Oneida Air Systems 10 HP User Manual

10 HP NYB Pulley/Belt Drive

Cyclonic

Dust Collectors

Owners Manual

Oneida Air Systems, Inc. 1001 West Fayette St., Syracuse, N.Y. 13204

Phone 1-800-732-4065 315-476-5151 Fax 315-476-5044 www.oneida-air.com

Thank You for Choosing an Oneida Air Systems Product!

OAS manufactures and sells dust collection equipment only. Our qualified technicians and

sales staff are available 7:30am - 6:00pm EST Mon. - Thur. and 7:30am - 5:00pm EST Fri. to

answer any questions concerning OAS products and dust collection. Call for ductwork design

and ductwork quotes, including system pricing and shipping cost.

Read the entire Owners Manual before installing or operating system!

Proudly

Made in

Table of Contents

the U.S.A.

Page

I.

II.

III.

IV.

V.

VI.

VII.

VIII.

IX.

X.

System Start-Up Information

Pulley Drive Configurations

General Specifications & Fan Performance Curves

Dimensions

Configuration Examples

General Assembly Instructions

External Filter Box Assembly

Wire Diagram

Fan / Blower Maintenance

Accessories

2

3

4

5 - 7

8

9 - 10

11

12

13 - 14

15

XI.

XII.

XIII.

XIV.

XV.

XVI.

10 HP Pulley Drive Owners Manual

Troubleshooting

Fire Hazards - Read Before Installing System

Terms and Conditions

Filter Cleaning Instructions

Optional Filter Efficiency Gauge Mounting Instructions

Supplemental Instructions for Magnetic Motor Starters

c

O.A.S. 2007

16

17

18

19

20

21 - 23

1

I. System Start-Up Information

1. Read the installation and maintenance instructions as well as the recommended

safety practices in this manual.

2. Install Ductwork completely:

A.) Seal ductwork with silicone sealant or duct tape.

B.) Have Dust Bin in place and sealed.

3. Have licensed electrician wire Fan / Blower according to wire diagram in this

owners manual.

4. Have licensed electrician check current draw on motor with all gates open. Current

draw should not exceed maximum motor amperage. (OAS is not responsible for

destroyed motors caused by improper wiring or improper installation.)

Caution

The Dust Collector & Fan/Blower are heavy. Handling and

installation should always be performed by experienced and

trained personnel who have experience with rotary equipment.

In addition to the following instructional manual, care should

be taken to ensure compliance with specific safety

requirements mandated by federal, state and local codes.

Warning

Do not operate Fan / Blower without connecting dustbin.

Never operate Fan/Blower without belt and shaft guard in

place. Keep clear of exhaust. Keep hands and objects clear

of inlet and outlet.

Warning

Check amperage draw during operation with all blast gates

open. Make certain amperage is not outside operating limit

indicated on motor plate! If amperage is too high - shut down

immediately! (See Troubleshooting section.)

