NCP6132A, NCP6132B

Dual Output 3 Phase & 2

Phase Controller with

Single SVID Interface for

Desktop and Notebook CPU

Applications

http://onsemi.com

The NCP6132A/NCP6132B dual output three plus two phase buck

solution is optimized for Intel IMVP−7 and VR12 compatible CPUs.

The controller combines true differential voltage sensing, differential

inductor DCR current sensing, input voltage feed−forward, and

adaptive voltage positioning to provide accurately regulated power for

both Desktop and Notebook applications. The control system is based

on Dual−Edge pulse−width modulation (PWM) combined with DCR

current sensing providing the fastest initial response to dynamic load

events and reduced system cost. It also sheds to single phase during

light load operation and can auto frequency scale in light load while

maintaining excellent transient performance.

There are three internal MOSFET drivers inside the chip. One of

these three integrated driver can be configured either to drive core

phase or aux phase. NCP6132A and NCP6132B have almost same

structure except that NCP6132A has two integrated drivers for the

core rail and one integrated driver for auxiliary rail, while the

NCP6132B has all three integrated drivers for the core rail.

Features

• Meets Intel’s VR12/IMVP7 Specifications

• Three Phase CPU Voltage Regulator, and Two Phase Auxiliary

Voltage Regulator, with Three Internal MOSFET Drivers in Total

• Current Mode Dual Edge Modulation for Fastest Initial Response to

Transient Loading

• Dual High Performance Operational Error Amplifier

• One Digital Soft Start Ramp for Both Rails

• Dynamic Reference Injection

• Accurate Total Summing Current Amplifier

• DAC with Droop Feed−forward Injection

• Dual High Impedance Differential Voltage and Total

Current Sense Amplifiers

• Phase−to−Phase Dynamic Current Balancing

• “Lossless” DCR Current Sensing for Current Balancing

• Summed Thermally Compensated Inductor Current

Sensing for Droop

• Power Saving Phase Shedding

• Start Up into Pre−charged Output Voltage

• Adaptive Voltage Positioning (AVP)

• Vin Feed Forward Ramp Slope

• Pin Programming for Internal SVID Parameters

• Over Voltage Protection (OVP) & Under Voltage

Protection (UVP)

• Over Current Protection (OCP)

• Dual Power Good Output with Internal Delays

• Pb−free and Halide−free Packages are Available

• True Differential Current Balancing Sense Amplifiers

for Each Phase

• Switching Frequency Range of 200 kHz − 600 kHz

Applications

• Desktop & Notebook Processors

MARKING

DIAGRAM

1

160

QFN60

CASE 485BB

x = A or B

A = Assembly Location

WL = Wafer Lot

YY = Year

WW = Work Week

G = Pb−Free Package

ORDERING INFORMATION

Device Package Shipping

NCP6132AMNR2G

NCP6132BMNR2G

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

QFN60

(Pb−Free)

