Oneida Air Systems 2005c3HP User Manual

3HP

High Vacuum

Dust Collector

Owners Manual

Oneida Air Systems, Inc. 1001 West Fayette St., Syracuse, N.Y. 13204

Phone 1-800-732-4065 315-476-5151 Fax 315-476-5044 www.oneida-air.com

Thank You for Choosing an Oneida Air Systems Product!

OAS manufactures and sells dust collection equipment only. Our qualified technicians and

sales staff are available 7:30am - 6:00pm EST Mon. - Thur. and 7:30am - 5:00pm EST Fri. to

answer any questions concerning OAS products and dust collection. Call for ductwork design

and ductwork quotes, including system pricing and shipping cost.

Read the entire Owners Manual before installing or operating system!

Proudly

Made in

the U.S.A.

Table of Contents

Page

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

System Start-Up Information

Direct Drive Configurations

General Specifications & Fan Performance Curve

Dimensions

Stand Assembly

General Assembly Instructions

Fan / Blower Maintenance

Filter Maintenance

Wire Diagram

2

3

4

5

6

7 - 8

8

9

10

X.

XI.

XII.

XIII.

XIV.

3HP High Vacuum Owners Manual

Accessories

Troubleshooting

Fire Hazards -

Terms and Conditions

Fan Motor Maintenance

Read Before Installing System

c

O.A.S. 2005

11

12

13

14

15

1

I. System Start-Up Information

1. Read the installation and maintenance instructions as well as the recommended

safety practices in this manual.

2. Install Ductwork completely:

A.) Seal ductwork with silicone sealant or duct tape.

B.) Have Dust Bin in place and sealed.

3. Have licensed electrician wire Fan / Blower according to wire diagram in this

owners manual.

4. Have licensed electrician check current draw on motor with all gates open. Current

draw should not exceed maximum motor amperage. (OAS is not responsible for

destroyed motors.)

Caution

The Dust Collector & Fan/Blower is heavy. Handling and

installation should always be performed by experienced and

trained personnel who have experience with rotary equipment.

In addition to the following instructional manual, care should

be taken to ensure compliance with specific safety

requirements mandated by federal, state and local codes.

Warning

Do not operate Fan / Blower without connecting ductwork.

Never operate Fan/Blower without belt and shaft guard in

place. Keep clear of exhaust. Keep hands and objects clear

of inlet and outlet.

Warning

Check amperage draw during operation with all blast gates

open. Make certain amperage is not outside operating limit

indicated on motor plate! If amperage is too high - shut down

immediately! (See Troubleshooting section.)

