Page 1

0BAG? 8?EA?F

0&')2# 0&(%2

BYSV[PO G(E(3 2/.^)0.1

1/96

Page 2

8=@?GI 6E?>=HGADCF

Redistribution or publication of this document,

by any means, is strictly prohibited.

Before operating the engine, read the Operator’s Manual and

become familiar with it and the equipment. Safe and efficient

operation can be achieved only if the equipment is

properly operated and maintained.

The following symbols, found throughout this manual, alert you

to potentially dangerous conditions to the operator, service per-

sonnel, or the equipment.

This symbol warns of immediate hazards

which will result in severe personal injury or death.

<.74341

practice which can result in severe personal injury or

death.

/.:9354

practice which can result in personal injury or product or

property damage.

Fuels, electrical equipment, batteries, exhaust gases and

moving parts present potential hazards that can result in severe

personal injury. Take care in following these recommended

procedures. All local, state and federal codes should be

consulted and complied with.

<.74341

use in any type of aircraft. Use of this engine in aircraft can

result in engine failure and cause severe personal injury or

death.

GENERAL

This symbol refers to a hazard or unsafe

This symbol refers to a hazard or unsafe

This engine is not designed or intended for

• Provide appropriate fire extinguishers and install them in

convenient locations. Use an extinguisher rated ABC by

NFPA.

• Make sure that all fasteners on the engine are secure and

accurately torqued. Keep guards in position over fans,

driving belts, etc.

• If it is necessary to make adjustments while the engine is

running, use extreme caution when close to hot exhausts,

moving parts, etc.

• Used engine oils have been identified by some state and

federal agencies as causing cancer or reproductive

toxicity. When checking or changing engine oil, take care

not to ingest, breathe the fumes, or contact used oil.

• Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol or

drug that makes the operation of equipment unsafe.

BATTERIES

• Before starting work on the engine, disconnect batteries

to prevent inadvertent starting of the engine. Disconnect

negative (–) cable first.

• DO NOT SMOKE while servicing batteries. Lead acid bat-

teries give off a highly explosive hydrogen gas which can

be ignited by flame, electrical arcing or by smoking.

• Verify battery polarity before connecting battery cables.

Connect negative (–) cable last.

PROTECT AGAINST MOVING PARTS

• Do not wear loose clothing in the vicinity of moving parts,

such as PTO shafts, flywheels, blowers, couplings, fans,

belts, etc.

• Keep your hands away from moving parts.

FUEL SYSTEM

• DO NOT fill fuel tanks while engine is running.

• DO NOT smoke or use an open flame in the vicinity of the

engine or fuel tank. Internal combustion engine fuels are

highly flammable.

• Fuel line must be of steel piping, adequately secured, and

free from leaks. Piping at the engine should be approved

flexible line. Do not use copper piping for flexible lines as

copper will work harden and become brittle enough to

break.

• Be sure all fuel supplies have a positive shutoff valve.

• Benzene and lead, found in some gasoline, have been

identified by some state and federal agencies as causing

cancer or reproductive toxicity. When checking, draining

or adding gasoline, take care not to ingest, breathe the

fumes, or contact gasoline.

EXHAUST SYSTEM

• Exhaust products of any internal combustion engine are

toxic and can cause injury, or death if inhaled. When

operating the engine in a confined area, make sure the

ventilation system is operating properly.

• DO NOT use exhaust gases to heat a compartment.

• Make sure that your exhaust system is free of leaks. Make

sure that exhaust manifolds are secure and are not

warped by bolts unevenly torqued.

EXHAUST GAS IS DEADLY!

Exhaust gases contain carbon monoxide, a poisonous gas that

can cause unconsciousness and death. It is an odorless and

colorless gas formed during combustion of hydrocarbon fuels.

Symptoms of carbon monoxide poisoning are:

• Dizziness • Vomiting

• Headache • Muscular Twitching

• Weakness and Sleepiness • Throbbing in Temples

If you experience any of these symptoms, get out into fresh air

immediately, shut down the unit and do not use it until it has

been inspected.

The best protection against carbon monoxide inhalation is

proper installation and regular, frequent inspections of the

complete exhaust system. If you notice a change in the sound

or appearance of exhaust system, shut the unit down immediately and have it inspected and repaired at once by a competent

mechanic.

KEEP THE UNIT AND SURROUNDING AREA CLEAN

• Make sure that oily rags are not left on or near the engine.

• Remove all unnecessary grease and oil from the unit.

Accumulated grease and oil can cause overheating and

subsequent engine damage and present a potential fire

hazard.

E-8

Page 3

Table of Contents

Redistribution or publication of this document,

by any means, is strictly prohibited.

TITLE PAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY PRECAUTIONS INSIDE FRONT COVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1. INTRODUCTION 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2. TOLERANCES AND CLEARANCES 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3. ASSEMBLY TORQUES 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4. TROUBLESHOOTING 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5. FUEL SYSTEM 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carburetor Removal / Installation 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carburetor (Beginning Spec C)5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carburetor (Prior to Spec C)5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impulse Fuel Pump 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor Arm5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reconnecting and Reclamping the Choke and Throttle Cables5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Speed Adjustments5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Cleaner Maintenance5-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6. ELECTRICAL SYSTEM 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 VDC Output System6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Connections6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7. STARTING SYSTEM 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recoil Starter7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid Shift Starter7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8. LUBRICATION SYSTEM 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Oil Pressure8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 8-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Relief Valve8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9. ENGINE BLOCK ASSEMBLY 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Compression Test 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel Removal9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Rocker Cover9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Valve Lash9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Rocker Arms9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Pushrods and Ta ppets 9-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valves9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Disassembly/Assembly9-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearcase9-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Balancer Shafts 9-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Camshaft9-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression Release System 9-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston / Connecting Rod9-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Block9-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ball Bearings9-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Oil Seals9-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

ii

Redistribution or publication of this document,

by any means, is strictly prohibited.

Page 5

Section 1. Introduction

Redistribution or publication of this document,

by any means, is strictly prohibited.

This is the service manual for the Model E125H and

E140H engines. These are 1-cylinder, 4-stroke

cycle, spark-ignited, overhead-valve (OHV), air-

cooled engines. Table 1-1 summarizes other in-

formation about these engines.

TABLE 1-1. USEFUL ENGINE INFORMATION

FEATURE

Rated Power

at 3600 rpm

Displacement 389 cm3(23.7 inch3)

Bore 84.2 mm (3.31 inch)

Stroke 70 mm (2.76 inch)

Compression Ratio 8.5:1

Minimum Cylinder

Compression Test

Pressure

Lubricating Oil

Capacity (with filter)

Minimum Lubricating

Oil Pressures at

1500/3300 rpm

(Beginning Spec D)

Minimum Lubricating

Oil Pressures at

1500/3300 rpm

(Prior to Spec D)

Ignition Timing

(not adjustable)

MODEL

E125H

12.5 bhp 14.0 bhp

483 kPa (70 psi)

0.95 litre

(1 quart)

New: 80/138 kPa (13/20 psi)

Worn: 62/103 kPa (9/15 psi)

New: 21/96 kPa (3/14 psi)

Worn: –/28 kPa (–/4 psi)

23° BTDC

MODEL

E140H

In this manual, the flywheel end is considered the

front of the engine. Right and left sides are determined by viewing the engine from the front.

Section 2. Tolerances and Clearances and Sec-

tion 3. Assembly Torques provide information nec-

essary for proper reassembly of the engine. They

are referenced throughout the manual.

Section 5. Fuel System, Section 6. Electrical System, Section 7. Starting System and Section 8. Lu-

brication System cover service of major subsys-

tems of the engine.

Section 9. Engine Block Assembly covers the com-

plete overhaul of the engine block assembly.

See the separate Operator’s Manual for engine op-

eration, maintenance and storage and for fuel and

lubricating oil recommendations.

See the separate Parts Manual for part identification

numbers and required quantities and for exploded

views of the engine subassemblies. Genuine Onan

replacement parts are recommended for best

results. When ordering parts, always give the

complete model and serial numbers appearing on

the engine nameplate. See Table 1-2 for a breakdown of the engine model number.

TABLE 1-2. ENGINE MODEL NUMBER

E

| || |||

1 2 3 4 5 6

140 H – N /11152 A

1. Model Letter

2.Rated Power—“140” designates 14.0 bhp

(brake horse power) and “125”, 12.5 bhp.

3.Shaft Orientation—“V” designates vertical

shaft and “H”, horizontal shaft.

4. Engine Fuel—“N” designates gasoline, “L”,

LPG and “D”, dual fuel.

5. Optional Equipment Code—designates muffler, fuel tank, electric starter, etc. or combina-

tions thereof.

Section 4. Troubleshooting provides a way to sys-

tematically locate engine problems.

IMPROPER SERVICE OR REPLACEMENT OF PARTS CAN RESULT IN SEVERE PERSONAL IN-

JURY AND EQUIPMENT DAMAGE. SERVICE PERSONNEL MUST BE QUALIFIED TO PERFORM

6.Spec Letter—designates production modifications.

WARNING

ELECTRICAL AND MECHANICAL SERVICE.

1-1

Page 6

1-2

Redistribution or publication of this document,

by any means, is strictly prohibited.

