CDR45I

s

Power Conditioner

User Manual

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS.

This Manual contains important instructions for the CDR Series Model CDR45I Power Conditioner

which should be followed during their unpacking, installation and maintenance.

Model Number CDR45I

Part Number _____________________________________________________

Serial Number____________________________________________________

©2004 ONEAC Corporation

Manufactured by

ONEAC Corporation

ONEAC USA

27944 North Bradley Road

Libertyville, IL 60048

United States

Toll Free: (800) 327-8801

Tel:(847) 816-6000

Fax: (847) 680-5124

ONEAC Europe

George Curl Way

Southampton, Hampshire SO18 2RY

United Kingdom

Tel: +44 (0) 2380 610311

Fax: +44 (0) 2380-612039

Visit our website at www.oneac.com

© 2004, ONEAC Corporation

ONEAC and Virtual Kelvin Ground are trademarks of ONEAC

Corporation. All other trademarks, products and corporate

names are property of their respective companies.

The information in this manual is subject to change without

notice.

2 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

About this Manual

This manual contains important information about the proper operation,

unpacking and installation for the ONEAC CDR45I Series Power Conditioners.

Please carefully read this manual before attempting to unpack your power

conditioner.

WARNING In order to avoid the risk of personal injury or damage to the equipment, the

installation sequence and the instructions given in each chapter must be

followed sequentially.

Before proceeding, confirm the conditioner output voltage matches tested input

voltage. If voltages do not match, damage to equipment may result.

Safety Information

The following general safety precautions must be observed during all phases of

operation, service, and repair of this system. Failure to comply with these

precautions or with specific warnings in this manual violates safety standards

and the intended use of the system. ONEAC assumes no liability for the

customer’s failure to comply with these requirements.

General

This is a Safety Class 1 instrument (provided with terminals for protective

grounding) and has been manufactured and tested according to international

safety standards.

Operation – Before Connecting Mains

Comply with the installation and service manuals. In addition, the following

must be observed:

• Do not remove system covers when operating.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 3

Safety Information

• Before the system is switched on, all protective ground terminals, extension

cords, auto-transformers and devices connected to it should be connected to

protective ground via a ground socket. Any interruption of the protective

ground connection will cause a potential shock hazard that could result in

serious personal injury.

• Make sure that only fuses with the required rated current and of the specified

type (normal blow, time delay, etc.) are used for replacement. The use of

repaired fuses and short-circuiting of fuse holders must be avoided.

• Adjustments described in this manual by a qualified technician are done with

power supplied to the system while protective covers are removed. Energy

available at many points may, if contacted, result in personal injury.

• Any adjustment, maintenance, or repair of the opened system under voltage

should be avoided as much as possible, and when inevitable, should be

carried out only by a skilled person who is aware of the hazard involved. Do

not attempt internal service or adjustment unless another person capable of

rendering first aid and resuscitation is present. Do not replace components

with the power cable connected.

• Do not operate the system in the presence of flammable gases or fumes.

Operation of any electrical system in such an environment constitutes a

definite safety hazard.

• Do not install substitute parts or perform any unauthorized modification to

the system.

• Capacitors inside the system may still be energized even if the system has

been disconnected from its power source.

Safety Symbols

The apparatus will be marked with the following symbol when it is necessary

for the user to Refer to the Manual in order to protect the apparatus from

damage:

!

This symbol is used to mark Protective Earth Terminals:

4 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Safety Information

WARNING A warning calls attention to a procedure, practice or the like, which, if not

CAUTION A caution calls attention to a procedure, practice or the like, which, if not

The apparatus can also be marked with the following warning:

“Hazardous voltage. Consult service manual.”

Ensure that this is observed and appropriate precautions taken when you

perform any procedure described in this manual.

Warnings and Cautions

This manual uses warnings and cautions to denote hazards.

correctly performed or adhered to, could result in injury or the loss of life. Do

not proceed beyond a warning until the indicated conditions are fully

understood and met.

correctly performed or adhered to, could result in damage to or destruction of

part or all of the equipment. Do not proceed beyond a caution until the

indicated conditions are fully understood and met.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 5

Safety Information

6 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Table of Contents

Table of Contents

Safety Information

About this Manual 3

Introduction 11

Technical Support 11

What Equipment Needs Power Conditioning? 12

Sizing Information

12

Operating Environment 12

Features and Controls

13

I/O Features and Controls 13

Installation 15

Principle of Operation 15

Installation Overview 17

3

Important Installation Guidelines 18

Verifying the Installation

19

Unpacking and Placement 20

Input Circuit Breaker

22

Input Connections 23

Emergency Mains Off 26

Output Connections 29

Maintenance 33

Cleaning 34

Fuse Replacement 34

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 7

Table of Contents

Operation of Additional Features

Physical Views

Specifications

37

39

41

CDR45I Specifications 41

CDR45I Schematics 45

Troubleshooting an Installation

Technical Support

49

49

Changing the Operating Voltage 51

Voltage Tap Selection and Range Change

Warranty 55

51

8 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

List of Figures

Figure 1 Input and output features and controls (front) . . . . . . . . 13

Figure 2 Input and output features and controls (rear). . . . . . . . . 14

Figure 3 Power conditioner configuration. . . . . . . . . . . . 18

Figure 4 Position of the seismic anchoring holes . . . . . . . . . . 21

Figure 5 Conduit hole . . . . . . . . . . . . . . . . . 24

Figure 6 24 Vac control circuit. . . . . . . . . . . . . . . 28

Figure 7 Position of emergency off fuses and emergency off transformer . . . . 29

Figure 8 Position of the output connections . . . . . . . . . . . 30

Figure 9 Fuse replacement . . . . . . . . . . . . . . . 35

Figure 10 Visual indication of the operational status . . . . . . . . . 37

Figure 11 Physical views . . . . . . . . . . . . . . . . 39

Figure 12A CDR45I Schematic (1) . . . . . . . . . . . . . . 45

Figure 13A CDR45I Schematic (2) . . . . . . . . . . . . . . 46

Figure 14A CDR45I Schematic (3) . . . . . . . . . . . . . . 46

Figure 15A CDR45I Schematic (4) . . . . . . . . . . . . . . 47

Figure 16A CRD45I Schematic (5) . . . . . . . . . . . . . . 47

Figure 17 Mains (T1) transformer voltage tap selection. . . . . . . . . 53

Figure 18 T2 – 24 Vac control Xfmr taps . . . . . . . . . . . . 54

List of Figures

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. - 9

List of Figures

10 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. -

Introduction

Thank you for selecting this power conditioner. ONEAC’s CDR Series offers

the most reliable protection from the harmful effects of electrical line

disturbances for your electronic test equipment.

ONEAC’s ISO 9001 certification represents our commitment to building world-

class products. We take pride in every unit that leaves our manufacturing

facility.

Technical Support

ONEAC Corporation offers 24-hour technical support. Contact ONEAC

Technical Services:

• North America: (800) 327-8801 (option 3),

(847) 816-6000 (option 3)

• Europe: +44 (0) 2380 610311

• email: ts@oneac.com

NOTE All calls received before 7 a.m. or after 7p.m. Central Standard Time are

forwarded to a cell phone. An ONEAC Technical Service Representative will

return your call within one half hour between 5 p.m. and 10 p.m. Central

Standard Time. Except for emergencies, calls received between 10 p.m. and 7

a.m. will be returned during normal business hours.

