ON ESD11N5.0ST5G Schematic [ru]

ESD11N5.0ST5G

Transient Voltage

Suppressors

Micro−Packaged Diodes for ESD Protection

The ESD11N is designed to protect voltage sensitive components

that require ultra−low capacitance from ESD and transient voltage

events. Excellent clamping capability, low capacitance, low leakage,

and fast response time, make these parts ideal for ESD protection on

designs where board space is at a premium. Because of its low

capacitance, it is suited for use in high frequency designs such as USB

2.0 high speed and antenna line applications.

http://onsemi.com

Specification Features

• Low Capacitance 0.6 pF

• Low Clamping Voltage

• Small Body Outline Dimensions: 0.60 mm x 0.30 mm

• Low Body Height: 0.3 mm

• Stand−off Voltage: 5.0 V

• Low Leakage

• Response Time is < 1 ns

• IEC61000−4−2 Level 4 ESD Protection

• These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

Mechanical Characteristics

MOUNTING POSITION:

QUALIFIED MAX REFLOW TEMPERATURE: 260°C

Device Meets MSL 1 Requirements

MAXIMUM RATINGS

Rating Symbol Value Unit

IEC 61000−4−2 (ESD) Contact

Total Power Dissipation on FR−5 Board

(Note 1) @ T

Thermal Resistance, Junction−to−Ambient

Junction and Storage Temperature Range TJ, T

Lead Solder Temperature − Maximum

(10 Second Duration)

Stresses exceeding Maximum Ratings may damage the device. Maximum

Ratings are stress ratings only. Functional operation above the Recommended

Operating Conditions is not implied. Extended exposure to stresses above the

Recommended Operating Conditions may affect device reliability.

1. FR−5 = 1.0 x 0.75 x 0.62 in.

= 25°C

A

Any

Air

°PD°

R

q

T

JA

−40 to +125 °C

stg

L

±8.0

±15

250

400

260 °C

mW

°C/W

kV

MARKING

DIAGRAM

PIN 1

DSN2

CASE 152AA

XXXX = Specific Device Code

YYY = Year Code

ORDERING INFORMATION

Device Package Shipping

ESD11N5.0ST5G DSN2

(Pb−Free)

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

XXXX

YYY

†

5000/Tape & Reel

See Application Note AND8308/D for further description of survivability specs.

© Semiconductor Components Industries, LLC, 2010

October, 2010 − Rev. 4

1 Publication Order Number:

ESD11N5.0S/D

ESD11N5.0ST5G

ELECTRICAL CHARACTERISTICS

(TA = 25°C unless otherwise noted)

Symbol

V

I

PP

V

RWM

I

V

I

Maximum Reverse Peak Pulse Current

Clamping Voltage @ I

C

Working Peak Reverse Voltage

Maximum Reverse Leakage Current @ V

R

Breakdown Voltage @ I

BR

Test Current

T

*See Application Note AND8308/D for detailed explanations of

Parameter

PP

RWM

T

BR

V

RWM

VCV

Bi−Directional TVS

I

I

PP

I

T

I

R

I

V

RWM

V

R

I

T

I

PP

BR

V

V

C

datasheet parameters.

ELECTRICAL CHARACTERISTICS (T

Device

Device

Marking

= 25°C unless otherwise noted)

A

V

RWM

(V)

I

R

@ V

(mA)

RWM

VBR (V) @ I

(Note 2)

T

I

T

C (pF)

Max Max Min mA Typ Max

VC (V) @

= 1 A

I

PP

Max

(Note 3)

V

C

Per IEC61000−4−2

(Note 4)

