PACDN006

6-Channel ESD Protection

Array

Product Description

The PACDN006 is a diode array designed to provide six channels of

ESD protection for electronic components or subsystems. Each

channel consists of a pair of diodes that steer an ESD current pulse to

either the positive (V

protects against ESD pulses up to:

8 kV contact discharge, per International Standard

IEC 61000−4−2

15 kV per Human Body Model MIL−STD−883, Method 3015

(based on a 100 pF capacitor discharging through a 1.5 kW

resistor)

This device is particularly well−suited for portable electronics

(e.g., cellular phones, PDAs, notebook computers) because of its

small package footprint, high ESD protection level, and low loading

capacitance. It is also suitable for protecting video output lines and I/O

ports in computers and peripherals and is ideal for a wide range of

consumer electronics products.

The PACDN006 is available with RoHS compliant lead−free

finishing.

) or negative (VN) supply. The PACDN006

P

http://onsemi.com

MSOP 8

MR SUFFIX

CASE 846AB

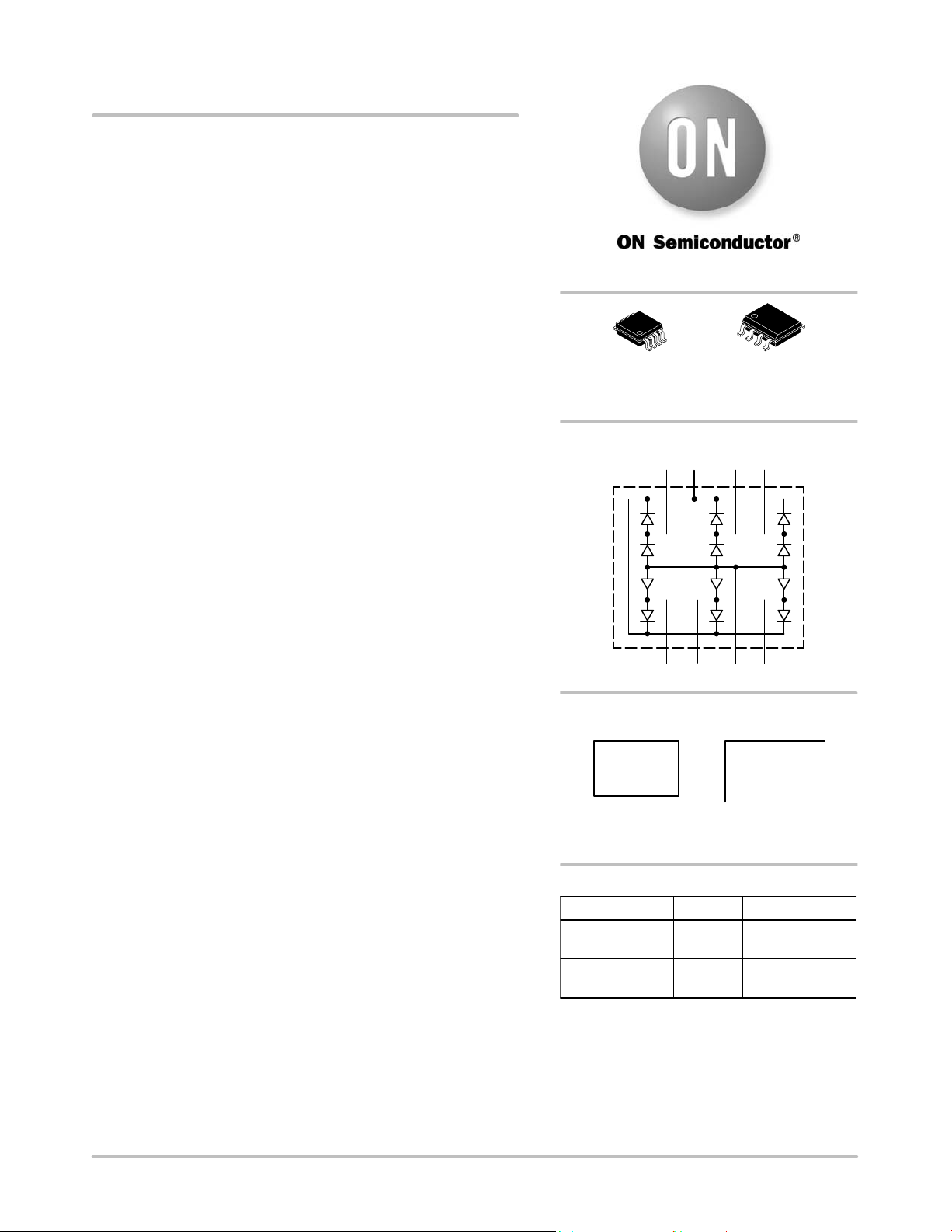

ELECTRICAL SCHEMATIC

87 65

V

P

V

N

SOIC 8

SM SUFFIX

CASE 751BD

Features

Six Channels of ESD Protection

8 kV Contact, 15 kV Air ESD Protection per Channel

(IEC 61000−4−2 Standard)

15 kV of ESD Protection per Channel (HBM)

Low Loading Capacitance (3 pF Typical)

Low Leakage Current is Ideal for Battery−Powered Devices

Available in Miniature 8−Pin MSOP and 8−Pin SOIC Packages

These Devices are Pb−Free and are RoHS Compliant

Applications

Consumer Electronic Products

Cellular Phones

PDAs

Notebook Computers

Desktop PCs

Digital Cameras and Camcorders

VGA (Video) Port Protection for Desktop and Portable PCs

1 234

MARKING DIAGRAM

006R

006R = PACDN006MR

PACDN 006SM = PACDN006SM

ORDERING INFORMATION

Device Package Shipping

PACDN006MR MSOP 8

(Pb−Free)