NCP6132x

AWLYYWWG

2500/Tape

& Reel

†

© Semiconductor Components Industries, LLC, 2012

October, 2012 − Rev. 1

1 Publication Order Number:

NCP6132A/D

NCP6132A, NCP6132B

EN

GND

VCC

VDDBP

TSNS

TSNSA

VRHOT#

SDIO

SCLK

ALERT#

VBOOT

VSP

VSN

DROOP

DIFF

COMP

TRBST#

CSSUM

CSREF

CSCOMP

ILIM

IOUT

CSP1

CSP2

CSP3

ENABLE

UVLO & EN

THERMAL

MONITOR

ENABLE

SVID

INTERFACCE

DAC

GND

DIFFAMP

CSREF

1.3 V

FB

ERROR

−

AMP

ENABLE

VSPA

VSNA

DACA

DROOPA

DATA

REGISTERS

TRBST

AUX VR READY

COMPARATOR

DAC

AUX

DAC

VSPA

VSNA

VSP

VSN

ADC

DAC

AUX

DAC

AUX OVP

OVP

ENABLE

MUX

OVPA

OVP

VSP

VSN

DAC

DROOP

VR READY

COMPARATOR

VSPA − VSNA

VSP − VSN

TSNS

TSNSA

IMON

IMONA

IMAX

IMAXA

IOUTA

ILIMA

AUX

DIFFAMP

AUX

CS

AMP

AUX

DAC

GND

CSREFA

1.3 V

−

+

−

VRDYA

VRDY

VSPA

VSNA

DROOPA

DIFFA

CSSUMA

CSREFA

CSCOMPA

ILIMA

IOUTA

FBA

DETECT

CSREF

+

1.3 V

−

+

IOUT

ILIM

MAIN

CURRENT

BALANCE

CS

AMP

ENABLE

CORE PHASE

GENERATOR

COMP

OVP

RAMP1

RAMP2

RAMP3

ENABLE

RAMP

GENERATORS

TRBSTA

DETECT

RAMPA2

RAMPA1

AUX

ERROR

AMP

AUX

PWM

GENERATOR

+

AUX

CURRENT

BALANCE

ENABLE

COMPA

OVPA

1.3 V

COMPA

TRBSTA#

CSP1A

CSP2A

CSREFA

BSTA

HGA

SWA

PVCC

LGA

PVCC

LG1

PGND

BST1

HG1

SW1

PGND

PVCC

LG2

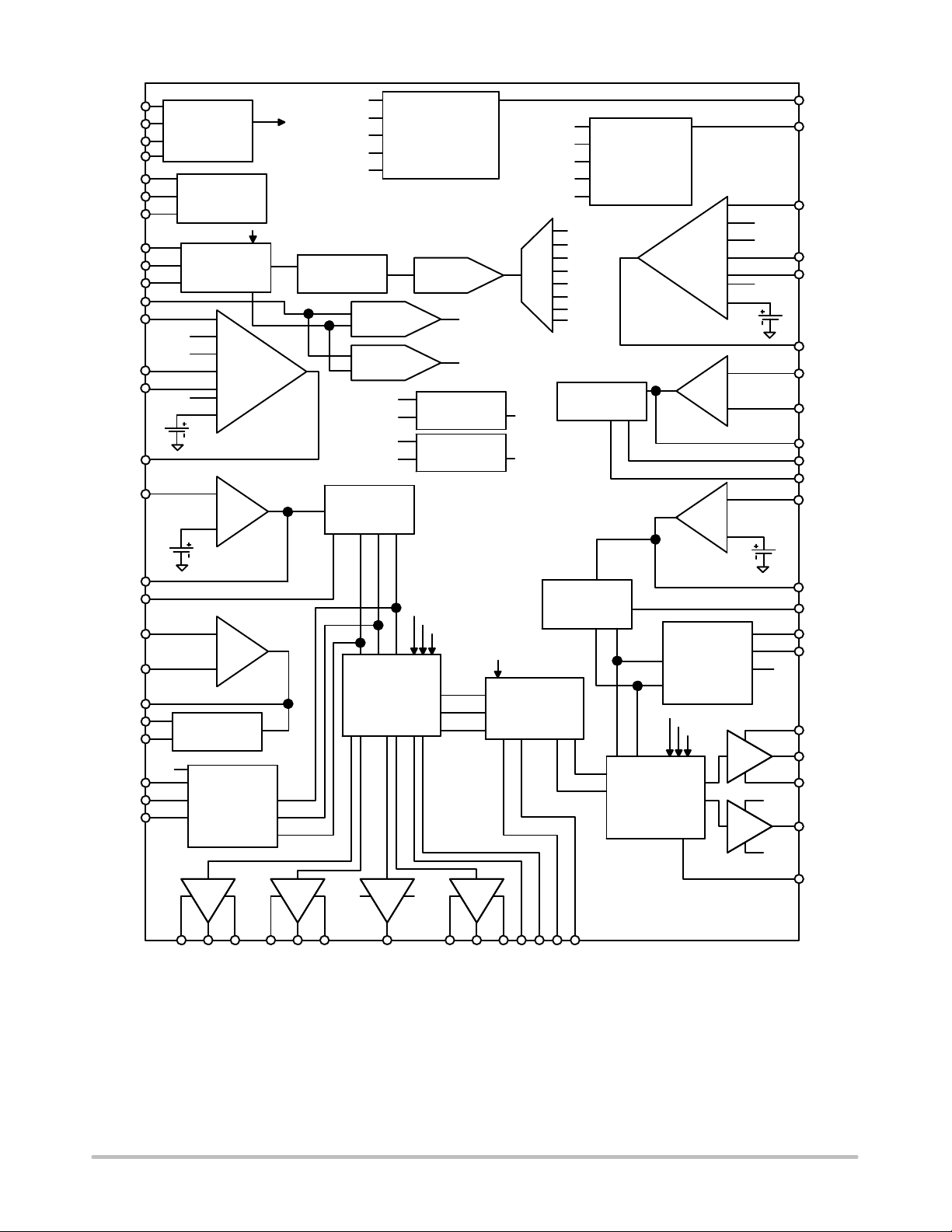

Figure 1. Block Diagram

http://onsemi.com

BST2

PGND

PWMA

HG2

SW2

PWM

VRMP

ROSC

DRVEN

2

VCC

VDDBP

VRDYA

EN

SDIO

ALERT#

SCLK

VBOOT

ROSC

VRMP

VRHOT#

VRDY

VSN

VSP

DIFF

NCP6132A, NCP6132B

FBA

DIFFA

VSNA

VSPA

60

1

15

16

COMPA

TRBSTA#

NCP6132A/NCP6132B

ILIMA

IOUTA

Tab: GND

DROOPA

CSSUMA

CSREFA

CSCOMPA

CSP2A

CSP1A

TSNSA

46

PWMA

45

BSTA

HGA

SWA

LGA

BST2

HG2

SW2

LG2

PVCC

PGND

LG1

SW1

HG1

31

BST1

30

FB

TRBST#

ILIM

IOUT

COMP

DROOP

CSREF

CSSUM

CSCOMP

CSP3

CSP1

CSP2

PWM

TSNS

DRVEN

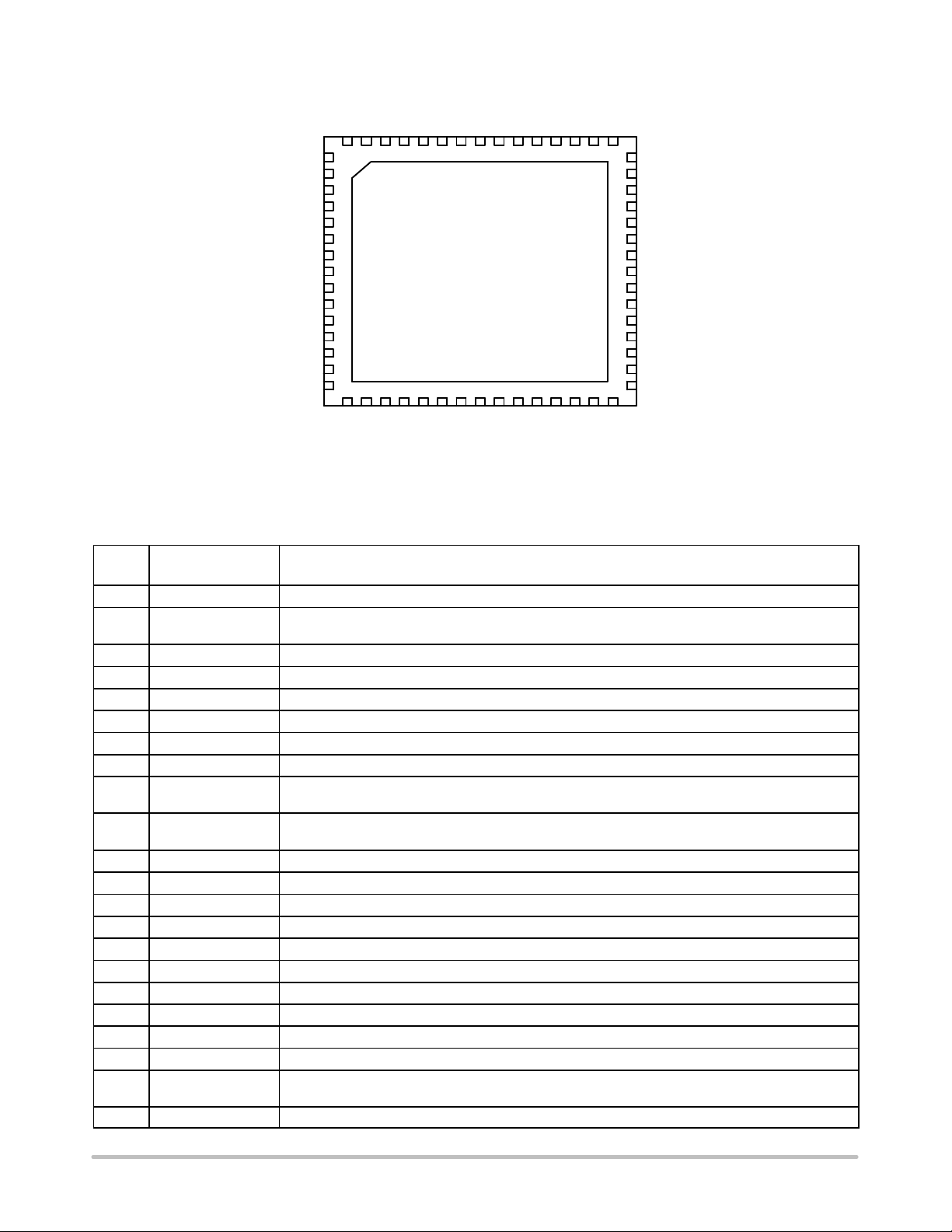

Figure 2. QFN60 Pin Diagram

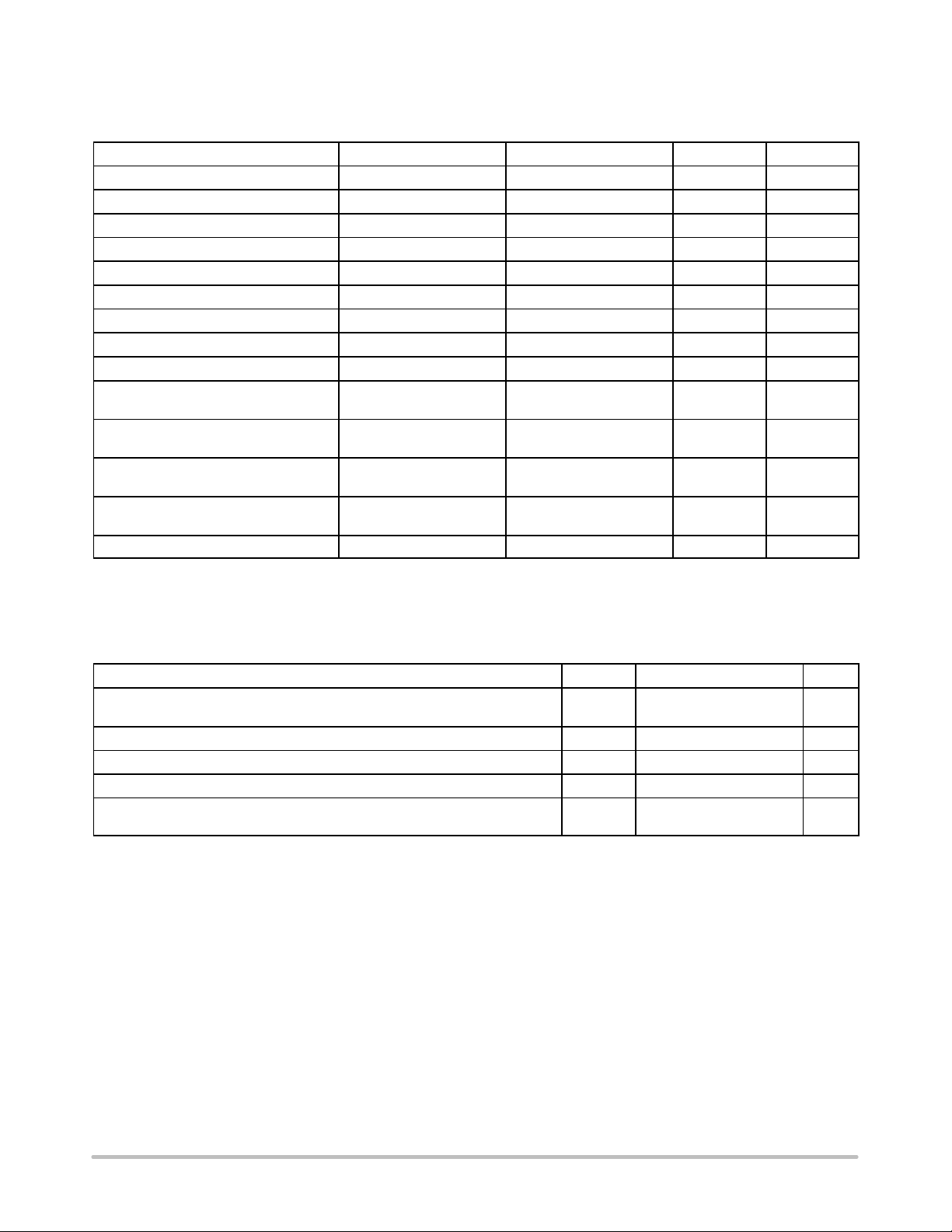

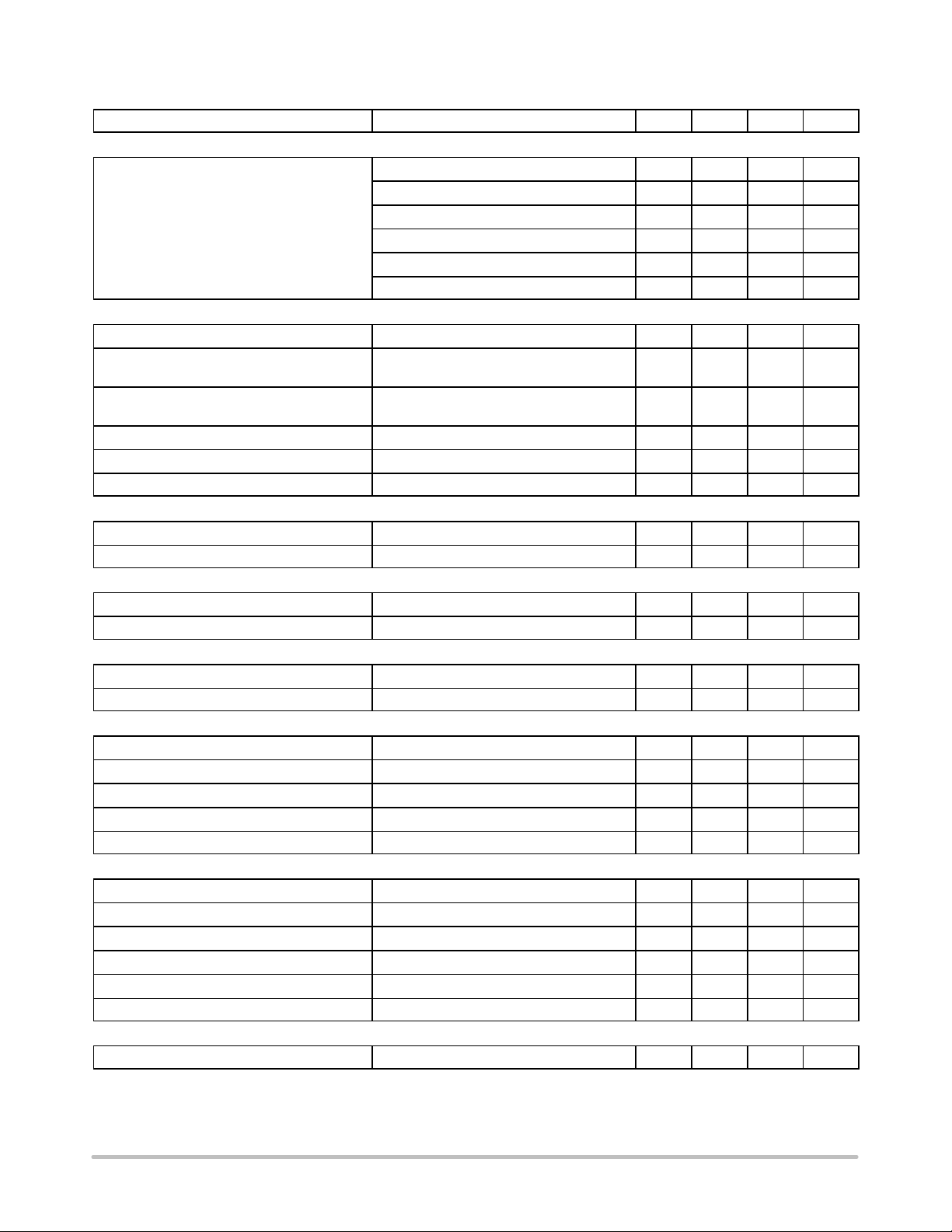

Table 1. QFN60 PIN LIST DESCRIPTION

Pin

No.

1 VCC Power for the internal control circuits. A decoupling capacitor is connected from this pin to ground.

2 VDDBP

3 VRDYA Open drain output. High indicates that the aux output is regulating.

4 EN Logic input. Logic high enables both outputs and logic low disables both outputs.

5 SDIO Serial VID data interface.

6 ALERT# Serial VID ALERT#.

7 SCLK Serial VID clock.

8 VBOOT A resistor to GND on this pin sets the Core and Aux Boot−up Voltage

9 ROSC A resistance from this pin to ground programs the oscillator frequency. This pin supplies a trimmed

10 VRMP Feed−forward input of Vin for the ramp slope compensation. The current fed into this pin is used to

11 VRHOT# Thermal logic output for over temperature.

12 VRDY Open drain output. High indicates that the core output is regulating.

13 VSN Inverting input to the core differential remote sense amplifier.

14 VSP Non−inverting input to the core differential remote sense amplifier.

15 DIFF Output of the core differential remote sense amplifier.

16 TRBST# Compensation pin for the load transient boost.

17 FB Error amplifier voltage feedback for core output

18 COMP Output of the error amplifier and the inverting inputs of the PWM comparators for the core output.

19 IOUT Total output current monitor for core output. Short it to GND if IMON function is not needed.

20 ILIM Over current shutdown threshold setting for core output. Resistor to CSCOMP to set threshold.

21 DROOP Used to program droop function for core output. It’s connected to the resistor divider placed between

22 CSCOMP Output of total current sense amplifier for core output.

Symbol Description

Digital Logic power. Connect this pin to VCC with 10 W. Connect 0.1 mF capacitor from this pin to

ground

output voltage of 2 V.

control of the ramp of PWM slope

CSCOMP and CSREF summing node.

http://onsemi.com

3

NCP6132A, NCP6132B

Table 1. QFN60 PIN LIST DESCRIPTION

Pin

No.

23 CSSUM Inverting input of total current sense amplifier for core output.

24 CSREF Total output current sense amplifier reference voltage input. And inverting input to core current bal-

ance sense amplifiers.

25 CSP3 Non−inverting input to current balance sense amplifier for phase 3

26 CSP2 Non−inverting input to current balance sense amplifier for phase 2

27 CSP1 Non−inverting input to current balance sense amplifier for phase 1

28 TSNS Temp Sense input for the core converter.

29 DRVEN Bidirectional gate driver enable for external drivers for both core and aux rails. It should be left floating

if unused.

30 PWM Phase 3 PWM output. A resistor to ground on this pin programs IMAX.

31 BST1 High−Side Bootstrap supply for phase 1

32 HG1 High−Side gate drive output for phase 1

33 SW1 Current return for high−side gate drive for phase 1

34 LG1 Low−Side gate drive output for phase 1

35 PGND Power ground for gate drivers

36 PVCC Power Supply for gate drivers

37 LG2 Low−Side gate drive output for phase 2

38 SW2 Current return for high−side gate drive for phase 2

39 HG2 High−Side gate drive output for phase 2

40 BST2 High−Side Bootstrap supply for phase 2

41 LGA Low−Side gate drive output for aux phase 1

42 SWA Current return for high−side gate drive for aux phase 1

43 HGA High−Side gate drive output for aux phase 1

44 BSTA High−Side Bootstrap supply for aux phase 1

45 PWMA Aux Phase 2 PWM output. A resistor to ground on this pin programs IMAXA.

46 TSNSA Temp sense for the aux converter

47 CSP1A Non−inverting input to aux current balance sense amplifier for phase 1

48 CSP2A Non−inverting input to aux current balance sense amplifier for phase 2

49 CSREFA Total output current sense amplifier reference voltage input for aux. Inverting input to aux current

balance sense amplifier for phase 1 and 2

50 CSSUMA Inverting input of total current sense amplifier for aux output

51 CSCOMPA Output of total current sense amplifier for aux output

52 DROOPA Used to program droop function for aux output. It’s connected to the resistor divider placed between

CSCOMPA and CSREFA.

53 ILMA Over current shutdown threshold setting for aux output. Resistor to CSCOMPA to set threshold.

54 IOUTA Total output current monitor for aux output. Short to GND if IMON function is not needed.

55 COMPA Output of aux error amplifier and inverting input of PWM comparator for aux output

56 FBA Error amplifier voltage feedback for aux output

57 TRBSTA# Compensation pin for load transient boost

58 DIFFA Output of the aux differential remote sense amplifier

59 VSPA Non−inverting input to aux differential remote sense amplifier

60 VSNA Inverting input to aux differential remote sense amplifier

61 GND Analog ground

DescriptionSymbol

http://onsemi.com

4

NCP6132A, NCP6132B

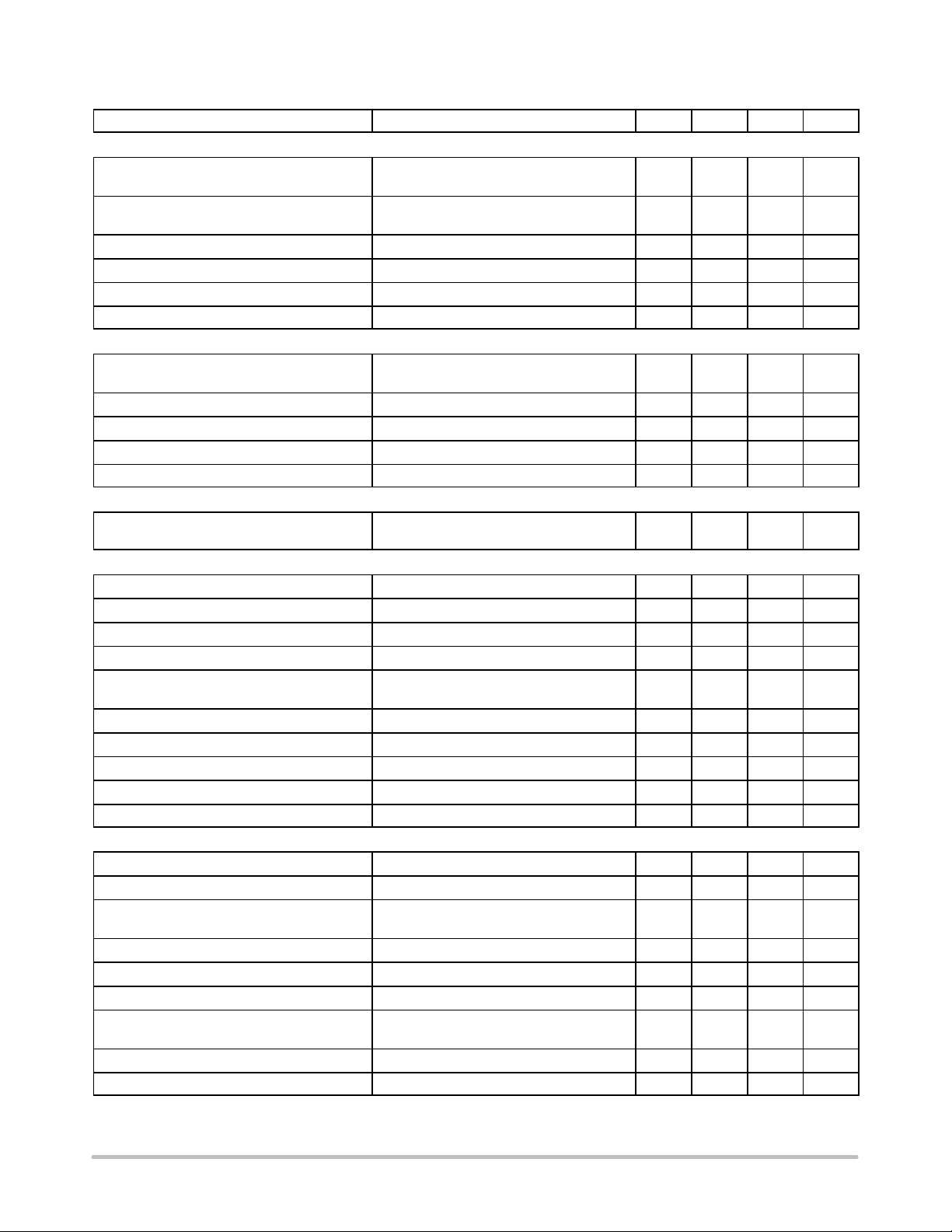

ABSOLUTE MAXIMUM RATINGS

Table 2. ELECTRICAL INFORMATION

Pin Symbol V

MAX

COMP, COMPA VCC + 0.3 V −0.3 V 2 mA 2 mA

CSCOMP, CSCOMPA VCC + 0.3 V −0.3 V 2 mA 2 mA

VSN, VSNA GND + 300 mV GND – 300 mV 1 mA 1 mA

DIFF, DIFFA VCC + 0.3 V −0.3 V 2 mA 2 mA

VRDY, VRDYA VCC + 0.3 V −0.3 V N/A 2 mA

VDDPB, VCC, PVCC 6.5 V −0.3 V N/A N/A

ROSC VCC + 0.3 V −0.3 V 1 mA N/A

IOUT, IOUTA Output TBD −0.3 V

VRMP +25 V −0.3 V

SW1, SW2, SWA 28 V −5 V

BST1, BST2, BSTA 34 V wrt/ GND

6.5 V wrt/ SW

LG1, LG2, LGA VCC + 0.3 V −0.3 V

HG1, HG2, HGA BST + 0.3 V −0.3 V wrt/ SW

−2 V ≤ 200 ns wrt/ SW

All Other Pins VCC + 0.3 V −0.3 V

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

*All signals referenced to GND unless noted otherwise.