Page 7

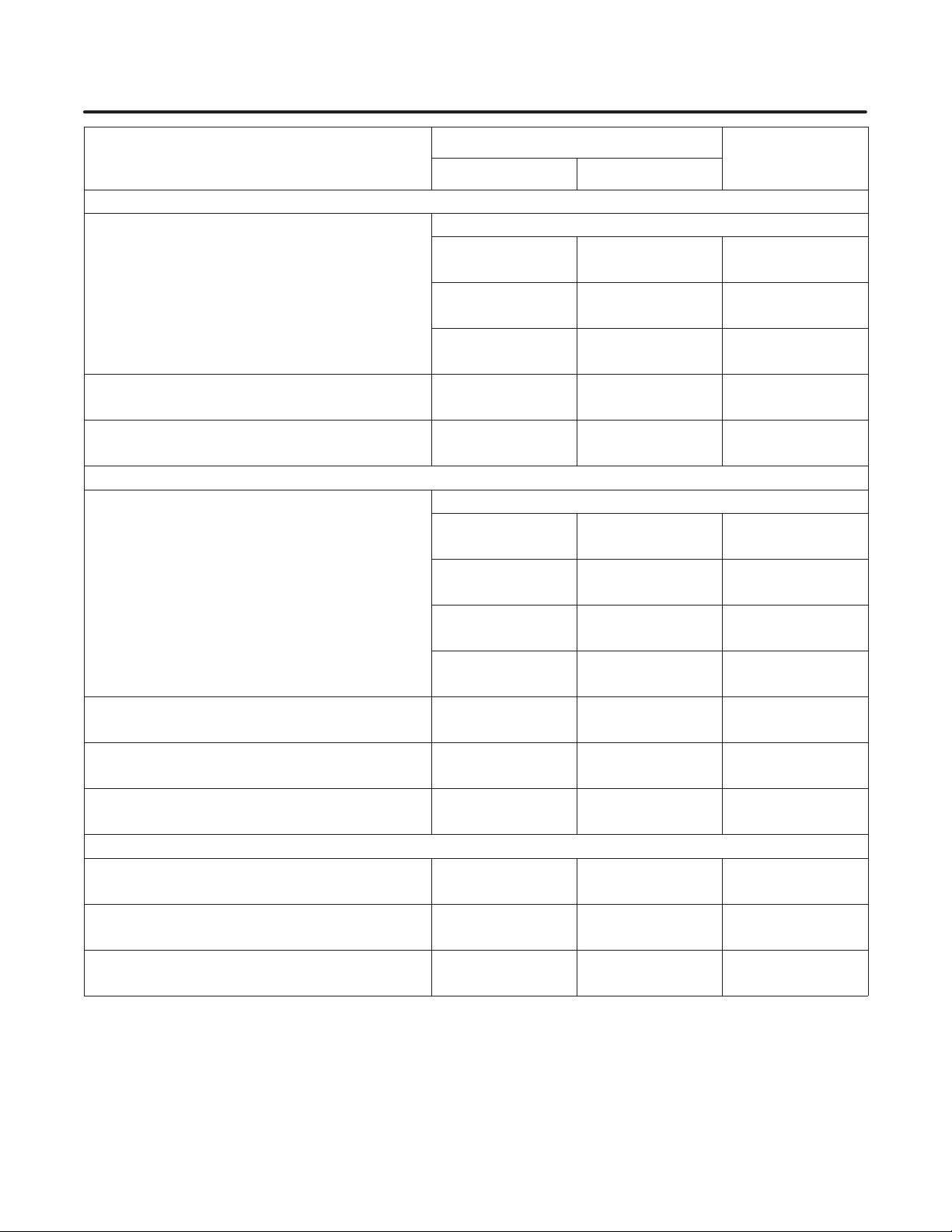

Section 2. Tolerances and Clearances

All dimensional tolerances and clear-

ALLOWABLE

ances are in millimetres (inches) at 21 ° C

(70° F) unless otherwise indicated.

LIMIT

Redistribution or publication of this document,

by any means, is strictly prohibited.

FACTORY SPECIFICATION

MINIMUM MAXIMUM

CYLINDER BLOCK

Cylinder Bore I.D.

Standard 84.200

(3.3150)

.25 Oversize 84.450

(3.3248)

.50 Oversize 84.700

(3.3347)

Cylinder Bore Ta per – – 0.10

Cylinder Bore Out-of-Round – – 0.05

CAMSHAFT

Lobe Height, Diameter Over Nose

E125 Intake 34.23

(1.348)

E125 Exhaust 34.53

(1.359)

E140 Intake 35.09

(1.381)

E140 Exhaust 35.09

(1.381)

End Clearance 0.10

(0.004)

Journal Bearing O.D. 17.975

(.7077)

Journal Bearing Clearance (in gearcase) 0.01

(.0004)

BALANCER SHAFTS

End Clearance (Both Shafts) 0.10

(0.004)

Journal Bearing O.D. 21.875

(0.8612)

Journal Bearing Clearance (in gearcase) 0.02

(0.0008)

84.225

(3.3160)

84.475

(3.3258)

84.725

(3.3356)

34.55

(1.360)

34.85

(1.372)

35.41

(1.394)

35.41

(1.394)

0.20

(0.008)

17.990

(.7083)

0.05

(.0020)

0.20

(0.008)

21.890

(0.8618)

0.056

(0.0022)

84.325

(3.3199)

84.575

(3.3297)

84.825

(3.3396)

(0.004)

(0.002)

33.73

(1.328)

34.03

(1.340)

34.59

(1.362)

34.59

(1.362)

0.25

(0.010)

17.93

(.7059)

0.08

(.0031)

0.25

(0.010)

21.83

(0.8594)

0.08

(0.0031)

2-1

Page 8

All dimensional tolerances and clear-

Redistribution or publication of this document,

by any means, is strictly prohibited.

FACTORY SPECIFICATION ALLOWABLE

ances are in millimetres (inches) at 21 ° C

(70° F) unless otherwise indicated.

CRANKSHAFT

Stroke 70

Connecting Rod Journal O.D.

Standard 33.475

(1.3179)

.25 Undersize 33.225

(1.3081)

.50 Undersize 32.975

(1.2982)

End Clearance 0.10

CONNECTING ROD

Pin Bore I.D. 20.015

(0.7880)

Large Bore I.D.

Standard 33.500

(1.3189)

.25 Undersize 33.250

(1.3091)

.50 Undersize 33.000

(1.2992)

Large Bore Clearance 0.015

(0.0006)

Side Clearance on Crankshaft 0.40

PISTON

Piston Skirt O.D. 90 Degrees to Pin and

26.5 mm (1.043 inch) from Top of Piston

Standard 84.09

.25 Oversize 84.34

.50 Oversize 84.59

Pin Bore I.D. 20.004

(0.7876)

(2.76)

(.004)

(0.016)

(3.311)

(3.320)

(3.330)

70

(2.76)

33.485

(1.3183)

33.235

(1.3085)

32.985

(1.2986)

0.20

(.008)

20.025

(0.7884)

33.525

(1.3199)

33.275

(1.3100)

33.025

(1.3002)

0.050

(0.0020)

1.10

(0.043)

84.12

(3.312)

84.37

(3.322)

84.62

(3.331)

20.012

(0.7879)

LIMIT

–

–

–

–

0.25

(0.010)

20.071

(0.7902)

–

–

–

0.100

(0.0040)

1.50

(0.059)

–

–

–

20.022

(0.7883)

2-2

Page 9

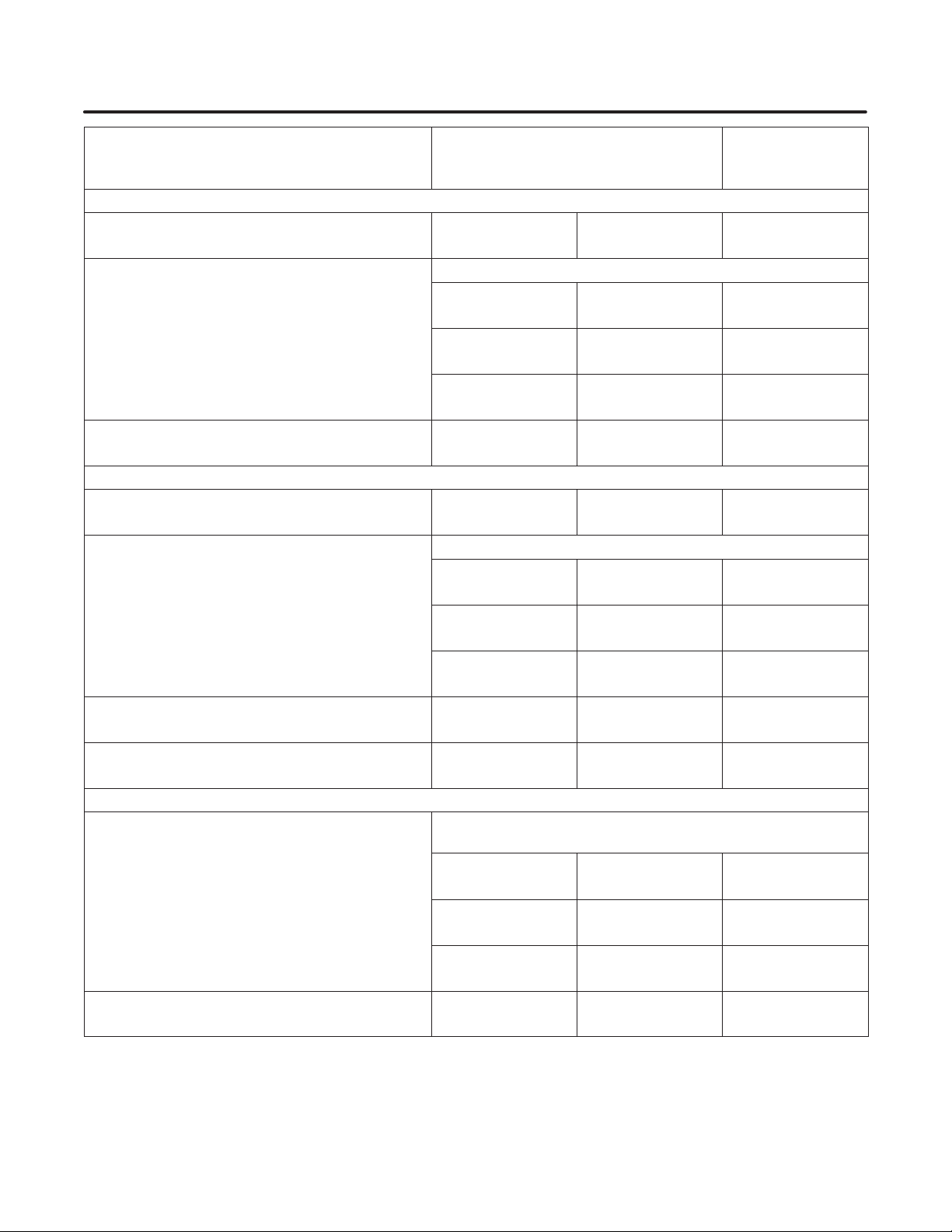

All dimensional tolerances and clear-

FACTORY SPECIFICATION

ALLOWABLE

ances are in millimetres (inches) at 21 ° C

(70° F) unless otherwise indicated.

LIMIT

Redistribution or publication of this document,

by any means, is strictly prohibited.

MINIMUM MAXIMUM

PISTON PIN

Piston Pin O.D. 20.000

(0.7874)

Clearance in Piston Pin Bore –.001

(.0000)

Clearance in Connecting Rod Pin Bore .010

(0.0004)

20.005

(0.7876)

.012

(0.0005)

.025

(0.0010)

PISTON RINGS

Top Compression Ring Thickness 1.47

(.058)

Second Compression Ring Thickness 1.47

(.058)

Top Compression Ring to Ring Groove

Clearance

Second Compression Ring to Ring

Groove Clearance

0.03

(0.001)

0.03

(0.001)

Top Compression Ring End Gap 0.25

(0.010)

Second Compression Ring End Gap 0.25

(0.010)

Oil Ring Side Rail Gap 0.38

(0.015)

1.49

(.059)

1.49

(.059)

0.08

(0.003)

0.08

(0.003)

0.51

(0.020)

0.51

(0.020)

1.40

(0.055)

INTAKE VALVE

Valve Stem O.D. 6.960

(0.2740)

Valve Guide I.D. 7.000

(0.2756)

Valve Stem to Valve Guide Clearance 0.03

(0.001)

6.975

(0.2746)

7.015

(0.2762)

0.06

(0.002)

Valve Lash 0.15

(.006)

Face Angle 45" –

INTAKE VALVE SEAT

Seat Width 1.1

(.043)

Seat Angle 45" –

19.990

(0.7870)

0.03

(0.0012)

.035

(0.0014)

1.42

(.056)

1.42

(.056)

0.13

(0.005)

0.13

(0.005)

1.00

(0.039)

1.00

(0.039)

1.80

(0.071)

–

–

0.10

(0.004)

