Page 1

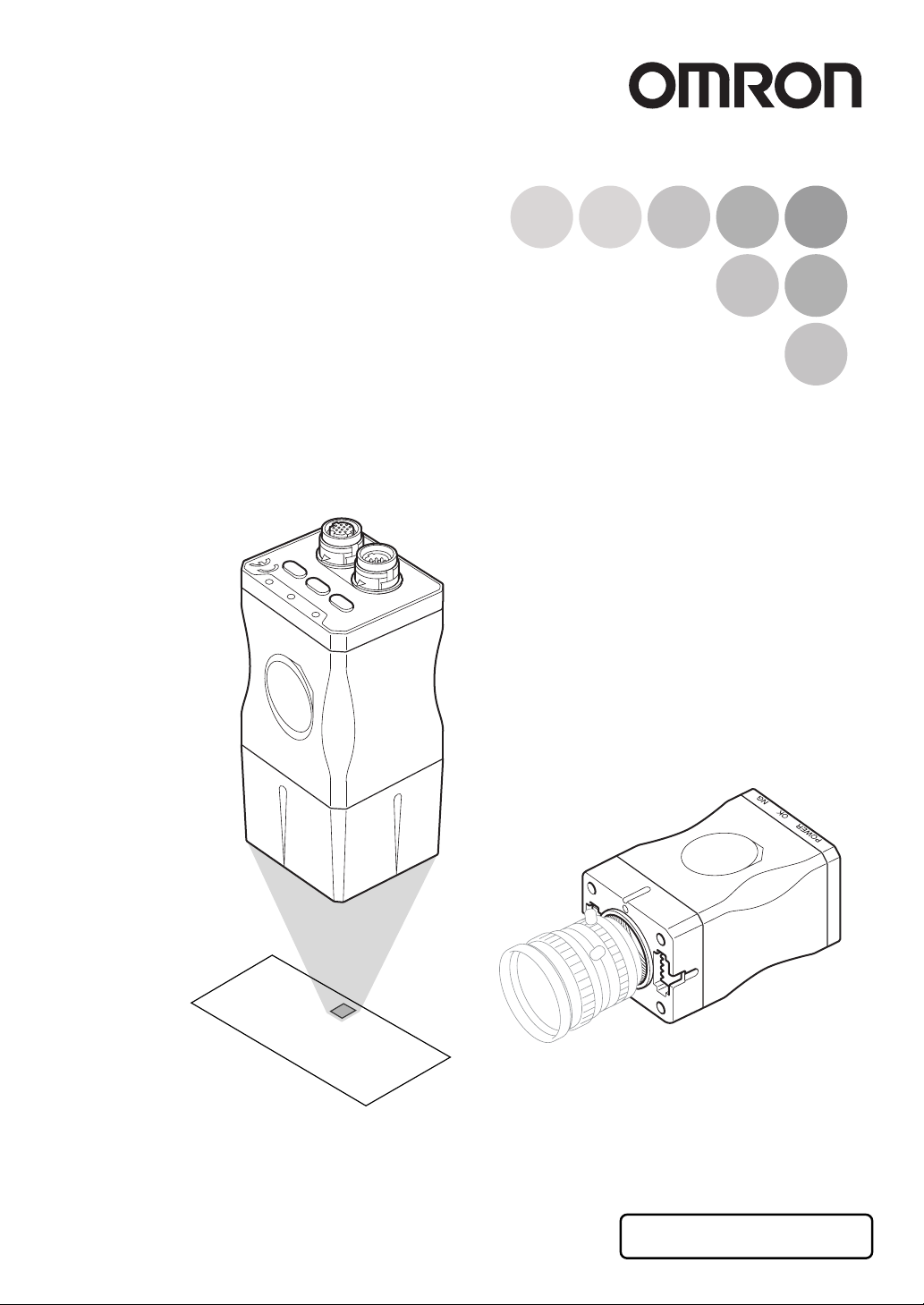

2D Code Reader

V400-F050/250/350

User’s Manual

N

A

P

A

DOWN

E

T

MODE

IVE

OW

P

J

CU

E

X

E

UP

L

ILL/

T

S

2

CN

G

TRI

NG

OK

ER

ADE IN

M

n

tio

ra

o

p

r

nCo

Omro

CN1

Cat. No.

Z242-E1-03

Page 2

Introduction

Thank you for purchasing the OMRON V400-F050/250/350.

This manual describes the functions, performance, and application

methods of the V400-F050/250/350.

This manual is intended for personnel with knowledge of electrical

systems. Be sure to read and understand this manual thoroughly before

using the product, and keep this manual in an easily accessible location

for quick reference when required.

Page 3

Introduction

ÇÕǹÇ?Ç ëÊ 1 èÕ ëÊ 2 èÕ ëÊ 3 èÕ ëÊ 4 èÕ

Introduction

Introduction

Section 1

Section 2

Section 3

Section 4

Section 5

Application Considerations (Read and understand this information first.)

Section 1 Section 2 Section 3 Section 4 Section 5

Studying the V400-F

Changing Reading Conditions

Setting RS-232C and Discrete I/O Communication Conditions

Other Settings

Communicating with PC and Programmable Controller

Section 6

Section 6

Appendix

Troubleshooting

2D Code Reader

Appendix

User’s Manual

V400-F050/250/350

Page 4

Introduction

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer

to separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

V400-F050/250/350

User’s Manual

2

Page 5

Introduction

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

Introduction

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

V400-F050/250/350

User’s Manual

3

Page 6

Introduction

Introduction

Meanings of Signal Words

In this manual, precautions are indicated using the following symbols and signal words to ensure safe

use of the

are important for safety and must be observed.

V400-F050/250/350. The precautions indicated by these symbols and signal words

Indicates a potentially hazardous situation which, if not avoided, will

WARNING

result in minor or moderate injury, or may result in serious injury or death.

Additionally there may be significant property damage.

Meanings of Alert Symbols

Indicates the possibility of explosion under specific conditions.

Indicates general prohibitions for which there is no specific symbol.

Alert Statements in this Manual

WARNING

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

V400-F050/250/350

User’s Manual

4

Page 7

Introduction

Regulations and Standards

The V400-F050/250/350 complies with the international regulations and standards listed

below.

EC Directives EMC Directive:No.89/336/EEC

EN Standards

(European Standards)

EN61326: 1997, +A1: 1998 +A2: 2001 (EMI: Class A)

Power line: 10 m max. Signal line: 30 m max.

Precautions for Safe Use

Observe the following precautions to ensure safe use of the product.

■ Installation Environment Precautions

• Do not use the product in environments with flammable or explosive gases.

• Do not install outdoors.

• Do not install the product close to high-voltage devices and power devices in order to

secure the safety of operation and maintenance.

• During installation, make sure that screws are tightened firmly.

Introduction

■ Power Supply and Wiring Precautions

• Use the product with the power supply voltages specified in this manual.

• Use a DC power supply with countermeasures against high-voltage spikes (safe

extra low-voltage circuits on the secondary side).

p.20

■ Other Precautions

• If the product becomes extremely hot, or abnormal odors or smoke occurs, stop using

the product immediately, turn OFF the power, and consult with your OMRON

representative.

• Dispose of the product as industrial waste.

• Do not apply pressure or deform the product when disposing of it.

V400-F050/250/350

User’s Manual

5

Page 8

Introduction

Introduction

Precautions for Correct Use

Always observe the following precautions to prevent operation failures, malfunctions, and

adverse effects on performance and equipment.

■ Installation of the Product

Do not install the product in the following locations:

• Locations subject to ambient temperature that exceeds the rated temperature range

• Locations subject to rapid changes in temperature (causing condensation)

• Locations subject to relative humidity that exceeds the rated humidity range

• Locations subject to corrosive or flammable gases

• Locations subject to dust, salt, or metallic powder

• Locations subject to direct vibration or shock outside the specified ranges

• Locations subject to direct sunlight

• Locations subject to oil or chemical spray

Ambient Temperature

• Maintain a minimum clearance of 50 mm above and below the product to improve air

circulation.

• Do not install the product immediately above significant heat sources, such as

heaters, transformers, or large-capacity resistors.

• Do not let the ambient operating temperature exceed 45°C.

• Provide a forced-air fan cooling or air conditioning if the ambient temperature is near

45°C so that the ambient temperature never exceeds 45°C.

Noise Resistance

• Do not install the product in areas where highvoltage equipment is installed.

• Do not install the product within 200 mm of power

Power cable

200mm min.

cables.

POWER OK NG

Main unit

200mm min.

V400-F050/250/350

User’s Manual

6

Page 9

Introduction

■ Installation and Handling of Components

• Use the cables specified in this manual.

p.20

• Keep the power supply cable as short as possible (10 m maximum).

• The power lines and discrete I/O lines of the communication/power cable should not

be short-circuited with each other.

• Power output lines of the monitor cable should not be short-circuited with each other.

• Do not supply power from the monitor's power cable, since it is provided for output

only.

• Do not attempt to dismantle, repair, or modify the product. Failure to observe this may

result in breakdown or fire.

■ Connecting and Removing Cables

• Do not connect or disconnect the cables while power is supplied.

• Do not connect a cable to the 2D Code Reader if the other end of the cable is

connected to a personal computer or a Programmable Controller.

• To prevent damage from static electricity, use a wrist strap or another device for

preventing electrostatic charges when touching terminals or signal lines inside

connectors.

Introduction

■ Turning OFF the Power Supply

• Do not turn OFF the power supply while a message is being displayed indicating that

processing is being performed. Data in memory will be destroyed, and the product

may not operate correctly the next time it is started.

• Do not turn OFF the power while the setting data is being saved. Data in memory will

be corrupted, and the product may not operate correctly the next time it is started.

V400-F050/250/350

User’s Manual

7

Page 10

Introduction

Introduction

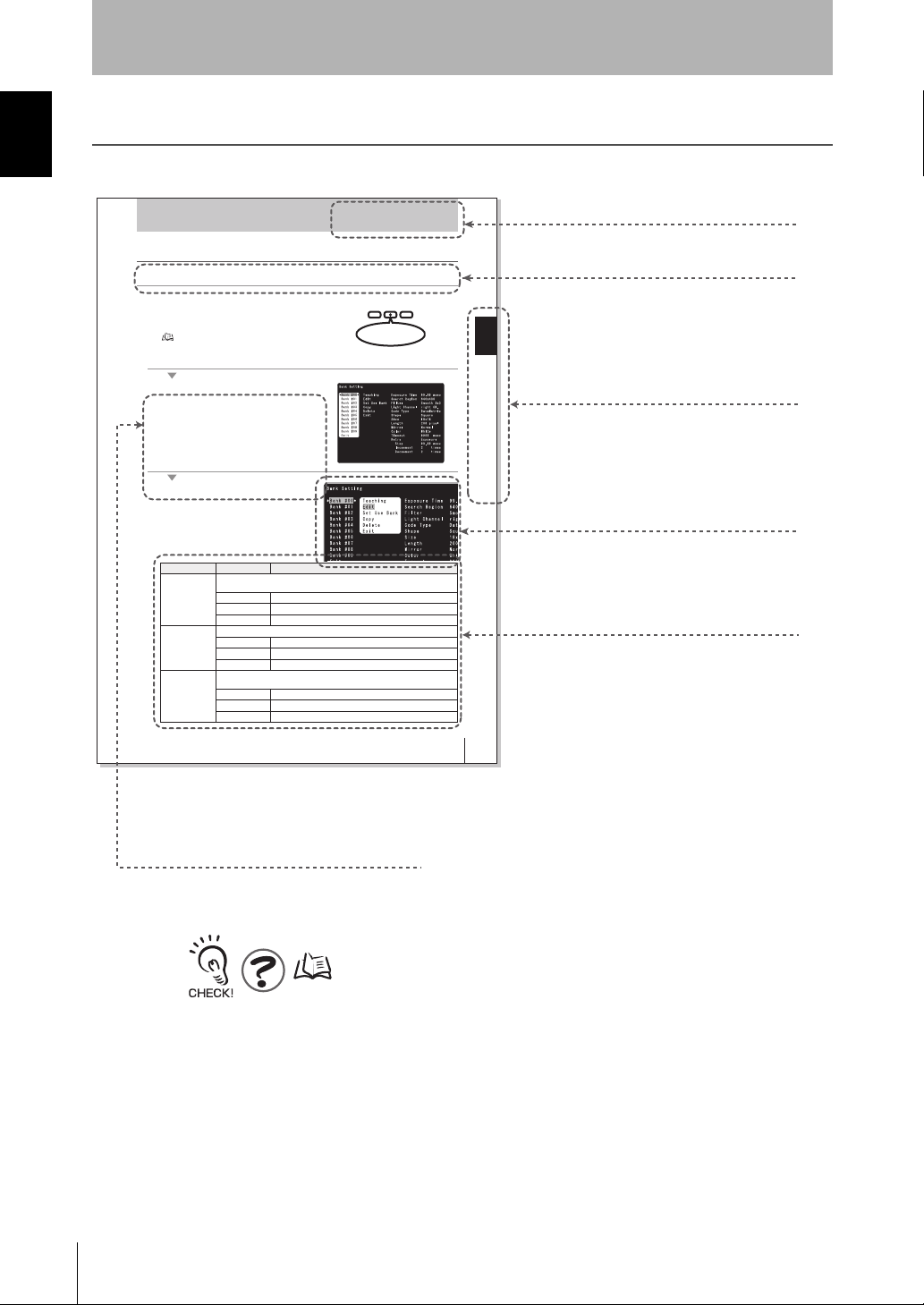

How to Use This Manual

How to Use This Manual

Page Format

Setting Reading Conditions Manually

This section explains how to set reading conditions manually.

