ON NUP2202W1 Schematic [ru]

NUP2202W1

Transient Voltage

Suppressors

ESD Protection Diodes with Low

Clamping Voltage

The NUP2202W1 transient voltage suppressor is designed to

protect high speed data lines from ESD, EFT, and lightning.

Features:

• Low Clamping Voltage

• Stand−Off Voltage: 5 V

• Low Leakage

• Protection for the Following IEC Standards:

IEC 61000−4−2 Level 4 ESD Protection

• UL Flammability Rating of 94 V−0

• This is a Pb−Free Device

Typical Applications:

• High Speed Communication Line Protection

• USB 1.1 and 2.0 Power and Data Line Protection

• Digital Video Interface (DVI) and HDMI

• Monitors and Flat Panel Displays

• MP3

MAXIMUM RATINGS (T

Rating Symbol Value Unit

Peak Power Dissipation

8 x 20 mS @ TA = 25°C (Note 1)

Operating Junction Temperature Range T

Storage Temperature Range T

Lead Solder Temperature −

Maximum (10 Seconds)

Human Body Model (HBM)

Machine Model (MM)

IEC 61000−4−2 Air (ESD)

IEC 61000−4−2 Contact (ESD)

IEC 61000−4−4 (5/50 ns) EFT 40 A

Stresses exceeding Maximum Ratings may damage the device. Maximum

Ratings are stress ratings only. Functional operation above the Recommended

Operating Conditions is not implied. Extended exposure to stresses above the

Recommended Operating Conditions may affect device reliability.

1. Nonrepetitive current pulse per Figure 5 (Pin 5 to Pin 2).

See Application Note AND8308/D for further description of

survivability specs.

= 25°C unless otherwise noted)

