ON NUP4212UPMU Schematic [ru]

NUP4212UPMU

Quad Transient Voltage

Suppressor Array

ESD Protection Diodes with Ultra−Low

(0.7 pF) Capacitance

The four−line voltage transient suppressor array is designed to protect

voltage−sensitive components that require ultra−low capacitance from

ESD and transient voltage events. This device features a common anode

design which can protect up to four independent high speed data lines

and 1 or 2 separate 15 V TVS lines in a single six−lead UDFN low

profile package.

Excellent clamping capability, low capacitance, low leakage, and fast

response time make these parts ideal for ESD protection on designs

where board space is at a premium. Because of its low capacitance, it is

suited for use in high frequency designs such as a USB 2.0 high speed.

This device can be configured as a dual port USB device.

Features

• Low Capacitance Data Lines (0.7 pF Typical)

• Protects up to Four Data Lines Plus a V

CC

Pin

• UDFN Package, 1.6 x 1.6 mm

• Low Profile of 0.50 mm for Ultra Slim Design

• V

, V2 Pin = 15 V Protection

1

• D

, D2, D3, and D4 Pins = 5.2 V Minimum Protection

1

• ESD Rating: IEC61000−4−2: Level 4

− Contact (14 kV)

• This is a Pb−Free Device

Typical Applications

• USB 2.0 High−Speed Interface

• Cell Phones

• MP3 Players

• SIM Card Protection

http://onsemi.com

D1D2D3D4V

1

MARKING

DIAGRAM

UDFN6 1.6 X 1.6

6

MU SUFFIX

1

(Note: Microdot may be in either location)

CASE 517AP

P2 = Specific Device Code

M

= Date Code

G = Pb−Free Package

1

PIN CONNECTIONS

6

D

1

1

D

2

D

3

GND

2

3

V

2

V

5

1

D

4

4

V

2

P2 MG

G

MAXIMUM RATINGS (T

Symbol Rating Value Unit

T

J

T

STG

T

L

ESD IEC 61000−4−2 Contact 14000 V

Stresses exceeding Maximum Ratings may damage the device. Maximum

Ratings are stress ratings only. Functional operation above the Recommended

Operating Conditions is not implied. Extended exposure to stresses above the

Recommended Operating Conditions may affect device reliability.

Operating Junction Temperature Range −40 to 125 °C

Storage Temperature Range −55 to 150 °C

Lead Solder Temperature – Maximum

(10 seconds)

= 25°C, unless otherwise specified)

J

260 °C

NUP4212UPMUTAG UDFN6

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

See Application Note AND8308/D for further description of survivability specs.

© Semiconductor Components Industries, LLC, 2009

August, 2009− Rev. 1

1 Publication Order Number:

ORDERING INFORMATION

Device Package Shipping

3000/Tape & Reel

(Pb−Free)

NUP4212UPMU/D

†

NUP4212UPMU

ELECTRICAL CHARACTERISTICS

(TA = 25°C unless otherwise noted)

Symbol

V

I

V

RWM

V

V

P

Maximum Reverse Peak Pulse Current

PP

Clamping Voltage @ I

C

Working Peak Reverse Voltage

I

Maximum Reverse Leakage Current @ V

R

Breakdown Voltage @ I

BR

I

Test Current

T

I

Forward Current

F

Forward Voltage @ I

F

Peak Power Dissipation

pk

C Max. Capacitance @ VR = 0 and f = 1.0 MHz

*See Application Note AND8308/D for detailed explanations of

datasheet parameters.

ELECTRICAL CHARACTERISTICS (T

Parameter Conditions Symbol Min Typ Max Unit

Reverse Working Voltage (D1, D2, D

Reverse Working Voltage (V1 and V2) (Note 1) V

Breakdown Voltage (D1, D2, D

Breakdown Voltage (V1, V2) IT = 5 mA, (Note 2) V

Reverse Leakage Current (D1, D2, D

Reverse Leakage Current (V1, V2) @ V

Capacitance (D1, D2, D

Clamping Voltage @ IPP = 1 A (Note 3) V

Clamping Voltage Per IEC61000−4−2 (Note 4) V

1. TVS devices are normally selected according to the working peak reverse voltage (V

or continuous peak operating voltage level.

is measured at pulse test current IT.

