Installation and operating instructions

Electrically height-adjustable

sit/stand work desks

System: 9029 FreeStand

with SMART motor control

(E-components 9901 + 9902)

Table of contents

1 Preface ............................................................................................................................................................ 4

1.1 Use as intended ............................................................................................................................................. 4

1.2 Target group and previous knowledge ........................................................................................................ 4

1.3 Symbols used in the safety instructions ...................................................................................................... 5

1.4 Safety Instructions ....................................................................................................................................... 5

1.4.1 General safety instructions .................................................................................................................... 5

1.4.2 Before installation, deinstallation or troubleshooting .............................................................................. 7

1.4.3 Before initial operation .......................................................................................................................... 7

1.4.4 During operation .................................................................................................................................... 7

1.4.5 Important information for resellers ........................................................................................................ 7

1.4.6 Indication service note .......................................................................................................................... 8

1.5 Repairs ........................................................................................................................................................ 9

2 Warranty .......................................................................................................................................................... 9

3 Maintenance / Cleaning ................................................................................................................................... 9

4 Assembly ....................................................................................................................................................... 10

4.1 Installing the actuators .............................................................................................................................. 10

4.2 Assembly of the worktop support and cross-beams ................................................................................. 11

4.3 Assembly of the desktop ........................................................................................................................... 11

4.4 Assembly of the controller and hand-switch .............................................................................................. 11

4.5 Commissioning .......................................................................................................................................... 12

4.5.1 Connections to the SMART motor controller ...................................................................................... 12

4.5.2 Procedure during commissioning ........................................................................................................ 13

4.5.3 Connect the drives .............................................................................................................................. 13

4.5.4 Connect the hand-switch ..................................................................................................................... 14

4.5.5 Connect the power supply cable /mains cable .................................................................................... 14

4.6 Assembly of optional accessories ............................................................................................................. 14

5 Initialisation / Reset ....................................................................................................................................... 14

6 Control ................................................................................................................................................................ 15

6.1 Normal operation ....................................................................................................................................... 15

6.2 Operation with 9901 1810 hand-switch with display (optional) ................................................................. 16

Change the height display unit (S5 menu) .................................................................................................... 16

Calibrate the height display ........................................................................................................................... 16

6.3 Operation with 9901 19xx hand-switch with display and memory (optional) ............................................ 16

How to save a position: ................................................................................................................................. 17

How to retrieve a saved position: .................................................................................................................. 17

Change the height display unit (S5 menu) .................................................................................................... 17

Calibrate the height display ........................................................................................................................... 17

6.3.1 9901 1910 Hand-switch with display and memory (optional) ............................................................. 18

6.3.2 9901 1970 Hand-switch with display and memory (optional) ............................................................. 19

6.3.3 9901 1970 Hand-switch with display and memory (optional) ............................................................. 20

2

7 Troubleshooting ............................................................................................................................................. 21

8 Error messages in the hand-switch display (optional) ................................................................................... 22

9 Click codes of the controller .......................................................................................................................... 23

10 Technical data ............................................................................................................................................... 24

11 Tests and certificates ..................................................................................................................................... 25

12 Address ......................................................................................................................................................... 26

3

1 Preface

Dear customer,

We are pleased that you have decided to purchase our product. These instructions explain how to assemble,

use and maintain the sit/stand desk. All sit/stand desks are put through a thorough quality inspection before

leaving our factory. If you ever have any problems with our desk base, feel free to contact our service

department any time.

It is important to follow these instructions when assembling the desk base. Any changes on the desk base or an

improper usage can have an effect on the safety, functioning and service life!

These operating instructions are intended for all sit/stand desks from the 9029 FreeStand system with the

SMART motor controller but, due to different versions/types, can deviate from the illustrations.

Oelschläger Metalltechnik GmbH

1.1 Use as intended

This sit/stand desk may be used solely as an office desk in the professional sector. Changes to the desk base

are prohibited. This sit/stand desk must be assembled, put into operation and functionally checked by skilled

personnel. The use of this sit/stand desk for any purpose other than the purpose stated above is only

permissible with the consent of Oelschläger Metalltechnik.

The basic function of the desk is the electromotive height adjustment of the desktop. This function can be

performed with all hand-switches that are available from us.

1.2 Target group and previous knowledge

These operating instructions are aimed at the following group of persons:

• The commissioning staff that assembles and commissions the sit/stand desks.

• Furniture installers, maintenance staff who commission the sit/stand desk in sales rooms or at the final

customer.

The following knowledge is required to commission, assemble the FreeStand sit/stand desk:

• Mechanical and electrical basic knowledge (corresponding illustration)

• Reading the instructions

4

1.3 Symbols used in the safety instructions

Danger: These safety instructions point out an imminent danger for the life and health of persons!

Non-compliance with these warnings can result in danger to life, life-threatening injuries and

property damage.

Attention: These safety instructions point out possible dangers from electrical current!

Non-compliance with these warnings can result in injuries and property damage!

Note: These safety instructions point out important information which you must follow for the safe

operation of the FreeStand sit/stand desk.

Danger: These safety instructions point out a possible danger of crushing which exists in

exceptional cases.

Non-compliance with these warnings can result in danger to life, life-threatening injuries and

property damage.

Note: Note on the obligation to read the operating instructions!

Note: Pull the power cord before going to the next step!

1.4 Safety Instructions

These operating instructions contain safety instructions which inform you about potential hazards and thus

facilitate the safe operation of the FreeStand sit/stand desk. Please be sure you comply with these safety

instructions!