Please check with ONEAC Technical Services before attempting to repair or

return any ONEAC product. If an ONEAC Power Conditioner needs repair or

replacement, ONEAC Technical Services issues a Return Material

Authorization (RMA) number along with instructions on how to proceed.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 11

Introduction What Equipment Needs Power Conditioning?

What Equipment Needs Power

Conditioning?

Only your electronic based equipment requires conditioned power. Fans, air

conditioners and motors do not require power conditioning. Placing fans, air

conditioners, motors or other noise generators between the conditioner and the

electronics introduces electrical interference into the already conditioned

power. In order to minimize electrical noise, each piece of equipment should be

individually wired back to the output of the power conditioner.

Sizing Information

The rating label of your ONEAC CDR45I Series Power Conditioner lists the

model’s current rating, nominal input and output voltage and serial number. The

combined steady state RMS current draw of all your equipment must not

exceed the power conditioner's output current rating on any of the three phases.

Your ONEAC CDR45I Series Power Conditioner can operate even with a 100%

unbalanced load.

Operating Environment

Clean room The ONEAC CDR45I Series Power Conditioner is intended for operation in a

clean room environment. Note that the conditioner incorporates two fans for air

circulation. These fans must not be impeded to maintain full circulation. The

finish on the conditioner is selected for minimum dusting.

Audible noise The ONEAC CDR45I Series Power Conditioner produces less than 45 dBA of

audible noise measured at a distance of one meter from the center of the front

door.

12 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Features and Controls

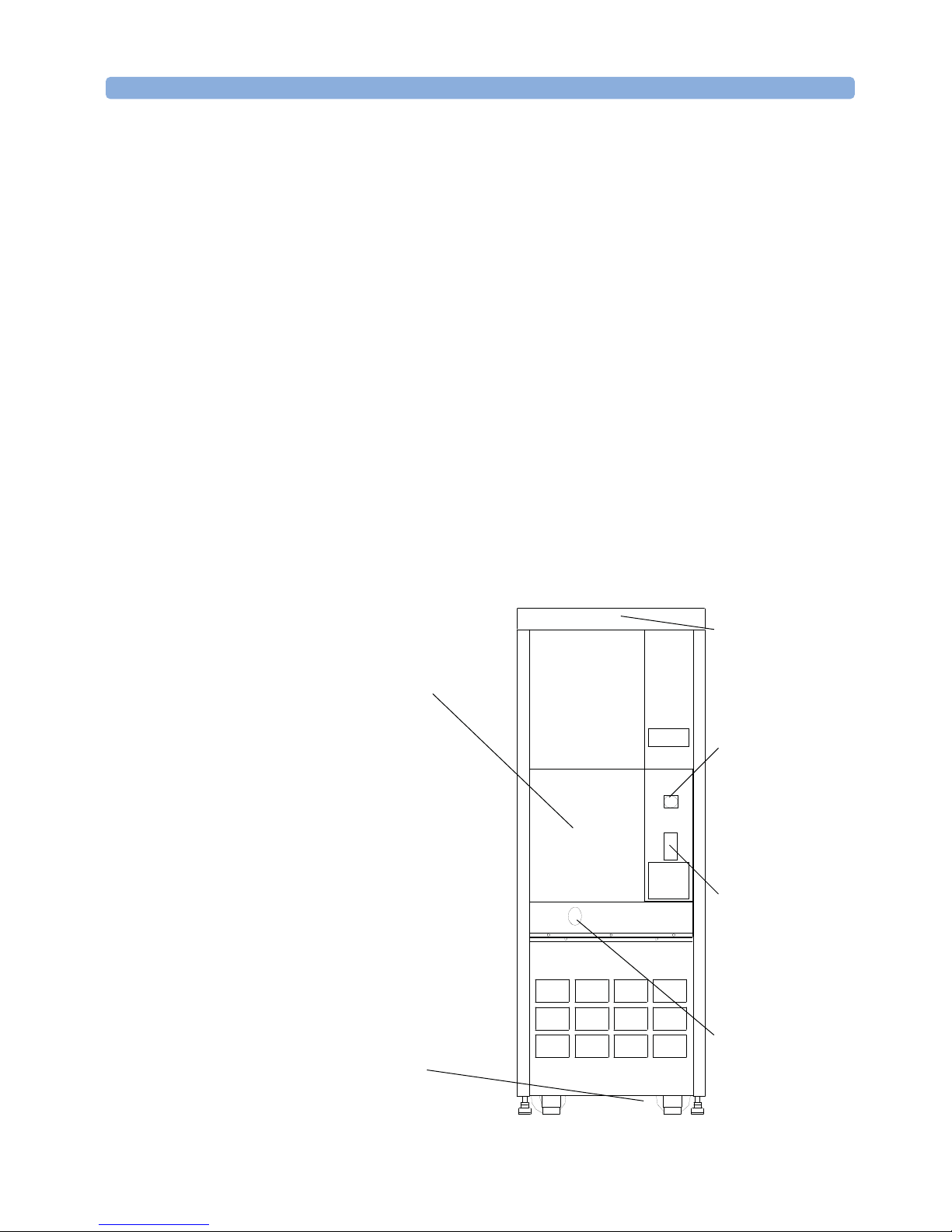

I/O Features and Controls

The input features and controls are outlined in Figures 1 and 2. Refer to the

section number identified for information on the operation, installation and

modification of each feature or control. All features and controls described are

already supplied with your power conditioner.

NOTE Field retrofitting requires your system power to be shut down.

Figure 1 Input and output features and controls (front)

Output power block

(see

“Output

Connections” on

page 29

Supply input feed

(see

Connections” on

page 23

)

“Input

)

Fans (see

“Unpacking and

Placement” on

page 20

CPC connector –

External EMO and

auxiliary contacts

(see

“Output

Connections” on

page 29

Convenience

receptacles (see

“Output

Connections” on

page 29

Output conduit (see

“Output

Connections” on

page 29

)

)

)