0.25

(0.010)

1.7

(.067)

2-3

Page 10

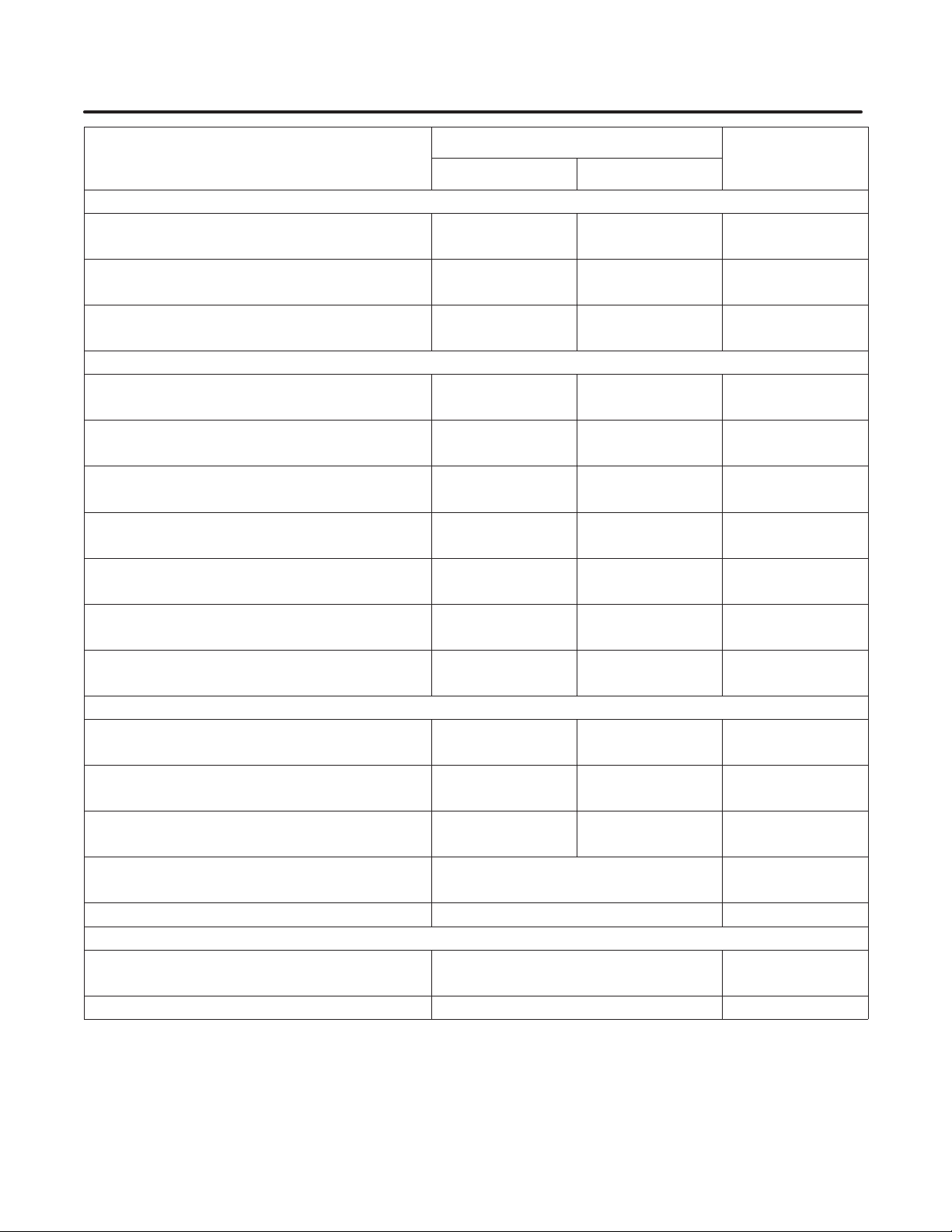

All dimensional tolerances and clear-

FACTORY SPECIFICATION

ALLOWABLE

ances are in millimetres (inches) at 21 ° C

(70° F) unless otherwise indicated.

LIMIT

Redistribution or publication of this document,

by any means, is strictly prohibited.

MINIMUM MAXIMUM

EXHAUST VALVE

Valve Stem O.D. 7.940

(0.3126)

Valve Guide I.D. 8.000

(0.3150)

Valve Stem to Valve Guide Clearance 0.04

(.002)

7.960

(0.3134)

8.015

(0.3156)

0.08

(.003)

Valve Lash 0.15

(.006)

Face Angle 45" –

EXHAUST VALVE SEAT

Seat Width 1.1

(0.043)

Seat Angle 45" –

VALVE SPRINGS—INTAKE AND EXHAUST

Valve Spring Free Length (Approx.) 43.5

(1.713)

Valve Spring Length

Valve Closed 32.6

(1.28)

Valve Open 23.2

(0.91)

Spring Load (Valve Closed Length) 12.6 kg

(27.7 lb)

Spring Load (Valve Open Length) 26.4 kg

(58.2 lb)

14.6 kg

(32.1 lb)

28.4 kg

(62.7 lb)

VALVE ROCKER ARM

Rocker Arm Bore I.D. 12.000

(0.4724)

Rocker Arm Shaft O.D. 11.973

(0.4714

Rocker Arm to Rocker Shaft Clearance 0.016

(0.0006)

12.018

(0.4718)

11.984

(0.4718)

0.045

(0.0018)

–

–

0.10

(.004)

0.25

(0.010)

1.7

(0.067)

–

–

–

–

24.9 kg

(55 lb)

–

–

0.15

(0.0059)

2-4

Page 11

All dimensional tolerances and clear-

FACTORY SPECIFICATION

ALLOWABLE

ances are in millimetres (inches) at 21 ° C

(70° F) unless otherwise indicated.

LIMIT

Redistribution or publication of this document,

by any means, is strictly prohibited.

MINIMUM MAXIMUM

LUBRICATING SYSTEM

Rotor Lobe Clearance 0.15 or less

(0.006 or less)

Outer Rotor to Pump Body Clearance 0.12

(0.005)

Rotor to Cover Clearance 0.02

(0.001)

IGNITION SYSTEM

Spark Plug Gap 0.89

(0.035)

Magneto Coil to Rotor Magnet Clearance 0.25

(0.010)

STARTER MOTOR

Commutator O.D. 28.0

(1.102)

Difference of Commutator O.D.’s – 0.05

Armature Shaft to Bushing Clearance 0.02

(0.001)

Mica Undercut 0.45

(0.018)

0.19

(0.007)

0.09

(0.004)

1.02

(0.040)

0.40

(0.016)

(0.002)

0.07

(0.003)

0.75

(0.030)

0.20

(0.008)

0.25

(0.010)

0.25

(0.010)

–

–

27.00

(1.063)

0.016

(0.41)

0.20

(.008)

0.20

(0.008)

2-5

Page 12

2-6

Redistribution or publication of this document,

by any means, is strictly prohibited.

Page 13

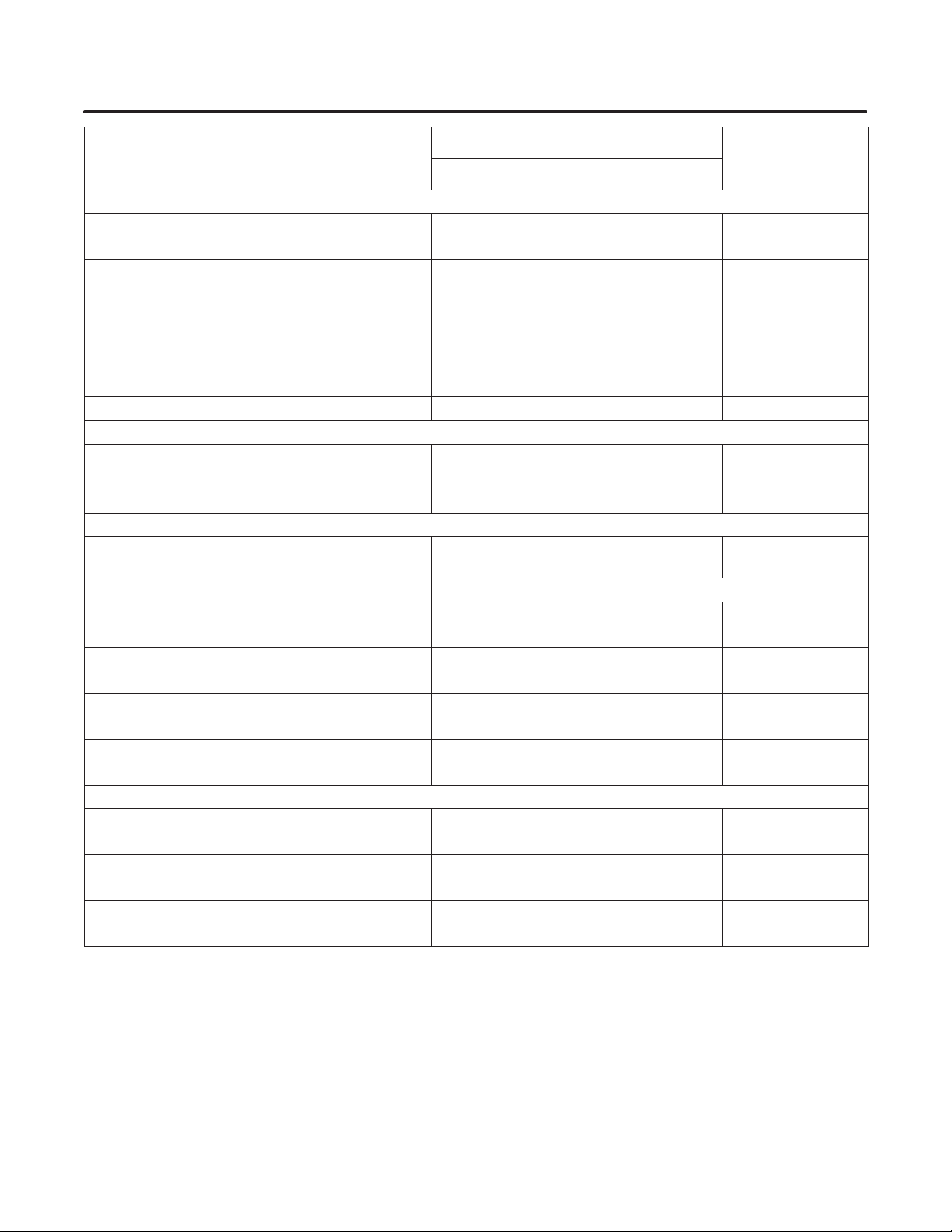

Section 3. Assembly Torques

BOLT “A”

GEARCASE

GEARCASE

BOLTS

CYLINDER HEAD

Redistribution or publication of this document,

by any means, is strictly prohibited.

DESCRIPTION BOLT

SIZE

Connecting Rod Bolts M8 x 44 24-27 18-20

Gearcase Bolts

Oil Pump Cover Screws M6 x 14 7-11 5-8

Oil Pickup Tube M6 x 14 7-11 5-8

Oil Drain Plugs 1/4” NPT 7-11 5-8

Fuel Pump Pulse Line

Elbow

LOPCO or Pipe Plug 1/8” NPT 7-9.5 5-7

Adapter Filter Head 3/4”-16 47-54 35-40

Oil Filter – – – <Turn the oil filter 3/4-1 turn after gasket contacts base.