This section provides you with general safety information that does not refer to any specific work step. You can

find the job-specific safety instructions in the respective section of the operating instructions. You will find

additional safety instructions on the individual parts of the FreeStand sit/stand desk.

1.4.1 General safety instructions

Note: Before assembly/commissioning, of the FreeStand sit/stand desk, you must read and comply

with the operating instructions!

Attention: Never open the SMART motor controller under any circumstances! There is a danger of

electric shock.

Attention: The FreeStand sit/stand desk is not designed for continuous duty. The desktop height

must not be adjusted without interruption for a time period longer than the operating time stated on

the rating plate.

Attention: The SMART motor controller must only be operated with the mains voltage specified on

the rating plate!

5

Before commissioning, make sure the mains voltage on the rating plate of the motor controller

matches your mains voltage!

Danger: This unit can be used by children aged 8 years and above and by persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge when they are

supervised or instructed on the safe use of the device and understand the resulting risks.

Danger: Do not let children play with the device!

Danger: Cleaning and user maintenance must not be carried out by unsupervised children.

Attention: You must use the supplied power supply cable! Make sure that the power supply cable

is not damaged. Operating the FreeStand sit/stand desk with a damaged power supply cable is

prohibited!

Attention: You must disconnect the power supply cable from the mains supply before switching

drives, hand-switches or any other accessories on the motor controller on or off.

Attention: Use solely original FreeStand accessories from Oelschläger Metalltechnik. Use of

components and parts from third parties is prohibited!

Use of unsuitable accessories can lead to damage or the destruction of the desk base.

Attention: In case of a fault (e.g. accidental operation of the desktop such as if a button on the

hand-switch jams), please immediately pull the mains plug!

Danger: Protect the desk base and, in particular, all electrical components on the desk base from

moisture, dripping water and spray water!

Danger: There is a danger of being crushed when the desktop position is changed! For that

reason, make sure no objects and no persons are in the hazardous area and do not reach into the

hazardous area.

The optionally available corrosion protection normally detects solid objects, but there is still

continued danger of crushing for persons! The corrosion protection is a system safeguard and NOT

personal protection!

Attention: Alterations on the components of the desk base including the motor controller and

controls are prohibited!

Danger: The electromotive driven FreeStand sit/stand desk must not be operated in explosive

atmospheres!

Danger: In case of faults it is possible that the desktop moves a bit during every start-up attempt

before the safety shut-down initiates. During this process, always watch out for the possible danger

of being crushed.

6

Danger: The optionally available corrosion protection is not activated during any reset process

(Section 5). During this process, always watch out for the possible danger of being crushed.

Attention: If the product is visibly damaged, never assembly it or continue to use it!

1.4.2 Before installation, deinstallation or troubleshooting

• Stop the sit/stand desk.

Note: Switch off the power supply and pull out the power cable!

• Remove all weights from the sit/stand desk.

• Only trained electricians are permitted to open or replace electrical equipment.

• Do not operate the desk in moist rooms such as bathrooms.

• Never use the desk in explosive environments.

1.4.3 Before initial operation

• Make sure the desk is assembled in accordance with these instructions.

• Check to see if the operating voltage of the desk matches the local power supply.

(See rating plate on the controller, standard = 230V)

• Connect the plug connectors from the actuator and the side panels to the controller.

• Connect the mains cable to the controller.

1.4.4 During operation

• If the drives or the controller make any unusual noises or cause any unusual odours during operation,

interrupt the power supply.

• Make sure that the cables are not damaged.

• When operating the sit/stand desk, make sure that no objects or body parts can get trapped.

• All moving parts of the desk base must have at least 25 mm clearance to the adjoining components.

1.4.5 Important information for resellers

We consider resellers companies that purchase the FreeStand sit/stand desk from Oelschläger Metalltechnik

and that resell it as their own product after adding a table surface.

Note: For reasons of EU conformity and product safety, we recommend that the users provide their

products with operating instructions in the respective official EU language.

7

Note: Be sure to enclose operating instructions in your finished product that include all safety

instructions required by the consumer for the safe handling of your product.

Note: The operating instructions for your finished product must include the following warning: You

must read these operating instructions before you start using the product (height-adjustable

workstation).

Point out to your consumer that the operating instructions must be kept near the product (heightadjustable workstation).

Danger: It is mandatory that you put your product (height-adjustable workstation) through a risk

analysis so that you can react to any possible residual hazards (e.g. through structural measures or

warnings in the operating instructions and/or safety instructions on your product).

Note: Make sure that no unauthorised persons (small children, persons under the influence of

medication, etc.) handle your product or the FreeStand sit/stand desk.

1.4.6 Indication service note

Danger: Use solely genuine original accessories! Only skilled personnel are permitted to perform

assembly work! Otherwise you will forfeit all claims for warranty or guarantee.

Danger: In case of a fault, please promptly contact your customer service representative! Only

original FreeStand sit/stand desk spare parts are approved for repairs. Only skilled/authorised

personnel are permitted to replace them! Otherwise you will forfeit all claims for warranty or

guarantee.

8

1.5 Repairs

In case of a technical defect on this device, please contact an authorised customer service representative. You

can find solutions for simple faults in Section 7!

Attention: In the interest of preventing malfunctions, only authorised service personnel are

permitted to make any repairs.

Attention: Opening any components of this desk base produces risks for the following

malfunctions.

2 Warranty

We provide a 24-month warranty on this desk base. The warranty covers all material and production errors and

applies from the date of production (see rating plate). The warranty is only valid under the condition that the

desk base has been properly and professionally assembled and has been used within the scope of the

described parameters; that maintenance has been performed correctly and that repairs have been performed

solely by authorised service staff.