1.

Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

2.

Select [Bank Setting] from [Setting Menu].

The [Bank Setting] screen will appear.

3.

From [Bank #00] to [Bank #09], select the

bank to which you want to set reading

condition.

The contents of the selected bank are displayed in the

right area of the screen.

The edit menu will be displayed.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

Section 2

Changing Reading Conditions

Section title

Outline

Section 2 Setting Reading Conditions Manually

Index label

Provides the section number

and subject matter. Can be

used to immediately open the

desired page.

Screen display

Setting item Settings Details

Light Channel

Code Type Set the code type.

Shape

Select the light to be used.

(For V400-F050)

Right CH.* The light connected to the right light connector will be used.

Left CH. The light connected to the left light connector will be used.

None No

DataMatrix The code will be read as a DataMatrix type code.

QRCode The code will be read as a QRCode type code.

Auto* The code type will be identified automatically.

Select the code shape.

This item is effective only when [DataMatrix] is selected for [Code Type].

Square The code will be read as a square code.

Rectangle The code will be read as a rectangular code.

Auto* The code shape will be identified automatically.

light will be used.

V400-F050/250/350

User's Manual

Describes the settings.

31

Procedure and additional explanations

Information useful during the operation and reference

pages are provided here with special marks to indicate

the kind of information being provided.

V400-F050/250/350

User’s Manual

8

*This page does not actually exist in this manual.

Page 11

Visual Aids

Introduction

Introduction

Indicates points that are important in using product functions or in application procedures.

Indicates page numbers providing related information.

Indicates helpful information when a problem occurs and explanations of technical terms.

Visual Aids

V400-F050/250/350

User’s Manual

9

Page 12

Introduction

Introduction

Contents

Contents

Introduction

Meanings of Signal Words 4

Meanings of Alert Symbols 4

Alert Statements in this Manual 4

Regulations and Standards 5

Precautions for Safe Use 5

Precautions for Correct Use 6

How to Use This Manual 8

Visual Aids 9

Contents 10

Section 1 Studying the V400-F 13

Features and Functions of V400-F 14

Installing and Connecting the Code Reader 18

Simple Teaching 22

Changing Settings 24

Reading Results 26

Section 2 Changing Reading Conditions 29

Setting Reading Conditions by Teaching 30

Setting Reading Conditions Manually 32

Selecting the Bank to be Used Normally 37

Copying a Bank 38

Deleting the Content of a Bank 40

Setting the Retry Method 41

V400-F050/250/350

User’s Manual

10

Page 13

Introduction

Section 3 Setting RS-232C and Discrete I/O Communication Conditions 43

Setting RS-232C Communication Conditions 44

Introduction

Setting Discrete I/O Communication Conditions 48

Section 4 Other Settings 51

Setting Screen Display 52

Viewing the Images Read in the Past 53

Saving/Initializing All the Settings 56

Displaying the Version Information 58

Section 5 Communicating with PC and Programmable Controller 59

RS-232C Communication 60

Discrete I/O Communication 73

Contents

Section 6 Troubleshooting 81

Error Codes and Corrective Actions 82

Troubleshooting 82

Appendix 85

Lens and Lighting 86

Line Speed and Reading Time/Exposure Time 91

Maintenance 93

Specifications and Dimensions 94

ASCII Table 99

Ladder Programming Example for Connecting to a PLC 100

FCS Check Program Example (BASIC) 104

Data Capacity Table 106

Menu Hierarchy 109

Revision History 110

V400-F050/250/350

User’s Manual

11

Page 14

Introduction

Contents

Introduction

MEMO

V400-F050/250/350

User’s Manual

12

Page 15

Section 1 Studying the V400-F

This section provides items, such as the V400-F is features, installation,

connections and operation flow, with which the operator should be familiar to

use the V400-F.

Features and Functions of V400-F 14

Compact and Easy-to-Operate 14

Advanced Functions 16

Other Features 17

Installing and Connecting the Code Reader 18

Mounting the Main Unit 18

Connecting Peripheral Devices 20

Simple Teaching 22

Section 1 Studying the V400-F

Changing Settings 24

Reading Results 26

Monitor Display 26

RS-232C Communications Output 28

V400-F050/250/350

User’s Manual

13

Page 16

Section 1

Studying the V400-F

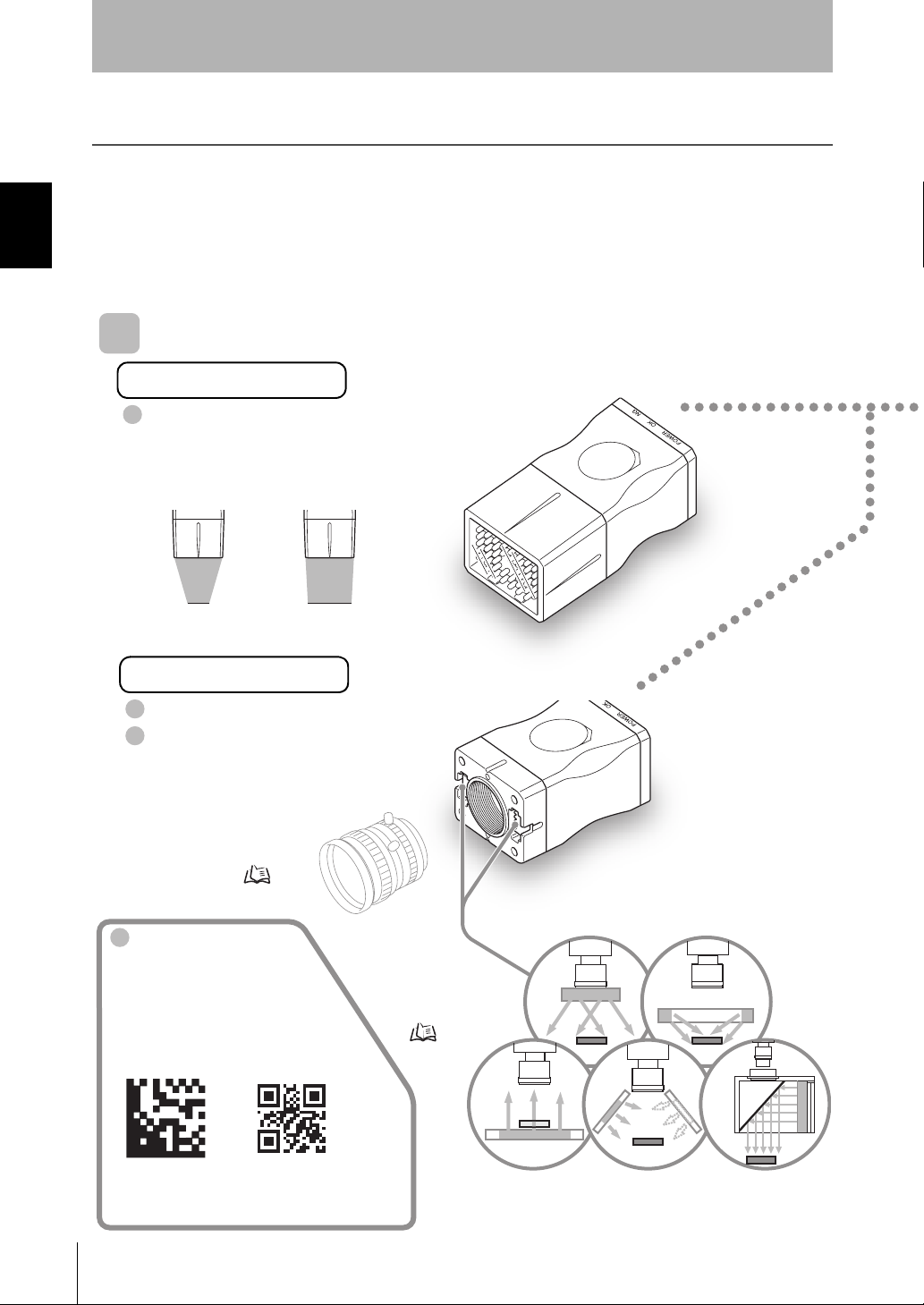

Features and Functions of V400-F

Section 1 Features and Functions of V400-F

This fixed type 2D code reader provides advanced reading functions and is designed for easy

operation by anyone. It reads 2D codes directly marked on boards and metal materials.

Two types of code reader are available: the V400-F250/350, whose lens and light are

integrated into one compact body, and the V400-F050, to which a C-mount lens can be

attached to enable use of various lights.

Compact and Easy-to-Operate

Light/Lens Integrated Type

Light and Lens are Integrated

Eliminates troublesome lens mounting and light.

V400-F250 V400-F350

Narrow-field light Wide-field light

C-mount Type

Allows Mounting of a C-mount Type Lens

Provides Two Connectors that

Allow Direct Connection of Light

No power source is required for the

light.

V400-F250/350

External size: 40 × 50 × 97 mm

V400-F050

Supports

DataMatrix ECC200

(max. 64 × 64)

Readable codes

DataMatrix QRCode

• ECC200

10 × 10 to 64 × 64

8 × 18 to 16 × 48

V400-F050/250/350

User’s Manual

14

C-mount type lens

(Recommended: p.89)

• Model 1, 2

21 × 21 to 57 × 57

(Version 1 to Version 10)

(Recommended:

p.86)

External size:

Direct ring light

Back light

40 × 50 × 75 mm

Low-angle ring light

Reflected light

Coaxial light

Page 17

Checking Reading Results by Easy-to-See LEDs

Section 1

Studying the V400-F

Easy Operations with 3 Buttons

POWER LED (green) OK LED (blue) NG LED (red)

Lit when power is ON.

Left button

Switches between still and realtime images.

(* Monitor required)

Adjusts brightness (hold down for

two seconds).

(* Monitor required)

Center button

----------Switches to setting mode

(hold down for two seconds)

(* Monitor required)

Programmable controller

PC

.

o

T

Power

supply

device

POWER OK NG

STILL/LIVE MODE TRIG

UP

CN1

e

c

r

u

o

s

r

Omron Corporation MADE IN JAPAN

e

w

o

p

/

e

c

i

v

e

d

t

s

o

h

2

.

p

(

Lights up when reading is successful.

EXECUTE DOWN

CN2

)

0

One-Touch Reading by

20)

.

p

(

r

o

t

i

n

o

m

o

T

“Simple Teaching” (p.22)

Teaching/reading can be executed

and completed by just holding down

the right button for two seconds.

Reading can be started without

monitor.

Various Retry Functions

( p.41)

Retry can be performed not only with

different exposure time, but also with

two or more reading conditions that

are switched automatically.

Section 1 Features and Functions of V400-F

Lights up when

reading has failed.

Right button

Performs reading.

“Simple Teaching”

(Hold down for two seconds)

Communication/power cable

connector

Monitor cable connector

POWER

SYNC

Connecting to a Monitor

Allows Advanced Settings

V400-F050/250/350

User’s Manual

15

Page 18

Section 1

Studying the V400-F

Advanced Functions

Section 1 Features and Functions of V400-F

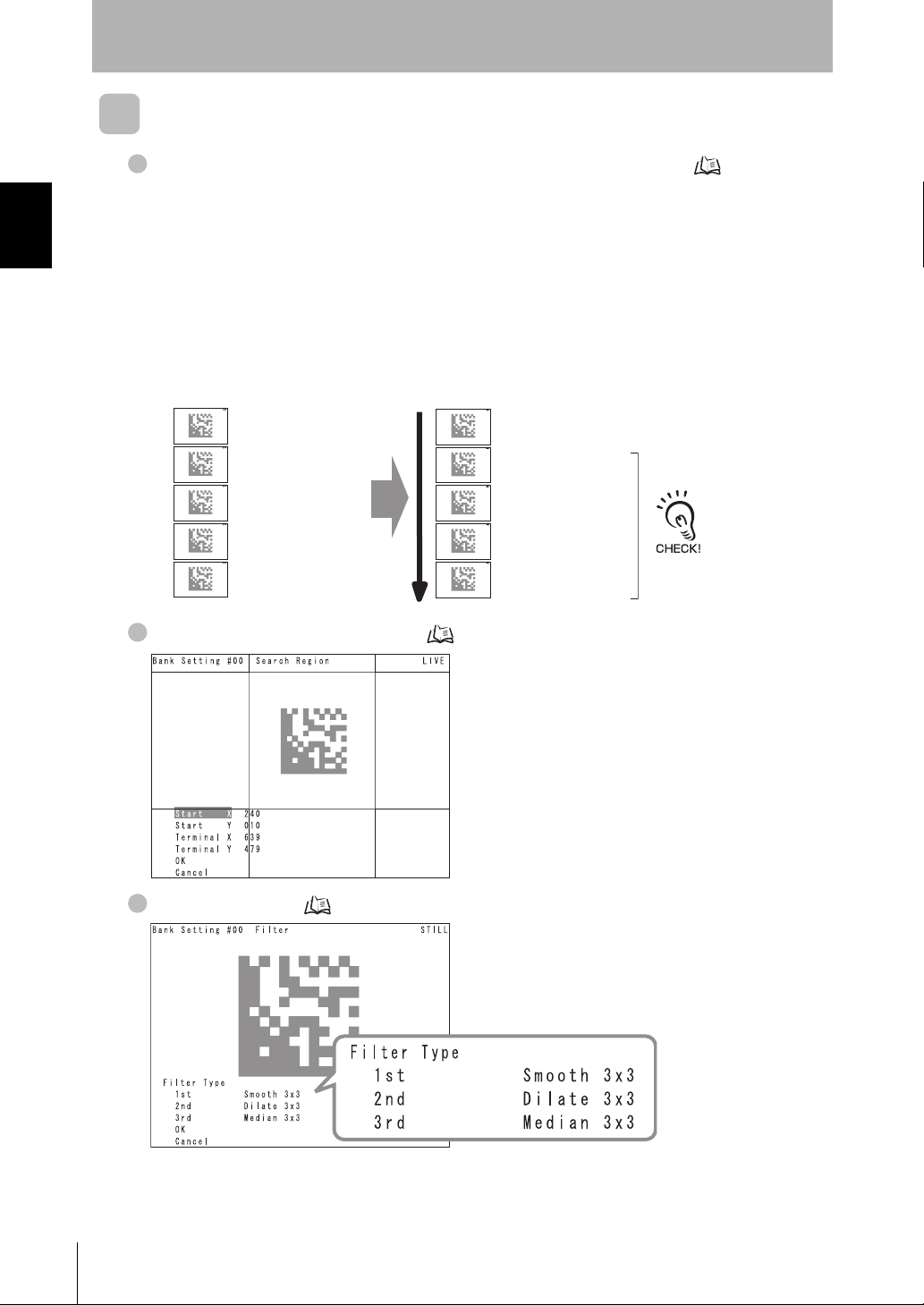

Retrying by switching to another bank automatically ( p.41)

Retry is performed by switching the reading condition (Bank) among the

maximum five conditions.