ESD11N5.0ST5G N5S0 5.0 1.0 5.8 1.0 0.6 0.9 12 Figures 1 and 2

See Below

2. VBR is measured with a pulse test current IT at an ambient temperature of 25°C.

3. Surge current waveforms per Figure 5.

4. For test procedure see Figures 3 and 4 and Application Note AND8307/D.

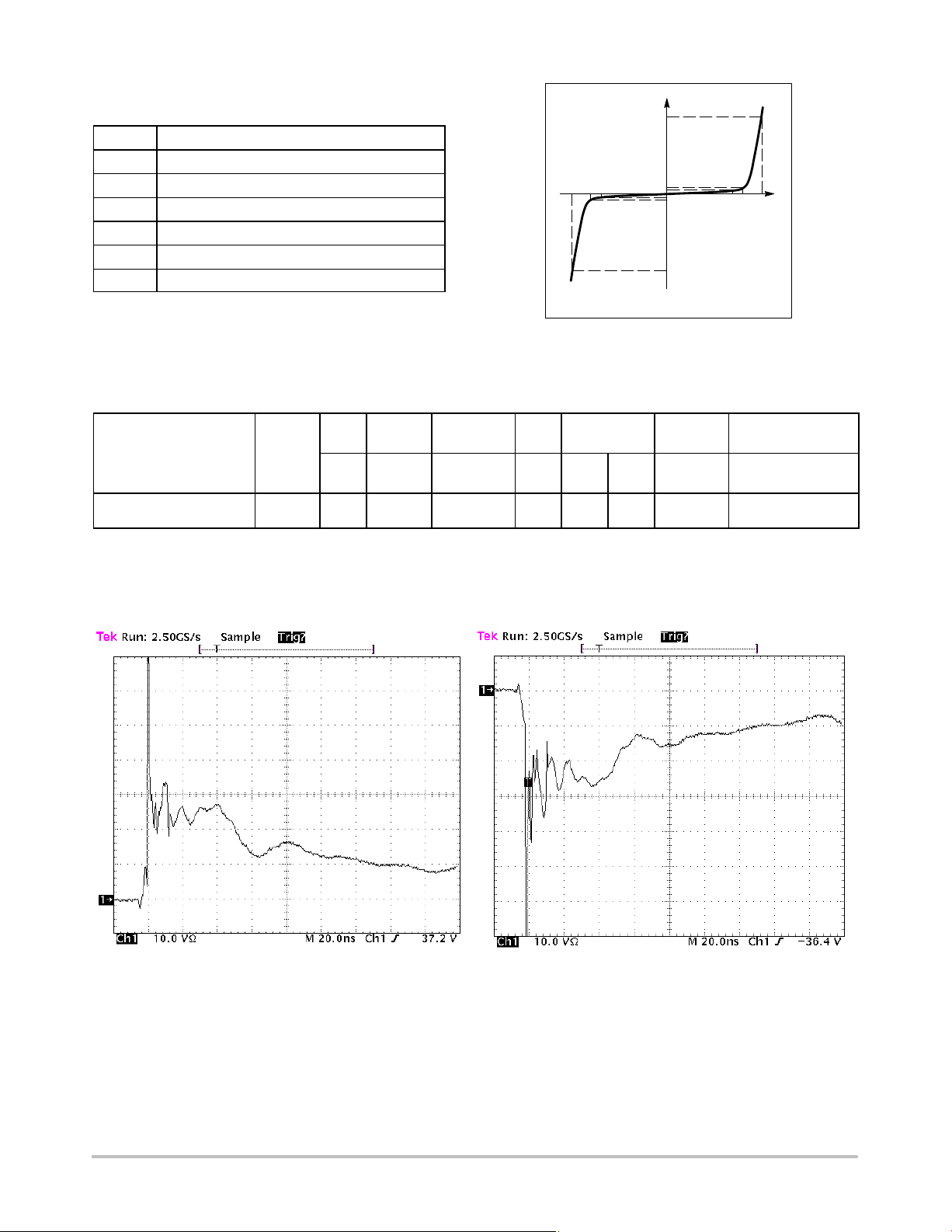

Figure 1. ESD Clamping Voltage Screenshot

Positive 8 kV Contact per IEC61000−4−2

http://onsemi.com

Figure 2. ESD Clamping Voltage Screenshot

Negative 8 kV Contact per IEC61000−4−2

2

ESD11N5.0ST5G

IEC 61000−4−2 Spec.

Test

Voltage

Level

1 2 7.5 4 2

2 4 15 8 4

3 6 22.5 12 6

4 8 30 16 8

(kV)

ESD Gun

First Peak

Current

(A)

Current at

30 ns (A)