The sit/stand desk must not be improperly handled or used and no changes are permitted to be made on the

desk base; otherwise the warranty expires. Please refer to our General Terms and Conditions for additional

information.

3 Maintenance / Cleaning

Regularly remove dust and dirt from the desk base, in particular from the guide tubes, and make sure that there

are no damages and cracks.

Check all fastening screws to make sure they are securely fastened and check all plug connectors, cables and

plugs including proper functioning.

Danger: Clean the controller, actuator and the desk base only with a dry or slightly moist cloth.

Danger to life!

Attention: Aggressive cleaning agents can cause damage or discolourations on the product. Use

only agents with pH-values of 6-8.

Danger: Never let any fluids get into the system (controller, actuator, cable and base). Danger to

life!

9

Run

Installation

4 Assembly

Use only screws that correspond to the enclosed base drawing for the assembly of your desk base.

Attention: Incorrect screws can cause damage to the desk.

Danger: The power cable of the motor controller must be disconnected during assembly of the

desk base!

Attention: Before assembly and commissioning of the FreeStand sit/stand desk, make sure the

product is acclimatised for the temperature and relative humidity values stated in the technical

data!

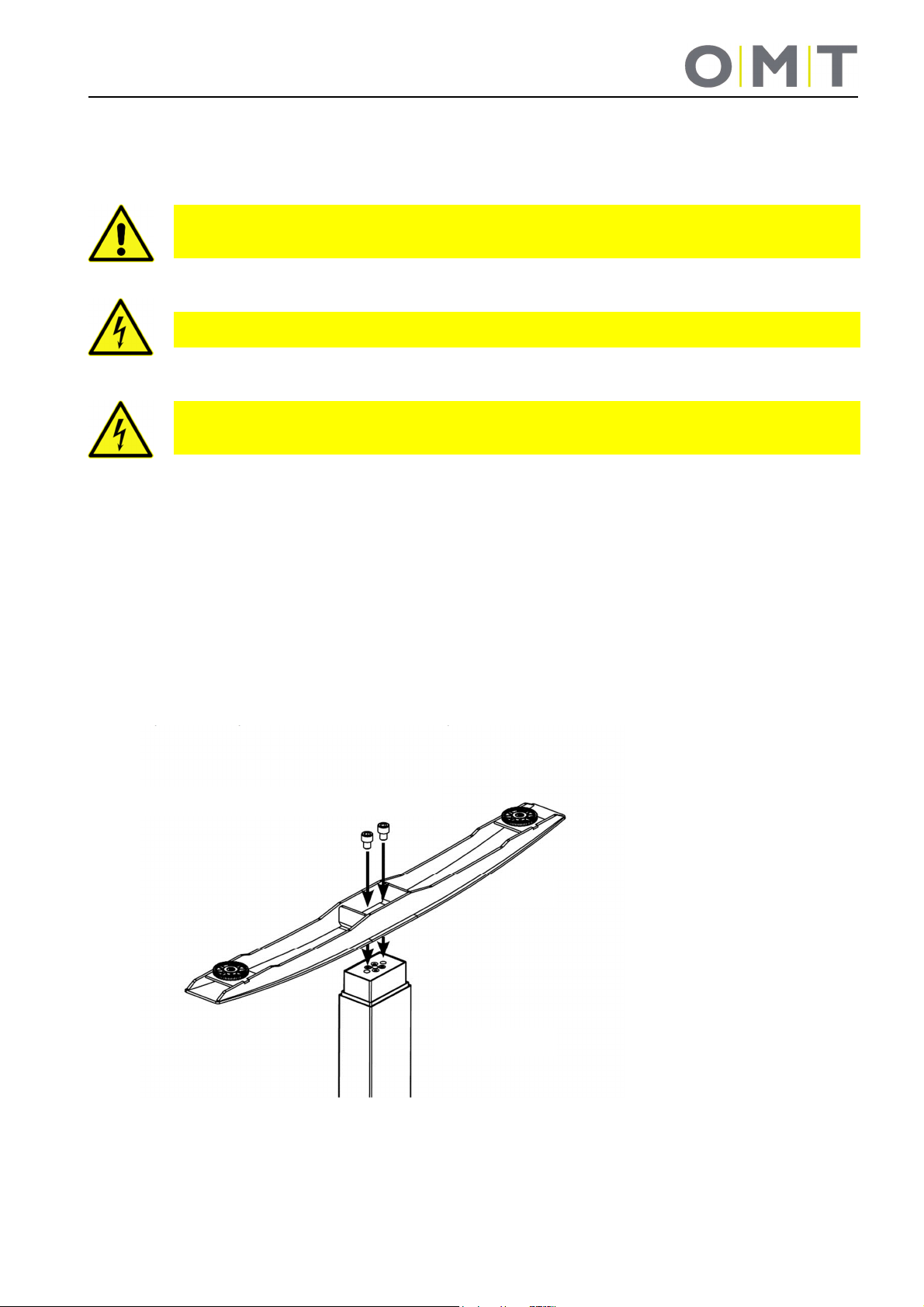

4.1 Installing the actuators

For side elements with permanently welded actuators, proceed with Point 4.2.

Side elements with bolted actuators must be installed first on the assembly columns. Use the bolts in the

desk base drawing.

The max. tightening torque is 10 Nm!

The max. depth of engagement of the M10 bolts is 9 mm!