J

P

pk

−40 to +125 °C

J

−55 to +150 °C

stg

T

L

ESD 16000

500 W

260 °C

V

400

20000

20000

http://onsemi.com

SC−88 LOW CAPACITANCE

DIODE TVS ARRAY

500 WATTS PEAK POWER

6 VOLTS

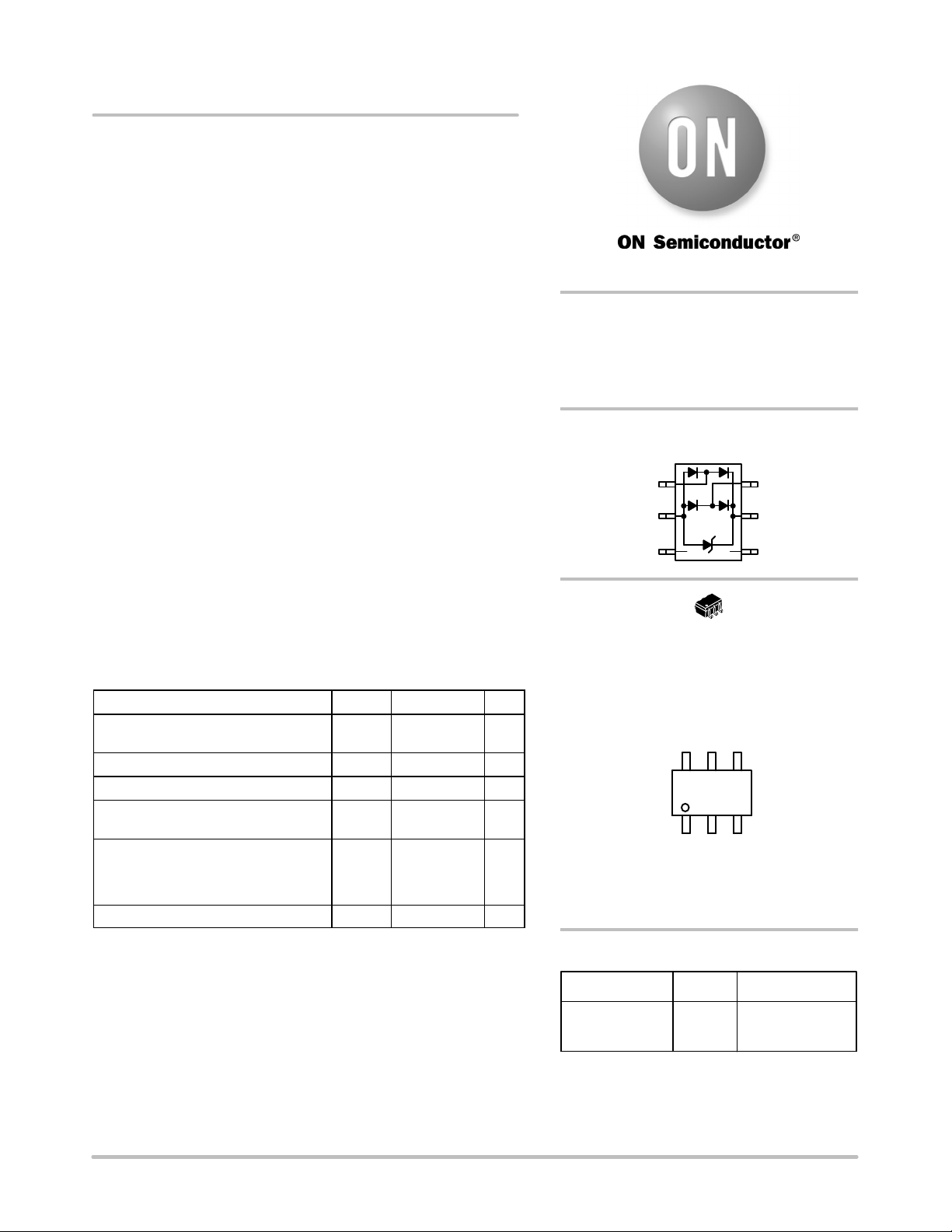

PIN CONFIGURATION

AND SCHEMATIC

I/O 1

VN 2

N/C 3

1

SC−88

CASE 419B

PLASTIC

MARKING DIAGRAM

6

62 MG

G

1

62 = Specific Device Code

M = Date Code

G = Pb−Free Package

(Note: Microdot may be in either location)

ORDERING INFORMATION

Device Package Shipping

NUP2202W1T2G SC−88

Pb−Free

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

6 I/O

5 V

P

4 N/C

†

3000/Tape & Reel

© Semiconductor Components Industries, LLC, 2009

September, 2009 − Rev. 3

1 Publication Order Number:

NUP2202W1/D

NUP2202W1

ELECTRICAL CHARACTERISTICS

(TA = 25°C unless otherwise noted)

Symbol Parameter

I

V

V

RWM

V

V

P

*See Application Note AND8308/D for detailed explanations of

datasheet parameters.

ELECTRICAL CHARACTERISTICS (T

Reverse Working Voltage V

Breakdown Voltage V

Reverse Leakage Current I

Clamping Voltage V

Clamping Voltage V

Maximum Peak Pulse Current I

Junction Capacitance C

Junction Capacitance C

Clamping Voltage V

2. TVS devices are normally selected according to the working peak reverse voltage (V

or continuous peak operating voltage level.

3. VBR is measured at pulse test current IT.

4. Nonrepetitive current pulse per Figure 5 (Pin 5 to Pin 2).

5. Surge current waveform per Figure 5.

6. For test procedure see Figures 3 and 4 and Application Note AND8307/D.

Maximum Reverse Peak Pulse Current

PP

Clamping Voltage @ I

C

Working Peak Reverse Voltage

I

Maximum Reverse Leakage Current @ V

R

Breakdown Voltage @ I

BR

I

Test Current

T

I

Forward Current

F

Forward Voltage @ I

F

Peak Power Dissipation

pk

PP

VCV

RWM

T

F

C Capacitance @ VR = 0 and f = 1.0 MHz

=25°C unless otherwise specified)

J

Parameter Symbol Conditions Min Typ Max Unit

RWM

(Note 2) 5.0 V

IT = 1 mA, (Note 3) 6.0 V

BR

V

R

C

C

PP

J

J

C

= 5 V 5.0

RWM

IPP = 5 A (Note 4) 8.5 12.5 V

IPP = 8 A (Note 4) 8.9 20 V

8x20 ms Waveform (Note 4)