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 13

Features and Controls I/O Features and Controls

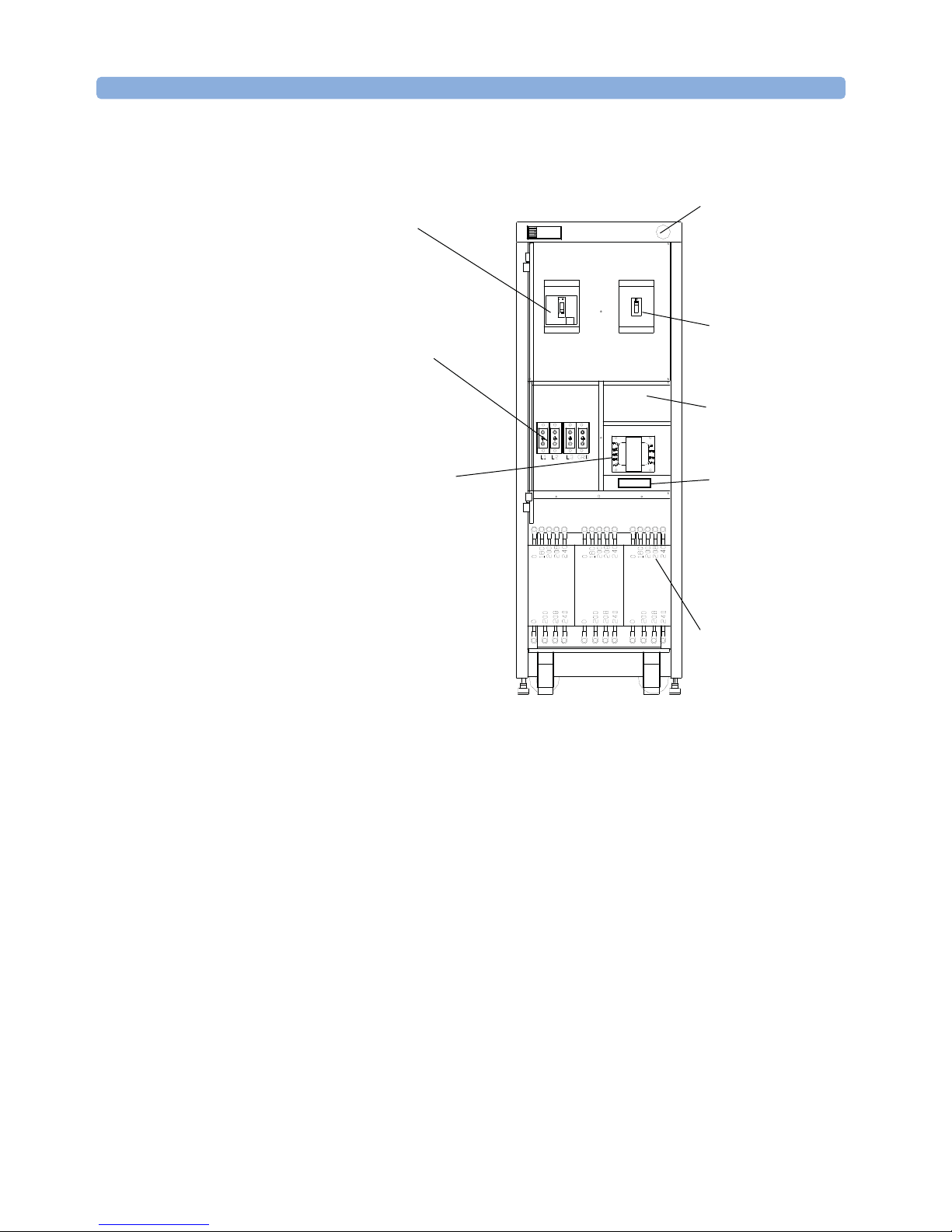

Figure 2 Input and output features and controls (rear)

Main input circuit

breaker

Input conduit

connection (see

“Input

Connections” on

page 23

EMO transformer (see

)

“Emergency

Mains Off” on

page 26

)

EMO red mushroom

turn-to-release

button (see

“Emergency

Mains Off” on

page 26

Main output circuit

breaker

Spares compartment

EMO transformer

fuses (see

“Emergency

Mains Off” on

page 26

and

“Cleaning” on

page 34

3 phase mains power

transformer (see

“Changing the

Operating

Voltage” on

page 51

)

14 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Installation

Principle of Operation

The following brief description of the ONEAC CDR45I Series Power

Conditioner’s principle of operation is provided to assist in the proper

installation and operation of your power conditioner.

Interconnections and Operations:

1. AC power is supplied to the power conditioner by connection to the input

terminal block. When AC power is supplied to this terminal block via the

service panel circuit breaker, the Input Power ON LED is illuminated.

2. Three phase AC power is connected from the terminal block to the main

input circuit breaker. The input circuit breaker for this product utilizes

modular current trip rating plugs which are inserted or plugged into a single

molded case circuit breaker frame. An undervoltage release accessory is

installed in the input breaker as a means of control.

3. A separate multi-tapped primary, 24 Vac secondary, transformer is utilized

for power control, and supplied from the input terminal block (L1 and L2).

The primaries of this transformer are fuse protected (2A, 600 V rating). The

secondary of this transformer is also fuse protected (1A, 250 V rating).

4. The 24 Vac control circuit energizes the undervoltage release accessory

within the main input circuit breaker when the Emergency Mains Off

(EMO) circuit is closed. An external connection for the EMO circuit is

provided by means of a circular plastic connector (CPC) located on the

lower right back panel above the convenience receptacles. The power

conditioner is shipped with a shorting plug secured to the panel mounted

CPC. The shorting plug has a wire jumper across pins 3 and 4 of the CPC. A

spare mating CPC is provided with the unit in the spares compartment to

allow for this shorting plug to be replaced with any series connected NC

contact string. (See “Emergency Mains Off” on page 26 for detailed

description of operation.)

5. In order to turn ON the main input circuit breaker, the EMO circuit must be

closed so that the undervoltage release accessory is energized.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 15

Installation Principle of Operation

6. Pins 1 and 2 of the CPC provide the user with a pair of contacts that are

opened when the EMO circuit has been alarmed and are closed during

normal unit operation. (See “Emergency Mains Off” on page 26 for detailed

description of operation.)

7. The secondaries of the Mains transformer are connected to the Virtual

Kelvin Ground®.

8. When the main input circuit breaker is turned ON, power is applied to the

cooling fans, and the main output circuit breaker. When the main output

circuit breaker in turned ON, the Output Power ON LED is illuminated and

power is available at the output power block.

NOTE Proper input voltage configuration is achieved by performing the following

three independent steps:

• Selection of the correct rating plug for the desired input voltage.

• Selection of the correct tap configuration for the Mains transformer (T1).

• Selection of the correct tap configuration for the Control transformer (T2).

The power conditioner is originally shipped from the manufacturer configured

for 400 Vac input operation unless otherwise stated on the label attached to the

input power block.

16 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Installation Overview Installation

Installation Overview

NOTE Only qualified electricians shall install this power conditioner. Follow local

codes such as the U.S. National Electrical Code® [NFPA 70], good wiring

practice, and this Installation Guide.

To install the power conditioner:

1 Unpack the power conditioner (see “Unpacking and Placement” on

page 20).

2 Move the power conditioner to the desired installation location.

3 Turn off the intended input power source for the conditioner. In order to

comply with SEMI-S2-93A; 11.2, which complies with 29 CFR 1910.147

(OSHA), the power feed to the power conditioner must be locked out

and tagged out at the service disconnect that feeds the power

conditioner input power block to de-energize the power conditioner.

Connect the input wires (see “Input Connections” on page 23). A 5/16 inch

hex key is included in the spares compartment of the power conditioner for

use in connecting the input wires to the input power block. Use a grounding

conductor that is equal to or larger than the current carrying conductors. Do

not connect a neutral wire to the delta input of this power conditioner.

4 Verify that the power conditioner's input is configured for the correct supply

voltage (see “Changing the Operating Voltage” on page 51). The power

conditioner is originally shipped configured for 400 Vac input operation

unless otherwise stated on the label attached to the input power block.

5 Turn on the power feed to the input.

6 Turn on the input circuit breaker.

7 Turn on the output circuit breaker.

8 Verify the correct operation of the power conditioner as presented at the

output power block (see “Verifying the Installation” on page 19).