If you have asymmetric actuators (C-shape) you will need a left-hand and a right-hand side element.

M10 bolts as per base drawing

10

4.2 Assembly of the worktop support and cross-beams

Now assemble the two cross-beams and the support elements on both side elements. To do that, use

solely the M8 bolts as per the base drawing! The max. tightening torque for these bolts is 20 Nm.

From the inside, screw

two bolts into the crosshead threads.

4x M8 bolt

From the outside, screw two

bolts into the bracket threads

of the support elements.

Note: Experience has shown that it is better to first loosely preassemble the bolts for the crossbeams and then tighten them in the described sequence.

4.3 Assembly of the desktop

If a CPU holder

should be

integrated into the

system, then please

connect both

interior bolts to the

cross-heads via the

column's head

plate.

Now fasten the desktop to the desk base in accordance with the base drawing. To accomplish that, 6.5

mm holes are provided on the desk frame; they are suitable for ø5.5 to ø6.0 mm bolts. Use all provided

bolting points.

*1)

4.4 Assembly of the controller and hand-switch

Now attach the controller and the hand-switch to the desktop. ø5.4 mm are provided on the controller

and ø4.5 mm holes are provide on the hand-switch for that purpose. For the controller, use bolts with a

11

raised or cylindrical head. The tightening torque depends on the desktop material, but should not exceed

*1)

2 Nm.

*1)

The screws are not included in the scope of delivery since they have to be selected depending on the

material and the thickness of the desktop.

4.5 Commissioning

Commissioning includes all jobs that are necessary for electrical height adjustment of the FreeStand

sit/stand desk with the aid of the SMART motor controller. The prerequisites for commissioning are:

• The desk base has been completely assembled as per 4.1 – 4.3

• The SMART motor controller and the hand-switch are assembled (as explained in Section 4.4)

Danger: Only expert/authorised personnel are allowed to commission the motor controller!

Expert/Authorised personnel have completed the required electrotechnical apprenticeship and are

familiar with these operating instructions.

Attention: Before assembly and commissioning of the FreeStand sit/stand desk, make sure the

product is acclimatised for the temperature and relative humidity values stated in the technical

data!

4.5.1 Connections to the SMART motor controller

12

4.5.2 Procedure during commissioning

Attention: Plug in the power supply cable/mains cable only after all other electrical connections

have been made! (All motors, the hand-switch and possibly additional accessories are connected

to the controller.)

To commission the FreeStand sit/stand desk, proceed as follows:

4.5.3 Connect the drives

Make sure that the connection cables of the drives reach from both sides up to the corresponding

controller connection. For extremely long desks, it might be necessary to assemble the controller offcentre. For especially large desks, if necessary use an extension cable for the connection cable of the

drives.

Connect the drives of the side panels and the controller using the motor cable. The plug connectors on

the 8-pin motor sockets must firmly latch! For controllers with more connections for drives than the

number of drives available, you must start by connecting the (M1) connection. If, for example, only a

drive is connected to the motor controller, the M2 connection remains open.

Note: When inserting the motor cable, the sequence of M1, M2 must be maintained!

13

4.5.4 Connect the hand-switch

Connect the hand-switch to the 7-pin hand-switch socket (HS)

of the controller.

Note: You can choose from a large number of hand-switches that fit the SMART motor controller!

Please ask Oelschläger Metalltechnik for information on the available types!

4.5.5 Connect the power supply cable /mains cable

Attention: Before you plug in the power supply cable, check again

• to see if the mains voltage matches the rating plate of your controller.

• to see if all components are plugged into the correct sockets.

The SMART motor controller is ready for operation as soon as the power supply cable is plugged

in!

Note: Initialisation of the desk base is required the first time the power supply cable is connected

(RESET). This is described in Section 5.

Attention: Use only the supplied mains cable! It is mandatory to provide the SMART motor

controller with a 3-pin mains cable with protective earth.

Attention: Fasten all cables to the desk base or the desktop so they cannot get damaged during

operation.

4.6 Assembly of optional accessories

If you have also ordered an optional cable tray, plug it onto both cross-beams as the last step. Do not

let any cable get jammed in. Route the mains cable left or right out of the cable tray on the side element.

On certain desk versions, assembly of the cable tray is only possible in the upper position of the desk

base. To do that, you must first initialise the desk base!

5 Initialisation / Reset

After assembling or if the desk has been disconnected from the power supply for a long time, malfunctions on

the desk are possible. The same applies if the connection between the drives and the controller was separated.

In these cases, the desk controller has to be initialised.

If the controller expects a reinitialisation, the downward movement of the desk is only possible at reduced

speed. For hand-switch versions with a display, this is indicated in addition by the “Reset LED”. It turns off as

soon as initialisation has been successfully concluded.

14

To initialise, move the desk to the bottom position; to do that, press the down key on the hand-switch until all

drives have reached the lowest position. Press the down key once again and keep it pressed (approx. 5

seconds) until the desk moves slightly down and then back up. Let go of the button only after the desk stops

moving. If you let go of the button too soon, that causes a malfunction on the desk. If this happens by mistake,

you have to repeat the process.

Attention: The top limit stop of the controller is preset. For this reason, use only controllers that

were supplied as suitable for the respective desk base.

Danger: The optionally available corrosion protection is not activated during any reset process.

During this process, always watch out for the possible danger of being crushed.

6 Control

6.1 Normal operation

Use the "up" and "down" buttons to move the desk up or down in the direction of the arrow. The desk stops

when it reaches the limit positions. Keep the button pressed until the desired position has been reached.