VR = 0 V, f = 1 MHz between I/O Pins and GND 3.0 5.0 pF

VR = 0 V, f = 1 MHz between I/O Pins 1.5 3.0 pF

Per IEC 61000−4−2 (Note 6) Figure 1 and 2 V

I

I

F

V

RWM

BR

I

V

R

F

I

T

I

PP

Uni−Directional TVS

28 A

), which should be equal or greater than the DC

RWM

V

mA

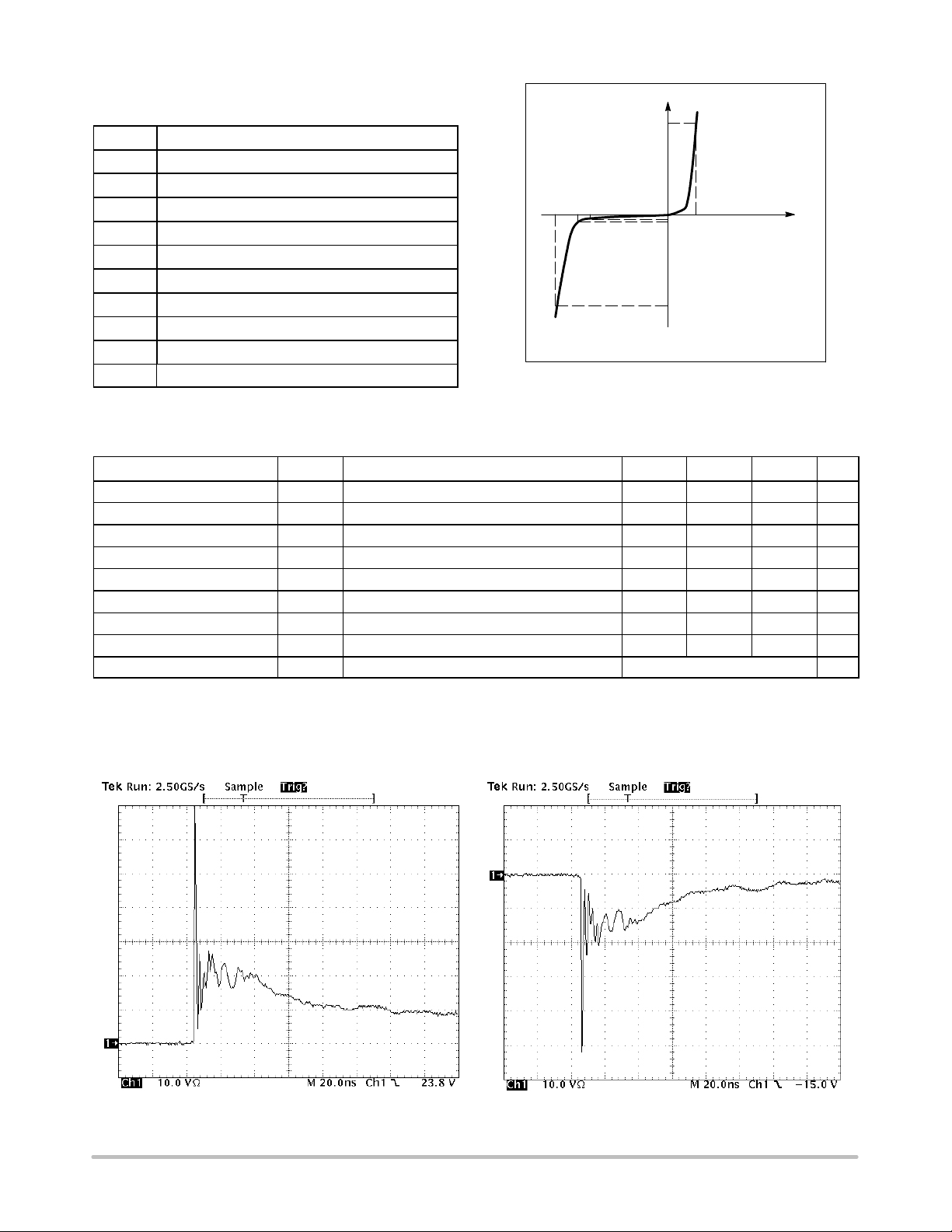

Figure 1. ESD Clamping Voltage Screenshot

Positive 8 kV Contact per IEC61000−4−2

http://onsemi.com

Figure 2. ESD Clamping Voltage Screenshot

Negative 8 kV Contact per IEC61000−4−2

2

NUP2202W1

IEC 61000−4−2 Spec.

Test

Voltage

Level

1 2 7.5 4 2

2 4 15 8 4

3 6 22.5 12 6

4 8 30 16 8

(kV)

ESD Gun

First Peak

Current

(A)

Current at

30 ns (A)

TVS

50 W

Cable

IEC61000−4−2 Waveform

I

peak

Current at

60 ns (A)

100%

90%

I @ 30 ns

I @ 60 ns

10%

Figure 3. IEC61000−4−2 Spec

Oscilloscope

50 W

tP = 0.7 ns to 1 ns

Figure 4. Diagram of ESD Test Setup

The following is taken from Application Note

AND8308/D − Interpretation of Datasheet Parameters

for ESD Devices.