PACDN006SM SOIC 8

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

PACDN 006SM

†

4000/Tape & Reel

2500/Tape & Reel

Semiconductor Components Industries, LLC, 2011

October, 2011 − Rev. 5

1 Publication Order Number:

PACDN006/D

PACDN006

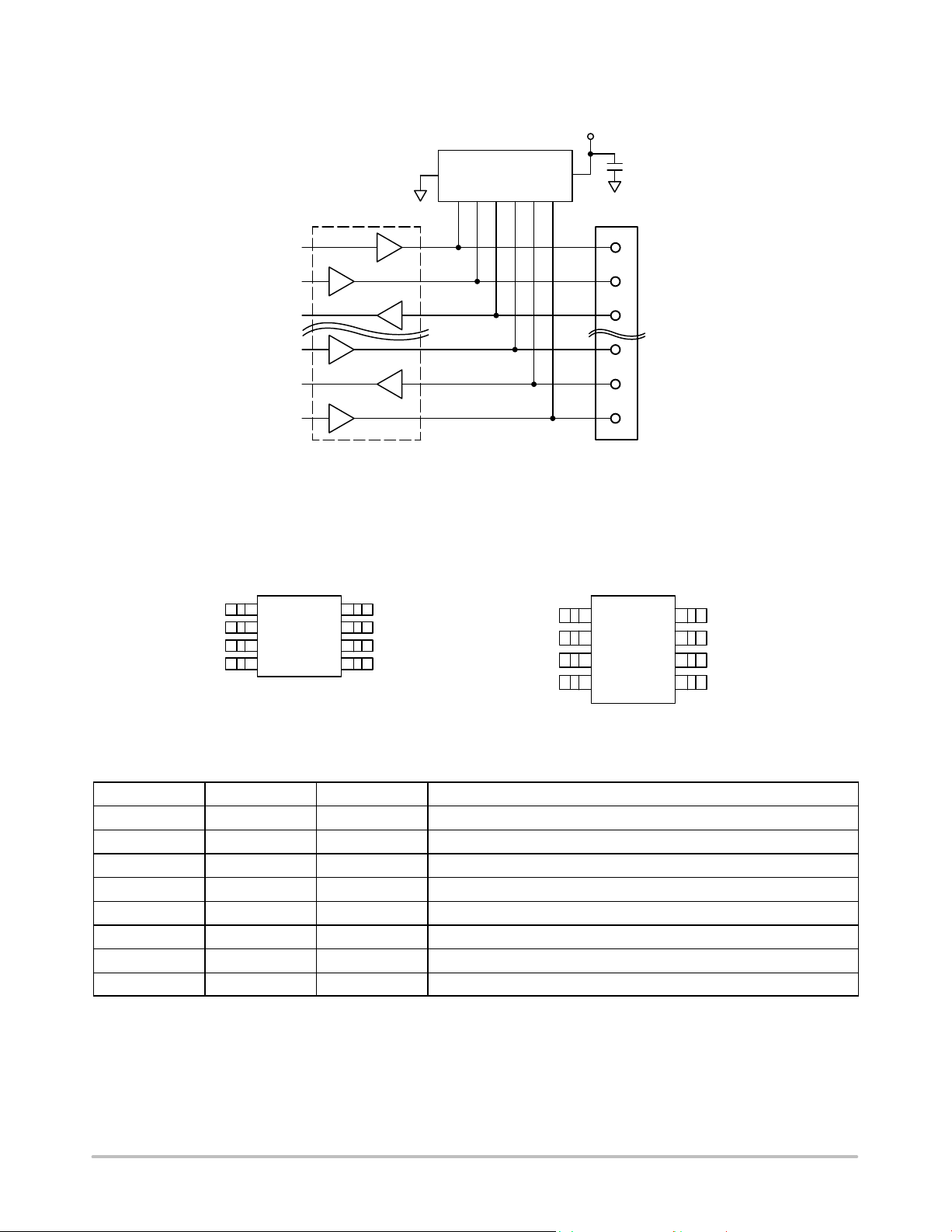

TYPICAL APPLICATION CIRCUIT

V

CC

CH1

CH2

V

CH3

N

I/O Port

Buffers

* Decoupling capacitor must be placed as close as possible to Pin7.