Two condition switching methods are available: one which determines the order

of the conditions to be used automatically according to the frequency of their use,

and the other that switches them according to the registered order.

Combining with the retry settings that are made for each reading condition

enables various retry settings.

[Automatically determining the order according to frequency of use]

1st Bank

Successful retry count: 25

2nd Bank

Successful retry count: 1

3rd Bank

Successful retry count: 50

4th Bank

Successful retry count: 15

5th Bank

Successful retry count: 9

Previous reading was successful.

Reading condition (example: 5th Bank)

3rd Bank

Successful retry count: 50

1st Bank

Successful retry count: 25

4th Bank

Successful retry count: 15

2nd Bank

Successful retry count: 1

For the 2nd and

subsequent

retries, the reading

condition used for

the 1st retry will be

excluded.

Setting the reading region ( p.33)

Set the image region to be read.

This shortens the processing time.

V400-F050/250/350

User’s Manual

16

Setting a filter ( p.34)

Performing image processing before

reading reduces possibility of reading error.

Filtering can be performed in 3 steps.

• Smooth, Dilate/Erosion, Median

Page 19

Section 1

Studying the V400-F

Enables switching between two lights (V400-F050 only) ( p.34)

The light to be used can be switched

between two lights according to the

situation.

Combining this function with the auto

bank switch retry function enables the

code reader to handle partially

reflecting work pieces.

Other Features

Saves up to 10 reading conditions ( p.30)

Saves up to 28 past read images ( p.53)

This allows you to identify the errors that occurred, by checking the saved past images.

Supports NPN/PNP by simply exchanging the cable.

Section 1 Features and Functions of V400-F

Allows direct power supply to the monitor.

Use of the monitor cable (V400-WM0) and LCD monitor (F150-M05L-2D) enables the

V400-F to supply power to the monitor, making settings monitoring and maintenance

easy.

Displays results in various ways ( p.26)

Highlights the reading state.

Highlighting ( p.26)

Displays the RS-232C communication history.

Communication history display

( p.27)

Displays analysis result of code quality numerically

and graphically (bar).

Code quality analysis display ( p.27)

V400-F050/250/350

User’s Manual

17

Page 20

Section 1

Studying the V400-F

Installing and Connecting the Code Reader

Section 1 Installing and Connecting the Code Reader

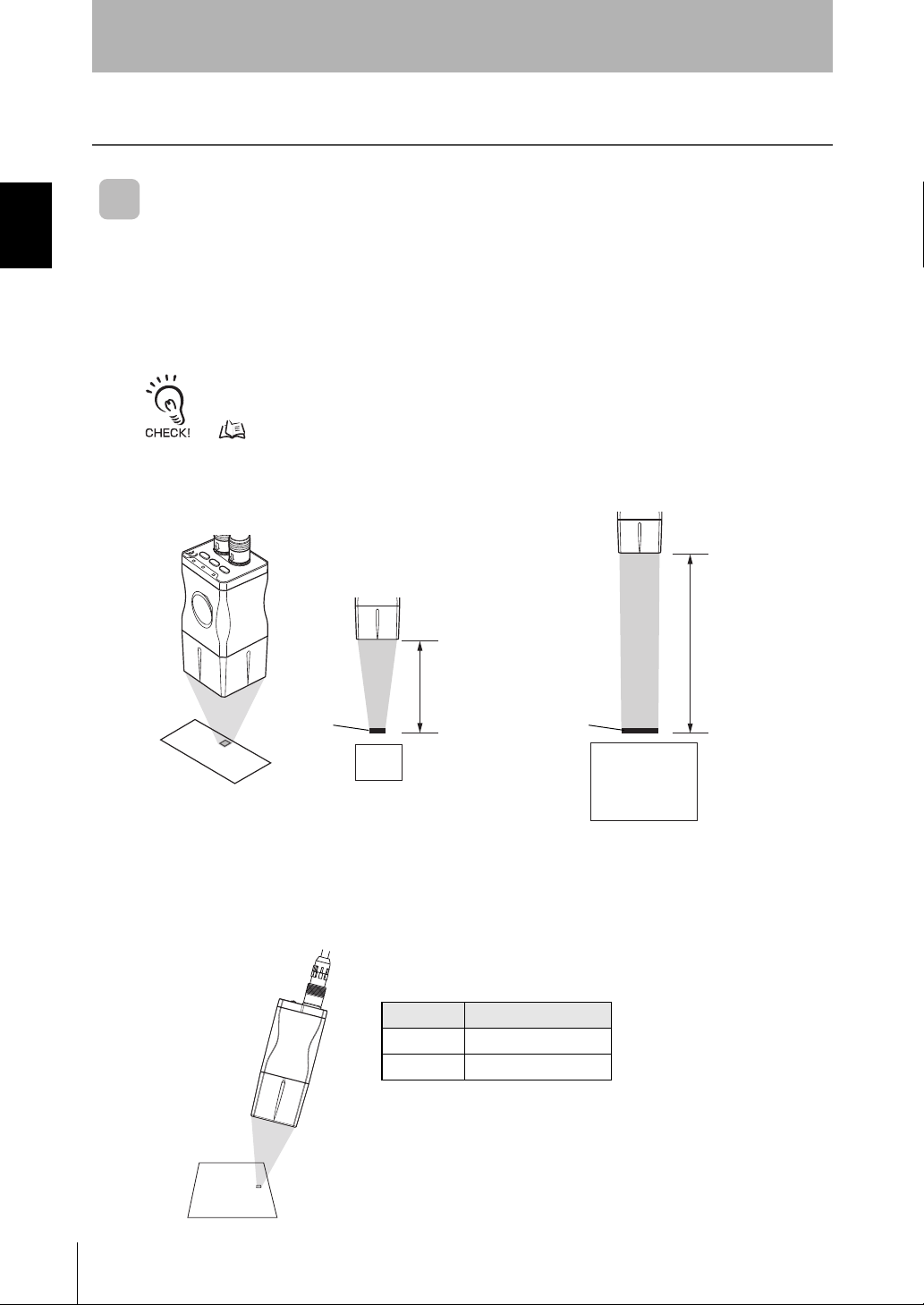

.

Mounting the Main Unit

Mount the reader at a distance where the code image can be shot correctly.

There are two mounting methods: “DIN track mounting” and “Base mounting”.

Field of Vision and Distance from the Code

• An accurate image will not be obtained if the installation distance is too long or too short. Always use

the installation distance given below.

• The field of vision and installation distance of the V400-F050 vary with the lens to be used.

“Selecting a Lens” p.89

V400-F250 V400-F350

MADE IN JAPAN

CN2

DOWN

TRIG

NG

OK

MODE

POWER

EXECUTE

UP

STILL/LIVE

Omron Corporation

CN1

Installation distance:

200 mm

Installation distance:

100 mm

Code

Code

Field of vision

14 × 18.5 mm

Field of vision

31 × 42 mm

Glossy Workpieces

Install the Main Unit at an angle so that regular reflective light is not included in the

image.

Recommended Installation Angle

Model Recommended angle

V400-F250 10°

V400-F350 5°

V400-F050/250/350

User’s Manual

18

Page 21

Section 1

Studying the V400-F

Base Mounting

Mount the reader with four M3 screws.

Mounting dimensions

2-M3

(Screw fitting length: 5 mm or less)

(Unit: mm)

Mounting the Mount Seat

First mount the mount seat, then mount the reader to the seat with two M4 screws. The

reader can also be mounted with one 1/4-20UNC screw.

Mounting dimensions

(Unit: mm)

Section 1 Installing and Connecting the Code Reader

2-M4

(Screw fitting length: 8 mm or less)

DIN Track Mounting

1. Mount the mount seat to the

undersurface of the base of the

reader with M3 screws (supplied

with the reader).

1/4-20 UNC

(Screw fitting length: 8 mm or less)

2.

Slide the seat into the DIN rail, and

then tighten the two screws at one

edge of the rail using the hexagonal

wrench (supplied with the reader).

V400-F050/250/350

User’s Manual

19

Page 22

Section 1

Studying the V400-F

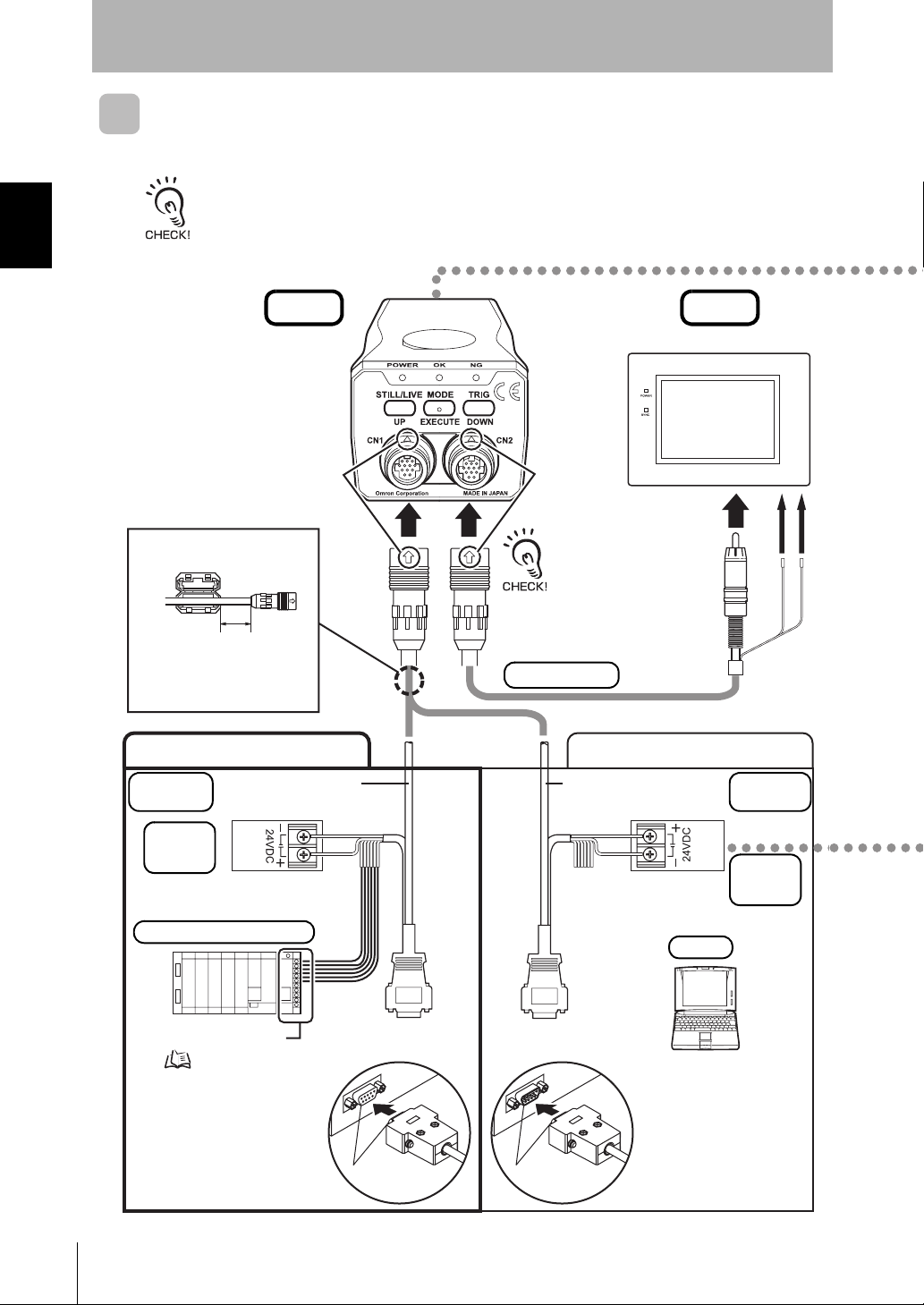

Connecting Peripheral Devices

Connect peripheral devices to the reader.