2. V

BR

3. Surge current waveform per Figure 5.

4. Typical waveform. For test procedure see Figures 3 and 4 and Application Note AND8307/D.

Parameter

PP

V

VCV

RWM

T

F

BR

RWM

Uni−Directional TVS

= 25°C, unless otherwise specified)

J

and D4) (Note 1) V

3,

and D4) IT = 1 mA, (Note 2) V

3,

and D4) @ V

3,

and D4) VR = 0 V, f = 1 MHz (Line to GND) C

3,

RWM1

RWM2

), which should be equal or greater than the DC

RWM

I

RWM1

RWM2

BR

BR2

I

R

I

R

J

C

C

I

F

I

V

R

F

I

T

I

PP

− − 4.0 V

− − 12 V

5.2 5.5 − V

13.5 15 15.8 V

− − 1.0

− − 1.0

− 0.7 0.9 pF

− − 14.3 V

Figures 1 and 2 V

V

mA

mA

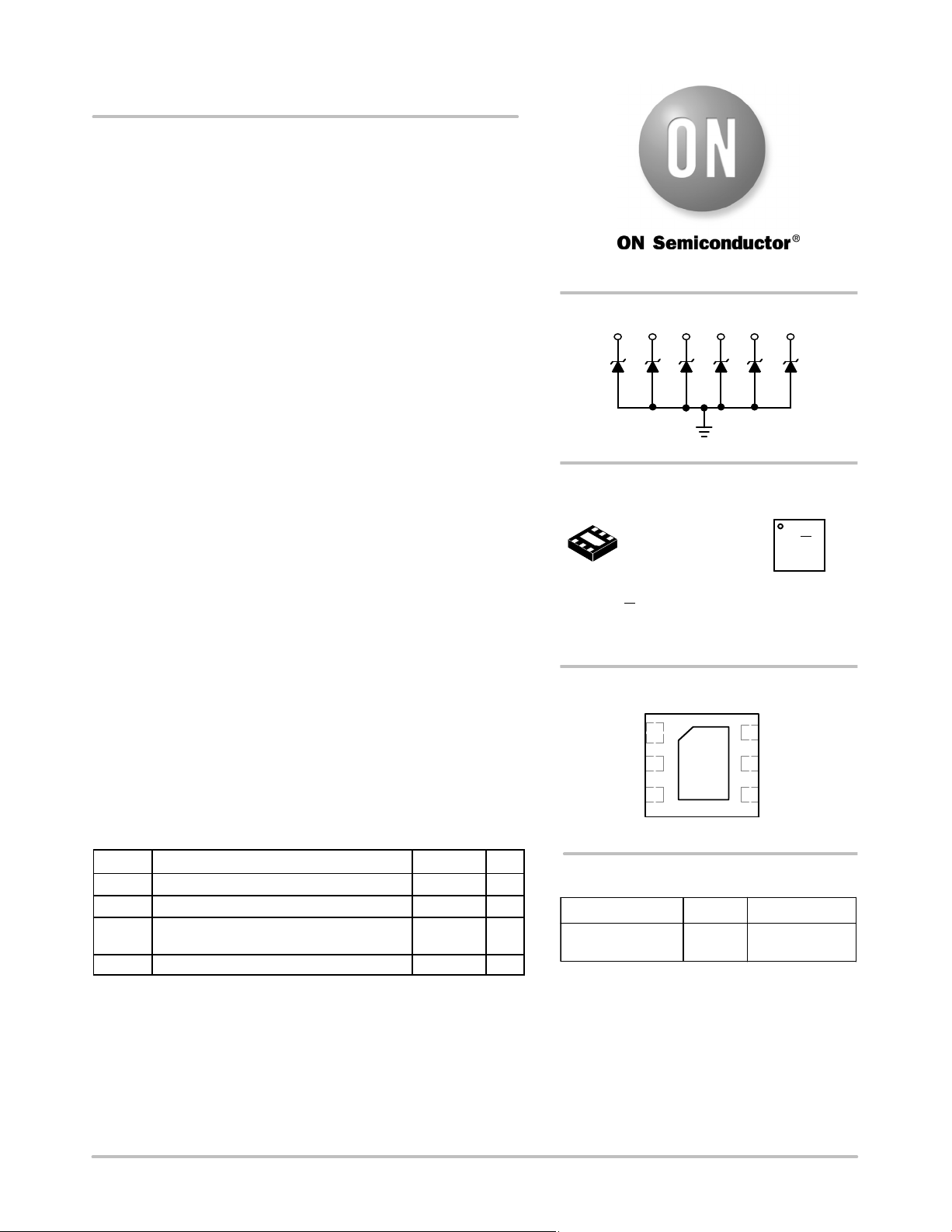

Figure 1. ESD Clamping Voltage Screenshot

Positive 8 kV Contact per IEC61000−4−2

http://onsemi.com

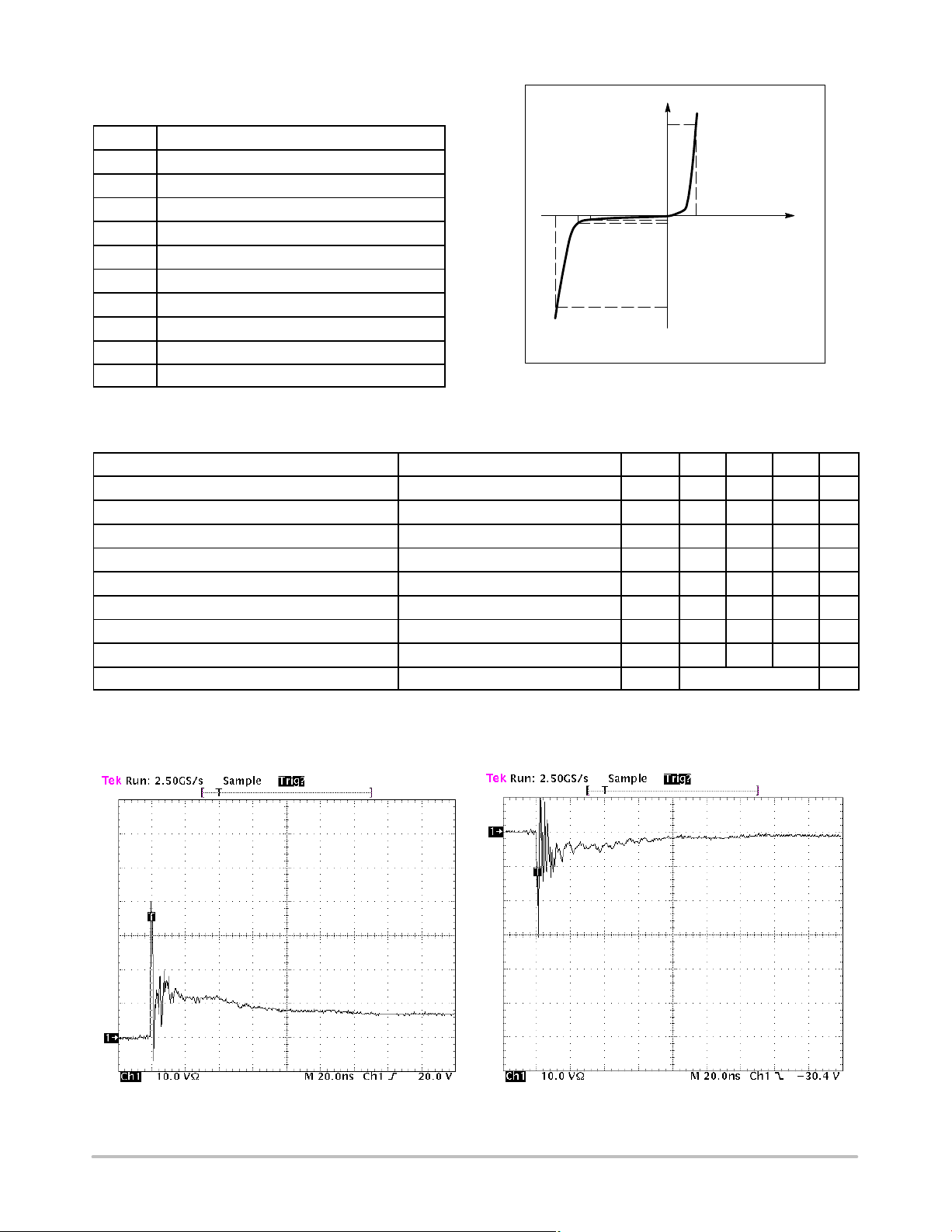

Figure 2. ESD Clamping Voltage Screenshot

Negative 8 kV Contact per IEC61000−4−2

2

Loading...

Loading...