Omron ZX2-LDA41, ZX2-LD100L, ZX2-LD50V, ZX2-XC1R, ZX2-XC4R User Manual

...

Smart Sensors

Laser Displacement Sensors CMOS Type

ZX2 Series

User’s Manual

Cat. No. Z310-E1-08

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

CONTENTS

Introduction

Meanings of Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Meanings of Alert Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Precautions for Safe Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Precautions for Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PREPARATION FOR MEASUREMENT

Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Basic Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Amplifier Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Calculating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing Sensor Heads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the Amplifier Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting Calculating Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting the Sensor Head to the Amplifier Unit . . . . . . . . . . . . . . . . . . . . . . . 28

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring Input/Output Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

I/O Circuit Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

FLOW OF OPERATION

FLOW OF OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

2

BASIC SETUP

BASIC SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Display of RUN Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Simplest Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

MAIN APPLICATIONS & SETTING METHODS

Height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Steps and Warpage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Double Sheet Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

ZX2 User’s Manual

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Eccentricity and Surface Deflection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

DETAILED SETTINGS

Smart Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Selecting the Initial Sub-Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Connecting Two or More Amplifier Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Mutual Interference Prevention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Setting the Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Setting the Hold Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Bank Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Zero Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Analog Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Output for Non-measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Setting the Differential Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

External Input for Bank, Timing Input, Reset Input. . . . . . . . . . . . . . . . . . 118

Setting the Detection Surface Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Key Lock Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Initializing Settings Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

TROUBLESHOOTING

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Q&A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

SPECIFICATIONS

Specifications and Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Amplifier Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Sensor Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Sensor Head Extension Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Calculating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Engineering Data (Reference Value). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Angle Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Linearity Characteristic for Different Materials. . . . . . . . . . . . . . . . . . . . . . . . . . 149

Beam Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Reference: Distance between two diffuse-reflective models that causes malfunc-

tion when mutual interference prevention is turned off . . . . . . . . . . . . . . . . . . . 151

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

SETTING TRANSITION CHARTS . . . . . . . . . . . . . . 158

ZX2 User’s Manual

INDEX

SETTING

TRANSITION

CHARTS

3

Introduction

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Thank you for purchasing the ZX2 Series Smart Sensor. This manual provides

information regarding functions, performance and operating methods that are required for

using the sensor.

When using the ZX2 Smart Sensor, make sure to observe the following:

• The ZX2 Smart Sensor must be operated by personnel knowledgeable in electrical

engineering.

• To ensure correct use, please read this manual thoroughly to deepen your

understanding of the product.

• Please keep this manual in a safe place so that it can be referred to whenever

necessary.

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

4

ZX2 User’s Manual

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and

workmanship for a period of twelve months from the date of sale by Omron (or such other

period expressed in writing by Omron). Omron disclaims all other warranties, express or

implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

ABOUT NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OF THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT

ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE

REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or

expenses based on infringement by the Products or otherwise of any intellectual property

right.

Buyer Remedy

Omron's sole obligation hereunder shall be, at Omron's election, to (i) replace (in the form

originally shipped with Buyer responsible for labor charges for removal or replacement

thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or

credit Buyer an amount equal to the purchase price of the non-complying Product;

provided that in no event shall Omron be responsible for warranty, repair, indemnity or

any other claims or expenses regarding the Products unless Omron's analysis confirms

that the Products were properly handled, stored, installed and maintained and not subject

to contamination, abuse, misuse or inappropriate modification. Return of any Products by

Buyer must be approved in writing by Omron before shipment. Omron Companies shall

not be liable for the suitability or unsuitability or the results from the use of Products in

combination with any electrical or electronic components, circuits, system assemblies or

any other materials or substances or environments. Any advice, recommendations or

information given orally or in writing, are not to be construed as an amendment or addition

to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published

information.

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

ZX2 User’s Manual

SETTING

TRANSITION

CHARTS

5

Limitation on Liability; Etc

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY,

NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the

Product on which liability is asserted.

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or

regulations which apply to the combination of the Product in the Buyer's application or

use of the Product. At Buyer's request, Omron will provide applicable third party

certification documents identifying ratings and limitations of use which apply to the

Product. This information by itself is not sufficient for a complete determination of the

suitability of the Product in combination with the end product, machine, system, or other

application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer's application, product or system. Buyer shall

take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO

LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS

BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S)

IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

6

Programmable Products

Omron Companies shall not be responsible for the user's programming of a

programmable Product, or any consequence thereof.

ZX2 User’s Manual

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as

a guide for the user in determining suitability and does not constitute a warranty. It may

represent the result of Omron's test conditions, and the user must correlate it to actual

application requirements. Actual performance is subject to the Omron's Warranty and

Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on

improvements and other reasons. It is our practice to change part numbers when

published ratings or features are changed, or when significant construction changes are

made. However, some specifications of the Product may be changed without any notice.

When in doubt, special part numbers may be assigned to fix or establish key

specifications for your application. Please consult with your Omron's representative at

any time to confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be

accurate; however, no responsibility is assumed for clerical, typographical or proofreading

errors or omissions.

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

ZX2 User’s Manual

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

7

CONTENTS

Meanings of Signal Words

The following signal words are used in this manual.

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

Indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury, or may result in

serious injury or death. Additionally there may be significant

property damage.

Meanings of Alert Symbols

The following alert symbols are used in this manual.

Indicates the possibility of laser radiation.

Indicates prohibition when there is a risk of minor injury from electrical

shock or other source if the product is disassembled.

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

8

ZX2 User’s Manual

Laser Safety

Sensor Head

ZX2-LD50L, LD50, LD100L, LD100: Class 2

CONTENTS

INTRODUCTION

Never look into the laser beam.

Doing so continuously will result in visual impairment.

Do not disassemble the product.

Doing so may cause the laser beam to leak, resulting in the danger of

visual impairment.

Sensor Head

ZX2-LD50V: Class 1

Do not disassemble the product.

Doing so may cause the laser beam to leak, resulting in the danger of

visual impairment.

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

ZX2 User’s Manual

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

9

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

In Europe, diffuse-reflective models in the ZX2 Series are categorized as Class 2 laser

products and the regular-reflective model is classified as a Class 1 laser product

according to EN60825-1 (see note).

The CE markings on the products also reflect these categorizations.

In the U.S.A., diffuse-reflective models in the ZX2 Series are categorized as Class II laser

products, and the regular-reflective model is classified as a Class I laser product

according to IEC60825-1 criteria, in accordance with the stipulations of the FDA standard

Laser Notice No. 50 (see note).

This product has already been registered with the CDRH (Center for Devices and

Radiological Health). (Accession Number: 1020665)

Place the laser warning label and the FDA label on the sensor.

The ZX2 Series is meant to be built into final system equipment. Pay special attention to

the following precautions for the safe use of the product:

Note: Europe: Class 1 and Class 2 of EN 60825-1: 1994 +A11:1996 +A2:2001

= IEC 60825-1:1993 +A1:1997 +A2:2001

U.S.A.: Class I and Class II of FDA (21 CFR1040.10)

(1) ZX2-LD emits visual laser beam. Do not stare directly into the laser.

Make sure that the laser beam path is terminated. If specular objects are present in

the laser beam path, make sure that they are prevented from reflecting the laser

beam.

When used without an enclosure, make sure the laser path from eye level is avoided.

(2) To avoid exposure to hazardous laser radiation, do not displace nor remove the

protective housing during operation, maintenance, and any other servicing.

(3) As for countries other than those of Europe and the U.S.A., observe the regulations

and standards specified by each country.

(4) Label Indications

The EN and FDA labels are supplied with the product.

Replace the current labels with them according to the instructions given in the

manuals.

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

10

ZX2 User’s Manual

Precautions for Safe Use

Please observe the following precautions for safe use of the products.

Installation Environment

• Do not use the product in environments where it can be exposed to inflammable/

explosive gas.

• Do not install the product close to high-voltage devices and power devices in order

to secure the safety of operation and maintenance.

Power Supply and Wiring

• The supply voltage must be within the rated range (DC12 to 24 V±10%).

• Reverse connection of power supply is not allowed. Connection to AC power supply

is also not allowed.

• Open-collector outputs should not be short-circuited.

• High-voltage lines and power lines must be wired separately from this product.

Wiring them together or placing in the same duct may cause induction, resulting in

malfunction or damage.

• Always turn off the power supply before connecting or disconnecting cables and

connectors.