Section 1 Installing and Connecting the Code Reader

Always turn OFF the reader before connecting or disconnecting a peripheral device's cable.

Peripheral devices may be damaged if the cable is connected or disconnected with the power ON.

The connector (CN2) for the monitor is capped when the reader is shipped. The cap must be left on

those connectors that are not used to protect them from dust, dirt and static electricity.

MonitorMain

F150-M05L-2D

Align the

marks.

Attach a ferrite core.

The ferrite core must

be located at least

10 mm away from the

base of the connector.

Programmable controller PC

Communication/

power cable

Power

supply

device

Recommended: OMRON

S8VS-03024

Programmable controller

V400-W23 (NPN type)

V400-W23P (PNP type)

Blue

Brown

or

Align the

marks.

When plugging in a

connector, push it with a

force of no more than

15 to 20 N.

Then, pull gently on the

cable (approximately

10 N) to make sure the

connector is securely

connected.

Monitor cable

V400-W24 (NPN type)

V400-W24P (PNP type)

Brown

Blue

Recommended: OMRON

S8VS-03024

V400-WM0

PC

+24 V

Brown0VBlue

Communication/

power cable

Power

supply

device

V400-F050/250/350

User’s Manual

20

Discrete I/O

Wiring method: p.73

Make sure that the

connector is oriented

correctly and not inserted

at an angle. Secure the

connector using the

screws on both sides of

the connector.

RS-232C connector

(male)

RS-232C connector RS-232C connector

RS-232C connector

(female)

Make sure that the

connector is oriented

correctly and not inserted

at an angle. Secure the

connector using the

screws on both sides of

the connector.

Page 23

Section 1

Studying the V400-F

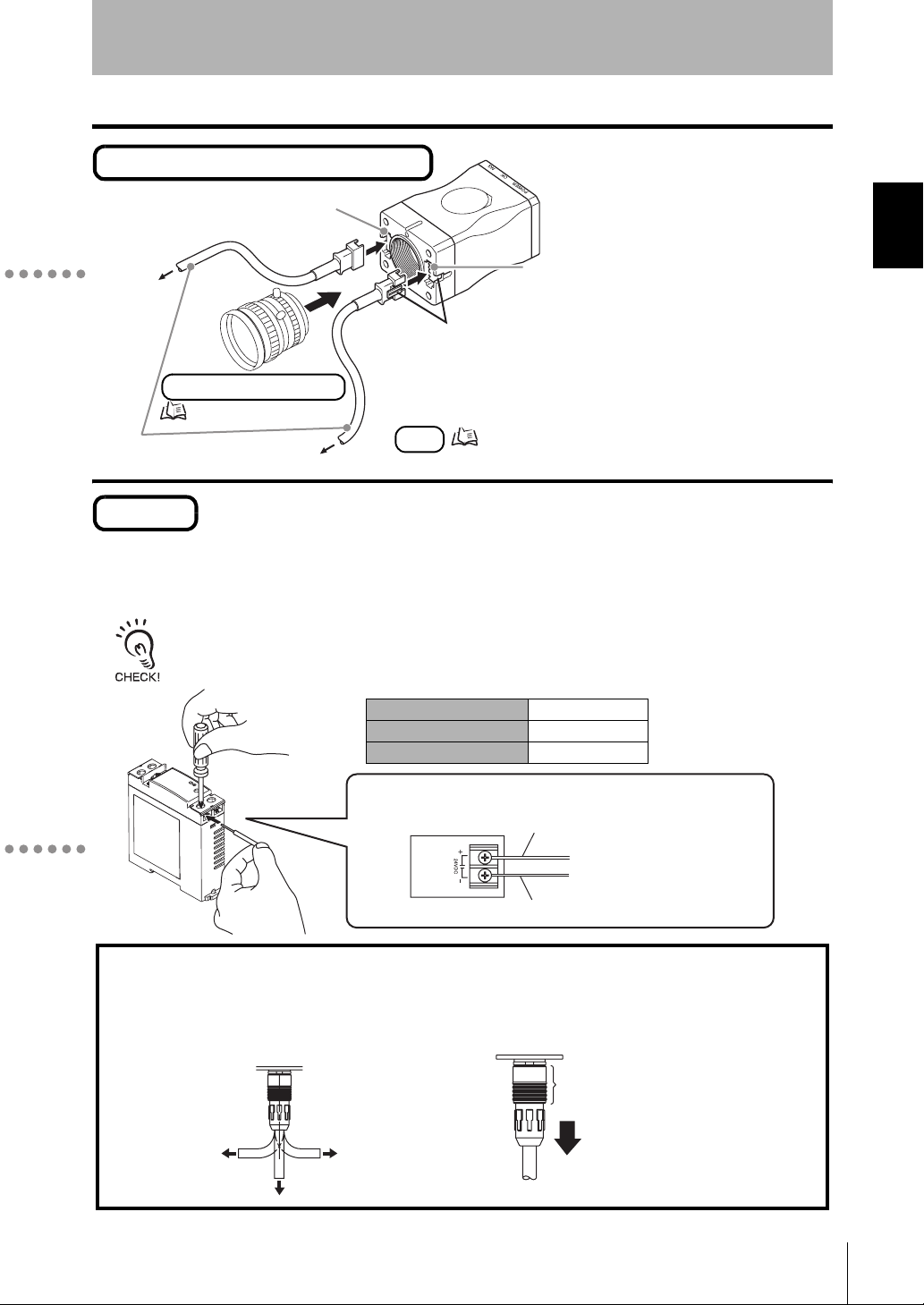

Lens and light (for V400-F050 only)

Left-side light cable connector

Right-side light cable connector

To the light

Align the projection on the light

cable is connector with the slot on

the connector of the reader.

C-mount type lens

Recommended lens: p.89

Light cable

Light

To the light

Recommended light: p.86

Power

For V400-F050/250/350, a power supply device must be provided separately.

Wire the power supply independently of other devices. In particular, keep the

power supply wired separately from inductive loads.

Use a DC power supply with safety measures against high-voltage spikes (safety extra lowvoltage circuits on the secondary side). If UL recognition is required for the overall system, use

a UL Class II DC power supply.

Use a power supply that meets the following requirements.

Output current 1.2 A min.

Power supply voltage 24 VDC ±10%

Recommended S8VS-03024

Section 1 Installing and Connecting the Code Reader

Connect the brown wire to the positive (+) side of the power

supply and the blue wire to the negative (-) side.

Handling the Cable

After the connector is plugged in, do not apply a

force of more than 30 N to the connector in the

directions shown below.

Excessive force will damage the connector.

30 N max.30 N max.

30 N max.

(+) side

(-) side

Brown

Blue

When disconnecting a cable, hold the part of the

plug shown below and then pull it out straight.

Hold this part.

V400-F050/250/350

User’s Manual

21

Page 24

Section 1

Studying the V400-F

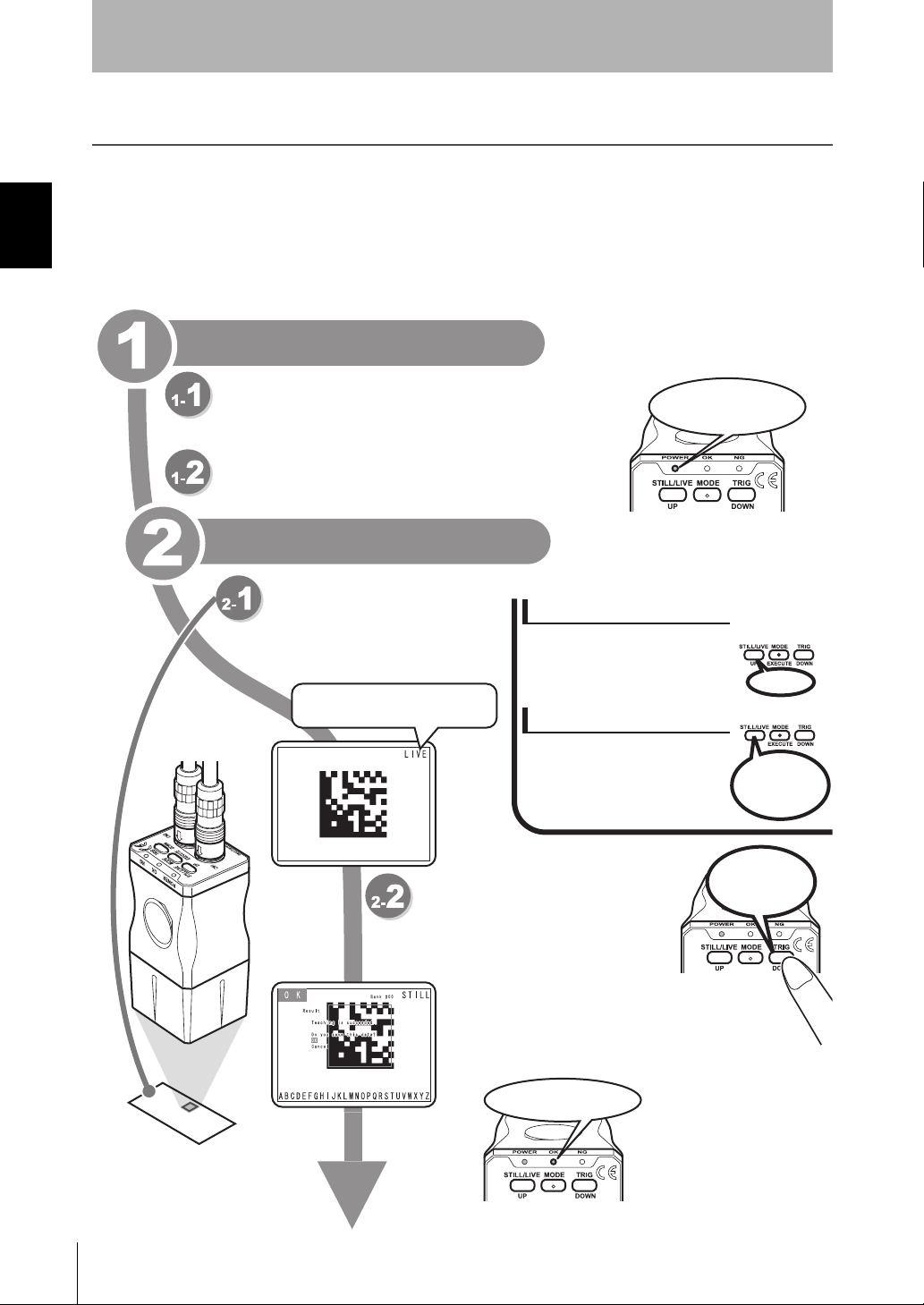

Simple Teaching

Section 1 Simple Teaching

Use “Simple Teaching” to check whether codes on the work piece are readable.

“Simple Teaching” enables you to set necessary reading conditions automatically by simple

operations.

To change reading conditions or set them in detail, use the setting mode.

Turning ON the power

Turn ON the power to the monitor.

• When using F150-M05L-2D, make sure

that it is connected before turning ON the

power to the power supply device.

Turn ON the power to the power supply device.

The POWER LED (green) will light up.

The POWER LED

(green) will light up.

Performing teaching

Capture the work piece.

Switch to the real-time image display

mode, and adjust the position and

brightness of the work piece while

observing the image on the monitor.

[STILL]: Still image

[LIVE]: Real-time image

Display switching

Press the left button to switch

from the still image to the realtime image or vice versa.

Brightness adjustment

Hold down the left button for more

than two seconds, to display the

exposure time adjustment screen.

The brightness will be adjusted

based on the exposure time.

Press

Hold down for

more than two

seconds.

V400-F050/250/350

User’s Manual

22

Perform teaching.

Hold down the right button for

more than two seconds, to perform

“Simple Teaching”.

When teaching is completed successfully, the

teaching and reading results will be displayed.

Three indicators will light: Power (green), OK

(blue), and NG (red). Select [OK] to save the

results.

Indicators light:

Power (green), OK (blue),

NG (red).

Hold down for

more than two

seconds.

Page 25

Section 1

Studying the V400-F

• The teaching results will be overwritten, registered to [Bank #00], and saved.

• If [Cancel] is selected in the result display screen, the results will not be saved.

Exiting

Turn OFF the power to the power supply device and then to the monitor.