10 HP Pulley Drive Owners Manual

c

O.A.S. 2007

2

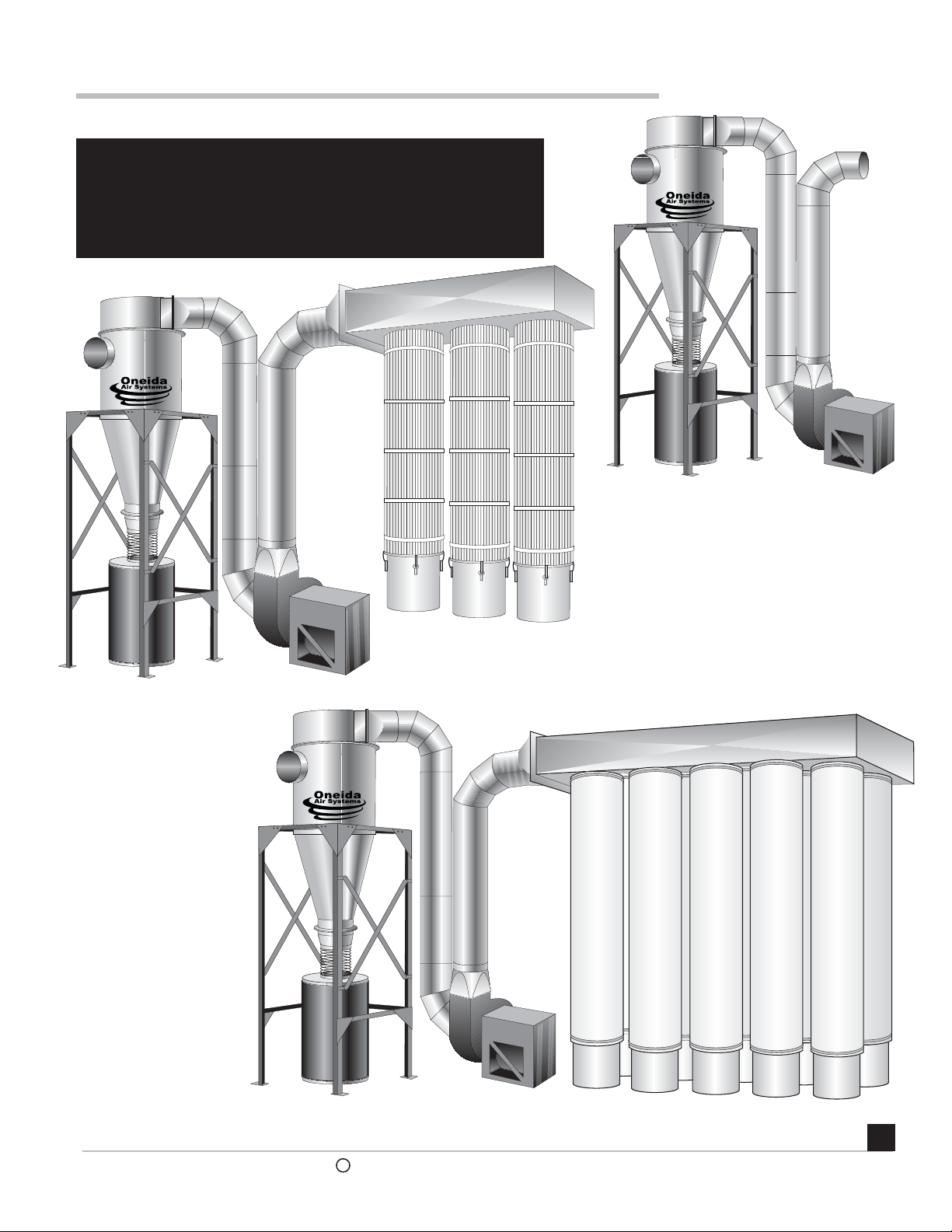

II. 10hp Pulley Drive Configurations

1. No Filter - Vent Outside -

Caution:

If exhaust air is vented outside you must provide make up /

return air.

Flue gases (carbon monoxide) can be drawn into the shop from

furnaces, water heaters or other appliances.

1. No

Filter

10hp has

10 tubes

2 rows of 5

2. External

Cartridge

Filters

10hp has 3 cartridges

3. External

Tube

Filters

10HP Pulley Drive Owners Manual

c

O.A.S. 2007

5 gal. dust buckets not included.