Applicable standards

• EN61326-1

• Electromagnetic environment : Industrial electromagnetic environment

(EN/IEC 61326-1 Table 2)

• There may be cases that current output or voltage output fluctuate within 1%F.S

when a sensor is experienced electromagnetic interference under the condition of

the response time 30µs.

Others

• Do not attempt to dismantle, repair, or modify the product.

• Dispose of this product as industrial waste.

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

ZX2 User’s Manual

INDEX

SETTING

TRANSITION

CHARTS

11

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or

Please observe the following precautions to prevent failure to operate, malfunctions, or

undesirable effects on product performance.

undesirable effects on product performance.

Installation of the Product

Installation of the Product

Installation Site

Installation Site

Do not install the product in locations subjected to the following conditions:

Do not install the product in locations subjected to the following conditions:

• Ambient temperature outside the rating

• Ambient temperature outside the rating

• Rapid temperature fluctuations (causing condensation)

• Rapid temperature fluctuations (causing condensation)

• Relative humidity outside the range of 35 to 85%

• Relative humidity outside the range of 35 to 85%

• Presence of corrosive or flammable gases

• Presence of corrosive or flammable gases

• Presence of dust, salt, or iron particles

• Presence of dust, salt, or iron particles

• Direct vibration or shock

• Direct vibration or shock

• Reflective sensor of intense light (such as other laser beams or electric arc-welding

• Reflective sensor of intense light (such as other laser beams or electric arc-welding

machines)

machines)

• Direct sunlight or near heaters

• Direct sunlight or near heaters

• Water, oil, or chemical fumes or spray

• Water, oil, or chemical fumes or spray

• Strong magnetic or electric field

• Strong magnetic or electric field

Component Installation and Handling

Component Installation and Handling

Power Supply and Wiring

Power Supply and Wiring

• To extend the output cables of amplifier units, shielded cables of the same specifi-

• When using a commercially available switching regulator, make sure that the FG

cations as the output cables must be used.

terminal is grounded.

• When using a commercially available switching regulator, make sure that the FG

• If surge currents are present in the power lines, connect surge absorbers that suit

terminal is grounded.

the operating environment.

• If surge currents are present in the power lines, connect surge absorbers that suit

• When connecting two or more amplifier units by using calculating units, make sure

the operating environment.

that the linear GND lines of the amplifier units are connected to each other. Supply

• When using two or more amplifier units or calculating units, make sure that the lin-

power to all connected amplifier units at the same time.

ear GND line of the amplifier units are connected to each other.

• Before turning ON the power after the product is connected, make sure that the

• Before turning ON the power after the product is connected, make sure that the

power supply voltage is correct, there are no incorrect connections (e.g. load short-

power supply voltage is correct, there are no incorrect connections (e.g. load short-

circuit) and the load current is appropriate. Incorrect wiring may result in breakdown

circuit) and the load current is appropriate. Incorrect wiring may result in breakdown

of the product.

of the product.

• The ferrite core accessory must be attached to the sensor head cable before use.

• The cables must be 10 m or shorter in total length, for both sensor head and ampli-

(For how to attach the ferrite core, see pages 24 and 28.)

fier units. To extend the cable from the sensor head, an optional extension cable

• The cables must be 10 m or shorter in total length for amplifier units. For extension

(ZX2-XCR) must be used. For extension of the cable of amplifier units, shielded

of the cable of amplifier units, shielded cables of the same type must be used. To

cables of the same type must be used.

extend the cable from the sensor head, an optional extension cable (ZX2-XCR)

• When using calculating units, make sure that the linear GND lines of the amplifier

must be used. Only one extension cable can be used.

units are connected to each other.

• When using calculating units, make sure that the linear GND lines of the amplifier

units are connected to each other.

12

ZX2 User’s Manual

Warming Up

After turning ON the power supply, allow the product to stand for at least 10 minutes

before use. The circuits are still unstable just after the power supply is turned ON, so

measured values may fluctuate gradually.

A warmup of at least 10 minutes is also required after canceling LD-OFF input if LD-

OFF input is being used.

Sensing Object

The product cannot accurately measure the following types of objects: Transparent

objects, objects with an extremely low reflective sensor ratio, objects smaller than the

beam size, objects with a large curvature, excessively inclined objects, etc.

Mutual Interference

Inserting a calculating unit between amplifier units can prevent mutual interference

between two sensor heads.

Maintenance

• Always turn OFF the power supply before adjusting or connecting/disconnecting

the sensor head.

• Do not use thinner, benzene, acetone or kerosene to clean the sensor head and

amplifier units. If large dust particles adhere to the front filter of the sensor head,

use a blower brush (used to clean camera lenses) to blow them off. Do not blow the

dust away with your mouth. To remove smaller dust particles, use a soft cloth (for

lenses) with a small amount of alcohol. Take care not to wipe them off with exces-

sive force.

Scratches on the filter may cause errors.

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

ZX2 User’s Manual

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

13

How to Use This Manual

g

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

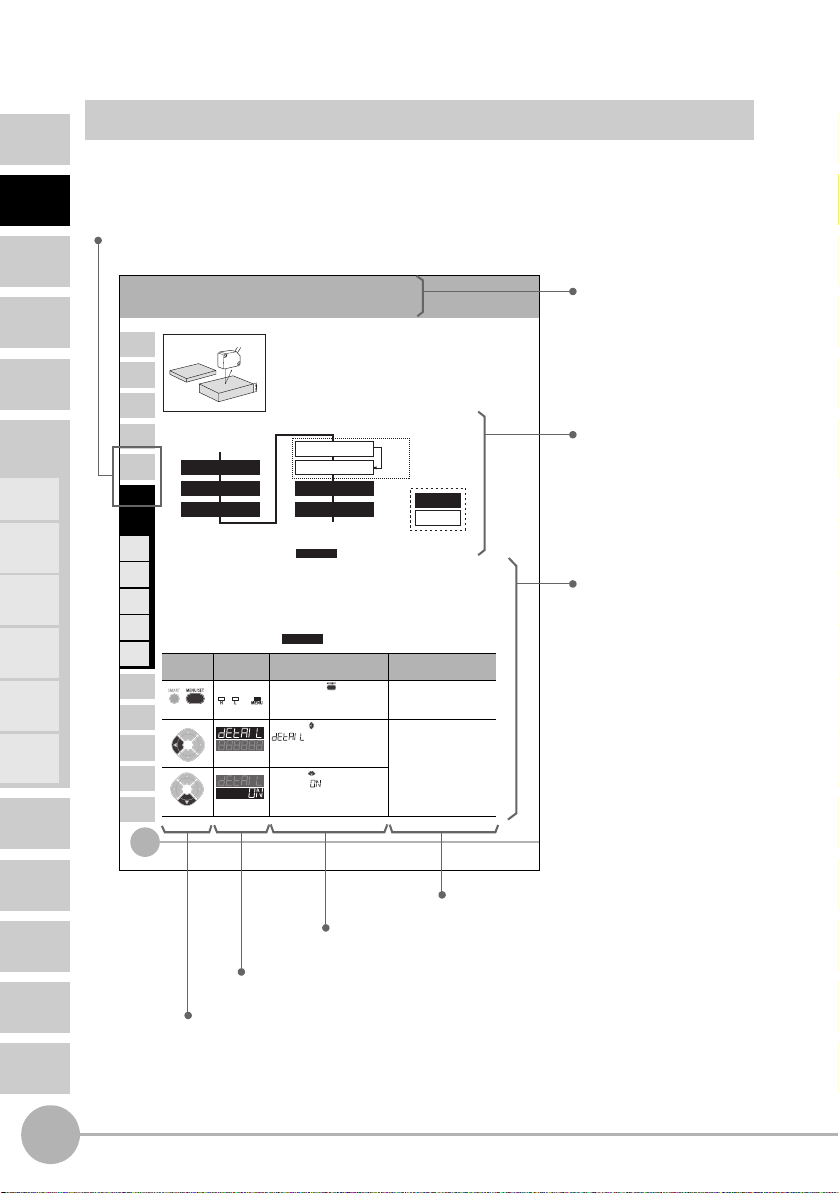

Page Format

This section explains the page format by using the Setting for MAIN APPLICATIONS AND

SETTING METHODS chapter as an example.

Index label

Shows the chapter and header titles with white characters.

Height

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

Procedure for setting up height

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

Sensor installation/wiring

1

Set to the MENU mode

2

Response time setting

3

4

1 Sensor installation/wiring

Has the Sensor been installed and wired? (See page 23.)

