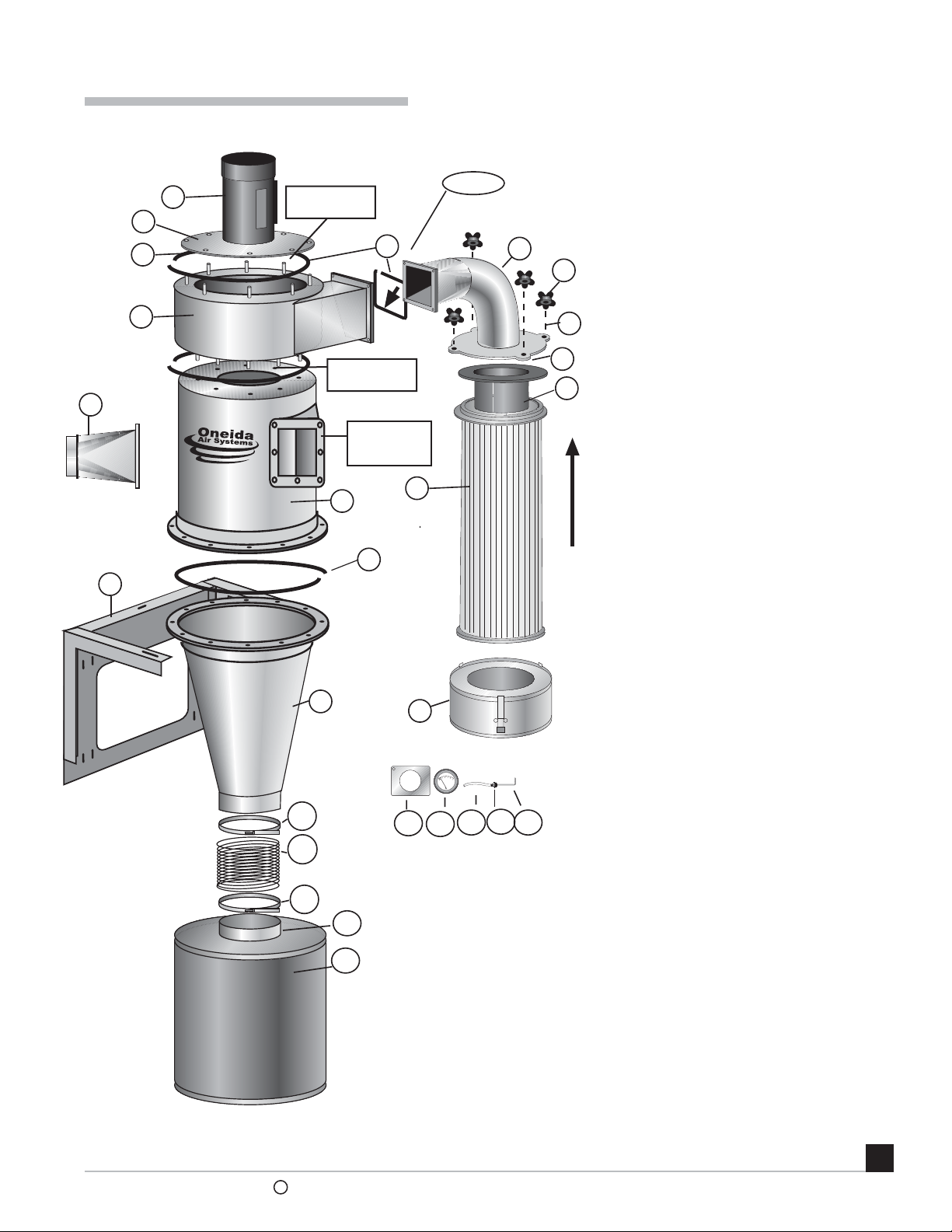

V. General Assembly

XXK200001 - 1 phase XXK200003 - 3 phase

1e

1f

1a

2

12

Square to Round

Connects to Inlet

11

Pro 2000 Owners Manual

Cyclone

Barrel

Cone

(8) 5/16 Washers

(8) 5/16 Nuts

4

13b

13e

13b

c

O.A.S. 2007

f7

(8) 5/16 Washers

(8) 5/16 Nuts

(7) 3/8 x 1 Bolts

(7) 3/8 Washers

(7) 3/8 Nuts

3

f7

14d

Optional Angle Iron Stand

30. Optional 55 gal. Angle Iron Stand Part # STG023055

1. Uprights - SXX000068 (4)

2. Braces - SXX000021 (7)

13a

3. Feet - STX002001 (4)

13c

Stand - Hardware Kit Part # AHX021023

A. (32) - 5/16 Bolts

Part # AFB155190

B. (32) - 5/16 Wiz Nuts

Part # AFT155175

C. (64) 5/16 Flat Washers

Part # AFW180000

7

5d

15 & 15a

2

3

1

4

0

5

INCHES W.C.