9901 1900 Hand-switch 9901 1800 Hand-switch (optional)

9901 1950 Hand-switch (BASIC), optional

(with all hand-switch variants)

9901 1960 Hand-switch (BASIC), optional Milling picture for installation of the hand-switch in a

desktop

15

6.2 Operation with 9901 1810 hand-switch with display (optional)

This hand-switch is additionally equipped with a display for indication of the current desk height in centimetres

or inches.

The reset LED indicates that initialisation is required (see initialisation section). It stays illuminated until the

initialisation is concluded.

The info LED indicates that the controller has detected a fault. Simultaneously the display shows the “Exx” error

code instead of the current desk height. To repair the error, see the troubleshooting section.

If you stop pressing the hand-switch after a while, the display turns off if no important operating condition is

being displayed. As soon as you press a button, the display switches back on.

Change the height display unit (S5 menu)

The height display of the hand-switch can be shown in either centimetres or inches. Use the S5 menu to convert

the unit. If the display was set to centimetres, after menu selection the height will be shown in inches; if inches

were previously displayed, you can revert to the centimetre display.

To change the unit proceed as below:

1. Press the menu button (approx. 3-5 sec.) until the display shows “S x”.

(x stands for a number; if “S 5” is being displayed, continue with 3.)

2. Press the UP or DOWN button until the display shows “S 5”.

3. Press the S-button. The display is now reset to the previous setting from centimetres to inches or from

inches to centimetres.

To exit the menu, wait about 10 seconds until the height display reappears.

Calibrate the height display

If the displayed height does not match the actual height you can correct the display as below:

1. Press the S-button and let it go again.

2. Press the DOWN button until the height display starts flashing. (approx. 5 sec.)

3. Measure the desk height and enter the measured value (depending on the setting, in centimetres or inches)

using the UP or DOWN button. Confirm the input by briefly pressing the S-button.

To exit the menu, wait about 10 seconds until the height display reappears.

6.3 Operation with 9901 19xx hand-switch with display and memory (optional)

All hand-switches with display and memory always have the same mode of functioning; possible differences are

described in the section on the individual hand-switch.

16

The display shows the current desk height in centimetres or inches and on top of that it shows the operating

condition of the controller along with any detected problems with the error code “Exx”. You can find a list of all

possible error codes in the troubleshooting section.

If you stop pressing the hand-switch after a while, the display turns off if no important operating condition is

being displayed. As soon as you press a button, the display switches back on.

The “Up” and “Down” buttons plus the “Move desk up” and “Move desk down” buttons move the desk as

described in 6.1.

Note: If the hand-switch type on the motor controller is replaced, this has to be done in an

unpowered state (pull the mains plug beforehand). Only then will the new type be correctly

detected by the motor controller.

How to save a position:

Move the desk to the desired height with the “Up” or “Down” buttons.

Press the “S” button (“S” appears in the display) and then one of the position buttons 1 to 2 or 4 (you can see,

e.g. “S 1” in the display). The controller confirms the storage procedure with a double-click sound and after

approx. 2 seconds the current desk height is shown in the display. This way you can save 2 or 4 different

positions.

How to retrieve a saved position:

Keep the desired memory setting pressed (1, 2, 3 or 4). The desk independently moves from the current

position to the saved position. The button has to be pressed until the position is reached; if you let go

beforehand, the desk stops moving.

Change the height display unit (S5 menu)

The height display of the hand-switch can be shown in either centimetres or inches. Use the S5 menu to convert

the unit. If the display was set to centimetres, after menu selection the height will be shown in inches; if inches

were previously displayed, you can revert to the centimetre display.

To change the unit proceed as below:

1. Simultaneously press the buttons “1”, “2” and “UP” (approx. 3-5 sec.) until the display shows “S x”. (x stands

for a number; if “S 5” is being displayed, continue with 3.)

2. Press the UP or DOWN button until the display shows “S 5”.

3. Press the S-button. The display is now reset to the previous setting from centimetres to inches or from

inches to centimetres.

To exit the menu, wait about 10 seconds until the height display reappears.

Calibrate the height display

If the displayed height does not match the actual height,

you can correct the display as below:

1. Press the S-button and let it go again.

2. Press the DOWN button until the height display starts flashing. (approx. 5 sec.)

3. Measure the desk height and enter the measured value (depending on the setting, in centimetres or inches)

using the UP or DOWN button. Confirm the input by briefly pressing the S-button.

17

To exit the menu, wait about 10 seconds until the height display reappears.

6.3.1 9901 1910 Hand-switch with display and memory (optional)

This hand-switch is equipped with a display to indicate the current desk height in centimetres or inches. In

addition, it is possible to save 4 “Memory” positions (desk heights).

The reset LED indicates that initialisation is required (see initialisation section). It stays illuminated until the

initialisation is concluded.

The info LED indicates that the controller has detected a fault. Simultaneously the display shows the “Exx” error

code instead of the current desk height. To repair the error, see the troubleshooting section.

The LED’s “Container, Flex, Ergotrainer and Pin” are reserved for optional functions and are not used in

standard systems.

The Up (2) and Down (2) buttons work like the up and down buttons in the standard version

18

6.3.2 9901 1970 Hand-switch with display and memory (optional)

with TOUCH functioning for undertable assembly

This hand-switch has a drawer push function and is equipped with a display to indicate the current desk height

in centimetres or inches. In addition, it is possible to save 4 “Memory” positions (desk heights). A button lock is

integrated to protect against accidental operation.