Set the reference workpiece in place, adjust the position of the Sensor Head while

looking at the digital display values on the Amplifier Unit or the indicators on the

Sensor Head so that the height to be measured is near the measurement center

distance, and install the Sensor Head at this position.

2 Set to the MENU mode

Button

Operation

Hold down for

3 seconds

Press to display.

Press to display.

42

Height

Hold

5

Trigger conditions

6

Threshold setting

7

8

Smart tuning

Display Description of Operation

Button Operation

Shows how to use the buttons.

Return to RUN mode

Settin

Required

Required

Hold down the button for

Lit

three seconds to switch to the

MENU mode.

Press the button to display .* This operation is not

Press the button to set the

display to to set display of

the detail menu.

Display

Shows what is displayed as a result of the operation.

Other than

OFF

completed

Select the desired mode to set

the measurement conditions in.

required when hold and

trigger conditions are not to

be set.

Description of Operation

Explains how to perform the operation by using buttons.

Required setting

Optional setting

Explanation of

Selection Menu

ZX2 User’s Manual

Explanation of Selection Menu

Provides a supplemental explanation of the selection menu.

Header

Indicates the measurement

contents.

Flow

Shows the flow of operation.

Operation procedure

Explains the operation

procedure.

14

ZX2 User’s Manual

Meanings of Symbols

Symbol Meaning

Important

(For details about xxx,

see page xx.)

Required

(white characters on a black

background)

Optional

(black characters on a white

background)

Press to display.

Menu name

Menu name

Press to select

Select the

desired value.

[Change numeric value]

[Move digit]

Press to set.

Set any value.

Indicates points that are important to achieve the full product

performance, such as operational precautions and application procedures.

Indicates pages where related information can be found.

Indicates a required setting in a setup procedure.

Indicates an optional setting in a setup procedure.

Indicates which button to press to display the menu shown in

the Display column.

Indicates that the user can select the menu that accords with

their usage conditions by pressing the relevant button.

Indicates that the user can specify a value that accords with

their usage conditions by pressing the relevant button.

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

ZX2 User’s Manual

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

15

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

MEMO

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

16

ZX2 User’s Manual

1

PREPARATION FOR

MEASUREMENT

Part Names and Functions 18

Installation 23

Wiring Diagram 30

PREPARATION FOR MEASUREMENT

Part Names and Functions

y

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

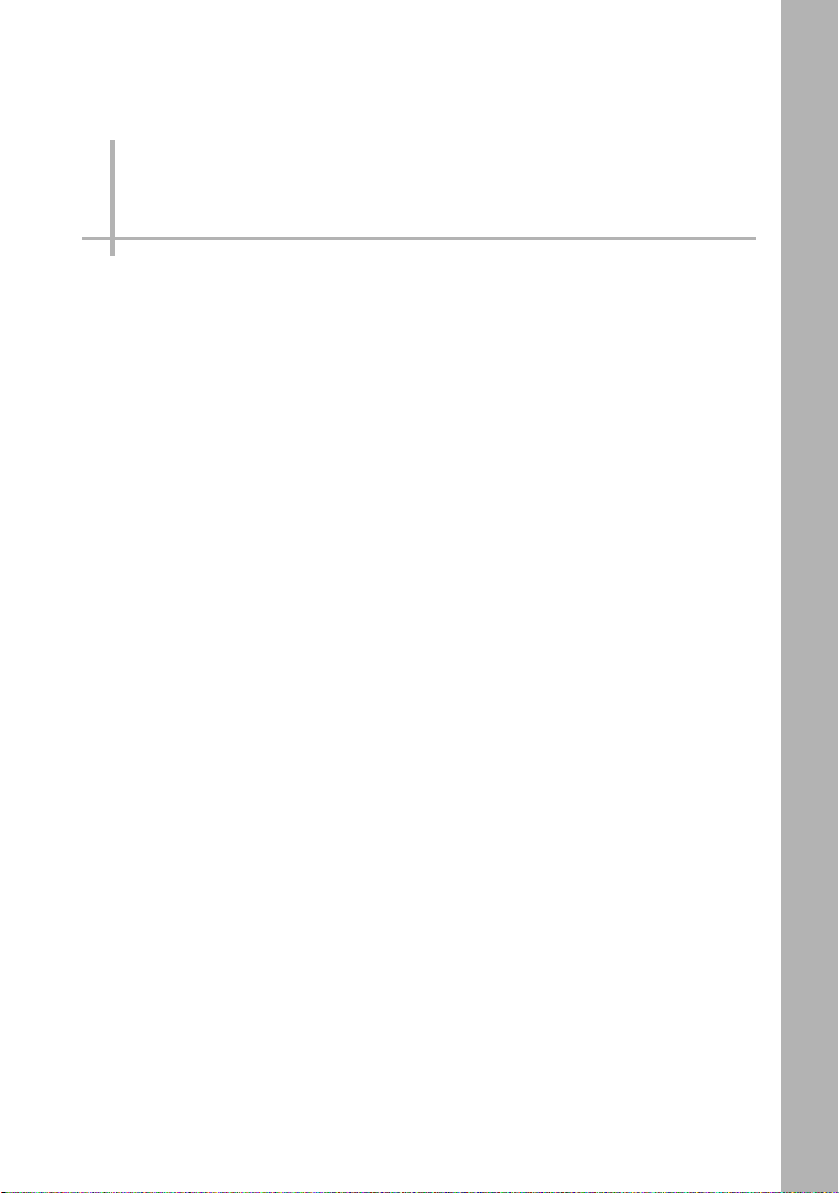

Basic Configuration

The basic configuration of the ZX2 series Smart Sensors is shown below.

(used for connecting two or more Amplifier Units)

(used for extending cable length)

Sensor Head

See the following pages for details:

Sensor Heads p. 22 p. 138

Amplifier Units p. 19 p. 136

Calculating Unit p. 22 p. 143

Extension Cables — p. 142

Calculating Unit

Extension Cable

*

* Only one extension cable can be used.

Amplifier Unit

Part Names and Functions Specifications and Dimensions

Power Suppl

(sold separately)

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

18

Part Names and Functions

ZX2 User’s Manual

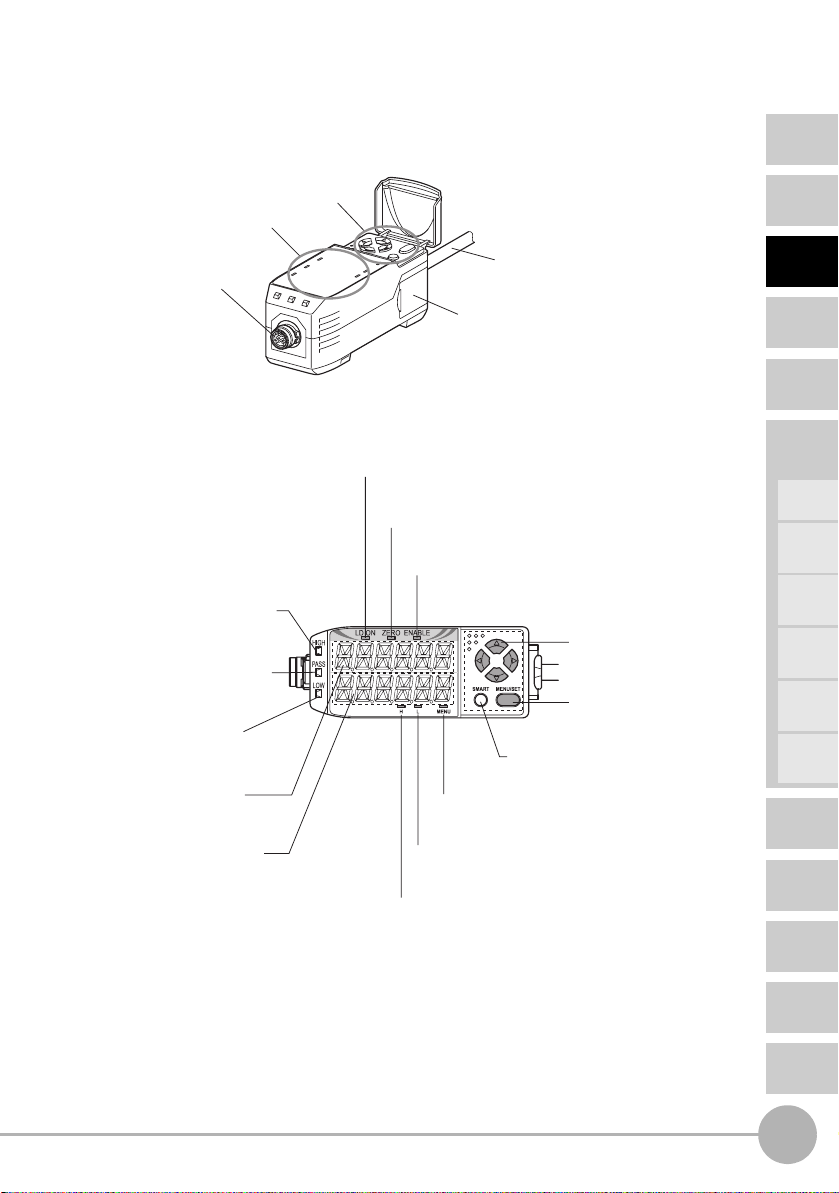

Amplifier Unit

CONTENTS

Operating Section (*)

Display section (*)

Sensor Head connector

This connector is for connecting

the Sensor Head.