3

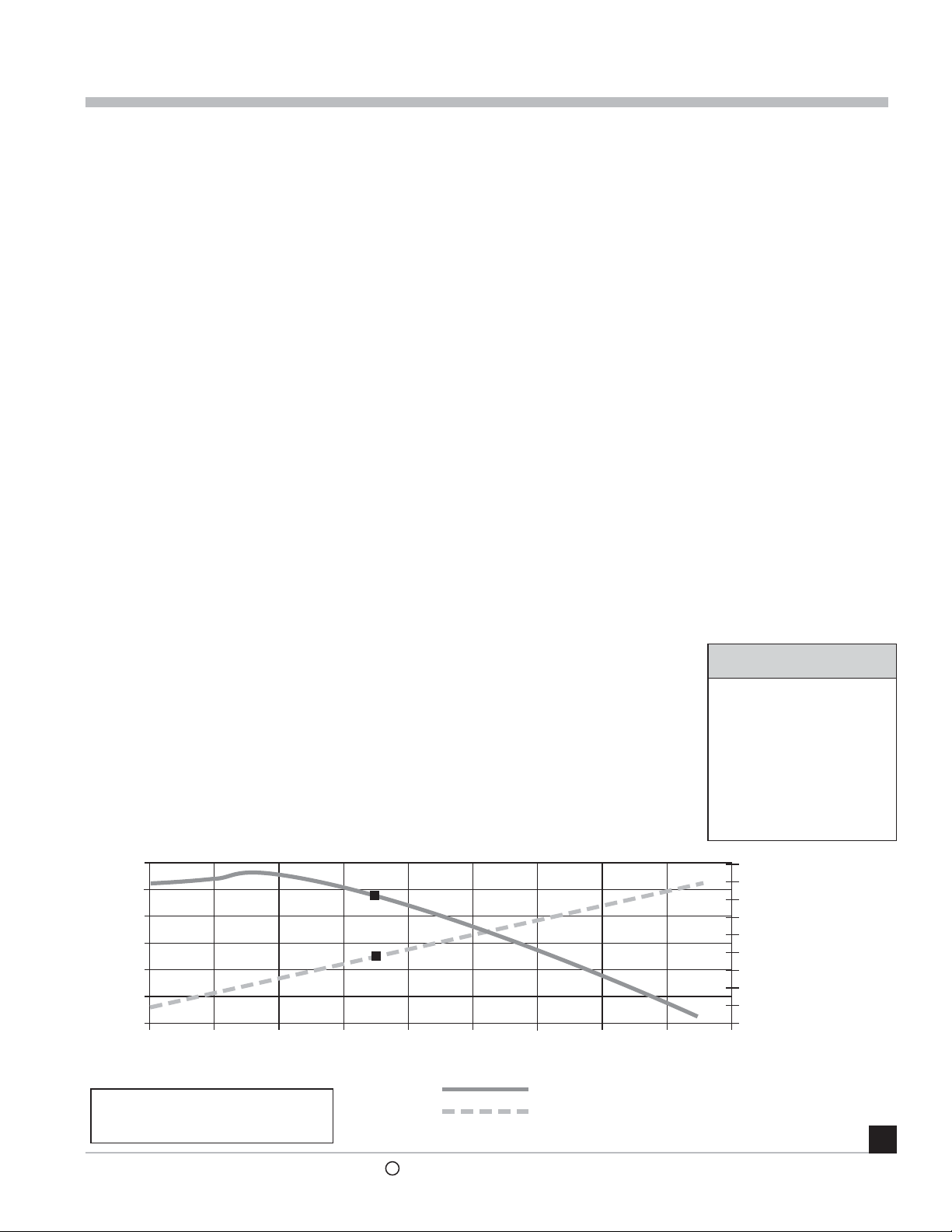

III. General Specifications & Fan Performance Curves

Filter Media

Cyclone C-3500

Full welded exterior

Main body, cone and inlet: 16 ga. galv.

Flanged 12 dia. Inlet; Flanged 13 dia. Outlet

80 high

14 rolled steel flange discharge

36 dia. rolled steel flange for mounting

System Packages Include:

10hp Fan / Blower

Made in USA NYB 224 DH Arrangement 10

10 horsepower, Pulley drive with weather/shaft guard

TECO - Westinghouse TEFC 60 Hz 10hp Motor

Three Phase: 230/460v 24/12A (Usable on 208v 25.9 A)

Fan Wheel Dia.: 22.625

3300 CFM @ 12 Static Pressure

Exterior Cartridge Filters

10hp - 3 Cartridges - 390 Sq. Ft.

Spun-Bonded Polyester BIA ZH1/487 Test - Rated C

Captures 99.99% of test material over 20 microns

Captures 99.9% of test material between 0.2 - 2.0

microns @ 11 fpm face velocity

Exterior Tube Filters

10hp - 10 Tube Filters

Needle Felted Media BIA ZH1/487 Test - Rated G

Captures 99.99% of test material over 20 microns

Captures 99.5% of test material between 0.2 - 2.0

microns @ 11 fpm face velocity

Dust Bins

55 Gal. Steel Drum

Other large dust bins available

Optional Items:

Angle Iron Wall Mount Brackets

Angle Iron Stand

Plenum Box - 10 or 14 hole ring thimble plenum box to hold Tube Filters.

Silencer - For fan / blower outlet to 13 I.D., will reduce noise level.

Magnetic Motor Starters

Rotary Air-Loc

10hp Fan Curves

10hp Performance Curve

12.5

10.0

7.5

5.0

2.5

0.0

Fan Static Pressure (In. Wg.)

0 1000 2000 3000 4000 5000 6000 7000 8000

Volume Flow Rate (CFM)

Static pressure and volume together determine

a fans performance. Several factors, such as

layout of ductwork and diameter of openings,

can affect a fans performance.

10 HP Industrial Systems Owners Manual

Performance -

Horsepower -

c

O.A.S. 2007

WARNING!

This fan has moving parts that can cause

serious injury. Read the installation and

maintenance instructions and the AMCA Safety

Practices manual before starting maintenance

or operating.