Cylinder Head Bolts

No. 1-5 Bolts

No. 6 Flange Bolt M8 x 50 16-22 12-16

Valve Lash Adjusting

Nut

Valve Rocker

Cover Bolts

Spark Plug M14-1.25 24-30 18-22

M8 x 35,

50, 75

1/8” NPT 7-9.5 5-7

M10 x 66,

86, 125

M7 7-11 5-8

M6 x 25 7-11 5-8

METRIC

(N-m)

16-22 12-16

42-50 31-37

ENGLISH

(LB-FT)

INSTRUCTIONS

<Torque the gearcase bolts in a clockwise direction starting

with bolt “A”. Torque bolt “A” twice.

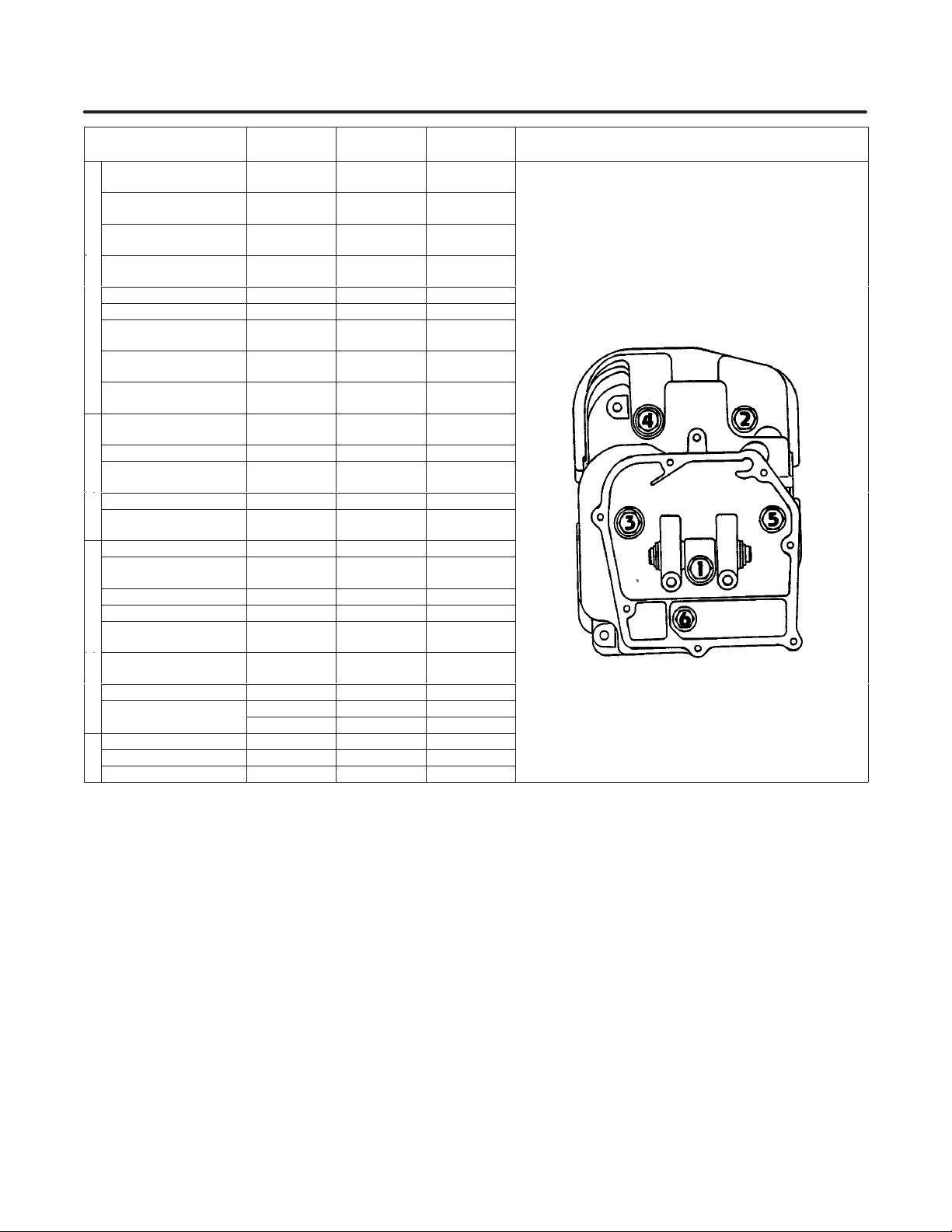

<Torque the cylinder head bolts in sequence shown. Two

bolts outside valve cover (#2 & #4) to be retorqued after

others are torqued.

<Tighten every other valve rocker cover bolt until all bolts

are tightened. Torque the first bolt twice.

3-1

Page 14

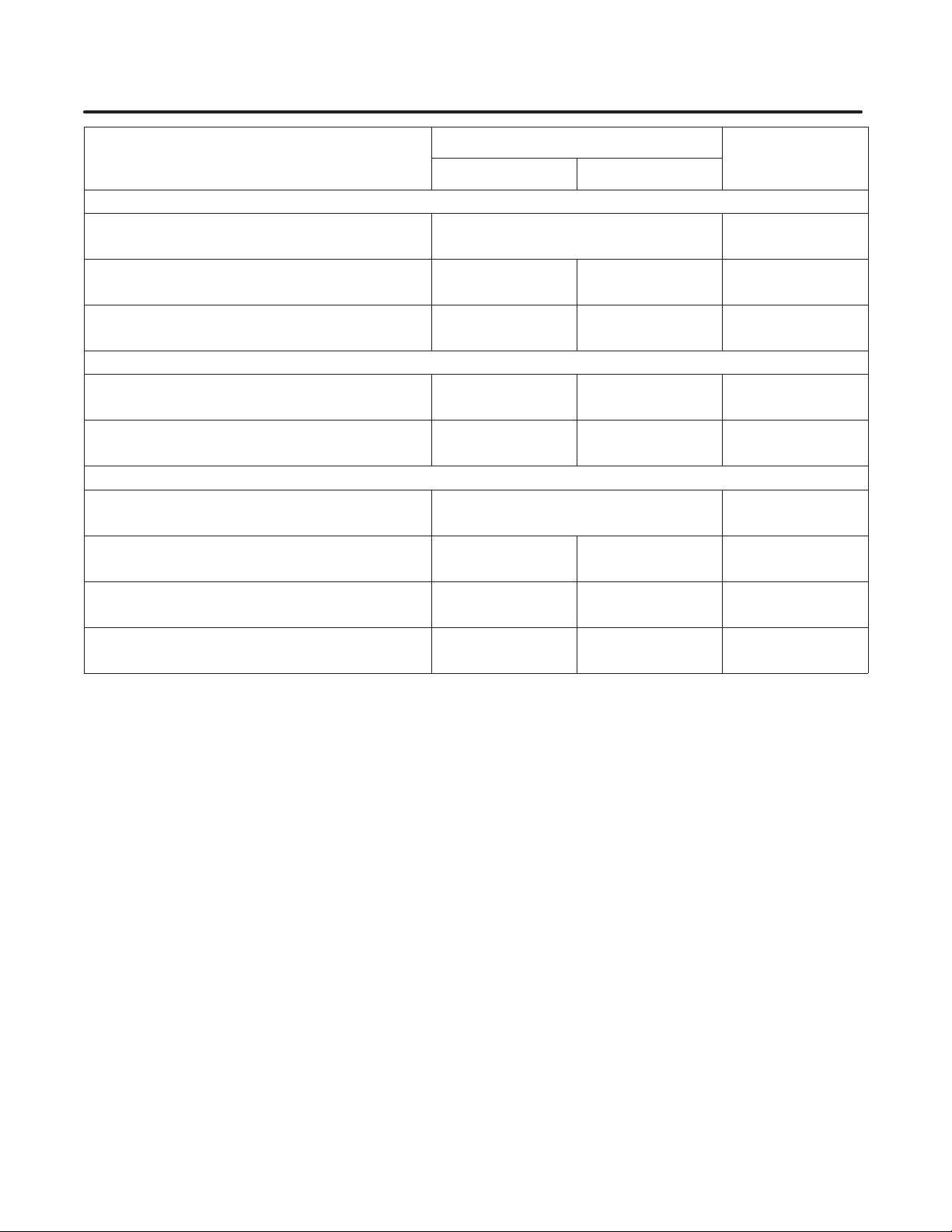

DESCRIPTION INSTRUCTIONSENGLISH

INTAKE SYSTEM

CYLINDER HEAD TORQUE SEQUENCE

ELECTRICAL

SHEET

NOTE: THESE TORQUE VALUES PROVIDE

Cylinder Air Housing

PROPER TIGHTNESS WITHOUT DANGER OF

Cylinder Air Housing

Bolt

STRIPPING THREADS. ALL THREADS MUST BE

CLEAN AND RUST-FREE. LIGHTLY OIL ALL

THREADS EXCEPT ON THE SPARK PLUG.

MISC

Redistribution or publication of this document,

by any means, is strictly prohibited.

BOLT

SIZE

Pulse Pump to Air

Cleaner Pan

Intake Elbow to Cylinder

Head

Air Cleaner Pan to

Cylinder Block

Carburetor to Intake El-

bow

Air Cleaner Wingnut 1/4”-20 - - <Tighten 6 to 8 clicks after seating air cleaner.

Control Plate Screws M5 x 16, 30 7-9.5 5-7

Throttle Stop Screw

Bracket

Fuel Line Hold Down

Screw

Throttle Cable Clamp

Screw

Voltage Regulator

Screws

Starter Bolts M8 x 40 16-22 12-16

Alternator Stator

Screws

Ignition Coil Bolt M6 x 30 10-15 7-11

Connector-Wire Har-

ness to Blower Housing

Blower Housing Bolts M6 x 20 7-11 5-8

Blower Housing to Man-

ifold Bolt

Starter Cover Bolts 3/8” x 16 25-35 18-26

Chaff Screen Bolts M6 x 10 7-11 5-8

Stationary Guard Bolts M6 x 20 1-1.2

Recoil Starter Cup

Screw

Recoil Starter Bolts M6 x 12 7-11 5-8

Governor Arm Nut M6 8.1-10.9 6-8

Flywheel Nut M18 122-138 90-102

Oil Fill Tube M8x20 11-16 8-12

#10 2.3-2.8

M8 x 50 11-16 8-12

M8 x 16 11-16 8-12 <Tighten twice (1-2-1).

M6 x 85 10-15 7-11 <Tighten twice (1-2-1).

M5 x 10 2.7-5.4 2-4

#10-16 1.4-2

#10-32 1.4-2

1/4” x 50 6.7-8.1

M6 x 25 10-15 7-11

M4 x 12 1.4-2

M6 x 14 10-15 7-11

1/4”-20 7-11 5-8

M6x10 7-11 5-8

M8x16 11-16 8-12

METRIC

(N-m)

(LB-FT)

1.7-2.1

(20-25 lb-in)

1-1.5

(12-18 lb-in)

1-1.5

(12-18 lb-in)

5-6

(60-72 lb-in)

1-1.5

(12-18 lb-in)

1-1.5

(12-18 lb-in)

3-2

Page 15

Section 4. Troubleshooting

Redistribution or publication of this document,

by any means, is strictly prohibited.