(*) Operating and Display Sections

Laser ON indicator (green)

This indicator lights while the Sensor Head

is emitting a laser beam.

Zero reset indicator (green)

This indicator lights when the zero reset function is enabled.

HIGH indicator (orange)

This indicator lights when the

judgement result is HIGH.

PASS indicator (green)

This indicator lights when the

judgement result is PASS.

LOW indicator (orange)

This indicator lights when the

judgement result is LOW.

Main display (red)

This display shows measured

values and function names.

Sub-display (orange)

This display shows additional

information and function

settings for measurements.

HIGH threshold indicator (orange)

Output Cable

This cable is for connecting the power supply

and sync sensors or external devices.

Connector (two connectors, one on each side)

This connector is for connecting Calculating Units.

ENABLE indicator (green)

This indicator lights while the Sensor is ready for measurement. It goes out

when measurement is not possible (e.g. when the received light amount is

excessive or insufficient, when the measurement range is exceeded, or

when the Sensor Head is not connected when the power is turned ON).

Cursor buttons

These buttons are used for

switching the display and setting

measurement conditions.

MENU/SET button

This button is used for switching

the mode and finalizing settings.

Smart tuning button

This is used for setting optimum sensing

conditions according to the operating conditions.

MENU indicator (green)

This indicator lights in the MENU mode.

It goes out in the RUN mode.

LOW threshold indicator (orange)

This indicator lights when the LOW threshold is displayed

on the sub-display.

This indicator lights when the HIGH threshold is displayed

on the sub-display.

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

ZX2 User’s Manual

Part Names and Functions

INDEX

SETTING

TRANSITION

CHARTS

19

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Digital Displays

The information displayed on the main and sub-displays depends on the currently

selected mode. The default mode is the RUN mode.

When the power is turned ON, the model of Amplifier Unit (ZX2-LDA) will be displayed on

the main display and the channel number will be displayed on the sub-display.

Subsequently, the Sensor Head software version will be displayed on the main display

and the Amplifier Unit software version will be displayed on the sub-display.

These details are displayed for approximately five seconds, and then data for the RUN

mode will be displayed.

Mode Main display

(upper section, red)

RUN The measured value (the value

after the measurement conditions

have been reflected) is displayed.

For example, when the hold

function is set, the held value will

be displayed.

Default measured values are as

follows:

Measurement range

NEAR side FAR side

By pressing the button, the HIGH

threshold, LOW threshold, analog output

value, resolution (max. value of measured

value during one second - min. value), current

value (value before execution of zero reset,

hold, scaling and 2-sensor operation), and

BANK are displayed in this order.

Sub-display

(lower section, orange)

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

20

+ indication

Measurement center distance

MENU The function names are

displayed in order by pressing

- indication

0

The setting for the function displayed on the

main display is displayed.

the buttons.

(For details on setting transition charts, see page 158.)

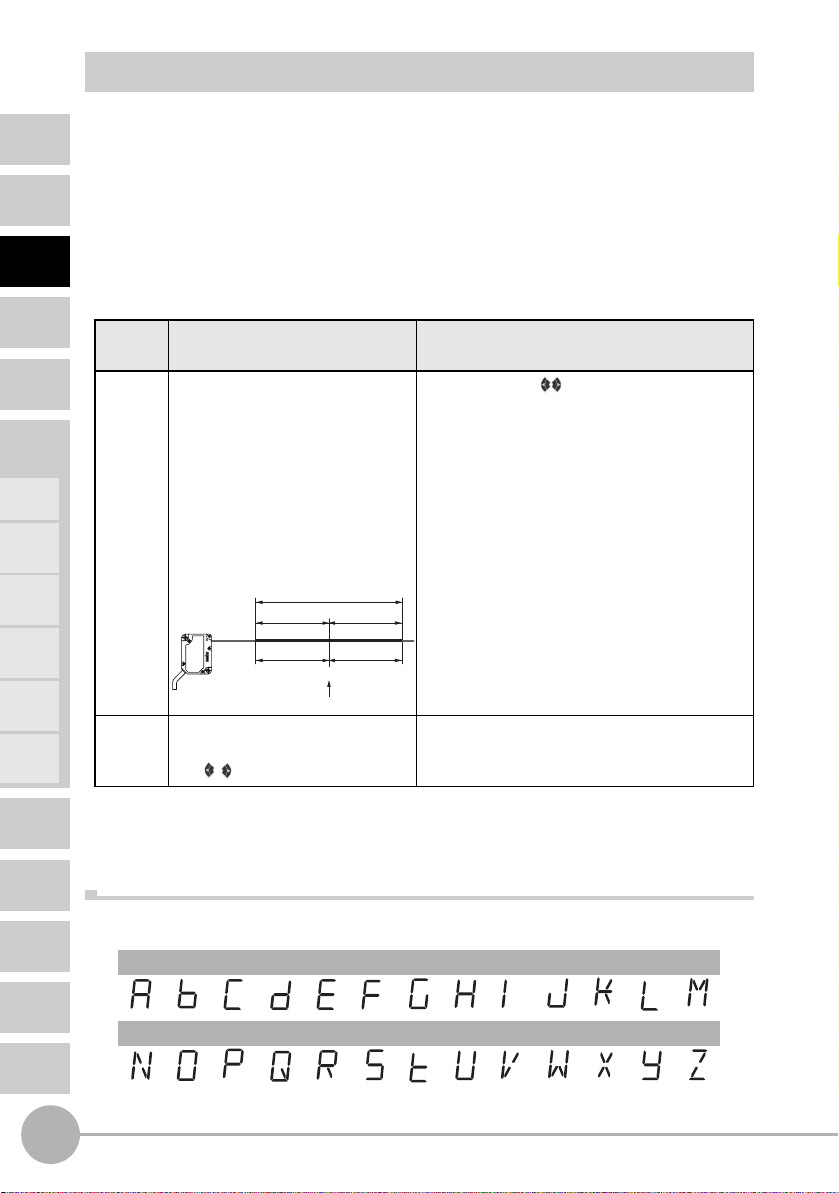

Alphabet Display Format

The alphabet appears on the main and sub-displays as shown in the following table.