V

MIN

−10 V ≤ 200 ns

−0.3 V wrt/ SW

−5 V ≤ 200 ns

I

SOURCE

I

SINK

Table 3. THERMAL INFORMATION

Parameters Symbol Typical Units

Thermal Characteristic

QFN Package (Note 1)

Operating Junction Temperature Range (Note 2) T

Operating Ambient Temperature Range −10 to +100

Maximum Storage Temperature Range T

Moisture Sensitivity Level

QFN Package

*The maximum package power dissipation must be observed.

1. JESD 51−5 (1S2P Direct−Attach Method) with 0 LFM

2. JESD 51−7 (1S2P Direct−Attach Method) with 0 LFM

R

JA

J

STG

−10 to +125

−40 to +150

MSL 1

31

_C/W

_C

_C

_C

http://onsemi.com

5

NCP6132A, NCP6132B

Table 4. NCP6132A/NCP6132B (3+2) ELECTRICAL CHARACTERISTICS

Unless otherwise stated: −10°C < TA < 100°C; VCC = 5.0 V; C

Parameter

ERROR AMPLIFIER

Input Bias Current −400 400 nA

Open Loop DC Gain CL = 20 pF to GND,

Open Loop Unity Gain Bandwidth CL = 20 pF to GND,

Slew Rate

Maximum Output Voltage I

Minimum Output Voltage I

DIFFERENTIAL SUMMING AMPLIFIER

Input Bias Current −400 − 400 nA

VSP Input Voltage Range −0.3 − 3.0 V

VSN Input Voltage Range −0.3 − 0.3 V

−3 dB Bandwidth CL = 20 pF to GND,

Closed Loop DC gain VS to DIFF VS+ to VS− = 0.5 to 1.3 V 1.0 V/V

Droop Accuracy CSREF − DROOP = 80 mV

Maximum Output Voltage I

Minimum Output Voltage I

3. Guaranteed by design/characterization, not in production test

4. Guaranteed by characterization

= 0.1 mF

VCC

Test Conditions Min Typ Max Units

80 dB

RL = 10 kW to GND

55 MHz

RL = 10 kW to GND

DVin = 100 mV, G = −10 V/V,

DV

= 1.5 V – 2.5 V,

out

CL = 20 pF to GND,

20

DC Load = 10k to GND

= 2.0 mA 3.5 − − V

SOURCE

= 2.0 mA − − 1 V

SINK

12 MHz

RL = 10 kW to GND

DAC = 0.8 V to 1.2 V

−10°C ~ 100°C

−10°C ~ 85°C

= 2 mA 3.0 − − V

SOURCE

= 2 mA − − 0.5 V

SINK

78.5

79

81.5

81

V/ms

mV

http://onsemi.com

6

NCP6132A, NCP6132B

Table 5. ELECTRICAL CHARACTERISTICS Unless otherwise stated: −10°C < T

< 100°C; VCC = 5.0 V; C

A

VCC

= 0.1 mF

Parameter Test Conditions Min Typ Max Units

CURRENT SUMMING AMPLIFIER

Offset Voltage (Vos) −300 300

mV

Input Bias Current (CSSUM) CSSUM = CSREF = 1 V −7.5 7.5 nA

Open Loop Gain 80 dB

Current Sense Unity Gain Bandwidth CL = 20 pF to GND,

10 MHz

RL = 10 kW to GND

Maximum CSCOMP (A) Output Voltage I

Minimum CSCOMP(A) Output Voltage

= 2 mA 3.5 − − V

source

I

sink

= 500 mA

− − 0.1 V

CURRENT BALANCE AMPLIFIER

Input Bias Current CSPx = CSREF = 1.2 V −50 − 50 nA

Common Mode Input Voltage Range CSPx = CSREF 0 − 2.0 V

Differential Mode Input Voltage Range CSREF = 1.2 V −100 − 100 mV

Input Offset Voltage Matching CSPx = CSREF = 1.2 V,

−1.5 − 1.5 mV

Measured from the average

Current Sense Amplifier Gain 0 V < CSPx − CSREF < 0.1 V,

−10°C ~ 85°C

−10°C ~ 100°C

5.7

5.5

6.0

6.0

6.3

6.3

V/V

Multiphase Current Sense Gain Matching CSREF = CSP = 10 mV to 30 mV −3 3 %

−3 dB Bandwidth 8 MHz

BIAS SUPPLY

VCC Quiescent Current EN = high 20 27 35 mA

EN = low 10 70

mA

UVLO Threshold VCC rising 4.5 V

VCC falling 4.0 V

VCC UVLO Hysteresis 200 mV

VDDBP Quiescent Current EN = Low

EN = High

0.8

12.0

mA

DAC SLEW RATE

Soft Start Slew Rate 2.33

Slew Rate Slow 3.5

Slew Rate Fast 13.5

AUX Soft Start Slew Rate 2.33

AUX Slew Rate Slow 3.5

AUX Slew Rate Fast 13.5

mv/ms

mv/ms

mv/ms

mv/ms

mv/ms

mv/ms

ENABLE INPUT

Enable High Input Leakage Current External 1k pull−up to 3.3 V − 1.0

Upper Threshold V

Lower Threshold V

Total Hysteresis V

UPPER

UPPER

LOWER

– V

LOWER

Enable Delay Time Measure time from Enable transitioning HI

to when DRON goes high, V

is not 0 V

boot

0.8 V

0.35 V

95 mV

5.0 ms

mA

3. Guaranteed by design/characterization, not in production test

4. Guaranteed by characterization

http://onsemi.com

7

NCP6132A, NCP6132B

Table 5. ELECTRICAL CHARACTERISTICS Unless otherwise stated: −10°C < T

< 100°C; VCC = 5.0 V; C

A

VCC

= 0.1 mF

Parameter UnitsMaxTypMinTest Conditions

DRVEN

Output High Voltage

Output Low Voltage

Rise Time

Fall Time − 2 − ns

Sourcing 500 mA

Sinking 500 mA

CL (PCB) = 20 pF,

DVo = 10% to 90%

Internal Pull Down Resistance EN = Low 70

3.5 V

0.1 V

− 255 − ns

kW

IOUT / IOUTA OUTPUT

Maximum Output Voltage R

Input Referred Offset Voltage I

Output Source Current

Current Gain (IOUT

R

I

limit

CURRENT

= 8.0 kW , Temp range: 0°C to 60°C

OUT

= 5k 2.5 V

lim

to CSREF −2.5 2.5 mV

limit

sink current = 80 mA

) / (ILIM

CURRENT

), R

ILIM

=

9.5 10 10.5

840

mA

OSCILLATOR

Switching Frequency Range 200 − 800 kHz

Switching Frequency Accuracy 200 kHz < Fsw < 800 kHz −10 − 10 %

3 Phase Operation

Rosc Output Voltage

R

osc

R

osc

= 67.4 kW

= 67.4 kW

360 400 440 kHz

1.95 2.00 2.05 V

OUTPUT OVER VOLTAGE & UNDER VOLTAGE PROTECTION (OVP & UVP)

Over Voltage Threshold During Soft−Start &

1.7 1.75 1.8 V

DVID

Over Voltage Threshold Above DAC VSP(A) Rising 225 250 275 mV

Over Voltage Delay VSP(A) rising to PWMx low 50 ns

Under Voltage Threshold Below DAC−DROOP VSP(A) Falling 350 400 450 mV

Under−voltage Hysteresis VSP(A) Rising 25 mV

Under−voltage Delay 5

VR12 DAC

System Voltage Accuracy −105C ~ 855C

1.0 V ≤ DAC < 1.52 V

0.8 V< DAC < 0.995 V

0.5 V < DAC < 0.795 V

0.25 V < DAC < 0.495 V

−0.5

−5

−8

−8

+0.5

+5

+8

+8

mV

mV

mV

−105C ~ 1005C

1.0 V ≤ DAC < 1.52 V

0.8 V< DAC < 0.995 V

0.5 V < DAC < 0.795 V

0.25 V < DAC < 0.495 V

Droop Feed−Forward Current Measure on DROOP pin 60 66 72

1

−12

−12

−12

1

+12

+12

+12

mV

mV

mV

mA

Droop Feed−Forward Pulse On−Time 0.16

OVERCURRENT PROTECTION

ILIM Threshold Current

(OCP shutdown after 50 ms delay)

Aux/Core Multiphase, PS0, R

Aux/Core 1−phase, PS1/2/3, R

Aux 2−phase, PS1, R

Core 2−phase, PS1, R

lim

lim

Aux/Core 2−phase, PS2/3, R

Core 3−phase, PS1/2/3, R

= 20 kW

lim

= 20 kW

lim

= 20 kW

= 20 kW

= 20 kW

lim

= 20 kW

lim

9.0 10 11.0

10

10

6.5

6.5

4.0

mA

mA

mA

mA

mA

mA

3. Guaranteed by design/characterization, not in production test

4. Guaranteed by characterization

ms

%

%

ms

http://onsemi.com

8

NCP6132A, NCP6132B

Table 5. ELECTRICAL CHARACTERISTICS Unless otherwise stated: −10°C < T

< 100°C; VCC = 5.0 V; C

A

VCC

= 0.1 mF

Parameter UnitsMaxTypMinTest Conditions

OVERCURRENT PROTECTION

ILIM Threshold Current

(immediate OCP shutdown)

Aux/Core Multiphase, PS0, R

Aux/Core 1−phase, PS1/2/3, R

Aux 2−phase, PS1, R

Core 2−phase, PS1, R

lim

lim

Aux/Core 2−phase, PS2/3, R

Core 3−phase, PS1/2/3, R

= 20 kW

lim

= 20 kW

lim

= 20 kW

= 20 kW

= 20 kW

lim

= 20 kW

lim

13.5 15 16.5

15

15

10

10

6

mA

mA

mA

mA

mA

mA

MODULATORS (PWM COMPARATORS) FOR CORE & AUX

Minimum Pulse Width Fsw = 350 kHz 60 ns

0% Duty Cycle COMP voltage when the PWM outputs

1.3 − V

remain LO

100% Duty Cycle COMP voltage when the PWM outputs

remain HI V

RMP

= 12.0 V

− 2.5 − V

PWM Ramp Duty Cycle Matching COMP = 2 V, PWM Ton matching −20 20 %

PWM Phase Angle Error Between adjacent phases −25 25 deg

Ramp Feed−forward Voltage range 5 22 V

TRBST#

TRBST/COMP offset TRBST Starts Sinking Current 350 mV

TRBST Sink Capability 500

mA

TRBSTA#

TRBSTA/COMPA offset TRBSTA Starts Sinking Current 350 mV

TRBSTA Sink Capability 500

mA

VRHOT#

Output Low Voltage I_VRHOT = −4 mA 0.3 V

Output Leakage Current High Impedance State −1.0 − 1.0

mA

TSNS/TSNSA

Alert# Assert Threshold 515 mV

Alert# De−assert Threshold 533 mV

VRHOT# Assert Threshold 496 mV

VRHOT# Rising Threshold 515 mV

TSNS Bias Current 115 120 125

mA

ADC

Voltage Range 0 2 V

Total Unadjusted Error (TUE) −1 +1 %

Differential Nonlinearity (DNL) 8−bit 1 LSB

Power Supply Sensitivity +/−1 %

Conversion Time 30

Round Robin 90

ms

ms

VRDY, VRDYA (Power Good) OUTPUT

Output Low Saturation Voltage I

= 4 mA − − 0.3 V

VRDY(A)

3. Guaranteed by design/characterization, not in production test

4. Guaranteed by characterization

http://onsemi.com

9

NCP6132A, NCP6132B

Table 5. ELECTRICAL CHARACTERISTICS Unless otherwise stated: −10°C < T

< 100°C; VCC = 5.0 V; C

A

VCC

= 0.1 mF

Parameter UnitsMaxTypMinTest Conditions

VRDY, VRDYA (Power Good) OUTPUT

Rise Time

Fall Time

Output Voltage at Power−up

External pull−up of 1 kW to 3.3 V,

C

= 45 pF, DVo = 10% to 90%

TOT

External pull−up of 1 kW to 3.3 V,

C

= 45 pF, DVo = 90% to 10%

TOT

VRDY, VRDYA pulled up to 5 V via 2 kW

− 100 ns

10 ns

− − 1.0 V

Output Leakage Current When High VRDY & VRDYA = 5.0 V −1.0 − 1.0

VRDY Delay (rising) DAC = TARGET to VRDY 500

VRDY Delay (falling) From OCP or OVP − 5 −

PWM, PWMA OUTPUTS

Output High Voltage

Sourcing 500 mA

VCC –

− − V

1.0 V

Output Mid Voltage No Load, SetPS = 02 1.3 2.0 2.7 V

Output Low Voltage

Rise and Fall Time

Sinking 500 mA

CL (PCB) = 50 pF, DVo = GND to VCC

− − 0.7 V

− 10 ns

Tri−State Output Leakage Gx = 2.0 V, x = 1−4, EN = Low −1.0 − 1.0

PHASE DETECTION

CSP1A, CSP2A, CSP2, CSP3

4.2 V

Pin Threshold Voltage

SCLK, SDIO

V

V

V

V

R

IL

IH

HYS

OH

ON

Input Low Voltage 0.45 V

Input High Voltage 0.65 V

Hysteresis Voltage 50 mV

Output High Voltage 1.05 V

Buffer On Resistance

4 13

(data line, ALERT#, and VRHOT#)