ESD Voltage Clamping

For sensitive circuit elements it is important to limit the

voltage that an IC will be exposed to during an ESD event

to as low a voltage as possible. The ESD clamping voltage

is the voltage drop across the ESD protection diode during

an ESD event per the IEC61000−4−2 waveform. Since the

IEC61000−4−2 was written as a pass/fail spec for larger

100

t

r

90

80

70

60

50

40

30

20

% OF PEAK PULSE CURRENT

10

0

020406080

PEAK VALUE I

t

P

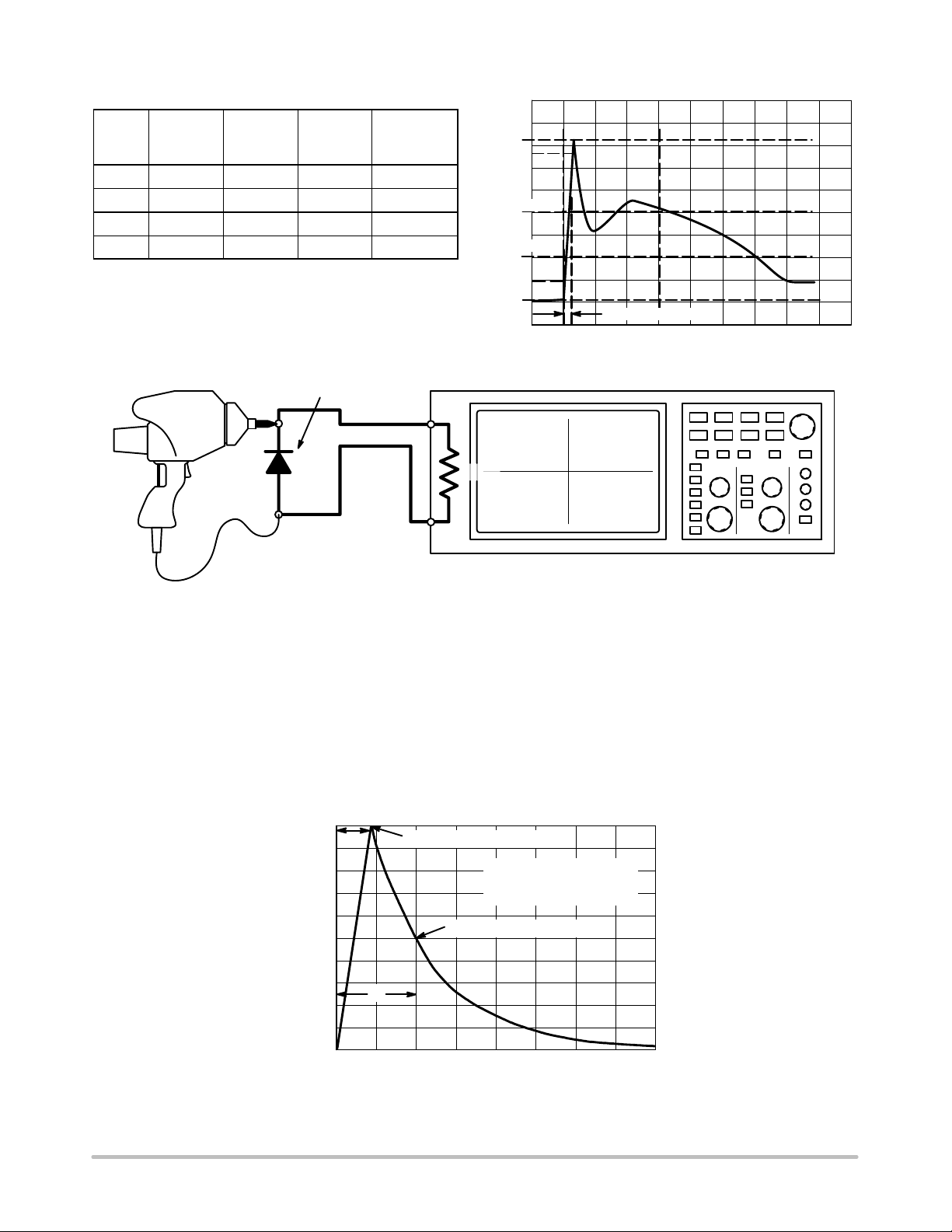

Figure 5. 8 X 20 ms Pulse Waveform

systems such as cell phones or laptop computers it is not

clearly defined in the spec how to specify a clamping voltage

at the device level. ON Semiconductor has developed a way

to examine the entire voltage waveform across the ESD

protection diode over the time domain of an ESD pulse in the

form of an oscilloscope screenshot, which can be found on

the datasheets for all ESD protection diodes. For more

information on how ON Semiconductor creates these

screenshots and how to interpret them please refer to

AND8307/D.

@ 8 ms

RSM

PULSE WIDTH (tP) IS DEFINED

AS THAT POINT WHERE THE

PEAK CURRENT DECAY = 8 ms

HALF VALUE I

t, TIME (ms)

/2 @ 20 ms

RSM

http://onsemi.com

3

Loading...

Loading...