Note: Use all 4 provided screws with a cylinder, round or flat head with a max. head diameter

of 10 mm and a max. thread diameter of 5 mm for the assembly of this hand-switch.

Note: For the assembly, use all provided attachment points. Do NOT overtighten the

assembly screws. The hole clearances must match the assembly holes. Otherwise the housing

could distort and lead to malfunctions of the push function. The correct tightening torque depends

on the type of screw being used and on the desktop material.

Activating and deactivating the display/button lock

The button in the display indicates an activated button lock.

You can activate and deactivate the button lock by swiping left or right under the display.

Note: The swiping direction is irrelevant.

Note: Make sure you only swipe lightly over the display without pressing any buttons!

19

Note: The display must be active (e.g. show the current height) when you activate/deactivate

the button lock. Briefly press a button, e.g. the UP button, to activate the display if applicable.

6.3.3 9901 1970 Hand-switch with display and memory (optional)

with TOUCH function for installation in the desktop

This hand-switch is for installation in a desktop from the top and is equipped with a display to indicate the

current desk height in centimetres or inches. In addition, it is possible to save 2 “Memory” positions (desk

heights). A button lock is integrated to protect against accidental operation.

Milling picture for installation of the hand-switch in a desktop

Activating and deactivating the display/button lock

The button in the display indicates an activated button lock.

You can activate and deactivate the button lock by swiping left or right

under the display.

20

Note: The swiping direction is irrelevant.

Note: Make sure you only swipe lightly over the display without pressing any buttons!

Note: The display must be active (e.g. show the current height) when you activate/deactivate

the button lock. Briefly press a button, e.g. the UP button, to activate the display if applicable.

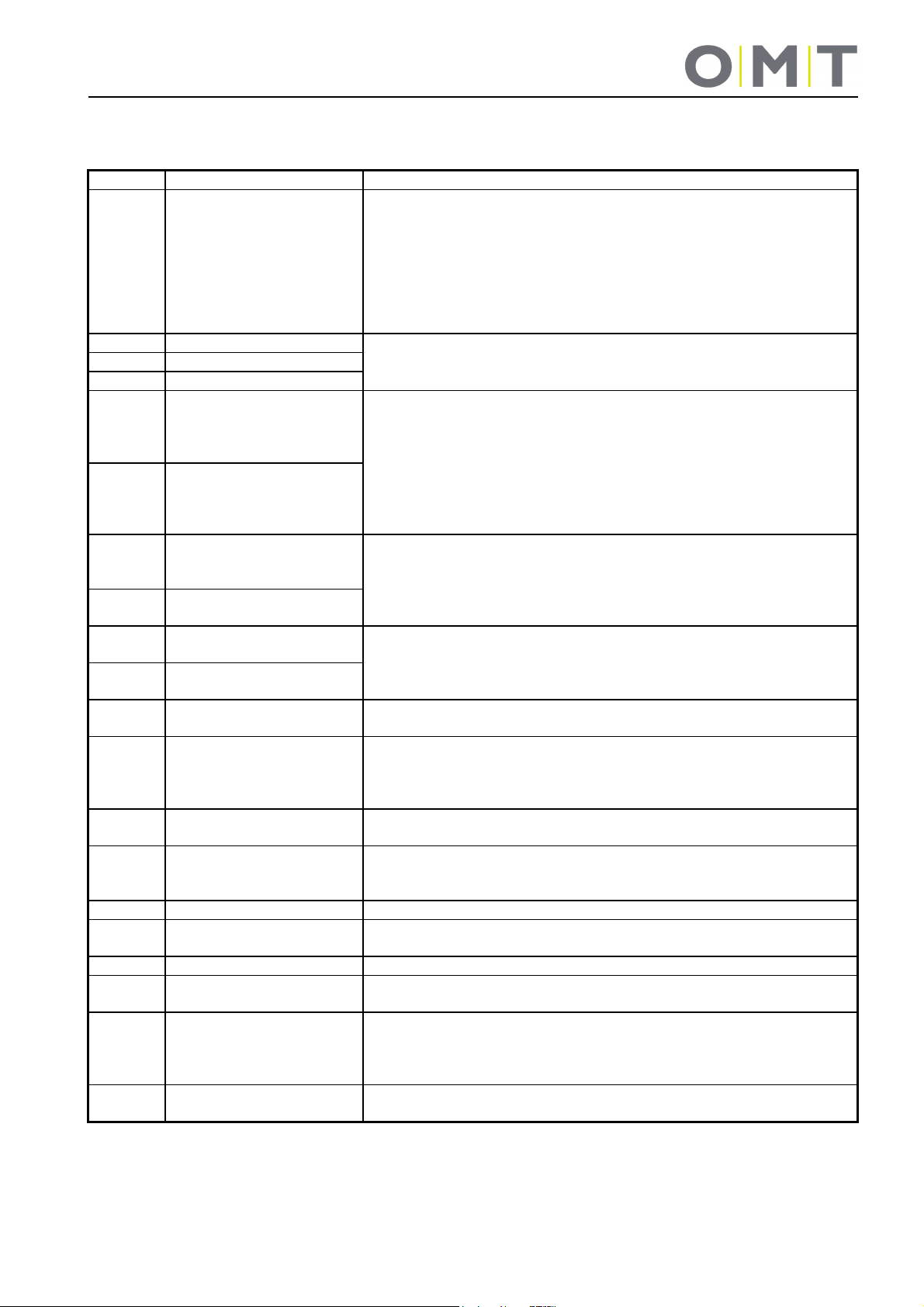

7 Troubleshooting

Fault Cause Repair

Desk does not move No power supply Plug in mains cable; if applicable, check the plug connector

on the controller

Desk only lowers

slowly

Desk only moves

slowly

Desk only moves

briefly on one side

and then remains

stationary

No connection or loose

connection to the

drives/side panels

No connection to the

hand-switch

Max. lifting force

exceeded

Max. operating time

exceeded

Drive defective Please contact Customer Service

Controller defective Please contact Customer Service

Actuator defective Replace actuator

Controller expects a

reinitialisation

Max. lifting force

exceeded

No connection or loose

connection to the

drives/side panels

Drive defective Please contact Customer Service

Check, if applicable fix plug connector connection from the

motor cable to the controller and the drives.