Leakage Current −100 100

Pad Capacitance (Note 3) 4.0 pF

VR clock to data delay (Tco) (Note 3) 4 8.3 ns

Setup time (Tsu) (Note 3) 7 ns

Hold time (Thld) (Note 3) 14 ns

HIGH−SIDE MOSFET DRIVER

Pull−up Resistance, Sourcing Current (Note 4) BST = PVCC 1.2 2.0

High Side Driver Sourcing Current BST = PVCC 4.17 A

Pull−down Resistance, Sinking Current

BST = PVCC 0.8 2.0

(Note 4)

High Side Driver Sinking Current BST = PVCC 6.25 A

HG1, HG2, HGA Rise Time VCC = 5 V, 3 nF load, BST − SW = 5 V 6 16 30 ns

HG1, HG2, HGA Fall Time VCC = 5 V, 3 nF load, BST − SW = 5 V 6 11 30 ns

HG1, HG2, HGA Turn−On Propagation Delay

tpdh

DRVH

C

= 3 nF 16 40 47 ns

LOAD

SW1, SW2, SWA Pull−Down Resistance SW to PGND 2

HG1, HG2, HGA Pull−Down Resistance HG to SWBST−SW = 0 V 260

3. Guaranteed by design/characterization, not in production test

4. Guaranteed by characterization

mA

ms

ms

mA

W

mA

W

W

kW

kW

http://onsemi.com

10

NCP6132A, NCP6132B

Table 5. ELECTRICAL CHARACTERISTICS Unless otherwise stated: −10°C < T

< 100°C; VCC = 5.0 V; C

A

VCC

= 0.1 mF

Parameter UnitsMaxTypMinTest Conditions

HIGH−SIDE MOSFET DRIVER

BST Quiescent Current EN = L (shutdown)

EN = H, no switching

1.0

300

10

LOW−SIDE MOSFET DRIVER

Pull−up Resistance, Sourcing Current (Note 4) 0.9 2.0

Low Side Driver Sourcing Current 5.56 A

Pull−down Resistance, Sinking Current

0.4 1.0

(Note 4)

Low Side Driver Sinking Current 12.5 A

LG1, LG2, LGA Rise Time 3 nF load 6 16 30 ns

LG1, LG2, LGA Fall Time 3 nF load 6 11 30 ns

LG1, LG2, LGA Turn−On Propagation Delay

tpdh

DRVL

C

= 3 nF 11 30 ns

LOAD

LG1, LG2, LGA Pull−Down Resistance LG to PGND, VCC = 5 V 45

PVCC Quiescent Current EN = L (Shutdown)

EN = H, no switching

1.0

490

10

BOOTSTRAP RECTIFIER SWITCH

On Resistance EN = L or EN = H and DRVL = H 5.0 9.0 14.0

3. Guaranteed by design/characterization, not in production test

4. Guaranteed by characterization

mA

W

W

kW

mA

W

tf

DRVL

DRVL

tpdh

DRVH

tr

DRVH

DRVH

(WITH RESPECT TO SW)

V

TH

SW

Figure 3. Timing Diagram

NOTE: Timing is referenced to the 90% and 10% points, unless otherwise noted.