A B C D E F G H I J K L M

N O P Q R S T U V W X Y Z

Part Names and Functions

ZX2 User’s Manual

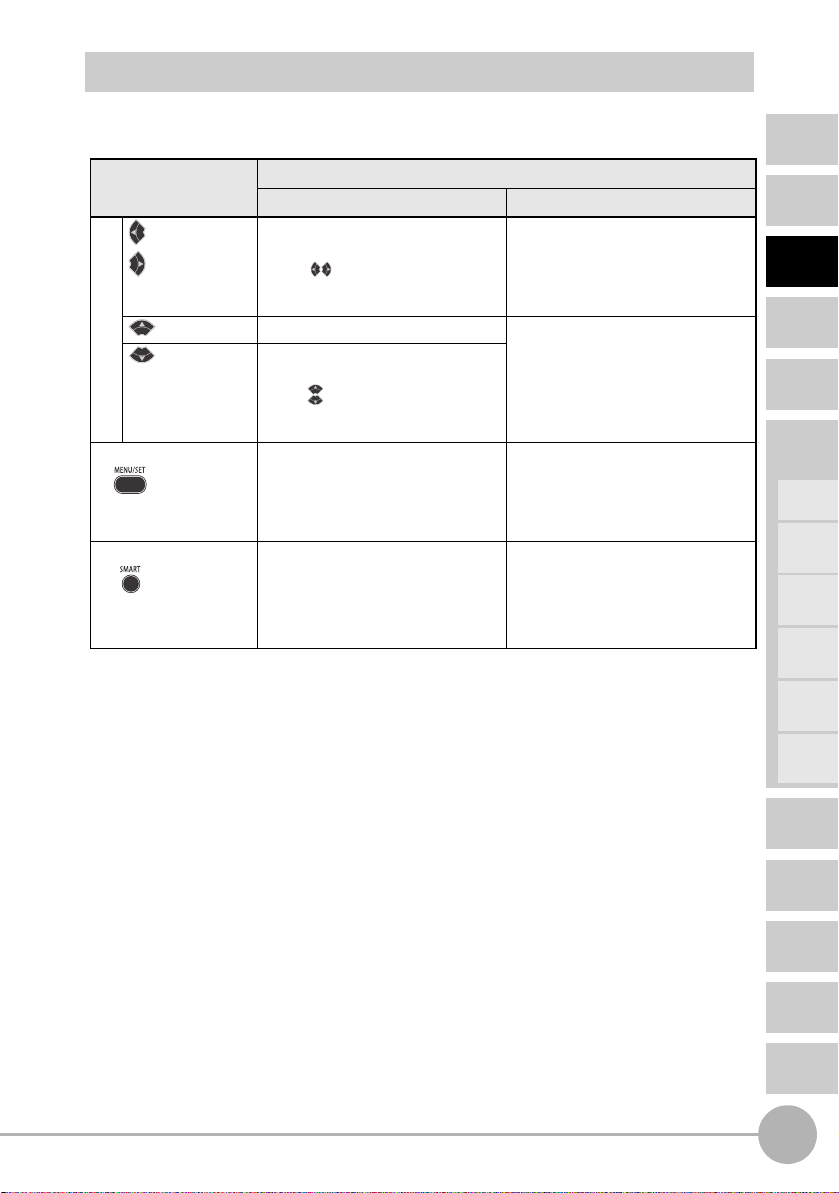

Button Operation

The functions of buttons change according to the currently selected mode.

Button type Button function

RUN mode MENU mode

button

button

button • Normal press: Executes timing input. The function changes depending on

button • Held down for one second:

Cursor buttons

MENU/SET button • Held down for 3 seconds:

Smart tuning button • Held down for one second, held

• Normal press:

Changes the sub-display content.*

• Both buttons held down for

three seconds:

Locks button operation.

Executes zero reset.

• Both buttons held down for one

second:

Cancels a zero reset.

Changes the mode to the MENU

mode.

down for three seconds, held down

for five seconds:

Executes smart tuning according

to the time the button is held

down.

* For how to select the initial sub-display to be displayed when the power is turned on, see

page 84.

Function changes depending on the

setting.

• Switches the function display.

• Selects the digit of numerical values.

• Stops setting.

the setting.

• Changes the selection menu.

• Changes numerical values.

• Normal press:

Finalizes the set condition or

value.

• Held down for 3 seconds:

Changes to the RUN mode.

• Held down for one second, held

down for three seconds, held down

for five seconds:

Executes smart tuning according

to the time the button is held

down.

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

ZX2 User’s Manual

Part Names and Functions

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

21

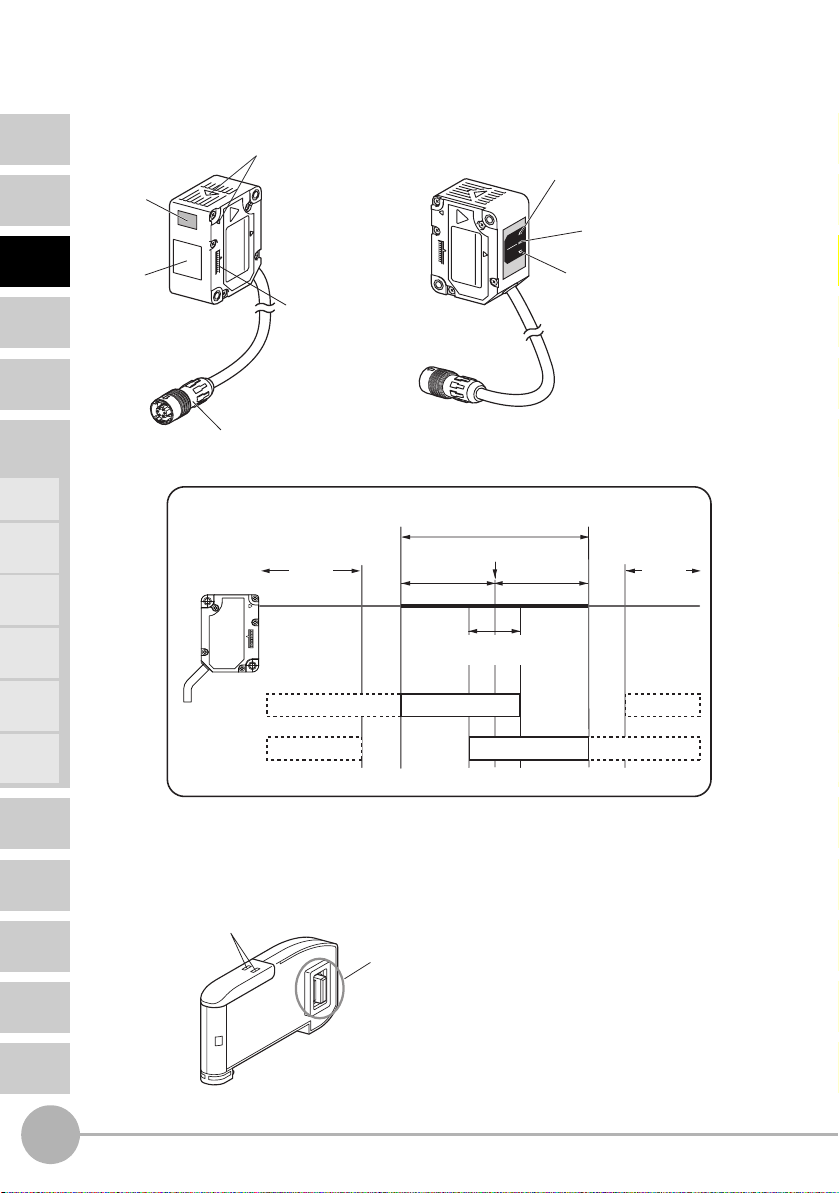

Sensor Head

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

Emitting

section

Receiving

section

Emission center position mark

This mark indicates the emission center

position.

FAR

NEAR

CMOS position mark

This mark indicates the position of the

CMOS light-receiving element.

Connector

This is connected to the Amplifier Unit.

Indicator Operation According to Position of Workpiece

Measurement range

Measurement center distance

NEAR side

Measurement center distance

± (measurement range x 10%)

FAR side

(outside measurement

range)

NEAR

indicator

FAR

indicator

Error

Flashing FlashingLit

Flashing FlashingLit

FAR Indicator (green)

See the table below.

Laser life indicator (red)

NEAR Indicator (green)

See the table below.

Error

(outside measurement

range)

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

22

Calculating Unit

Connection indicator

This indicator lights when the

Amplifier Unit is connected.

Part Names and Functions

(used for connecting two or more Amplifier Units)

Connector (two connectors, one on each side)

This is connected to the Amplifier Unit.

ZX2 User’s Manual

Installation

5

Important

Before connecting/disconnecting Smart Sensor components, make sure that the power to the

Amplifier Unit is turned OFF. The Smart Sensor may malfunction if components are connected

or removed while the power is ON.