During Operation

1. Keep body, hands and objects away from

the inlet, outlet and other moving parts of the

fan such as belts, pulleys and shafts.

2. Do not operate at excessive speeds or

temperatures.

Before starting maintenance work:

Lock power supply in off position and

immobilize fan wheel.

22

Fan Input Power (bhp)

20

17

15

12

10

7.5

5

2.5

0

9000

4

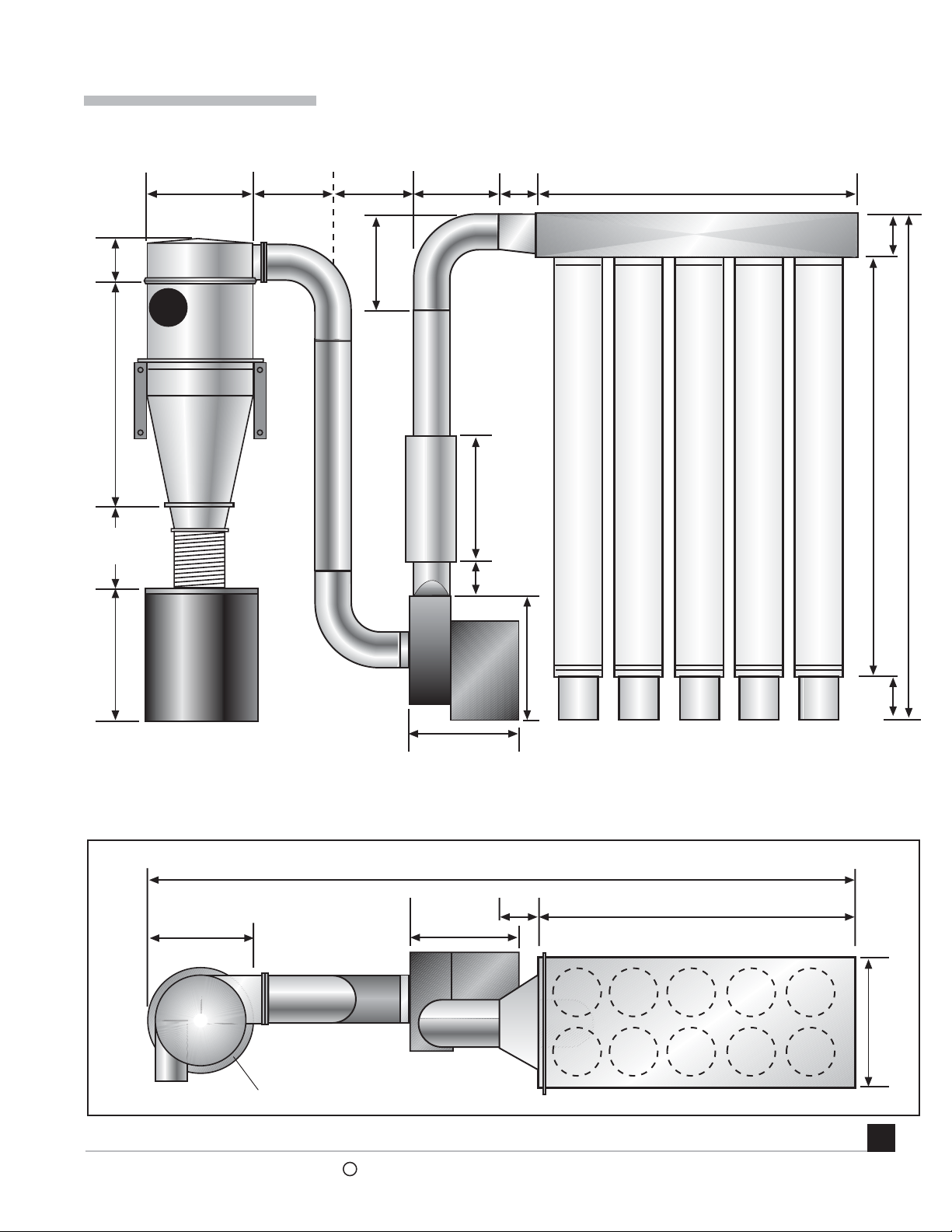

IV. Dimensions

- External Tube Filters

17

80

Approx.

18

32.534

32.5

1439

10hp - 10 tube - 83

12

39

8

10

36

8

36

55 Gal.

42

Top View Dimensions - Largest Configuration

10hp - 229

34

42

1 1/2 Flange w/ Bolt Holes

14

29 1/8

5 Gal. Dust Buckets Not Included.

They can be bought separately.