TVS

50 W

Cable

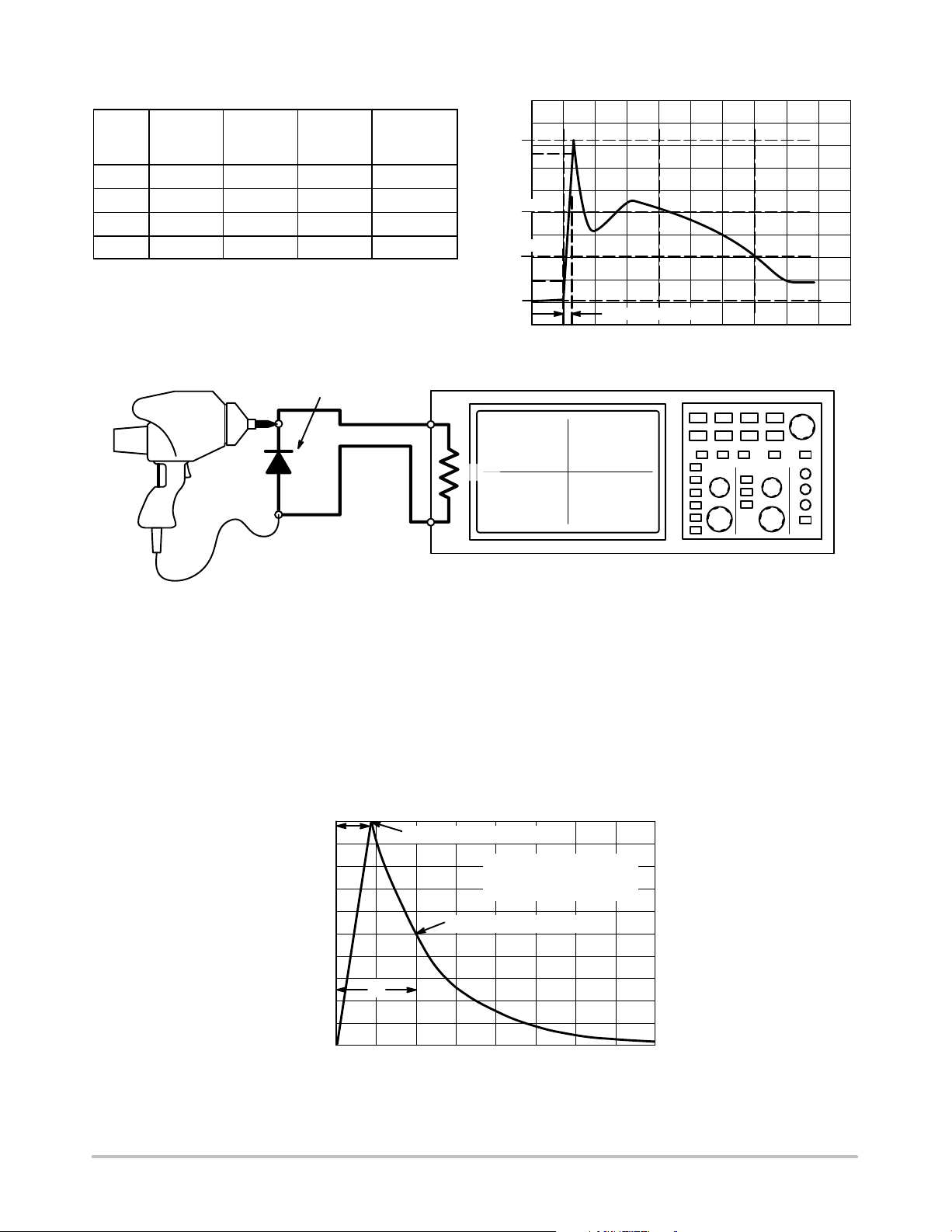

IEC61000−4−2 Waveform

I

peak

Current at

60 ns (A)

100%

90%

I @ 30 ns

I @ 60 ns

10%

Figure 3. IEC61000−4−2 Spec

Oscilloscope

50 W

tP = 0.7 ns to 1 ns

Figure 4. Diagram of ESD Test Setup

The following is taken from Application Note

AND8308/D − Interpretation of Datasheet Parameters

for ESD Devices.

ESD Voltage Clamping

For sensitive circuit elements it is important to limit the

voltage that an IC will be exposed to during an ESD event

to as low a voltage as possible. The ESD clamping voltage

is the voltage drop across the ESD protection diode during

an ESD event per the IEC61000−4−2 waveform. Since the

IEC61000−4−2 was written as a pass/fail spec for larger

100

t

r

90

80

70

60

50

40

30

20

% OF PEAK PULSE CURRENT

10

0

020406080

PEAK VALUE I

t

P

Figure 5. 8 X 20 ms Pulse Waveform

systems such as cell phones or laptop computers it is not

clearly defined in the spec how to specify a clamping voltage

at the device level. ON Semiconductor has developed a way

to examine the entire voltage waveform across the ESD

protection diode over the time domain of an ESD pulse in the

form of an oscilloscope screenshot, which can be found on

the datasheets for all ESD protection diodes. For more

information on how ON Semiconductor creates these

screenshots and how to interpret them please refer to

AND8307/D.

@ 8 ms

RSM

PULSE WIDTH (tP) IS DEFINED

AS THAT POINT WHERE THE

PEAK CURRENT DECAY = 8 ms

HALF VALUE I

t, TIME (ms)

/2 @ 20 ms

RSM

http://onsemi.com

3

Loading...

Loading...