9 Turn OFF the input and output circuit breakers and the power feed to the

power conditioner. Refer to Item 3 above regarding lock out/tag out at the

service disconnect that feeds the power conditioner.

10 Confirm that tester input voltage is configured to match conditioner output

voltage.

11 Connect tester to the output power block (see “Output Connections” on

page 29).

12 Turn on the input circuit breaker.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 17

Installation Important Installation Guidelines

13 Turn on the output circuit breaker.

14 Turn on your equipment.

15 Start normal operation of your system.

Important Installation Guidelines

Only qualified electricians should install or retrofit this power conditioner.

WARNING This power conditioner contains dangerous voltages. Accidental contact can

result in serious electrical shock. Always follow the U.S. National Electrical

Code® or your local electrical codes and good wiring practice.

CAUTION This Power Conditioner is 3-phase, wired in a “DELTA-WYE” configuration.

Figure 3 Power conditioner configuration

L1

L2

L3

PE

In order to comply with SEMI-S2-93A; 11.2, which complies with 29 CFR

1910.147 (OSHA), the power feed to the power conditioner must be locked

out and tagged out at the service disconnect that feeds the power

conditioner input power block to de-energize the power conditioner.

The input requires only 3-phase wires and a grounding conductor connection.

Do not connect a neutral wire to this delta configured input. The use of rigid

or flexible steel conduit is strongly preferred for this power conditioner model.

Physically separate the input power connections to the power conditioner from

the equipment power connections on the output. Data cables should be kept as

far away as possible from any power cables.

L1

L2

L3

N

PE

18 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Verifying the Installation Installation

For maximum performance, use the flexible steel conduit provided with this

power conditioner to connect your equipment to the power conditioner. Always

include a ground wire for each auxiliary circuit on the output of the power

conditioner. Do not use extension cords or power strips. Do not connect your

equipment to the power conditioner’s output until the input connections have

been made and proper power conditioner configuration and operation has been

verified.

Verifying the Installation

Proceed as follows to verify the installation:

1 Turn OFF the input and main output circuit breakers on the power

conditioner. Verify that the installation follows the guidelines outlined in

“Important Installation Guidelines” on page 18. In order to comply with

SEMI-S2-93A; 11.2, which complies with 29 CFR 1910.147 (OSHA), the

power feed to the power conditioner must be locked out and tagged out

at the service disconnect that feeds the power conditioner input power

block to de-energize the power conditioner.

2 With your equipment still not connected to the power conditioner, turn ON

the main power source.

WARNING Dangerous voltages are present.

The Input Power ON LED indicator, located in the upper left hand corner of

the front of the power conditioner, will be illuminated and the 24 Vac control

circuit will then be activated.

3 Verify that the remote EMO shorting plug is connected to the power

conditioner (see “Emergency Mains Off” on page 26 and “Output

Connections” on page 29). Place the power conditioner’s input circuit

breaker in the ON position

4 Place the power conditioner’s output circuit breaker in the ON position. The

Output Power ON LED indicator, located in the upper left corner of the front

of the power conditioner will be illuminated.

Use a voltmeter to determine if voltage is present at the input and output.

Check the output voltage at the Output Power Block. The power

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 19

Installation Unpacking and Placement

conditioner's output voltage may run a few volts higher than the rated

voltage until the load is switched on.

If the operating voltage matches that suggested by the equipment

manufacturer, turn OFF the main input and output circuit breakers on the

power conditioner, connect your equipment to the output power block, and

turn ON the main input circuit breaker followed by the main output circuit

breaker. Your equipment can now be turned ON and operated as usual

If voltage variations greater than the manufacturer's specifications exist on

any phase, a tap selection for that phase may be made to adjust the voltage

level (see “Voltage Tap Selection and Range Change” on page 51).

If there is power at the input with no power at the output:

1 Turn OFF the main output and input circuit breakers.

2 Turn OFF the main power source supplying the power conditioner.

3 Follow the procedure in “Troubleshooting an Installation” on page 49.

Unpacking and Placement

Your ONEAC CDR45I Series Power Conditioner is delivered on a wooden

pallet. Upon arrival, inspect the unit and pallet for signs of damage. The pallet

has two types of shipping indicators (tip and drop). Check these indicators for

signs of shipping stress.

In case you encounter an activated tip or drop sensor or any visible damage

proceed as follows:

1 Make a note on the delivery receipt and inspect for damage.

2 Leave in original container and packaging and request immediate inspection

from carrier within 3 days.

3 Collect the following information and inform SSTD about the incident:

– Name of the carrier

– Shipment information

– Pictures showing the damage

– Detailed report explaining the damage

20 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

4 Keep all sensors and packaging material for further investigations.

Unpacking and Placement Installation

ONEAC recommends that your power conditioner be left on the pallet during

handling. Remove the conditioner from the pallet once it is as close as possible

to its final installation location. Unbolt the power conditioner and remove the

shipping brackets and roll it off the pallet using the shipping ramp.

WARNING Follow the ramp use instructions provided with the ramp. Do not use the

seismic anchoring holes on the side of the unit for lifting the power

conditioner into place.

Figure 4 Position of the seismic anchoring holes

3/8-16 UNC threaded

holes for seismic

mounting 12 places

The actual physical placement of the power conditioner should be as close as

possible to your equipment. The power conditioner should be installed inside

the room containing your equipment. Allow at least 2 inches (5.1 cm) around

all sides of the power conditioner. Do not allow the conditioner to be installed

where direct contact with water is possible or where the fans on the top of the

unit would be blocked.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 21

Once the location of your power conditioner has been determined, carefully roll

it into place. Lower and adjust the glides on the power conditioner so that the

unit is level and stable. Run the glide locknut up to the base of the power

conditioner and tighten 1/4 turn to secure the glide at the height selected.

Installation Input Circuit Breaker

There are six, 3/8-16 size anchoring holes on each side of the conditioner. Three

bottom holes on each side are used in conjunction with two brackets to secure

the conditioner to the shipping pallet. Save the bolts and brackets when

unpacking the conditioner. Also included are six caps to cover the holes when

not in use.

Always anchor the conditioner with the bottom six holes for seismic restraint.

The shipping brackets may be used as part of the restraint if more suitable to a

specific installation. The 3/8-16 bolts may be used for supplementary restraint

in the top seismic holes. Never use the top seismic holes unless the conditioner

is already secured by the bottom six holes.

The power conditioners will not adversely impact system air conditioning. See

“Specifications” on page 41 for the air conditioning load per hour.

Input Circuit Breaker

This feature is needed to protect your equipment and the power conditioner.

Make sure the branch circuit breaker feeding the power conditioners input, at

the service disconnect, has ratings that are equal to or better than those listed

below for full rated power usage of the power conditioner.

Table 1 Input overcurrent protection

Product Input Voltage (Vac)

CDR45I 200, 208, 240 150 A 65,000

380, 400, 415, 440 90 A 25,000

448, 480 70 A 25,000

The input current rating can be changed with a plug-in module (rating plug)

which fits into the input circuit breaker.

Circuit Breaker

Current Rating

Interrupting Rating

(Minimum RMS

Symmetrical Amps)

22 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Input Connections Installation

Input Connections

This feature is used for connecting the input AC power connections to the

power conditioner. The internal input power block is located in the front-

middle, on the left side, below the main input circuit breaker. The power block

will accept wire size 6 AWG-350 MCM (16-177 mm2). There is a conduit hole

on the bottom of the power conditioner to connect a 51 mm (2 inch) conduit.