10hp - 83

12

30

10 HP Pulley Drive Owners Manual

c

O.A.S. 2007

5

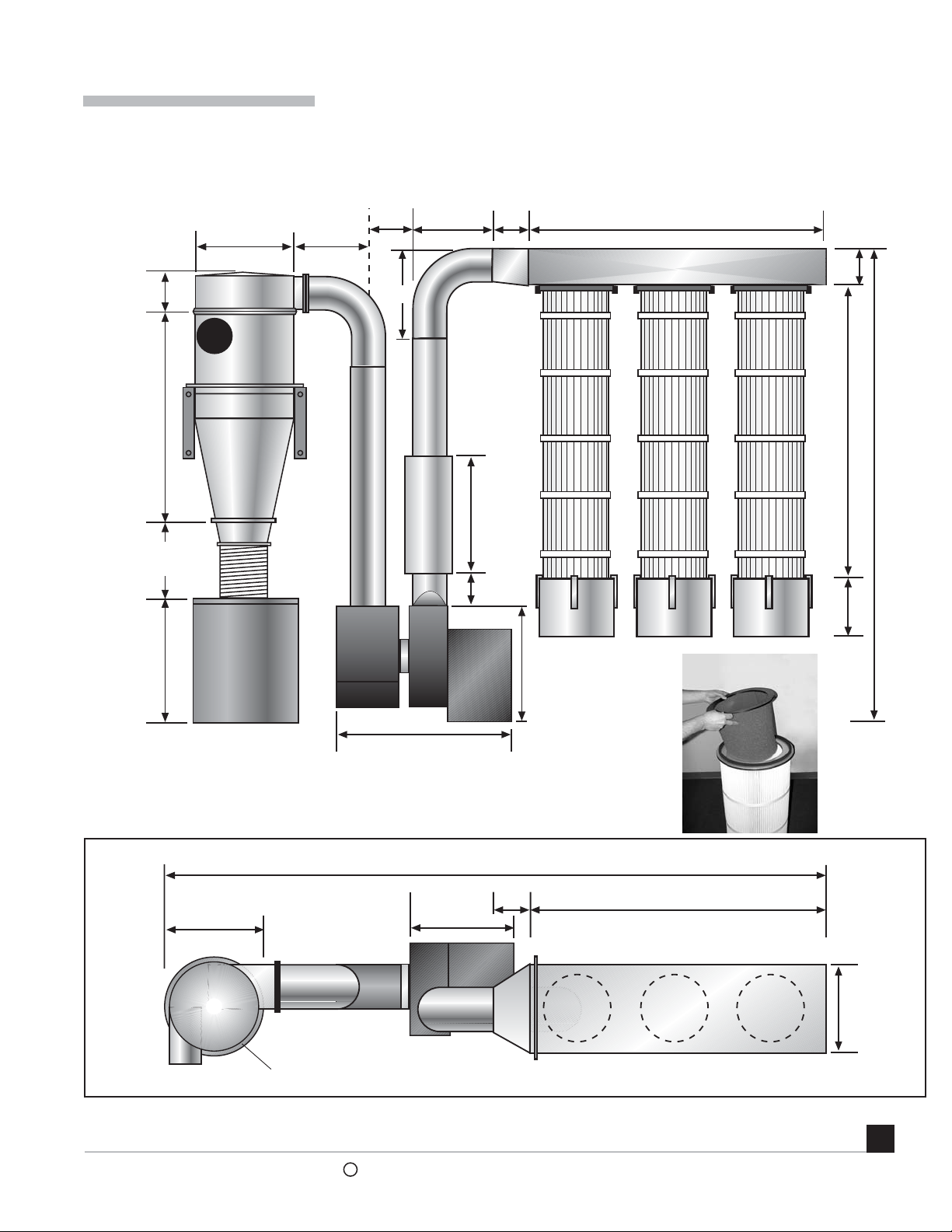

IV. Dimensions

34

- External Cartridge Filters

10hp - 3 filters -Single Row - 66

1439

14

17

80

Approx.

18

36

55 Gal.

39

60

36

8

29 1/8

Silencer easily drops

into Filter. Hold filter

up to Flange Plate

and clamp.