Top View

1

27

006R

8

36

4

5

8−Pin MSOP−8

37

PACDN006

2 4 5 6 81

Handheld/PDA ESD Protection

PACKAGE / PINOUT DIAGRAMS

CH6

V

P

CH5

CH4

CH1

CH2

V

CH3

N

0.22 mF*

Expansion

Connector

Top View

PACDN 006SM

1

8

27

36

4

5

CH6

V

P

CH5

CH4

8−Pin SOIC−8

Table 1. PIN DESCRIPTIONS

Pin Name Type Description

1 CH1 I/O ESD Channel

2 CH2 I/O ESD Channel

3 V

N

4 CH3 I/O ESD Channel

5 CH4 I/O ESD Channel

6 CH5 I/O ESD Channel

7 V

P

8 CH6 I/O ESD Channel

GND Negative Voltage Supply Rail or Ground Reference Rail

Supply Positive Voltage Supply Rail

http://onsemi.com

2

PACDN006

SPECIFICATIONS

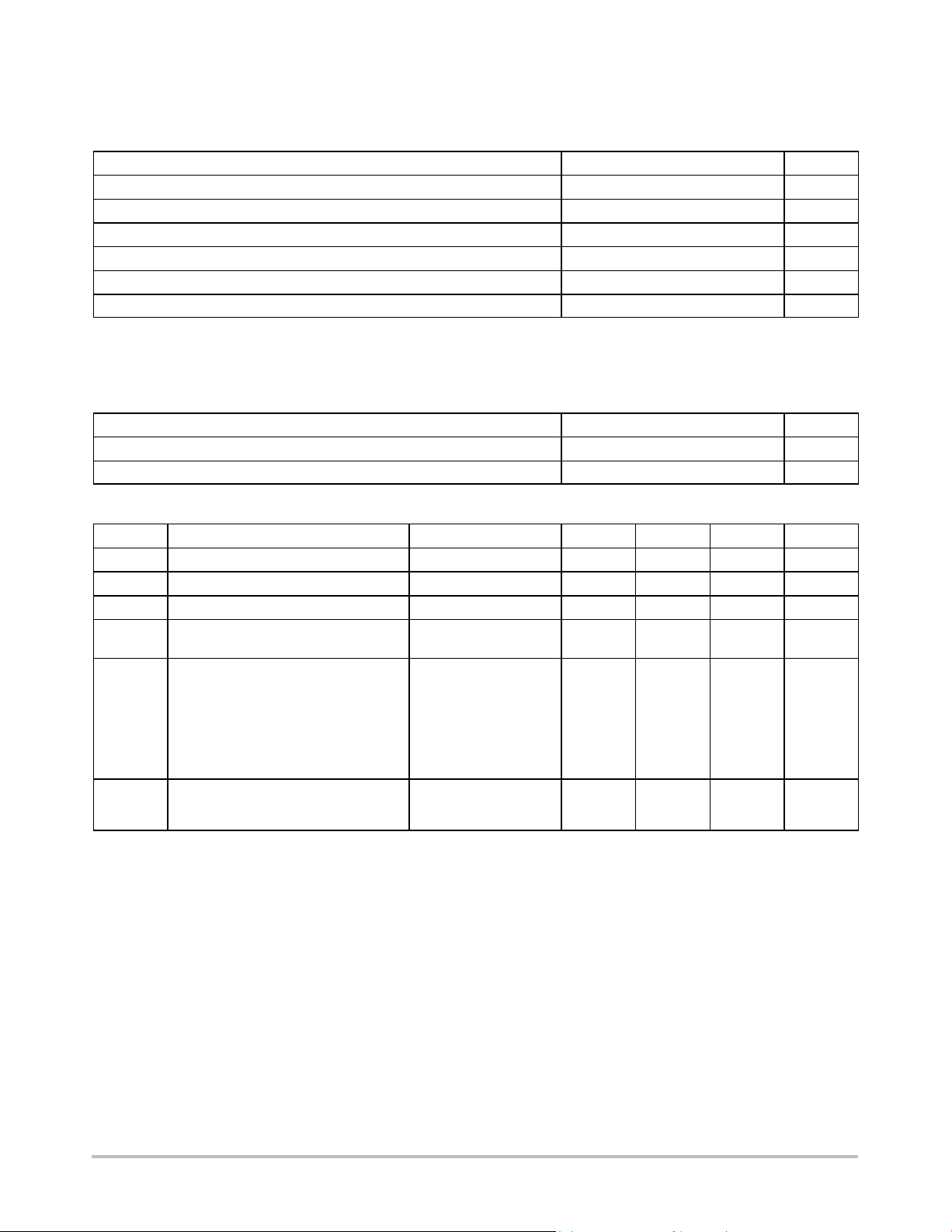

Table 2. ABSOLUTE MAXIMUM RATINGS

Parameter Rating Units

Supply Voltage (VP − VN) 6.0 V

Diode Forward DC Current (Note 1) 20 mA

Operating Temperature Range −40 to +85 C

Storage Temperature Range −65 to +150 C

DC Voltage at any Channel Input (VN − 0.5) to (VP + 0.5) V

Package Power Rating 200 mW

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. Only one diode conducting at a time.