V

TH

1.0V

tr

tf

DRVL

DRVH

tpdh

DRVL

http://onsemi.com

11

NCP6132A, NCP6132B

Table 6. VR12, IMVP−7 VID CODES

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 Voltage (V) HEX

0 0 0 0 0 0 0 0 OFF 00

0 0 0 0 0 0 0 1 0.25000 01

0 0 0 0 0 0 1 0 0.25500 02

0 0 0 0 0 0 1 1 0.26000 03

0 0 0 0 0 1 0 0 0.26500 04

0 0 0 0 0 1 0 1 0.27000 05

0 0 0 0 0 1 1 0 0.27500 06

0 0 0 0 0 1 1 1 0.28000 07

0 0 0 0 1 0 0 0 0.28500 08

0 0 0 0 1 0 0 1 0.29000 09

0 0 0 0 1 0 1 0 0.29500 0A

0 0 0 0 1 0 1 1 0.30000 0B

0 0 0 0 1 1 0 0 0.30500 0C

0 0 0 0 1 1 0 1 0.31000 0D

0 0 0 0 1 1 1 0 0.31500 0E

0 0 0 0 1 1 1 1 0.32000 0F

0 0 0 1 0 0 0 0 0.32500 10

0 0 0 1 0 0 0 1 0.33000 11

0 0 0 1 0 0 1 0 0.33500 12

0 0 0 1 0 0 1 1 0.34000 13

0 0 0 1 0 1 0 0 0.34500 14

0 0 0 1 0 1 0 1 0.35000 15

0 0 0 1 0 1 1 0 0.35500 16

0 0 0 1 0 1 1 1 0.36000 17

0 0 0 1 1 0 0 0 0.36500 18

0 0 0 1 1 0 0 1 0.37000 19

0 0 0 1 1 0 1 0 0.37500 1A

0 0 0 1 1 0 1 1 0.38000 1B

0 0 0 1 1 1 0 0 0.38500 1C

0 0 0 1 1 1 0 1 0.39000 1D

0 0 0 1 1 1 1 0 0.39500 1E

0 0 0 1 1 1 1 1 0.40000 1F

0 0 1 0 0 0 0 0 0.40500 20

0 0 1 0 0 0 0 1 0.41000 21

0 0 1 0 0 0 1 0 0.41500 22

0 0 1 0 0 0 1 1 0.42000 23

0 0 1 0 0 1 0 0 0.42500 24

0 0 1 0 0 1 0 1 0.43000 25

0 0 1 0 0 1 1 0 0.43500 26

0 0 1 0 0 1 1 1 0.44000 27

0 0 1 0 1 0 0 0 0.44500 28

0 0 1 0 1 0 0 1 0.45000 29

0 0 1 0 1 0 1 0 0.45500 2A

http://onsemi.com

12

NCP6132A, NCP6132B

Table 6. VR12, IMVP−7 VID CODES

VID7 HEXVoltage (V)VID0VID1VID2VID3VID4VID5VID6

0 0 1 0 1 0 1 1 0.46000 2B

0 0 1 0 1 1 0 0 0.46500 2C

0 0 1 0 1 1 0 1 0.47000 2D

0 0 1 0 1 1 1 0 0.47500 2E

0 0 1 0 1 1 1 1 0.48000 2F

0 0 1 1 0 0 0 0 0.48500 30

0 0 1 1 0 0 0 1 0.49000 31

0 0 1 1 0 0 1 0 0.49500 32

0 0 1 1 0 0 1 1 0.50000 33

0 0 1 1 0 1 0 0 0.50500 34

0 0 1 1 0 1 0 1 0.51000 35

0 0 1 1 0 1 1 0 0.51500 36

0 0 1 1 0 1 1 1 0.52000 37

0 0 1 1 1 0 0 0 0.52500 38

0 0 1 1 1 0 0 1 0.53000 39

0 0 1 1 1 0 1 0 0.53500 3A

0 0 1 1 1 0 1 1 0.54000 3B

0 0 1 1 1 1 0 0 0.54500 3C

0 0 1 1 1 1 0 1 0.55000 3D

0 0 1 1 1 1 1 0 0.55500 3E

0 0 1 1 1 1 1 1 0.56000 3F

0 1 0 0 0 0 0 0 0.56500 40

0 1 0 0 0 0 0 1 0.57000 41

0 1 0 0 0 0 1 0 0.57500 42

0 1 0 0 0 0 1 1 0.58000 43

0 1 0 0 0 1 0 0 0.58500 44

0 1 0 0 0 1 0 1 0.59000 45

0 1 0 0 0 1 1 0 0.59500 46

0 1 0 0 0 1 1 1 0.60000 47

0 1 0 0 1 0 0 0 0.60500 48

0 1 0 0 1 0 0 1 0.61000 49

0 1 0 0 1 0 1 0 0.61500 4A

0 1 0 0 1 0 1 1 0.62000 4B

0 1 0 0 1 1 0 0 0.62500 4C

0 1 0 0 1 1 0 1 0.63000 4D

0 1 0 0 1 1 1 0 0.63500 4E

0 1 0 0 1 1 1 1 0.64000 4F

0 1 0 1 0 0 0 0 0.64500 50

0 1 0 1 0 0 0 1 0.65000 51

0 1 0 1 0 0 1 0 0.65500 52

0 1 0 1 0 0 1 1 0.66000 53

0 1 0 1 0 1 0 0 0.66500 54

0 1 0 1 0 1 0 1 0.67000 55

http://onsemi.com

13

NCP6132A, NCP6132B

Table 6. VR12, IMVP−7 VID CODES

VID7 HEXVoltage (V)VID0VID1VID2VID3VID4VID5VID6

0 1 0 1 0 1 1 0 0.67500 56

0 1 0 1 0 1 1 1 0.68000 57

0 1 0 1 1 0 0 0 0.68500 58

0 1 0 1 1 0 0 1 0.69000 59

0 1 0 1 1 0 1 0 0.69500 5A

0 1 0 1 1 0 1 1 0.70000 5B

0 1 0 1 1 1 0 0 0.70500 5C

0 1 0 1 1 1 0 1 0.71000 5D

0 1 0 1 1 1 1 0 0.71500 5E

0 1 0 1 1 1 1 1 0.72000 5F

0 1 1 0 0 0 0 0 0.72500 60

0 1 1 0 0 0 0 1 0.73000 61

0 1 1 0 0 0 1 0 0.73500 62

0 1 1 0 0 0 1 1 0.74000 63

0 1 1 0 0 1 0 0 0.74500 64

0 1 1 0 0 1 0 1 0.75000 65

0 1 1 0 0 1 1 0 0.75500 66

0 1 1 0 0 1 1 1 0.76000 67

0 1 1 0 1 0 0 0 0.76500 68

0 1 1 0 1 0 0 1 0.77000 69

0 1 1 0 1 0 1 0 0.77500 6A

0 1 1 0 1 0 1 1 0.78000 6B

0 1 1 0 1 1 0 0 0.78500 6C

0 1 1 0 1 1 0 1 0.79000 6D

0 1 1 0 1 1 1 0 0.79500 6E

0 1 1 0 1 1 1 1 0.80000 6F

0 1 1 1 0 0 0 0 0.80500 70

0 1 1 1 0 0 0 1 0.81000 71

0 1 1 1 0 0 1 0 0.81500 72

0 1 1 1 0 0 1 1 0.82000 73

0 1 1 1 0 1 0 0 0.82500 74

0 1 1 1 0 1 0 1 0.83000 75

0 1 1 1 0 1 1 0 0.83500 76

0 1 1 1 0 1 1 1 0.84000 77

0 1 1 1 1 0 0 0 0.84500 78

0 1 1 1 1 0 0 1 0.85000 79

0 1 1 1 1 0 1 0 0.85500 7A

0 1 1 1 1 0 1 1 0.86000 7B

0 1 1 1 1 1 0 0 0.86500 7C

0 1 1 1 1 1 0 1 0.87000 7D

0 1 1 1 1 1 1 0 0.87500 7E

0 1 1 1 1 1 1 1 0.88000 7F

1 0 0 0 0 0 0 0 0.88500 80

http://onsemi.com

14

NCP6132A, NCP6132B

Table 6. VR12, IMVP−7 VID CODES

VID7 HEXVoltage (V)VID0VID1VID2VID3VID4VID5VID6

1 0 0 0 0 0 0 1 0.89000 81

1 0 0 0 0 0 1 0 0.89500 82

1 0 0 0 0 0 1 1 0.90000 83

1 0 0 0 0 1 0 0 0.90500 84

1 0 0 0 0 1 0 1 0.91000 85

1 0 0 0 0 1 1 0 0.91500 86

1 0 0 0 0 1 1 1 0.92000 87

1 0 0 0 1 0 0 0 0.92500 88

1 0 0 0 1 0 0 1 0.93000 89

1 0 0 0 1 0 1 0 0.93500 8A

1 0 0 0 1 0 1 1 0.94000 8B

1 0 0 0 1 1 0 0 0.94500 8C

1 0 0 0 1 1 0 1 0.95000 8D

1 0 0 0 1 1 1 0 0.95500 8E

1 0 0 0 1 1 1 1 0.96000 8F

1 0 0 1 0 0 0 0 0.96500 90

1 0 0 1 0 0 0 1 0.97000 91

1 0 0 1 0 0 1 0 0.97500 92

1 0 0 1 0 0 1 1 0.98000 93

1 0 0 1 0 1 0 0 0.98500 94

1 0 0 1 0 1 0 1 0.99000 95

1 0 0 1 0 1 1 0 0.99500 96

1 0 0 1 0 1 1 1 1.00000 97

1 0 0 1 1 0 0 0 1.00500 98

1 0 0 1 1 0 0 1 1.01000 99

1 0 0 1 1 0 1 0 1.01500 9A

1 0 0 1 1 0 1 1 1.02000 9B

1 0 0 1 1 1 0 0 1.02500 9C

1 0 0 1 1 1 0 1 1.03000 9D

1 0 0 1 1 1 1 0 1.03500 9E

1 0 0 1 1 1 1 1 1.04000 9F

1 0 1 0 0 0 0 0 1.04500 A0

1 0 1 0 0 0 0 1 1.05000 A1

1 0 1 0 0 0 1 0 1.05500 A2

1 0 1 0 0 0 1 1 1.06000 A3

1 0 1 0 0 1 0 0 1.06500 A4

1 0 1 0 0 1 0 1 1.07000 A5

1 0 1 0 0 1 1 0 1.07500 A6

1 0 1 0 0 1 1 1 1.08000 A7

1 0 1 0 1 0 0 0 1.08500 A8

1 0 1 0 1 0 0 1 1.09000 A9

1 0 1 0 1 0 1 0 1.09500 AA

1 0 1 0 1 0 1 1 1.10000 AB

http://onsemi.com

15

NCP6132A, NCP6132B

Table 6. VR12, IMVP−7 VID CODES

VID7 HEXVoltage (V)VID0VID1VID2VID3VID4VID5VID6

1 0 1 0 1 1 0 0 1.10500 AC

1 0 1 0 1 1 0 1 1.11000 AD

1 0 1 0 1 1 1 0 1.11500 AE

1 0 1 0 1 1 1 1 1.12000 AF

1 0 1 1 0 0 0 0 1.12500 B0

1 0 1 1 0 0 0 1 1.13000 B1

1 0 1 1 0 0 1 0 1.13500 B2

1 0 1 1 0 0 1 1 1.14000 B3

1 0 1 1 0 1 0 0 1.14500 B4

1 0 1 1 0 1 0 1 1.15000 B5

1 0 1 1 0 1 1 0 1.15500 B6

1 0 1 1 0 1 1 1 1.16000 B7

1 0 1 1 1 0 0 0 1.16500 B8

1 0 1 1 1 0 0 1 1.17000 B9

1 0 1 1 1 0 1 0 1.17500 BA

1 0 1 1 1 0 1 1 1.18000 BB

1 0 1 1 1 1 0 0 1.18500 BC

1 0 1 1 1 1 0 1 1.19000 BD

1 0 1 1 1 1 1 0 1.19500 BE

1 0 1 1 1 1 1 1 1.20000 BF

1 1 0 0 0 0 0 0 1.20500 C0

1 1 0 0 0 0 0 1 1.21000 C1

1 1 0 0 0 0 1 0 1.21500 C2

1 1 0 0 0 0 1 1 1.22000 C3

1 1 0 0 0 1 0 0 1.22500 C4

1 1 0 0 0 1 0 1 1.23000 C5

1 1 0 0 0 1 1 0 1.23500 C6

1 1 0 0 0 1 1 1 1.24000 C7

1 1 0 0 1 0 0 0 1.24500 C8

1 1 0 0 1 0 0 1 1.25000 C9

1 1 0 0 1 0 1 0 1.25500 CA

1 1 0 0 1 0 1 1 1.26000 CB

1 1 0 0 1 1 0 0 1.26500 CC

1 1 0 0 1 1 0 1 1.27000 CD

1 1 0 0 1 1 1 0 1.27500 CE

1 1 0 0 1 1 1 1 1.28000 CF

1 1 0 1 0 0 0 0 1.28500 D0

1 1 0 1 0 0 0 1 1.29000 D1

1 1 0 1 0 0 1 0 1.29500 D2

1 1 0 1 0 0 1 1 1.30000 D3

1 1 0 1 0 1 0 0 1.30500 D4

1 1 0 1 0 1 0 1 1.31000 D5

1 1 0 1 0 1 1 0 1.31500 D6

http://onsemi.com

16

NCP6132A, NCP6132B

Table 6. VR12, IMVP−7 VID CODES

VID7 HEXVoltage (V)VID0VID1VID2VID3VID4VID5VID6

1 1 0 1 0 1 1 1 1.32000 D7

1 1 0 1 1 0 0 0 1.32500 D8

1 1 0 1 1 0 0 1 1.33000 D9

1 1 0 1 1 0 1 0 1.33500 DA

1 1 0 1 1 0 1 1 1.34000 DB

1 1 0 1 1 1 0 0 1.34500 DC

1 1 0 1 1 1 0 1 1.35000 DD

1 1 0 1 1 1 1 0 1.35500 DE

1 1 0 1 1 1 1 1 1.36000 DF

1 1 1 0 0 0 0 0 1.36500 E0

1 1 1 0 0 0 0 1 1.37000 E1

1 1 1 0 0 0 1 0 1.37500 E2

1 1 1 0 0 0 1 1 1.38000 E3

1 1 1 0 0 1 0 0 1.38500 E4

1 1 1 0 0 1 0 1 1.39000 E5

1 1 1 0 0 1 1 0 1.39500 E6

1 1 1 0 0 1 1 1 1.40000 E7

1 1 1 0 1 0 0 0 1.40500 E8

1 1 1 0 1 0 0 1 1.41000 E9

1 1 1 0 1 0 1 0 1.41500 EA

1 1 1 0 1 0 1 1 1.42000 EB

1 1 1 0 1 1 0 0 1.42500 EC

1 1 1 0 1 1 0 1 1.43000 ED

1 1 1 0 1 1 1 0 1.43500 EE

1 1 1 0 1 1 1 1 1.44000 EF

1 1 1 1 0 0 0 0 1.44500 F0

1 1 1 1 0 0 0 1 1.45000 F1

1 1 1 1 0 0 1 0 1.45500 F2

1 1 1 1 0 0 1 1 1.46000 F3

1 1 1 1 0 1 0 0 1.46500 F4

1 1 1 1 0 1 0 1 1.47000 F5

1 1 1 1 0 1 1 0 1.47500 F6

1 1 1 1 0 1 1 1 1.48000 F7

1 1 1 1 1 0 0 0 1.48500 F8

1 1 1 1 1 0 0 1 1.49000 F9

1 1 1 1 1 0 1 0 1.49500 FA

1 1 1 1 1 0 1 1 1.50000 FB

1 1 1 1 1 1 0 0 1.50500 FC

1 1 1 1 1 1 0 1 1.51000 FD

1 1 1 1 1 1 1 0 1.51500 FE

1 1 1 1 1 1 1 1 1.52000 FF

http://onsemi.com

17

12V

5V

EN

SCLK

NCP6132A, NCP6132B

SVID bus idle

SDIO VSPA VID PKT

VSPA

VSP

SVID Alert

VRDYA

VRDY

CPU Driving, Single Data Rate

SCLK

CPU

send

VR latch

SDIO

VSP VID pkt

Figure 4. Start Up Timing Diagram

VR Driving, Single Data Rate

SCLK

VR

send

SDIO

Status PKT

CPU latch

TCO _CPU

T

co_CPU = clock to data delay in CPU

TCO_CPU

thld

tSU

tsu =0.5*T −Tco_CPU

thld =0.5*T +Tco_CPU

TCO_ VR

T

co_VR = clock to data delay in VR

tsu =T −2*Tfly −Tco_VR

thld =2*Tfly +Tco_VR

Tfly propagation time on Serial VID bus

Figure 5. SVID Timing Diagram

http://onsemi.com

18

tSU

thld

NCP6132A, NCP6132B

Table 7. STATE TRUTH TABLE

Error AMP

STATE VRDY(A) Pin

POR

0 < VCC < UVLO

Disabled

EN < threshold

UVLO > threshold

Start up Delay &

Calibration

EN > threshold

UVLO > threshold

DRVEN Fault

EN > threshold

UVLO > threshold

DRVEN < threshold

Soft Start

EN > threshold

UVLO > threshold

DRVEN > High

Normal Operation

EN > threshold

UVLO > threshold

DRVEN > High

Over Voltage Low N/A DAC + 150 mV High

Over Current Low Operational Last DAC Code Low

VID Code = 00h Follows the

N/A N/A N/A Resistive pull down

Low Low Disabled Low

Low Low Disabled Low

Low Low Disabled Resistive pull up Driver must release

Low Operational Active /

High Operational Active /

MultiVR Config

register (34h)

Bit 0 setting

Comp(A) Pin

Low Disabled High, PWM/PWMA

OVP(A) &

UVP(A)

No latch

Latching

DRVEN PIN Method of Reset

DRVEN to high

High

High N/A

Set Valid VID Code

outputs in low state

LGx outputs in high

state

http://onsemi.com

19

NCP6132A, NCP6132B

Controller

POR

VCC < UVLO

OVP

VCC > UVLO

Drive Off

EN = 0

VDRP > ILIM

NO _ CPU

INVALID VID

Soft Start

DAC = Vboot

Soft Start

Disable

EN = 1

Calibrate

3. 5 ms and CAL DONE

Phase

Detect

VCCP > UVLO and DRON HIGH

Ramp

Ramp

VS > OVP

DAC = VID

Normal

VRDY

VS > UVP

VS < UVP

UVP

Figure 6. State Diagram

http://onsemi.com

20

NCP6132A, NCP6132B

General

The NCP6132A/NCP6132B is a dual output three phase plus

two phase dual edge modulated multiphase PWM controller

designed to meet the Intel VR12 and IMVP−7 specifications

with a serial SVID control interface. It is designed to work

in notebook, desktop, and server applications.

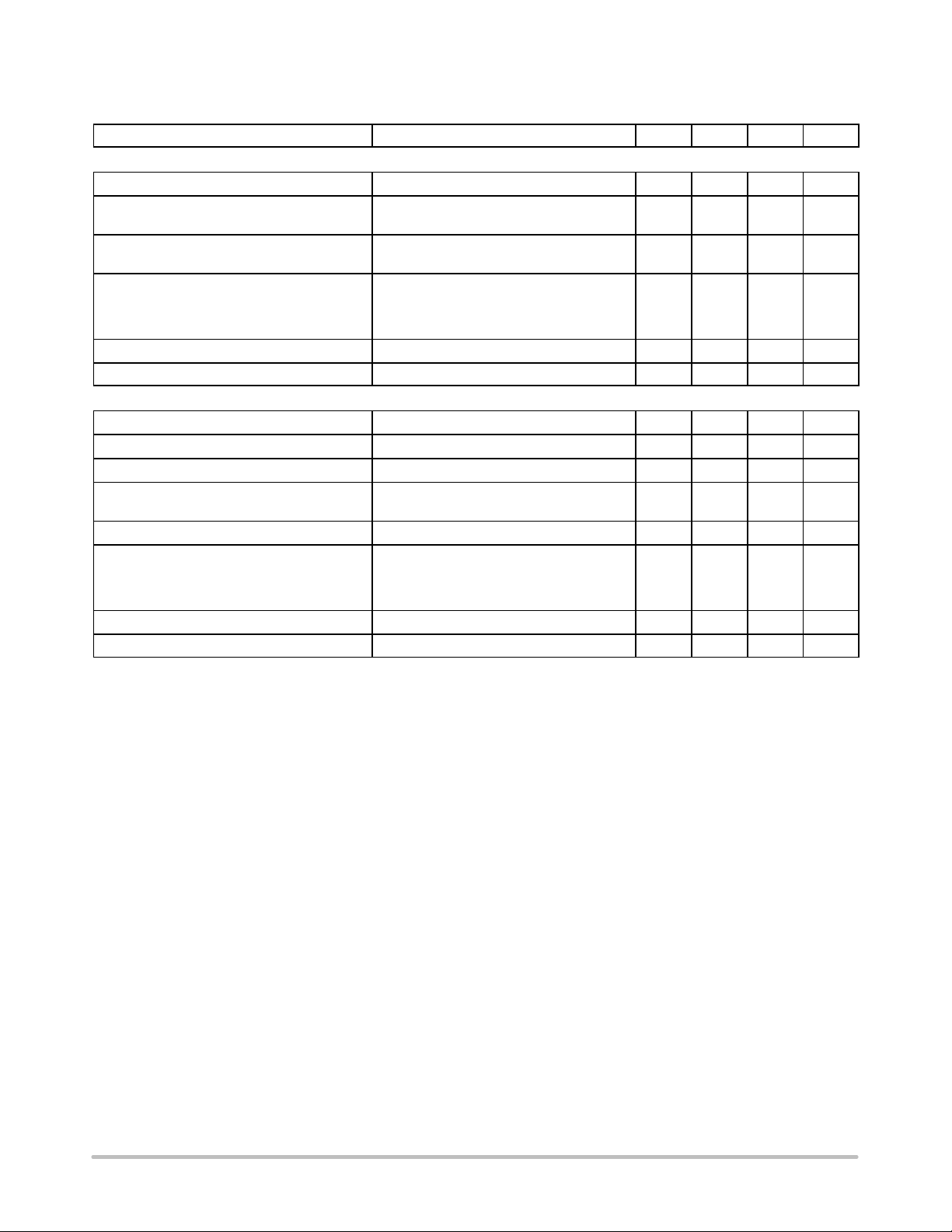

User−set Phase and Driver Selection

NCP6132A/NCP6132B can be user−configured to

operate under different phase and driver combinations.

Phase selection for core and aux regulator can be set up

separately by configuring the pin connections of CSP2,

CSP3, CSP1A, and CSP2A. During start−up (before SVID

is available), CSPx pins are monitored to detect user−set

configuration. If a pin is connected to VCC directly or

through a low value (1 kW) resistor, the monitored input

signal is driven to logic high indicating that the

corresponding phase is disabled. Otherwise, if a pin is

connected normally, the monitored input signal is driven to

logic low and that phase is operational. During initialization,

the configuration defined by CSPx is written into a User

Configuration Register (UCR). If the detected configuration

doesn’t match any of the valid configurations listed in the

table below then it is considered as unsupported. With an

unsupported configuration the chip doesn’t start switching

but remains power−up. After initialization the UCR acts as

a Read−Only reg.

The user configuration for core and aux regulator is shown as below:

No Core Rail Aux Rail CSP2 CSP3 CSP1A CSP2A PART

1 2 int. + 1 ext. 1 int. + 1 ext. normal normal Normal normal NCP6132A

2 2 int. + 1 ext. 1 int. normal normal Normal VCC NCP6132A

3 2 int. + 1 ext. off normal normal VCC VCC NCP6132A

4 3 int. 2 ext. normal normal Normal normal NCP6132B

5 3 int. 1 ext. normal normal Normal VCC NCP6132B

6 3 int. off normal normal VCC VCC NCP6132B

7 2 int. 1 int. + 1 ext. normal VCC Normal normal NCP6132A

8 2 int. 1 int. normal VCC Normal VCC NCP6132A

9 2 int. 2 ext. normal VCC Normal normal NCP6132B

10 2 int. 1 ext. normal VCC Normal VCC NCP6132B

11 2 int. off normal VCC VCC VCC NCP6132A or

12 1 int. 1 int. VCC VCC Normal VCC NCP6132A

13 1 int. 1 ext. VCC VCC Normal VCC NCP6132B

14 1 int. off VCC VCC VCC VCC NCP6132A or

*NCP6132A supports configurations: 1, 2, 3, 7, 8, 11, 12 and 14; NCP6132B supports configurations: 4, 5, 6, 9, 10, 11, 13, 14.