PROBLEM

Engine Does Not Start

• • Battery Connections Poor

• • Battery Low or Discharged

• • Starter Faulty

• Starter Solenoid Faulty

• • Spark Plug Gap Wrong

• • Magneto Coil Faulty

• • Spark Plug Wires Faulty

• • • • • • Magneto Gap Wrong

• • Fuel Ta nk Empty

• • • • • Fuel Mixture Too Lean

• • • • • Fuel Mixture Too Rich

• • • • Engine Flooded

• • • • • • Fuel Quality Poor

• • • • • Carburetor Dirty

• • • • • • • • Air Cleaner Dirty

• • • Fuel Filter Dirty

• • • • Fuel Pump Defective

• • • • • Valve Clearance Wrong

• • • • • • Valve Spring Broken

• • • • Piston Rings Worn or Broken

• • • • Head Gasket Blown

• • • • • • • • • • Oil Level Too Low

• • • • • • • • • • • Oil Viscosity Too Low or Diluted

• • Linkage Out of Adjustment

• • Linkage Worn or Disconnected

• • Linkage Binding

• • Governor Assembled Wrong

Engine Stops

Engine Cranks Slowly

• • • • • Bearing Clearance Wrong

• • Oil Viscosity Too High

Engine Misfires

• • • • • Valve or Valve Seal Leaking

• • Air Circulation Poor

• • Cylinder Cooling Fins Dirty

Engine Overheats

Engine Backfires

Governor Hunts

Black Exhaust

Blue Exhaust

Burned Valves

Connecting Rod Wear

• • • • • • Oil or Oil Filter Dirty

• • • • • • • Oil Pump Faulty

High Oil Pressure

Cylinder Wear

• • Oil Gauge Faulty

• • Relief Valve Stuck

Mechanical Noise

Low Oil Pressure

Piston Wear

Low Compression

Bearing Wear

Sticking Valves

Ring Wear

PROBABLE CAUSE

STARTING SYSTEM

IGNITION SYSTEM

FUEL SYSTEM

INTERNAL ENGINE

COOLING SYSTEM

LUBRICATING SYSTEM

THROTTLE/GOVERNOR

4-1

Page 16

4-2

Redistribution or publication of this document,

by any means, is strictly prohibited.

Page 17

Section 5. Fuel System

Redistribution or publication of this document,

by any means, is strictly prohibited.

WARNING

Improper service or replacement of

parts can result in severe personal injury and

equipment damage. Service personnel must be

qualified to perform electrical and mechanical

service.

WARNING

Accidental starting of the engine

can result in severe personal injury or death.

Disconnect the negative (–) battery cable and

spark plug wire before servicing the engine,

controls, or associated equipment.

WARNING

Ignition of fuel can result in severe

personal injury or death. Do not smoke or allow

any spark, pilot light, or arcing switch or equip-

ment near the fuel system or in areas with

shared ventilation.

Provide adequate ventilation when working on

the fuel system.

CARBURETOR REMOVAL/INSTALLATION

Before replacing or overhauling a carburetor, make

certain 1) that all other necessary engine and gener-

ator adjustments and repairs have been performed

and 2) that the carburetor is actually malfunctioning.

Carburetor Removal

Refer to Figure 5-1. Remove the air cleaner assem-

bly. Disconnect the governor linkage, fuel line, throt-

tle linkage, and choke control linkage. Remove the

carburetor assembly from the intake elbow.

Carburetor Installation

Install the carburetor assembly on the intake elbow.

Tighten the through bolts as specified in Section 3.

Assembly Torques. Connect choke control linkage,

throttle linkage, fuel line, and governor linkage.

Make sure the breather tube and rubber seal are

installed properly. Install the air cleaner assembly

as instructed in this section. Always use new gas-

kets when installing a carburetor.

Instructions for control cable and speed adjust-

ments follow in this section.

?AG@F;@9

E5D7IE

DG447D

E73>

3;D

5>73@7D

93E=7F

4D73F:7D

FG47

;@F3=7

7>4AI

53D4GD7FAD

3EE7?4>K

53D4GD7FAD

EGBBADF

FIGURE 5-1. CARBURETOR ASSEMBLY

5-1

Page 18

CARBURETOR (BEGINNING SPEC C)

Redistribution or publication of this document,

by any means, is strictly prohibited.

Carburetor Replacement

Other than replacing the carburetor main fuel jet

(fixed-type) with the optional high-altitude jet (Fig-

ure 5-2), fuel mixture adjustments should not be at-

tempted. Nor should the carburetor be overhauled.

Instead, a malfunctioning carburetor should be re-

placed. See CARBURETOR REMOVAL / INSTAL-

LATION in this section.

Carburetor High-Altitude Jet (Optional)

If the engine is operated at an altitude above 5000

feet (1524 metres), it is recommended that the carburetor main fuel jet be replaced with the optional

high-altitude jet (which has a slightly smaller orifice).

5:A=7

>7H7D

F:DAFF>7

>7H7D

CAUTION

To avoid slipping and gouging the

main fuel jet, use a screwdriver with a 5/16 inch

(8 mm) wide blade.

;6>7 EB776

EFAB E5D7I

F3?B7D^D7E;EF3@F

B>G9 AH7D ;6>7

?;JFGD7 @776>7

?3;@ 8G7> <7F

$ZRW]V PVTLYQPO%

5-2

D7?AH7 F:7 8>A3F

4AI> 8AD 3557EE FA

F:7 ?3;@ 8G7> <7F

FIGURE 5-2. CARBURETOR

Page 19

CARBURETOR (PRIOR TO SPEC C)

Redistribution or publication of this document,

by any means, is strictly prohibited.

CO Adjustment

Carburetor parts are fragile and must be handled

with care. Never force a part when disassembling or

assembling the carburetor.

Carburetor Disassembly

Remove the chamber set plug and washer from the

float chamber (Figure 5-3). Remove the float cham-

ber and gasket. Slide the float pin out from the pas-

sage in the carburetor. Remove the float and float

valve from the carburetor. Remove the main jet.

Remove the idle adjust screw.

Carburetor Inspection/Service

Soak metal components in a carburetor cleaner. Do

not soak non-metal parts and gaskets in carburetor

cleaner. Follow the cleaner manufacturer’s recom-

mendations.

Clean carbon from the carburetor bore, especially

around the throttle and choke plates. Dry out all air

passages with low air pressure (35 psi). Do not use

wire or other objects for cleaning passages; this

may damage critical passages.

Replace the float if cracked, damaged, or if it con-

tains fuel.

If a CO (Carbon Monoxide) meter is available, ad-

just the idle mixture screw to provide 5% to 6% CO

at 3300 rpm with no load on the engine. If a meter is

not available, set the idle mixture screw at 2 turns

out.

;6>7

36<GEF?7@F

E5D7I

?3;@

<7F

8>A3F

8>A3F

H3>H7

Inspect the idle adjustment needle. Replace if it’s

bent, worn, or damaged in any way.

Check the choke and throttle shafts for excessive

play in the bore. This condition may necessitate replacement of the carburetor.

Assembly

CAUTION

ment screw will cause carburetor damage. Turn

mixture adjustment screw in only until light ten-

sion can be felt.

Install idle adjust screw. Turn screw in until a LIGHT

tension is felt. Turn the screw out 2 turns.

Install the main jet. Install the float valve in the float.

Turn the carburetor upside down and install the float

valve in the carburetor. Slide float pin into passage

in carburetor and float. Install float chamber and

gasket on carburetor by screwing in chamber set

plug and gasket into carburetor.

Overtightening the mixture adjust-

8>A3F

B;@

93E=7F

8>A3F

5:3?47D

I3E:7D

5:3?47D

E7F B>G9

FIGURE 5-3. CARBURETOR COMPONENTS

(PRIOR TO SPEC C)

5-3

Page 20

IMPULSE FUEL PUMP

Redistribution or publication of this document,

by any means, is strictly prohibited.

The engine may be equipped with an impulse-type

fuel pump which has a spring-loaded diaphragm operated by crankcase pressure pulses. The fuel flow

direction is marked on the cover of the pump. Replace the pump if it leaks or fails to pump.

The Engine Will Not Start: If the engine still will not

start after performing any necessary preliminary

service, crank the engine and then remove and in-

spect the spark plug.

If the spark plug is wet and has a strong gasoline

smell, the fuel pump is probably okay. Check for:

WARNING

Ignition of fuel can result in severe

personal injury or death. Do not smoke or allow

any spark, pilot light, or arcing switch or equip-

ment near the fuel system or in areas with

shared ventilation.

Provide adequate ventilation when working on

the fuel system.

Inspection/Service

Preliminary Checks and Service: Perform the fol-

lowing checks and service before inspecting the fuel

pump if it is suspected that fuel delivery is the problem causing the engine not to start or to starve for

fuel under load.

1. Check the fuel tank and refill it as necessary.

Replace the fill cap if the vent is plugged.

2.Open all fuel shutoff valves (if any) in the fuel

supply line.

3.Check the engine oil level and refill as necessary.

• A fouled spark plug. Clean and regap or re-

place a fouled spark plug. Note that a fouled

spark plug may indicate the need for engine

service.

• An improperly adjusted carburetor choke.

See RECONNECTING AND RECLAMPING

THE CHOKE AND THROTTLE CABLES in

this section.

• A defective or improperly connected “Off” or

“Kill” switch. See Section 6. Electrical Sys-

tem.

If the spark plug is dry, check fuel pump operation

as follows:

• Ground the spark plug lead so that ignition

sparks can not ignite the gasoline.

• Disconnect the fuel outlet hose (to the carbu-

retor), connect a hose at least 200 mm (8 in-

ches) long and direct the end of the hose into

a container to collect the gasoline.

4. Check the fuel hose for kinks, pinches and

leaks and service as necessary. Note that dips

and long runs of fuel line can lead to vapor lock

in hot weather.

5. Replace the fuel filter if necessary.

6.Inspect the crankcase for visible oil leaks, especially around the seal on the oil fill tube, and

service as necessary. If the crankcase is not

properly sealed the pressure pulses may be too

weak to operate the fuel pump as required.

7.If the gasoline in the supply tank is more than

six months old, dispose of it properly and refill

the tank with fresh fuel. See the Operator’s

Manual for fuel recommendations.

• Crank the engine with the electric starter or

the recoil starter for 20 seconds.

Replace the fuel pump as instructed in this section if

there is no fuel flow from the pump. If there is fuel

flow, service the carburetor as instructed in this sec-

tion.

The Engine Runs But Starves For Fuel Under

Load: If the engine appears to starve for fuel under

load, disconnect the regular fuel supply to the engine, or close the fuel shutoff valve, and connect a

gravity supply fuel system directly to the carburetor.

Replace the fuel pump as instructed in this section if

the problem is eliminated by direct gravity feed. If

not, service the carburetor as instructed in this sec-

tion.