Supply access to the power conditioner can be easily accomplished from the

front or back sides through this bottom conduit hole. If desired, access through

the top of the power conditioner is provided through the internal sheet metal. A

63.5 mm (2.5 inch) hole, or smaller, can be punched or drilled through the top

of the power conditioner, above the main input circuit breaker to allow access to

the input power block below.

A 5/16" hex key is supplied with the power conditioner for use in connecting

the input and output wires to their respective power blocks. The hex key is

stored in the spares compartment, behind the middle panel on the front of the

unit.

Installation of Input Connections

WARNING Turn off the main power source supplying the power conditioner at the service

disconnect before proceeding.

In order to comply with SEMI-S2-93A; 11.2, which complies with 29 CFR

1910.147 (OSHA), the power feed to the power conditioner must be locked

out and tagged out at the service disconnect that feeds the power

conditioner input power block to de-energize the power conditioner.

To install the input connections:

1 Open the door and remove the lower and middle cover panels to access the

internal input connections for bottom feed input. For top feed input, remove

the upper and middle cover panels.

2 Install an appropriate conduit and fitting or cord with cord connector to the

power conditioner.

A conduit hole for 51 mm (2 inch) conduit is provided (see Figure 5).

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 23

Installation Input Connections

Figure 5 Conduit hole

Hole for 2 inch (51 mm)

conduit

3 Connect the input ground or protective earth (PE) conductor to the terminal

block (PE).

Heavy gauge wire, equal to or larger in diameter than the power carrying

conductors should be used to connect the safety ground or protective earth

conductor (PE). It is recommended that ground or PE be wired back to the

service ground/main earth terminal.

Do not rely on the conduit alone for connection to ground or earth.

Do not use a ground conductor size that is smaller than the phase conductor.

Refer to the wiring charts on the following page.

If in doubt regarding wire sizing, consult the U.S. National Electrical Code

Table 310-16, or your local electrical code.

®

,

24 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Input Connections Installation

4 Connect the input phase wires to the input terminals. Phase rotation

sequence is maintained by the power conditioner. Refer to the following

wiring charts:

Table 2 Minimum wire sizes (in conduit) for different input voltages and Full Rated Load

of Power Conditioner

Product CDR45I

Input Voltage

200 #0 AWG #0 AWG

208 #0 AWG #0 AWG

240 2 AWG 2 AWG

380 4 AWG 4 AWG

400 4 AWG 4 AWG

415 4 AWG 4 AWG

440 4 AWG 6 AWG

448 4 AWG 6 AWG

480 6 AWG 6 AWG

* Wire insulation rated for 75 ˚C minimum is required.

Table 3 Wire size metric conversion chart

Wire Size

(AWG)

Diameter

(MILS)

0000 AWG 460 MILS 11.7 mm 107 mm

000 AWG 410 MILS 10.4 mm 85.0 mm

00 AWG 365 MILS 9.27 mm 67.4 mm

0 AWG 325 MILS 8.25 mm 53.5 mm

2 AWG 258 MILS 6.54 mm 33.6 mm

3 AWG 229 MILS 5.88 mm 26.7 mm

4 AWG 204 MILS 5.19 mm 21.2 mm

6 AWG 162 MILS 4.12 mm 13.3 mm

8 AWG 128 MILS 3.26 mm 8.37 mm

10 AWG 102 MILS 2.59 mm 5.26 mm

Input Wire Size* Input Grd. Wire Size*

Diameter

(mm) Area (mm2)

2

2

2

2

2

2

2

2

2

2

Standard

Metric (mm2)

110 mm

85 mm

70 mm

60 mm

35 mm

30 mm

25 mm

16 mm

10 mm

6 mm

2

2

2

2

2

2

2

2

2

2

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 25

5 Follow the procedure in “Verifying the Installation” on page 19.

Installation Emergency Mains Off

Emergency Mains Off

This feature will allow you to shut down your power conditioner by pushing the

red, mushroom-type EMERGENCY MAINS OFF (EMO) turn-to-release

button located on the front upper right corner.

After the EMO circuit has been deployed, the input circuit breaker will need to

be reset (switched to the OFF position, then the ON position) to resume normal

operation.

CAUTION Hazardous voltages will still be present within the power conditioner even after

the EMO has been deployed.

You must turn off the power source supplying the power conditioner at the

service disconnect to remove all hazardous voltages before servicing or

working within the power conditioner. In order to comply with SEMI-S2-

93A; 11.2, which complies with 29 CFR 1910.147 (OSHA), the power feed

to the power conditioner must be locked out and tagged out at the service

disconnect that feeds the power conditioner input power block to de-

energize the power conditioner.

The EMO circuitry is integrated with the input circuit breaker with a 24 Vac

undervoltage release circuit and controlled by a 24 Vac transformer, which is

located in the control transformer area. The transformer is powered prior to the

input circuit breaker and is protected by two fuses (2 A, 600 V) on the primary

side located below the transformer and behind the middle front panel. The

secondary side of the transformer is fuse protected (1 A, 250 V) to limit the

current to 1 A maximum. This fuse is also located in the same compartment. A

schematic of the 24 Vac control circuit is found at the end of this section.

The conditioner 24Vac EMO circuit is forms a closed loop for normal

operation. The loop includes: the red EMO button (contacts open when button

depressed), a microswitch S2 behind lower front access panel (contacts closed

when switch is depressed by panel), and remote EMO contacts J1-3 and J1-J4

(a closed loop is required between these pins). When the EMO loop is closed,

24Vac is provided to the undervoltage coil of the input circuit breaker

permitting it to be set to ON Opening the loop by depressing the red button or

other interruption will cause the input circuit breaker to OPEN and remove

power from the conditioner load. Releasing the red EMO button (turn to

release) will restore 24 Vac to the undervoltage coil and permit the input circuit

breaker to be re-set to OFF then to ON.

26 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Emergency Mains Off Installation

A circular plastic connector (CPC) is provided on the back of the power

conditioner, located above the convenience receptacles, to allow for an external

connection to the EMO circuit. A series connected, normally closed string of

contacts or switches must be connected between J1-3 and J1-4 of the CPC. The

conditioner will not function unless a closed loop exists between these two

pins. The power conditioner is shipped with a shorting plug (P1) connected to

the panel to allow for field installation and verification. An additional plug with

4 loose pins is shipped with the conditioner. They are stored in the spares

compartment above the control transformer.

Pins P1-1 and P1-2 are not used in the shorting plug provided. A pair of

contacts, K1A is connected to J1-1 and J1-2 for future user specific circuits.

The contact pair is rated at 250 Vac, 1 A. The relay coil, K1, is energized when

power is available to the input circuit breaker undervoltage coil for normal

operation. The contact pair K1A is closed when relay K1 is energized.

Alarming the EMO circuit removes power from K1 at the same time as the

input circuit breaker undervoltage coil is de-energized. The contact pair K1A

will open. Restoring 24 Vac power to normal will close the contact pair K1A.

Note that K1A will be closed whenever the EMO 24V ac power loop is normal

even if the input circuit breaker has not been turned ON.