Table 3. STANDARD OPERATING CONDITIONS

Parameter Rating Units

Operating Temperature Range −40 to +85 C

Operating Supply Voltage (VP − VN) 0 to 5.5 V

Table 4. ELECTRICAL OPERATING CHARACTERISTICS (Note 1)

Symbol

I

V

I

LEAK

C

V

ESD

P

Supply Current (VP − VN) = 5.5 V 10

Diode Forward Voltage I

F

Channel Leakage Current 0.1 1.0

Channel Input Capacitance @ 1 MHz, VP = 5 V,

IN

ESD Protection

Peak Discharge Voltage at any

Channel Input, in System

a) Human Body Model,

MIL−STD−883, Method 3015

b) Contact Discharge per

IEC 61000−4−2

c) Air Discharge per IEC 61000−4−2

V

CL

Channel Clamp Voltage

Positive Transients

Negative Transients

1. All parameters specified at TA = 25C unless otherwise noted. VP = 5 V, VN = 0 V unless noted.

2. From I/O pins to V

3. Human Body Model per MIL−STD−883, Method 3015, C

4. Standard IEC 61000−4−2 with C

Parameter Conditions Min Typ Max Units

= 20 mA 0.65 0.95 V

F

V

= 0 V, VIN = 2.5 V

N

(Note 2)

(Note 3)

(Note 4)

(Note 4)

15

8

15

@ 15 kV ESD HBM

or VN only. VP bypassed to VN with a 0.22 mF ceramic capacitor (see Application Information for more details).

P

= 150 pF, R

Discharge

Discharge

= 100 pF, R

Discharge

= 330 W, VP = 5.0 V, VN grounded.

Discharge

= 1.5 kWVP = 5.0 V, V

mA

mA

3 5 pF

kV

VP + 13.0

VN − 13.0

grounded.

N

V

http://onsemi.com

3

Input Capacitance vs. Input Voltage

PACDN006

PERFORMANCE INFORMATION

Figure 1. Typical Variation of CIN vs. V

(VP = 5 V, VN = 0 V, 0.1 mF Chip Capacitor between VP and VN)

IN

APPLICATION INFORMATION

Design Considerations

In order to realize the maximum protection against ESD pulses, care must be taken in the PCB layout to minimize parasitic

series inductances on the Supply/Ground rails as well as the signal trace segment between the signal input (typically

a connector) and the ESD protection device. Refer to Figure 2, which illustrates an example of a positive ESD pulse striking

an input channel. The parasitic series inductance back to the power supply is represented by L

and L2. The voltage VCL on

1

the line being protected is:

where I

+ FwdVoltageDropofD1) V

V

CL

is the ESD current pulse, and V

ESD

is the positive supply voltage.

SUPPLY

SUPPLY

) L1 d(I

)ńdt ) L2 d(I

ESD

ESD

)ńdt

An ESD current pulse can rise from zero to its peak value in a very short time. As an example, a level 4 contact discharge

per the IEC61000−4−2 standard results in a current pulse that rises from zero to 30 Amps in 1 ns. Here d(I

approximated by DI

increment in V

CL

/Dt, or 30/(1x10−9). So just 10 nH of series inductance (L

ESD

!

Similarly for negative ESD pulses, parasitic series inductance from the V

1

pin to the ground rail will lead to drastically

N

and L

combined) will lead to a 300 V

2

)/dt can be

ESD

increased negative voltage on the line being protected.

Another consideration is the output impedance of the power supply for fast transient currents. Most power supplies exhibit

a much higher output impedance to fast transient current spikes. In the V

given by (V

of the power supply respectively. As an example, a R

DC

+ I

ESD

x R

), where VDC and R

OUT

are the nominal supply DC output voltage and effective output impedance

OUT

of 1 W would result in a 10 V increment in VCL for a peak I

OUT

equation above, the V

CL

term, in reality, is

SUPPLY

ESD

of

10 A.

If the inductances and resistance described above are close to zero, the rail−clamp ESD protection diodes will do a good job

of protection. However, since this is not possible in practical situations, a bypass capacitor must be used to absorb the very high

frequency ESD energy. So for any brand of rail−clamp ESD protection diodes, a bypass capacitor should be connected between

the V

pin of the diodes and the ground plane (VN pin of the diodes) as shown in the Application Circuit diagram below. A value

P

of 0.22 mF is adequate for IEC−61000−4−2 level 4 contact discharge protection (8 kV). Ceramic chip capacitors mounted with

short printed circuit board traces are good choices for this application. Electrolytic capacitors should be avoided as they have

poor high frequency characteristics. For extra protection, connect a zener diode in parallel with the bypass capacitor to mitigate

http://onsemi.com

4

PACDN006

the effects of the parasitic series inductance inherent in the capacitor. The breakdown voltage of the zener diode should be

slightly higher than the maximum supply voltage.

