Datasheet NCP367DPMEBTBG, NCP367DPMUECTBG, NCP367DPMUEETBG, NCP367DPMUELTBG, NCP367OPMUEATBG Datasheet (ON) [ru]

...

NCP367

Battery Charge Front-End

Protection, USB and AC/DC

Supply Compliant

NCP367 is a charge path protection device which allows

disconnecting the systems from its output pin in case wrong charging

conditions are detected. The system is positive overvoltage protected

up to +30 V. Thanks to a very low current consumption, the USB

charge is compatible with this integrated component.

This device uses internal PMOS FET, making external devices

unnecessary, which reduces the system cost and PCB area of the

application board. First, NCP367 is able to instantaneously

disconnect the output from the input if the input voltage exceeds the

overvoltage threshold. Additional overcurrent protection function

allows turning off internal PMOS FET when the charge current

exceeds current limit, which is externally selectable.

The current limit value can be modified with control logic pin to

divide it by internal gain, allowing USB 100 mA/500 mA charging or

USB/Wall adapter charging up to overcurrent threshold. At the same

time, Li ion Battery voltage is continuously monitored, providing

more safety during the charge. Thermal shutdown protection is also

available.

NCP367 provides a negative going flag (FLAG) output, which

alerts the system that a fault has occurred as overvoltage (power

supply or battery voltage), overcurrent or thermal event.

In addition, the device has ESD−protected input (15 kV Air) when

bypassed with a 1 mF or larger capacitor.

Features

• Overvoltage Protection Up to + 30 V

• Fast Turn Off Time

• Very Low Current Consumption/USB Compliant

• Li ion Battery Voltage Monitoring

• Overvoltage Lockout (OVLO)

• Undervoltage Lockout (UVLO)

• Overcurrent Protection Externally Adjustable (OCP) up to 2.8 A

• Thermal Shutdown

• Shutdown EN and Gain Input Pins

• Soft−Start to Eliminate Inrush Current

• Alert FLAG Output

• Compliance to IEC61000−4−2 (Level 4)

8 kV (Contact), 15 kV (Air)

• ESD Ratings: Machine Model = B

ESD Ratings: Human Body Model = 2

• 8 Lead DFN 2.2x2 mm Package

• These are Pb−Free Devices

T ypical Application

• USB Devices

• Mobile Phones

• Peripheral

• Personal Digital Applications

• MP3 Players

www.onsemi.com

8

1

DFN8

MU SUFFIX

CASE 506BP

MARKING DIAGRAM

1

XX MG

G

XX = Specific Device Code

M = Date Code

G = Pb−Free Device

(Note: Microdot may be in either location)

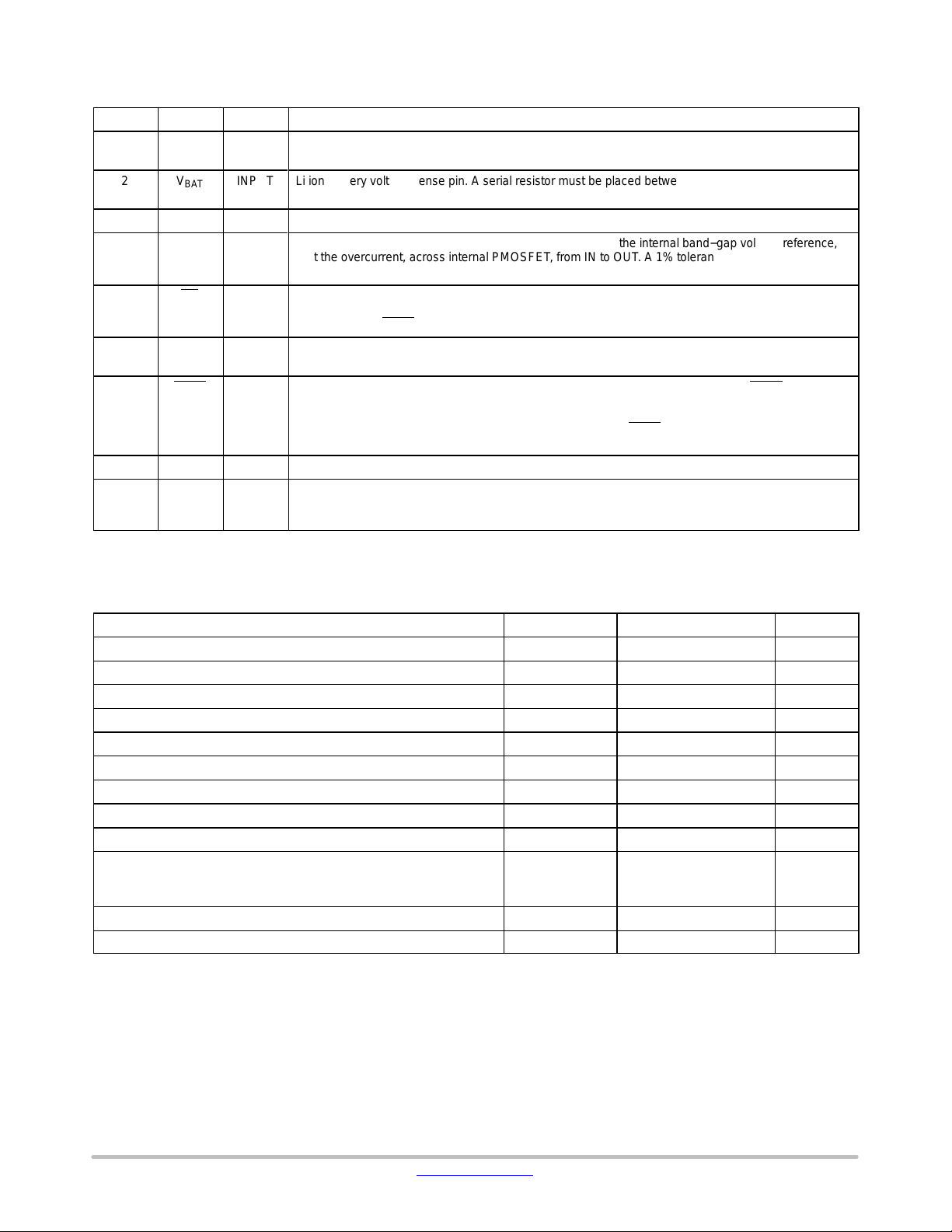

PIN ASSIGNMENT

IN

1

2

VBAT

NC

ILIM

ORDERING INFORMATION

See detailed ordering, marking and shipping information in the

package dimensions section on page 12 of this data sheet.

OUT

3

4

(Top View)

8

7

6

5

GND

FLAG

GS

EN

© Semiconductor Components Industries, LLC, 2015

February, 2015 − Rev . 11

1 Publication Order Number:

NCP367/D

NCP367

Wall Adapter / USB

1 mF

VIN/VUSB

ILIM

GS

NCP367

MCU

1

IN

5

EN

6

GS

GND

8

OUT

FLAG

VBAT

ILIM

9

7

2

4

DCDC

Figure 1. Typical Application Circuit

I limit

+

GAIN

1/2.75

LDO

1 mF

Soft−Start

Driver

B+

Battery Charger

10 k

100 k

Li+

BATTERY

OUT

VBAT

4.35 V

VREF

OVLO

UVLO

GND

EN Pin

Figure 2. Functional Block Diagram

Logic

+

Timer

Thermal

Shutdown

FLAG

www.onsemi.com

2

NCP367

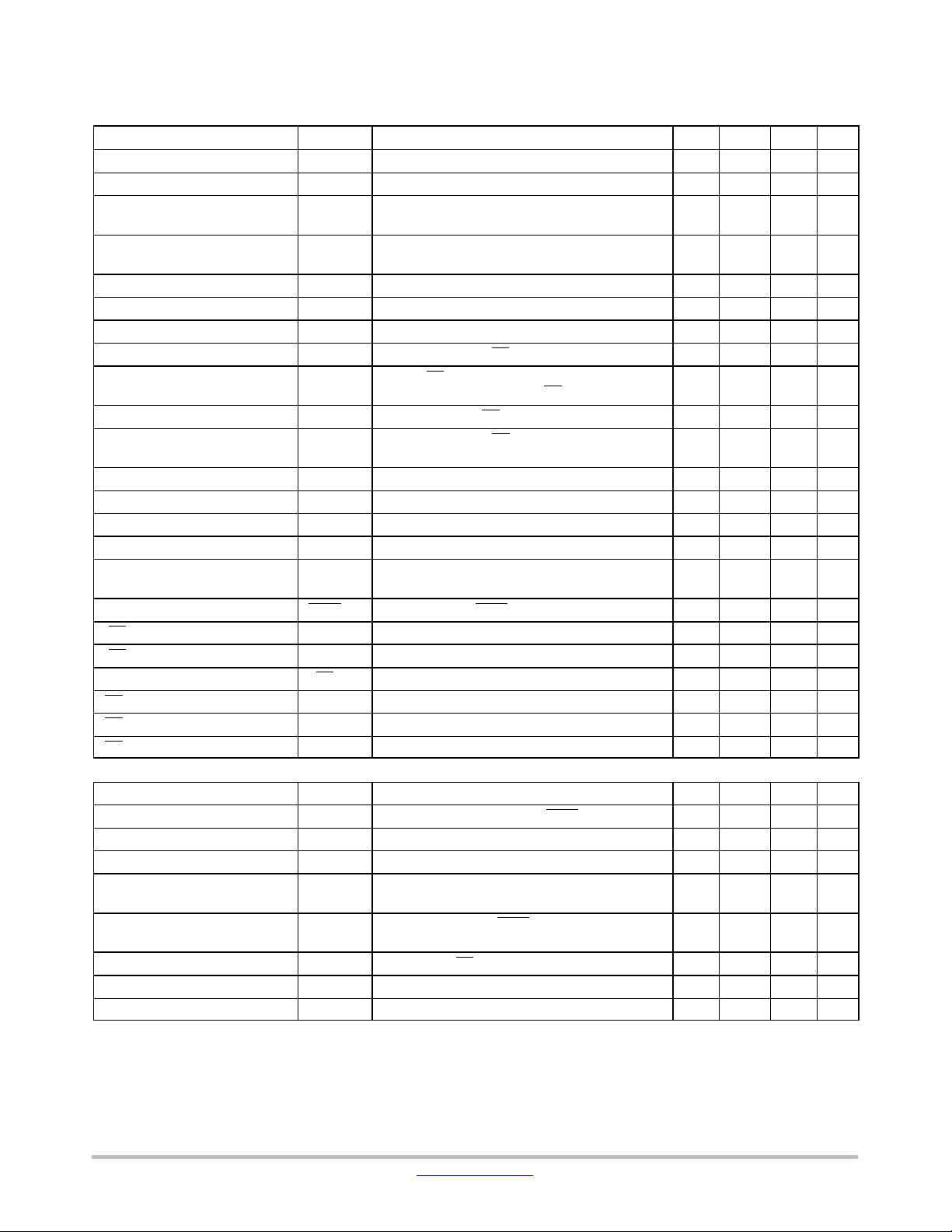

PIN FUNCTION DESCRIPTION

Pin Name Type Description

1 IN POWER Input Voltage Pin. This pin is connected to the power supply: W all Adapter or USB. A 1 mF low ESR

2

V

BAT

INPUT

3 NC OUTPUT Not Connected

4

I

LIM

OUTPUT

5 EN INPUT Enable Mode Pin. The device enters in shutdown mode when this pin is tied to a high level. In this case

6 GS INPUT Gain Select Pin. When the GS pin is tied to 0 level, the Overcurrent threshold is defined by Ilimit set-

7 FLAG OUTPUT Fault Indication Pin. This pin allows an external system to detect fault condition. The FLAG pin goes

8 GND POWER Ground.

9 OUT OUTPUT Output Voltage Pin. This pin follows IN pin when “no input fault” is detected. The output is disconnected

ceramic capacitor, or larger, must be connected between this pin and GND.

Li ion Battery voltage sense pin. A serial resistor must be placed between this pin and positive pin of

the battery pack.

Current Limit Pin. This pin provides the reference, based on the internal band−gap voltage reference, to

limit the overcurrent, across internal PMOSFET, from IN to OUT. A 1% tolerance, or better, resistor

shall be used to get the highest accuracy of the Overcurrent Limit.

the output is disconnected from the input. The state of this pin does not have an impact on the fault

detection of the FLAG pin.

ting. See logic table. When GS pin is tied to high, the Overcurrent threshold is set to Ilimit/GS

low when input voltage is below UVLO threshold, exceeds OVLO threshold, charge current from wall

adapter to battery exceeds programmed current limit, Li ion Battery voltage (4.3 V) is exceeded or internal temperature exceeds thermal shutdown limit. Since the FLAG pin is open drain functionality, an

external pull−up resistor to VBattery must be added (10 kW minimum value).

from the Vin power supply when voltage, current or thermal fault events are detected. A 1 mF low ESR

ceramic capacitor, or larger, must be connected between this pin and GND.

NOTE: Pin out provided for concept purpose only and might change in the final product

MAXIMUM RATINGS

Rating Symbol Value Unit

Minimum Voltage (IN to GND) Vmin

in

Minimum Voltage (All others to GND) Vmin −0.3 V

Maximum Voltage (IN to GND) Vmax

in

Maximum Voltage (All others to GND) Vmax 7.0 V

Maximum DC Current from Vin to V out (PMOS) Imax 3.4 A

Thermal Resistance, Junction−to−Air (without PCB area) R

Operating Ambient Temperature Range T

Storage Temperature Range T

Junction Operating Temperature T

ESD Withstand Voltage (IEC 61000−4−2)

q

JA

A

stg

J

Vesd 15 Air, 8.0 Contact

Human Body Model (HBM), Model = 2 (Note 1)

Machine Model (MM) Model = B (Note 2)

Latchup LU Class 1 −

Moisture Sensitivity MSL Level 1 −

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Human Body Model, 100 pF discharged through a 1.5 kW resistor following specification JESD22/A114.

2. Machine Model, 200 pF discharged through all pins following specification JESD22/A115.

−0.3 V

30 V

190 °C/W

−40 to +85 °C

−65 to +150 °C

150 °C

kV

2000

200

V

V

www.onsemi.com

3

NCP367

FLAG Output Low Voltage

FLAG Leakage Current

EN Leakage Current

FLAG going up Delay

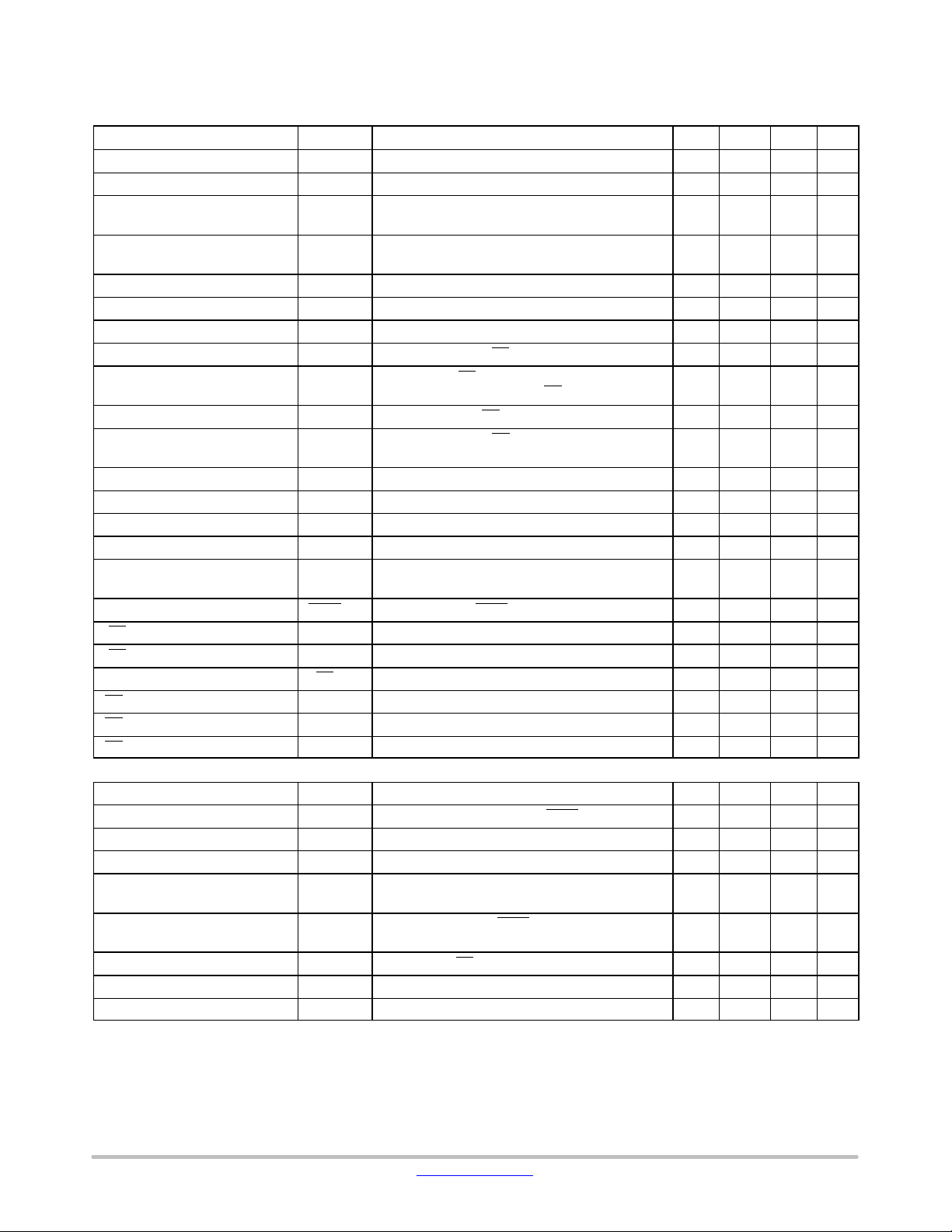

ELECTRICAL CHARACTERISTICS − NCP367OPMUEA

(Min/Max limits values (−40°C < T

Characteristic Symbol Conditions Min Typ Max Unit

Input Voltage Range V

Undervoltage Lockout Threshold UVLO Vin falls down UVLO threshold 1.75 1.85 1.9 V

Undervoltage Lockout

Hysteresis

Overvoltage Lockout Threshold

NCP367OPMUEA

Overvoltage Lockout Hysteresis OVLO

Vin versus Vout Resistance R

Supply Quiescent Current Idd No Load 42 130 mA

Disable Mode Idd

Overcurrent Threshold

NCP367OPMUEA

Overcurrent Response I

Current Limit Gain

NCP367OPMUEA

Battery Overvoltage Threshold OV

Battery Overvoltage Hysteresis OV

V

Pin Leakage VBAT

BAT

V

Deglitch Time VBAT

BAT

EN Voltage High V

EN Voltage Low V

GS Voltage High V

GS Voltage Low V

GS Leakage Current GS

TIMINGS

Start Up Delay t

Rearming Delay t

Overcurrent Regulation Time t

Output Turn Off T ime t

Alert Delay t

Disable Time t

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis Tsd

NOTE: Electrical parameters are guaranteed by correlation across the full range of temperature.

< +85°C) and Vin = +3.5 V . Typical values are TA = +25°C, unless otherwise noted.)

A

1.2 28 V

UVLO

in

hyst

OVLO Vin rises up OVLO threshold

3.65 3.8 3.95

hyst

Enable Mode, Load Connected to V

out

EN = 1.2 V 35 110 mA

EN = low, Load Connected to V

R

= 0 W, 1 A/ms, GS = 0.4 V 2.30 2.85 3.40

ilim

1 A/ms, GS = low, I

= 1.51 A 5.0 %

lim

out

,,

GS = 1.2 V

0°C to 85°C 4.3 4.35 4.4 V

0°C to 85°C 100 150 200 mV

V

BAT

> OV

BAT

0.2 2.0 4.0 ms

Vin > OVLO

I

GS

Vol

DS(on)

dis

OCP

reg

value

BAT

HYS

LEAK

DEG

flag

Sink 1 mA on FLAG pin

FLAG

EN

t

start

REARM

REG

ih

leak

ih

leak

on

off

leak

il

il

From Vin > UVLO to V

From V

From Vin > OVLO to V

FLAG level = 5 V 10 nA

1.2 V

1.2 V

= 0.8xV

out

> 0.2xVin to FLAG = 1.2 V 15 30 45 ms

out

in

15 30 45 ms

OCP Active 15 30 45 ms

OCP Active 1.2 1.8 3.0 ms

≤ 0.3 V, Vin increasing

out

from 3.5 V to 6.5 V at 3 V/ms.

stop

From Vin > OVLO to FLAG ≤ 0.4 V, (see Figure 16)

Vin increasing from 3.5 V to 6.5 V at 3 V/ms

dis

From EN 0.4 to 1.2 V to V

sd

hyst

≤ 0.3 V 3.0 ms

out

60 100 mV

45 150 mV

50 100 mW

2.55

20 nA

400 mV

0.4 V

200 nA

0.4 V

200 nA

1.5 5.0 ms

1.5 ms

150 °C

30 °C

V

A

www.onsemi.com

4

NCP367

FLAG Output Low Voltage

FLAG Leakage Current

EN Leakage Current

FLAG going up Delay

ELECTRICAL CHARACTERISTICS − NCP367DPMUEB

(Min/Max limits values (−40°C < T

Characteristic Symbol Conditions Min Typ Max Unit

Input Voltage Range V

Undervoltage Lockout Threshold UVLO Vin falls down UVLO threshold 1.75 1.85 1.9 V

Undervoltage Lockout

Hysteresis

Overvoltage Lockout Threshold

NCP367DPMUEB

Overvoltage Lockout Hysteresis OVLO

Vin versus Vout Resistance R

Supply Quiescent Current Idd No Load 42 130 mA

Disable Mode Idd

Overcurrent Threshold

NCP367DPMUEB

Overcurrent Response I

Current Limit Gain

NCP367DPMUEB

Battery Overvoltage Threshold OV

Battery Overvoltage Hysteresis OV

V

Pin Leakage VBAT

BAT

V

Deglitch Time VBAT

BAT

EN Voltage High V

EN Voltage Low V

GS Voltage High V

GS Voltage Low V

GS Leakage Current GS

TIMINGS

Start Up Delay t

Rearming Delay t

Overcurrent Regulation Time t

Output Turn Off T ime t

Alert Delay t

Disable Time t

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis Tsd

NOTE: Electrical parameters are guaranteed by correlation across the full range of temperature.

< +85°C) and Vin = +4.0 V . Typical values are TA = +25°C, unless otherwise noted.)

A

1.2 28 V

UVLO

in

hyst

OVLO Vin rises up OVLO threshold

4.38 4.54 4.7

hyst

Vin = 5 V , Enable Mode, Load Connected to V

EN = 1.2 V 35 110 mA

Vin = 4.3 V , EN = low, Load Connected to V

R

= 0 W, 1 A/ms, GS = 0.4 V 1.25 1.45 1.80

ilim

1 A/ms, GS = low, I

= 1.51 A 5.0 %

lim

GS = 1.2 V

Vin = 4.2 V , 0°C to 85°C 4.3 4.35 4.4 V

Vin = 4.2 V , 0°C to 85°C 100 160 200 mV

Vin = 4.0 V , 20 nA

V

> OV

BAT

BAT

Vin > OVLO

out

out

,,

0.2 2.0 4.0 ms

I

GS

Vol

DS(on)

dis

OCP

reg

value

BAT

HYS

LEAK

DEG

flag

Sink 1 mA on FLAG pin

FLAG

EN

t

start

REARM

REG

ih

leak

ih

leak

on

off

leak

il

il

From Vin > UVLO to V

From V

From Vin > OVLO to V

FLAG level = 5 V 10 nA

1.2 V

1.2 V

= 0.8xV

out

> 0.2xVin to FLAG = 1.2 V 15 30 45 ms

out

in

15 30 45 ms

OCP Active 15 30 45 ms

OCP Active 1.2 1.8 3.0 ms

≤ 0.3 V, Vin increasing

out

from 4 V to 7 V at 3 V/ms.

stop

From Vin > OVLO to FLAG ≤ 0.4 V, (see Figure 16)

Vin increasing from 4 V to 7 V at 3 V/ms

dis

From EN 0.4 to 1.2 V to V

sd

hyst

≤ 0.3 V 3.0 ms

out

60 100 mV

45 100 mV

50 100 mW

2.77

400 mV

0.4 V

200 nA

0.4 V

200 nA

1.5 5.0 ms

1.5 ms

150 °C

30 °C

V

A

www.onsemi.com

5

NCP367

Current Limit Gain NCP367Dx

Ox

FLAG Output Low Voltage

FLAG Leakage Current

EN Leakage Current

FLAG going up Delay

ELECTRICAL CHARACTERISTICS − Other OVLO version

(Min/Max limits values (−40°C < T

Characteristic Symbol Conditions Min Typ Max Unit

Input Voltage Range V

Undervoltage Lockout Threshold UVLO Vin falls down UVLO threshold 1.75 1.85 1.9 V

Undervoltage Lockout

Hysteresis

Overvoltage Lockout Threshold

NCP367xPMUEC

NCP367DPMUEE

NCP367DPMUEL

NCP367OPMUEO

Overvoltage Lockout Hysteresis OVLO

Vin versus Vout Resistance R

Supply Quiescent Current Idd No Load 42 130 mA

Disable Mode Idd

Overcurrent Threshold

NCP367Dx

NCP367Ox

Overcurrent Response I

NCP367

Battery Overvoltage Threshold OV

Battery Overvoltage Hysteresis OV

V

Pin Leakage VBAT

BAT

V

Deglitch Time VBAT

BAT

EN Voltage High V

EN Voltage Low V

GS Voltage High V

GS Voltage Low V

GS Leakage Current GS

TIMINGS

Start Up Delay t

Rearming Delay t

Overcurrent Regulation Time t

Output Turn Off T ime t

Alert Delay t

Disable Time t

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis Tsd

NOTE: Electrical parameters are guaranteed by correlation across the full range of temperature.

< +85°C) and Vin = +5.0 V . Typical values are TA = +25°C, unless otherwise noted.)

A

1.2 28 V

UVLO

in

hyst

OVLO Vin rises up OVLO threshold

5.64

5.85

6.60

6.90

hyst

DS(on)

dis

I

OCP

Vin = 5 V , Enable Mode, Load Connected to V

EN = 1.2 V 40 110 mA

Vin = 5 V , EN = low, Load Connected to V

R

= 0 W, 1 A/ms, GS = 0.4 V 1.25

ilim

out

out

,,

2.30

GS

Vol

reg

value

BAT

HYS

LEAK

flag

DEG

1 A/ms, GS = low, I

GS = 1.2 V 2.70

0°C to 85°C 4.3 4.35 4.4 V

0°C to 85°C 100 150 200 mV

V

BAT

Vin > OVLO

= 1.51 A 5.0 %

lim

> OV

BAT

0.2 2.0 4.0 ms

Sink 1 mA on FLAG pin

FLAG

EN

t

start

REARM

REG

ih

leak

ih

leak

on

off

leak

il

il

From Vin > UVLO to V

From V

From Vin > OVLO to V

FLAG level = 5 V 10 nA

Vin from 3.3 V to 5.25 V 1.2 V

Vin from 3.3 V to 5.25 V 0.4 V

EN = 5.5 V or GND 200 nA

Vin from 3.3 V to 5.25 V 1.2 V

Vin from 3.3 V to 5.25 V 0.4 V

EN = 5.5 V or GND 200 nA

= 0.8xV

out

> 0.2xVin to FLAG = 1.2 V 15 30 45 ms

out

in

15 30 45 ms

OCP Active 15 30 45 ms

OCP Active 1.2 1.8 3.0 ms

≤ 0.3 V, Vin increasing

out

from 5 V to 8 V at 3 V/ms.

stop

From Vin > OVLO to FLAG ≤ 0.4 V, (see Figure 16)

Vin increasing from 5 V to 8 V at 3 V/ms

dis

From EN 0.4 to 1.2 V to V

sd

hyst

≤ 0.3 V 3.0 ms

out

80 100 mV

5.85

6.07

6.84

7.20

6.05

6.28

7.08

7.50

100 150 mV

50 100 mW

1.51

2.85

1.80

3.40

2.55

20 nA

400 mV

1.5 5.0 ms

1.5 ms

150 °C

30 °C

V

A

www.onsemi.com

6

NCP367

TYPICAL OPERATING CHARACTERISTICS

Vin

V

in

V

in

V

in

t

on

t

start

/FLAG

/FLAG

Figure 3. Hot Plug−in from 0 to 5 V,

and t

t

t

V

t

on

start

on

in

start

V

out

/Flag

Vout

V

/FLAG

/FLAG

t

stop

t

off

Figure 4. Overvoltage from 5 to 8 V,

and t

t

Vin

off

V

Vin

in

V

Vout /Flag

Vout

/Flag

out

stop

out

Figure 5. Retrieve Normal Operation,

and t

t

on

start

V

in

/Flag

Figure 7. Battery Overvoltage, Deglitch Time

VBat

DEG

V

bat

www.onsemi.com

7

Figure 6. Overvoltage from 0 to 10 V

V

out

NCP367

TYPICAL OPERATING CHARACTERISTICS

2.00

1.98

1.96

1.94

1.92

1.90

1.88

UVLO (V)

1.86

1.84

1.82

1.80

4.40

4.35

4.30

(V)

4.25

BAT

OV

4.20

4.15

5.66

5.64

UVLO + hysteresis

UVLO

0−50 50 100 125

25−25 75 25−25 75

TEMPERATURE (°C)

5.62

5.60

5.58

OVLO (V)

5.56

5.54

5.52

5.50

0−50 50 100 125

TEMPERATURE (°C)

OVLO

OVLO − Hysteresis

Figure 8. UVLO and Hysteresis Figure 9. OVLO and Hysteresis vs. Temperature

(5.6 V version)

20

15

(nA)

10

LEAK

VBAT

5

4.10

Figure 10. V

0−50 50 100 125

25−25 75 25−25 75

TEMPERATURE (°C)

Threshold and Hysteresis vs.

BAT

0

Figure 11. V

0−50 50 100 125

TEMPERATURE (°C)

Pin Leakage vs. Temperature

BAT

Temperature

www.onsemi.com

8

NCP367

APPLICATION INFORMATION

Operation

The NCP367 is an integrated IC which offers a complete

protection of the portable devices during the Li ion battery

charge.

First, the input pin is protected up to +30 V, protecting

the down stream system (charger, transceiver, system...)

against the power supply transients such as inrush current

or defective functionality. Additional protection level is

offered with the overcurrent block which eliminates

current peak or opens the charge path if an overcurrent

default appears.

More of that, the battery voltage is monitored all along

the input power supply is connected, allowing to open

charge path if Li ion battery voltage exceeds 4.3 V, caused

by CCCV charger or battery pack fault.

The integrated pass element (PMOS FET) is sized to

support very high charge DC current up to 2.3 A. The

overcurrent threshold can be externally adjusted with a

pull−down resistor and gain select pin is available to divide

current limit threshold with internal fixed gain. Allowing

to adjust with logic pin the overcurrent threshold if

USB/500 mA or WA/1.5 A is detected, without changing

R

resistor, in example.

ILIM

Undervoltage, Overvoltage, Overcurrent and thermal

faults are signalized thanks to the open drain FLAG pin, by

pulling its down.

Undervoltage Lockout (UVLO)

To ensure proper operation under any conditions, the

device has a built−in undervoltage lock out (UVLO)

circuit. During V in positive going slope, the output remains

disconnected from input until Vin voltage is above 1.85 V

plus hysteresis nominal. This circuit has a 80 mV

hysteresis to provide noise immunity to transient condition.

Overvoltage Lockout (OVLO)

To protect connected systems on Vout pin from

overvoltage, the device has a built−in overvoltage lock out

(OVLO) circuit. During overvoltage condition, the output

remains disabled as long as the input voltage exceeds this

threshold.

FLAG output is tied to low as long as Vin is higher than

OVLO. This circuit has a 100 mV hysteresis to provide

noise immunity to transient conditions.

FLAG Output

NCP367 provides a FLAG output, which alerts external

systems that a fault has occurred.

This pin is tied to low as soon as the OVLO, OV

BAT

, I

OCP

or internal temperature thresholds are exceeded and

remains low until between minimum driving voltage and

UVLO threshold. When Vin level recovers normal

condition, FLAG is held high. The pin is an open drain

output, thus a pull up resistor (typically 1 MW − Minimum

10 kW) must be provided to VCC. FLAG pin is an open drain

output, which is able to support 1 mA maximum.

EN Input

To enable normal operation, the EN pin shall be forced

to low or connected to ground. A high level on the pin,

disconnects OUT pin from IN pin. EN does not overdrive

a UVLO or OVLO fault.

Overcurrent Protection (OCP)

This device integrates the overcurrent protection

function, from wall adapter to battery. That means the

current across the internal PMOS is regulated and cut when

the value, set by external RSEL resistor, exceeds I

longer than t

REG

.

LIM

An internal resistor is placed in series with the pin

allowing to have a maximum OCP value when I

LIM

pin is

directly connected to GND.

By adding external resistors in series with I

and GND,

LIM

the OCP value is decreased.

An additional logic pin, GS (gain select), is very useful

in case of different charge rate is necessary (Wall adapter

and USB, for example).

By setting GS to 0.4 V, overcurrent thresholds are

depending on R select resistor, which is connect between

pin 4 and GND. When the GS pin is tied to 1.2 V (high logic

level) the preselected current limit is divided by 2.75. Due

www.onsemi.com

9

NCP367

to this option, both fast charge or USB charge are

authorized with the same device.

1500

1000

GS = Low

IOCP (mA)

500

GS = High

0

0 100 200 300 400 500 600 700 800

Rilim(kW)

Figure 12. I

3

2

IOCP (mA)

1

GS = High

0

0 100 200 300 400 500 600 700 800

Figure 13. Over Current Threshold versus

Typical R

LIM

versus R

OCP

GS = Low

1.5 A version

R

LIMIT

, GS = low and high,

LIM

Rilim (kW)

2.85 A Version

calculation is following:

NCP367DxMUxxTBG

R

(kW) = 249 / I

LIM

OCP

− 165

NCP367OxMUxxTBG

R

(kW) = 532 / I

LIM

OCP

− 180

During overcurrent event, charge area is opened and

FLAG output is tied to low , allowing the mController to take

into account the fault event and then open the charge path.

At power up (accessory is plugged on input pins), the

current is limited up to I

allow capacitor charge and limit inrush current. If the I

during 1.8 ms (typical), to

LIM

LIM

threshold is exceeded over 1.8 ms, the device enter in OCP

burst mode until the overcurrent event disappears.

V

Sense

BAT

The connection of the V

pin to the positive

BAT

connection of the Li ion battery pack allows preventing

overvoltage transient, greater than 4.35 V. In case of wrong

charger conditions, the PMOS is then opened, eliminating

Battery pack over voltage which could create safety issues

and temperature increasing.

The 4.35 V comparator has a 150 mV built−in hysteresis.

More of that, deglitch function of 2 ms is integrated to

prevent voltage transients on the Battery voltage. If the

battery over voltage condition exceeds deglitch time, the

charge path is opened and FLAG pin is tied to low level

until the V

is greater than 4.35 V – hysteresis.

BAT

At wall adapter insertion, and if the battery is fully

charged, V

comparator stays locked until battery needs

bat

to be recharged (4.2 V typ − 4.1 V min).

A serial resistor has to be placed in series with Vbat pin

and battery connection, with a 200 kW recommended

value.

PCB Recommendations

The NCP367 integrates low R

PMOS FET,

DS(on)

nevertheless PCB layout rules must be respected to

properly evacuate the heat out of the silicon. The DFN

PAD1 corresponds to the PMOS drain so must be connected

to OUT plane to increase the heat transfer. Of course, in any

case, this pad shall be not connected to any other potential.

Following figure shows package thermal resistance of a

DFN 2.2x2 mm.

www.onsemi.com

10

NCP367

240

220

200

180

160

140

Theta JA (°C/W)

120

100

80

0 100 200 300 400 500 600 700

Theta JA curve with PCB cu thk 1.0 oz

Theta JA curve with PCB cu thk 2.0 oz

Power curve with PCB cu thk 2.0 oz

Power curve with PCB cu thk 1.0 oz

COPPER HEAT SPREADER AREA

(mm2)

Figure 14.

Internal PMOS FET

NCP367 includes an internal PMOS FET to protect the

systems, connected on OUT pin, from positive

over−voltage. Regarding electrical characteristics, the

R

V

, during normal operation, will create low losses on

DS(on)

pin versus Vin, due to very low R

out

DS(on)

.

1.2

1.1

1

0.9

0.8

Max Power (W)

T_ambient

25°C

0.7

0.6

0.5

ESD Tests

NCP367 fully support the IEC61000−4−2, level 4 (Input

pin, 1 mF mounted on board). That means, in Air condition,

Vin has a ±15 kV ESD protected input. In Contact condition,

Vi n h as ±8 kV ESD protected input. Please refer to Figure 16

to see the IEC 61000−4−2 elect rostati c discha rge waveform.

100

90

80

70

(mW)

60

DS(on)

50

R

40

30

20

−50 −25 0 25 50 75 100 125

Figure 15. Typical R

TEMPERATURE (°C)

versus Temperature

DS(on)

Figure 16. IEC 61000−4−2 Electrostatic Discharge

www.onsemi.com

11

NCP367

ORDERING INFORMATION

Device Marking Package Shipping

NCP367DPMUECTBG DC DFN8

(Pb−Free)

NCP367DPMUEETBG DE DFN8

(Pb−Free)

NCP367DPMUELTBG DL DFN8

(Pb−Free)

NCP367OPMUEOTBG P3 DFN8

(Pb−Free)

NCP367OPMUEATBG EA DFN8

(Pb−Free)

NCP367DPMEBTBG PE DFN8

(Pb−Free)

NCP367OPMUECTBG EC DFN8

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

3000 / Tape & Reel

SELECTION GUIDE

The NCP367 can be available in several undervoltage and overvoltage thresholds versions. Part number is designated as follows:

†

NCP367xxMUxxTBG

a

bcd

Code Contents

a Overcurrent threshold

b V

(additional thresholds available for a wide

c UVLO Typical Threshold

d OVLO Typical Threshold

(Additional thresholds available)

a = D: 1.51 A

a = O: 2.85 A

Voltage

BAT

b: P = 4.36 V

Lithium ion material range)

c: E = 1.85 V

d: C = 5.85 V

d: E = 6.07 V

d: L = 6.85 V

d: O = 7.20 V

d: A = 3.80 V

d: B = 4.54 V

www.onsemi.com

12

NCP367

P

cal

PACKAGE DIMENSIONS

DFN8, 2.0x2.2, 0.5P

CASE 506BP

ISSUE A

REFERENCE

2X

2X

9X

NOTE 4

PIN ONE

0.10 C

0.05 C

0.05 C

L8X

0.10 C

SIDE VIEW

DETAIL A

K8X

e

e/2

BOTTOM VIEW

D

TOP VIEW

DETAIL B

D2

1

4

58

A1

0.10 BAC

E2

A B

E

(A3)

b

8X

0.10 B

0.05ACC

A

C

0.10 BAC

L1

SEATING

PLANE

NOTE 3

L

DETAIL A

ALTERNATE TERMINAL

CONSTRUCTIONS

MOLD CMPDEXPOSED Cu

DETAIL B

ALTERNATE

CONSTRUCTIONS

NOTES:

L

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED TERMINAL

AND IS MEASURED BETWEEN 0.15 AND

0.30 mm FROM TERMINAL.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

DIMAMIN TYP

A1 0.00 ---

A3 0.20 REF

D 2.00 BSC

D2 1.43 ---

E 2.20 BSC

E2

K

L1

MILLIMETERS

0.80 ---

b 0.20 ---

1.05 ---

e 0.50 BSC

0.20 0.22

L

0.25 ---

--- ---

MAX

1.00

0.05

0.30

1.53

1.25

0.30

0.35

0.15

SOLDERING FOOTPRINT*

1.63

1.15

1

0.50

PITCH

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

8X

0.28

8X

0.45

2.50

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC owns the rights to a number of patents, trademarks,

copyrights, trade secrets, and other intellectual property. A listing of SCILLC’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. SCILLC

reserves the right to make changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products

for any particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including

without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different

applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer ’s technical

experts. SCILLC does not convey any license under its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components

in systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the SCILLC product

could create a situation where personal injury or death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall

indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney

fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was

negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws

and is not for resale in any manner.

UBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

www.onsemi.com

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your lo

Sales Representative

NCP367/D

13

Loading...

Loading...