The following is a list of ONEAC and manufacturer part numbers for the CPC

plug, cable clamp and pins used for this circuit.:

Table 4 ONEAC and manufacturer part numbers

Part Description Oneac Part # Manufacturer Mfr Part #

CPC Plug (P1) 435-260 AMP 206429-1

CPC Cable Clamp 435-262 AMP 206062-3

Pin (#18-#14 AWG) 421-270 AMP 66361-4

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 27

Installation Emergency Mains Off

When the power source voltage supplying the power conditioner is

changed, the EMO transformer, T2, must be reconfigured on the primary

to match the source voltage (refer to Figure 6 for information).

Figure 6 24 Vac control circuit

WARNING You must turn off the power source supplying the power conditioner at the

28 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

In order to comply with SEMI-S2-93A; 11.2, which complies with 29 CFR

1910.147 (OSHA), the power feed to the power conditioner must be locked

out and tagged out at the service disconnect that feeds the power

conditioner input power block to de-energize the power conditioner.

service disconnect to remove all hazardous voltages before servicing or

working within the power conditioner.

Output Connections Installation

WARNING You must turn off the power source supplying the power conditioner at the

service disconnect to remove all hazardous voltages before servicing or

working within the power conditioner.

Figure 7 Position of emergency off fuses and emergency off transformer

Emergency off

transformer

Emergency off fuses

Output Connections

Output Overview

The output power block allows easy connection of output wiring to your

equipment connections. The output conduit landing area is located just below

the output power block. Please confirm that conditioner output voltage and

tester input voltage match before connecting power.

All power, control, and sense circuits are connected between the power

conditioner and your equipment via the output conduit connections and the

CPC connector located on the back of the power conditioner.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 29

Installation Output Connections

Figure 8 Position of the output connections

Convenience

Receptacle Circuit

Breakers

CPC connector –

external EMO and

auxiliary contacts

Output power block

Three IEC-320

receptacles, 208 Vac,

Conduit landing

total 10 A max

Two duplex NEMA

5-15R receptacles,

120 Vac, 15 A max,

each (Behind cover)

Conduits

The landing area can be fitted with up to five conduits landing points, and up to

51 mm (2 inch) diameter conduits. Knockout scribe points are located on the

back side of the conduit landing cover plate for your convenience.

Convenience Receptacles

Convenience receptacles are located on the back of the conditioner. Three (3)

IEC320 outlets are provided and rated at 208Vac,10 A maximum for all three.

Two (2) separate NEMA 5-15R duplex receptacles are provided and rated at

120 Vac, 15 A maximum for each duplex. These NEMA style receptacles are

shipped covered by a panel for compliance with the EU's low voltage directive.

Each convenience circuit is circuit breaker protected. The convenience

receptacles can be energized by their individual circuit breakers once the main

input circuit breaker is turned ON.

30 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Output Connections Installation

Installation of Output Connections

WARNING Turn off the main power source supplying the power conditioner at the service

disconnect before proceeding.

Turn OFF the service disconnect supplying power to the power conditioner

and connect your equipment to the power conditioner’s output. The power

conditioner maintains phase rotation sequence. Follow lock out

procedures.

1 Turn OFF the equipment power switch or circuit breaker before turning ON

the main output circuit breaker on the power conditioner.

2 Turn ON the appropriate circuit breaker(s) on the power conditioner's input

and output and then turn ON the protected equipment power switch or circuit

breaker.

Each power run should be unique to each piece of equipment in the system.

The use of temporary power taps should be avoided. Even the use of duplex

receptacles should be avoided in the case of electrically noisy loads. (i.e.

laser printers, phase regulated power supplies, etc.).

It is recommended that the power runs on the output of the conditioner be as

short as possible, with a maximum length of 15 m (50 feet).

3 Torque all connections.

Refer to the torque specifications in “Maintenance” on page 33.

4 Follow the procedure in “Verifying the Installation” on page 19.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 31

Installation Output Connections

32 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Maintenance

Maintaining the correct operation of your power conditioner is limited to

annually checking the operating voltage and torquing all the connections.

WARNING Turn off the input and main output circuit breakers on the power conditioner.

Turn off the power source supplying the power conditioner at the service

disconnect before proceeding.

In order to comply with SEMI-S2-93A; 11.2, which complies with 29 CFR

1910.147 (OSHA), the power feed to the power conditioner must be locked

out and tagged out at the service disconnect that feeds the power

conditioner input power block to de-energize the power conditioner.

Torque specifications Circuit Breakers torque specification—on circuit breaker label.

Power Blocks torque specification—on power block label.

Table 5 Torque specifications

Location

example

Transformer

Mounting

Wires 5/16 Steel 12 140 16.3

Misc. Conn. #10 Steel 32 3.6

Capacitors #8 Steel 20 2.3

PCB #6 Steel 11 1.2

TWL Recept #6 16 1.8

Dup Recept #6 12 1.4

Note: normalized torque conversions S.A.E. to metric.

Bolt size Material

1/2 Stainless

Steel

1/4 Steel 6 75 8.1

3/8 Brass 20 240 27

5/16 Brass 11 132 14.9

1/4 Brass 6 75 8.1

#10 Brass 20 2.3

#8 Brass 16 1.8

#6 Brass 8 0.9

Torque

(ft./lb) (in./lb) (Nm)

45 540 61

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 33

Maintenance Cleaning

Cleaning

The power conditioner is painted with a textured paint to minimize noticeable

dirt and fingerprints. The outside may be wiped clean with a slightly damp

cloth.

Fuse Replacement

The ONEAC CDR45I Series Power Conditioners require fuses in some

locations. In the unlikely event that a fuse needs to be replaced, spare fuses have

been provided in the internal spares compartment behind the middle front panel

which covers the EMO transformer and the power terminal block.

All fuses are service personnel replaceable only. Since all fuses are located

behind secured panels and/or covers limiting access to hazardous voltages, only

qualified electricians should replace them. The fuse locations and specifications

are as follows:

Table 6 Fuse locations and specifications

Location Input

Emergency OFF

Primary (2) 600 Vac 2 Amp Littelfuse KLDR2

Secondary (1) 250 Vac 1 Amp Littelfuse FLM-1

Follow lock out recommendations described in “Installation Overview” on

page 17 (step 3).

Fuse current

rating Sources Part numbers

Bussmann LP-CC-2

Gould ATDR2

Bussman FNM-1

34 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Fuse Replacement Maintenance

To replace a fuse:

WARNING Turn off the power source supplying the power conditioner at the service

disconnect before proceeding.

1 Turn OFF the power conditioner’s output circuit breaker.

2 Turn OFF the power conditioner’s input circuit breaker.

3 Turn OFF the power conditioner’s input power feed.

4 To replace the fuse(s), open the door. Remove middle panel over the EMO

transformer.

5 Remove and replace the fuse(s) as needed.

6 Replace the middle panel and close the door.

Figure 9 Fuse replacement

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 35

Emergency OFF

Safety interlock

switch

Emergency OFF

(EMO) fuses

(EMO)

transformers

7 Follow the procedure in “Verifying the Installation” on page 19.

Maintenance Fuse Replacement

36 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Operation of Additional Features

Indicators This feature provides a visual indication of the operational status of your power

conditioner as integrated to your equipment.