14a 14b

14

14c

1. Motor/Blower Assembly BXI012309-1ph - - 3ph

1a. Fan Wheel - BWX159800

Magnetic Starter w/ Remote Option: 1 phase

1b. Motor Starter - AMR221417 1phase only

1c. Cord Connector - WWC027063 1 phase only

1d. Cord Connector Locknut - WCN340000 1 phase only

1e. 5hp Motor BMZ050170 - 1 ph / BMZ050370-3 ph

1f. Motor Plate - RMP002301

Magnetic Starter not factory wired 3 phase

Enclosed contactor with 220v coil - AMC183600

Overload 12-18 amps - AMO121800

Start Stop Push Button - AMP000000

2. Fan Housing - BHX030009

5

3. Cyclone Barrel - SXI002309

5a

4. Cyclone Cone - SCX002309

5. Plenum Assembly for Filter 8 Elbow - FPX010300

5a. Thumb Nut (4) - AFT000001

5b

5b. Cartridge Filter Threaded Clamp (4) - AFX000000

5c

5b1. AFB155180 Bolt 5/16-18 x 2 1/2

5c. Fender Washer 5/16 (4) - AFW170000

6

5d. Dust Pan 4 - FPZ016040

5e. Hardware Kit - AHX000000

f1. (14) 3/8 Washers - AFW190000

f2. (7) 3/8 Wiz Nuts - AFT00004

f3. (7) 3/8 x 1 Bolts - AFS015100

f4. (12) 5/16 x 1 Bolts - AFB155190

f5. (24) 5/16 Washers - AFW180000

f6. (28) 5/16 Wiz Lock Nuts AFT155175

f7. Gasket - RGZ000000 (25)

f8. (3) 3/8 x 1 14 Bolts - AFS0157007

6. Internal Silencer (Pat. Pend.) - BSC180000

7. Filter - 18 Dia. x 62L - FCS186200

8. Owners Manual - ZBM000015

9. Decal - (1) Oneida Logo - ZBC000015

10. Labels

10a. Rotation Label - ZBC000029

10b. Caution / Exhaust Label - ZBS000004

10c. General Caution Label - ZBS000001

10d. Filter Maintenance Label - ZBS000007

10e. Caution / Check Frequently Label - ZBS000006

10f. Caution / Drum Cover Label - ZBS000005

11. Wall Bracket -Standard- SMS30000

12. Square to Round Inlet Transition to 8 dia. - BQX082000

Options for Dust Drums: OKD000000

13. 35 Gal. Fiber Drum Kit (Standard) - SDK351001

13a. Drum Lid w/ 10 Ring - SDX001000

13b. Hose Clamp 12 dia. (2) - ACB120000

13c. 35 Gal. Fiber Drum - SDS350000

13e. Flex Hose (10 dia. x 1) - DHF100000

13. 55 Gal. Fiber Drum Kit - SDK551001

13a. Drum Lid w/ 10 Ring - SDX001000

13b. Hose Clamps 12 (2) - ACB120000

13c. 55 Gal. Fiber Drum - SDS550000

13e. Flex Hose (10dia. x 1) - DHF100000

13. 55 Gal. Steel Drum Kit - SEK551001

13a. Drum Lid w/ 10 Ring - SEX551000

13b. Hose Clamps (2) - ACB120000

13c. 55 Gal. Steel Drum - SES550000

13e. Flex Hose (10 dia. x 1) - DHF100000

14.Filter Efficiency Gauge 0-5 H20 - VRG001005

14a. Vinyl Tubing Clear 5/16 O.D. - VRV003125 (8)

14b. Static Pressure Tip - VRP001875

14c. Mounting Flange for Pitot Tube - VRP010000

14d. Filter Efficiency Gauge Bracket - FXX000000

Optional Fan/Blower Outlet Transitions:

15. Square to 8 dia. For Fan Outlet - BQX308000 Uncrimped

15a. Square to 8 dia. For Fan Outlet - BQX308001 Crimped

6

Loading...

Loading...