Section 1 Simple Teaching

V400-F050/250/350

User’s Manual

23

Page 26

Section 1

Studying the V400-F

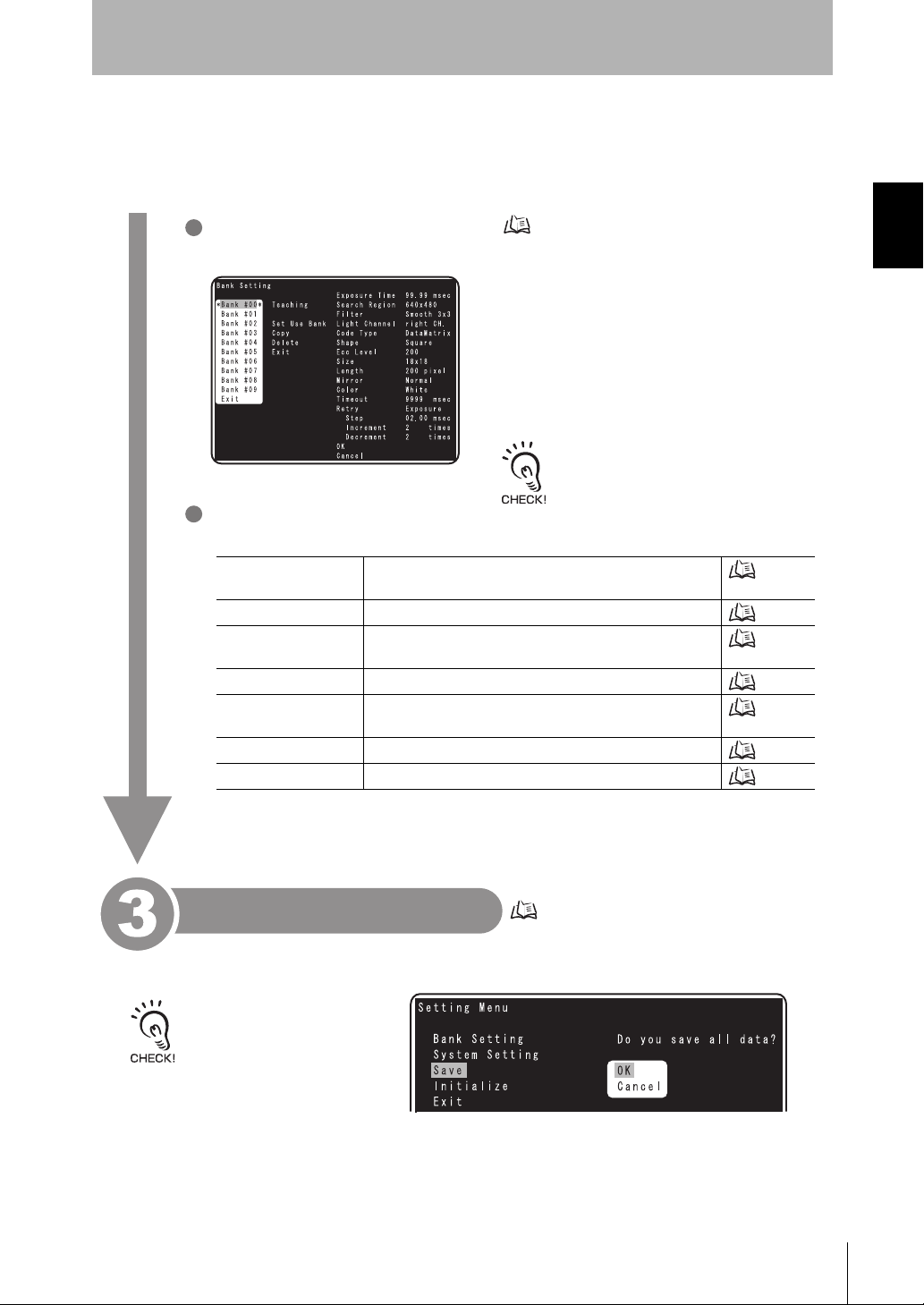

Changing Settings

Section 1 Changing Settings

The setting mode allows you to make changes to reading conditions and system settings. This

section explains operations for the setting mode.

Switch to the setting mode.

Hold down the center button for more than two seconds.

All the LEDs will light up and the [Setting Menu] appears.

Hold down for more

than two seconds.

All LEDs light up.

Make settings

Basic operation for setting mode

Use the right and left buttons to select the desired item, and

then press the center button to confirm the selection.

To close the current menu, select [Exit] and then press the

center button.

Name of currently

selected menu

Selectable menus are

enclosed in a white frame.

V400-F050/250/350

User’s Manual

24

Select an item.

Confirm

(Example) When [Bank Setting] is selected

Indicates that this reading condition is

normally used.

* Only when [Bank Setting] is selected

Select an item.

Numerical value inputting method

Move the cursor to the desired item

and press the center button.

Change the value using the right and

left buttons.

Press the center button to confirm the

setting.

Select [Exit] to

close the menu.

The currently

selected item is

enclosed in a

blue frame.

(Cursor)

Page 27

Section 1

Studying the V400-F

Section 1 Changing Settings

Setting the reading conditions

Select [Bank Setting] from [Setting Menu].

Other settings

Select [System Setting] from [Setting Menu].

[RS-232C]

[Data Format]

[Discrete I/O]

[Display]

[Image Store]

[Bank Switching]

[Version Information]

Set RS-232C communication related parameters such as

baud rate and parity.

Set data format setting for RS-232C communication.

Set discrete I/O related settings including trigger mode

and busy input.

Change the monitor display method.

Select the methods for storing images and referring to

stored images.

Change the automatic bank switch retry setting.

Displays the software version.

p.29

• Up to 10 reading conditions are available.

• When a reading condition is selected, its

settings will be displayed in the right area of the

screen.

• Select the desired reading condition from

among the ten conditions, and set each

condition item manually or by teaching.

• Reading conditions can be copied or deleted.

Reading condition [Bank #00]

contains the contents of

“Simple Teaching”.

p.44

p.46

p.48

p.52

p.53

p.41

p.58

Saving the settings

Select [Save] from [Setting Menu].

All the settings including reading conditions will be saved.

Before exiting, make sure to save

the settings in the setting mode.

If the settings are not saved, the

reading conditions and other

settings will be lost.

p.56

V400-F050/250/350

User’s Manual

25

Page 28

Section 1

Studying the V400-F

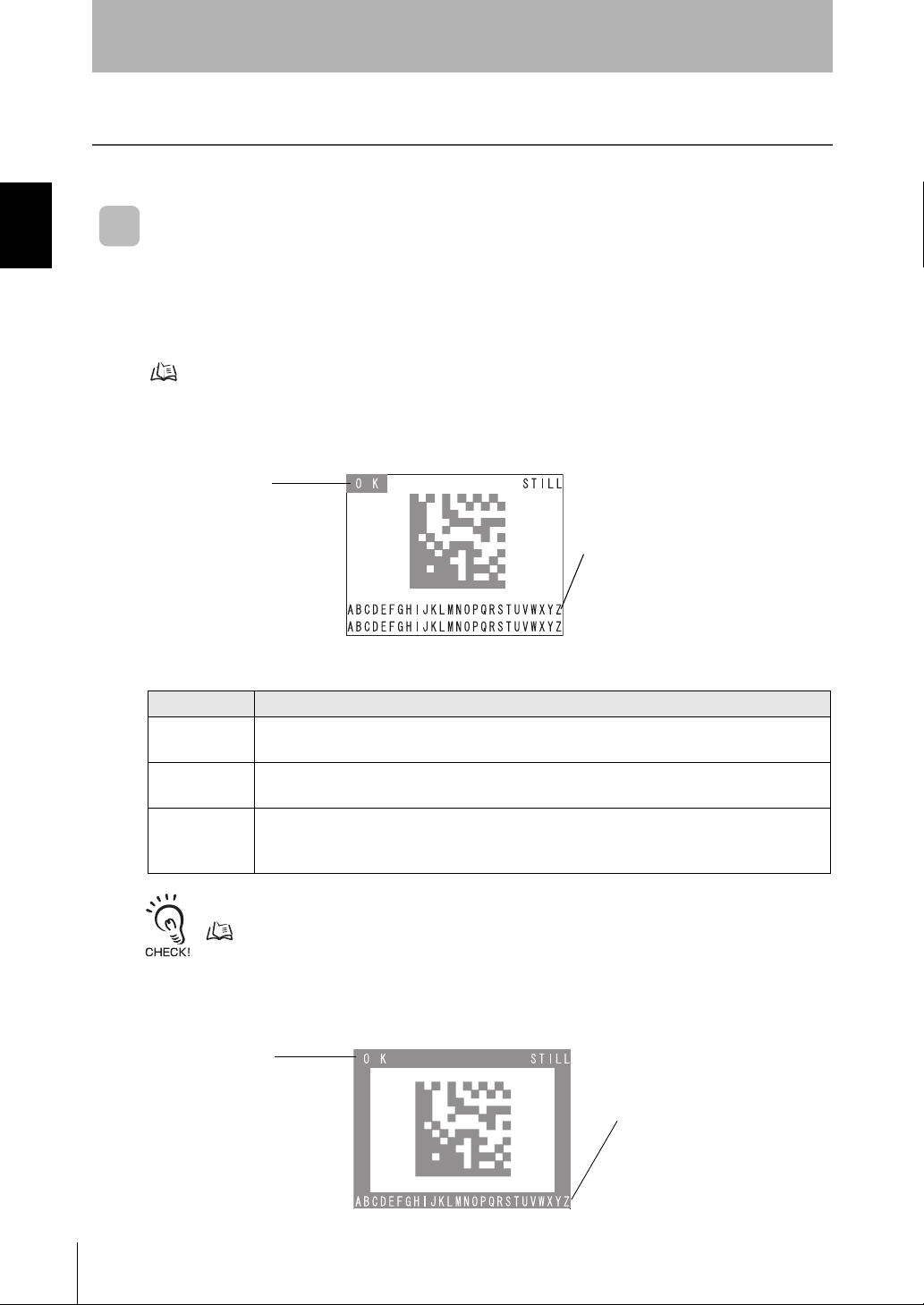

Reading Results

Section 1 Reading Results

This section explains details of the read results.

Monitor Display

Explanation of reading results displayed on the monitor is given below.

There are four display methods: normal display, highlighting display, code quality

analysis display and communication display.

The desired display method can be set in the setting mode.

Display setting: p.52

Normal Display

Normal screen

Reading status

The reading status is

displayed.

OK (blue):Reading is

completed

NG (red): Reading has

• Error code contents

?E000

?E100

?E200

successfully.

failed.

Error code Action

2D code cannot be found, possibly due to uneven background. Check the work piece

surface and lighting condition.

2D code cell cannot be recognized correctly. Check the marking and lighting conditions,

and then perform teaching again.

Reading was not completed within the specified period of time. Check the work piece and

lighting condition, then perform teaching again.

Increase the reading timeout value.

Read data

The read data is displayed.

(Max. 208 characters =

8 lines × 26 characters)

An error code is displayed in case of

reading error.

Highlighting Display

V400-F050/250/350

User’s Manual

26

If reading has failed, it may be possible that the cause can be identified by checking the read image.

p.53

The screen is enclosed in a frame whose color that indicates the reading status.

Reading status

The reading status is

displayed.

OK (blue):Reading is

completed

successfully.

NG (red): Reading has failed.

Read data

The read data is displayed.

(Max. 26 characters)

An error code is displayed in

case of reading error.

Page 29

Section 1

Studying the V400-F

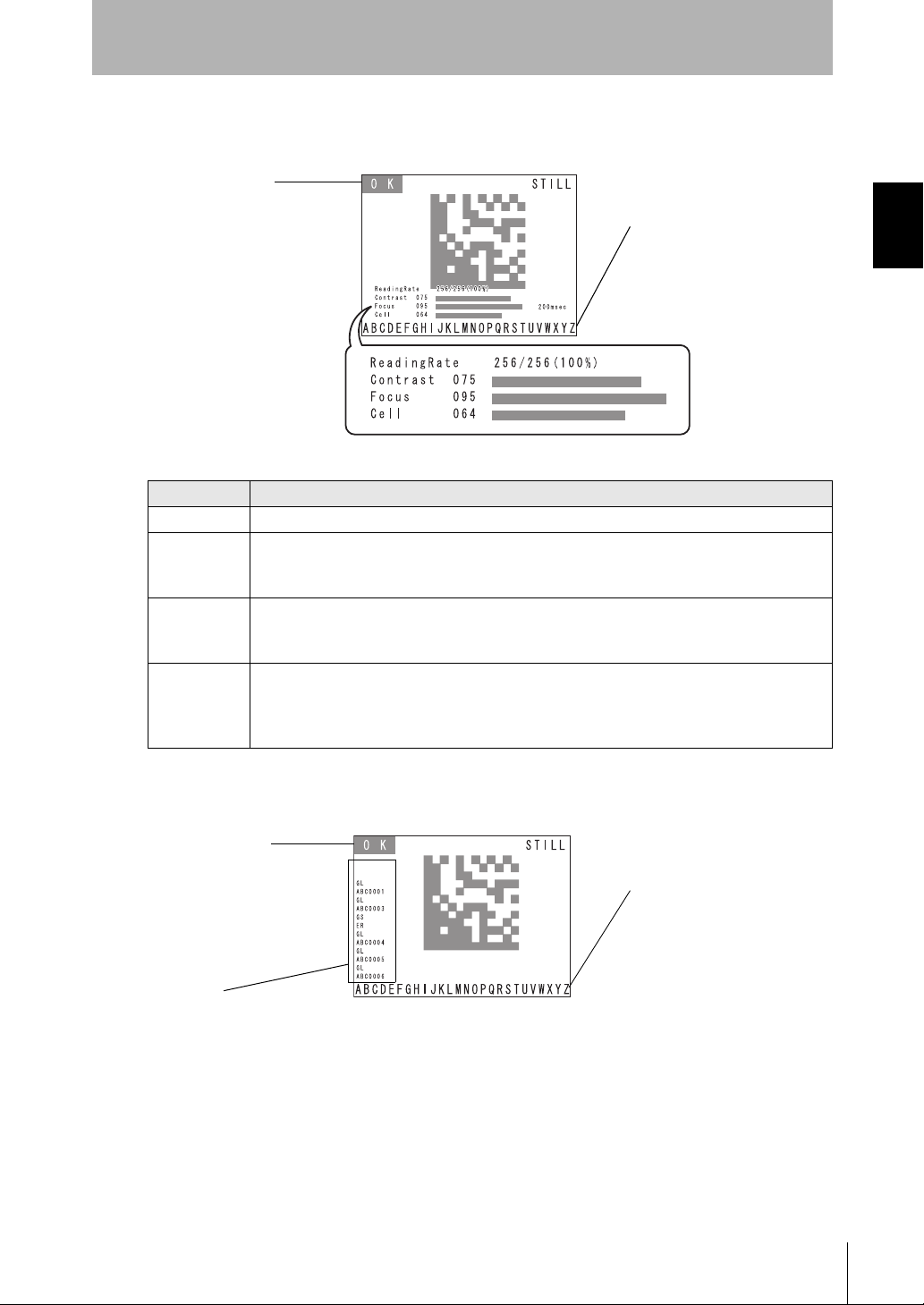

Code quality analysis display

This screen displays analysis result of code quality numerically and graphically (bar).