All LEDs used as indicators are Class I devices (as per IEC 845/84 and 21 CFR

1040.10).

Figure 10 Visual indication of the operational status

Input power applied to power conditioner

Main output circuit breaker

ON Power available at output

power block

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 37

Operation of Additional Features

38 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Physical Views

Figure 11 Physical views

Front Back Side

Top

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 39

Bottom

Physical Views

40 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Specifications

CDR45I Specifications

Output ratings 45 kVA 3-phase 208/120 Vac Wye, 125 amps/phase max.

Convenience circuits Single phase 120 Vac; 2 @ 15 A max

Single phase 208 Vac; 1 @ 10 A max

Input ratings 3-phase DELTA (Nominal voltages measured phase to phase)

Voltage/V Current/A

200 130

208 130

240 110

380 75

400 70

408 70

415 65

440 65

448 60

480 55

Frequency 50/60 Hz

Voltage tolerance ± 10%

Input overcurrent protection Single frame circuit breaker with trip current rating plug for 90 A. Spare rating

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 41

plugs for 70 A and for 150 A included inside unit.

Specifications CDR45I Specifications

Input voltage tap Factory configured for 400 Vac, unless otherwise labelled on the input power

block. Any mains transformer jumpers required that are not already in use on

the transformer primaries will be shipped inside the unit within the spares

compartment.

Input connections Prepared for fixed wiring of power line cable to internal power block. Accepts

wire size 6AWG - 350 MCM (16-177 mm2)

Adaptable for steel or flexible steel conduit fed from bottom or top of unit (2

inch (51 mm) hole in base or shim or punch to size).

Output connections Prepared for fixed wiring of power line cable to internal power block. Accepts

wire size 6AWG - 350 MCM (16-177 mm2).

Conduit steel or flexible steel fed from rear of unit (up to five (5) 2 inch (51

mm) holes in conduit landing panel punched as required.)

Convenience outlets Three (3) IEC 320 outlets rated 120 Vac, 10 A max.

Outlets labeled “1:10A 208 V Max. Output”.

Two (2) NEMA 5-15R duplex outlets rated 120 Vac, 15 A max, each. Covered

with a steel plate for CE compliance.

Outlets labeled: “2: 15 A 120 V Max. Output” and “3: 15 A 120 V Max.

Output”.

Corresponding circuit breakers labeled: “Convenience outlets: 1,2,3”.

Convenience outlets are energized when main input circuit breaker is turned

ON and individual convenience circuit breaker is turned ON.

Main output circuit breaker Energizes main output power block only.

Failsafe EMO Red mushroom push button remains depressed in activated position until

manually released. Button labeled “EMERGENCY OFF”.

Employs a 24 Vac control circuit powered from an isolation transformer with

dual primaries for various input voltage configurations from 200 to 480 Vac.

The 24 Vac control transformer is energized prior to the main input circuit

breaker. The control circuit is fuse protected on both the primary and secondary

sides.Two (2) spare primary fuses (2A, 600 Vac) and one (1) spare secondary

fuse (1A, 250 Vac) are provided and shipped with the unit in the spares

compartment.

Limited to 1.0 amp. An external normally closed (NC) contact or series string

of NC contacts, can be connected in the series contact circuit by removing the

shorting plug shipped with the unit and connecting across pins J1-3 and J1-4 of

the CPC connector. This CPC connector is located on the back of the

conditioner. A spare mating plug (P1) is supplied with 4 loose pins and one

cable strain relief with each unit in the spares compartment.

42 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

CDR45I Specifications Specifications

Normally open contacts. A single pair of normally open contacts are provided

whose coil is de-energized if the EMO contact circuit is opened. The normally

open contacts are accessed at pins J1-1 and J1-2 of the CPC connector.

Indicator lights Green LED for incoming Input Power ON or power applied to the conditioner.

Green LED for Output Power ON or power applied to the main output power

block.

Forward transfer impedance < 0.5 Ohms @ 1 KHz, L-N

< 0.05 Ohms @ 50/60 Hz L-N

Efficiency at rated load > 97% @ 50 Hz.

Heat loss @ 80% of rated load 1170 watts (4000 BTU/hr.).

Load regulation response time < 2 msec for a 50% change in load.

Surge Voltage withstand ANSI/IEEE C62.41: Category A, 6 kV, 200 A 100 kHz ringwave, And

Category B, 6 kV, 500 A 100 kHz ringwave and 3000 A impulse.

Surge voltage let-thru With unit under power, ANSI/IEEE C62.41 Category A 6 KV, 200 A. 100 kHz

ringwave surge applied yields < 10 V normal mode (L-N) and < 0.5 V common

mode (N-PE) at the output power block.

Overload capability Can typically tolerate 10 times rated output for 0.5 cycle, 5.5 times rated output

for 1 second, and 3.5 times rated output for 5 seconds without degradation.

Magnetic stray field operating < 5 Gauss (0.5 mTesla) anywhere on the conditioner’s surface for frequencies

less than or equal to 198 Hz under full rated load current into resistive load.

(Actual measurements indicate that < 1 Gauss peak except immediately above

the fans where < 3 Gauss peak.

Magnetic stray field non operating < 2 mGauss (0.2 µTesla) anywhere around conditioner. Measured at a distance

of 2.1m from conditioner. (IATA-Limit)

Operating temperature 0 ˚C to +40 ˚C

Storage temp –40 ˚C to +70 ˚C

Elevation 3,000 meters (10,000 ft.) max.

Relative humidity 80% @ 30 ˚C

Qualified for 48 hours in 91% to 95% RH @ 25 ˚C (as per EN60950)

Qualification test, non operating 12 hours at 65 ˚C and 90% RH

Cooling Forced air cooled

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 43

Specifications CDR45I Specifications

Approvals & markings UL, cUL, under bi-national standard UL1012.

CE Marked in compliance with EU directives and relative to EN60950.

SEMI S2-93A-compliant

Dimensions

(W x H x D): 55.1 cm x 157.5 cm x 52.1 cm (21.67" x 62.00" x 20.50")

Total footprint 2870 cm (445 inch)

Unit weight Approx. 400 kilograms (885 lbs.). Shipping weight approx. 470 kilograms

(1035 lbs).

Packaging Reusable pallet and crate with included ramp having dimensions of (LxWxH)

95.3 cm x 83.8 cm x 181.0 cm (37.5" x 33" 71.75")

Packaging specifications Crated unit meets ISTA test procedure 1B (6/99).

44 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

CDR45I Schematics Specifications

CDR45I Schematics

Figure 12A CDR45I Schematic (1)

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 45

Specifications CDR45I Schematics

Figure 13A CDR45I Schematic (2)

Figure 14A CDR45I Schematic (3)

46 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

CDR45I Schematics Specifications

Figure 15A CDR45I Schematic (4)

Figure 16A CRD45I Schematic (5)

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 47

Specifications CDR45I Schematics

48 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Troubleshooting an Installation

NOTE The conditioner is designed for repair ONLY by personnel trained to

repair this model. Repair by other personnel is not recommended.

1 If there is power at the input with no power at the output, turn OFF the

output circuit breaker and then the input power to the conditioner—the main

power source or service disconnect.