5-4

Page 21

Fuel Pump Removal

Redistribution or publication of this document,

by any means, is strictly prohibited.

Replace a defective fuel pump assembly as follows:

1. Close the fuel shutoff valve.

2.Place a drip pan under the fuel pump and carburetor to collect fuel.

3.Disconnect the starting battery (if equipped).

Disconnect the negative (–) cable first to re-

duce the risk of arcing.

4. Remove the air cleaner cover and air filter

assembly.

5. Loosen the screws that secure the fuel pump to

the air cleaner pan assembly. (It may be neces-

sary to loosen the air cleaner pan mounting

screws to gain access to the fuel pump.)

6.Disconnect the hoses and remove the pump.

Fuel Pump Installation

Installation is the reverse of removal. Replace any

damaged or deteriorated fuel lines. Tighten all

mounting hardware to that specified in Section 3.

Assembly Torques .

If it was necessary to loosen the air cleaner pan

mounting screws to remove the pump (Step 5), it will

be necessary to reposition the governor arm on its

shaft and to readjust the engine idle speeds. See

GOVERNOR ARM and ENGINE SPEED ADJUSTMENTS in this section.

AGF>7F 8G7>

:AE7

BG>E7 :AE7

;?BG>E7 8G7>

BG?B

8G7> 8;>F7D

;@>7F 8G7>

:AE7

FIGURE 5-4. IMPULSE FUEL PUMP

5-5

Page 22

GOVERNOR ARM

Redistribution or publication of this document,

by any means, is strictly prohibited.

For top performance it is essential that the governor

arm, control cables and idle speeds be adjusted

properly. The governor arm (Figure 5-5) must be re-

positioned on its shaft whenever the intake manifold

or carburetor is replaced or reinstalled. This must be

done BEFORE making speed adjustments so as to

compensate for the slightly different alignment of

parts after reassembling the carburetor or intake

manifold to the engine. See Section 9. Engine Block

Assembly regarding the internal governor parts.

2.Loosen lock nut 3 until it extends slightly be-

yond the end of the shaft.

3.Place the puller arms around the hub of the

governor arm, center the puller screw so that it

bears on the lock nut and then turn the screw

until the governor arm breaks loose.

Governor Arm Adjustment

1. Loosely assemble the governor arm to the gov-

ernor shaft and start the lock nut.

The governor arm and shaft have been designed so

that a standard battery cable clamp lifter available at

any automotive parts store can be used to pull the

arm from the shaft taper.

WARNING

Accidental starting of the engine

can result in severe personal injury or death. Al-

ways disconnect the spark plug and battery

(negative [–] cable) before adjusting the governor.

Governor Arm Removal

1. Remove throttle link 4 from governor arm 6 to

prevent damage to the link and carburetor.

9AH7D@AD

EBD;@9 $*%

4

4

2.Re-attach link 4 to the governor arm and carbu-

retor. Replace clips 5 if they are worn or broken.

3.Push the top of the governor arm toward the

carburetor until it stops and hold it there while

performing the next steps.

4. Check to see that the governor spring is pulling

the carburetor throttle to the wide open posi-

tion.

5. Tighten the lock nut, making sure the governor

shaft rotates clockwise against the internal

governor parts and tighten as specified in Sec-

tion 3. Assembly Torques .

5>;B $.%

F:DAFF>7

>;@= $-%

9AH7D@AD

3D? $/%

H;7I 4'4

3

3

H;7I 3'3

FIGURE 5-5. ENGINE GOVERNOR ADJUSTMENTS

5-6

9AH7D@AD

E:38F $+%

>A5= @GF

$,%

Page 23

RECONNECTING AND RECLAMPING THE

Redistribution or publication of this document,

by any means, is strictly prohibited.

CHOKE AND THROTTLE CABLES

If the engine is so equipped, the choke and throttle

cables are secured by a single clamp (choke cable

above throttle cable) to a bracket at the top of the en-

gine (Figure 5-6). If necessary, reconnect and re-

clamp the cables as follows:

1. Stop the engine and disconnect the spark plug

and, if so equipped, the battery (negative [–]

cable).

CHOKE CABLE

CHOKE CABLE

(above throttle

cable)

SLACK OUT

THIS WAY

ALTERNATE

CABLE CLAMP

LOCATIONS

WARNING

Accidental starting of the en-

gine can result in severe personal injury or

death. Always disconnect the spark plug

and battery (negative [–] cable) before resetting the engine control cables.

2.Push the choke knob in to the full open-choke

position and the equipment throttle lever to its

lowest speed position.

3.Loosen the cable clamp at the engine bracket if

necessary and hook the cable wires into the

hook holes in the choke and throttle control

arms, if not already hooked. Note that there are

two hook holes in each control arm. Make sure

the wires are hooked appropriately, as shown,

for the cable clamp location being used. Otherwise, the cable will bind, preventing full move-

ment.

4. Rotate the choke and throttle control arms

clockwise, and while holding them against their

stops, pull the slack out of the cables and tight-

en the cable clamp.

5. Check for smooth movement and full travel of

the equipment choke knob and throttle lever.

Remove the air cleaner element as instructed

in this section to see that the choke plate opens

and closes fully. Move the equipment throttle le-

ver to see that the throttle control arm touches

the stop plate and that the throttle shaft arm

touches the stop screw.

CHOKE

CONTROL ARM

(above throttle

control arm)

THROTTLE CABLE

STOP PLATE

(HIGH-IDLE)

THROTTLE

CABLE

(below choke

cable)

THROTTLE

CONTROL ARM

(below choke

control arm)

FULL-OPEN

CHOKE

POSITION

THIS WAY

SLACK OUT

ALTERNATE

CABLE CLAMP

LOCATIONS

THROTTLE

SHAFT ARM

AND STOP

SCREW

(LOW-IDLE)

6.Reassemble the air cleaner and reconnect the

spark plug and battery.

FIGURE 5-6. CHOKE AND THROTTLE CABLES

5-7

Page 24

ENGINE SPEED ADJUSTMENTS

Redistribution or publication of this document,

by any means, is strictly prohibited.

Engine speed adjustment must be attempted only

by a qualified mechanic and the adjustments must

be made using an accurate tachometer. Set the low-

idle and high-idle speeds to the values specified in

the equipment Operator’s Manual. In the absence

of such specifications it is recommended that low-

idle speed be adjusted to 1400 RPM and high-idle

speed to 3400 RPM.

WARNING

ue above that specified by the equipment

manufacture could cause the equipment to operate at speeds in violation of Federal and State

Standards for Safety for the equipment.

WARNING

sonal injury or death. Take care when measuring engine speed with a tachometer and follow

the meter instructions. You must be a qualified

mechanic.

Adjusting the engine speed to a val-

Moving parts can cause severe per-

Then adjust the low-idle and high-idle engine

speeds as follows:

1. Start the engine, observing all of the equipment

manufacturer’s instructions and precautions,

and move the equipment (engine) throttle lever

to its lowest speed position.

2.Adjust the low-idle speed stop screw (on the

carburetor) to obtain the specified low-idle

speed.

3.On cable controlled engines move the equipment throttle lever to its highest speed position.

Loosen the high-idle speed stop plate clamping

screw and rotate the stop plate while holding

the throttle control arm against it until the specified high-idle speed is obtained and then retighten the clamping screw. On lever controlled engines adjust the lever stop screw while holding

the throttle lever up against it until the specified

high-idle speed is obtained.

Refer to Figure 5-7. If necessary, first adjust the gov-

ernor arm and reconnect and adjust the choke and

throttle control cables as instructed in this section.

CABLE CONTROLLED ENGINES LEVER CONTROLLED ENGINES

HIGH-IDLE

SPEED STOP

PLATE

THROTTLE

CONTROL ARM

(below choke

control arm)

LOW-IDLE SPEED

STOP SCREW

(on the carburetor)

Note: Do not loosen the high-idle speed stop plate (stop screw) unless you are a qualified mechanic and have an

accurate tachometer to set the high-idle speed in accordance with the equipment manufacturer’s specifications.

4. Check for full, smooth movement of the throttle

control arm (lever) between its two stop posi-

tions.

THROTTLE LEVER

(high-idle position)

CHOKE LEVER

(full open position)

HIGH-IDLE SPEED

STOP SCREW

FIGURE 5-7. SPEED ADJUSTMENTS

5-8

Page 25

AIR CLEANER MAINTENANCE

Redistribution or publication of this document,

by any means, is strictly prohibited.

Refer to Periodic Maintenance in the Operator’s

Manual for scheduled foam wrapper maintenance

and air cleaner element replacement. Refer to Fig-

ure 5-8.

Outer Cover

To remove the outer cover, rotate the quarter-turn

fastener counterclockwise to its vertical position.

Then lift the cover and remove it. To reinstall the outer cover, place the cover over the base, push the

quarter-turn fastener in and then rotate it clockwise

to its horizontal position.

Foam Wrapper Maintenance

When performing maintenance on the foam wrapper only, do not remove the inner air cleaner cover.

Remove and wash the foam wrapper in water and

detergent. Squeeze the foam wrapper dry like a

sponge. Rinse with clean water and allow it to dry.

Coat the wrapper evenly with one tablespoon

(14 grams) of SAE 30 engine oil. Knead the oil into

the wrapper and wring out the excess oil.

Failure to adequately wring out excess oil from the

wrapper may cause a drop in engine power due to a

restriction of inlet air.

Install the foam wrapper over the paper air cleaner

element by stretching it over the inner cover. Completely cover all exposed paper pleats. Replace the

foam wrapper when it becomes torn or stretched.

Air Cleaner Element Replacement

To keep anything from entering the carburetor and

engine while the air cleaner element is off, pull the

choke knob to the full-choke position to close the

choke plate in the carburetor. Remove the outer

cover and wipe away loose dust and debris from the

air cleaner assembly. Remove the mounting nut, in-

ner cover and air cleaner element. Wipe off dust and

debris from the air cleaner base.

Install the new paper element and secure it with the

inner cover and mounting nut. Tighten the nut 1-1/2

turns after seating it on the cover. Reinstall the foam

wrapper and outer cover.

QUARTER-TURN

FASTENER

OUTER

COVER

MOUNTING

NUT

?^+)*)

INNER

COVER

FIGURE 5-8. AIR CLEANER ASSEMBLY

FOAM

WRAPPER

SEAL

AIR CLEANER

ELEMENT

AIR CLEANER

ASSEMBLY BASE

5-9

Page 26

5-10

Redistribution or publication of this document,

by any means, is strictly prohibited.

Page 27

Section 6. Electrical System

Redistribution or publication of this document,

by any means, is strictly prohibited.

IGNITION SYSTEM

Spark Plug

See Periodic Maintenance in the Operator’s Manual

for scheduled spark plug inspection and replace-

ment. See Section 2. Tolerances and Clearances

for spark plug gap (Figure 6-1).

Clean the area around the plug before removing it.

Never assemble a cold spark plug into a hot cylinder

head because the plug will get too tight when the en-

gine cools down. To prevent crossthreading the

spark plug, always thread it in by hand until it seats.