*When both CSP1A and CSP2A are pulled to VCC, the aux regulator is totally disabled. It does not respond to any SVID command with address 01h.

NCP6132B

NCP6132B

http://onsemi.com

21

NCP6132A, NCP6132B

If aux rail is disabled, the unused pins’ connection should follow the below table:

UNUSED PIN CONNECTION WITH DISABLED AUX RAIL

Pin Name Connect to

CSP1A V

CSP2A V

LGA Float

SWA Float

HGA Float

BSTA Float

VSPA GND

VSNA GND

DIFFA Float

FBA COMPA

COMPA FBA

TRBSTA# Float or VCC

CSREFA GND

CSCOMPA CSSUMA

CSSUMA CSCOMPA

DROOPA CSCOMPA

ILIMA Float

TSNSA GND

IOUTA GND

PWMA Float

CC

CC

There are three integrated drivers: HG1/LG1, HG2/LG2

and HGA/LGA. There are 5 internal PWM signals:

PWM1/2/3 from core controller and PWM1A/2A from aux

controller. HG1/LG1 is driven by PWM1, HG2/LG2 is

driven by PWM2, and HGA/LGA is driven by PWM1A

when aux rail uses one internal driver, driven by PWM3

when core rail uses 3 internal drivers.

To drive the external drivers, NCP6132A/NCP6132B has

two PWM signal outputs: PWM and PWMA, whose internal

connections depend on the phase and driver configuration.

For example, PWM can be driven by PWM3 when there is

one external driver needed for core rail, or driven by

PWM2A when aux rail requires two external drivers.

Similarly, PWMA can be driven either by PWM1A or

PWM2A. The detailed phase configuration table is shown

below:

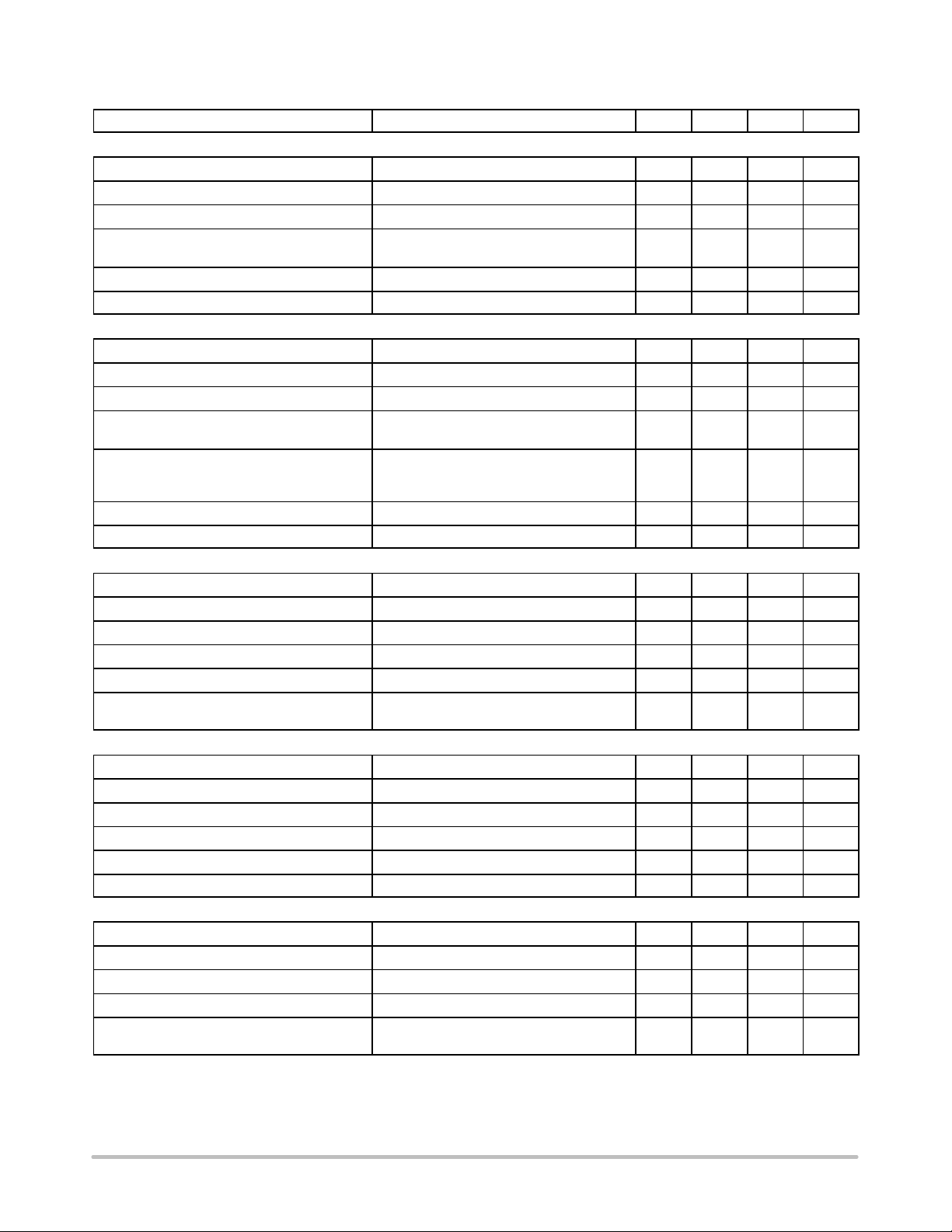

PHASE CONFIGURATION TABLE

Aux

1 int. + 1 ext.

Core

2 int. + 1 ext.

Core

3 int.

Core

2 int.

Core

1 int.

Core drivers :

HG1/LG1

HG2/LG2

PWM

Aux drivers :

HGA/LGA

PWMA

No Core drivers :

Core drivers :

HG1/LG1

HG2/LG2

Aux drivers :

HGA/LGA

PWMA

No No Core drivers :

Aux

2 ext.

No Core drivers :

HG1/LG1

HG2/LG2

HGA/LGA

Aux drivers :

PWMA (phase 1)

PWM (phase 2)

Core drivers :

HG1/LG1

HG2/LG2

Aux drivers :

PWMA (phase 1)

PWM (phase 2)

Aux

1 int.

HG1/LG1

HG2/LG2

PWM

Aux drivers :

HGA/LGA

No Core drivers :

Aux drivers :

Core drivers :

HG1/LG1

HG2/LG2

Aux drivers :

HGA/LGA

HG1/LG1

Core drivers :

Aux drivers :

Core drivers :

Aux

1 ext.

No Core drivers :

HG1/LG1

HG2/LG2

HGA/LGA

PWMA

HG1/LG1

HG2/LG2

PWMA

HG1/LG1

HG1/LG1

HG2/LG2

Aux drivers :

Core drivers :

HG1/LG1

HG2/LG2

HGA/LGA

Aux drivers :

Core drivers :

HG1/LG1

HG2/LG2

Aux drivers :

Core drivers :

HG1/LG1

Aux

off

PWM

Aux drivers :

HGA/LGA

http://onsemi.com

22

Aux drivers :

PWMA

Aux drivers :

NCP6132A, NCP6132B

Phase Interleaving

When both core and graphic rails are in multiphase user

configuration, NCP6132A/NCP6132B uses phase

interleaved PWM operation for dual output rails, i.e., there’s

a phase shift between the two rails. The phase shift between

core rail and aux rail is to ensure PWM on−cycle of each

Core

Phase 1

0

˚

Aux

Phase 2

270

Core

Phase 3

240

˚

3+2

˚

Aux

Phase 1

90

Core

Phase 2

120

˚

˚

interleaved phase has no overlap. It helps reduce the RMS

current of the input capacitor connected to Vin and therefore

lower power dissipation over capacitor ESR.

The interleaved phase angle for different phase

configurations is shown in the following diagram.

Core

Phase 1

˚

0

Aux

Phase 2

270

˚

2+2

Core

Phase 2

180

˚

Aux

Phase 1

90

˚

Figure 7. Interleaved Phases Diagram

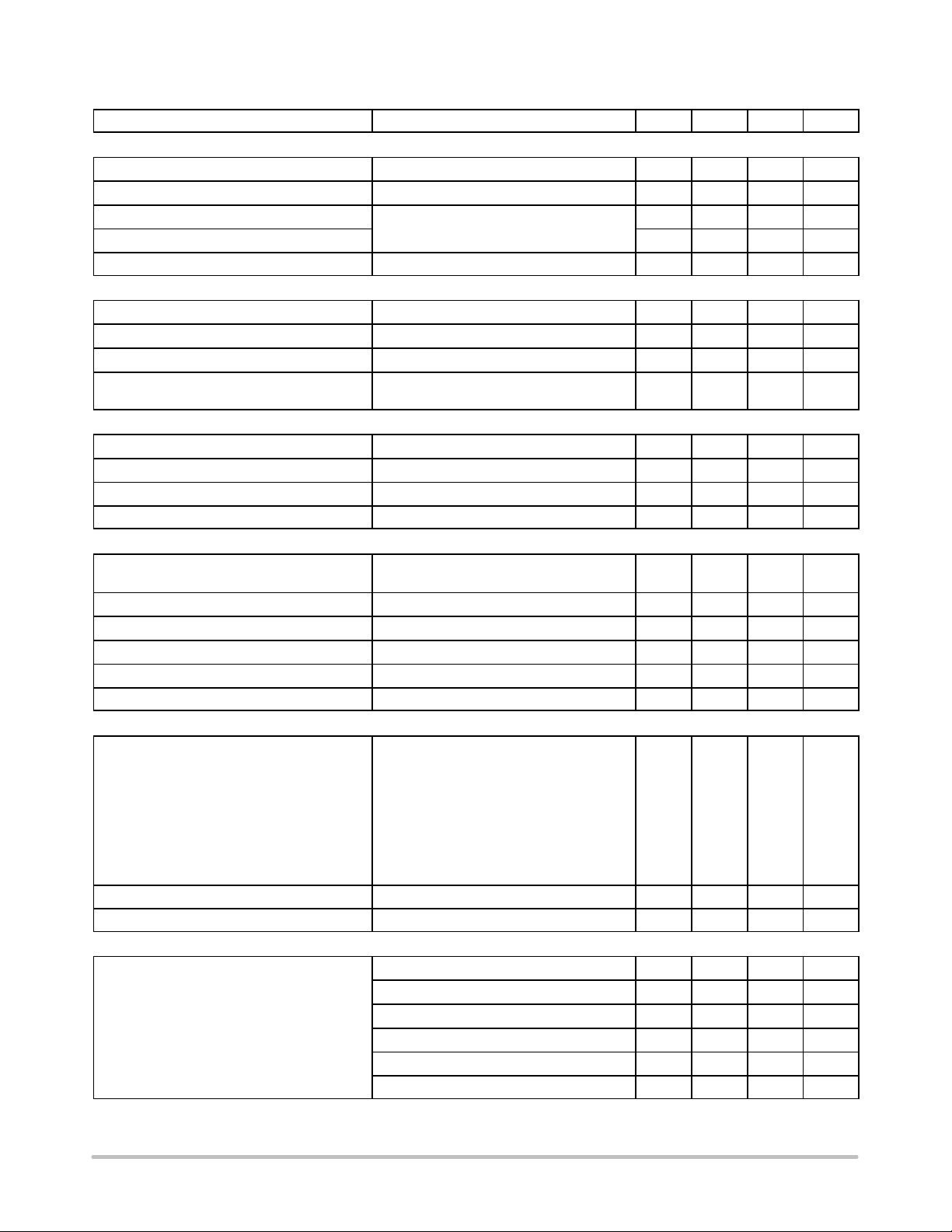

Phase Shedding (PS)

The NCP6132A/NCP6132B supports phase shedding

based by CPU/GPU PSx states. (Auto Phase Shedding

triggered by user−set phase shedding threshold without any

PS state transition is not supported.) The NCP6132A/

NCP6132B implements PS0, PS1, PS2 and PS3 power

saving states for CPU/GPU shown as follows:

For CPU (3−phase or 2−phase user configuration):

Power Status Phases Operating Mode Control Method

PS0 Heavy load condition Multi−phase interleaving CF DEPWM

PS1 Medium load condition Single−phase Forced CCM mode QCF RPM

PS2/3 Light load condition Single−phase Automatic CCM/DCM mode VF RPM

For GPU (2−phase user configuration):

Power Status Phases Operating Mode Control Method

PS0 Heavy load condition 2−phase interleaving CF DEPWM

PS1 Medium load condition 2−phase interleaving CF DEPWM

PS2/3 Light load condition Single−phase Automatic CCM/DCM mode VF RPM

For CPU & GPU (1−phase user configuration):

Power Status Phases Operating Mode Control Method

PS0 Heavy load condition Single−phase Forced CCM mode QCF RPM

PS1 Medium load condition Single−phase Forced CCM mode QCF RPM

PS2/3 Light load condition Single−phase Automatic CCM/DCM mode VF RPM

*CF – Constant Frequency

DEPWM − Dual Edge Pulse Width Modulation

QCF − Quasi Constant Frequency

RPM – Ramp Pulse Modulation

VF – Variable Frequency

http://onsemi.com

23

NCP6132A, NCP6132B

In PS2/3 state, transition from CCM to DCM is triggered

by a Zero Current Detector (ZCD) latch. ZCD latch is set by

a ZCD comparator monitoring switch node (SWN) voltage

during PWM off−time. ZCD latch is reset at negative edge

of PWM signal and is ready to be set after a set minimum

PWM off−time delay. As SWN voltage is stably ramping up

toward zero, if the SWN voltage crosses a set (a few negative

mV) threshold, then ZCD latch is set and LG1 output is

driven to logic low to turn off low−side power switch and

phase is operating in DCM. If ZCD latch remains reset

during PWM off−cycle, then the low−side power switch

remains turned on and the phase is operating in CCM.

If aux phase 1 is configured with external driver, the driver

should have built−in ZCD comparator (like NCP5911) to

support DCM.