3HP High Vacuum Owners Manual

c

O.A.S. 2005

2

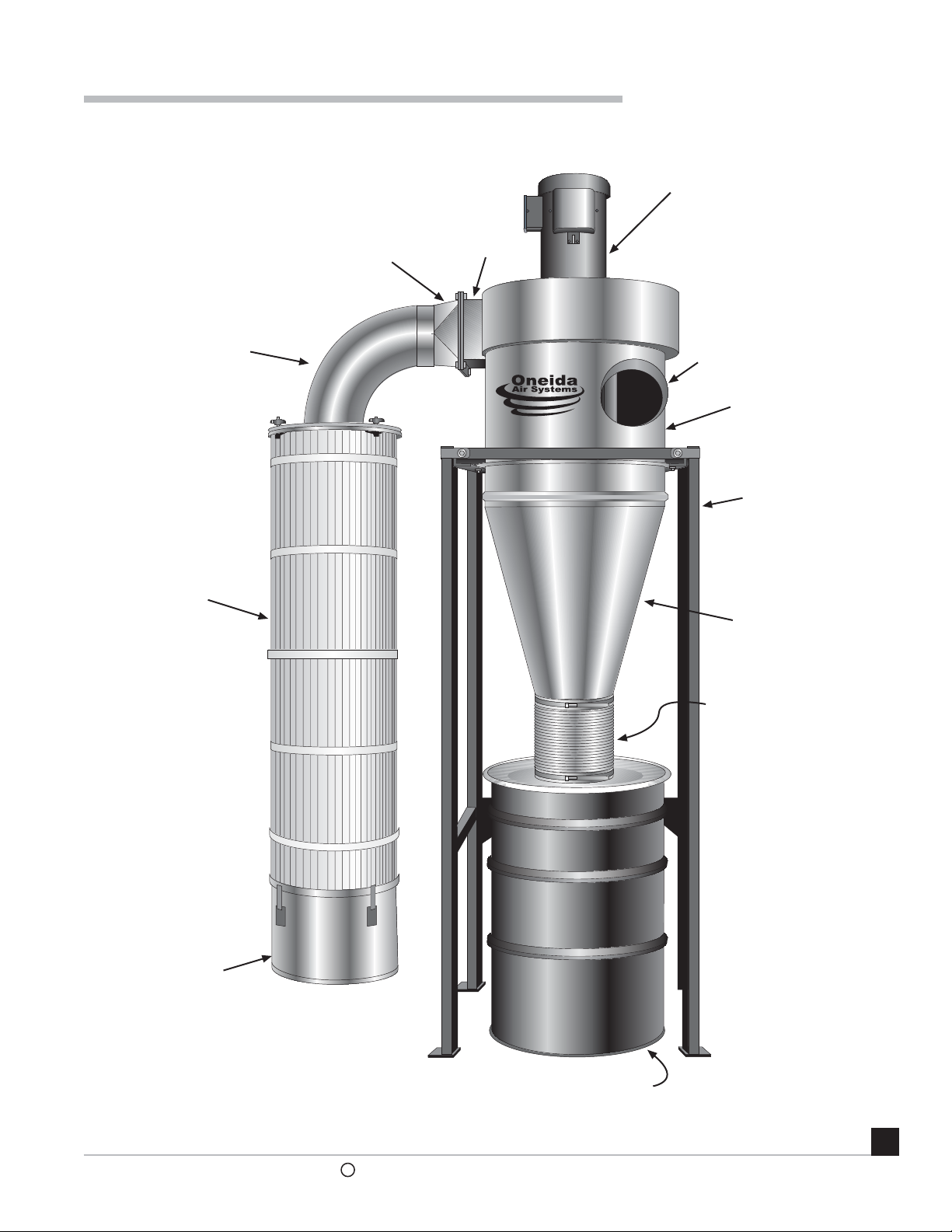

II. 3hp High Vacuum Configuration

3hp Integral

Fan Blower

Square-to-Round

Elbow

Pleated

Cartridge

Filters

(Do not remove

fabric straps

from cartridge.)