If the spark plug is being reused, tighten it with a

wrench an additional 1/4 turn. If the spark plug is

new, tighten it an additional 3/8 to 1/2 turn. If you

have a torque wrench, tighten it to 20 lbs-ft (26 N-m).

Ignition Spark Check: If the spark plug has been

serviced or replaced but the ignition system still ap-

pears to be the cause of the problem (see Section 4.

Troubleshooting), perform an ignition spark check

by disconnecting the spark plug cable from the

spark plug (do not remove the plug) and connecting

it to a test plug. (If you do not have a test plug, use a

new plug of the same type.) Ground the side elec-

trode of the test plug to the engine block, crank the

engine and observe the test plug. Do not touch the

plug or plug wire during testing.

• Good Spark – The ignition system is not the

problem.

• Weak Spark – Check and readjust the magne-

to air gap as instructed in this section. Replace

the magneto coil assembly if the spark plug

cable and connector are not in good condition.

• No Spark – First check to see that:

• The grounding lead is not damaged or

being pinched (see Figure 6-5)

FIGURE 6-1. SPARK PLUG GAP

Magneto

These engines use a magneto consisting of a stationary coil and flywheel magnet to fire the spark

plug (Figures 6-2 and 6-3). The primary winding of

the coil has a grounding terminal for connecting a

shutoff (kill) switch (Figure 6-5). Ignition timing is determined by the angular relationship of the flywheel

magnet to the shaft keyway and is not adjustable

(Table 1-1, Section 1. Introduction).

WARNING

can cause severe personal injury or death. Make

certain that no gasoline or other flammable

fumes are present during ignition testing

WARNING

personal injury or death. Do not touch the igni-

tion components during testing.

Gasoline is highly flammable and

Electrical shock can cause severe

• The stop (kill) switch is connected prop-

erly

• The low oil pressure cutoff switch is func-

tioning properly.

Then, if there is still no spark, and the grounding

terminal is not being grounded, replace the

magneto coil assembly.

EB3D= B>G9

534>7& F7D?;@3>

5A@@75FAD 3@6

4AAF

9DAG@6;@9

F7D?;@3>

$E:GFA88%

FIGURE 6-2. MAGNETO COIL ASSEMBLY

6-1

Page 28

Magneto Air Gap: Measure the air gap between

Redistribution or publication of this document,

by any means, is strictly prohibited.

the core of the magneto coil and flywheel magnet

(Figure 6-3). If necessary, loosen the magneto coil

mounting screws and readjust the gap as specified

( Section 2. Tolerances and Clearances ).

12 VDC OUTPUT SYSTEM

The engine may be equipped to provide a 12 volt DC

(Direct Current) output for powering equipment ac-

cessories and/or recharging the cranking battery

(Figure 6-4). The system consists of a permanent

magnet flywheel alternator and a solid state rectifier/voltage regulator. There are two output ratings

available: 5 amp and 20 amp. The 5 amp system

has 3 magnets in the flywheel and the 20 amp sys-

tem 6.

The flywheel must be removed for access to the al-

ternator stator. See Section 9. Engine Block Assem-

bly.

?39@7FA

5A;>

8>KI:77>

?39@7F

FIGURE 6-3. MEASURING MAGNETO AIR GAP

ALTERNATOR

STATOR

RECTIFIER/VOLTAGE

REGULATOR

12 VDC

OUTPUT

STATOR

LEADS

FIGURE 6-4. FLYWHEEL ALTERNATOR AND VOLTAGE REGULATOR

PATH OF FLYWHEEL MAGNETS

(FLYWHEEL REMOVED)

6-2

Page 29

12 VDC System Tests

Redistribution or publication of this document,

by any means, is strictly prohibited.

Keep the following points in mind when testing or

servicing the 12 VDC output system.

CAUTION

and negative (–) battery connections or without

connection to a battery will damage the voltage

regulator and/or the alternator stator.

1. Never reverse the battery leads.

2.Charging system tests require a fully charged

battery in good condition. Make sure the engine

is being run long enough and fast enough in

service to recharge the battery after each start.

Alternator output is proportional to engine

speed and accessories consume power other-

wise available for battery recharging.

Operation with reversed positive (+)

TABLE 6-1. 12 VDC OUTPUT SYSTEM TEST

SPECIFICATIONS

BATTERY

VOLTAGE

12 to 13

VDC

VOLTAGE

REGULATOR

OUTPUT

13.6 to 14.7

VDC

@ Any Speed

Within Operat-

ing Range

STATOR

OUTPUT

Approx.

29 VAC @

1800 RPM

&

57 VAC @

3600 RPM

STATOR

RESISTANCE

5 amp system:

0.54 to 0.66

Ohms

20 amp system:

0.27 to 0.33

Ohms

1. Check battery voltage when the engine is not

running. If not within specifications (Table 6-1),

charge the battery before going to Step 2.

2.With the engine running, check voltage regula-

tor output (DC voltage) at the battery terminals.

Replace the voltage regulator if output is

greater than specified. If voltage regulator out-

put is less than specified, go to Step 3.

3.The voltage regulator has built in protection

against open circuit and short circuit faults (B+

terminal). It will not “turn on” under either condi-

tion or when battery discharge is extreme.

4. Check to see that the connections at the termi-

nals of the voltage regulator (three) are clean

and tight.

5. Check to see that the wiring connected to the

B+ terminal (middle) of the voltage regulator is

not damaged, shorted or grounded.

6.To ensure a good ground path to battery nega-

tive ( – ), check to see that the voltage regulator

mounting surface is clean and that the screws

are tight.

7.Check to see that the positive and negative battery cables have good connections at the battery and engine and that they are not damaged.

After checking all of the above perform the following

tests if there still is no alternator output when the engine is running between 1800 and 3600 RPM. Refer

to Ta ble 6-1 for test specifications. Use a multi-meter (Simpson 270) when testing the alternator.

3.Disconnect the alternator stator leads from the

voltage regulator (see Figure 6-4) and test for

alternator stator output (AC voltage) with the

engine running. If stator output is less than

specified, go to Step 4. If stator output is as

specified but voltage regulator output is low, re-

place the voltage regulator.

4. Shut down the engine and check for electrical

resistance between either alternator stator lead

and ground (bare engine metal) using an ohm-

meter. The meter should indicate infinite resis-

tance on its highest scale. If resistance is high,

go to Step 5. If not, replace the stator.

5. Check alternator stator resistance by connect-

ing an ohmmeter across the stator leads. Replace the alternator stator assembly if stator re-

sistance on the lowest scale of the meter is ei-

ther higher or lower than specified. Replace the

flywheel assembly if alternator stator resistance is as specified but alternator stator output

is less than specified. The probable cause is

loss of magnetism.

WIRING CONNECTIONS

Figure 6-5 includes schematics of typical engine

wiring connections.

6-3

Page 30

WIRING HARNESS WITH 4-PIN CONNECTOR FOR CUSTOMER CONNECTIONS

Redistribution or publication of this document,

by any means, is strictly prohibited.

OPTIONAL CHARGING SYSTEM

25 A FUSEAMMETER

A

B

OPTIONAL STARTER

C

MAGNETO COIL

SPARK PLUG

STOP

STOP

KEY SWITCH

ENGINE

CONNECTOR

ENGINE WITH OPTIONAL START/STOP SWITCH

OPTIONAL CHARGING SYSTEM

25 A FUSE

A

B

START

STOP

OPTIONAL STARTER

BASIC ENGINE WITH OPTIONAL KILL SWITCH

PRESSURE SWITCH

C

MAGNETO COIL

SPARK PLUG

MAGNETO COIL

SPARK PLUG

OPTIONALOIL

N. O. OR N. C.

NOTE:

ENGINE WIRING SHOWN BY SOLID LINES

AND CUSTOMER SUPPLIED WIRING BY DASHED LINES

FIGURE 6-5. SCHEMATICS OF TYPICAL ENGINE WIRING CONNECTIONS

BASIC ENGINE WITH LEAD FOR KILL SWITCH

KILL SWITCH

6-4

MAGNETO COIL

SPARK PLUG

Page 31

Section 7. Starting System

Redistribution or publication of this document,

by any means, is strictly prohibited.

WARNING

Accidental starting of the engine

can result in severe personal injury or death.

Disconnect the negative (–) battery cable and

spark plug wire before servicing the engine,

controls, or associated equipment.

RECOIL STARTER

Disassembly: Refer to Figure 7-1. Remove the four

capscrews holding the recoil assembly on the en-

gine. Remove the recoil assembly from the blower

housing.

Inspection/Service: Inspect the assembly as a

unit. The rope should pull out freely with spring ten-

sion, pulling the rope back in without binding or

slack. When pulling the rope out, the dog ears

should come out of their cup and they should not be

bent, broken, or missing.

Assembly: Place the recoil assembly on the blower

housing and rotate it so that the cord pull handle is

conveniently located for starting the engine. Install

and tighten the four capscrews to the torque speci-

fied in Section 3. Assembly Torques.

SOLENOID SHIFT STARTER

See Section 6. Electrical for typical wiring connec-

tions at the starter solenoid.

Inspection: Refer to Figure 7-2. Before removing a

starter because the engine does not crank:

1. Make sure that the battery is fully charged and

that the connections are clean and tight and

that the battery cables are in good condition. If

it is necessary to reconnect the battery, connect

the positive ( + ) battery cable first.

2.Disconnect the spark plug cable so that the engine will not start. Then bypass the start circuit

with a jumper between the Start and the Battery

Positive ( + ) terminals on the solenoid (Figure

7-2). If the engine cranks, the solenoid and

starter are probably okay. If the engine does not

crank, go to Step 3.

3.Bypass the starter solenoid with a jumper be-

tween the Motor and the Battery Positive ( + )

terminals on the solenoid (Figure 7-2). If the

motor responds, it is probably okay and it may

only be necessary to replace the solenoid.

D75A;>

3EE7?4>K

FIGURE 7-1. RECOIL STARTER REMOVAL

53B E5D7I

START

TERMINAL

(B)

FIGURE 7-2. STARTER SOLENOID TERMINALS

7-1

BATTERY

POSITIVE ( + )

TERMINAL

(A)

MOTOR

TERMINAL

(C)

Page 32

WARNING

Redistribution or publication of this document,

by any means, is strictly prohibited.

Accidental starting of the engine

can result in severe personal injury or death.

Disconnect the negative (–) battery cable and

spark plug wire before servicing the engine,

controls, or associated equipment.

Disassembly: Refer to Figure 7-3 . Remove the

starter assembly from the engine if either the solenoid or motor appears to be the part that is malfunctioning. Remove the solenoid mounting nuts and

disconnect the connecting lead to the motor. Re-

move the solenoid by sliding it up to disconnect the

shift fork. If the motor is the part that is malfunction-

ing, continue by removing the two motor through

bolts. Before loosening the through bolts, however,

scratch register lines on the drive housing, motor

frame and end bell so that these parts can be easily

reassembled the same way relative to each other.

While removing the motor end bell be prepared to

catch the brush springs, which tend to spring loose.

Remove the brush insulating barrier, brush springs

and brush holder. Separate the motor frame from

the drive housing and then withdraw the shift fork

and armature.