CONTENTS

INTRODUCTION

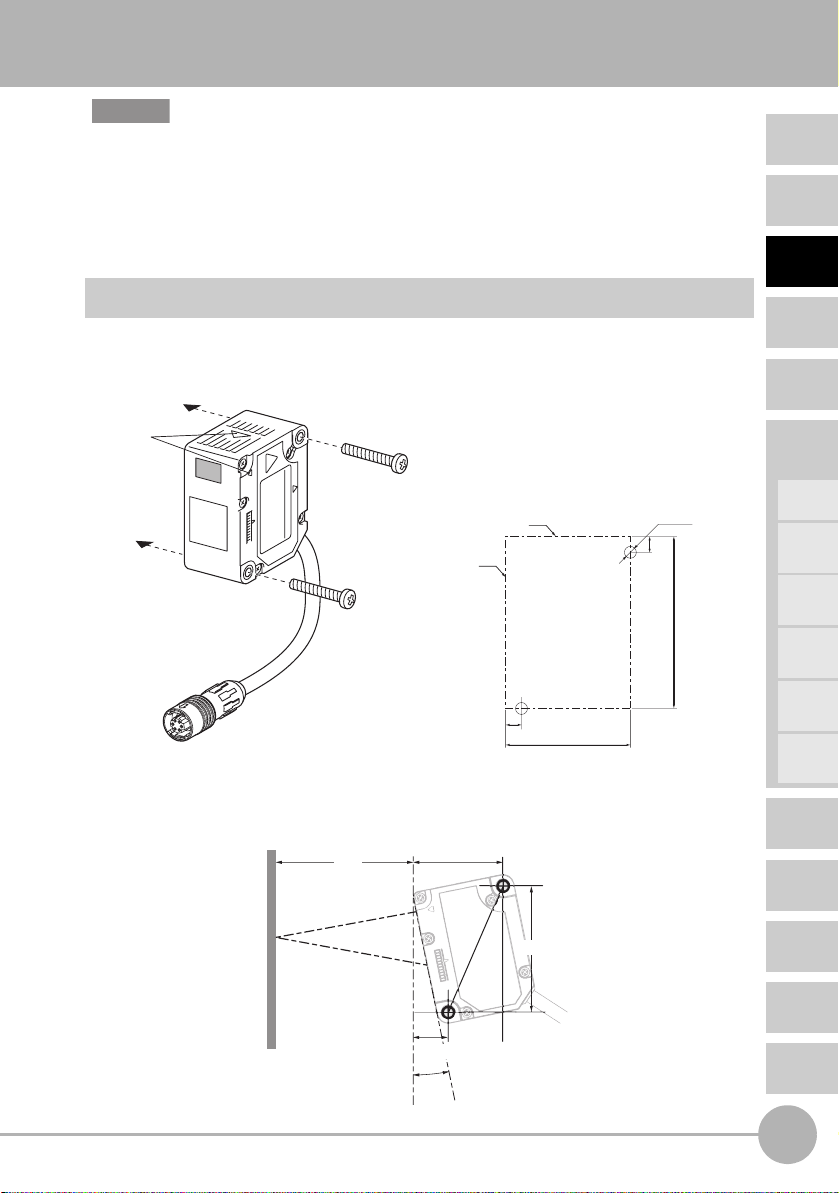

Installing Sensor Heads

Installation Method

• Check the Sensor Head setting position by its emission center mark.

• Fix the sensor head in place with M3 screws. The screws must be tightened with a

torque of 0.5 N•m.

Emission

center position

mark

Mounting dimensional drawing

(unit: mm)

Mounting reference

Mounting reference

4 ±0.05

31.5 ±0.05

• Tilt the regular-reflective model as shown below with respect to the workpiece.

A mounting bracket can also be attached to the regular-reflective model to tilt it

correctly. (E39-L178; see page 141.)

ZX2-LD50V

48

(Measurement center

distance)