Outlet

Inlet

Cyclone

Angle Iron

Stand

Cone

Flex Hose

Removable

Dust

Container

3HP High Vacuum Owners Manual

c

O.A.S. 2005

Removable

55 Gal. Metal

Chip / Dust Bin

3

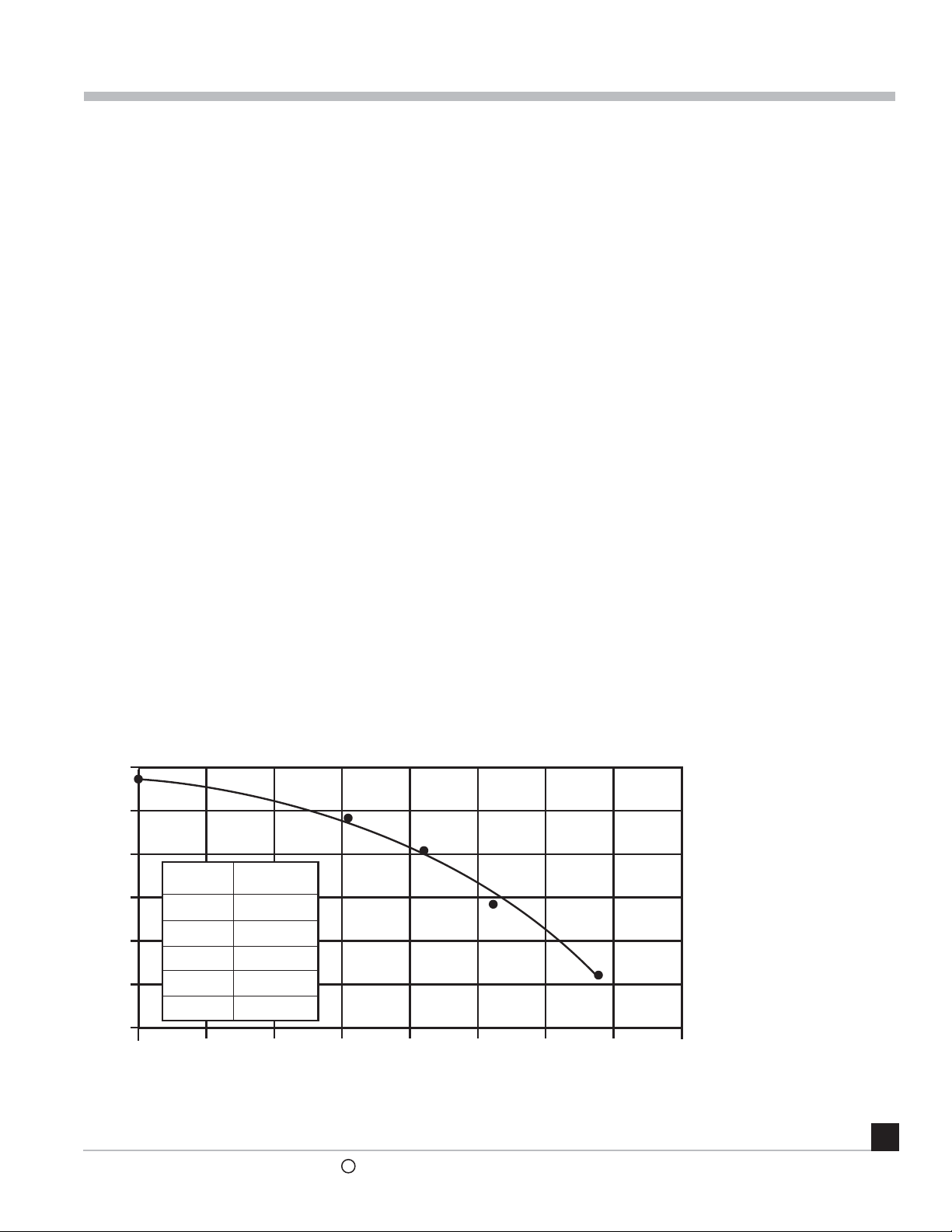

III. General Specifications & Fan Performance Curves

Physical and Electrical Data for 3 hp High Vacuum Unit.

System Performance

3hp - 1342 cfm @ 3.5 SP

Dust Bin

55 Gal. Steel Drums

Large dust bins available

System Dimensions

Height w/ 55 Gal. Drum: 110 1/8

Footprint: 56 x 34

Fan Wheel diameter: 15 Backward Incline design

Cyclone Inlet: 6

Included:

Magnetic Motor Starter

Filter Efficiency Gauge

Integral Fan Blower - 3hp

TEFC 60 Hz Motor - Single Phase

Insulation Class: F4

Voltage: 230

Amperage: 14.5

Made in U.S.A.

External Cartridge Filter

1 Pleated Cartridge - 130 sq. ft.

Spun-Bonded polyester BIA ZH1 / 487 test - Rated C

Captures 99.99% of test material over 20 microns

Captures 99.9% of test material between 0.2 - 2.0 microns @ 11fpm

System Performance Curve

13

12.5

11

9

CFM

7

1342

5

1045

842

3

Static Pressure at Cyclone Inlet

0

0 200 400 600 800 1000 1200 1400 1600

Static pressure and volume together determine a fans performance. Several factors, such as layout of

ductwork and diameter of openings, can affect a fans performance.

3HP High Vacuum Owners Manual

618

0

Static @

Cyclone Inlet

3.5

6.8

9.1

10.9

12.5

10.9

CFM

c

O.A.S. 2005

9.1

6.8

3.5

4

Loading...

Loading...