Reading status

The reading status is displayed.

OK (blue):Reading is

completed

successfully.

NG (red): Reading has failed.

Read data

The read data is displayed.

(Max. 26 characters)

An error code is displayed in

case of reading error.

Code quality analysis

The code quality analysis

result is displayed

numerically (0 to 100) and

graphically (bar).

• Code quality analysis items

Item Description

Reading Rate Displays the rate of successful reading count to the total reading count.

Contrast Evaluates the code is white/black contrast that varies with the lighting condition.

The larger the difference between the white and black parts of the code, the larger the

contrast. “1” will be displayed if the code is contrast is the minimum readable level.

Focus Evaluates the focus level of the image.

If the code is out of focus, it can no longer be recognized. The more the code is out of

focus, the smaller the value displayed.

Cell Evaluates the number of recognition fails for each cell in the finder pattern, timing pattern

and data.

The more cells in which recognition failure occurs and the more unstable the reading is, the

smaller the value displayed.

Section 1 Reading Results

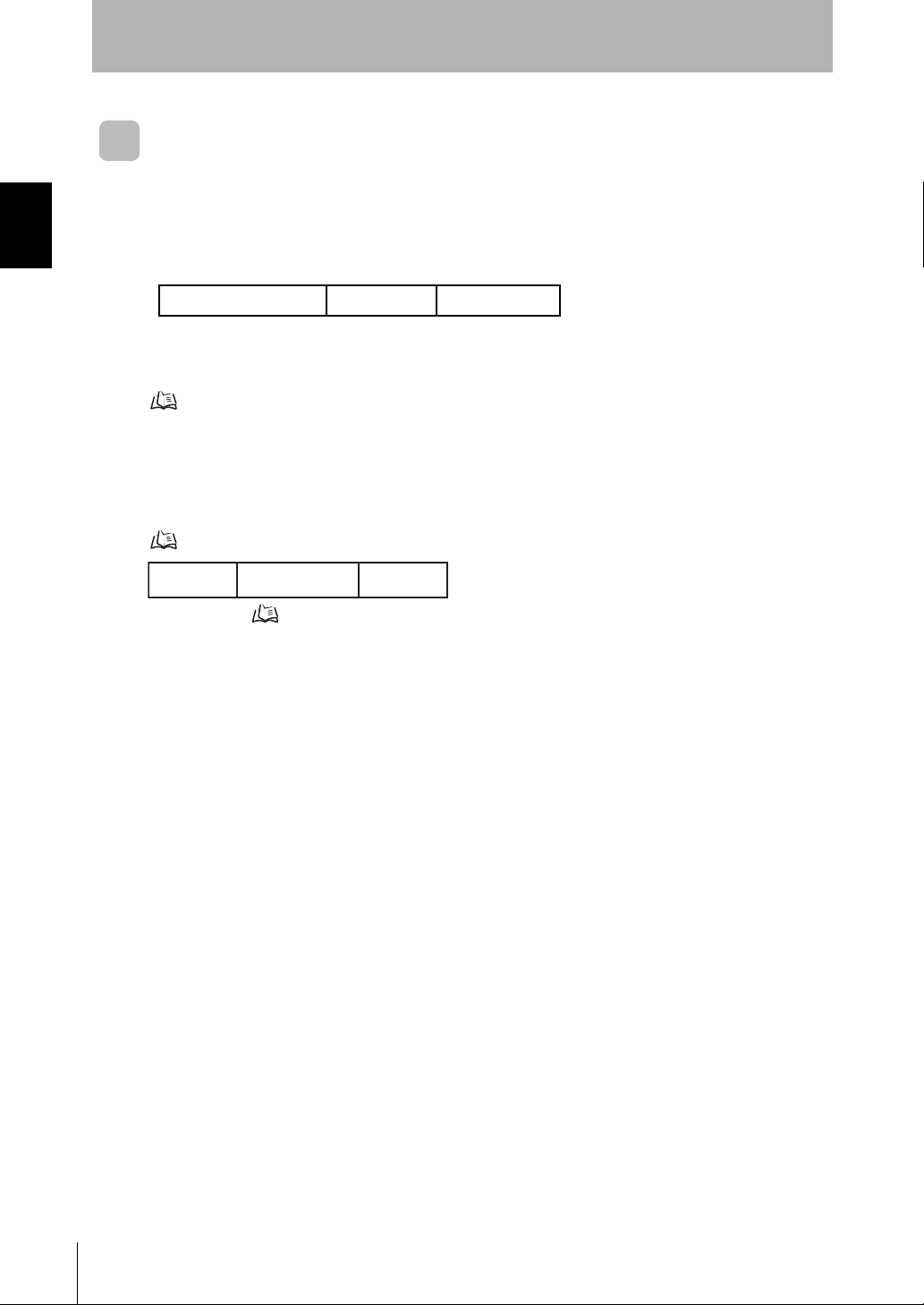

Communication Display

This screen displays the RS-232C communication history.

Reading status

The reading status is

displayed.

OK (blue):Reading is

completed

successfully.

NG (red): Reading has failed.

Communication history

The RS-232C communication history is indicated by yellow and green characters.

Communication contents are displayed from the bottom to the top of the history display area.

Yellow: Indicates that the content was input to the main body.

Green: Indicates that the content was output from the main body.

Read data

The read data is displayed.

(Max. 26 characters)

An error code is displayed in

case of reading error.

V400-F050/250/350

User’s Manual

27

Page 30

Section 1

Studying the V400-F

RS-232C Communications Output

Section 1 Reading Results

This section explains the reading results to be output via RS-232C communication.

When reading is successful

The read data is output in the following format.

Number of read data digits

“Number of read data digits” and “Code quality” are output only if [Digit Data] and

[Checker Data] are set to [ON] in the data format setting.

p.46

Read dataCode quality

When reading has failed

By factory default, an error code is output in the following format. However, it is

possible to make a data format setting so that no error code will be output.

Error code output setting: p.47

Header Footer?E000

Error code: p.26, p.82

V400-F050/250/350

User’s Manual

28

Page 31

Section 2 Changing Reading Conditions

This section provides information required for changing reading conditions.

Setting Reading Conditions by Teaching 30

Setting Reading Conditions Manually 32

Selecting the Bank to be Used Normally 37

Copying a Bank 38

Deleting the Content of a Bank 40

Setting the Retry Method 41

Setting the Bank Switching Retry Function 41

Section 2 Changing Reading Conditions

V400-F050/250/350

User’s Manual

29

Page 32

Section 2

Changing Reading Conditions

Setting Reading Conditions by Teaching

Teaching uses one sample to read it and sets a reading condition based on the results.

Section 2 Setting Reading Conditions by Teaching

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

2. Select [Bank Setting] from [Setting Menu].

The [Bank Setting] screen will appear.

3. From [Bank #00] to [Bank #09], select the

bank to which the teaching results are to be

saved.

The contents of the selected bank are displayed in the

right area of the screen.

[Bank #00] contains the reading condition set by

“Simple Teaching”.

The edit menu will be displayed.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

4. Select [Teaching].

V400-F050/250/350

User’s Manual

30

The [Teaching] screen will appear and the screen brightness is adjusted automatically.

Menu name

Displays the name of the currently

selected menu and the name of the

upper hierarchical level.

Exposure time

Displays the currently set exposure

time.

Guidance

Displays the operating method in

brief.

Page 33

5. Adjust the brightness.

Check the automatically adjusted brightness.

To change the brightness, press the right and left buttons.

The brightness is adjusted based on the exposure

time. The longer the exposure time, the brighter

the image but the image is easily blurred if the work

piece is not stationary.

p.91

Section 2

Changing Reading Conditions

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Press

Section 2 Setting Reading Conditions by Teaching

6. Confirm the brightness.

Press the center button.

Teaching will start.

When teaching is complete, the teaching results are

displayed.

7. Checking the results.

Check the teaching results.

To change the reading condition, select the condition item

to be changed. For details, refer to “Setting Reading

Conditions Manually” p.32.

8. Confirm the reading condition.

Select [OK] to confirm the reading condition. This will

bring you to the operation menu.

If you select [Cancel], the operation menu will reappear

without reflecting the teaching results.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Press

9. Save the settings.

Select [Save] from [Setting Menu] to save the changes

you have made to the reading condition.

p.56

V400-F050/250/350

User’s Manual

31

Page 34

Section 2

Changing Reading Conditions

Setting Reading Conditions Manually

This section explains how to set reading conditions manually.

Section 2 Setting Reading Conditions Manually

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

1. Switch to the setting mode.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

2. Select [Bank Setting] from [Setting Menu].

The [Bank Setting] screen will appear.

3. From [Bank #00] to [Bank #09], select the

bank to which you want to set reading

condition.

The contents of the selected bank are displayed in the

right area of the screen.

The edit menu will be displayed.

4. Select [Edit].

5. Make changes to the reading condition.

6. Confirm the reading condition.

V400-F050/250/350

User’s Manual

32

The reading condition change menu will appear.

For reading condition items, refer to “Reading Condition

Items” ( p.33).

Select [OK] to confirm the reading condition. This will

bring you to the operation menu.

If you select [Cancel], the operation menu will reappear

without reflecting the changes.

Page 35

Changing Reading Conditions

7. Save the settings.

Select [Save] from [Setting Menu] to save the changes you have made to the reading condition.

p.56

Reading Condition Items

Section 2

[Exposure Time]

Set the desired exposure time. The longer the exposure time, the brighter the image is, but the image is

blurred easily if the work piece is not stationary. p.91

The brightness changes in real time

as you change the setting.

Set the desired exposure time.

0.03 to 10.00 (msec)

Select [OK] to confirm the changes

and return to the edit menu.

Select [Cancel] to cancel the

changes and return to the edit menu.

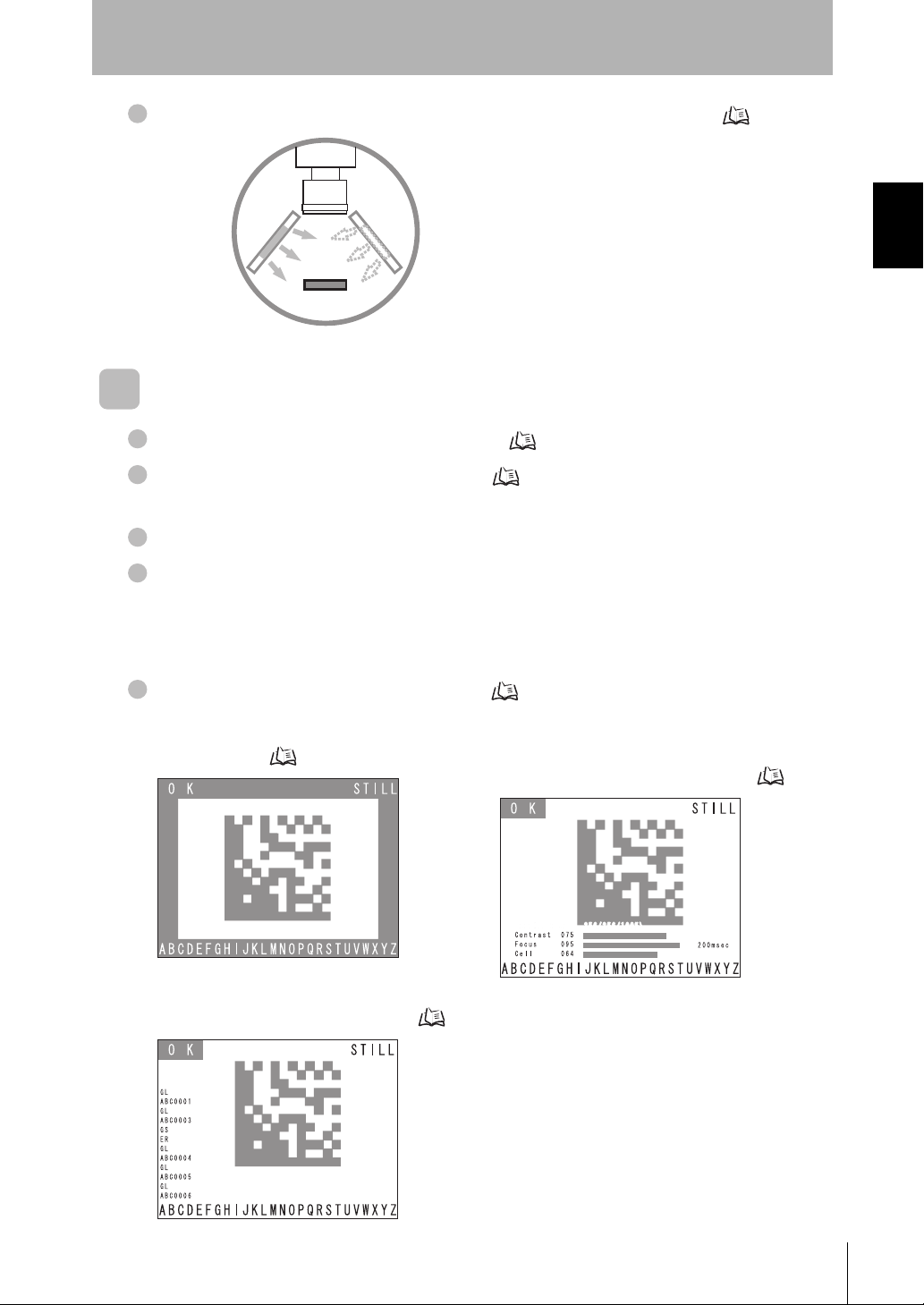

[Search Region]

Set the image region to be read. The region enclosed by the red and green boundary lines will be the subject

of reading.