Transition from PS1 to PS0 state triggering phase

shedding is called PS1 assertion. Similarly, PS2 assertion is

the transition to PS2 state. Note that PS1 assertion in aux rail

should be ignored as PS1 and PS0 have the same phase

operating mode.

PS1 or PS2 assertion is ignored and user−set multiphase

operation is enforced for the following circumstances:

during startup, in current limit (CLIMx) operation, and

during DVID transition.

Phase shedding is always from multiphase to single phase

in one single step.

• For core rail:

♦ Phase shedding from 3−phase is done by driving

PWM output (internally connected to PWM3) to

mid−level while DRVEN output is still driven to

logic high, and by keeping both HG2, LG2 outputs

to logic low.

♦ Phase shedding from 2−phase is done by driving

both HG2, LG2 outputs to logic low.

• For aux rail:

♦ Phase shedding from 2−phase is done by driving

both HGA, LGA outputs to logic low.

Transition from PS1/2/3 to PS0 state triggers phase

un−shedding.

Phase un−shedding is instantaneous and happens from

single−phase to user−set multiphase configuration in one

single step.

Serial VID

The NCP6132A/NCP6132B supports the Intel serial VID

interface. It communicates with the microprocessor through

three wires (SCLK, SDIO, ALERT#). The table of

supported registers is shown below.

Index Name Description Access Default

00h Vendor ID Uniquely identifies the VR vendor. The vendor ID assigned by Intel to

01h Product ID Uniquely identifies the VR product. The VR vendor assigns this number. R 0x00

02h Product

Revision

05h Protocol ID Identifies the SVID Protocol the NCP6132A/NCP6132B supports R 0x01

06h Capability Informs the Master of the NCP6132A/NCP6132B’s Capabilities,

10h Status_1 Data register read after the ALERT# signal is asserted. Conveying the status

11h Status_2 Data register showing optional status_2 data. R 00h

12h Temp zone Data register showing temperature zones the system is operating in R 00h

15h I_out 8 bit binary word ADC of current. This register reads 0xFF when the IOUT(A)

16h V_out 8 bit binary word ADC of output voltage, measured between VSP and VSN.

17h VR_Temp 8 bit binary word ADC of voltage. Binary format in deg C, IE 100C = 64h. A

ON Semiconductor is 0x1Ah

Uniquely identifies the revision or stepping of the VR control IC. The VR

vendor assigns this data.

1 = supported, 0 = not supported

Bit 7 = Iout_format. Bit 7 = 0 when 1A = 1LSB of Reg 15h. Bit 7 = 1 when

Reg 15 FFh = Icc_Max. Default = 1

Bit 6 = ADC Measurement of Temp Supported = 1

Bit 5 = ADC Measurement of Pin Supported = 0

Bit 4 = ADC Measurement of Vin Supported = 0

Bit 3 = ADC Measurement of Iin Supported = 0

Bit 2 = ADC Measurement of P

Bit 1 = ADC Measurement of V

Bit 0 = ADC Measurement of I

of the VR.

pin voltage is 2 V. The IOUT(A) voltage should be scaled with an external

resister to ground such that a load equal to Icc_Max generates a 2 V signal.

LSB size is 8 mV

value of 00h indicates this function is not supported

Supported = 1

out

Supported = 1

out

Supported = 1

out

R 0x1Ah

R 0x03

R 0xC7

R 00h

R 01h

R 01h

R 01h

http://onsemi.com

24

NCP6132A, NCP6132B

Index DefaultAccessDescriptionName

18h P_out 8 bit binary word representative of output power. The output voltage is

1Ch Status 2 Last

read

21h Icc_Max Data register containing the Icc_Max the platform supports. The value is

22h Temp_Max Data register containing the max temperature the platform supports and the

24h SR_fast

25h SR_slow Slew Rate for SetVID_slow commands. It is 4X slower than the SR_fast rate.

26h Vboot The NCP6132A/NCP6132B will ramp to Vboot and hold at Vboot until it

30h Vout_Max Programmed by master and sets the maximum VID the VR will support. If a

31h VID setting Data register containing currently programmed VID voltage. VID data format. RW 00h

32h Pwr State Register containing the current programmed power state. RW 00h

33h Offset Sets offset in VID steps added to the VID setting for voltage margining. Bit 7

34h MultiVR Config

multiplied by the output current value and the result is stored in this register. A

value of 00h indicates this function is not supported

When the status 2 register is read its contents are copied into this register.

The format is the same as the Status 2 Register.

measured on the ICCMAX pin on power up and placed in this register. From

that point on the register is read only.

level VR_hot asserts. This value defaults to 100°C and programmable over

the SVID Interface

Slew Rate for SetVID_fast commands. Binary format in mV/ms.

Binary format in mV/ms

receives a new SVID SetVID command to move to a different voltage. Default

value = 0 V.

higher VID code is received, the VR should respond with “not supported”

acknowledge. VR 12 VID format.

is sign bit, 0 = positive margin, 1 = negative margin. Remaining 7 BITS are #

VID steps for margin 2s complement.

00h = no margin

01h = +1 VID step

02h = +2 VID steps

FFh = −1 VID step

FEh = −2 VID steps.

R 01h

R 00h

R 00h

R/W 64h

R 0Ah

R 02h

R 00h

RW FBh

RW 00h

For NCP6132A/NCP6132B, VID code change is supported by SVID interface with three options as below:

SVID Command

Option

SetVID_Fast 01h

SetVID_Slow 02h =1/4 of SetVID_Fast VID code

SetVID_Decay 03h No slew rate control, VID code

Code

Feature

>10 mV/ms VID code change

slew rate

change slew rate

down

Boot Voltage Programming

The NCP6132A/NCP6132B has a VBOOT voltage

register that can be externally programmed for both core and

aux boot−up output voltage. The VBOOT voltage can be

programmed with a resistor from VBOOT pin to GND, or it

can be set to 1.1 V by connecting VBOOT pin to GND to

facilitate mass production. See the Boot Voltage Table.

(Indicating the slew rate of VID code change)

BOOT VOLTAGE TABLE

Boot Voltage (V)

0 10k

0.9 20k

1.0 30k

1.1 40k

1.2 50k

1.35 60k

Register Address

24h

25h

N/A

Resistor Value (W)

Or connect VBOOT pin to GND

Or connect VBOOT pin to V

CC

http://onsemi.com

25

NCP6132A, NCP6132B

SVID Addressing

The NCP6132A/NCP6132B has fixed SVID device

addresses for core and aux rail. The core rail address is 0000,

and aux rail address is 0001.

Remote Sense Amplifier

A high performance high input impedance true

differential amplifier is provided to accurately sense the

output voltage of the regulator. The VSP and VSN inputs

should be connected to the regulator’s output voltage sense

points. The remote sense amplifier takes the difference of

the output voltage with the DAC voltage and adds the droop

voltage to

V

DIFF

+ǒV

)ǒV

VSP

DROOP

* V

VSN

* V

Ǔ)ǒ

CSREF

1.3 V * V

Ǔ

DAC

Ǔ

(eq. 1)

This signal then goes through a standard error

compensation network and into the inverting input of the

error amplifier. The non−inverting input of the error

amplifier is connected to the same 1.3 V reference used for

the differential sense amplifier output bias.

High Performance Voltage Error Amplifier

A high performance error amplifier is provided for high

bandwidth transient performance. A standard type 3

compensation circuit is normally used to compensate the

system.

Differential Current Feedback Amplifiers

Each phase has a low offset differential amplifier to sense

that phase current for current balance and per phase OCP

protection during soft−start. The inputs to the CSREF and

CSPx pins are high impedance inputs. It is recommended

that any external filter resistor RCSN not exceed 10 kW to

avoid offset issues with leakage current. It is also

recommended that the voltage sense element be no less than

0.5 mW for accurate current balance. Fine tuning of this time

constant is generally not required.

L

+

C

CSN

SWNx

PHASE

*DCR

RCSN

DCR

Figure 8.

CSPx

CCSN

LPHASE

12

CSREF

VOUT

R

CSN

The individual phase current is summed into to the PWM

comparator feedback in this way current is balanced is via

a current mode control approach.

Total Current Sense Amplifier

The NCP6132A/NCP6132B uses a patented approach to

sum the phase currents into a single temperature

compensated total current signal. This signal is then used to

generate the output voltage droop, total current limit, and the

output current monitoring functions. The total current signal

is floating with respect to CSREF. The current signal is the

difference between CSCOMP and CSREF. The Ref(n)

resistors sum the signals from the output side of the

inductors to create a low impedance virtual ground. The

amplifier actively filters and gains up the voltage applied

across the inductors to recover the voltage drop across the

inductor series resistance (DCR). Rth is placed near an

inductor to sense the temperature of the inductor. This

allows the filter time constant and gain to be a function of the

Rth NTC resistor and compensate for the change in the DCR

with temperature.

CSN1

CSN2

CSN3

SWN1

SWN2

SWN3

Rref1

Rref2

Rref3

Rph1

Rph2

Rph3

Cref

1n

CSREF

CSSUM

Figure 9.

+

-

CSCOMP

Ccs1

Ccs2

Rcs1Rcs2

Rth

The DC gain equation for the current sensing:

Rcs1*Rth

Rcs1)Rth

Rph

*DCR

Total

(eq. 2)

Ǔ

V

CSCOMP−CSREF

Rcs2 )

+

*ǒIout

Set the gain by adjusting the value of the Rph resistors.

The DC gain should set to the output voltage droop. If the

voltage from CSCOMP to CSREF is less than 100 mV at

ICCMAX then it is recommended to increase the gain of the

CSCOMP amp and add a resister divider to the Droop pin

filter. This is required to provide a good current signal to

offset voltage ratio for the ILIM pin. When no droop is

needed, the gain of the amplifier should be set to provide

~100 mV across the current limit programming resistor at

full load. The values of Rcs1 and Rcs2 are set based on the

220k NTC and the temperature effect of the inductor and

should not need to be changed. The NTC should be placed

near the closest inductor. The output voltage droop should

be set with the droop filter divider.

The pole frequency in the CSCOMP filter should be set

equal to the zero from the output inductor. This allows the

circuit to recover the inductor DCR voltage drop current

http://onsemi.com

26

NCP6132A, NCP6132B

signal. Ccs1 and Ccs2 are in parallel to allow for fine tuning

of the time constant using commonly available values. It is

best to fine tune this filter during transient testing.

DCR@25° C

FZ+

2*PI*L

FP+

ǒ

2 * PI *

Programming the Current Limit

Rcs2 )

Rcs1*Rth@25° C

Rcs1)Rth@25° C

Phase

1

Ǔ

*(Ccs1 ) Ccs

(eq. 3)

(eq. 4)

The current−limit thresholds are programmed with a

resistor between the ILIM and CSCOMP pins. The ILIM pin

mirrors the voltage at the CSREF pin and mirrors the sink

current internally to IOUT (reduced by the IOUT Current

Gain) and the current limit comparators. Set the value of the

current limit resistor based on the user−set output current

limit Iout

or CSREF− CSCOMP voltage at Iout

LIMIT

LIMIT

condition as shown below:

Rcs1*Rth

Rcs2 )

R

+

ILIM

Rcs1)Rth

Rph

10 mA

*ǒIout

LIMIT

* DCR

Ǔ

(eq. 5)

If the Droop at maximum load is less than 100 mV at

ICCMAX we recommend altering this filter into a voltage

divider such that a larger signal can be provided to the ILIM

resistor by increasing the CSCOMP amp gain for better

current monitor accuracy. The DROOP pin divider gain

should be set to provide a voltage from DROOP to CSREF

equal to the amount of voltage droop desired in the output.

A current is applied to the DROOP pin during dynamic VID.

In this case Rdroop1 in parallel with Rdroop2 should be

equal to Rdroop.

Rdroop2

Cdroop

CSREF

CSSUM

5

6

DROOP

+

−

Figure 11.

7

Rdroop1

CSCOMP

or

V

R

ILIM

Programming DROOP and DAC Feed−Forward Filter

CSREF−CSCOMP@ILIMIT

+

10 mA

(eq. 6)

The signals DROOP and CSREF are differentially

summed with the output voltage feedback to add precision

voltage droop to the output voltage. The total current

feedback should be filtered before it is applied to the

DROOP pin. This filter impedance provides DAC

feed−forward during dynamic VID changes. Programming

this filter can be made simpler if CSCOMP−CSREF is equal

to the droop voltage. Rdroop sets the gain of the DAC

feed−forward and Cdroop provides the time constant to

cancel the time constant of the system per the following

equations. Cout is the total output capacitance and Rout is

the output impedance of the system.

Cdroop

CSREF

CSSUM

5

6

Rdroop + Cout * Rout * 453.6x10

Cdroop +

DROOP

+

−

Rout * Cout

Rdroop

Figure 10.

7

Rdroop

CSCOMP

6

Programming IOUT

The IOUT pin sources a current equal to the ILIM sink

current gained by the IOUT Current Gain. The voltage on

the IOUT pin is monitored by the internal A/D converter and

should be scaled with an external resistor to ground such that

a load equal to ICCMAX generates a 2 V signal on IOUT. A

pull−up resistor from 5 V VCC can be used to offset the

IOUT signal positive if needed.

R

+

IOUT

Programming ICC_MAX and ICC_MAXA

Rcs2)

10 *

2.0 V * R

Rcs1*Rth

Rcs1)Rth

Rph

LIMIT

*ǒIout

ICC_MAX

*DCR

(eq. 7)

Ǔ

The SVID interface provides the platform ICC_MAX

value at register 21h for both the core and the aux rails. A

resistor to ground on the PWM and PWMA pins program

these registers at the time the part in enabled. 10 mA is

sourced from these pins to generate a voltage on the program

resistor. The value of the register is 1 A per LSB. When

ICC_MAX is less than 118 A, resistor value is set according

to the equation below. The resistor value should be no less

than 10 k.

R

ICC_MAX

Programming TSNS and TSNSA

ICC_MAX

+

10 mA * 256 A

21h

2V

) 3.5 kW

(eq. 8)

Two temperature sense inputs are provided. A precision

current is sourced out the output of the TSNS and TSNSA

http://onsemi.com

27

NCP6132A, NCP6132B

pins to generate a voltage on the temperature sense network.

The voltages on the temperature sense inputs are sampled by

the internal A/D converter and then digitally converted to

temperature and stored in SVID register 17h. A 100 k NTC

should be used. The Rcomp1 and Rcomp2 vary with NTC’s

temperature characteristics.