Assembly: Assembly is the reverse of disassem-

bly. Apply grease to the shift fork hinge and prongs

and the splines on the armature shaft.

6D;H7 :AGE;@9

?AFAD 8D3?7

E:;8F 8AD=

B;@;A@

4DGE:7E

EA>7@A;6

4DGE: EBD;@9

4DGE: :A>67D

3D?3FGD7

4DGE: ;@EG>3F;@9

43DD;7D

F:DAG9:

4A>FE

7@6 47>>

FIGURE 7-3. SOLENOID SHIFT STARTER

7-2

Page 33

Armature

Redistribution or publication of this document,

by any means, is strictly prohibited.

Checking Integrity of Winding Insulation: Refer

to Figure 7-4. To check winding insulation integrity,

check electrical resistance (use an ohmmeter) be-

tween any commutator segment and the armature

core and again between the segment and the armature shaft. Replace the armature if the meter does

not indicate high (infinite) resistance.

3D?3FGD7 5AD7

5A??GF3FAD

5A??GF3FAD

08J&,+'

FIGURE 7-5. CHECKING INTEGRITY OF ARMA-

TURE WINDINGS

Motor Frame

Checking Integrity of Windings : Refer to Figure

7-6 . Two of the four brushes are connected directly

to the motor frame windings, one to each pair of

windings. The other ends of the two pairs of wind-

ings are crimped directly to the motor frame

(grounded). To check the integrity of each winding

pair, check continuity (use an ohmmeter) between

its brush and the crimp on the motor frame. Replace

the motor frame if either winding pair is open (high

resistance). (This test will not detect if a single wind-

ing of a pair is open. If the windings look burnt or

smell bad, it is recommended that the motor frame

be replaced.)

FIGURE 7-4. CHECKING INTEGRITY OF ARMA-

TURE WINDING INSULATION

Checking Integrity of Windings: Refer to Figure

7-5. To check winding integrity, check electrical con-

tinuity (use an ohmmeter) between pairs of commutator segments all the way around the commutator.

Make sure every segment is checked. Replace the

armature if a winding is open (high resistance) at

any segment.

3D?3FGD7 E:38F

?AFAD

8D3?7

4DGE:

08J&,,%

FIGURE 7-6. CHECKING INTEGRITY OF MOTOR

FRAME WINDINGS

7-3

Page 34

Brushes

Redistribution or publication of this document,

by any means, is strictly prohibited.

Refer to Figure 7-7.Clean up the brushes with sandpaper and measure their lengths. Replace the mo-

tor frame, brush holder and brush springs if any

brush is shorter than specified ( Section 2. Toler-

ances and Clearances ).

5A??GF3FAD

08J&,+,

FIGURE 7-8. MEASURING COMMUTATOR O. D.

4DGE:

08J&,,&

FIGURE 7-7. MEASURING BRUSH LENGTH

Commutator

Commutator: Refer to Figure 7-8. Clean the com-

mutator surface with sandpaper and measure the

outside diameter at several locations around the

commutator. Turn the commutator in a lathe if the

differences in measurements are greater than specified ( Section 2. Tolerances and Clearances ). Re-

place the armature assembly if the commutator can-

not be cleaned up and still meet the specified diam-

eter.

Commutator Mica: Refer to Figure 7-9. Use a saw

blade to undercut the commutator mica if the under-

cut is less than specified ( Section 2. Tolerances and

Clearances ) and chamfer the segment edges.

E79?7@F

7697E

FIGURE 7-9. MICA UNDERCUT DEPTH

?;53

G@67D5GF

67BF:

E3I 4>367

08J&,+-

7-4

Page 35

Pinion

Redistribution or publication of this document,

by any means, is strictly prohibited.

Inspection/Service: Refer to Figure 7-10. Replace

the pinion assembly if the pinion teeth and armature

shaft splines are worn or damaged. Check the overrunning clutch by rotating the pinion clockwise and

counterclockwise. Replace the pinion assembly if it

does not turn smoothly counterclockwise or lock

clockwise.

bell and the corresponding shaft diameters. Re-

place the bushings if the clearances are greater

than specified ( Section 2. Tolerances and Clear-

ances ).

CAUTION

Cleaning the pinion over-running

clutch in liquid cleaning solution will result in

starter damage.

B;@;A@

08J&,,'

FIGURE 7-10. CHECKING OPERATION OF THE PIN-

ION OVER-RUNNING CLUTCH

Armature Shaft Bushings

Refer to Figure 7-11. Measure the inside diameters

of the bushings in the starter drive housing and end

4GE:;@9

EF3DF7D 6D;H7 :AGE;@9

3D?3FGD7 E:38F

FIGURE 7-11. MEASURING BUSHING I. D. AND AR-

MATURE SHAFT O. D.

7-5

Page 36

7-6

Redistribution or publication of this document,

by any means, is strictly prohibited.

Page 37

Section 8. Lubrication System

Redistribution or publication of this document,

by any means, is strictly prohibited.

WARNING

Improper service or replacement of

parts can result in severe personal injury and/or

equipment damage. Service personnel must be

qualified to perform electrical and mechanical

service.

An oil pump is used to provide pressure lubrication,

via the oil filter, to the journal bearings in the gear-

case and to the crankshaft connecting rod journal

(Figure 8-1). The oil pump is located in the gearcase

and is driven by a balancer shaft. It is accessible by

removing the oil pump cover on the gearcase (Figure 8-3). Oil pressure is controlled by an oil relief

valve (Figure 8-7).

Refer to the Operator’s Manual for lubricating oil

specifications and instructions on how to check the

oil level and change the oil and oil filter. The crank-

case and oil filter hold 0.95 litre (1 quart) of oil.

A;>

:A>7

5D3@=E:38F

5A@@75F;@9

DA6 <AGD@3>

should not be less than that specified in Table 1-1,

Section 1. Introduction. Low oil pressure may indi-

cate:

• low oil level

• oil of the wrong viscosity

• oil diluted by fuel

• clogged oil filter

• defective oil pump

• clogged oil gallery

• worn crank journal / connecting rod

• defective relief valve or spring

Determine the cause of the low oil pressure and per-

form the necessary service.

FIGURE 8-1. OIL HOLE IN THE CRANKSHAFT CON-

NECTING ROD JOURNAL

CHECKING OIL PRESSURE

Refer to Figure 8-2 . Install an engine oil pressure

gauge in the gearcase as shown. The engine will

have an oil pressure switch or a 1/8 inch pipe plug in

the tapped hole. Start the engine and observe the oil

pressure as the engine warms up. The oil pressure

;@EF3>> A;> BD7EEGD7

93G97 :7D7

FIGURE 8-2. OIL PRESSURE CHECK

8-1

Page 38

OIL PUMP

Redistribution or publication of this document,

by any means, is strictly prohibited.

Disassembly

Refer to Figure 8-3 . Remove the capscrews holding

the oil pump cover to the gearcase. Separate the inner and outer rotor.

5AH7D

A;>

BG?B

A^D;@9

FIGURE 8-4. MEASURING ROTOR LOBE COMPO-

NENTS

Outer Rotor and Pump Body Clearance: Refer to

Figure 8-5. Measure the clearance between the

outer rotor and the pump body with a feeler gauge. If

the clearance is not as specified in Section 2. Toler-

ances and Clearances, replace the oil pump.

FIGURE 8-3. OIL PUMP DISASSEMBLY

Inspection/Service

Rotor Lobe Clearance: Refer to Figure 8-4. Meas-

ure the clearance between the inner rotor lobes and

the outer rotor lobes with a feeler gauge. If the clear-

ance is not as specified in Section 2. Tolerances and

Clearances, replace the oil pump.

FIGURE 8-5. MEASURING OUTER ROTOR TO

PUMP BODY CLEARANCE

8-2

Page 39

Rotor and Cover Clearance: Refer to Figure 8-6 .

Redistribution or publication of this document,

by any means, is strictly prohibited.

Put a strip of plastigauge on the rotor face. Install the

pump cover and tighten the screws to that specified

in Section 3. Assembly Torques. Remove the cover

carefully and measure the width of the plastigauge

with the table provided. If clearance is not as speci-

fied in Section 2. Tolerances and Clearances, re-

place the oil pump.

after the gearcase has been removed from the en-

gine block. See Section 9. Engine Block Assembly.

Remove the retaining ring, relief valve spring, and

check ball.

D7>;78

H3>H7

EBD;@9

5:75=

43>>

D7F3;@;@9

D;@9

;E^*+*.

;E^*+*1

FIGURE 8-6. MEASURING ROTOR TO COVER

CLEARANCE

Assembly

Lubricate each part with oil before reassembling.

Follow torques given in Section 3. Assembly

Torques when tightening hardware. Check the oil

pressure after servicing or replacing any lubrication

system component.

OIL PRESSURE RELIEF VALVE

Disassembly

Refer to Figure 8-7 . The oil pressure relief valve is

assembled in the gearcase and is accessible only

FIGURE 8-7. OIL RELIEF VALVE COMPONENTS

Inspection/Service

WARNING

can cause severe personal injury or death if

used improperly. Follow the manufacturer’s

recommendations when cleaning parts.

Wash the components in solvent and allow to dry.

Inspect components for damage, wear, etc. Re-

place parts as necessary.

Most solvents are flammable and

Assembly

Oil the check ball and oil passage in the gearcase

before assembling. Use a new retaining ring and

drive it in down to the bottom of the passage coun-

terbore.

8-3

Page 40

8-4

Redistribution or publication of this document,

by any means, is strictly prohibited.

Page 41

Section 9. Engine Block Assembly

Redistribution or publication of this document,

by any means, is strictly prohibited.

WARNING

can result in severe personal injury or death.

Disconnect the negative (–) battery cable and

spark plug wire before servicing the engine,

controls, or associated equipment.

Accidental starting of the engine

CYLINDER COMPRESSION TEST

It is recommended that a cylinder compression test

be performed to determine the condition of valves,

piston, piston rings and cylinder. To check cylinder

compression pressure:

1. Run the engine until it is thoroughly warm, stop

it and remove the spark plug.

2.Remove the air cleaner and place the throttle

and the choke in their wide open positions.

3.Insert the compression gauge in the spark plug

hole, crank the engine and read the pressure.

The compression gauge should indicate at least

483 kPa (70 psi). There may be variations due to

equipment, temperature, atmospheric conditions

and altitude. This value is for a warm engine at

cranking speed (about 300 rpm).

FLYWHEEL REMOVAL

WARNING

result in severe personal injury. Loosen the

flywheel nut only a couple of turns before using

a flywheel puller so that the nut will restrain the

flywheel when it breaks loose from the shaft ta-

per.

Improper flywheel removal can

ing sure the shaft taper and flywheel bore are clean

and free of oil. Reinstall the key in the shaft and tight-

en the flywheel nut to the specified torque ( Section

3. Assembly Torques ).

VALVE ROCKER COVER

Remove the valve rocker cover to gain access to the

cylinder head bolts, breather assembly, valve rock-

er arms,push rods and valves. Always use a new

gasket when reinstalling the cover and make sure

the mating surfaces are clean and undamaged.