Start Y

Start X

Terminal X

Terminal Y

Set the region boundary lines.

Select [OK] to confirm the changes and return to the

edit menu.

Select [Cancel] to cancel the changes and return to

the edit menu.

The region boundary lines move in

real time as you change the setting.

Line type

Red: Currently

changed region

boundary line

Green: Region

boundary line

Black: Boundary line

outside region

In the actual screen, the

same line type and

thickness are used.

Different type and

thickness are used to

make color distinction

easier.

Section 2 Setting Reading Conditions Manually

V400-F050/250/350

User’s Manual

33

Page 36

Section 2

Changing Reading Conditions

[Filter]

Set the image processing to be performed at completion of reading. This will lower the possibility of reading

failure.

Filtering can be performed in 3 steps (filter type can be selected from Smooth, Dilate, Erosion and Median).

Section 2 Setting Reading Conditions Manually

The image changes in real time as

you change the setting.

Filter

Select [OK] to confirm the changes

and return to the edit menu.

Select [Cancel] to cancel the

changes and return to the edit menu.

Settings Details

Smooth 3 × 3 Smoothing filter. This filter smooths the image.

Smooth 5 × 5

Dilate 3 × 3 Dilate filter. This filter makes the cell smaller if the code is black.

Dilate 5 × 5

Erosion 3 × 3 Erosion filter. This filter makes the cell larger if the code is black.

Erosion 5 × 5

Median 3 × 3 Median filter. This filter eliminates noise.

Median 5 × 5

None* No filtering is performed.

The default settings are indicated with an asterisk (*).

The filter size can be selected from 3 × 3 and 5 × 5.

The filter size can be selected from 3 × 3 and 5 × 5.

The filter size can be selected from 3 × 3 and 5 × 5.

The filter size can be selected from 3 × 3 and 5 × 5.

V400-F050/250/350

User’s Manual

34

Other Settings

Setting item Settings Details

Light Channel

(For V400-F050)

Lighting

(For V400-F250/

350)

Code Type Set the code type.

Select the light to be used.

Left CH.* The light connected to the left light connector will be used.

Right CH. The light connected to the right light connector will be used.

None No light will be used.

ON* The light will be used.

OFF The light will not be used.

DataMatrix The code will be read as a DataMatrix type code.

QRCode The code will be read as a QRCode type code.

Auto* The code type will be identified automatically.

Page 37

Section 2

Changing Reading Conditions

Setting item Settings Details

Shape Select the code shape.

This item is effective only when [DataMatrix] is selected for [Code Type].

Square The code will be read as a square code.

Rectangle The code will be read as a rectangular code.

Auto* The code shape will be identified automatically.

Model Select the QR code model.

This item can be selected only when [QRCode] is selected for [Code Type].

Model 1 The code will be handled as Model 1 code.

Model 2 The code will be handled as Model 2 code.

Auto* The code model will be identified automatically.

Ecc Level Select the error correction level (ECC level).

200 The code will be read as the ECC level recommended by ECC200

(AIM).

Only this item is available if [DataMatrix] is selected for [Code

Type].

L (7%)* Up to 7% damage can be handled.

This item can be selected only when [QRCode] is selected for

[Code Type].

M (15%) Up to 15% damage can be handled.

This item can be selected only when [QRCode] is selected for

[Code Type].

Q (25%) Up to 25% damage can be handled.

This item can be selected only when [QRCode] is selected for

[Code Type].

H (30%) Up to 30% damage can be handled.

This item can be selected only when [QRCode] is selected for

[Code Type].

Auto* The ECC level will be identified automatically.

Size Select the number of cells present for each side of the code. The size varies with the

code.

10 × 10 to 64 × 64 This item can be selected only when [Square] is selected for

[Shape].

8 × 18 to 16 × 48 This item can be selected only when [Rectangle] is selected for

[Shape].

21 × 21 to 57 × 57 This item can be selected only when [QRCode] is selected for

[Code Type].

Auto* The size will be identified automatically.

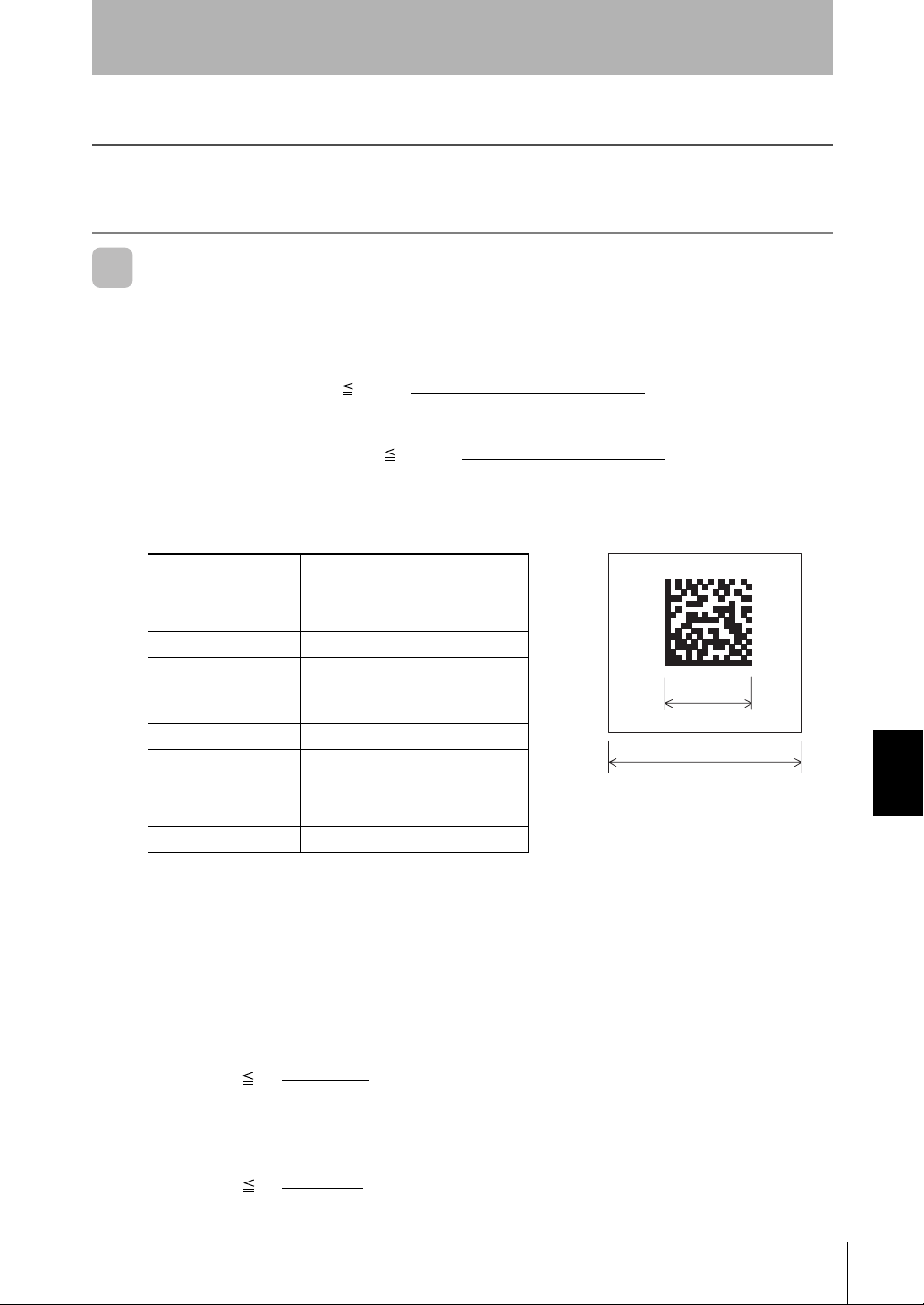

Length Enter the code length (the length on the screen) in pixels.

50 to 480 -

Auto* The length will be identified automatically.

Mirror Select the mirror image.

Normal The code will be read as a non-reverse image (in normal direction).

Reverse The code will be read as a mirrored image (in reverse direction).

Auto* Whether the code is a normal or reverse image will be identified

automatically.

Section 2 Setting Reading Conditions Manually

V400-F050/250/350

User’s Manual

35

Page 38

Section 2

Changing Reading Conditions

Setting item Settings Details

Color Set the code cell color.

Black The code will be read as a black code.

White The code will be read as a white code.

Auto* The color will be identified automatically.

Timeout Enter the time (in msec) allowed before reading is completed after it is started.

Section 2 Setting Reading Conditions Manually

Retry Set this item when you need to retry (capture the image twice or more) after reading is

Step 0.01 to 05.00*

Increment 0 to 4 (2*) Set the number of times (Times) the exposure time is to be

Decrement 0 to 4 (2*) Set the number of times (Times) the exposure time is to be

Interval 32 to 999 (100*) Set the interval (msec) at which capture is to be performed.

Max Count 0 to 8 (4*) Set the number of times (Times) capture is to be repeated.

The default settings are indicated with an asterisk (*). However, in the case of [Bank #00], [Exposure] will be

set for [Retry] as the default.

100 to 9999

(2000*)

executed. Capturing the image can be performed with a different exposure time.

It is possible to retry capturing the image twice or more with different reading

conditions.

-

“Setting the Bank Switching Retry Function” p.41

None* Capture will not be retried (i.e. capture will be performed only

once).

Exposure Allows retry with different exposure time. Capturing the image can

be performed twice or more with a different exposure time.

For instance, if [02.00 msec] is set for [Step], [2 times] for

[Increment] and [2 times] for [Decrement], the exposure time will

be changed each time capture is performed, starting from 10 msec

to 12 msec, 8 msec, 14 msec and then 6 msec (if the original

exposure time is 10 msec).

Normal Simple retry. Capture will be retried with the same reading

condition.

Set the step (msec) in which the exposure time is changed.

(0.30*)

This item can be selected only when [Exposure] is selected for

[Retry].

increased.

This item can be selected only when [Exposure] is selected for

[Retry].

decreased.

This item can be selected only when [Exposure] is selected for

[Retry].

This item can be selected only when [Normal] is selected for

[Retry].

This item can be selected only when [Normal] is selected for

[Retry].

V400-F050/250/350

User’s Manual

36

Page 39

Changing Reading Conditions

Selecting the Bank to be Used Normally

This section explains how to select the bank that is to be used normally.

Section 2

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

2. Select [Bank Setting] from [Setting Menu].

The [Bank Setting] screen will appear.

3. From [Bank #00] to [Bank #09], select the

bank that is to be used normally.

The contents of the selected bank are displayed in the

right area of the screen.

The edit menu will be displayed.

4. Select [Set Use Bank].

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

Section 2 Selecting the Bank to be Used Normally

A confirmation message will be displayed.

5. Confirm the reading condition.

Select [OK] to confirm the setting. This will bring you to

the operation menu.

If you select [Cancel], the operation menu will reappear

without reflecting the changes.

An asterisk (*) will appear at both right and left ends of the reading condition to be normally used.

6. Save the settings.

Select [Save] from [Setting Menu] to save the changes you have made to the reading condition.

p.56

V400-F050/250/350

User’s Manual

37

Page 40

Section 2

Changing Reading Conditions

Copying a Bank

This section explains how to copy the content of one bank to another bank.

Section 2 Copying a Bank

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

1. Switch to the setting mode.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

2. Select [Bank Setting] from [Setting Menu].

The [Bank Setting] screen will appear.

3. From [Bank #00] to [Bank #09], select the

bank whose content is to be copied to another

bank.

The contents of the selected bank are displayed in the

right area of the screen.

The edit menu will be displayed.

4. Select [Copy].

5. Select the copy destination bank.

V400-F050/250/350

User’s Manual

38

A confirmation message will be displayed.

If you select [Cancel], the operation menu will reappear

without reflecting the changes.

Page 41

A confirmation message will be displayed.

6. Execute copy.

Select [OK] to execute copy. This will bring you to the

operation menu.

If you select [Cancel], the previous menu will reappear

without reflecting the changes.

7. Save the settings.

Select [Save] from [Setting Menu] to save the changes

you have made.

p.56

Section 2

Changing Reading Conditions

Section 2 Copying a Bank

V400-F050/250/350

User’s Manual

39

Page 42

Section 2

Changing Reading Conditions

Deleting the Content of a Bank

This section explains how to delete the content of a bank and restore the default settings for

that bank.

Section 2 Deleting the Content of a Bank

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

2. Select [Bank Setting] from [Setting Menu].

The [Bank Setting] screen will appear.