31.4

±

0.05

2-M3

0.05

±

4

0.05

±

43.5

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

ZX2 User’s Manual

Workpiece

12.3 ±0.05

10.5°

44.1 ±0.0

Installation

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

23

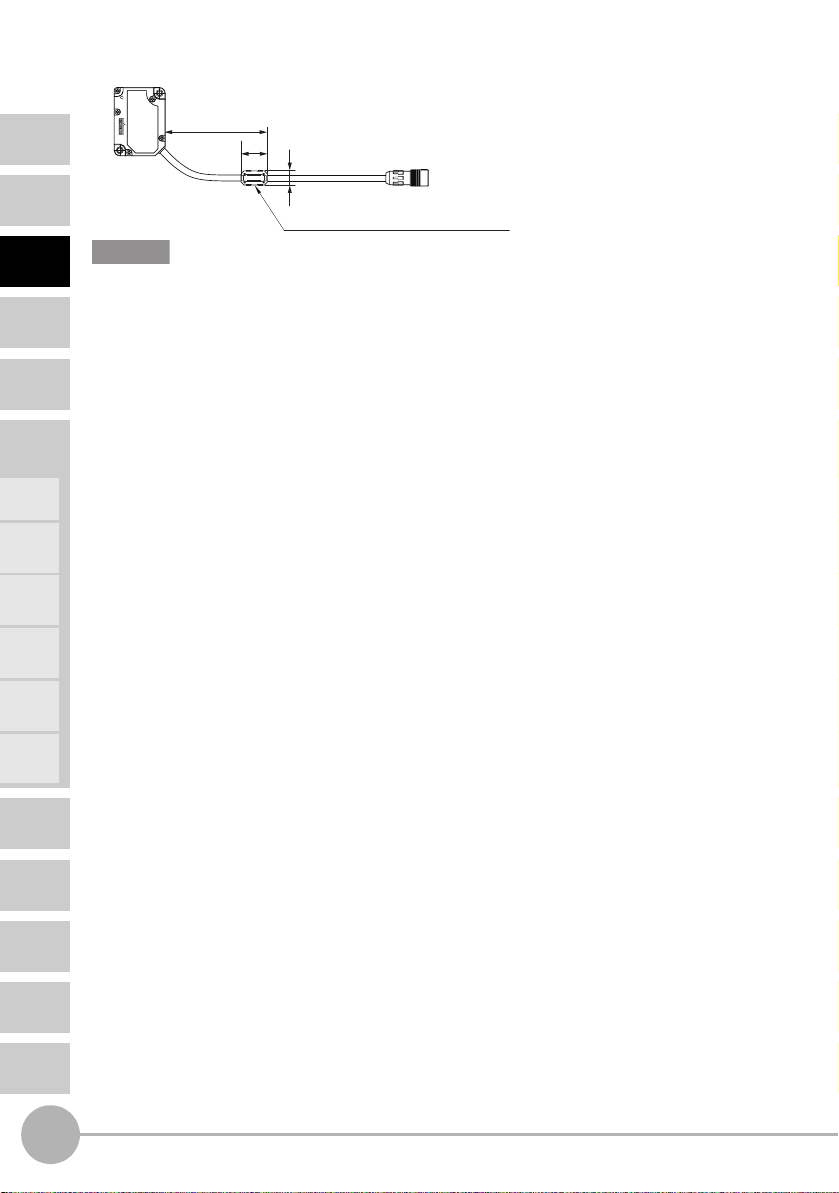

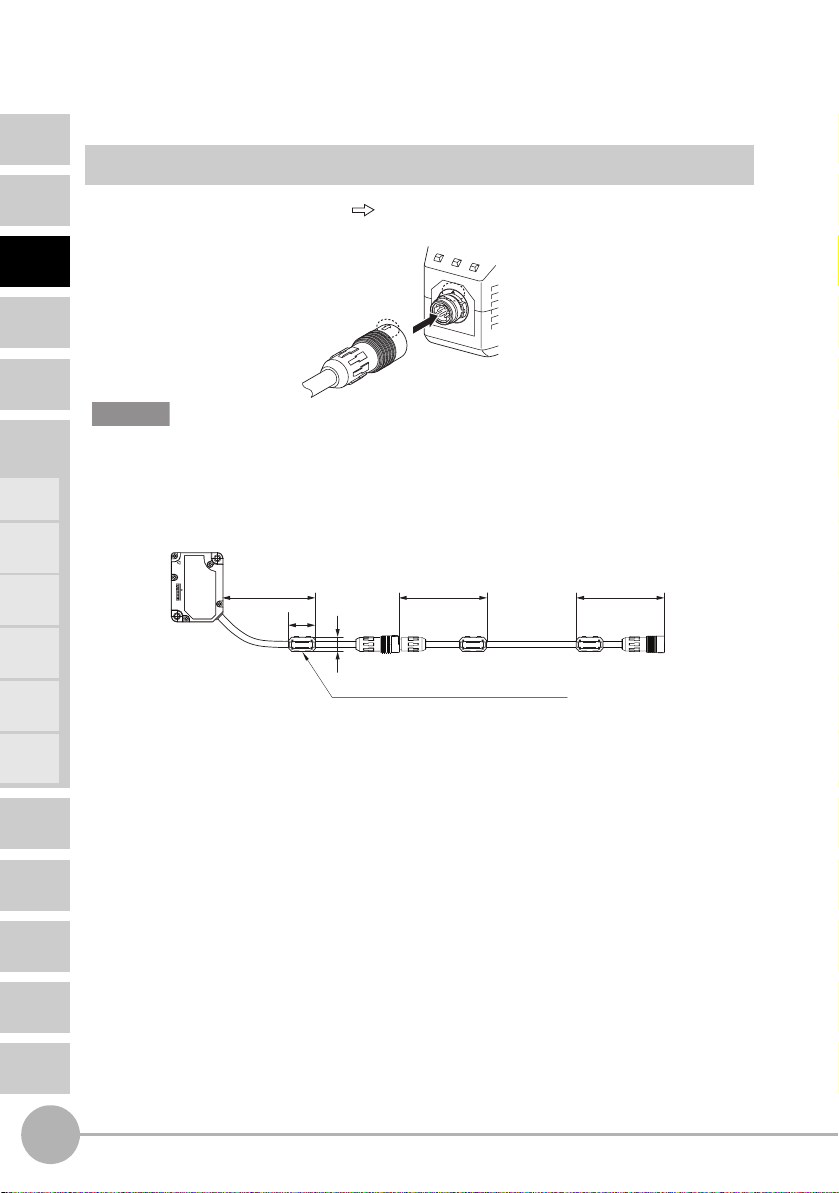

• Be sure to attach the ferrite core accessory to the Sensor Head. Attach it within

100 mm of the Sensor Head side.

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Within 100 mm

30

16.5 dia.

Made by TDK Corporation ZCAT1730-0730A

Important

• When mounting a Sensor Head, take care not to touch the emitter and receiver. Finger

marks on the emitter and receiver may hinder correct measurements. If you have touched

them by mistake, wipe them with a clean, soft cloth.

• Fix the connectors in places that are not subject to vibration or impact.

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

24

Installation

ZX2 User’s Manual

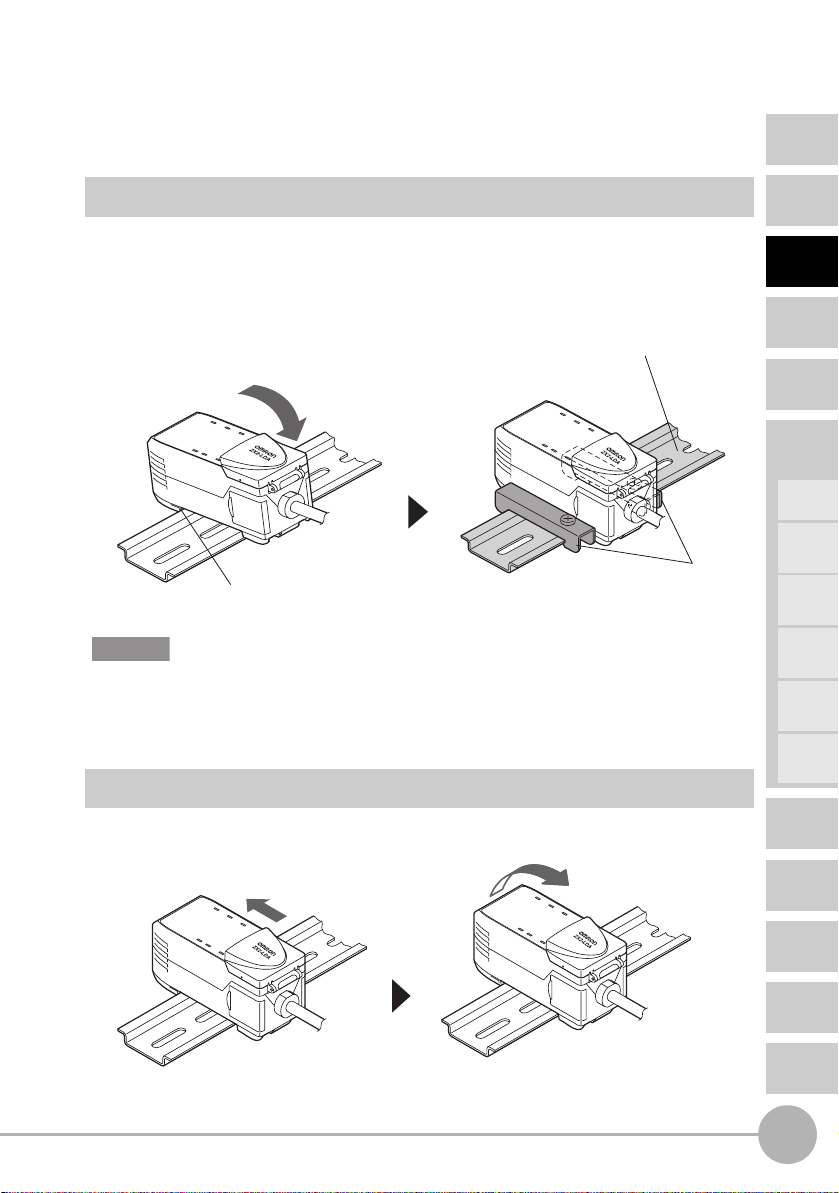

Installing the Amplifier Unit

Amplifier Units can be easily mounted to 35-mm DIN Track.

Installation Method

Hook the connector end of the Sensor Head on the DIN Track, and press in at the bottom

until the Amplifier Unit locks into place. If necessary, fix it in place by the End Plate.

DIN Track (Option)

PFP-100N (shallow type/1 m)

PFP-50N (shallow type/0.5 m)

PFP-100N2 (shallow type/1 m)

End Plate (Option)

Hook on the connector end

Important

Hook the connector end of the Sensor Head on the DIN Track first. The mounting strength may

decrease if the output cable end is hooked on the DIN Track first.

PFP-M

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Removal Method

Push the Amplifier Unit and pull out from the connector end of the Sensor Head.

ZX2 User’s Manual

Installation

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

25

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

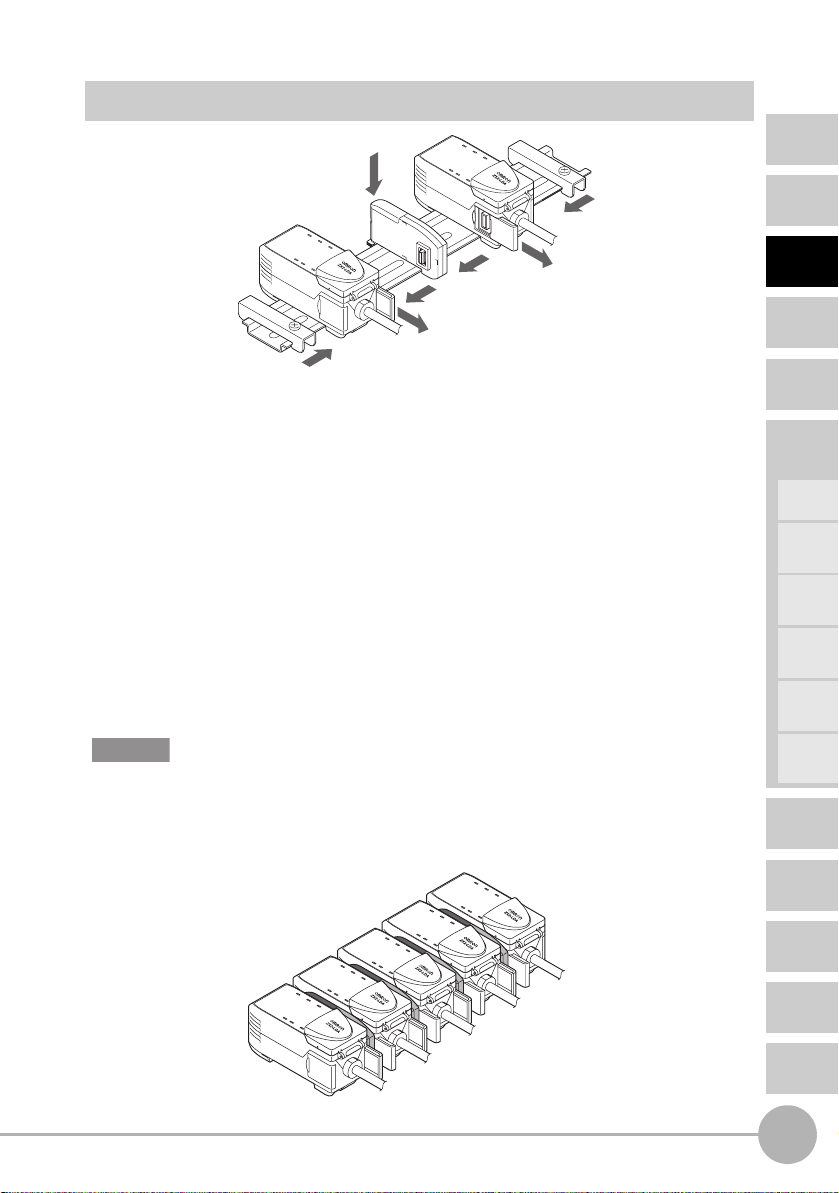

Connecting Calculating Units

Use a Calculating Unit to connect Amplifier Units when performing calculations between

Amplifier Units and to prevent mutual interference between Sensor Heads.