TSNS

Rcomp1

0.0

Cfilter

0.1 mF

Rcomp2

8.25K

AGND

Figure 12.

Precision Oscillator

RNTC

100K

AGND

A programmable precision oscillator is provided. The

clock oscillator serves as the master clock to the ramp

generator circuit. This oscillator is programmed by a resistor

to ground on the ROSC pin. The ROSC pin provides

approximately 2 V out and the source current is mirrored

into the internal ramp oscillator. The oscillator generates

triangle ramps that are 0.5 ~ 2.5 V in amplitude depending

on the VRMP pin voltage to provide input voltage feed

forward compensation. The oscillator frequency is

approximately proportional to the current flowing in the

ROSC resistor.

f

OSC

+

V

OSC

ǒ

2

V

ref

1

R

OSCCOSC

) 2t

(eq. 9)

Ǔ

d

Where

f

OSC

V

OSC

PWM master oscillator frequency

oscillator ramp peak−to−peak voltage

(1 V)

V

ref

R

ROSC pin frequency setting resistor

OSC

C

OSC

ROSC pin reference voltage (2 V)

oscillator timing capacitor (2.5 pF)

td oscillator loop delay (10 ns)

And the per phase switching frequency fsw is given by

f

fsw+

OSC

12

(eq. 10)

The switching frequency range is between 200 kHz/phase to

800 kHz/phase.

Programming the Ramp Feed−Forward Circuit

The ramp generator circuit provides the ramp used by the

PWM comparators. The ramp generator provides voltage

feed−forward control by varying the ramp magnitude with

respect to the VRMP pin voltage. The VRMP pin also has

a 4 V UVLO function. The VRMP UVLO is only active

after the controller is enabled. The VRMP pin is a high

impedance input when the controller is disabled.

The PWM ramp time is changed according to the following,

V

RAMPpk+pk

Vin

Comp−IL

Duty

Programming TRBST#

+ 0.1 * V

PP

Figure 13.

VRMP

(eq. 11)

Vramp_pp

The TRBST# pin provides a signal to offset the output

after load release overshoot. This network should be fine

tuned during the board tuning process and is only necessary

in systems with significant load release overshoot. The

TRBST# network allows maximum boost for low frequency

load release events to minimize load release ringing back

undershoot. The network time constants are set up to provide

a TRBST# roll of at higher frequencies where it is not

needed. Cboost1*Rbst1 controls the time constant of the

load release boost. This should be set to counter the under

shoot after load release. Rbst1 + Rbst2 controls the

maximum amount of boost during rapid step loading. Rbst2

is generally much larger then Rbst1. The Cboost2 * Rbst2

time constant controls the roll off frequency of the TRBST#

function.

Cboost2

Rbst1

FB TRBST

Cboost1

Rbst2

Figure 14.

Rbst3

http://onsemi.com

28

NCP6132A, NCP6132B

PWM Comparators

During steady state operation, the duty cycle is centered

on the valley of the triangle ramp waveform and both edges

of the PWM signal are modulated. During a transient event

PROTECTION FEATURES

Input Under Voltage Protection

NCP6132A/NCP6132B monitors the 5 V VCC supply

and the VRMP pin for under voltage protection. The gate

driver monitors both the gate driver VCC and the BST

voltage. When the voltage on the gate driver is insufficient

it will pull HG1, HG2, HGA, LG1, LG2, LGA, DRVEN low

and notify the controller the power is not ready. The gate

driver will hold HG1, HG2, HGA, LG1, LG2, LGA,

DRVEN low for a minimum period of time to allow the

controller to restart its startup sequence. In this case the

PWM and PWMA are set back to the MID state and soft start

would begin again. See the figure below.

DAC

Gate Driver Pulls DRVEN

Low during driver UVLO

Figure 15. Gate Driver UVLO Restart

Soft Start

If DRVEN is pulled low the

controller will hold off its

startup

and Calibration

Soft start is implemented internally. A digital counter

steps the DAC up from zero to the target voltage based on the

predetermined slew rate in the spec table. The PWM signals

will start out open with a test current to collect data on

IMAX/IMAXA and for setting internal registers. After the

IMAX/IMAXA configuration data is collected the

controller enables and sets the PWM signal to the 2.0 V MID

state to indicate that the drivers should be in diode mode.

DRVON will then be asserted and the COMP pin released to

begin soft−start. The DAC will ramp from Zero to the target

DAC codes and the PWM outputs will begin to fire. Each

phase will move out of the MID state when the first PWM

pulse is produced preventing the discharge of a pre−charged

output.

the duty will increase rapidly and proportionally turning on

all phases as the error amp signal increases with respect to

the ramps to provide a highly linear and proportional

response to the step load.

Figure 16. Soft−Start Sequence

Over Current Latch− Off Protection

The NCP6132A/NCP6132B provides two different types

of current limit protection. During normal operation a

programmable total current limit is provided that scales with

the phase count during power saving operation. A second

fixed per−phase current limit is provided for VID lower than

0.25 V, such as during soft−start.

The level of total current limit is set with the resistor from

the ILIM pin to CSCOMP pin. Internally the current through

ILIM pin is scaled and then compared to two current

thresholds 10 mA and 15 mA, where 10 mA threshold is

scaled to indicate the 100% current limit and 15 mA

indicates the 150% current limit. If 100% current limit is

exceeded, an internal latch−off counter starts. The controller

shuts down if the over current fault is not removed after

50 ms. If 150% current limit is exceeded, the controller shuts

down immediately. To recover from an OCP fault the EN pin

must be cycled low. The current limit is scaled down along

with the phase shedding. Phase shedding from 3−phase to

single phase scales the current limit to its 1/3; phase

shedding from 2−phase to single phase scales the current

limit to its half. For example, for a 3−phase design in PS0

state the 100% current limit trips if ILIM current exceeds

10 mA, but in PS1/2/3 state (phase shedding to single phase)

ILIM current above 3.3 mA will trigger the 100% current

limit.

Under Voltage Monitor

The output voltage is monitored at the output of the

differential amplifier for UVLO. If the output falls more

than 300 mV below the DAC−DROOP voltage the UVLO

comparator will trip sending the VRDY/VRDYA signal low.

http://onsemi.com

29

NCP6132A, NCP6132B

Over Voltage Protection

During normal operation the output voltage is monitored

at the differential inputs VSP and VSN. If the output voltage

exceeds the DAC voltage by approximately 250 mV, LGx

from integrated drivers will be forced high and

PWM/PWMA will be forced low when OVP is triggered.

And then the DAC will ramp down to zero to avoid a

negative output voltage spike during shutdown. When the

DAC gets to zero, LGx will be forced high and

PWM/PWMA will be forced low with DRVEN remaining

high. To reset the part the EN pin must be cycled low.

During soft−start & DVID, the OVP has a fix threshold at

1.75 V.

OVP Threshold

DAC

VSP_VSN

OVP

Triggered

Latch Off

PWM

Figure 17. OVP Threshold Behavior

R

THPlace as close as possible

to nearest inductor

Layout Notes

The NCP6132A/NCP6132B has differential voltage and

current monitoring. This improves signal integrity and

reduces noise issues related to layout for easy design use. To

insure proper function there are some general rules to

follow:

Careful layout in per phase and total current sensing are

critical for jitter minimization, accurate current balancing

and ILIM and IOUT monitoring. Give the first priority in

component placement and trace routing to per phase and

total current sensing circuit. The per phase inductor current

sense RC filters should always be placed as close to the

CSREF and CSP pins on the controller as possible. The filter

cap from CSCOMP to CSREF should also be close to the

controller. The temperature−compensate resistor R

should be placed as close as possible to the Phase 1 inductor.

The wiring path between R

CSx

and R

should be kept as

PHx

short as possible and well away from switch node lines. The

Refx resistors (10 W) connected to CSREF pin should be

placed near the inductors to reduce the length of traces. The

resistors R

are better to have 0603 package. The above

PHX

layout notes are shown in Figure 18.

Place the VCC decoupling caps as close as possible to the

controller VCC pin. For any RC filter on the VCC and

VDDBP pins, the resistor should be no higher than 2.2 W to

prevent large voltage drop.

The small high feed back cap from COMP to FB should

be as close to the controller as possible. Keep the FB traces

short to minimize their capacitance to ground.

To V

OUT

To Switch Nodes

Sense

TH

CSCOMP

CSSUM

−

CSREF

+

−

+

−

+

CSP1

CSP2

R

R

C

CS2

C

CS1

CS1

R

CS2

Keep this path as short as

PH1

R

PH2

R

possible and well away

from switch node lines

REF1

R

REF2

REFx resistors could

be placed near the

inductors to reduce

the number of long

traces

R

CSN1

C

CSN1

To

Switch

Nodes

C

R

CSN2

CSN2

Per phase current sense RC should be

placed close to CSPx pins

Figure 18.

http://onsemi.com

30

PIN 1

l

LOCATION

0.10 C

0.05 C

0.08 C

NOTE 4

DETAIL A

DETAIL C

0.10 C

NCP6132A, NCP6132B

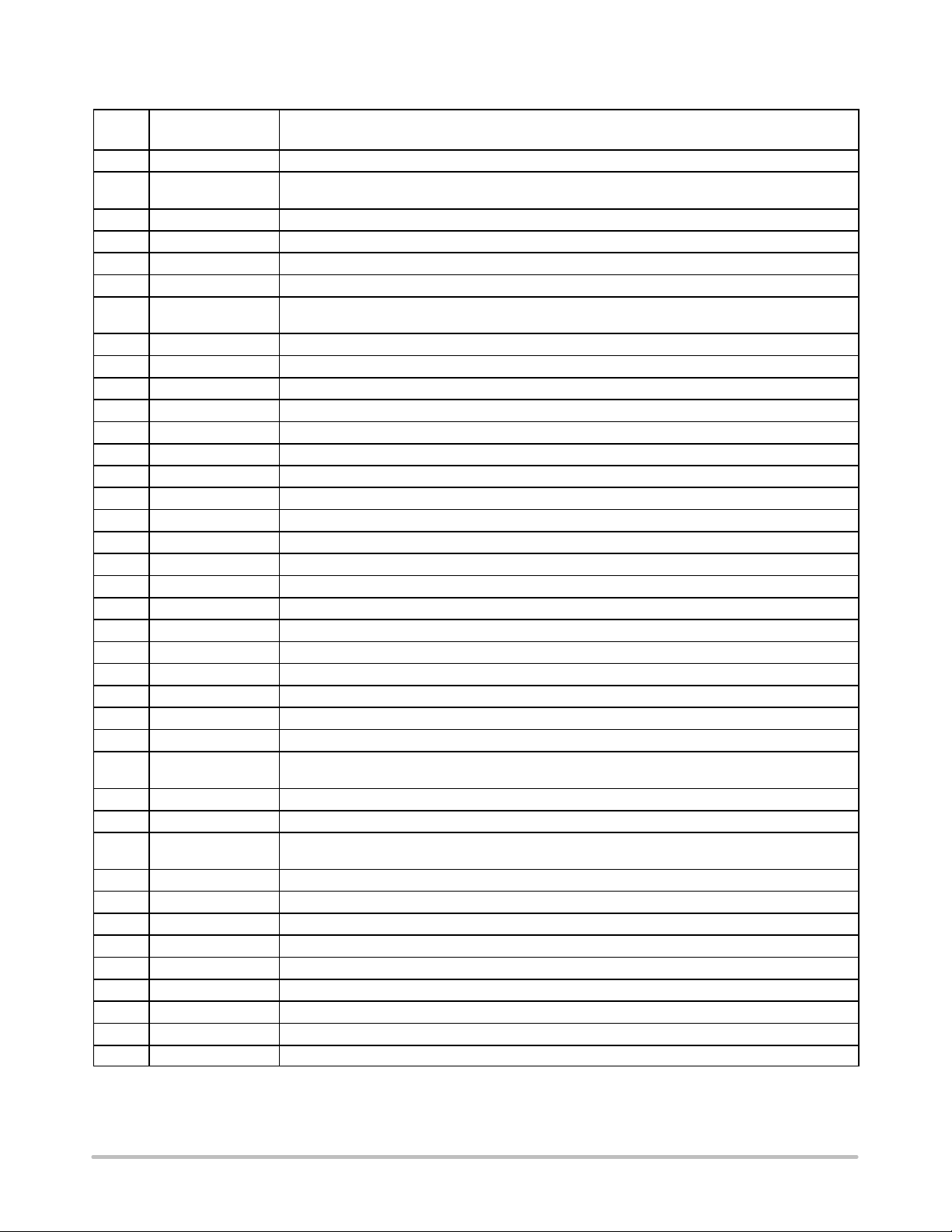

PACKAGE DIMENSIONS

QFN60 7x7, 0.4P

CASE 485BB

ISSUE A

NOTES:

D A B

L

L

L1

DETAIL A

ALTERNATE TERMINAL

E

CONSTRUCTIONS

MOLD CMPDEXPOSED Cu

TOP VIEW

SIDE VIEW

(A3)

A1

A

SEATING

C

PLANE

DETAIL B

ALTERNATE

CONSTRUCTIONS

SOLDERING FOOTPRINT*

D2

K

30

15

31

L3

1

L3

E2

DETAIL C

ALTERNATE CORNER

LEAD CONSTRUCTION

60X

0.63

1. DIMENSIONS AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO THE PLATED

TERMINAL AND IS MEASURED ABETWEEN

0.15 AND 0.30 MM FROM TERMINAL TIP.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

MILLIMETERS

DIM MIN MAX

A 0.80 1.00

A1 0.00 0.05

A3 0.20 REF

b 0.15 0.25

D 7.00 BSC

D2 5.50 5.70

E 7.00 BSC

E2 5.50 5.70

e 0.40 BSC

K

0.30 REF

L 0.30 0.50

L1 −−− 0.15

L3 0.10 REF

RECOMMENDED

2X

5.74

2X

7.30

60X

1

60 46

L

e

BOTTOM VIEW

45

60X

b

0.07 C

0.05 C

A B

NOTE 3

60X

0.25

DIMENSIONS: MILLIMETERS

0.40 PITCH

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC owns the rights to a number of patents, trademarks,

copyrights, trade secrets, and other intellectual property. A listing of SCILLC’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. SCILLC

reserves the right to make changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without

limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications

and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC