NCL30100

Fixed Off Time Switched

Mode LED Driver Controller

The NCL30100 is a compact switching regulator controller intended

for space constrained constant current high−brightness LED driver

applications where efficiency and small size are important. The

controller is based on a peak current, quasi fixed−off time control

architecture optimized for continuous conduction mode step−down

(buck) operation. This allows the output filter capacitor to be

eliminated. In this configuration, a reverse buck topology is used to

control a cost effective N−type MOSFET. Moreover, this controller

employs negative current sensing thus minimizing power dissipation

in the current sense resistor. The off time is user adjustable through the

selection of a small external capacitor, thus allowing the design to be

optimized for a given switching frequency range. The control loop is

designed to operate up to 700 kHz allowing the designer the flexibility

to use a very small inductor for space constrained applications.

The device has been optimized to provide a flexible inductive

step−down converter to drive one or more high power LED(s). The

controller can also be used to implement non−isolated buck−boost

driver topologies.

Features

• Quasi−Fixed OFF Time, Peak Current Control Method

• N−FET Based Controller Architecture

• Up to 700 kHz Switching Frequency

• Up to >95% Efficiency

• No Output Capacitor Needed

• V

Operation from 6.35 − 18 V

CC

• Adjustable Current Limit with Negative Sensing

• Inherent Open LED Protected

• Very Low Current Consumption at Startup

• Undervoltage Lockout

• Compact Thin TSOP−6 Pb−Free Package

• −40 to + 125°C Operating Temperature Range

• This is a Pb−Free Device

Typical Applications

• Low Voltage Halogen LED Replacement (MR 16)

• LED Track Lighting

• Landscape Lighting

• Solar LED Applications

• Transportation Lighting

• 12 V LED Bulb Replacement

• Outdoor Area Lighting

• LED Light Bars

http://onsemi.com

MARKING

DIAGRAM

TSOP−6

(SOT23−6, SC59−6)

1

(Note: Microdot may be in either location)

ORDERING INFORMATION

Device Package Shipping

NCL30100SNT1G 3000 / Tape & Reel

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

SN SUFFIX

CASE 318G

AAA = Specific Device Code

A =Assembly Location

Y = Year

W = Work Week

G = Pb−Free Package

PIN CONNECTIONS

1

CS

2GND

CT

3

(Top View)

TSOP−6

(Pb−Free)

6

5

4

AAAAYWG

1

Gate

V

CC

IVC

G

†

© Semiconductor Components Industries, LLC, 2011

January, 2011 − Rev. 3

1 Publication Order Number:

NCL30100/D

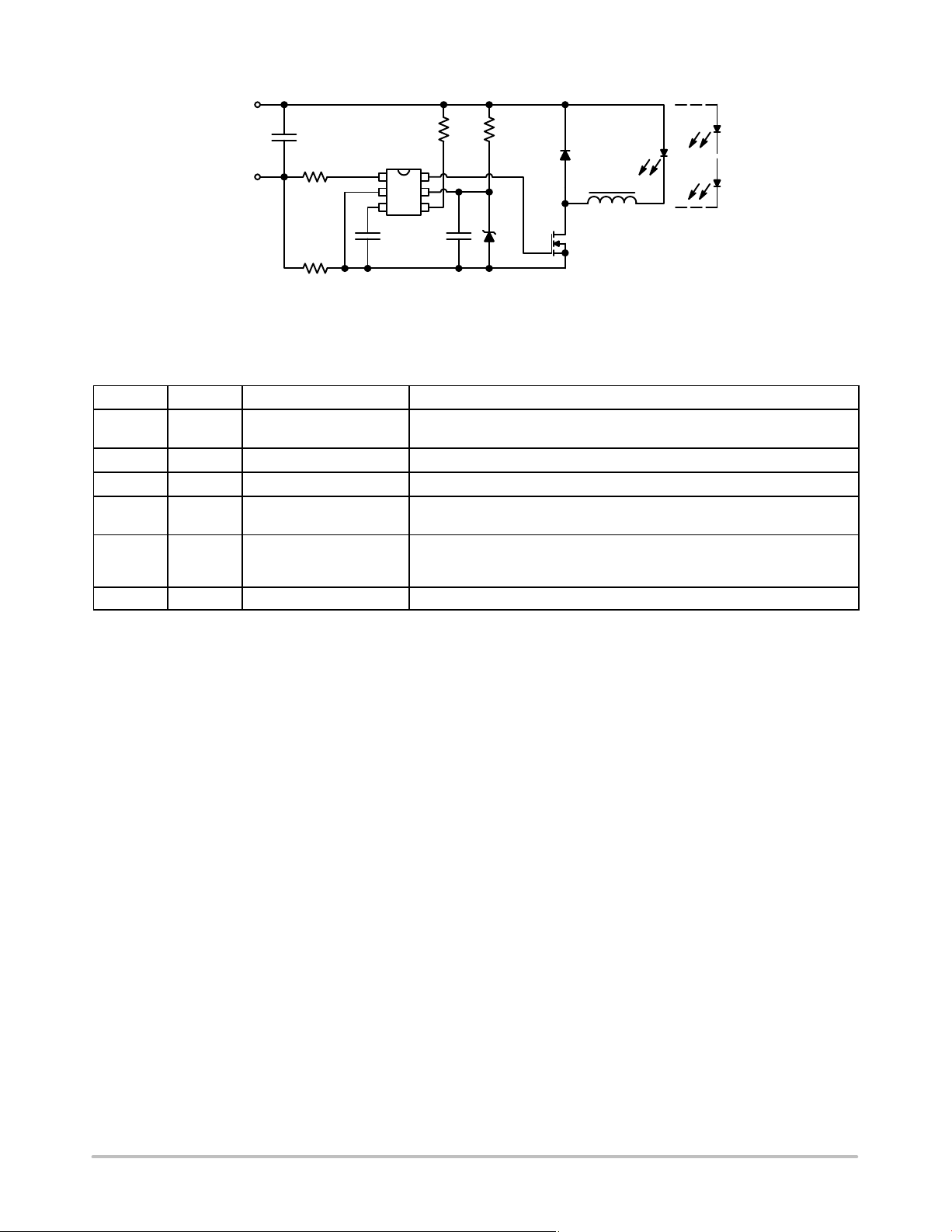

6.5 – 24 V

NCL30100

+

C1

IC1

C2

NCL30100

DRV

CS

VCC

GND

IVC

CT

C3

R3

−

R4

R2R1

D1

D2

Q1

LED1

L1

LED2

LEDX

Figure 1. Typical Application Example of the LED Converter

PIN FUNCTION DESCRIPTION

Pin N5 Pin Name Function Pin Description

1 CS Current sense input A resistor divider consisting of R3 and R4 is used to set the peak current

2 GND Ground Power ground.

3 C

T

Timing capacitor Capacitor to establish the off time duration

4 IVC Input voltage compensation The current injected into the input varies the switch off time and I

5 V

CC

Input supply Supply input for the controller. The input is rated to 18 V but as illustrated

6 DRV Driver output Output drive for an external power MOSFET

sensed through the MOSFET switch

feedforward compensation.

Figure 1, a simple zener diode and resistor can allow the LED string to be

powered from a higher voltage

allowing for

PK

http://onsemi.com

2

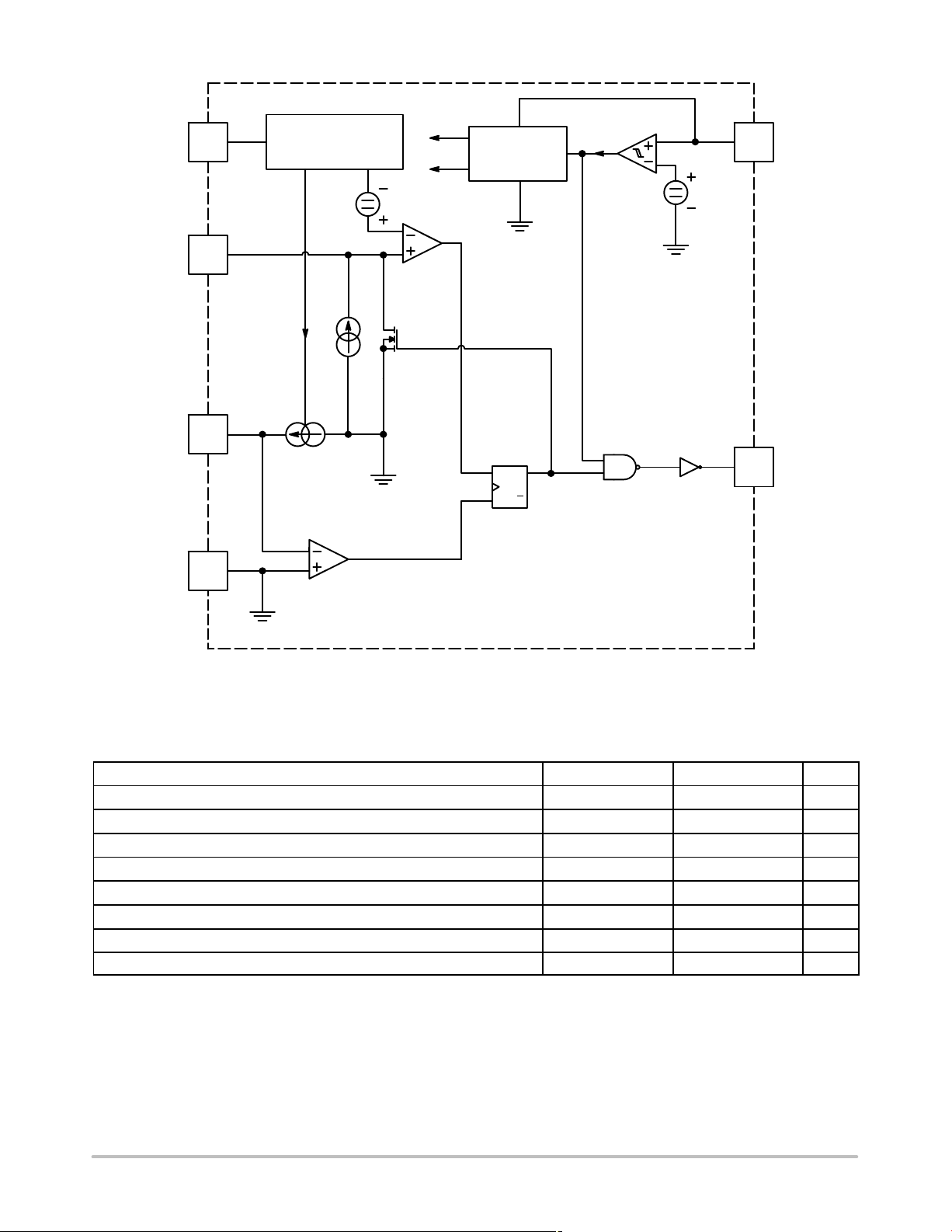

IVC

Input Voltage

Regulator

NCL30100

VDD

Reference

Iref

Regulator

Undervoltage

Lockout

V

CC

CT

CS

GND

50 mA

12.5−50 mA

Current Sense

Comparator

VOffset

0−3.9 V

OFF Time

Comparator

Reset

Set

S

R

SET

CLR

6.35/5.85 V

Gate Driver

Q

Q

DRV

Figure 2. Simplified Circuit Architecture

MAXIMUM RATINGS

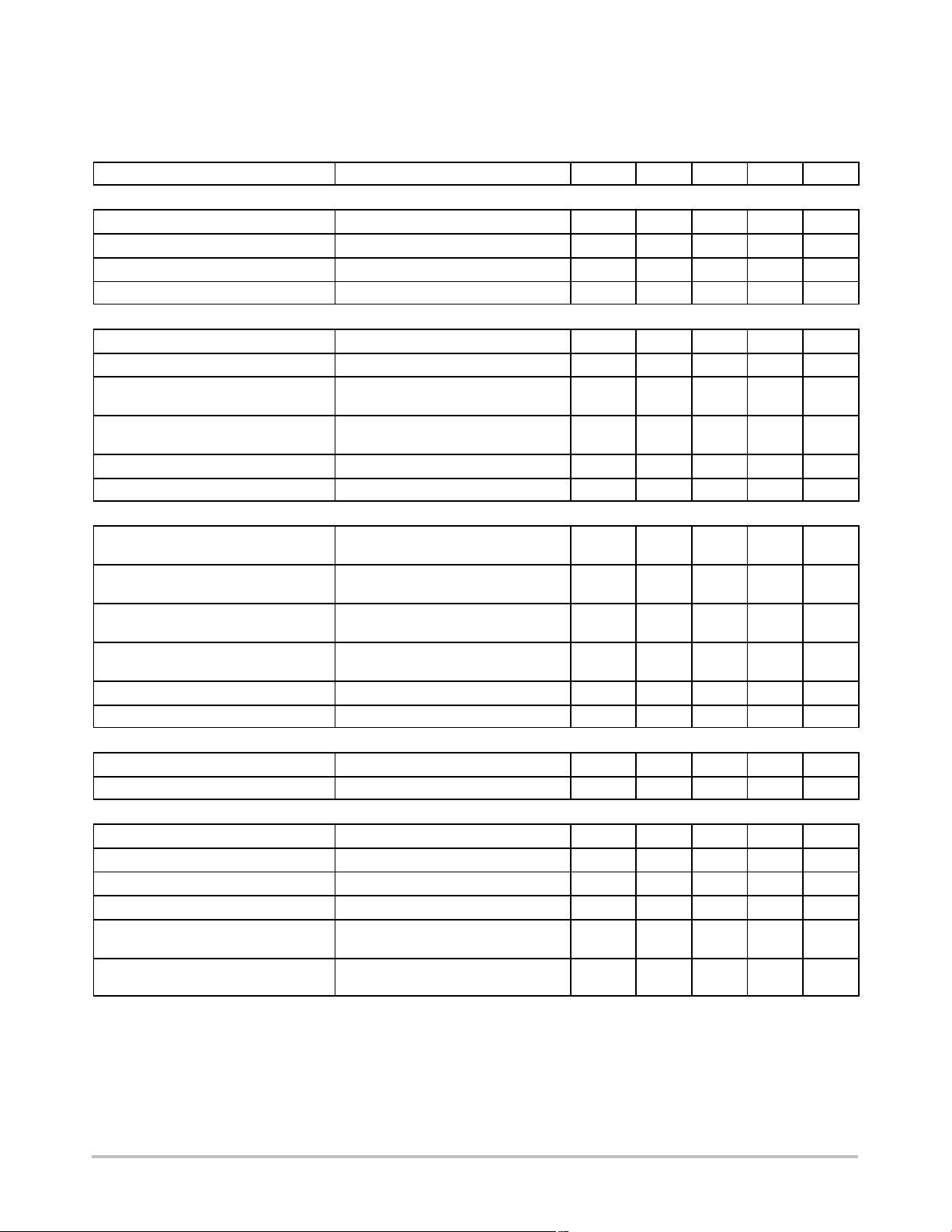

Rating Symbol Value Unit

Power Supply Voltage V

CC

IVC Pins Voltage Range IVC −0.3 to 18 V

CS and CT Pin Voltage Range V

Thermal Resistance, Junction−to−Air

Junction Temperature T

Storage Temperature Range T

ESD Voltage Protection, Human Body Model (HBM) V

ESD Voltage Protection, Machine Model (MM) V

in

R

q

JA

J

stg

ESD−HBM

ESD−MM

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. This device(s) contains ESD protection and exceeds the following tests:

Human Body Model 2000 V per JEDEC Standard JESD22−A114E

Machine Model 200 V per JEDEC Standard JESD22−A115−A

2. This device meets latchup tests defined by JEDEC Standard JESD78.

3. Moisture Sensitivity Level (MSL) 1.

18 V

−0.3 to 10 V

178 °C/W

150 °C

−60 to +150 °C

2 kV

200 V

http://onsemi.com

3

NCL30100

ELECTRICAL CHARACTERISTICS (V

= 12 V, for typical values TJ = 25°C, for min/max values TJ = −40°C to +125°C, unless

CC

otherwise noted)

SUPPLY SECTION

Parameter Conditions Symbol Min Typ Max Unit

INPUT VOLTAGE COMPENSATION

Offset Voltage

CT Pin Voltage

CT Pin Voltage

IVC pin internal resistance (Note 4) R

CT PIN – OFF TIME CONTROL

Source Current

Source Current CT Pin Grounded, −40 v T

Source Current Maximum Voltage Capability (Note 4)

Minimum CT Pin Voltage (Note 4) Pin Unloaded, Discharge Switch TurnedonV

Pin to ground capacitance (Note 4) C

Propagation Delay (Note 4) CT Reach VCT Threshold to Gate Output CT

CURRENT SENSE

Minimum Source Current

Minimum Source Current

Maximum Source Current

Maximum Source Current

Comparator Threshold Voltage (Note 4) V

Propagation Delay CS Falling Edge to Gate Output CS

GATE DRIVER

Sink Resistance

Source Resistance I

POWER SUPPLY

Startup Threshold

Minimum Operating Voltage VCC decreasing V

Vcc Hysteresis (Note 4) V

Startup Current Consumption VCC = 6 V I

Steady State Current Consumption

(Note 4)

Steady State Current Consumption C

4. Guaranteed by design

IVC Current = 25 mA (Including V

IVC Current = 50 mA (Including V

CT Pin Grounded, 0 v T

J

J

IVC = 180 mA, CT Pin Grounded,

0 v T

v 85°C

J

IVC = 180 mA, CT Pin Grounded,

−40 v T

v 125°C

J

IVC = 0 mA, CT Pin Grounded,

0 v T

v 85°C

J

IVC = 0 mA, CT Pin Grounded,

−40 v T

v 125°C

J

I

= 30 mA R

sink

= 30 mA R

source

VCC increasing V

C

= 0 nF, fSW = 100 kHz, IVC = open,

DRV

= 1 nF, fSW = 100 kHz, IVC = open,

DRV

V

= 7 V

CC

V

= 7 V

CC

) V

(offset)

) V

(offset)

v 85°C I

v 125°C I

V

(offset)

CT−25

CT−50mA

IVC

CT

CT

V

CT(max)

CT(min)

CT

delay

I

CS(min)

I

CS(min)

I

CS(max)

I

CS(max)

delay

OL

OH

CC(on)

CC(off)

CC(hyst)

CC1

I

CC2

I

CC2

1.10 1.30 1.45 V

1.69 2.08 2.47 V

mA

2.12 2.6 3.05 V

47.25 50 52.75

45.25 50 52.75

− 4.3 − V

− − 20 mV

− 8 − pF

− 220 − ns

11. 75 12.5 13.25

11.35 12.5 13.25

47.25 50 52.75

45.25 50 52.75

th

− 38 − mV

− 215 310 ns

5 15 40

20 60 100

− 6.35 6.65 V

5.45 5.85 − V

− 0.5 − V

− 22 35

0.5 1 1.15 mA

17

300

kW

mA

mA

mA

mA

mA

mA

W

W

mA

mA

http://onsemi.com

4

NCL30100

6.260

6.255

6.250

(V)

CC(on)

6.245

V

6.240

6.235

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

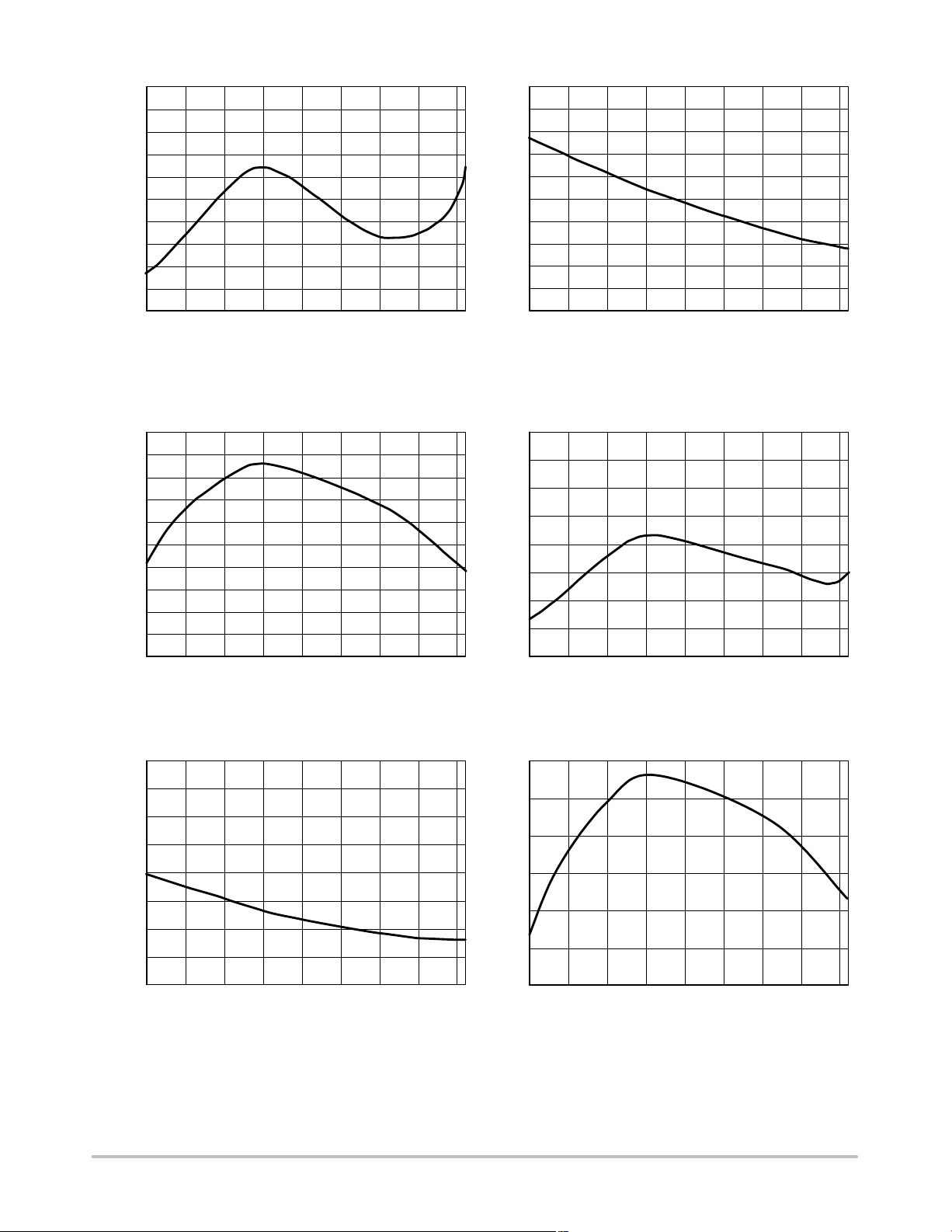

Figure 3. V

Threshold vs. Junction

startup

Temperature

12.6

12.5

12.4

12.3

12.2

(mA)

12.1

12.0

CS(min)

I

11.9

11.8

11.7

11.6

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 5. Minimum Source Current vs.

Junction Temperature

30

28

26

24

22

(mA)

20

CC1

I

18

16

14

12

10

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 4. Startup Current Consumption vs.

Junction Temperature

5.780

5.775

5.770

5.765

(V)

5.760

CC(off)

5.755

V

5.750

5.745

5.740

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 6. Minimum Operating Voltage

Threshold vs. Junction temperature

1.10

1.05

(mA)

1.00

CC2

I

0.95

0.90

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 7. Steady State Current Consumption

vs. Junction Temperature

50.0

49.5

49.0

(mA)

48.5

CS(max)

I

48.0

47.5

47.0

http://onsemi.com

5

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 8. Maximum Source Current vs.

Junction Temperature

NCL30100

55

50

45

40

(mV)

th

V

35

30

25

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

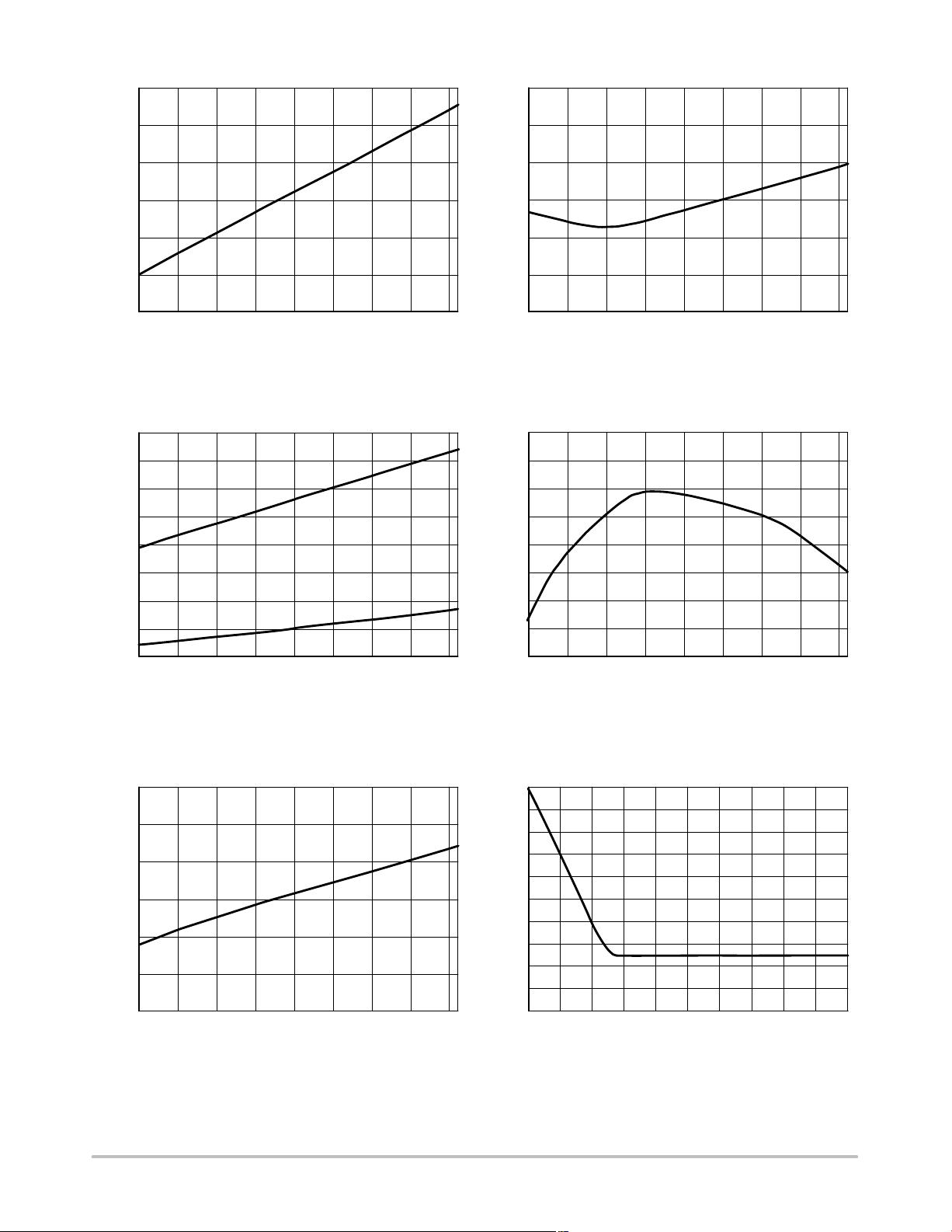

Figure 9. Comparator Threshold Voltage vs.

Junction Temperature

85

75

65

R

55

OH

1.350

1.345

1.340

(V)

1.335

(offset)

V

1.330

1.325

1.320

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 10. Offset Voltage vs. Junction

Temperature

51.0

50.5

50.0

49.5

45

35

RESISTANCE (W)

25

R

15

5

−40 −20 0 20 40 60 80 100 120

OL

TEMPERATURE (°C)

Figure 11. Drive Sink and Source Resistance

vs. Junction Temperature

2.60

2.55

2.50

(V)

A

m

2.45

CT−50

V

2.40

2.35

2.30

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 13. CT Pin Voltage vs. Input Voltage

Compensation Current

49.0

(mA)

CT

I

48.5

48.0

47.5

47.0

−40 −20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 12. CT Source Current vs. Junction

Temperature

50

45

40

35

30

25

(mA)

CS

I

20

15

10

5

0

0 20 20018016014012040 60 80 100

IVC (mA)

Figure 14. ICT Dependence on IVC Current

http://onsemi.com

6

NCL30100

APPLICATION INFORMATION

The NCL30100 implements a peak current mode control

scheme with a quasi−fixed OFF time. An optional input

feedforward voltage control is provided to enhance

regulation response with widely varying input voltages.

Only a few external components are necessary to implement

the buck converter. The NCL30100 incorporates the

following features:

• Very Low Startup Current: The patented internal supply

block is specially designed to offer a very low current

consumption during startup.

• Negative Current Sensing: By sensing the total current,

this technique does not impact the MOSFET driving

voltage (V

) during switching. Furthermore, the

GS

programming resistor together with the pin capacitance

forms a residual noise filter which blanks spurious

spikes. This approach also supports a flexible resistor

selection. Finally unlike a positive sensing approach,

there is virtually no power dissipation in the current

sense resistor thus improving efficiency.

• Controller architecture supports high brightness LED

drive current requirements: Selection of the external

n−channel MOSFET can be easily optimized based on

operation voltage, drive current and size giving the

designer flexibility to easily make design tradeoffs.

• Typical $5.5% Current Regulation: The I

pin offers

CS

$5.5% from 0 to 85°C (+5.5% −9.5% across −40°C to

125°C) accuracy of the current typically, so the LED

peak current is precisely controlled

• No output capacitor is needed: By operating the

controller in continuous conduction mode, it is possible

to eliminate the bulky output filter capacitor.

The following section describes in detail each of the control

blocks

the switch and the inductor. This approach offers several

benefits over traditional positive current sensing.

• Maximum peak voltage across the current sense resistor

is user controlled and can be optimized by changing the

value of the shift resistor.

• The gate drive capability is improved because the

current sense resistor is located out of the gate driver

loop and does not deteriorate the switch on and also

switch off gate drive amplitude.

• Natural leading edge blanking is filter switching noise

at FET turn−in

• The CS pin is not exposed to negative voltage, which

could induce a parasitic substrate current within the IC

and distort the surrounding internal circuitry.

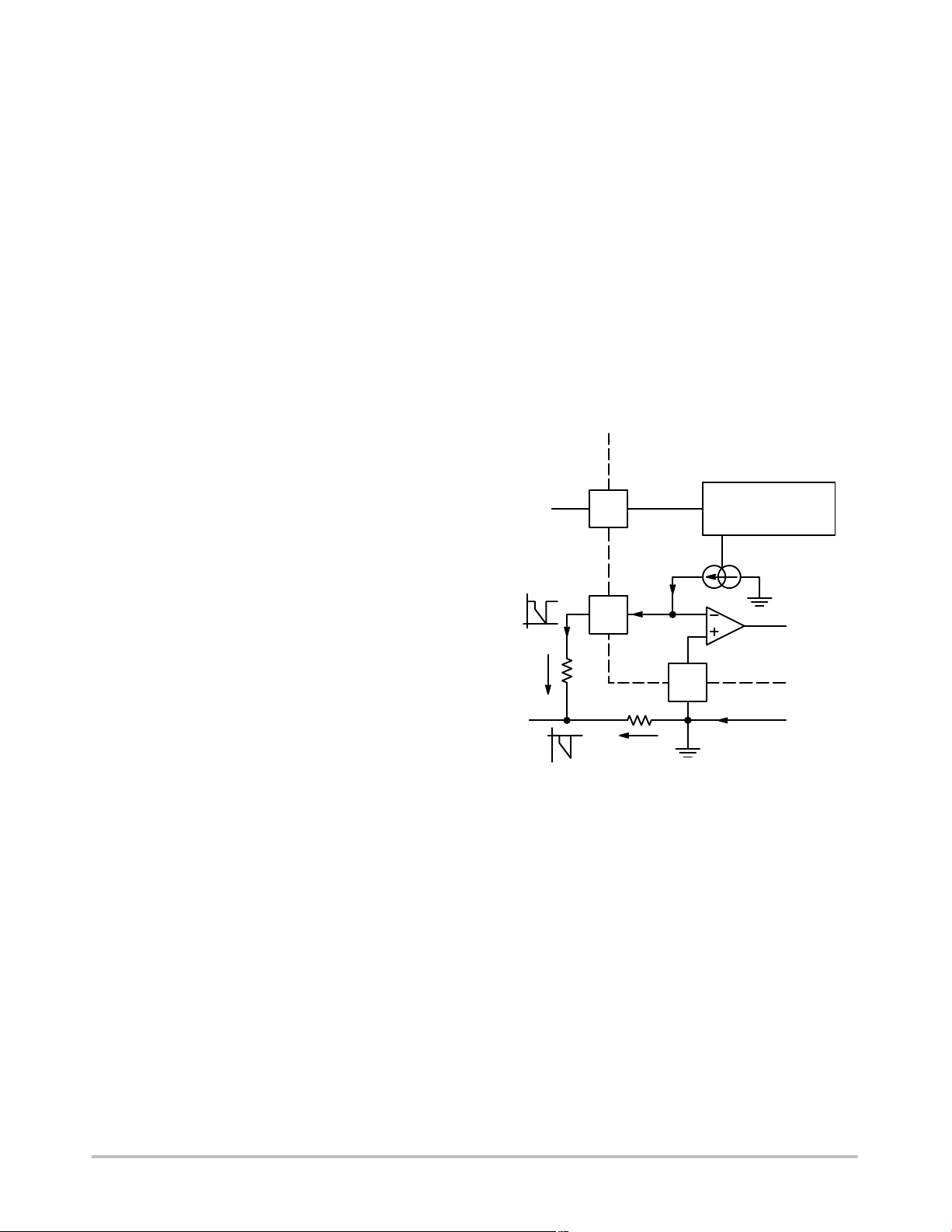

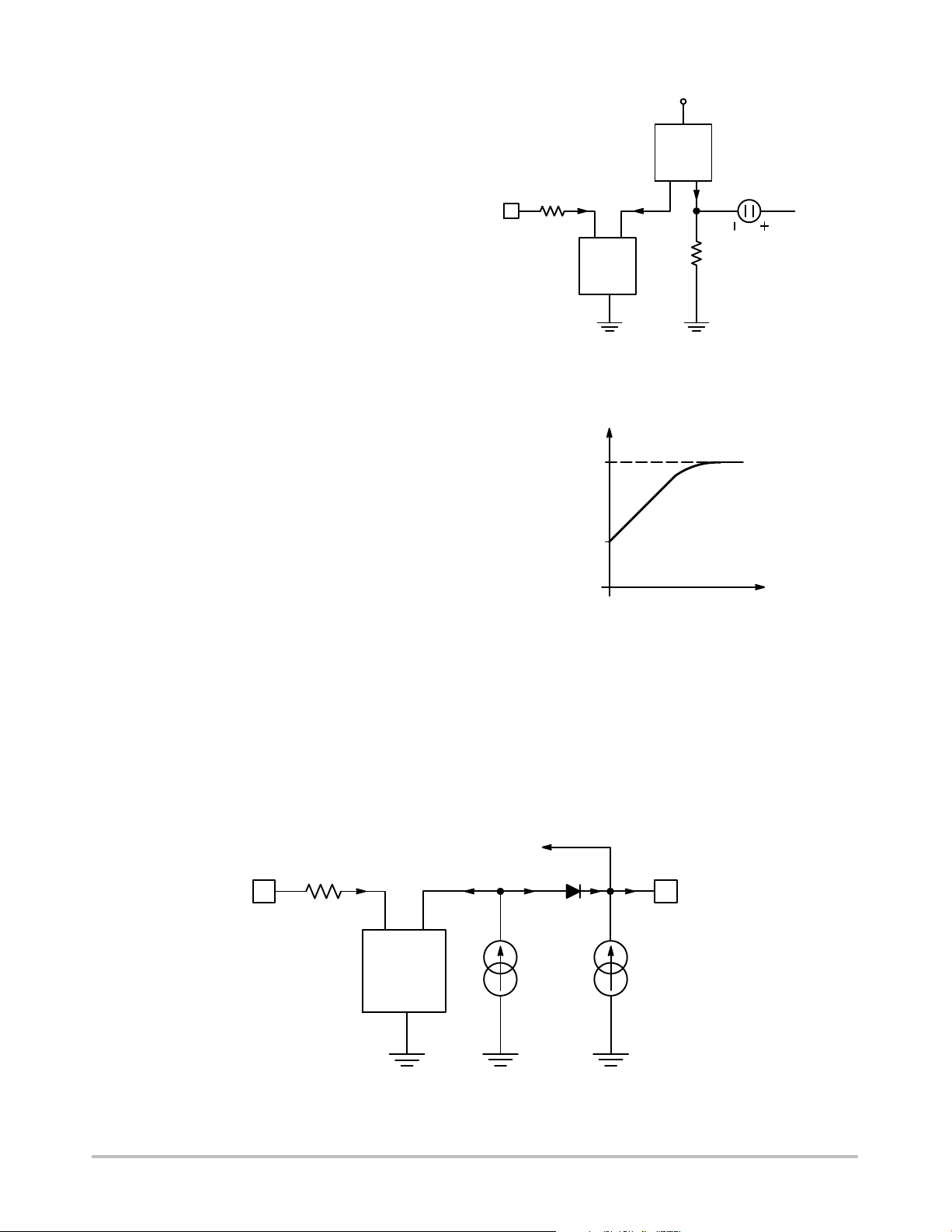

The current sensing circuit is shown in Figure 15.

IVC

Input Voltage

Regulator

12.5−50 mA

CS

To Latch

Vshift

Rshift

RCS

VCS

GND

Iprimary

Current Sensing Block

The NCL30100 utilizes a technique called negative

current sensing which is used to set the peak current through

http://onsemi.com

Figure 15. Primary Current Sensing

7

NCL30100

Once the external MOSFET is switched on, the inductor

current starts to flow through the sense resistor R

current creates a voltage drop V

on the resistor RCS, which

CS

CS

. The

is negative with respect to GND. Since the comparator

connected to CS pin requires a positive voltage, a voltage

V

is developed across the resistor R

shift

source which level−shifts the negative voltage V

by a current

shift

CS

. The

level−shift current is in the range from 12.5 to 50 mA

depending on the optional input voltage compensation loop

control block signal (see more details in the input voltage

compensation section). The peak inductor current is equal

to:

I

@ R

* V

Ipk+

R

shift

CS

To achieve the best Ipk precision, higher values of I

CS

th

(eq. 1)

CS

should be used. The Equation 1 shows the higher drop on

R

reduces the influence of the Vth tolerance. Vth is the

CS

comparator threshold which is nominally 38 mV.

A typical CS pin voltage waveform for continuous

condition mode is shown in Figure 16.

V

I

shift = 50 mA

From Input Voltage

Compensation Block

VOffset

VOffset to VDD

CT

CT

50 mA

To Latch’s Set Input

To Latch’s Output

GND

Figure 17. OFF Time Control

During the switch−on time, the CT capacitor is kept

discharged by an internal switch. As soon as the latch output

changes to a low state, the I

across C

threshold given by the V

starts to ramp−up until its value reaches the

T

offset

is enabled and the voltage

source

. The current injected into IVC

can change this threshold. The IVC operation will be

discussed in the next section.

shift = 12.5 mA

I

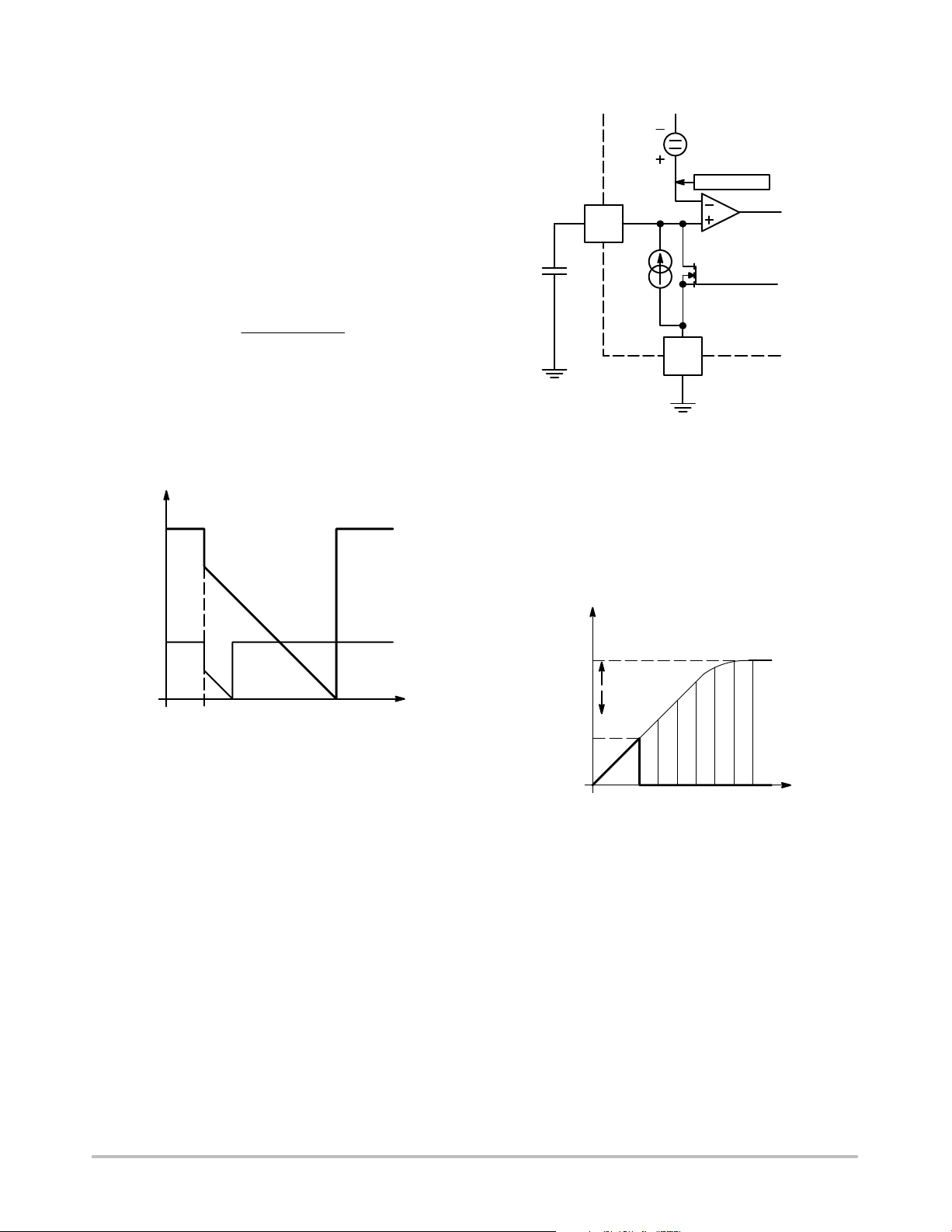

0

Switch

Turn on

t

Figure 16. CS Pin Voltage

Figure 16 also shows the effect of the inductor current

based on the range of control possible via the IVC input.

OFF Time Control

The internal current source, together with an external

capacitor, controls the switch−off time. In addition, the

optional IVC control signal can modulate the off time based

on input line voltage conditions. This block is illustrated in

Figure 17.

V

VDD

Goes Up

I

CT pin

Voltage

Voffset

VC

Goes Down

I

VC

I3

I2

t

off−min

I1

t

0

Figure 18. CT Pin Voltage

The voltage that can be observed on CT pin is shown in

Figure 18. The bold line shows the minimum IVC current

when the off time is at its minimum. The amount of current

injected into the IVC input can increase the off time by

changing the turn off comparator switching threshold. I1, I2,

http://onsemi.com

8

NCL30100

and I3 represent different delays depending on the

magnitude of IVC.

V

CC

Gate Driver

The Gate Driver consists of a CMOS buffer designed to

directly drive a power MOSFET. It features unbalanced

source and sink capabilities to optimize switch on and off

performance without additional external components. The

power MOSFET is switched off at high drain current, to

minimize its switch off losses the sink capability of the gate

driver is increased for a faster switch off. On the other hand,

the source capability of the driver is reduced to slow−down

the power MOSFET at switch on in order to reduce EMI

generation. Whenever the IC supply voltage is lower than

the under voltage threshold, the Gate Driver is low, pulling

down the gate to ground thus eliminating the need for an

external resistor.

Input Voltage Compensation:

The Input Voltage Compensation block gives the user

optional flexibility to sense the input voltage and modify the

current sense threshold and off time. This function provides

a feed forward mechanism that can be used when the input

voltage of the controller is loosely regulated to improve

output current regulation. If the input voltage is well

regulated, the IVC input can also be used to adjust the offset

of the off time comparator and the current sense control to

achieve the best current regulation accuracy.

An external resistor connected between IVC and the input

supply results in a current being injected into this pin which

has an internal 17 kW resistor connected to a current mirror.

This current information is used to modify V

By changing V

the off time comparator threshold is

offset

offset

and ICS.

modified and the off time is increased. A small capacitor

should be connected between the IVC pin and ground to

filter out noise generated during switching period. Figure 19

shows the simplified internal schematic:

Current

Mirror

1:1

25 kW

VOffset

To OFF

Time

Comparator

mA

17 kW

IVC

Current

Mirror

1:1

Figure 19. Input Voltage Compensation, OFF Time

Control

V

VDD

Voltage

Voffset

OFF Time Comparator Input

0

IVC Pin Sink Current

Figure 20. IVC Loop Transfer Characteristic

The transfer characteristic (output voltage to input

current) of the input voltage compensation loop control

block can be seen in Figure 20. V

refers to the internal

DD

stabilized supply. If no IVC current is injected, the off time

comparator is set to V

offset

.

The value of the current injected into IVC also change Ics.

This is accomplished by changing the voltage drop on R

shift

The corresponding block diagram of the IVC pin can be seen

in Figure 21.

.

To Current Sense Comparator

17 kW

IVC

Current

Mirror

4:3

Figure 21. Input Voltage Compensation Loop – Current Sense Control

http://onsemi.com

9

37.5 mA

CS

12.5 mA

Loading...

Loading...