2 Check the values specified on the nameplate.

3 Verify that your main power source is correct for the power conditioner’s

input voltage.

4 Verify that the power conditioner’s input voltage has not been changed in the

field.

If everything seems correct, disconnect the line and ground input wires and then

contact ONEAC Technical Services.

Technical Support

ONEAC offers 24-hour technical support. If you have questions or problems

regarding your ON Series UPS.

If you are unable to troubleshoot the problem, contact ONEAC Technical

Services. Refer to “Technical Support” on page 11, for the correct telephone

number in your area. Technical Services will ask you to describe the problem.

We will help solve the problem over the telephone or issue a Return Material

Authorization (RMA) number along with instructions on how to return the

power conditioner.

You will need to supply the service representative with the power conditioner

part number and serial number. These are found on the serial number/rating

label on the left side of the power conditioner.

Always check with ONEAC Technical Services before attempting to repair or

return any ONEAC product.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 49

Troubleshooting an Installation Technical Support

50 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Changing the Operating Voltage

V oltage Tap Selection and Range

Change

Tap selection allows a permanent adjustment to the voltage level of any phase.

If the nominal output level is not within the equipment manufacturer’s

suggested operating range, you can move the power tap on the primary of the

power conditioners transformer.

Multiple input primary taps allow for a wide variety of input voltage

configurations presented around the world. Tap selection can also correct for

steady-state variances in nominal line voltage.

Tap selection is not available on the output.

Voltage tap selection:

1 Turn OFF the power conditioner’s output circuit breaker.

2 Turn OFF the power conditioner’s input circuit breaker.

3 Turn OFF the power conditioner’s input power at the service disconnect.

WARNING Turn off the power source supplying the power conditioner at the service

disconnect before proceeding. The MAINS OFF transformer will still be

powered unless the service disconnect is open!

In order to comply with SEMI-S2-93A; 11.2, which complies with 29

CFR 1910.147 (OSHA), the power feed to the power conditioner must be

locked out and tagged out at the service disconnect that feeds the power

conditioner input power block to de-energize the power conditioner.

4 Take off the bottom cover panel to expose the main transformer

compartment. The safety interlock will shut down power when the cover

panel is removed.

5 Remove the mid-front panel to expose the EMO transformer and its taps.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 51

Changing the Operating Voltage Voltage Tap Selection and Range Change

6 Refer to the transformer tap selection chart attached to the inside of the

power conditioner’s door or the figure at the end of this section.

7 Verify that the correct input circuit breaker rating plug has been installed

(see “Input Circuit Breaker” on page 22).

8 Do not change the location of any wires which are connected to the

transformer's primary circuit breaker or on the transformer's secondary.

9 Torque all connections as per section “Maintenance” on page 33.

10 Re-install both cover panels.

11 Mark any nominal voltage changes on or near the rating nameplate.

12 Follow the procedure in “Verifying the Installation” on page 19.

52 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Voltage Tap Selection and Range Change Changing the Operating Voltage

TapJ

Table 7 Mains (T1) transformer voltage tap selection

Input A

Voltage

200 A1 B1 C1 A1-A6 A3-A7 A3-B1 B1-B6 B3-B7 B3-C1 C1-C6 C3-C7 C3-A1

208 A1 B1 C1 A1-A6 A4-A8 A4-B1 B1-B6 B4-B8 B4-C1 C1-C6 C4-C8 C4-A1

240 A1 B1 C1 A1-A6 A5-A9 A5-B1 B1-B6 B5-B9 B5-C1 C1-C6 C5-C9 C5-A1

380 A1 B1 C1 A2-A6 A7-B1 B2-B6 B7-C1 C2-C6 C7-A1

400 A1 B1 C1 A3-A6 A7-B1 B3-B6 B7-C1 C3-C6 C7-A1

408 A1 B1 C1 A3-A6 A8-B1 B3-B6 B8-C1 C3-C6 C8-A1

415 A1 B1 C1 A4-A6 A8-B1 B4-B6 B8-C1 C4-C6 C8-A1

440 A1 B1 C1 A5-A6 A7-B1 B5-B6 B7-C1 C5-C6 C7-A1

448 A1 B1 C1 A5-A6 A8-B1 B5-B6 B8-C1 C5-C6 C8-A1

480 A1 B1 C1 A5-A6 A9-B1 B5-B6 B9-C1 C5-C6 C9-A1

(black)

Input B

(red)

Input C

(blue)

Jumper Jumper

Delta

Jumper

Jumper Jumper

Delta

Jumper

Jumper Jumper

Delta

Jumper

Figure 17 Mains (T1) transformer voltage tap selection

Input Breaker Module:

Must match current rating for selected

input voltage (see User Manual).

umpers:

Stored in spares

compartment

behind panel

200, 208, 240 V 150 A

380, 400, 415, 440 V 90 A

448, 480 V 70 A

T2:

24 Vac Control

Transformer

T1:

Mains Transformer

T1 – Mains transformer taps

To Configure Input Voltage:

1. Change/verify types are correct for both T1 and T2

2. Change/verify Input Breaker Module correct for input voltage

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 53

Changing the Operating Voltage Voltage Tap Selection and Range Change

Table 8 24 Vac control (T2) transformer voltage tap selection

Voltage Black lead Red lead Jumper Jumper

200 D7 D6 D1 – D6 D3 – D7

208 D8 D6 D1 – D6 D4 – D8

240 D9 D6 D1 – D6 D5 – D9

380 D2 D6 D1 – D7

400 D3 D6 D1 – D7

408 D3 D6 D1 – D8

415 D4 D6 D1 – D8

440 D5 D6 D1 – D7

448 D5 D6 D1 – D8

480 D5 D6 D1 – D9

Figure 18 T2 – 24 Vac control Xfmr taps

54 ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A

Warranty

Warranty

ONEAC warrants its products to be free from defects in materials and

workmanship for a period of five years. This warranty is limited to repairing or

replacing, at ONEAC’s option, any defective component, circuit board or

module contained within the product only when it is returned with an ONEAC

Return Material Authorization (RMA) number to ONEAC or to an ONEAC-

designated repair facility. In all cases, shipping charges to and from ONEAC or

the ONEAC-designated repair facility are at the customer’s expense.

Certain modules or peripherals included with the product but not manufactured

by ONEAC are warranted for ninety days or to the extent of the manufacturer’s

warranty, whichever is longer.

Limitations of Warranty – This limited warranty does not cover any losses or

damage resulting from shipment to or from the customer, or from improper

installation, environment or abuse, or from any modifications, adjustments or

repair by other than ONEAC-authorized personnel.

Exclusive Remedies – Except as set forth herein and except as to title, there are

no warranties, express or implied, or any affirmations of fact or promises by

ONEAC with reference to the products or their merchantability or fitness for

any particular purpose. In no event shall ONEAC be liable for lost profits,

goodwill or any other special or consequential damages.

If it becomes necessary to return a power conditioner, contact ONEAC for a

Return Material Authorization (RMA) number. This number must be marked

on the shipping carton and packing slip of the unit being returned. Shipping

charges are to be borne buy the customer. Customers will be billed repair

charges for shipping damages resulting from inadequate packaging of the

product being returned.

ONEAC CDR45I Series Power Conditioner, Installation Guide, 913-521 Rev. A 55

Loading...

Loading...