3. From [Bank #00] to [Bank #09], select the

bank whose content is to be deleted.

The contents of the selected bank are displayed in the

right area of the screen.

The edit menu will be displayed.

4. Select [Delete].

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

5. Execute deletion.

6. Save the settings.

V400-F050/250/350

User’s Manual

40

A confirmation message will be displayed.

Select [OK] to confirm the settings. This will bring you to

the operation menu.

If you select [Cancel], the operation menu will reappear

without deletion.

The content of the selected bank will be deleted, and the default settings will be restored for that bank.

Select [Save] from [Setting Menu] to save the settings.

p.56

Page 43

Section 2

Changing Reading Conditions

Setting the Retry Method

This section explains how to set the retry method (to execute reading and then capture an

image twice or more).

Two retry methods are available: “Same bank” and “Bank Switching”.

Item Details

Same bank Exposure time

change retry

(Exposure)

Simple retry (Normal) Capture is performed the specified number of times for the same

Automatic bank switch retry (Bank Switching) Capture is performed continuously by switching from one bank

Setting the Bank Switching Retry Function

Capture is performed for the same bank by changing the

exposure time in steps.

p.36

bank.

p.36

to another.

Section 2 Setting the Retry Method

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

2. Select [System Setting] [Bank Switch] from

[Setting Menu].

3. Make the desired bank switch settings.

4. Confirm the settings.

Select [OK] to confirm the settings. This will bring you to

the operation menu.

If you select [Cancel], the operation menu will reappear

without reflecting the settings.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

V400-F050/250/350

User’s Manual

41

Page 44

Section 2 Setting the Retry Method

Section 2

Changing Reading Conditions

5. Save the settings.

Select [Save] from [Setting Menu] to save the settings.

p.56

Setting item Settings Details

Switch Function OFF*/ON If [ON] is selected, the bank will be switched from one to

another as specified.

1st Bank

2nd Bank

3rd Bank

4th Bank

5th Bank

Total Timeout 1000 to 9999 (9999*) Set the time at which reading is to be stopped following start of

Switch Order Select the reading condition switching method.

1st Bank:

#00 to #09 (*#00)

Other:

#00 to #09, None*

Auto* The switching order is determined automatically based on the

Fixed Banks will be switched in the order they have been registered,

Select the reading conditions to be switched.

No reading condition will be selected if [None] is selected.

bank switch retry in case of reading failure.

frequency of use.

starting from [1st Bank].

V400-F050/250/350

User’s Manual

42

Page 45

Section 3 Setting RS-232C and Discrete I/O Communication Conditions

This section explains how to set RS-232C and discrete I/O communication

conditions.

Setting RS-232C Communication Conditions 44

Setting Communication Conditions 44

Setting the Data Format 46

Setting Discrete I/O Communication Conditions 48

Section 3 Setting RS-232C and Discrete I/O Communication Conditions

V400-F050/250/350

User’s Manual

43

Page 46

Section 3

Setting RS-232C and Discrete I/O Communication Conditions

Setting RS-232C Communication Conditions

This section explains how to set RS-232C communication conditions and data format.

Setting Communication Conditions

Set RS-232C communication conditions as follows.

Section 3 Setting RS-232C Communication Conditions

1. Switch to the setting mode.

2. Select [System Setting] [RS-232C] from [Setting Menu].

3. Make the desired changes to the settings.

4. Confirm the changes.

5. Save the settings.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

The RS-232C setting menu will appear.

Select [OK] to confirm the changes made to the [RS232C] settings. This will bring you to the operation menu.

If you select [Cancel], the operation menu will reappear

without reflecting the changes.

Select [Save] from [Setting Menu] to save the settings.

p.56

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

V400-F050/250/350

User’s Manual

44

Page 47

Setting RS-232C and Discrete I/O Communication Conditions

Setting item Settings Details

Baud Rate 9600*/19200/38400/

57600/115200

Parity Select the desired parity. Parity is used to detect data failure.

None* No parity will be used.

Odd Odd parity will be used.

Even Even parity will be used.

Data Length 8*/7 Select the data length to be used.

Stop Bit 1*/2 Select the stop bit length to be used.

The default settings are indicated with an asterisk (*).

Select the desired baud rate (bps).

Baud rates exceeding 20 kbps are not defined in the RS232C standards. Therefore, if [38400 bps] or higher

baud rate is selected, communications may be

unreliable depending on the cable length.

If there are problems with communications, a baud rate

of [19200 bps] or below must be used.

The data length is the number of bits required to send one

character.

The stop bit indicates the end of data.

Section 3

Section 3 Setting RS-232C Communication Conditions

Make the communication settings as follows when using save or load command (e.g. CB, CU).

Parity: None, Data Length: 8, Stop Bit: 1

p.71

V400-F050/250/350

User’s Manual

45

Page 48

Section 3

Setting RS-232C and Discrete I/O Communication Conditions

Setting the Data Format

Set the RS-232Cdata format as follows.

1. Switch to the setting mode.

Section 3 Setting RS-232C Communication Conditions

2. Select [System Setting] [Data Format] from [Setting Menu].

3. Make the desired changes to the settings.

4. Confirm the changes.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

The [Data Format] setting menu will appear.

“Description of Format” p.63

Select [OK] to confirm the changes made to the [Data

Format] settings. This will bring you to the operation

menu.

If you select [Cancel], the operation menu will reappear

without reflecting the changes.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

5. Save the settings.

V400-F050/250/350

User’s Manual

46

Select [Save] from [Setting Menu] to save the settings.

p.56

Page 49

Section 3

Setting RS-232C and Discrete I/O Communication Conditions

Setting item Settings Details

Input Set the basic input format items.

Output Set the basic output format items.

Prefix None*/STX/ESC Select the symbol that indicates the beginning (header) of the

command format.

No symbol will be selected if [None] is selected.

Suffix CR*/CR+LF/ETX/LF Select the symbol that indicates the end (footer) of the

command format.

FCS OFF*/ON Select whether to use the frame check sequence to detect data

input/output errors. Use of FCS will improve communication

reliability.

“FCS Check Program Example (BASIC)” p.104

Checker Data OFF*/ON Select whether to add a value that indicates the code quality

when the data is output.

Digit Data Select whether to add a value that indicates the number of read data digits when the

data is output.

OFF* No value will be added.

ON 2Byte A 2-byte value will be added.

ON 4Byte A 4-byte value will be added.

NG Output OFF/ON* Select whether to output an error code when reading fails.

Limit Data OFF*/ON Set the read data output range. If [ON] is selected, the settings

made for [Start Point] and [End Point] will be effective.

Start Point 001 to 999 (001*) Enter the start digit position.

End Point 001 to 999 (999*) Enter the end digit position.

The default settings are indicated with an asterisk (*).

Section 3 Setting RS-232C Communication Conditions

V400-F050/250/350

User’s Manual

47

Page 50

Section 3

Setting RS-232C and Discrete I/O Communication Conditions

Setting Discrete I/O Communication Conditions

This section explains the procedure of setting the input/output of discrete I/O.

Section 3 Setting Discrete I/O Communication Conditions

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

2. Select [System Setting] [Discrete I/O] from [Setting Menu].

The [Discrete I/O] setting menu will appear.

3. Make the desired changes to the settings.

4. Confirm the changes.

Select [OK] to confirm the changes made to the [Discrete

I/O] settings. This will bring you to the operation menu.

If you select [Cancel], the operation menu will reappear

without reflecting the changes.

5. Save the settings.

Select [Save] from [Setting Menu] to save the settings.

p.56

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

V400-F050/250/350

User’s Manual

48

Page 51

Section 3

Setting RS-232C and Discrete I/O Communication Conditions

Setting item Settings Details

Trigger Mode Select how to use the trigger signal for discrete I/O.

One Shot* Reading is performed once at the rise of trigger signal (OFF

ON). If reading is successful, it will be exited and the reading

results will be output.

Since the trigger signal is synchronized with the camera shutter

input, shooting of moving workpieces can be performed at

accurate positions.

Level Reading is repeated while the trigger signal is ON, until reading

is successful. If reading is not successful, “NG” will be output

when the trigger signal is turned OFF.

Continuous Reading is performed continuously while the trigger signal is

ON.

Trigger Error Select whether to output a discrete I/O error when a trigger is received during BUSY.

ON* A discrete I/O error will be output when a trigger is received

during BUSY.

OFF No discrete I/O error will be output even if a trigger is received

during BUSY.

Polarity Set the trigger signal active polarity.

Low Active* The trigger signal is active when it is low.

High Active The trigger signal is active when it is high.

OK/NG Output Select the OK/NG signal output method.

OK Pulse* A pulse signal will be output when reading is successful.

NG Pulse A pulse signal will be output when reading fails.

Level Output Outputs OK/NG at low/high levels.

Pulse Width 10 to 100 (10*) Specify the width (msec) of the pulse signal if a pulse signal is

to be output.

The default settings are indicated with an asterisk (*).

Section 3 Setting Discrete I/O Communication Conditions

V400-F050/250/350

User’s Manual

49

Page 52

Section 3 Setting Discrete I/O Communication Conditions

Section 3

Setting RS-232C and Discrete I/O Communication Conditions

MEMO

V400-F050/250/350

User’s Manual

50

Page 53

Section 4 Other Settings

This section explains how to set screen display, operate images read in the

past, save and initialize settings of the V400-F.

Setting Screen Display 52

Viewing the Images Read in the Past 53

Viewing Stored Images 53

Selecting the Images to be Stored 55

Saving/Initializing All the Settings 56

Saving All the Settings 56

Initializing All the Settings 57

Displaying the Version Information 58

Section 4 Other Settings

V400-F050/250/350

User’s Manual

51

Page 54

Section 4

Other Settings

Setting Screen Display

Set how the reading results and standby state are to be displayed.

Section 4 Setting Screen Display

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

2. Select [System Setting] [Display] from [Setting Menu].

The [Display] menu will be displayed.

3. Select the desired display mode.

Setting item Settings Details

Display Mode Select the reading result display method.

Normal* Normal display

Checker Displays analysis result of code quality numerically and

graphically (bar).

COM Monitor This screen displays the RS-232C communication history.

Emphasis Highlights the reading state.

Image State Select how the standby state is to be displayed at completion of start-up.

STILL* Displays a still image.

LIVE Displays a real-time image.

The default settings are indicated with an asterisk (*).

4. Select [OK] to close the [Display] menu.

V400-F050/250/350

User’s Manual

52

The [System Setting] menu will be displayed.

Page 55

Section 4

Other Settings

Viewing the Images Read in the Past

This section explains how to view the images that were read in the past and stored in the

reader temporarily. This will help you analyze the causes of reading failures.

Up to 28 images can be stored in the reader. If more than 28 images are taken, the stored

images will be replaced with new ones, starting from the oldest image. These images will be

deleted when the power is turned OFF.

Viewing Stored Images

View the images that were read in the past and stored in the reader temporarily.

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

Section 4 Viewing the Images Read in the Past

2. Select [System Setting] [Image Store] [Refer to Image] from [Setting Menu].

The [Reference] screen will be displayed.

Menu name

Displays the name of the currently

selected menu and the name of the

upper hierarchical level.

Saved image No.

Image Nos. (Last 00 to 27) are

assigned to the images, starting

from the latest image.

For instance, when a new image is

taken, the image “Last00” will

change to “Last01”.

Status display

Displays an error code or reading

status.

Guidance

Displays the operating method in

brief.

3. Press the left or right button to select a saved

image.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Press

V400-F050/250/350

User’s Manual

53

Page 56

Section 4

Other Settings

Section 4 Viewing the Images Read in the Past

4. After you have viewed the desired image,

press the center button to close the

[Refer to Image] screen.

The [Image Store] menu will be displayed.

5. Select [Cancel] to close the [Image Store]

menu.

If the current setting for [Store Mode] is satisfactory, select

[OK] to close the menu.

The [System Setting] menu will be displayed.

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Press

V400-F050/250/350

User’s Manual

54

Page 57

Selecting the Images to be Stored

Select the read images to be stored in the reader temporarily.

Section 4

Other Settings

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

2. Select [System Setting] [Image Store] [Store Mode] from [Setting Menu].

3. Select the images to be stored.

Setting item Settings Details

Store Mode NG only* Only the reading-failed images will be stored.

All All the images will be stored.

The default settings are indicated with an asterisk (*).

4. Select [OK] to close the [Image Store] menu.

Section 4 Viewing the Images Read in the Past

The [System Setting] menu will be displayed.

V400-F050/250/350

User’s Manual

55

Page 58

Section 4

Other Settings

Saving/Initializing All the Settings

This section explains how to save all the settings including reading conditions and system

settings, as well as initializing them to the factory settings.

Saving All the Settings

Save all the settings including reading conditions and system settings to the internal

ROM as follows. Once they are saved to the internal ROM, they will not be deleted

even if the power is turned OFF.

Section 4 Saving/Initializing All the Settings

1. Switch to the setting mode.

Hold down the center button for more than two seconds to

activate the setting mode.

“Changing Settings” p.24

STILL/LIVE MODE TRIG

UP EXECUTE DOWN

Hold down for more

than two seconds.

2. Select [Save] from [Setting Menu].

A confirmation menu will appear.

3. Select [OK].

All the settings will be saved, and the [Setting Menu] will reappear.

V400-F050/250/350

User’s Manual

56

Page 59

Section 4

Other Settings

Initializing All the Settings

Reset all the settings including reading conditions and system settings to the factory

settings as follows.