As a general rule, the ESD Protection Array should be located as close as possible to the point of entry of expected

electrostatic discharges. The power supply bypass capacitor mentioned above should be as close to the V

Array as possible, with minimum PCB trace lengths to the power supply, ground planes and between the signal input and the

ESD device to minimize stray series inductance.

Additional Information

See also ON Semiconductor Application Notes AP209, “Design Considerations for ESD Protection” and AP219, “ESD

Protection for USB 2.0 Systems”.

L

2

V

P

PATH OF ESD CURRENT PULSE I

POSITIVE SUPPLY RAIL

ESD

pin of the Protection

P

0.22 mF

V

N

D

1

ONE

CHANNEL

D

2

OF

PACDN006

L

1

CHANNEL

INPUT

0 A

20 A

LINE BEING

PROTECTED

V

CL

GROUND RAIL

SYSTEM OR

CIRCUITRY

BEING

PROTECTED

CHASSIS GROUND

Figure 2. Application of Positive ESD Pulse between Input Channel and Ground

http://onsemi.com

5

PACDN006

PACKAGE DIMENSIONS

MSOP8

CASE 846AB−01

ISSUE O

SEATING

PLANE

−T−

0.038 (0.0015)

PIN 1 ID

8X

0.041

DD

H

E

e

E

b

A

A1

SOLDERING FOOTPRINT*

1.04

0.38

0.015

8 PL

M

0.08 (0.003) A

B

T

c

8X

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE

BURRS. MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED

0.15 (0.006) PER SIDE.

4. DIMENSION B DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSION.

INTERLEAD FLASH OR PROTRUSION SHALL NOT EXCEED 0.25 (0.010) PER SIDE.

5. 846A-01 OBSOLETE, NEW STANDARD 846A-02.

DIMAMIN NOM MAX MIN

S

S

A1 0.05 0.08 0.15 0.002

b 0.25 0.33 0.40 0.010

c 0.13 0.18 0.23 0.005

D 2.90 3.00 3.10 0.114

E 2.90 3.00 3.10 0.114

e 0.65 BSC

L 0.40 0.55 0.70 0.016

H

E

MILLIMETERS

−− −− 1.10 −−

4.75 4.90 5.05 0.187 0.193 0.199

INCHES

NOM MAX

−− 0.043

0.003 0.006

0.013 0.016

0.007 0.009

0.118 0.122

0.118 0.122

0.026 BSC

0.021 0.028

L

6X

0.0256

3.20

0.126

0.65

0.167

4.24

SCALE 8:1

5.28

0.208

ǒ

inches

mm

Ǔ

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

http://onsemi.com

6

PIN # 1

IDENTIFICATION

PACDN006

PACKAGE DIMENSIONS

SOIC 8, 150 mils

CASE 751BD−01

ISSUE O

E1 E

SYMBOL MIN NOM MAX

A1

E1

A

1.35

0.10

b

c

D

E

0.33

0.19

4.80

5.80

3.80

e

h

L

θ

0.25

0.40 1.27

0º 8º

1.27 BSC

1.75

0.25

0.51

0.25

5.00

6.20

4.00

0.50

TOP VIEW

D

A1

A

θ

h

c

e

SIDE VIEW

b

L

END VIEW

Notes:

(1) All dimensions are in millimeters. Angles in degrees.

(2) Complies with JEDEC MS-012.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

http://onsemi.com

7

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

PACDN006/D

Loading...

Loading...