Check, plug-in plug connector to the controller

Reduce weight

The controller will independently reactivate after approx. 3

minutes

ATTENTION!

The max. travel time of 2 minutes is only available after an

idle time of at least 18 minutes.

See page 11

Reduce weight

Check, if applicable fix plug connector connection from the

motor cable to the controller and the drives.

21

8 Error messages in the hand-switch display (optional)

Display Cause Repair

HOT The controller monitors

the operating time (timecontrolled) and its max.

temperature value was

exceeded.

E00 M1 – Internal error Pull the mains plug!

E01 M2 – Internal error

E02 M3 – Internal error

E12 M1 – Defective

E13 M2 – Defective

E24

E25 M2 – Overcurrent

E36 M1 – Not connected The motor is not connected

E37 M2 – Not connected

M1 – Overcurrent

Wait until the controller has cooled off and the “HOT” display has

disappeared. The desk is then operational again.

ATTENTION!

The operating time is calculated only as long as the mains voltage is

applied. If the controller is disconnected from the mains, the most

recent value in the controller is saved!

and contact the your customer service representative!

Pull the mains plug!

Repair the external short-circuit, check the cable to the monitors for

possible damages

or

Plug in the involved socket of the correct motor.

Put the controller back into operation.

Collision? -> if applicable, repair

Max. load exceeded -> take the load off the desk.

If the error persists, please contact customer service.

Check the cable/plug connection to the motors and do a reset

E48 Overcurrent

Motor group 1

E55 Motor group 1 –

Synchronisation lost

E60 Collision detected Optional ISP and sensor function

E61 Motor replaced Connection to the motor was interrupted or a new motor was

E62 Overcurrent Controller – total overcurrent, overload

E63 External sensor or cable

not connected

E64 Authentication error Reinitialise desk (RESET)

E65 Overcurrent or

short-circuit

E67 Overvoltage Pull the mains plug!

E70 Change the

drive configuration

(Motor = Drive in the installation column or in the side panel)

Collision? -> if applicable, repair

Max. load exceeded -> take the load off the desk.

Motor positions too different

If applicable, reduce the load on the desk

Reinitialise the desk (RESET)

Remove cause

connected

Reinitialise desk (RESET)

External crushing protection strip or special add-on module not

connected; if applicable check plug connector

If error occurs during drive.

Collision? Load too heavy?

and contact the your customer service representative!

Mains or power pack fluctuations?

Pull the mains plug and wait at least 5 seconds. Then reinitialise the

desk (RESET)

22

Normal operation:

Emergency mode:

Last shut

-

down incomplete / forced reset:

Display Cause Repair

E71 Sensor – configuration

changed

E81 Internal error Reinitialise desk (RESET)

Note: The PowerFail detection of the motor controller detects power failures and saves all

relevant data before the voltage drops below a critical level.

In a few exceptional cases, this saving process is not possible, and during the next controller startup, E81 is displayed and the controller clicks three times.

To repair this error, a manual reset is required (see Section 5).

Note: If there is a power failure during the height adjustment or if the mains cable is pulled, a

manual reset might be necessary.

If the error cannot be repaired as described above, pull the mains plug, wait for several minutes and try to

reinitialise the desk!

If the error continues to occur, unplug the desk from the mains and contact customer service.

This error list is suitable for firmware 1.9.14 and higher!

An (optionally) mounted sensor was removed or the connection has

been lost.

Comply with the separate instructions for the sensor!

Pull the power supply cable and reconnect after several seconds.

If the error occurs regularly, unplug the power supply cable and

contact customer service.

9 Click codes of the controller

As soon as the motor controller is supplied with power, the controller uses the integrated relay to acoustically

inform the user about the system status and the reason for the most recent shut-down.

Number

of clicks

2x When

1x

3x – 6x

When Status information

The system is functioning without problems

mains on

The system is running in emergency mode; the drives cannot be used. Check the

LED if applicable and/or the error code on the display of the hand-switch.

Check the LED if applicable and/or the error code on the display of the handswitch.