62

12

10

Top View Dimensions - Largest Configuration

10hp - 212

34

42

1 1/2 Flange w/ Bolt Holes

10 HP Pulley Drive Owners Manual

c

O.A.S. 2007

14

10hp - 3 filters -Single Row - 66

10hp - 22

6

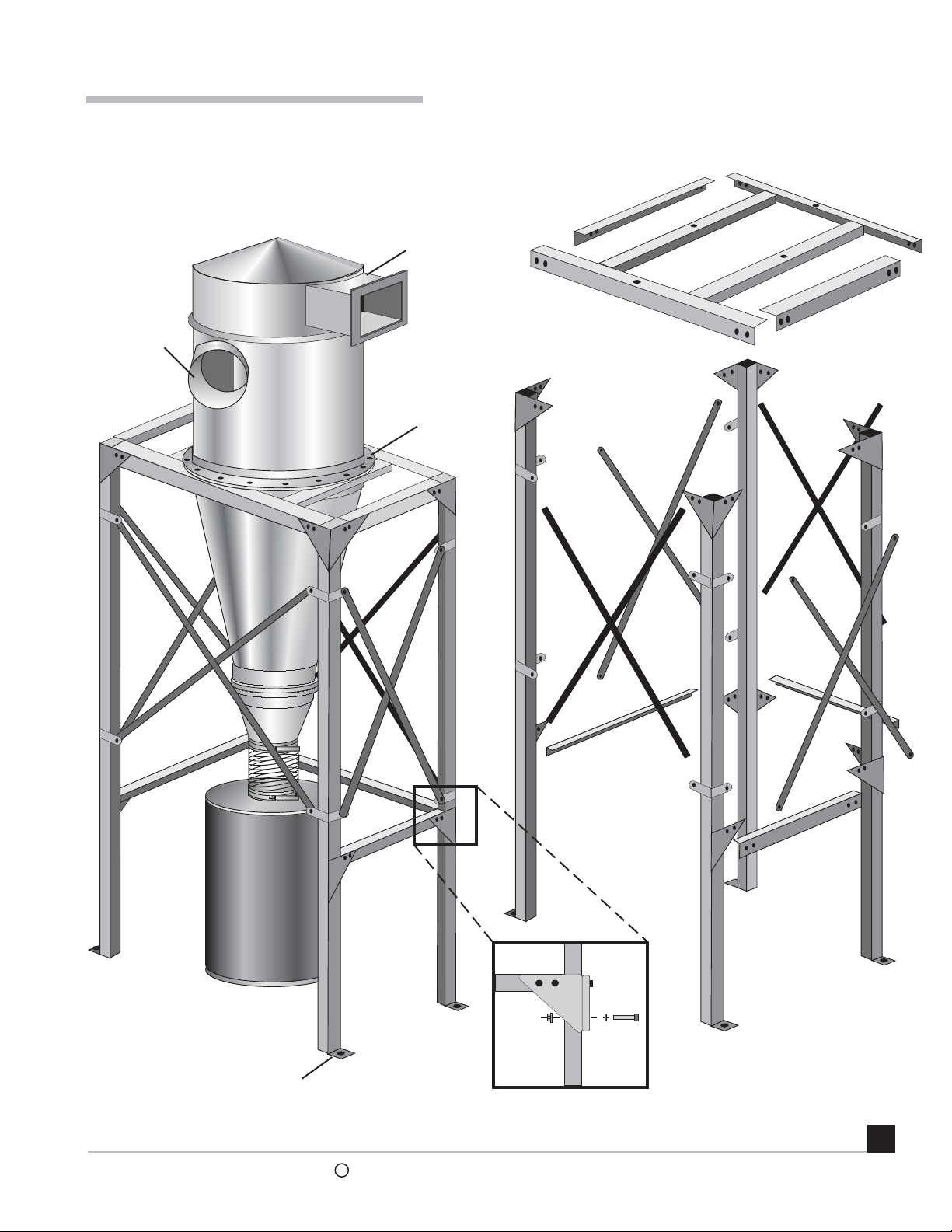

C-3500 Cyclone Stand -

Unit should be shipped with:

(4) 3/8-16 x 1 bolts for Cyclone mount

(20) 3/8-16 x 1 bolts for Cross Brace mount

(28) 3/8-16 x 1 bolts for Triangle Brackets

(48) 3/8 flat Washers

(48) 3/8 serrated Nuts

Outlet

Inlet

Choose Mount

Holes to Orient

Inlet in Desired

Location

w/ 55 Gal. Drum - Part # STZ350055

Anchor Feet Securely

to Floor to Prevent

Tipping

10HP Pulley Drive Owners Manual

c

O.A.S. 2007

7

Loading...

Loading...