The number of Amplifier Units that can be connected differs depending on the functions to

be used.

Function Number of Connectable Amplifier Units See:

Calculation Up to two units (Up to five units can be connected.

However, calculations are done between pairs of two.)

For (A-B) calculations

A: CH2 or later

B: CH1

CH2

(CH2-CH1)

CH3

(CH3-CH1)

CH4

(CH4-CH1)

CH5

(CH5-CH1)

Mutual interference

Up to five units Page 88

prevention

For details on the connection method, see the next page.

CH1

(A-B)

calculation:

Page 47

Thickness

calculation:

Page 57

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

26

Installation

ZX2 User’s Manual

Connection Method

2

5

4

1

3

1

5

1 Open the connector cover on the Amplifier Unit.

Open the connector cover by lifting and sliding it.

2 Mount the Calculating Unit to the DIN Track.

3 Slide and connect the Calculating Unit to the Amplifier Unit connector.

4 Slide and connect the second Amplifier Unit to the Calculating Unit

connector.

5 Fix in place with the End Plate (sold separately: PFP-M).

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Important

• To disconnect Amplifier Units and Calculating Units, perform the above operations in reverse

order.

• The following diagram shows the channel numbers when multiple Amplifier Units are

connected.

CH1

CH2

CH3

CH4

CH5

ZX2 User’s Manual

Installation

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

27

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Connecting the Sensor Head to the Amplifier Unit

Installation Method

Align the position of the connector mark with the S mark on the Amplifier Unit, and

insert the connector until it is locked in place.

Important

• Extending the Sensor Head cable

An optional extension cable (ZX2-XCR) must be used.

Only one extension cable can be used.

Be sure to attach the two supplied ferrite cores within 100 mm of each end of the extension

cable.

Within 100 mm Within 100 mm Within 100 mm

30

16.5 dia.

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

28

Installation

Made by TDK Corporation ZCAT1730-0730A

ZX2 User’s Manual

Removal Method

CONTENTS

To disconnect the Sensor Head, hold the Sensor Head's connector ring and the Amplifier

Unit connector, and then pull them straight out.

Connector Ring

Important

• Do not touch the terminals inside the connector.

• Prevent the connector from being subjected to static electricity.

• When the Sensor Head is replaced with a different type, set all the setting data inside the

Amplifier Unit again since it will be cleared.

(default values: → See page 123.)

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

ZX2 User’s Manual

Installation

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

29

Wiring Diagram

CONTENTS

INTRODUCTION

PREPARATION

FOR

MEASUREMENT

FLOW OF

OPERATION

BASIC

SETUP

MAIN

APPLICATIONS

& SETTING

METHODS

Height

Steps

and

Warpage

Double

Sheet

Detection

Thickness

Positioning

Eccentricity

and Surface

Deflection

DETAILED

SETTINGS

TROUBLESHOOTING

SPECIFICATIONS

INDEX

SETTING

TRANSITION

CHARTS

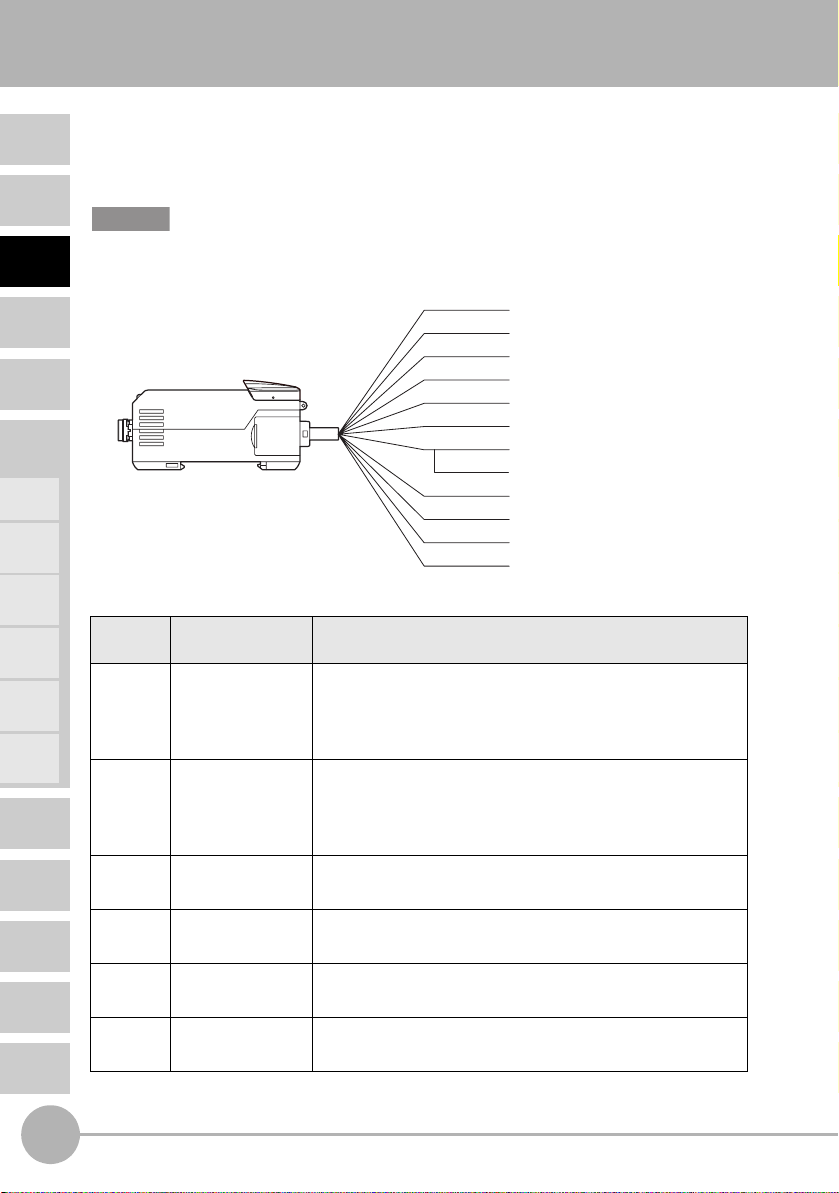

Wiring Input/Output Cables

The input/output cable has the following wires.

Important

Wire the cable correctly. Incorrect wiring may damage the Smart Sensor.

(For details on the cable’s conductor cross-section and insulation resistance, see page 136.)

Brown

White

Green

Yellow

Black

Shield

Orange

Purple

Cable

Name Function

color

Brown Power supply Connects the 10 to 30 VDC (including (p-p) 10% ripple)

power supply. When using an Amplifier Unit with a PNP

output, the power supply terminal is also the common I/O

terminal for all I/O except for the analog output.

Blue GND (0 V) The GND terminal is the 0 V power supply terminal. When

using an Amplifier Unit with an NPN output, the power

supply terminal is also the common I/O terminal for all I/O

except for the analog output.

White HIGH judgement

output

Green PASS judgment

output

Gray LOW judgment

output

The HIGH judgement output outputs judgement results

(HIGH).

The PASS judgement output outputs judgement results

(PASS).

The LOW judgement output outputs judgement results

(LOW).

Yellow Error output This is output when the system detects an error.

(For details on error messages, see page 130.)

Power supply

Blue

GND

HIGH judgement output

PASS judgement output

Gray

LOW judgement output

Error output

Analog output

Analog GND

Pink

LD-OFF input

Zero reset input

Timing input/BANK input 0

Red

Reset input/BANK input 1

30

Wiring Diagram

ZX2 User’s Manual

Loading...

Loading...