23

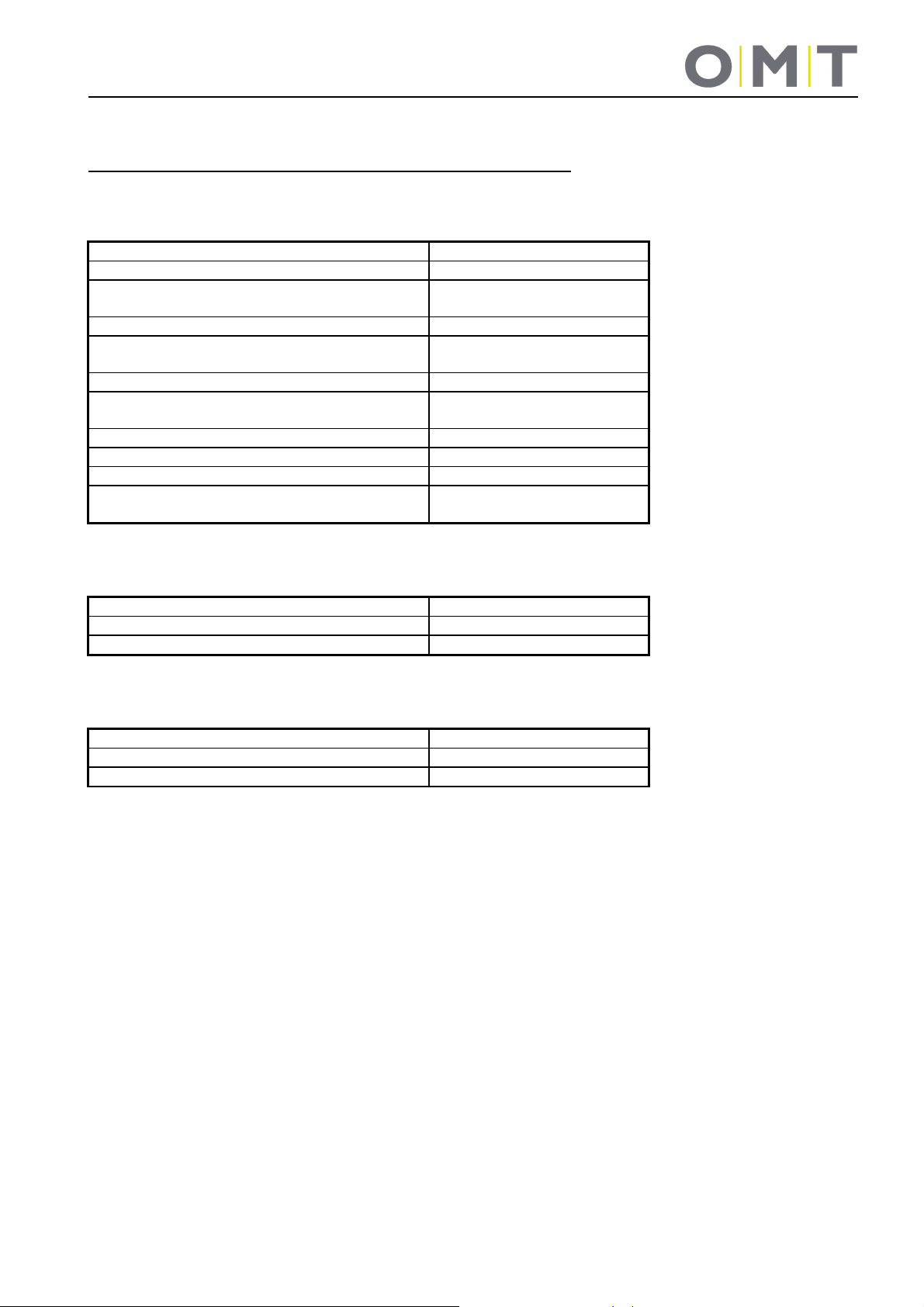

10 Technical data

System: 9029 FreeStand with SMART motor controller

General

Individual drive (installation column or side panel, support foot) with SMART-e-2

Desk base with 2 drives (installation column or side panels) with SMART-e-2

Operating voltage 207-253 V / 50-60 Hz

Nominal voltage 220-230 V / 50-60 Hz

Standby power at nominal voltage,

primary (typical)

Ambient temperature during operation 0-30°C

Permissible relative humidity

(for operation)

Storage and transport temperature -40°C to +85°C

Permissible relative humidity

(for storage)

Protection class I

IP Class IP 20

Max. operating time 10% (2 min. on / 18 min. off)

Nominal lift speed of the drive columns

(reduced under max. load)

Lifting capacity max. 600 N (≈ 60 kg)

Lift length depending on version See drawing

Current consumption max., primary 216 W

Lifting capacity max. 750 N (≈ 75 kg)

Lift length depending on version See drawing

Current consumption max., primary 216 W

≤0.3 W

5-85% (non-condensing)

5-90% (non-condensing)

38 mm/s

24

3089061

11 Tests and certificates

The drive system has been tested in accordance with the following standards:

Electromagnetic compatibility (EMC Standard 2004/108/EEC)

EN 61000-6-2:2005 Electromagnetic compatibility (EMC)

EN 61000-6-3:2007 Electromagnetic compatibility (EMC)

EN 61000-3-2:2006 Electromagnetic compatibility (EMC)

EN 61000-3-3:2008 Electromagnetic compatibility (EMC)

Low Voltage Directive (Low Voltage Directive 2006/95/EC)

EN 62233:2008 Measurement methods for electromagnetic fields of household appliances and similar

apparatus with regard to human exposure

EN 60335-1:2012 Household and similar electrical appliances

Internal and similar uses

Safety-related parts of control systems

EN ISO 13849-1:2008 Safety of Machinery

Safety-related parts of control systems

Performance Level „b“

25

12 Address

Oelschläger Metalltechnik GmbH

Hertzstraße 1-3

27318 Hoya - Germany

Tel.: +49 (0) 4251 - 816 - 0

Fax: +49 (0) 4251 - 816 - 81

E-mail: info@oelschlaeger.de

Internet: www.oelschlaeger.de

Company Headquarters: Hoya

District Court – HRB 31030

Managing Director: Andreas Spreen

9029_Bedienungsanleitung_SMART_E9901_Rev1.doc - Version: 07/07/2015 - MR

26

Loading...

Loading...